Ardco OptiMax2 Installation Manual

OptiMax2 LED Retrofit

Instructions

(web only)

99-18258-I001_A

Document Revision History

Revision History

Version Date Revised by Comments

Rev A 18 May 2010 SWatstein New release. Replace individual LED retrofit manual.

Contributors

Name Name Name Name

Sherman Watstein

Frank Carbajal

Harvey Tsui

Copyright © 2010 by

ALL rights reserved. Information in this document is subject to change without notice. Companies, names and data used in examples

herein are fictitious unless otherwise noted. No part of this document may be reproduced or transmitted in any form or by any means,

electronic or mechanical, for any purpose, without express permission of Anthony Manufacturing Co., Inc.

12391 Montero Street, Sylmar, CA 91342

800.772.0900 www.anthonyintl.com

99-18258-I001_A

Table of Contents

Table of Contents

WARNINGS AND IMPORTANT NOTES ........................................................................................................ 1

Safety ..................................................................................................................................................... 1

Tools....................................................................................................................................................... 2

TIPS........................................................................................................................................................ 2

RETROFIT LED COMPONENTS ....................................................................................................................3

ADDITIONAL PARTS REQUIRED FOR Ardco FRAME ............................................................................... 5

ADDITIONAL PARTS REQUIRED FOR MODELS 1001, 401, 1KDR/1KDB, 401D/401B ............................ 5

REMOVING EXISTING LIGHTING SYSTEM ................................................................................................. 6

Removing Existing Lighting System: ...................................................................................................... 6

Locate, Drill and Mount Clip Mounting Fixtures For Center Mullion ....................................................... 7

ORIENTATION OF CENTER FIXTURES ....................................................................................................... 8

Center Mullion LED Fixture Mounting Instructions ................................................................................. 8

Locking LED Fixture to Center Mullion Fixture....................................................................................... 8

END MULLION FIXTURE ............................................................................................................................. 10

Removing Existing Lighting System ..................................................................................................... 10

Locate, Drill and Mount the LED Fixture Mounting Clip For End Mullion ............................................. 10

Orientation Of End Fixtures .................................................................................................................. 11

End Mullion LED Fixture Mounting Instructions.................................................................................... 11

Locking LED Fixture to Right End Mullion Fixture (Wires Connected at Bottom of Frame) ................. 12

Locking LED Fixture to Left End Mullion Fixture (Wires Connected at Top of Frame)......................... 13

OptiMax2 RETROFIT INSTRUCTIONS FOR

ANTHONY MODEL 401D AND 1KDR .......................................................................................................... 14

Removing Existing Lighting System ..................................................................................................... 14

Locate, Drill and Mount the Top and Bottom LED Fixture

Mounting Clips on Center Mullion (Model 401) .................................................................................... 14

Center Mullion LED Fixture Mounting Instructions ............................................................................... 16

Locate, Drill and Mount the Top and Bottom LED Fixture Mounting Clips for End Mullion .................. 17

End Mullion LED Fixture Mounting Instructions.................................................................................... 19

Locking LED Fixture to Center Mullion Fixture..................................................................................... 20

Locate, Drill and Mount the Top and Bottom LED Fixture Mounting Clips for Center Mullion.............. 21

Connecting LED Light Fixture to Wire Plug Assembly ......................................................................... 23

Ardco FRAMES ............................................................................................................................................ 24

Typical Orientations.............................................................................................................................. 24

Parts Removal ...................................................................................................................................... 24

HUSSMANN FRAME .................................................................................................................................... 26

Removing Existing Lighting System ..................................................................................................... 26

Locate, Drill and Mount the LED Fixture Mounting Clips for Hussmann Frame................................... 26

End Mullion Fixture LED Mounting Instructions.................................................................................... 27

CONNECTING THE WIRE PLUG ASSEMBLY TO THE

LED FIXTURE WIRES .................................................................................................................................. 28

Connecting Wires at the Bottom of the Frame ..................................................................................... 28

Connecting Wires at the Top of the Frame........................................................................................... 28

MOUNTING THE LED POWER SUPPLIES ................................................................................................. 30

Low Power (3-in-1 Driver)..................................................................................................................... 30

Low and High Power ............................................................................................................................ 31

Table 1 Fixture Orientation ......................................................................................................................... 32

ORIENTATION OF CENTER FIXTURES ................................................................................................

STANDARD CONFIGURATION ................................................................................................................... 36

TYPICAL INSTALLATION (HALF POWER END FIXTURES WITH SINGLE FIXTURE DRIVERS) ....36

5/18/2010 i 99-18258-I001_A

..... 34

Table of Contents

STANDARD CONFIGURATION (1-Door) ............................................................................................ 36

STANDARD CONFIGURATION (2-Door) ............................................................................................ 36

STANDARD CONFIGURATION (3-Door) ............................................................................................ 37

Standard Configuration (4-Door) .......................................................................................................... 37

(Standard Configuration (5-Door) ......................................................................................................... 37

STANDARD CONFIGURATION (6-Door) ............................................................................................ 38

OPTIONAL CONFIGURATION (FULL POWER ENDS) ...................................................................... 38

FULL POWER ENDS OPTION ............................................................................................................ 38

FULL POWER End Option (1-Door) .................................................................................................... 39

FULL POWER End & MULL Option (2-Door) ...................................................................................... 39

FULL POWER End & MULL Option (3-Door) ...................................................................................... 39

CONFIGURATION (MULTI-FIXTURE DRIVER) .................................................................................. 40

TYPICAL INSTALLATION (4-Dr Frame Shown, 3-in-1 Driver) ............................................................ 40

HALF POWER End Options (3-in-1, Driver 1-Door) ............................................................................ 40

HALF POWER End & MULL Options (3-in-1 Drive, 2-Door) ................................................................ 40

HALF POWER End & MULL Options (3-in-1 Driver, 4-Door) .............................................................. 41

HALF POWER End & MULL Options (3-in-1 Driver, 5-Door) .............................................................. 41

HALF POWER End & MULL Options (6-Door) .................................................................................... 41

3-Door (Upper Raceway) ..................................................................................................................... 42

MULLION CONFIGURATIONS .....................................................................................................................44

LED CLEANING INSTRUCTIONS ................................................................................................................46

5/18/2010 ii 99-18258-I001_A

WARNINGS AND IMPORTANT NOTES

WARNINGS AND IMPORTANT NOTES

BEFORE YOU BEGIN

Read these instructions completely and carefully.

WARNING: TO REDUCE THE RISK OF FIRE, ELECTRICAL SHOCK OR INJURY,

OBSERVE THE FOLLOWING:

1. INSTALLATION OF THIS RETROFIT ASSEMBLY REQUIRES A PERSON FAMILIAR WITH THE CONSTRUCTION AND OPERATION OF ELECTRICAL SYSTEMS AND THE HAZARD INVOLVED.

2. Use this unit in the manner intended by the manufacturer.

3. Before servicing or cleaning, switch power off.

4. Turn power off before removing existing lighting system and follow appropriate lock out/tag out safety procedures.

5. For use in a commercial refrigeration case with packaged foods only.

6. When drilling for installation hardware, be careful not to nick wires or electrical components which may result in risk

of fire or electrical shock.

7. Only those open holes indicated in the photographs and/or drawings may be made or altered as a result of kit

installation. Do not leave any other open holes in an enclosure of wiring or electrical components

8. Risk of fire or electrical shock. Install this kit only in the luminaries that has the construction features shown in the

photographs and/or drawings.

9. To prevent wiring damage or abrasion, do not expose wiring to edges of sheet metal or other sharp objects.

NOTE: Remove and dispose of existing ballasts per any local or Federal guidelines.

Safety

Proper safety equipment includes:

safety glasses

TURN OFF ALL ELECTRICAL POWER PRIOR TO BEGINNING WORK ON THE

DOOR OR ON ANY ELECTRICAL. USE EXTRA CAUTION WHEN WORKING WITH

OR AROUND THE DOOR GLASS PACKAGE.

work gloves

work shoes

5/18/2010 1 99-18258-I001_A

WARNINGS AND IMPORTANT NOTES

Tools

Tools required for this procedure include:

#2 Phillips-head screwdriver Rubber or plastic mallet

Cordless drill w/attachments Flat-head screwdriver

Needle-nose pliers Wire stripper and cutter

Razor Knife Tape measure

TIPS

• Always use the correct tool for the job to be performed. This ensures proper installation and minimizes safety

risks.

• If there is any doubt about the work to be performed, consult with a certified technician or Anthony

representative.

• Preventative maintenance is recommended to ensure product longevity.

5/18/2010 2 99-18258-I001_A

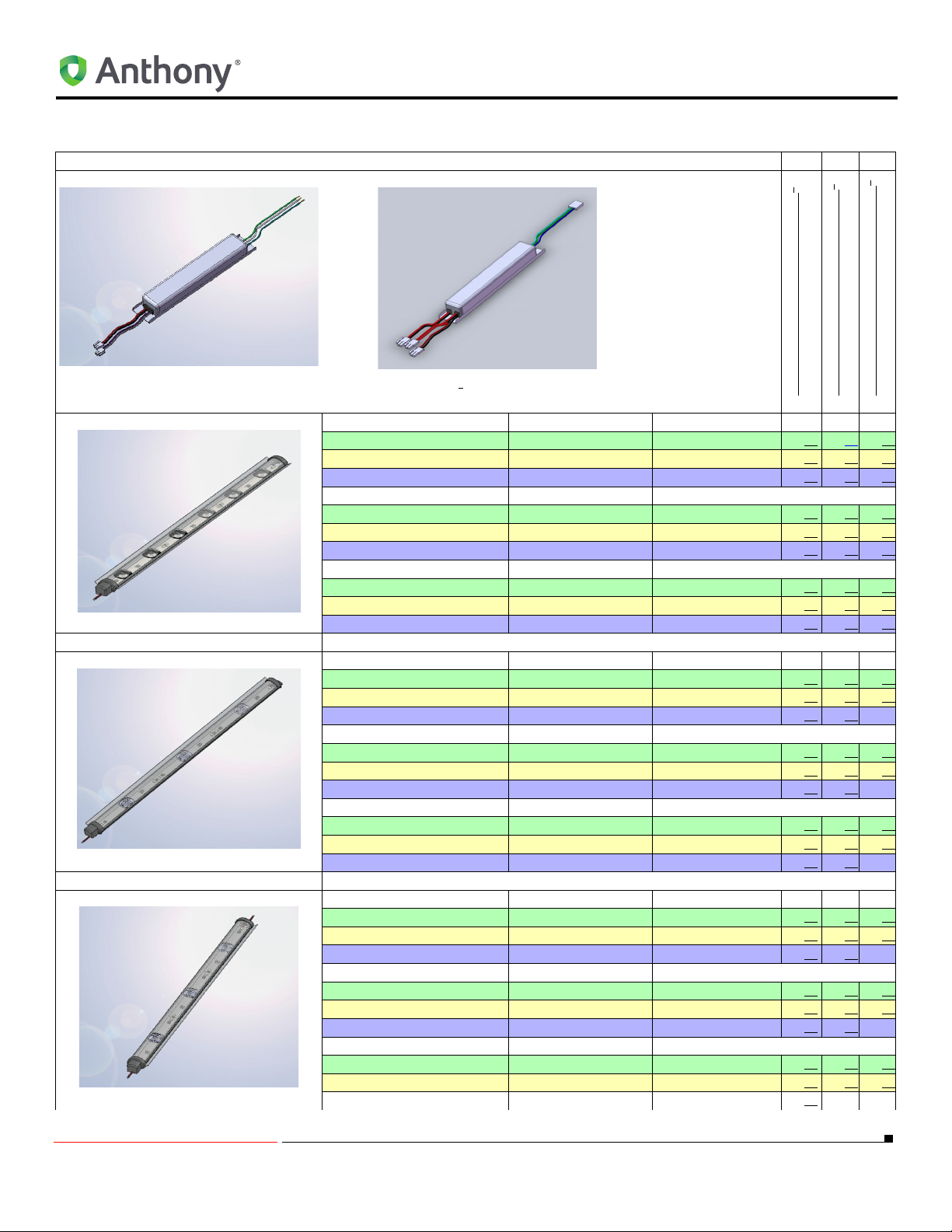

LED Power Supply Part No.

RETROFIT LED COMPONENTS

RETROFIT LED COMPONENTS

1

2

1

60-16979-0002

1

or 60-16851-0002

1

60-17544-0001

2

60-16979-0002 - 500 ma, Low Power

60-16851-0002 - 700 ma, High Power

60-17544-0001 - 500 ma, Multi-Fixture

Center Fixture Part No. Description Color Temp (K)

60-17447-0001 60” Light Fixture 4100

60-17447-0002 72” Light Fixture 4100

60-17447-0003 48” Light Fixture 4100

60-17447-1001 60” Light Fixture 5000

60-17447-1002 72” Light Fixture 5000

60-17447-1003 48” Light Fixture 5000

60-17447-2001 60” Light Fixture 3500

60-17447-2002 72” Light Fixture 3500

60-17447-2003 48” Light Fixture 3500

HALF POWER END

Right End Fixture Part No. Description Color Temp (K)

60-17445-0001 60” Light Fixture 4100

60-17445-0002 72” Light Fixture 4100

60-17445-0003 48” Light Fixture 4100

60-17445-1001 60” Light Fixture 5000

60-17445-1002 72” Light Fixture 5000

60-17445-1003 48” Light Fixture 5000

60-17445-2001 60” Light Fixture 3500

60-17445-2002 72” Light Fixture 3500

60-17445-2003 48” Light Fixture 3500

HALF POWER END

Left End Fixture Part No. Description Color Temp (K)

60-17446-0001 60” Light Fixture 4100

60-17446-0002 72” Light Fixture 4100

60-17446-0003 48” Light Fixture 4100

60-17446-1001 60” Light Fixture 5000

60-17446-1002 72” Light Fixture 5000

60-17446-1003 48” Light Fixture 5000

60-17446-2001 60” Light Fixture 3500

60-17446-2002 72” Light Fixture 3500

60-17446-2003 48” Light Fixture 3500

5/18/2010 3 99-18258-I001_A

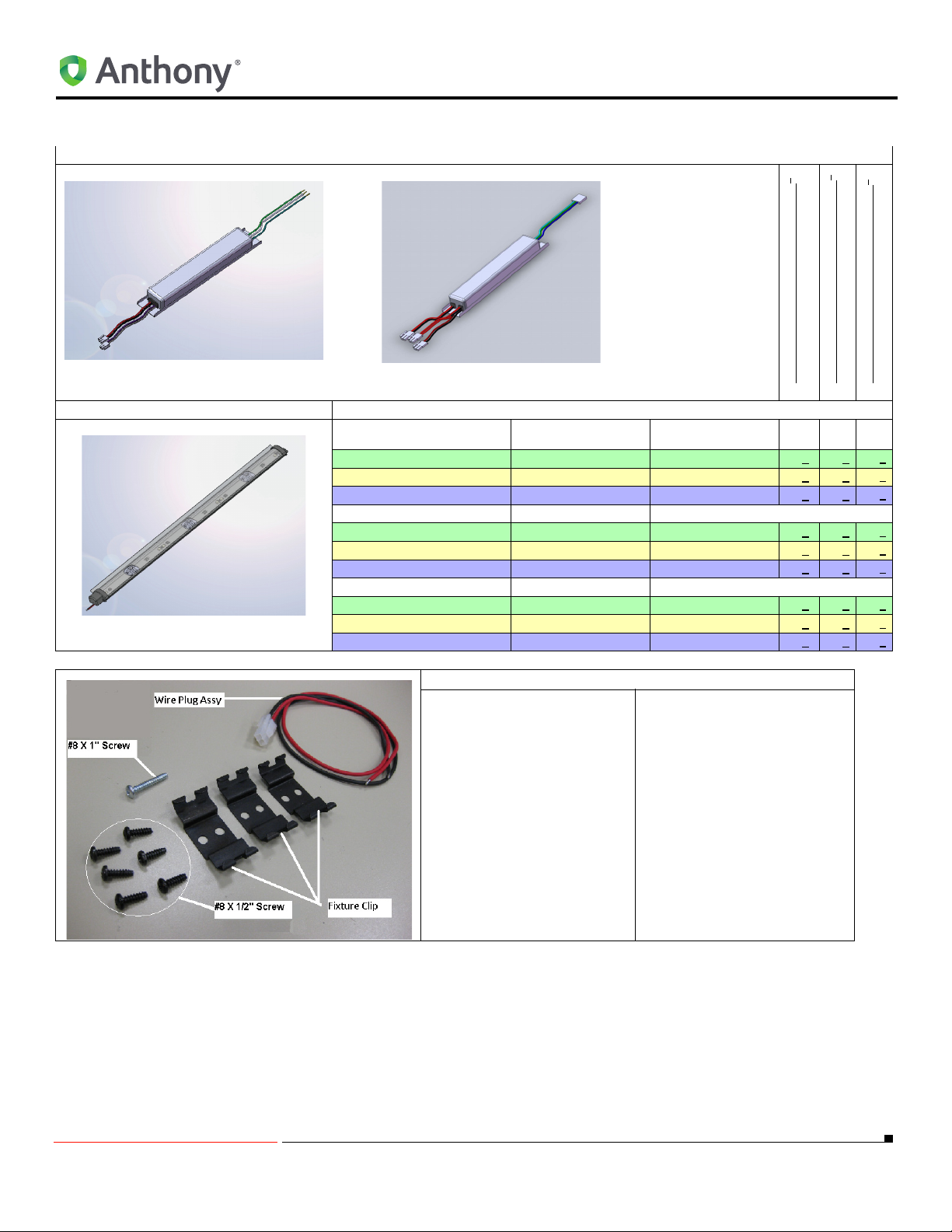

LED Power Supply Part No.

RETROFIT LED COMPONENTS

1

2

60-16979-0002

1

or 60-16851-0002

1

60-17544-0001

2

60-16979-0002 - 500 ma, Low Power160-16851-0002 - 700 ma, High Power

60-17544-0001 - 500 ma, Multi-Fixture

Full POWER END

Right End Fixture Part

No.

60-17554-0001 60” Light Fixture 4100 x x

60-17554-0002 72” Light Fixture 4100 x x

60-17554-0003 48” Light Fixture 4100 x x

60-17554-1001 60” Light Fixture 5000 x x

60-17554-1002 72” Light Fixture 5000 x x

60-17554-1003 48” Light Fixture 5000 x x

60-17554-2001 60” Light Fixture 3500 x x

60-17554-2002 72” Light Fixture 3500 x x

60-17554-2003 48” Light Fixture 3500 x x

Mounting Kit Part No.

04-18201-0001 OptiMax2 Mounting Kit

Description Color Temp (K)

x

x

x

x

x

x

x

x

x

5/18/2010 4 99-18258-I001_A

ADDITIONAL PARTS REQUIRED FOR Ardco FRAME

ADDITIONAL PARTS REQUIRED FOR Ardco FRAME

Part Number Description

15-12314-0001 UL approved enclosure

40-12348-1002 #8/32 zinc nuts

40-10997-1005 #8-32 X 3/8” screws

40-11012-1007 #10X 1/2” hex screw with washers

70-13705-0001 #1/32” thick foam sealant tape

77-12036P018 #10-32 hex nuts

NOTE:1 The OptiMax2 lamp assemblies are available from Anthony Inc. Specify the lamp length and

color temperature required when ordering LED lamp assemblies.

Items listed must be ordered before retrofiting the Ardco frame.

ADDITIONAL PARTS REQUIRED FOR MODELS 1001, 401, 1KDR/1KDB,

401D/401B

Part Number Description

40-12348-1002 #8/32 zinc nuts

40-10997-1005 #8-32 X 3/8” screws

70-13705-0001 #1/32” thick foam sealant tape

NOTE:1 The OptiMax2 lamp assemblies are available from Anthony Inc. Specify the lamp length and

color temperature required when ordering LED lamp assemblies.

Items listed must be ordered before retrofiting the model 1001, 401, 1KDR/1KDB or 401D/401B.

5/18/2010 5 99-18258-I001_A

REMOVING EXISTING LIGHTING SYSTEM

REMOVING EXISTING LIGHTING SYSTEM

Removing Existing Lighting System:

1. Remove the following items:

a. Lens

b. Fluorescent lamps

c. Lamp holder

d. Mounting clips

e. Ballasts from existing lighting system

2. For Anthony 401D and 1KDR with ELS option only:

a. Remove Mullion cover using a flat screwdriver.

b. Remove the raceway cover by inserting a flat screwdriver into the seam between the metal raceway and the

plastic cover and pry open.

NOTE: Refer to case manufactures instructions for any questions on removing the fluorescent

system and ballast.

3. Seal any open holes on Mullion using neutral cure silicone sealant (not provided).

4. Make sure you save the two #8 tapping screws used to hold the ballast.

5/18/2010 6 99-18258-I001_A

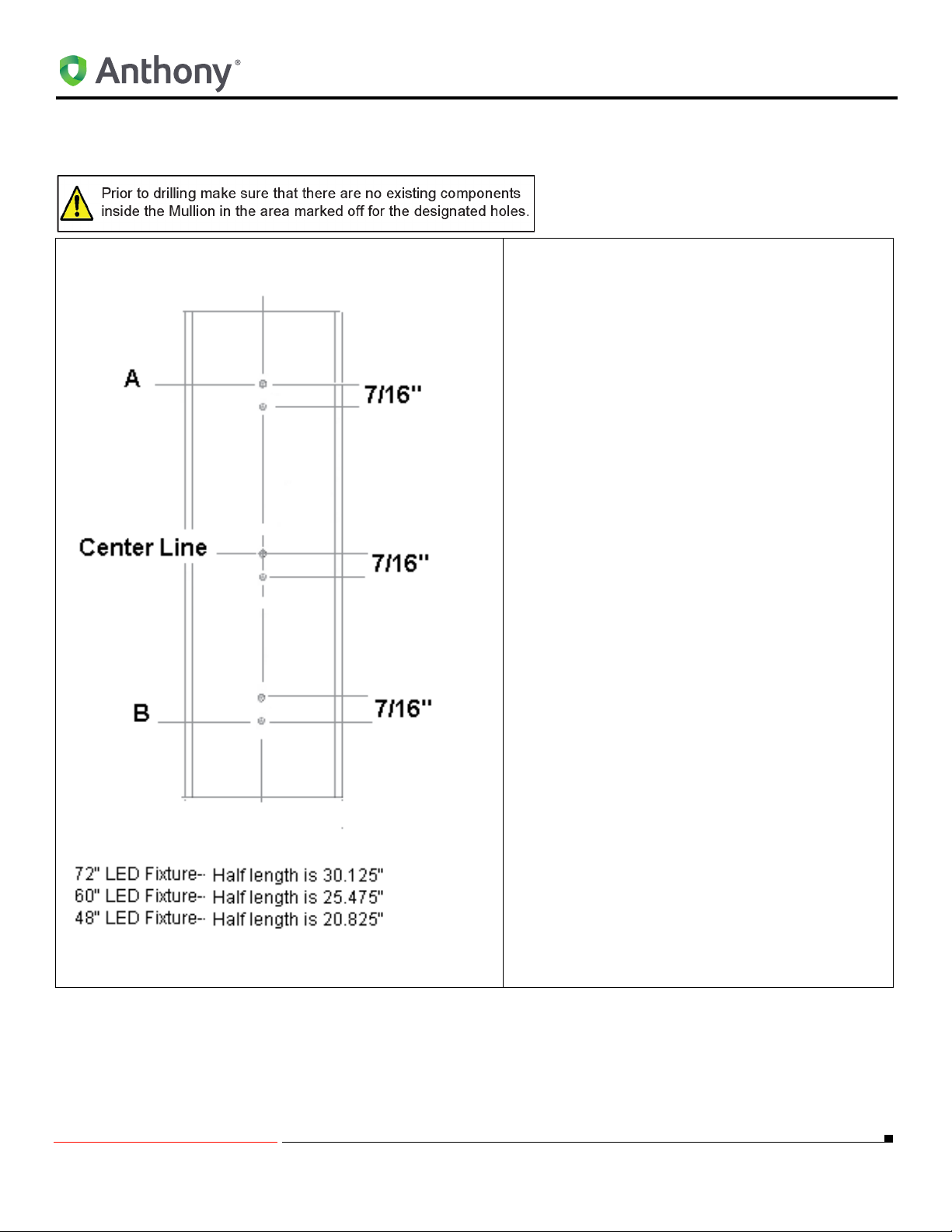

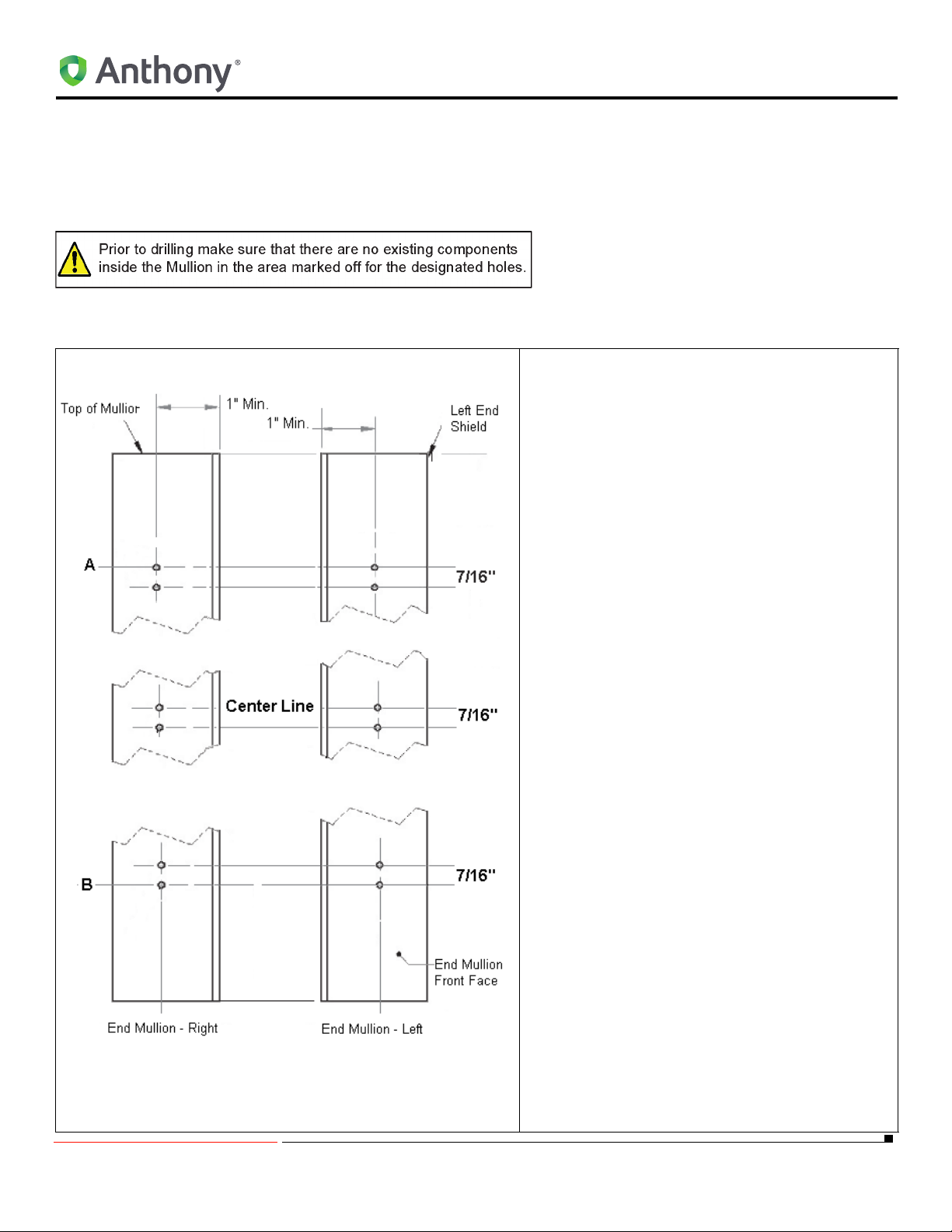

Locate, Drill and Mount Clip Mounting Fixtures For Center Mullion

1. Using a ruller measure the total width of the

Mullion and mark a vertical line half the total

width near the top and bottom of the Mullion.

2. Mark a vertical line from the top of the Mullion

to the bottom of the Mullion thru the lines measurement in step 1.

3. Divide the vertical line distance in half and

mark as a Center Line.

4. Mark a horizontal line 7/16” (0.438”) below the

center line.

5. Mark two horizontal lines, one from the center

as follows:

a. For 72” fixture-- 30.125” (

and (

B) to Center line.

REMOVING EXISTING LIGHTING SYSTEM

A) to Center Line

b. For 60” fixture-- 25.475” (

and (

B) to Center Line.

c. For 48” fixture-- 20.825” (

and (

B) to Center Line.

6. Mark one horizontal line 7/16” (0.438”) below

the line (

7. Mark one horizontal line 7/16” (0.438”) above

the line (

8. Position the center punch directly over at the

intersection of the horizontal lines (6 total) and

the vertical line (top, center and bottom) and

establish a dimple.

9. Use a power drill and (#29) 0.136” dia. drill bit,

drill (6) holes at the intersection of the vertical

center line and the horizontal lines.

10. Using a Phillips screw driver, tread the the two

#8 tapping screws (supplied) to hold each

mounting clip. A total of (6) screws and (3)

mounting clips should be installed.

11. Go to ORIENTATION OF CENTER FIXTURES

on page 8.

A).

B).

A) to Center Line

A) to Center Line

5/18/2010 7 99-18258-I001_A

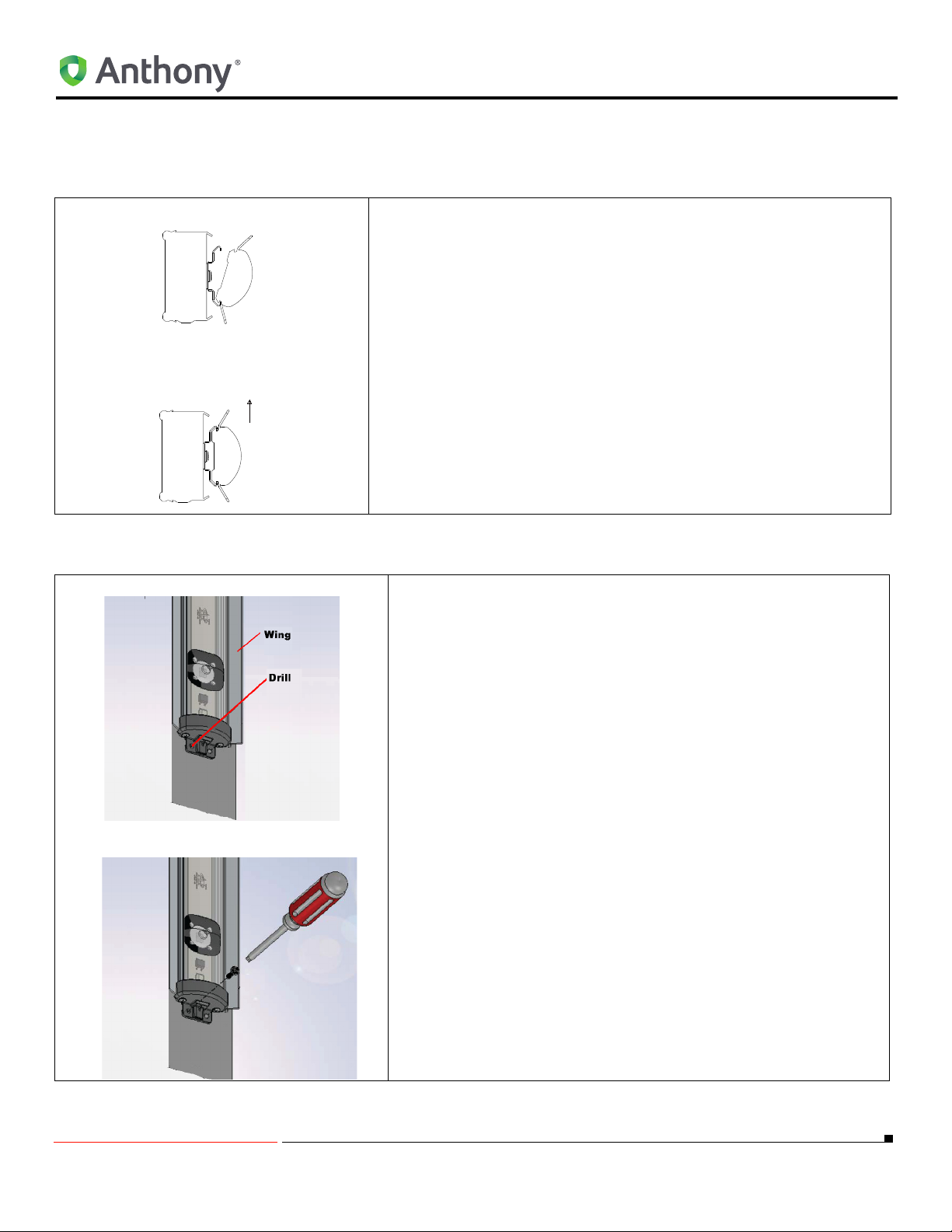

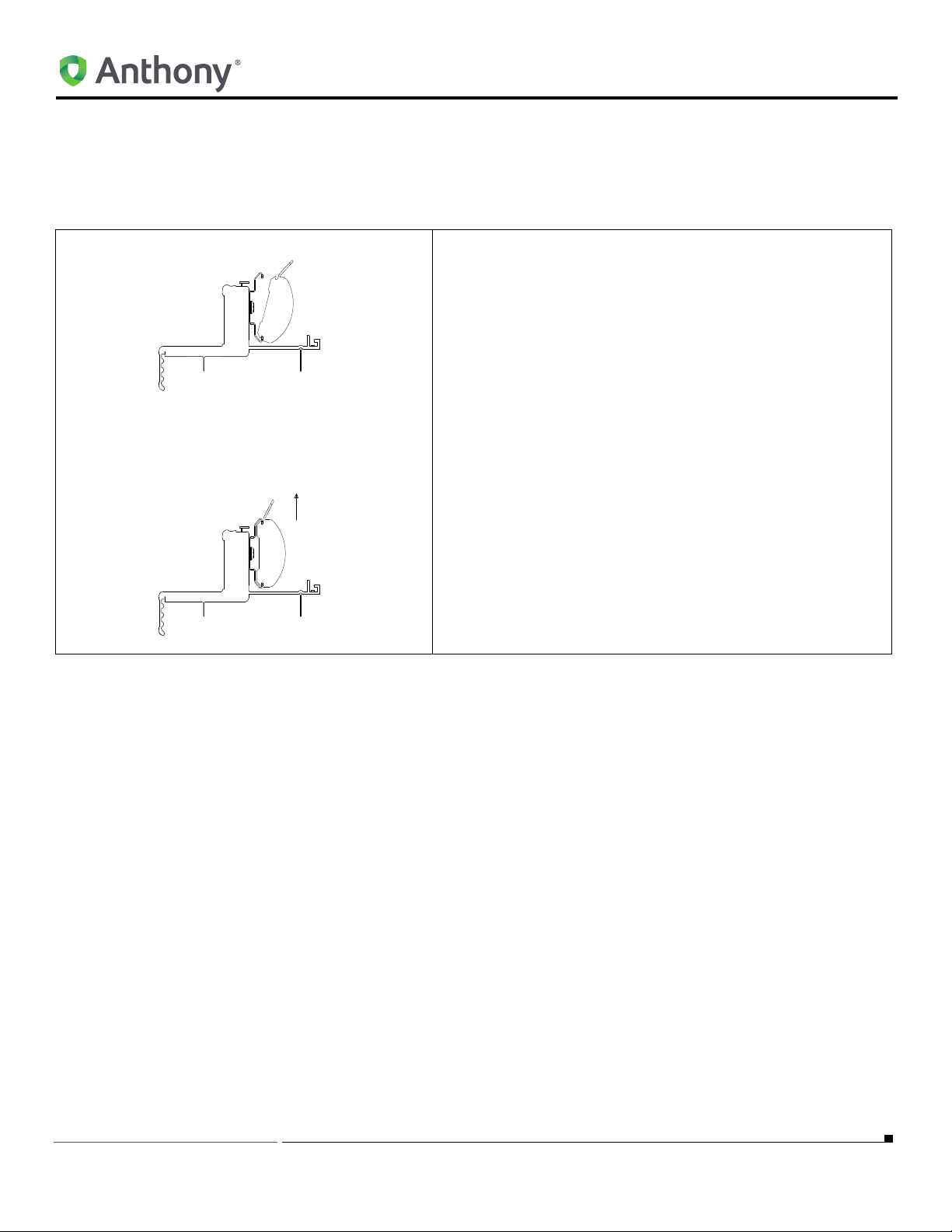

ORIENTATION OF CENTER FIXTURES

Light

Center Mullion LED Fixture Mounting Instructions

1. Align the LED light with the mounting clips so that the LEDs are

facing the display case interior. Snap the LED light into the mounting clips:

a. By placing one edge of the LED light into the groove.

b. Gently rotate until the opposite edge firmly locks into the

NOTE: Ensure that the mounting clips lock into the outer

edge of the LED light aluminum extrusion.

c. Adjust the lamp position until it is centered on the Mullion.

2. Go to Locking LED Fixture to Center Mullion Fixture on page 8.

mounting clip

ORIENTATION OF CENTER FIXTURES

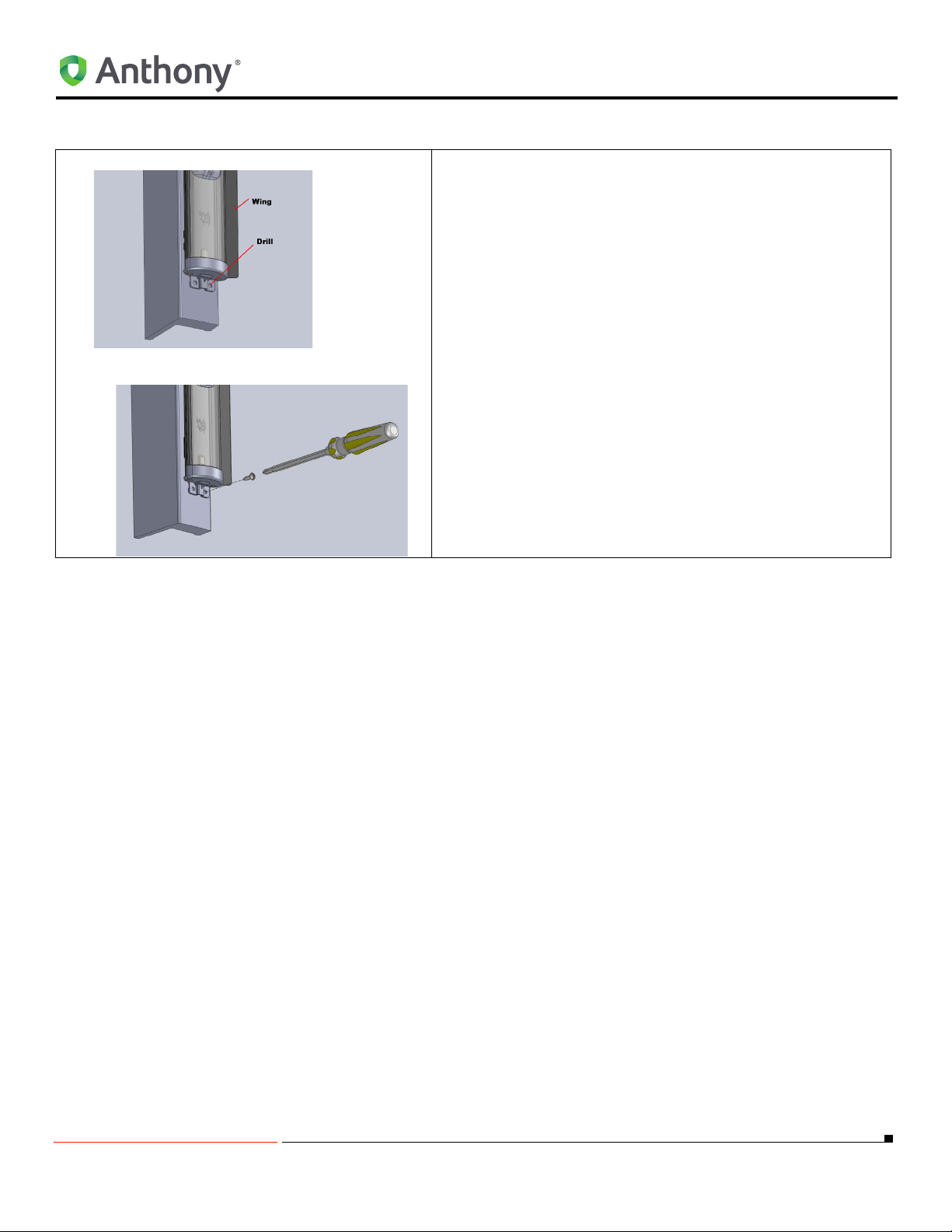

Locking LED Fixture to Center Mullion Fixture

1. Using a (#29) 0.136 dia. drill bit, drill a hole through the LED

Lighting fixture end cap and through the Center Mullion Fixture.

2. Using a Phillips screw driver to start threading the #8 X 1” long

self-tapping screw to hold the end cap to the Center Mullion.

3. Continue to “CONNECTING THE WIRE PLUG ASSEMBLY TO

THE LED FIXTURE WIRES" on page 28.

5/18/2010 8 99-18258-I001_A

ORIENTATION OF CENTER FIXTURES

5/18/2010 9 99-18258-I001_A

END MULLION FIXTURE

Removing Existing Lighting System

Refer to "Removing Existing Lighting System:" on page 6.

Locate, Drill and Mount the LED Fixture Mounting Clip For End Mullion

1. Using a ruller measure 1” min. from the inside

of the end Mullion exclusion at the top and

bottom.

2. Mark a vertical line from the top of the Mullion

to the bottom of the Mullion thru the lines

measurement in step 1.

3. Divide the vertical line distance in half and

mark as a center line.

4. Mark a horizontal line 7/16” (0.438”) below

the Center Line (

5. Mark two horizontal lines, one from the center (

A) as follows:

a. For 72” fixture-- 30.125” (

and (

A).

B) to Center Line.

END MULLION FIXTURE

A) to Center Line

b. For 60” fixture-- 25.475” (

Line and (

c. For 48” fixture-- 20.825” (

Line and (

6. Mark one horizontal line 7/16” (0.438”) below

the line (

7. Mark one horizontal line (H) 7/16” (0.438”)

above the line (

8. Position the center punch directly over at the

intersection of the horizontal lines (6 total)

and the vertical line (top, center and bottom)

and establish a dimple.

9. Use A power drill and (#29) 0.136” dia. drill

bit, drill (6) holes at the intersection of the

vertical center line and the horizontal lines.

10. Repeat step 1. thru step 9.for the opposite

side end Mullion.

11. Using a Phillips screw driver, tread the two #8

tapping screws (supplied) to hold each

mounting clip. A total of (6) screws and (3)

mounting clips should be installed per

Mullion.

12. Go to Orientation Of End Fixtures on page

11.

B) to Center Line.

B) to Center Line.

A).

B).

A) to Center

A) to Center

5/18/2010 10 99-18258-I001_A

Orientation Of End Fixtures

Light

Refer to Orientation Of End Fixtures.

End Mullion LED Fixture Mounting Instructions

END MULLION FIXTURE

1. Align the LED light with the mounting clips so that the

LEDs are facing the display case interior. Snap the LED

light into the mounting clips:

a. By placing one edge of the LED light into the groove.

b. Gently rotate until the opposite edge firmly locks into

the mounting clip.

NOTE: Ensure that the mounting clips lock into the

outer edge of the LED light aluminum extrusion.

c. Adjust the LED lamp assembly until it is centered on

the Mullion.

2. Go to Locking LED Fixture to Right End Mullion Fixture

(Wires Connected at Bottom of Frame) on page 12 or go

to “Locking LED Fixture to Left End Mullion Fixture

(Wires Connected at Top of Frame) on page 13.

5/18/2010 11 99-18258-I001_A

Locking LED Fixture to Right End Mullion Fixture (Wires Connected at Bottom of Frame)

1. Using a (#29) 0.136 dia. drill bit, drill a hole through the

LED Lighting fixture end cap and through the End Mullion

Fixture.

2. Using a Phillips screw driver to start threading the #8 X 1”

long self-tapping screw to hold the clip to the End Mullion

fixture.

3. Continue to “CONNECTING THE WIRE PLUG

ASSEMBLY TO THE LED FIXTURE WIRES" on page

28.

END MULLION FIXTURE

5/18/2010 12 99-18258-I001_A

Loading...

Loading...