Page 1

Northfire 42

WARNING: If the information in this manual is not

followed exactly, fire or explosion may result

causing property damage, personal injury or loss

of life.

Do not store or use gasoline or other flammable

vapors and liquids in the vicinity of this or any

other appliance.

WHAT TO DO IF YOU SMELL GAS:

42-dvt40n

Direct Vent

Gas Fireplace

For use with natural gas or propane*

USERS’ INSTALLATION

OPERATION &

MAINTENANCE MANUAL

∗ Do not try to light any appliance.

∗ Do not touch any electrical switch; do not use

any phone in your building.

∗ Immediately call your gas supplier from a

neighbor’s phone. Follow the gas supplier’s

instructions.

∗ If you cannot reach your gas supplier, call the

fire department.

Installation and service must be performed by a

qualified installer, service agency or the gas

supplier.

Installer: Please leave this manual with the appliance owner for future reference

7116 Beatty Dr

Mission, BC V2V 6B4

Canada

This appliance may be installed in an

aftermarket permanently located,

manufactured home (USA only) or mobile

home, where not prohibited by local codes.

This appliance is only for use with the type

of gas indicated on the rating plate. This

appliance is not convertible for use with

other gases, unless a certified kit is used.

*Conversion kit required for Propane use

200-1912

JUNE 2010

Page 2

Page 3

CONTENTS

Introduction 4

Requirements for the state of Massachusetts 5

General Information 6

Appliance Description 7

Dimensions and Clearances 8

Installation Instructions 9 - 20

Operation Instructions 21 - 22

Maintenance 23

Trouble Shooting Instructions 24 - 25

Wiring Diagrams 26

Servicing 27 - 29

Replacement Parts 30

Warranty 31

Warranty Registration Form 32

CAUTION

Due to high temperatures, the appliance should be located out of traffic and away from

furniture and draperies.

Children and adults should be alerted to the hazards of high surface temperature and stay

away to avoid burns or clothing ignition.

Young children should be carefully supervised when they are in the same room as the

appliance.

Clothing or other flammable material should not be placed on or near the appliance.

Do not operate with cracked or broken glass. Be careful not to strike or slam the glass.

Any safety screen or guard removed for servicing an appliance must be replaced prior to

operating.

Installation and Repair should be done by a qualified service person. The appliance should be

inspected before use and at least annually by a professional service person. More frequent

cleaning may be required due to excessive lint from carpeting, bedding materials, etc. It is

imperative that the control compartments, burners and circulating air passageways of the

appliance are kept clean.

Patents Pending

Page 4

Northfire 42 4

INTRODUCTION

Congratulations on choosing an Archgard fireplace!

The Northfire 42 is one of the most advanced direct vent fireplace heaters available. It is solidly

designed using the latest technology and manufactured to the highest quality. It is our aim to

provide you with an appliance for many trouble-free years of reliable service.

Some of the many features are:

Heater Classification The Northfire 42 is classified as a heating appliance.

Therefore, it has additional safety devices built-in and it can

be operated continuously for zone heating.

High Efficiency The Northfire 42 has one of the highest efficiencies of any

gas fireplace, which means that it is less expensive to

operate.

Adjustable Flame The flame aesthetics and heat output can be adjusted to suit

the owner’s liking and heating needs.

Solid Construction The Northfire 42 is constructed mainly of 14 and 18 gauge

galvanized and aluminized steel for long life and durability.

Optional Thermostatic Control The gas control system is “thermostat-ready” for any millivolt

wall thermostat or wireless remote control.

Please read the manual carefully prior to installation and operation of the appliance.

Proper installation, operation and maintenance of the appliance will provide you with

many years of enjoyment.

We recommend you record the following information:

Fireplace Model Number: 42-DVT40N Serial Number:

Date of Installation:

Type of Gas Used by the Fireplace: Natural Gas Propane

Dealer’s Name & Address:

Dealer’s Phone Number:

Page 5

Northfire 42 5

Requirements for the state of Massachusetts

5.08: Modifications to NFPA-54, Chapter 10

(2) Revise 10.8.3 by adding the following additional requirements:

(a) For all side wall horizontally vented gas fueled equipment installed in every dwelling, building or structure used in whole or in part for residential purposes,

including those owned or operated by the Commonwealth and where the side wall exhaust vent termination is less than seven (7) feet above finished grade in

the area of the venting, including but not limited to decks and porches, the following requirements shall be satisfied:

1. INSTALLATION OF CARBON MONOXIDE DETECTORS. At the time of installation of the side wall horizontal vented gas fueled equipment, the installing

plumber or gasfitter shall observe that a hard wired carbon monoxide detector with an alarm and battery back-up is installed on the floor level where the gas

equipment is to be installed. In addition, the installing plumber or gasfitter shall observe that a battery operated or hard wired carbon monoxide detector with

an alarm is installed on each additional level of the dwelling, building or structure served by the side wall horizontal vented gas fueled equipment. It shall be

the responsibility of the property owner to secure the services of qualified licensed professionals for the installation of hard wired carbon monoxide detectors

a. In the event that the side wall horizontally vented gas fueled equipment is installed in a crawl space or an attic, the hard wired carbon monoxide detector

with alarm and battery back-up may be installed on the next adjacent floor level.

b. In the event that the requirements of this subdivision can not be met at the time of completion of installation, the owner shall have a period of thirty (30) days

to comply with the above requirements; provided, however, that during said thirty (30) day period, a battery operated carbon monoxide detector with an alarm

shall be installed.

2. APPROVED CARBON MONOXIDE DETECTORS. Each carbon monoxide detector as required in accordance with the above provisions shall comply with

NFPA 720 and be ANSI/UL 2034 listed and IAS certified.

3. SIGNAGE. A metal or plastic identification plate shall be permanently mounted to the exterior of the building at a minimum height of eight (8) feet above

grade directly in line with the exhaust vent terminal for the horizontally vented gas fueled heating appliance or equipment. The sign shall read, in print size no

less than one-half (1/2) inch in size, "GAS VENT DIRECTLY BELOW. KEEP CLEAR OF ALL OBSTRUCTIONS".

4. INSPECTION. The state or local gas inspector of the side wall horizontally vented gas fueled equipment shall not approve the installation unless, upon inspection, the inspector observes carbon monoxide detectors and signage installed in accordance with the provisions of 248 CMR 5.08(2)(a)1 through 4.

(b) EXEMPTIONS: The following equipment is exempt from 248 CMR 5.08(2)(a)1 through 4:

1. The equipment listed in Chapter 10 entitled "Equipment Not Required To Be Vented" in the most current edition of NFPA 54 as adopted by the Board; and

2. Product Approved side wall horizontally vented gas fueled equipment installed in a room or structure separate from the dwelling, building or structure used

in whole or in part for residential purposes.

(c) MANUFACTURER REQUIREMENTS - GAS EQUIPMENT VENTING SYSTEM PROVIDED. When the manufacturer of Product Approved side wall horizontally vented gas equipment provides a venting system design or venting system components with the equipment, the instructions provided by the manufacturer for installation of the equipment and the venting system shall include:

1. Detailed instructions for the installation of the venting system design or the venting system components; and

2. A complete parts list for the venting system design or venting system.

(d) MANUFACTURER REQUIREMENTS - GAS EQUIPMENT VENTING SYSTEM NOT PROVIDED. When the manufacturer of a Product Approved side wall

horizontally vented gas fueled equipment does not provide the parts for venting the flue gases, but identifies "special venting systems", the following requirements shall be satisfied by the manufacturer:

1. The referenced "special venting system" instructions shall be included with the appliance or equipment installation instructions; and

2. The "special venting systems" shall be Product Approved by the Board, and the instructions for that system shall include a parts list and detailed installation

instructions.

(e) A copy of all installation instructions for all Product Approved side wall horizontally vented gas fueled equipment, all venting instructions, all parts lists for

venting instructions, and/or all venting design instructions shall remain with the appliance or equipment at the completion of the installation.

For the State of Massachusetts, installation and repair must be done by a plumber or gasfitter licensed in the Common-

wealth of Massachusetts.

For the State of Massachusetts, flexible connectors shall not exceed 36 inches in length.

The State of Massachusetts requires the installation of a carbon monoxide alarm in accordance with NFPA 720 and a CO

alarm with battery back up in the same room where the gas appliance is installed.

For the State of Massachusetts the appliances individual shut – off must be a t-handl e type valve

.

Page 6

Northfire 42 6

GENERAL INFORMATION

APPLIANCE CERTIFICATION

This appliance is tested and certified to the following US and Canadian gas appliance

standards.

- ANSI Z21.88b-2003 / CSA 2.33b-2003, Vented Gas Fireplace Heaters

- CAN / CGA-2.17-M91, Gas-Fired Appliances for Use at High Altitudes

Please contact Archgard Industries Ltd., if you have any questions regarding the certification of

this appliance.

INSTALLATION CODES

This appliance must be installed by a qualified gas appliance installer.

The installation must conform with the local codes or, in the absence of local codes, with the

current National Fuel Gas Code, ANSI Z223.1/ NFPA 54, in the US or Installation Code, CAN/

CGA-B149, in Canada. Electrical connections and grounding must conform with local code, or

current National Electrical code, ANSI/NFPA No. 70-1987, in the US and in Canada, the

current Canadian Electrical Code, CSA C22.1.

We recommend that our gas hearth products be installed and serviced by professionals

who are certified in the U.S. by the National Fireplace Institute® (NFI) as NFI Gas

Specialists

SPECIFICATIONS

Manifold Pressure

Minimum Supply Pressure for

Purpose of Input Adjustment

Orifice Size

Nominal Input Rating

Altitude

Primary Air Opening

Natural Gas (NG) Propane (LP)

1.6 - 3.5 in. W.C. (0.4 - 0.9 kPa) 6.3 - 10.0 in. W.C. (1.6 - 2.5kPa)

4.5 in. w.c. (1.1 kPa) 11.0 in. w.c. (2.7 kPa)

#31 DMS (3.05 mm dia.) #50 DMS (1.60 mm dia.)

27,000 - 40,000 BTU/hr

(7.9 - 11.7 kW)

0 - 4500 ft (0 - 1372 m) 0 - 4500 ft (0 - 1372 m)

¼ in. (9.6 mm) ¼ in. (9.6 mm)

30,000-35,50000 BTU/hr

(9.1 - 10.7 kW)

HIGH ALTITUDE INSTALLATION

When installing this appliance beyond 4500 ft. (1372 m) above sea level. The appliance must

be properly de-rated and installed according to local codes, in the absence of local codes, with

the current National Fuel Gas Code, ANSI Z223.1/ NFPA 54, in the US or Installation Code,

CAN/CGA-B149, in Canada.

Page 7

Northfire 42 7

APPLIANCE DESCRIPTION

FLAT FRONT

Top Louvers

(removable)

Ceramic glass front

Hinged bottom louvers

for control access

Page 8

Northfire 42 8

DIMENSIONS AND CLEARANCES

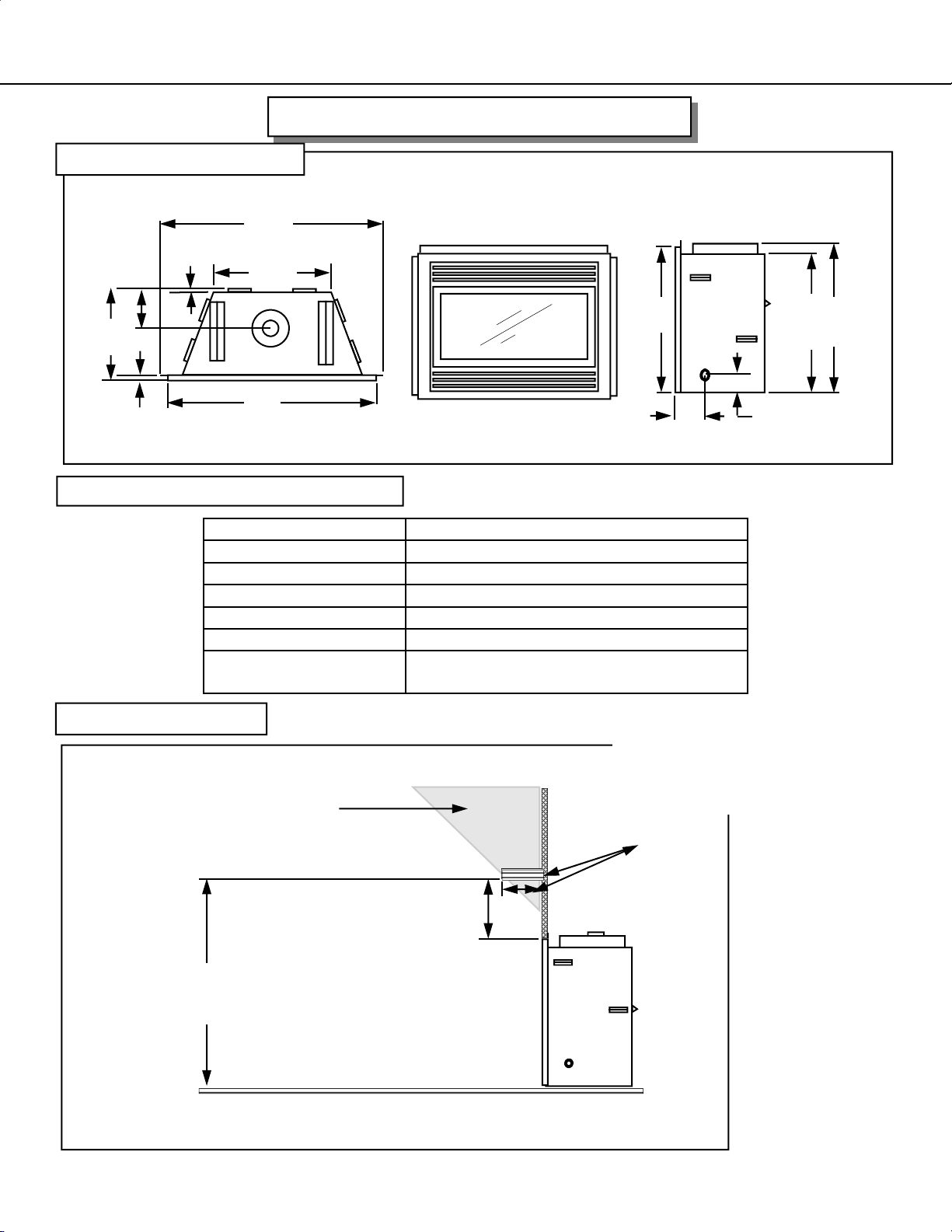

APPLIANCE DIMENSIONS

44”

½”

23 ¼”

6 ½”

18”

42”

3/8 ¾”

CLEARANCES TO COMBUSTIBLES

BACK

SIDES

TOP

BOTTOM

ADJACENT SIDE WALL

MANTLE

VENT

MANTLE CLEARANCE

Combustible mantle allowed in

shaded area. Mantle extension

may be increased 1” (25mm)

for each additional 1” (25mm)

increase in clearance height.

34”

SIDE VIEW FRONT VIEW TOP VIEW

0” to stand-offs

0” to stand-offs

0” to stand-offs

0”

1” to side of faceplate

see diagram

1” to outside side and bottom surface,

2” to outside top surface.

NOTE: Low profile wooden crowns and

moldings above the unit are not

considered as mantles. I.E. 1” or less

protrusions on the upper mantle facing

are acceptable

6” (152 mm)

6 ½”

4 ½”

32 ½”

35 ½”

Minimum Height From Top

Surround: 12” (304mm)

Minimum Height From Bottom

of Appliance: 46” (1165mm)

Page 9

Northfire 42 9

INSTALLATION INSTRUCTIONS

PRECAUTIONS

• This appliance must be installed by a qualified gas installer and the

installation must conform to the installation codes.

• Provide adequate clearance around air openings of the appliance. Never

obstruct front openings.

• Provide adequate clearances for proper operation and servicing of the

appliance.

• This appliance must be properly connected to a venting system.

• This gas appliance must not be connected to a chimney serving a separate

solid-fuel burning appliance.

• Do not use this appliance if any part has been under water. Immediately call a

qualified service technician to inspect the appliance and to replace any part

of the control system and any gas control which has been under water.

• Caution: Label all wires prior to disconnection when servicing controls.

Wiring errors can cause improper and dangerous operation.

• Verify proper operation after servicing.

• Do not use substitute materials.

• Do not abuse glass doors by striking or slamming shut.

• Do not use abrasive cleaners.

• Use only approved fireplace glass cleaner for cleaning your glass.

LOCATING GAS FIREPLACE

This appliance must be installed in any location that is free of plumbing, electrical wiring and

heating or air conditioning ducts. Select a location that is accessible for venting. See

ALLOWABLE TERMINATION LOCATIONS on page 13.

GAS CONNECTIONS

Have your gas supplier or a qualified gas fitter run a gas supply line into the fireplace. The line

must be properly sized and fitted according to the installation codes. Immediately up stream of the

supply connection, the fitter shall provide an accessible manual shut-off valve and a ⅛ NPT

plugged tapping accessible for connection to a test gauge.

CAUTION: The appliance and its individual shutoff valve must be disconnected from the gas

supply piping system during any pressure testing of that system at test pressures in excess of ½

psig (3.5 kPa). The appliance must be isolated from the gas supply piping system by closing its

individual manual shutoff valve during any pressure testing of the gas supply piping system at test

pressures equal to or less than ½ psig (3.5 kPa). Failure to do so will damage the appliance’s gas

valve. Such damage is not covered by the manufacturer’s warranty.

Page 10

Northfire 42 10

INSTALLATION INSTRUCTIONS Cont...

Natural Gas Pressure Settings:

The inlet supply or line pressure must be a minimum of 4.5” w.c. (1.1 kPa) and a maximum of

8” w.c. (2 kPa). The orifice has a #31 DMS drill size.

ELEVATION INPUT RATING

0-4500 ft. (0-1372 m) 40,000 BTU/hr (11,700 watts)

4500 ft. (1372 m) + 40,000 BTU/hr (11,700 watts) less 4% per 1000 ft. (300 m)

Please contact your local distributor for the appropriate orifice size.

Propane Pressure Settings:

The inlet supply or line pressure must be a minimum of 11” w.c. (2.8 kPa) and a maximum of

14” w.c. (3.5 kPa). The orifice has a #50 DMS drill size.

ELEVATION INPUT RATING

0-4500 ft. (0-1372 m) 36,500 BTU/hr (10,700 watts)

4500 ft. (1372 m) + 36,500 BTU/hr (10,700 watts) less 4% per 1000 ft. (300m)

Please contact your local distributor for the appropriate orifice size.

NOTE: THE INPUT RATING SHOULD ALWAYS BE CHECKED WHEN FIRST RUNNING

THIS APPLIANCE. To do this, reduce the background flow rate, time the meter, light the

fireplace and take another reading after 15 mins. of operation. Check with your gas supplier for

the gas BTU content at your elevation. Input is the rate of flow multiplied by the heating value

of the gas (cubic feet/hour x BTU per cubic feet). Adjust the manifold pressure so that the unit

does not operate above the rated input. To do this, loosen the screw on the variable input knob

on the valve and reposition that the maximum input is correct. Retighten the screw.

ELECTRICAL CONNECTIONS

The Northfire 42 comes complete with a Blower installed and wired to an internal junction box.

Have a qualified electrician run a 120VAC supply line to the lower left side of the fireplace

before installing the appliance. He should leave 18” (460mm) of the supply line free for ease of

connection to the appliance. Connect the electrical supply line to the appliance at the same

time the gas line is being connected to the appliance.

Flip open the bottom grill and undo the 2 screws holding the control panel. Run the line into the

left side of the appliance through the hole in the rear of the junction box and hold with a

standard ⅞” clamp. Connect the ‘live’ (black) supply conductor to the free black conductor from

the speed controller with a marrette type wire connector. Connect the ‘neutral’ white supply

conductor to the free white conductor from the convection fan with a marrette type wire

connector. Connect the ‘ground’ (green or bare) conductor to the ground screw in the junction

box. Replace the junction box cover and control panel and fasten with the 2 screws.

Page 11

Northfire 42 11

INSTALLATION INSTRUCTIONS Cont...

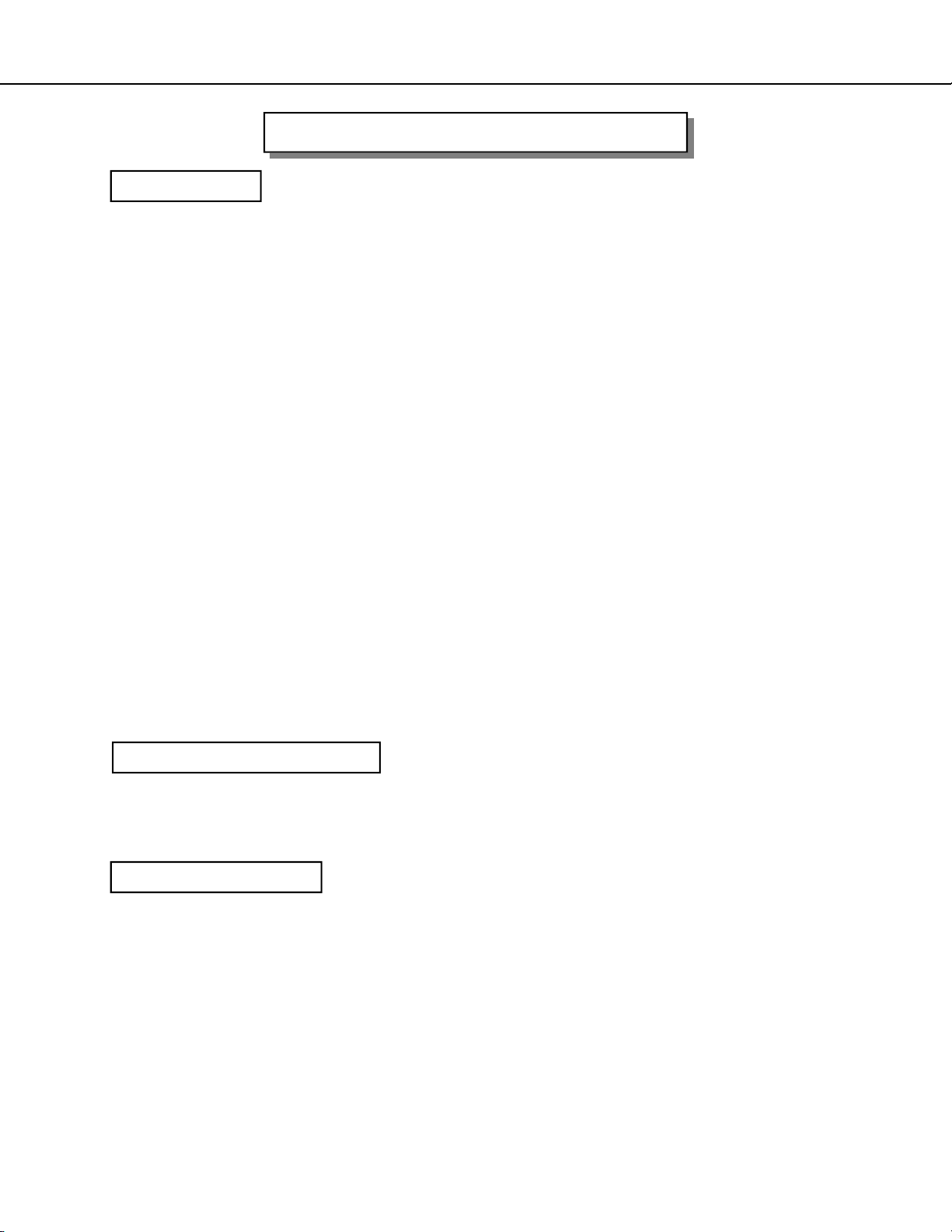

WIRING DIAGRAM

120 VAC

LINE

NEUTRAL

GROUND

NEUTRAL

GROUND

LINE

SPEED CONTROL

black

white

SIDE OF GAS

FIREPLACE

SPEED

CONTROL

MO

CONVECTION BLOWER

110F (43ºC) N.O. THERMAL

SNAP SWITCH

CONVECTION BLOWER

110F (43ºC) N.O.

THERMAL SNAP

SWITCH

VENT TERMINATION

1. See ALLOWABLE TERMINATION LOCATIONS and establish a suitable vent termination

location.

2. In heavy snowfall areas make sure vent termination is located where it cannot be blocked by

snow or snow from snow removal equipment.

3. Locate vent termination away from plants, bushes or any other object near the vent

termination that will interfere or obstruct the air flow around it.

4. DO NOT recess vent termination into walls, sidings or planters.

5. Vent terminations located below 7ft from grade level or anywhere that it can be a burn hazard

to the public, such as patios and balconies, must be protected with an Archgard approved

termination cage.

ALLOWABLE FIREPLACE LOCATIONS

See venting chart for

maximum and minimum

vertical/horizontal

venting configurations.

Page 12

Northfire 42 12

INSTALLATION INSTRUCTIONS Cont...

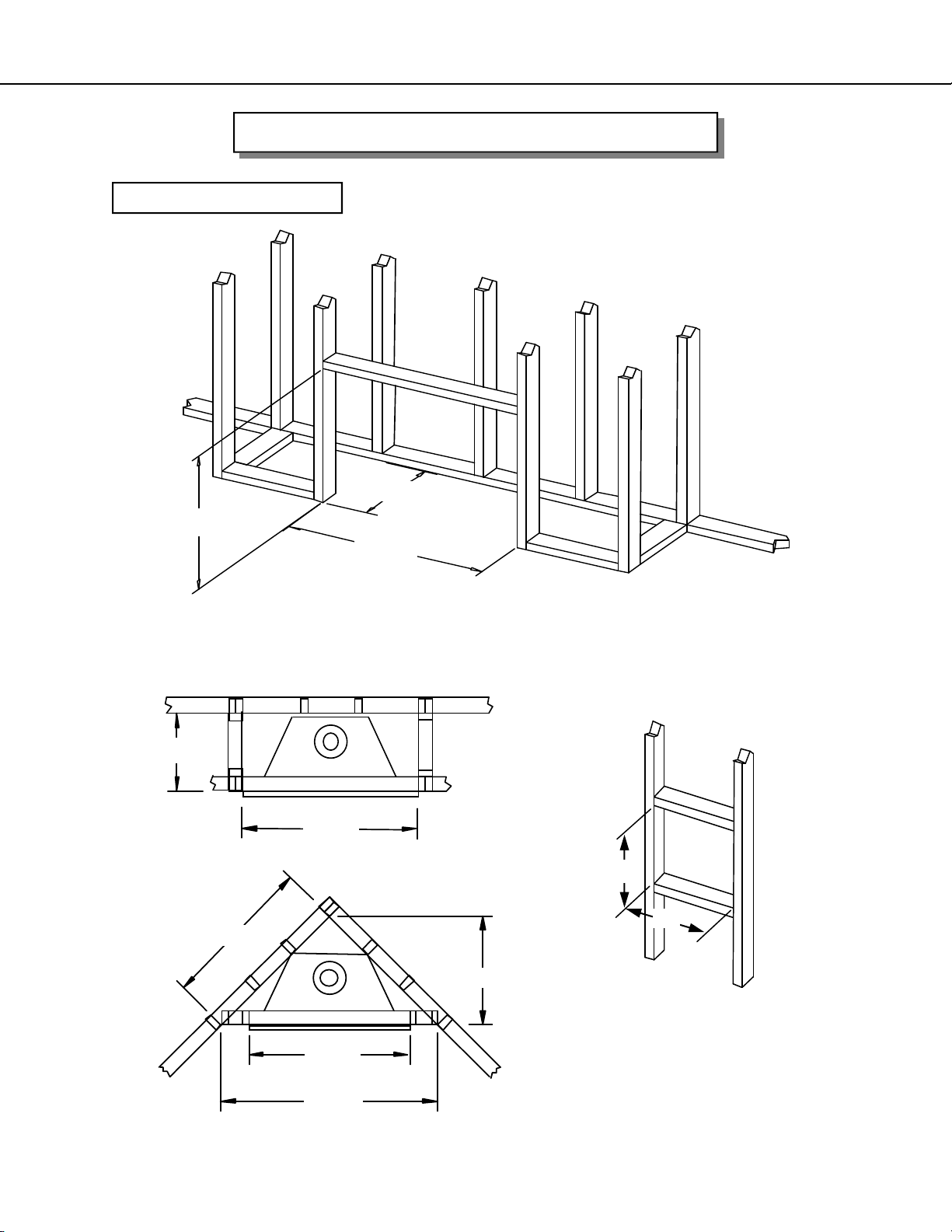

FRAMING DIMENSIONS

17 ½”

35 ¾”

17 ½”

42”

TERMINATION

FRAMING

42”

11”

10”

41”

42”

58”

29”

NOTE: Be sure to include ¼” rise per

foot of horizontal length.

For rear vented fireplace be

sure to include 1” vertical rise

minimum per foot of horizontal

length beyond 6”.

Page 13

Northfire 42 13

INSTALLATION INSTRUCTIONS Cont...

VENTING

The appliance will not function without being connected to a proper venting system.

This appliance may only use direct vent system supplied by Archgard, or Simpson

Dura-Vent direct vent systems with Archgard #999-DV-SDA adapter.

VENTING CHART

FT.

28

26

24

22

20

18

16

14

12

Restrictor 2

Restrictor 1

10

8

VERTICAL HEIGHT

6

4

2

No Restrictor

VERTICAL HIEGHT

Note:

12108642

Note: No Installations

are permitted outside

of this range.

2

4681012

Restrictors are to be used in

vertical vent installations.

See page 14 for

restrictor placement

HORIZONTAL LENGTH

NOTE: Minimum vertical rise of 18” is required for a horizontal run of 36” or less. Measured from the top of

the unit to the center of the elbow.

• Chart is for one 90° bend, with ¼” (7 mm)vertical raise minimum per foot of horizontal length.

• For each additional 90° or two 45°, add one foot of vertical height.

• Maximum three 90º bends, or equivalent.

• Minimum 2 ft (610 mm) straight length between bends.

VENTING ABOVE ROOF OF THE HOUSE USING A VERTICAL TERMINATION

Use Simpson Dura-Vent listed direct vent system caps for all vertical vent termination

applications (through the roof).

Please follow the venting instructions as strictly as possible to

obtain the best performance from the appliance.

Page 14

Northfire 42 14

ALLOWABLE TERMINATION LOCATIONS

horizontally

within 10 feet (3 m)

12 inches (30 cm) 9 inches (23 cm)

supply inlet to building or the

6 feet (1.83 m) 3 feet (91 cm) above if

combustion air inlet o any other

appliance

air supply inlet

7 feet (2.13 m) + *

12 inches (30 cm) ++ *

(1) In accordance with the current CSA B149.1, National Gas and Propane Installation Code (2) In accordance with the current ANSI Z223.1/NFPA 54, National Fuel Gas Code

(+) A vent shall not terminate directly above a side walk or paved driveway that is located

between two single family dwellings and serves both dwellings (++) Permitted only if veranda, porch, deck, or balcony is fully open on a minimum of two

sides beneath the floor. (*) For clearances not specified in ANSI Z223.1/NFPA 54 or CSA B149.1, “Clearances shall

sidewalk or paved driveway

located on public property

porch, deck, or balcony

*

be in accordance with local installation codes and the requirements of the gas supplier.”

12 inches (30 cm) 12 inches (30 cm) J= Clearance to non-mechanical air

Canadian Installations (1) US Installations (2) Canadian Installations (1) US Installations (2)

A= Clearance above grade,

veranda, porch, deck, or

balcony

12 inches (30 cm) 12 inches (30 cm) K= Clearance to a mechanical

B= Clearance to window or

door that may be opened

* * L= Clearance above paved

C= Clearance to permanently

closed window

* * M= Clearance under veranda,

D= Vertical clearance to

ventilated soffit located

above the terminal within a

horizontal distance of 2 feet

(61 cm) from the center line

of the terminal

E= Clearance to unventilated soffit * *

above the

3 feet (91 cm) *

height 15 feet (4.5 m)

3 feet (91 cm) within a

meter/regulator assembly

F= Clearance to outside corner * *

G= Clearance to inside corner * *

H= Clearance to each side of

center line extended above

meter/regulator assembly

L= Clearance to service

regulator vent outlet

Page 15

Northfire 42 15

VENTING - RESTRICTOR PLACEMENT

RESTRICTOR PLACEMENT “FOR ROOFTOP VENTED APPLICATIONS ONLY”

WARNING: These restrictors are only to be installed in the vent system if the vent exceeds 8’

in vertical height, *Restrictor Number 1 below is required and if the vent system

exceeds 15’ vertically, *Restrictor Number 2 below is Required. Installing them

under any other circumstances may cause hazardous venting conditions

and may result in personal injury, property damage or death.

“NOT FOR USE IN SIDEWALL VENTED APPLICATIONS”

Restrictor Number #1

Vertical Venting - Above

Eight Feet (8’)

NOTE: Vent restrictors are designed to reduce vertical stack action for vent

terminations which will reduce the velocity of incoming combustion air and

not adversely affect the standing pilot or the efficiency of the appliance.

Simpson Dura-Vent

With Simpson Dura-Vent,

locate the restrictor in the exhaust

section fitting into the formed lip.

Restrictor Number #2

Vertical Venting - Above

Fifteen Feet (15’)

Archgard System

In the Archgard system, the

restrictors are placed on the

exhaust outlet on the appliance.

Simpson Dura-Vent

Archgard System

Page 16

Northfire 42 16

INSTALLATION INSTRUCTIONS Cont...

VENTING - Continued

For best venting performance, here are some general venting rules that we recommend:

1. Use only Archgard or Simpson Dura Vent direct vent systems and components.

2. Maintain a minimum of 1” (26 mm) clearance to combustibles from the outside surfaces of

vertical vents and minimum of 1” (26 mm) sides and bottom, and 2” (51 mm) from top surfaces

of horizontal vents.

3. Observe any local code restrictions, if any, regarding the installation of this type of gas

appliance.

4. Observe the venting chart given in this manual.

5. Use vent spacers between the inside and outside vents at every 3 ft (915 mm) intervals

(Archgard vent kits only).

6. Never slope horizontal vents downwards.

7. Maintain at least a rise of ¼” (7 mm) for every 1 ft (305 mm) of horizontal vent.

8. Terminate the vent with a suitable vent termination supplied by Archgard Part #999-DV-HTC or

Simpson Dura Vent.

9. Support horizontal vents every 3 ft (915 mm) to prevent it from sagging.

APPROVED VENT COMPONENTS

PART # DESCRIPTION

999-DV-TVK3 Flex Vent Kit with 36” vent length (includes 999-DV-HTC)

999-DV-TVK5 Flex Vent Kit with 60” vent length (includes 999-DV-HTC)

999-DV-HTC Horizontal termination head only

999-DV-VSD Vinyl siding deflector

999-DV-STC 24” Snorkel

999-DV-SDA Adaptor, Flex to Simpson Dura-Vent

999-DV-SDA Adaptor, Appliance to Simpson Dura-Vent

DV-GS Simpson Dura-Vent venting system

VENTING CONNECTION

The intake pipe must be securely fastened to the appliance and to the terminal and all joints

shall be secured using a minimum of 3 screws evenly spaced around the pipe.

Approximately 1” from the end of the 4” pipe outlet at the appliance and at the 4” terminal inlet

apply a bead of Mil Pac ¼” wide. Slide the 4” pipe onto the appliance and secure with 3 screws

evenly spaced to the outlet. Repeat the procedure at the terminal inlet.

Install a vent spacer between the outer and the inner liner to maintain clearances. Spacers

should be installed at every change of direction. (See diagram)

Clearance to combustible material and fire-stops must be installed as required by the installation

codes.

Page 17

Northfire 42 17

INSTALLATION INSTRUCTIONS Cont...

VENT KIT COMPONENTS (999-DV-TVK3)

VENT ASSEMBLY

Termination

Fire-stop

Sleeve

7” and 4” flex

vent lengths

(compressed

Cement

Screws

Spring

spacers

4” exhaust vent

with spring spacers

Vent system

assembled

Cut sleeve to fit wall thickness

Page 18

Northfire 42 18

INSTALLATION INSTRUCTIONS Cont...

GLASS DOOR

WARNING: Do not attempt to remove the glass door when the appliance is hot.

Removing the Glass Door

Remove the top louver by lifting off and open bottom louver.

There are 3 buckle latches under the door frame. Lift the lever on the back of the

latches to release them. Unhook the latches from the bottom of the door. Swing the

bottom of the door towards you. Lift up on the whole door to unhook the top of door.

Carefully remove the door put it away at a safe location where it cannot be scratched

or damaged.

Replacing the Glass Door

The reverse procedure of Removing the Glass Door.

Page 19

Northfire 42 19

INSTALLATION INSTRUCTIONS Cont...

LOG PLACEMENT

• Locator pins are provided to assist in log location

• LOCATOR PINS

• Locate the rear log on the locator pins in the rear of the firebox and then the front logs on

the 3 pins located on the rear log.

• Carefully place the ember chunks on the ledge between the grate and the front of the

burner.

• Do not allow the embers to obstruct the burner ports.

WARNING: Do not place logs in any other configuration than that

shown. Under no circumstances are logs to be modified.

Page 20

Northfire 42 20

Locate the rear top log onto the locater pin on the top of the rear log as shown

Locate the right log onto the locater pins as shown as shown

Page 21

Northfire 42 21

Locate the back left log on the locater pins

Locate the left front log on the locater pins as shown

Page 22

Northfire 42 22

Locate the right log onto the locater pin on the bottom log and the

locater pin on the burner pan

Locate the center log on the locater pin on the burner and rest it

on the rear log as shown

Page 23

Northfire 42 23

Place the coals on the burner making sure not to block any burner ports or air passages. Do not place coals over the gap between the burner and the base.

Page 24

Northfire 42 24

INSTALLATION INSTRUCTIONS Cont...

OPTIONAL BAY DOOR INSTALLATION

WARNING: THE OPTIONAL BAY DOOR IS A DECORATIVE

OPTION ONLY AND IS MANUFACTURED WITH TEMPERED

GLASS. THIS UNIT MUST NOT BE OPERATED WITHOUT

THE FLAT CERAMIC DOOR SECURED IN PLACE, BEHIND IT.

NOTE: Ensure that the fireplace is turned off and cool.

1 Remove the upper grilles by pulling the assembly forward.

2 Remove the lower grilles by removing the four hex head mounting screws.

3 Install The knob extensions on the valve.

4 Move the bay assembly over the front of the appliance, center in front of the flat

door and hang over existing door.

Retaining hooks

(behind)

Access door

Page 25

Northfire 42 25

OPERATION INSTRUCTIONS

FOR YOUR SAFETY, READ BEFORE LIGHTING

INITIAL OPERATION

• Check that the appliance is properly vented and connected to the gas supply.

• Check that the logs and branches are properly placed.

• Check that all external parts, such as grills, door and faceplate are properly attached

and fastened.

• Check that there are no finger prints left on gold surfaces as high temperature can

bake these prints permanently.

NOTE : When operated for the first few times, the appliance will emit some odor and

fumes. This is due to the heat from the appliance evaporating the oils and solvents

used in fabricating the appliance. Close off the room to the rest of the house and

open all windows. Keep the room well ventilated as smoke alarm may sound. Run

the appliance for at least 4 hours at maximum setting with blower set to “OFF” to

allow paint to cure.

WARNING : If you do not follow these instructions exactly, a fire or explosion

may result, causing property damage, personal injury or loss of

life. Do not operate the appliance with the glass front removed,

cracked or broken. Replacement of the glass should be done by a

licensed or qualified service person.

Page 26

Northfire 42 26

OPERATION INSTRUCTIONS Cont..

LIGHTING INSTRUCTIONS (copy of instruction plate found in control panel)

FOR YOUR SAFETY READ BEFORE LIGHTING

WARNING: If you do not follow these instructions exactly, a fire of explosion may result causing property damage,

personal injury or loss of life.

A. This appliance has a pilot which must be lighted by a spark

ignitor. When lighting the pilot follow these instructions

exactly.

B. BEFORE LIGHTING smell all around the appliance area for

gas. Be sure to smell next to the floor because some gas is

heavier than air and will settle on the floor.

WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use any phone in

your building.

• Immediately call your gas supplier from a neighbor’s phone.

Follow the gas supplier’s instructions.

• If you cannot reach your gas supplier, call the fire

department.

C. Use only your hand to push in or turn the gas control knob.

Never use tools. If the knob will not push in or turn by hand

don’t try to repair it, call a qualified service technician. Force

or attempted repair may result in a fire or explosion.

D. Do not use this appliance if any part has been under water.

Immediately call a qualified service technician to inspect the

appliance and to replace any part of the control system and

any gas control which has been under water.

LIGHTING INSTRUCTIONS

1. STOP! Read the safety information above on this label.

2. Set the remote switch to “OFF”. Set the thermostat to the

lowest setting. (Only if your appliance is equipped with these

devices.)

3. Turn off all electric power to the appliance.

4. Open lower louvers or access door.

3. Press slightly and turn the control knob clockwise to the

“OFF” position.

4. Wait 5 minutes to clear out any gas. Then smell for gas,

including near the floor. If you smell gas, STOP! and follow

instruction “B” above.

5. Find pilot. It is located between the logs near the center behind the burner.

6. Press slightly and turn control knob counterclockwise to

“PILOT”. Depress knob and light pilot by repeatedly pressing

the sparker. Once flame is established, hold knob

Flame Adjustment Knob

Sparker

depressed for approximately 30 seconds. Release knob. If

pilot should go out, repeat steps 3 to 5.

• If the knob does not pop up when released, stop and

immediately call your service technician or gas supplier.

• If the pilot will not stay lit after serveral tries, turn the gas

control knob to “OFF” and call your service technician or

gas supplier.

7. If the appliance has a manual valve, turn gas control knob

counterclockwise to the desired heat setting from “LO” to

HI”. If the appliance has an automatic valve, turn gas control

knob counterclockwise to “ON” and set the flame

adjustment knob to the desired heat setting from “LO” to “HI”.

8. Set the remote switch to “ON”. Set the thermostat to the

desired setting. (Only if your appliance is equipped with these

devices.)

9. Turn on all electric power to the appliance.

10. Close louver or access door.

Control Knob

Automatic Valve

Control Knob

TO TURN OFF GAS TO APPLIANCE

1. Set the thermostat to the lowest setting and turn the remote

switch to “OFF”.

2. Turn off all electric power to the appliance if service is to be

performed.

Manual Valve

3. Open lower louvers or access door.

4. Press slightly and turn control knob clockwise to “OFF”. Do

not force.

5. Close lower louvers or access door.

Pilot

Page 27

Northfire 42 27

MAINTENANCE

CAUTION : Do not conduct maintenance on the appliance while it is operating or while it is still hot.

CLEANING THE APPLIANCE

The exterior painted surfaces, glass and gold trims may be cleaned with a soft, non-abrasive

cloth and water or a suitable, mild, non-abrasive cleaner.

Regularly:

• Clean and remove any lint accumulations or debris from the grills and in any

combustion and convection air passage ways.

• Keep the appliance area free from combustible materials, such as paper, wood,

clothing, gasoline and flammable solids, liquids and vapors.

• Visually check the height and color of the burner and pilot flames.

Every 2 to 3 months:

• Remove the glass door and clean the inside of the glass with a soft, non-abrasive

cloth and water or a suitable, mild, non-abrasive cleaner. DO NOT CLEAN WHILE

HOT.

• Carefully remove the logs and gently brush off any loose carbon deposits. This job is

best done outside the house, wearing a dust mask.The logs are very fragile, take

care not to break them. Do not wash logs with any liquid. While logs are removed,

also remove the coals and “embers” and check that all burner openings are not

obstructed. It is recommended you use a vacuum cleaner to clean off any dust or lint.

• After cleaning, the logs, coals and embers must be replaced as per the instructions in

this manual.

Once a year, have a qualified service technician:

• Completely inspect the appliance and the venting system. Vent connection can be

checked by removing the vent baffle in the firebox. Remove the five ¼ hex head

screws holding the baffle. Replace baffle after inspection.

• Clean and remove any lint accumulations or debris in the firebox, on the burners,

on the pilot, at the primary air opening, on the convection air blower and in any

combustion and convection air passage ways.

• Check the safety system of the gas valve and the appliance.

WARNING : All parts removed or disturbed including guards and grills must

be properly replaced after maintenance. Service and repair must

be conducted by a qualified service person. If these instructions

are not followed, a fire or explosion may result, causing property

damage, personal injury or loss of life.

Page 28

Northfire 42 28

TROUBLESHOOTING

Please check to make sure the instructions are followed exactly before attempting

troubleshooting of the appliance.

WARNING: Troubleshooting and servicing of gas and electrical devices of the

appliance should only be conducted by a qualified service technician.

SYMPTOM ACTION

Pilot will not light after

pressing the sparker many

times.

Pilot will not remain on

after being lit.

1. When lighting the appliance for the first time after installation or

after servicing, there is air in the gas line. It takes a while for all

the air to purge out of the pilot before gas can reach the pilot

and ignite. Remove the glass door and try lighting the pilot

many times to purge the air.

2. Check to make sure the gas supply to the appliance is turned

on and there is adequate gas supply pressure to the appliance.

3. Check for sparks between the spark electrode and the pilot

head when the sparker is pressed. If there are no sparks,

a. Check for broken or poor connection from the sparker to the

electrode.

b. Check for the spark shorting or arcing at other locations.

c. Check for defective sparker.

d. Check for defective spark electrode.

4. With the door removed, try lighting the pilot with a match.

a. If air is blowing on the flame of the match, hold the control

knob in at the ‘PILOT’ setting until all the air is purged out of

the line.

b. If there is no gas or air coming out of the pilot and there is

gas pressure to the appliance, the pilot orifice may be

blocked or the gas valve may be defective.

1. Press the control knob all the way in.

2. Hold the control knob in for a longer period of time.

3. If you are trying to re-light the pilot immediately after you have

shut-off the pilot, you have to wait 5 minutes for the valve to

reset.

4. Check to see if the pilot flame is large enough to reach and

surround the thermocouple. If the flame is too small, check for

correct gas supply pressure. If pressure is good, adjust the pilot

flame size with the adjustment screw on the valve. If the flame

cannot be adjusted, there might be some debris obstructing the

pilot orifice, or a wrong size pilot orifice.

5. Check for poor connection of the thermocouple to the valve.

6. Check for proper millivolts of the thermocouple. The

thermocouple should generate at least 30 mV or it is defective.

7. Check for defective gas valve.

The main burner does not

turn on with the pilot lit.

1. Check to make sure the control knob is turned to the ‘ON’

position.

2. Allow enough time for the pilot to heat up the thermopile to generate sufficient voltage to activate the valve.

Page 29

Northfire 42 29

TROUBLESHOOTING - Continued

SYMPTOM ACTION

The main burner does not

turn on with the pilot lit.

The main burner shuts off

when the appliance is

warm.

Sooty deposits on the glass

door.

3. Check to make sure the thermostat is set high enough to turn

on the appliance.

4. Check that the remote switch or the thermostat is turned on.

5. Check for weak pilot flame. If flame is weak, check gas supply,

check pilot flame adjustment and check for blockage of pilot

orifice.

6. Check all connections to the valve for tight electrical contact.

7. Check spill switch for continuity.

8. Check for 400-500 mV from the thermopile with the burner off

and 200-250 mV with the burner on. If the voltages are lower,

the thermopile is defective.

9. Check for defective gas valve.

1. This may be the normal operation of a wall thermostat installed

to appliances.

2. Check for good pilot flames on the thermopile (see page 22).

3. Check for good voltage from the thermopile.

4. Check for proper functioning of venting system.

5. Check wire connections. Expansion from heat affects a loose

connection

1. If the flame is yellow and lazy, check for lint etc. around primary air shutter. Increase primary air by opening the primary

air shutter if necessary.

2. Check for proper placement of the logs and branches. Ensure

logs and burner are clean. See that section in the instruction

manual.

3. Check for obstruction of the burner ports by the embers. See

that section in the instruction manual.

4. Check for proper venting and blockage of the vent termination.

5. Check manifold pressure and clock input rating for over-firing.

Sharp blue flames with

flames lifting off the burner

at the ends.

Convection blower does not

turn on.

1. Too much primary air. Reduce primary air by closing the

primary air shutter. During cold temperatures, some flame

lifting may occur during start-up.

1. The convection fan is thermostatically controlled. It will only

turn on when the appliance is warmed-up. This may take up to

15 minutes with the appliance on high.

2. Check for 120 VAC electrical supply to the appliance. (Is the

cord plugged in?)

3. Check for proper mounting of the thermal snap disc.

4. Check electrical connections.

5. Check for defective thermal snap disc.

6. Check for defective convection blower speed controller.

7. Check for defective convection blower.

Page 30

Northfire 42 30

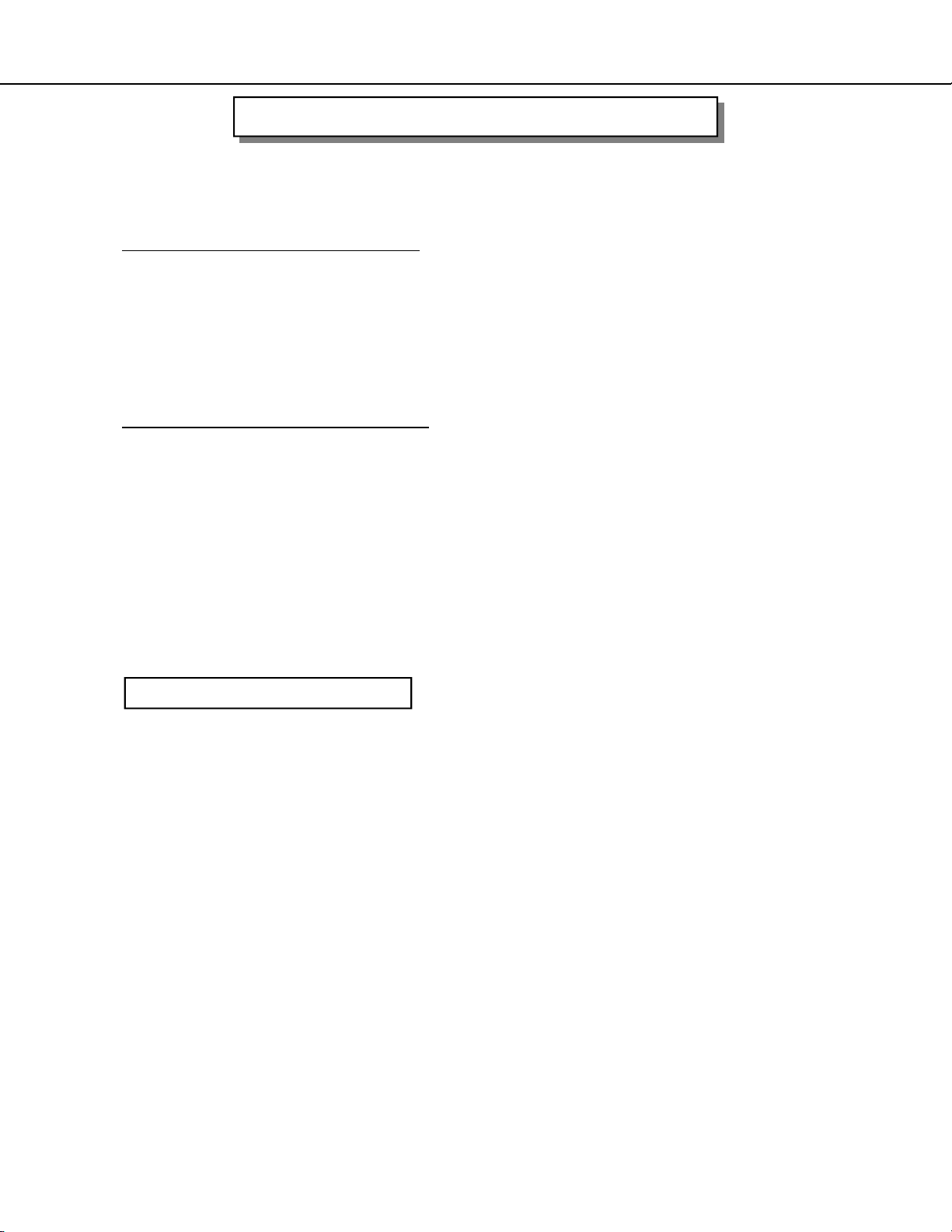

WIRING DIAGRAMS

VALVE CONNECTIONS

PILOT BURNER

THERMOPILE

ASSEMBLY

SPARK ELECTRODE

PILOT

THERMOCOUPLE

To SPARKER

OPTIONAL

THERMOSTAT

OPTIONAL REMOTE WALL SWITCH

ON/OFF SWITCH

Page 31

Northfire 42 31

SERVICING

SERVICING UNDER WARRANTY

Before servicing, read the terms and conditions of the Archgard warranty at the back of the

manual. Contact the Archgard authorized dealer where you purchased the appliance from and

provide them with details of the problem and the installation information that the installer has

filled in at the back of the manual.

WARNING: Servicing of this appliance must be conducted by a qualified service

technician. Improper servicing, adjustment or alteration of this appliance may

cause property damage, personal injury or loss of life. All servicing should be

conducted with the appliance cold. All replacement parts must be authorized by

Archgard for suitability.

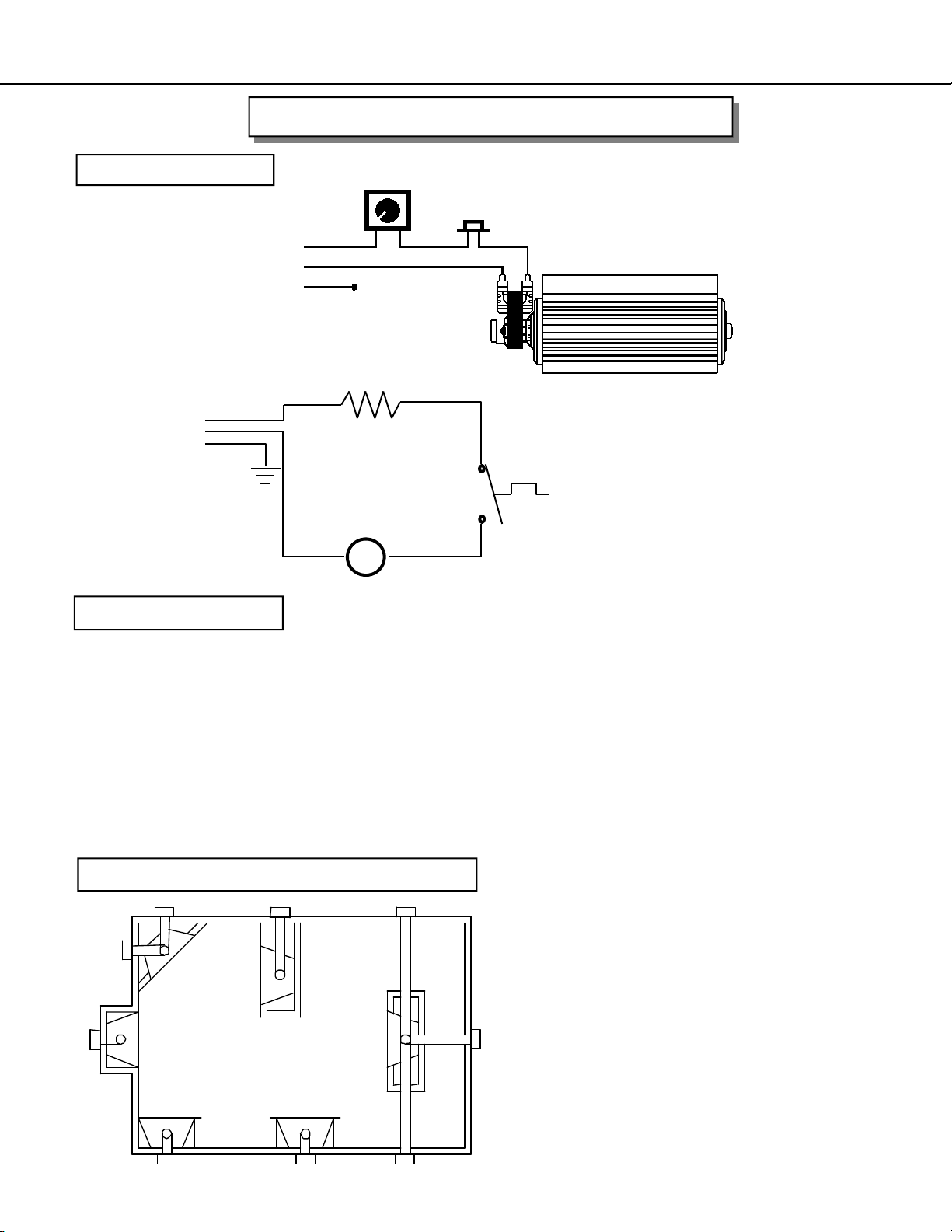

ADJUSTING PRIMARY AIR

Note: the Shutter is set at the factory and normally only requires setting at higher altitudes.

• Open the lower grilles.

• Unscrew the 2 screws holding the blower speed control panel and remove the panel.

• The primary air adjustment wing nut is located behind and to the left of the control valve.

• Loosen the wing nut and slide the primary air shutter to the right to increase primary air and

to left to reduce primary air.

• Tighten the wing nut after adjustment.

Caution: Wear gloves when adjusting the primary air with the appliance hot.

BLOWER SPEED

CONTROL BOX

ORIFICE HOLDINGING BRACKET

ELBOW FITTING

ORIFICE

PRIMARY AIR SHUTTER

ADJUSTMENT WING NUT

INCREASE DECREASE

FLAMES...

The left side shows correct adjustment. The right side shows yellow

sooty flames requiring increase in

shutter opening or cleaning of shutter area due to lint buildup.

Page 32

Northfire 42 32

SERVICING

CHANGING MAIN BURNER ORIFICE

• Remove the glass door, log branches and the front log.

• Unscrew the 2 screws holding the left burner shields between the burner tubes and remove

the shield.

• Remove the adjustment wing nut and slide the air shutter away from the orifice cap.

• Use a ½” wrench to remove the orifice cap.

• Change the orifice cap. Use a small quantity of gas thread seal compound. Do not over

tighten.

• Replace the adjustment wing nut and properly set the primary air shutter according to the

specifications.

• Replace the burner shield, front log, branches and the glass door.

CHECKING SUPPLY AND MANIFOLD GAS PRESSURE

• Open the lower grills.

• The pressure test taps are located on the valve.

Automatic valve: The taps are located in the front. The supply pressure is marked ‘IN’ and

the manifold pressure is marked ‘OUT’. There is also an arrow marking the

direction of gas flow.

Manual valve: The taps are located on the left side of the valve. The connection closest to

the back, marked with ‘IN’ is the supply pressure and the manifold pressure

marked with ‘OUT’ is closest to the front.

• Loosen the set screw inside the tap with a ⅛” wide flat screw driver.

• Connect a ¼” rubber tube to the tap and to the manometer.

• Be sure to tighten the set screw inside the tap after you are finish taking pressure readings.

• Check for leaks.

CHECKING AND ADJUSTING PILOT

The pilot flame should have the characteristic as shown in the illustration below. The flame

should not have yellow tips but should engulf the thermocouple and thermopile. It can be adjusted by turning the screw marked “pilot” on the control valve.

Page 33

Northfire 42 33

SERVICING Cont...

CONVERTIBLE PILOT ORIFICE

The pilot assembly is convertible to the type of

gas being used. Simply unscrew the body by

using a 7/16” (11 mm) wrench and turn ¼

open - then push the small metal tab across to

the other side of the body and retighten. Call

your local Authorized Archgard Dealer to

purchase the correct fuel conversion kit

for your gas appliance.

7/16”

(11 mm)

WRENCH

(HERE)

IF YOUR GLASS BREAKS

In the event your glass cracks or breaks, it must be replaced by the exact same size and

material. It is made from high temperature ceramic material. See replacement parts list and

contact your nearest Archgard dealer.

• Remove door and carefully remove all traces of glass and gasket material.

• Replacement requires Ceramic glass part #307-0042, gasket part #314-0007 and sealer

part #319-0005.

• Install new glass with new gasketing in place. The “thicker” side of the gasket fits against

the fireplace opening.

• Hold glass in place by using the sealer between gasket and door. Use sparingly so that no

excess will be visible. DO NOT PUT ANY SEALER BETWEEN GLASS AND UNIT

OPENING.

• Replace the door carefully making sure all three clamps are closed.

REPLACING CONVECTION BLOWER

• Remove the gas component assembly, see above.

• Mark all wires to be removed for proper reassembly. CAUTION: Wiring errors cause

improper and dangerous operation.

• The convection blower is located at the bottom of the appliance at the back. Remove the

three screws holding the blower.

• Lift the blower out and disconnect the wires from the blower.

Page 34

Northfire 42 34

REPLACEMENT PARTS FOR THE NORTHFIRE 42

ITEM # DESCRIPTION QTY UNIT

200-1912

300-0031

300-0034

301-0068

301-0068

305-0013

RF-305-0024

305-0021

307-0042

308-0005

308-0013

308-0093

310-0020

OWNER’S MANUAL NORTHFIRE 42-DVT40N 1 EA

MAGNET 0.25 X 0.875 X 1.0 (7 Lb PULL) 2 EA

LATCH, DOOR 1 11/16” X 1 3/16” 3 EA

ORIFICE CAP #49 ( PROPANE GAS) 1 EA

ORIFICE CAP #31 (NATURAL GAS) 1 EA

SPEED CONTROL (KBMS-13BV) c/w KNOB 1 EA

ELECTRIC FAN - CROSSFLOW (120VAC) 1 EA

FAN THERMODISC (110°F) 1 EA

REPLACEMENT FLAT GLASS (CERAMIC GLASS 5 mm CLR) 1 EA

PIEZO IGNITORC/W NUT (66270-003) 1 EA

“S I T” GAS CONTROL VALVE HIGH / LOW NATURAL GAS

(CONVERTIBLE WITH L. P. CONVERSION KIT).

“P S E” PILOT ASSEMBLY (CONVERTIBLE) 1 EA

COALS, MEDIUM GRADE 4Oz BAG 1 BG

1 EA

310-6420-1

310-6420-2

310-6420-3

310-6420-4

310-6420-5

310-6420-6

310-6420-7

314-0101

314-0115

42-CKLP

CERAMIC FIBER LOG REAR 1 EA

CERAMIC FIBER LOG LEFT TOP 1 EA

CERAMIC FIBER LOG RIGHT 1 EA

CERAMIC FIBER LOG LEFT 1 EA

CERAMIC FIBER LOG LEFT FRONT 1 EA

CERAMIC FIBER LOG RIGHT FRONT TOP 1 EA

CERAMIC FIBER LOG CENTER TOP 1 EA

GASKET (RELIEF PLATE) 3 1/2 X 15 2 EA

GASKET (VENTURI / BURNER) 1 EA

CONVERSION KIT-NATURAL GAS TO PROPANE 1 EA

Parts can be ordered through your local dealer or distributor by giving ITEM #

and DESCRIPTION.

Page 35

This Limited Warranty is made by ARCHGARD INDUSTRIES LTD., hereinafter referred to as “Archgard”. Archgard warrants

to the original purchaser of an Archgard gas burning fireplace (s) that the product will be free of defects in materials and

workmanship under normal use and service, for a “lifetime”.

INCLUSIONS: “LIFETIME LIMITED WARRANTY“

ARCHGARD

ARCHGARD

LIMITED WARRANTY

LIMITED WARRANTY

❖ All heat exchangers, combustion chamber, burner tubes and pans.

❖ Ceramic Fiber Logs and Ceramic Brick Panels against splitting or cracking.

❖ Ceramic Glass against thermal breakage.

❖ All 24 K gold trims and accessories against tarnishing.

❖ All trim accessories against tarnishing and paint defects.

❖ NOTE: Discoloration and some minor movement of certain parts are normal and are not a defect and therefore, not cov-

ered under warranty.

The above will be covered “parts & labor” to the original purchaser for FIVE years and “parts” only thereafter from original

date of purchase.

INCLUSIONS: “FIVE YEAR LIMITED WARRANTY”

❖ Five year limited warranty on the “FiberFlame Technology Burner System.” Warranty will cover any defective burner and

ceramic ember bed if defect is deemed as original by the manufacturer.

The above will be covered “parts & labor” to the original purchaser for TWO years and “parts” only thereafter from original

date of purchase.

INCLUSIONS: “ONE YEAR LIMITED WARRANTY”

❖ Blowers, fans and fan motors, wiring, rheostats and thermodiscs.

❖ Rocker switches, spill switches and wiring to them.

❖ Gas control valves, pilot assemblies including thermopiles, thermocouples, electrodes, and igniters.

The above will be covered “parts & labor” to the original purchaser for ONE year from date of purchase.

EXCLUSIONS:

❖ Archgard does not offer wall mounted thermostats, programmable thermostats (wiring for hook-up of said product), hand-

held remote controls, fireplace mantel (s), trims or tiles.

❖ Ember Material.

❖ Tempered Glass is warranty for ONE year to the original purchaser from date of purchase.

❖ Travel time or mileage to original purchasers residence. Archgard suggests that you pre-arrange travel expenses with

your Authorized Archgard Dealer.

WHAT TO DO IN THE EVENT OF A PROBLEM:

❖ Thoroughly read your manual.

❖ If you cannot solve the problem, contact your Archgard Dealer or representative.

❖ When calling for help please have the following information:

Model of your Fireplace Serial Number Place of Purchase

Date of Purchase Problem Description

❖ NOTE: Warranty may be void if work is carried out by an unqualified person (s). Only original Archgard parts may be

used. Please consult your Archgard dealer or representative if in doubt about a replacement part (s).

OBTAINING WARRANTY SERVICE:

To obtain warranty service, the original purchaser shall return the defective part (s) to the original authorized Archgard selling

dealer transportation prepaid, along with the serial number of the appliance and proof of purchase. Any defective part, in our

judgment, will be repaired or replaced at Archgard’s discretion. The dealer must obtain approval from Archgard before any

repairs are made.

WARRANTY LIMITATION:

THIS LIMITED WARRANTY IS MADE IN LIEU OF ALL OTHER WARRANTIES, EXPRESSED OR IMPLIED AS TO QUALITY, MERCHANTABILITY OR FITNESS FOR PARTICULAR PURPOSE.

The appliance is only warranted for the use as intended by the installation and operating instruction and local building codes.

The warranty will not cover damage due to accident, misuse, abuse, alteration, improper installation or “Acts Of God”.

This limited warranty is void unless the appliance is installed by a qualified installer, in accordance with the instructions

furnished with the appliance. Some Provinces or States do not allow limitations on how long an implied warranty lasts, so the

above limitation may not apply to the original purchaser. Any damage resulting from defects in this product, is limited to the

replacement of the defective part (s) and does not include incidental and consequential exposures sustained in connection

with the product. This includes facing (s), mantle (s), cabinet (s), tile (s) or any other finishes resulting from removal of any

gas appliance. This warranty is limited to residential use only and gives the consumer specific rights. These rights may vary

from State to State or Province to Province.

Page 36

WARRANTY REGISTRATION

ARCHGARD INDUSTRIES LTD.

7116 BEATT Y D RIV E

POSTAGE

CUT ALONG LINE

CUT ALONG LINE

MISSION, B.C. CANADA

V2V 6B4

FOLD DOWN AT LINE

FOLD DOWN AT LINE & TAPE CLOSED

Model # : 42-DVT40N Serial #: Date Installed: / /

Name:

Address:

mm dd yyyy

City:

State/Prov: ZIP: Phone: ( _____ )

Dealer's Name & Address:

City:

State/Prov: ZIP: Phone: ( _____ )

Installer's Name & Address:

CUT ALONG LINE

City:

State/Prov: ZIP: Phone: ( _____ )

Why did you choose this product?

Thank you for purchasing our product and filling out this warranty card.

Page 37

Page 38

Archgard Industries Ltd.

7116 Beatty Drive

Mission, B.C. V2V 6B4

Canada

Website: www.archgard.com

Loading...

Loading...