Arcam FMJ AV-8 Service manual

Service Manual

ARCAM

FMJ AV8

Preamp Processor

AV8

Issue 2.0

ARCAM

Contents List

Section Issue

Manual Updates

! Service Manual changes issue 1.0 to 2.0 -

Technical specifications

! Front & rear view diagram -

! Dimension diagram -

! Specification -

Service guide

! Engineering Mode -

! AV8 Programmer software -

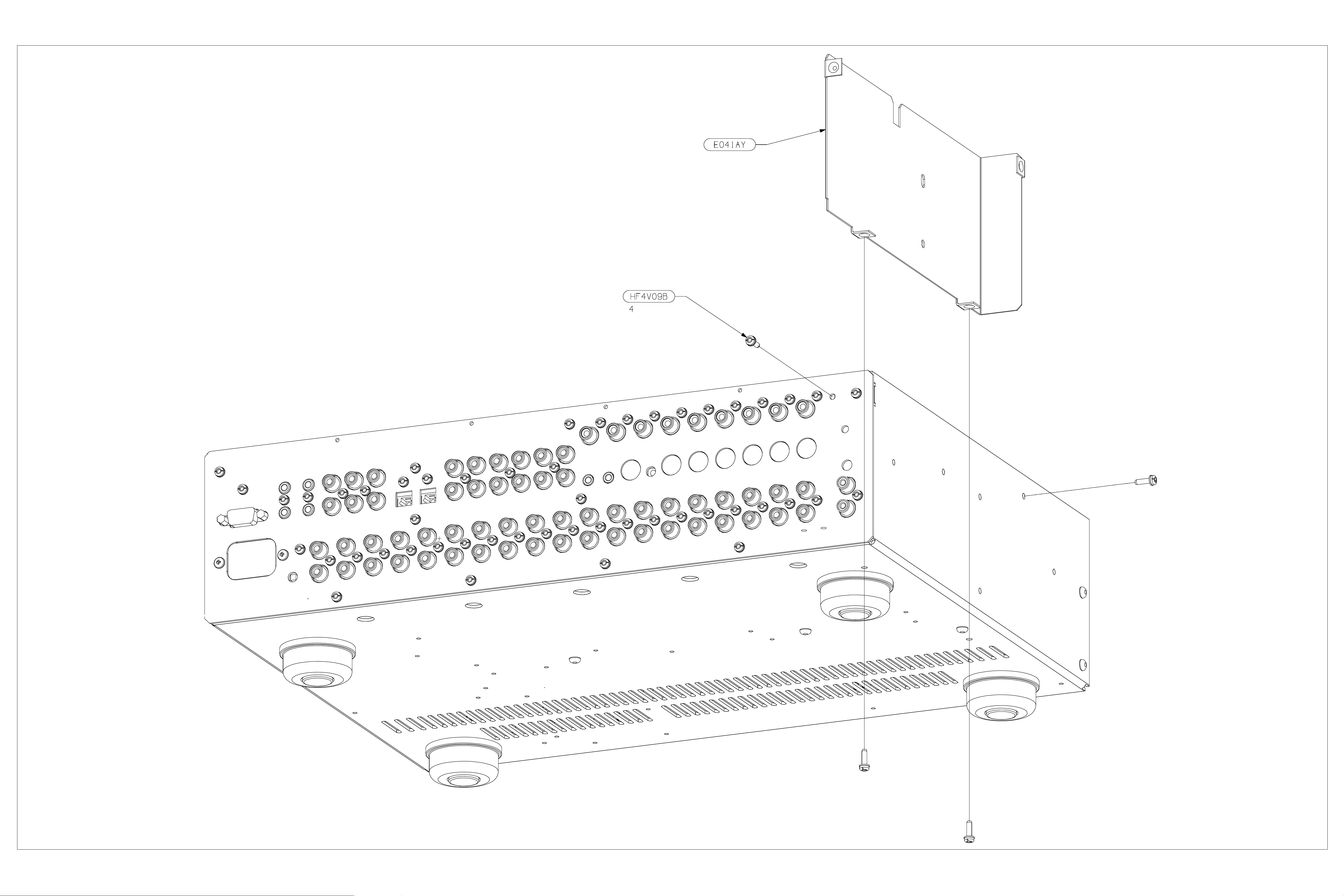

! AV8 Loader software -

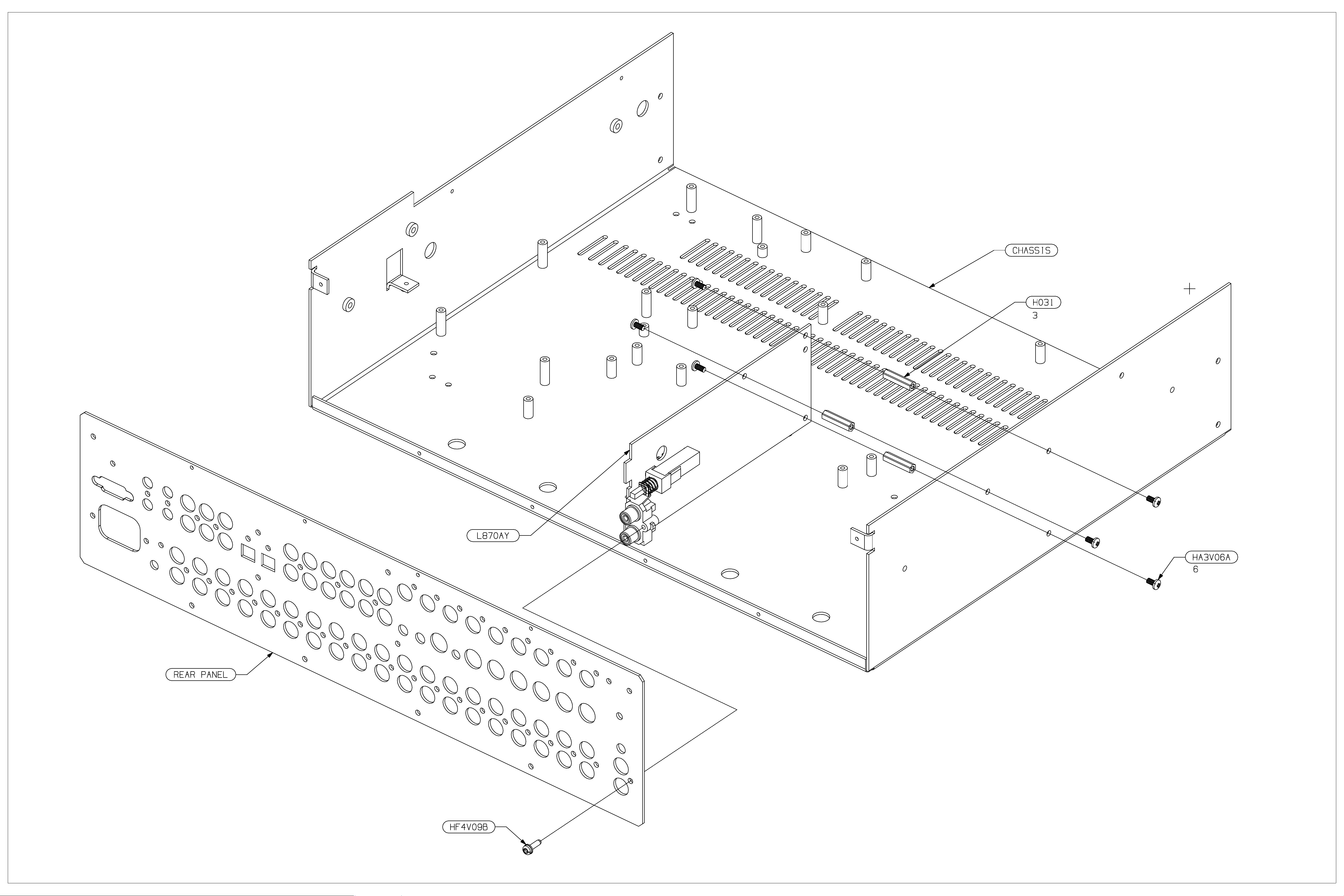

Build Sequence

! How to assemble the AV8 -

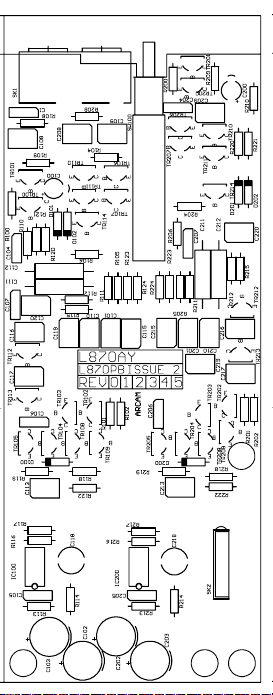

Phono board L870

! Circuit description -

! Component overlay 2

! Parts list 2.0

! Circuit diagrams 2.0

Digital board L896

! Circuit description -

! Component overlay 1

! Parts list 1.6

! Circuit diagrams 1.6

PSU board L897

! Circuit description -

! Component overlay 4

! Parts list 4.1

! Circuit diagrams 4.0

Display board L898

! Circuit description -

! Component overlay 1

! Parts list 1.2

! Circuit diagrams 1.2 (N.B. circuit diagram marked as 1.1 not 1.2)

Audio board L921

! Circuit description -

! Component overlay 1

! Parts list 1.2

! Circuit diagrams 1.2

Video board L922

Circuit description Component overlay 3

Parts list 3.2

Circuit diagrams 3.2

Phase Locked Loop board L948

Circuit description Component overlay 1

Parts list 1.0

Circuit diagrams 1.0

Mechanical

Mechanical parts list Phono card upgrade parts list -

Manual Updates

Service Manual changes issue 1.0 to 2.0

L896 Digital Boar d

02_E101 IC906 EEPROM changed from 5G24LC08 to 5G24LC16

Parts list updated to issue 1.3

02_E127 R803 removed from parts list

02_E160 R921 changed from 10K 0805 1% (1M310 ) to 33K 0805 1% (1M333)

02_E161 IC907 changed from 74HC14 (5K7414) to 74LVC14 (5KLVC14)

IC803 changed from CS8415A-CZ (5A8415) to CS8415A-CR (5A8415R)

R820 changed from 5K1 (1M251) to 1K2 (1M212)

C820 chan ged from 82N (2J382) to 100N (2J410)

C821 changed from 2N2 (2J222) to 4N7 (2JA247)

Circuit plus parts list updated to issue1.6

L897 Power Supply Board

02_E090 V ias ad ded to connect chassis planes be tween top and bottom layers

Plating removed from holes of PSU heat sink HS3

On mechanical parts list for E918RS 1xHA3V06A removed and 1xHA3V10B added

02_E094 1xHA3V06A deleted

1xHA3V10A added for MOSFET clip

1x F224 removed

Parts list updated to issue 3.1

02_E142 R1 removed

Opto added HCNW137

Circuit plus parts lis t up da ted to issue 4.0

PCB changed to allow wider opto to be fitted

Parts list updated to issue 4.1

L898 Display Board

02_E081 R128 changed from 22K (1M322) to 33K (1M333)

arts list updated to issue 1. 2

L922 Video Board

02_E103 Change of PCB routin g

Circuit plus parts lis t up da ted to issue 3.0

02_E112 R431 and R430 changed from 4K7 (1M247) to 470R (1M147)

Circuit plus parts lis t up da ted to issue 3.1

L948 Phase Locked Loop Board

02_E100 Circuit plus parts list updated to issue 1.0 fo r pro d uction release

Summary Issue 1.0 to 2.0

Update New section added

Technical S pecification Specification included

Service Guide Engineering mode updat ed

AV8 programmer software added

AV8 Loader software added

Build Sequence Layout ch anges to manual

Figure 3 changed (F224 blanking plug removed)

Figure 8 changed (E042AY replaced with E876MC)

Figure 12 changed (note for blanking plug removed)

Digital Board L896 Updated circuit diagrams and parts list issue 1.2 to 1.6

Power Supply L897 Updated circuit diagrams to issue 4.0 and parts list issue to 4.1

Display Board L898 Updated parts list issue 1.1 to 1.2

Audio Board L921 Circuit plus parts list updated from 1.1 to 1.2

Video Board L922 Updated circuit diagrams and parts list issue 2.0 to 3.2

Phase Looked Loop L948 Updated circuit diagrams and parts list issue B to 1.0

Technical

Specifications

Contents

!

!

!

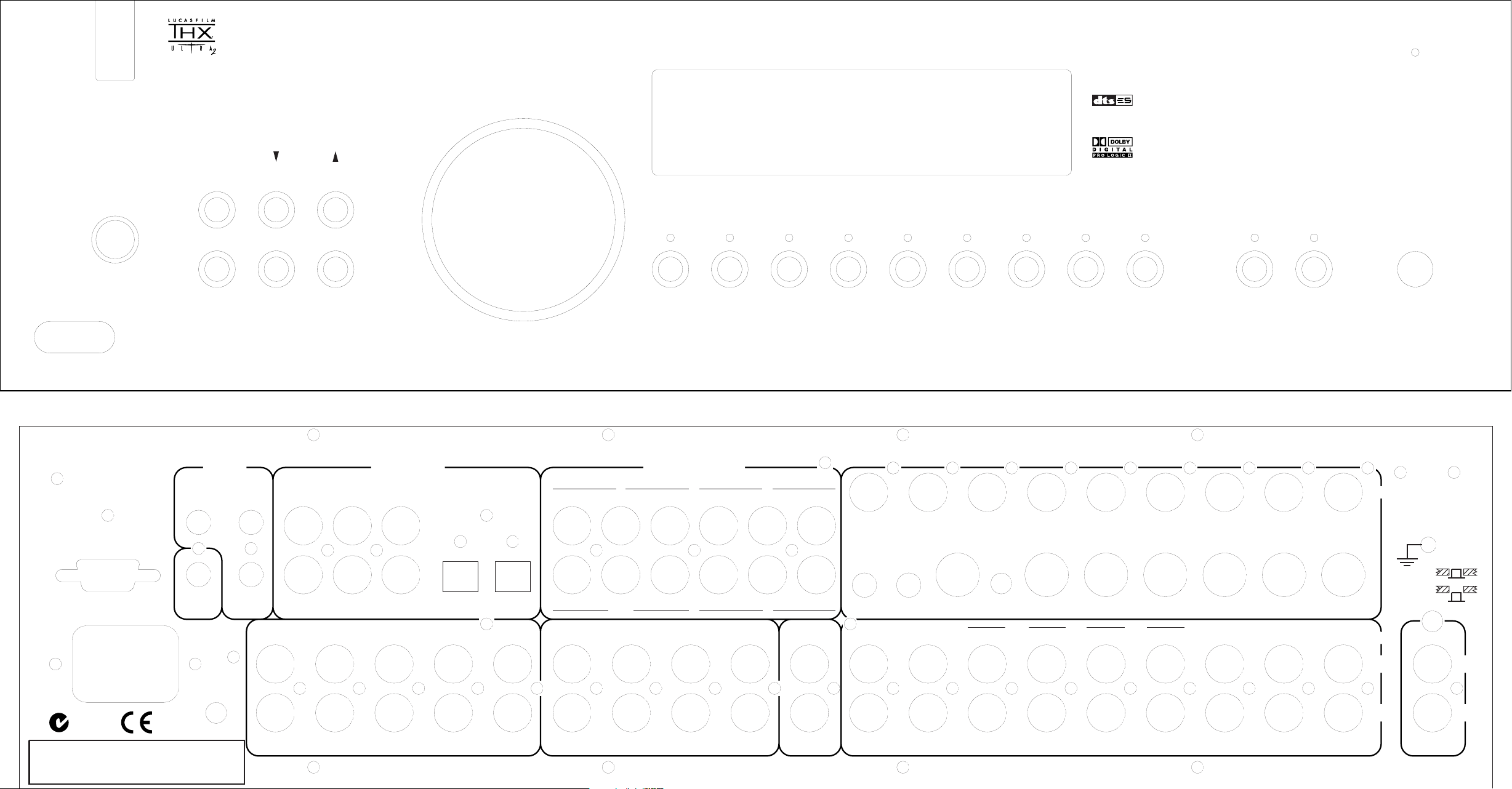

Front & rear view

diagram

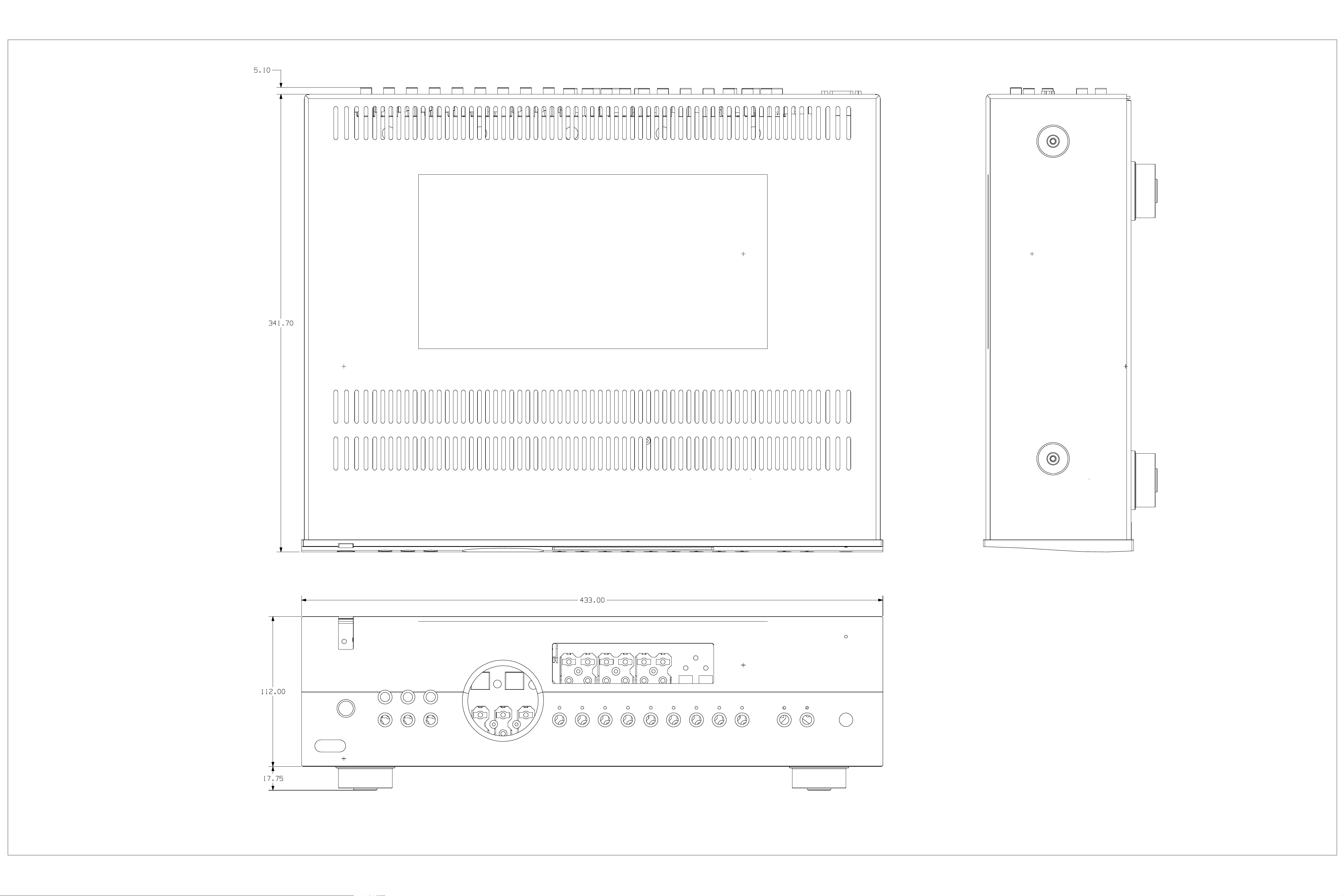

Dimensions diagram

Specifications

THX SURROUND EX

AV8 PREAMP PROCESSOR

MODEEFFECTTHX

DESIGNED & MADE

IN THE UK BY:A & R CAMBRIDGE,

WATERBEACH, CB5 9PB.

RS232

CONTROL

50/60Hz

100-240VAC

MAX 40VA

~

REMOTE DIGITAL INPUTS HIGH QUALITY VIDEO

1

U/B

U/B

OUT

V/R

V/R

OUT

12V

TRIGGER

IN

LOCAL

IN

ZONE 2

DVD

OUT

LEFT CENTRE SUB 2L SURR LS BACK LEFT CENTRE L SURR

AV

TUNER

TAPE

CD

VCR SAT

Y/G

Y/G

DVD-A MUTEDIRECTTAPETUNERCDPHONO/AUXVCRAVSATDVDOKMENUDISPLAY

Y/G

Y/G

2

U/B

U/B

3

LS BACK TUNER CD OUT IN OUT IN AV SAT DVD

V/R

V/R

ZONE 2

VIDEO

TRIGGERS

1/RGB 2/S-VIDEO

1

MONITOR OUT

2

TAPE

PROG

TAPE VCR

VCR

OUT

VCR

IN

AV SAT DVD

POWER

VIDEO

MM

MC

AUDIO

N1501

SERIAL No. LABEL

GROUND

LIFT (IN)

RIGHT SUB 1 SUB 3R SURR RS BACK RIGHT SUB R SURR

OUTPUTS DVD-A/SACD IN

WARNING: THIS APPLIANCE MUST BE EARTHED

ACHTUNG – VOR OEFFNEN DES GERAETES NETZSTECKER ZIEHEN. ATTENTION – RISQUE DE CHOC, NE PAS ENLEVER. PRECAUCION – PELIGRO DESCARGA, NO ABRIR.

RS BACK ZONE 2 OUT

L

R

L

R

AUX/

PHONO

L

R

CAUTION – SHOCK HAZARD, DO NOT OPEN.

Technical Specifications

Audio

Line input sensitivity (set to Reference) 2V rms

Input impedance 10k ohm

Preamp output level (nominal) 2V rms

Output impedance 25 ohm

Signal/noise ratio (unwtd 20Hz –20kHz)– analogue >100dB

Signal/noise ratio (unwtd 20Hz –20kHz)– digital (24-bit) >98dB

THD+N – analogue 0.0012%

THD+N – digital (24-bit) 0.0015%

Headphone maximum output level into 600 ohm 5V p-p

Output impedance 5 ohm

Video inputs and outputs

Input and output impedance 75 ohm

Composite video level 1V

HF response to (–3dB) 12MHz

S-video level (Y/C) 1V/0.28V

HF response to (–3dB) 12MHz

HQ (component) video

level (Y/Cr/Cb) 1V/0.5V/0.5V

level (R/G/B) 1V/1V/1V

HF response to (–3dB) 300MHz

Digital inputs

Coaxial connection (level/impedance) 0.5V/75 ohm

Acceptable sampling frequencies, all inputs 44.1kHz, 48kHz,

(96kHz stereo only)

Digital output

Output level/impedance 0.5V/75 ohm

Sampling frequency in ADC output mode 44.1kHz

Trigger outputs

Output D.C. voltage (excl. RGB status) 12V ±1V

Allowable load 30mA max (min 400 ohm)

Remote inputs and output

Signal modulated 36kHz carrier

Coding Philips RC-5

General

Mains voltage range 85V to 265V

Power consumption 35VA

Power consumption (standby) 32VA

Dimensions Width x Depth x Height (including feet) 433mm x 360mm x 130mm

Weight (net) 9kg

Weight (packed) 14kg

Supplied accessories Mains lead

CR80 remote control

2 x AAA batteries

Service Guide

Contents

!

!

!

Engineering mode

AV8 Programmer

software

AV8 Loader software

AV8 Engineering Mode

To access the software versions simultaneously press OK,

DVD & CD on the front panel.

The software versions will be displayed on the OSD.

AV8 Version: 2.0

THX Ul2: 13.0 DTS –ES: 15.0

Dolby D: 16.0 DTSNeo6: 18.0

Plogic 2 : 4.0 Cos Eff : 15.0

Exit this menu

Select EXIT and OK to leave the menu.

If no buttons have been pressed for 30 seconds the AV8

will automatically exit the menu.

Press THX, this takes you to the engineering menu first

page.

Use the up/down buttons on the front panel to select the

option followed by the volume control to adjust the

setting.

Engineering Menu

RC5 Code Zone 1 : 16* (or 19)

RC5 Code Zone 2 : 16* (or 19)

Scrolling Message: Off (or On)

Restore Defaults: No (or Yes)

Diagnostics : Off (or On)

Front Panel IR Rx : On (or Off)

EXIT

RC5 Code Zone 1

This allows you to select which RC5 system code zone 1

responds to (16 or 19). If set to code 19 the AV8 will not

respond to the CR 80 remote control.

RC5 Code Zone 2

This allows you to select which RC5 system code zone 2

responds to (16 or 19).

Scrolling Message

This allows you to turn the display scrolling message

on/off. When the messages are turn ed on you can select

the displa yed mess a ge by pressing t h e c orr esp on d in g i nput

button.

Button Message

DVD Arcam AV8 FMJ Home Theatre

SAT AV8 Multichannel Processor

AV arcam sideways

VCR Arcam AV8 Sound and Vision

AUX AV8 Designed in Cambridge UK

CD Arcam AV8 Preamp Processor

TUNER AV8 THX ULTRA 2, DTS ES, DOLBY PL2

Restore Defaults

This allows you to reset the AV8 to the factory default

settings.

Diagnostics (For factory diagnostics only)

This switches on RS232 messaging to allow remote

analysis (hyperterminal at 38400 baud, 8 data bits, no

parity, 1 stop bit and no flow control).

Please note tha t this will disable the R S232 interface for

user control via crest ron or similar controllers.

Front Panel IR Rx

This allows you to disable the front panel IR receiver and

prevent the AV8 f r o m respondin g to these signals.

With th e Engineering Menu title bar highlighted use the

volume control to select the second engineering page.

Engineering Menu 2

PLL Module

DVD : AUTO (or OFF)

SAT : AUTO (or OFF)

AV : AUTO (o r OFF)

VCR : AUTO (or OFF)

AUX : AUTO (or OFF)

CD : AUTO (or OFF)

TUNER :AUTO (or OFF)

TAPE : AUTO (or OFF)

EXIT

If the source equipment clock rates are operating outside

the specification of the AV8 phase locked loop circuit you

may experience “a hissing noise” from the audio outputs.

In this situation it is advisable to switch the phase locked

loop circuit off of th e input gi ving the problem. Using the

second page of th e engineering menu select the input and

turn the PLL (phase locked loop) from AUTO t o Off.

This can happen with Broadcast signa ls particularly from

satellite, cable or terrestrial digital TV.

AV8 Programmer

Future software up grades can be installed via the RS232

port on the back of the AV8. The following equipment will

be required:

! IBM PC compatible computer running Windows 98

or later

! Software – ARCAM AV8 Programmer utility

(included on the AV8 CD-ROM)

! Lead – RS232 9-way female D type to 9-way female

D type (null modem)

Installation procedure

The AV8 Programmer utility needs to be installed on your

PC before you can use it:

! Close down any programs which are running, then

insert the CD-RO M into the CD drive

! The setup program normally starts up automatically

when the disc is inserted. If this does not happen,

you can instruct the PC to install the program as

follows:

o Click on ‘Start’ and select ‘Run…’ from the

pop-up menu

o In the box, type ‘D:\setup.exe’, where ‘D’ is

your CD-ROM drive

o Click ‘OK’

The install process will then begin. You will be prompted

for your Name, Organization and Destination Folder for

the installation (default is C:\Program Files\Arcam\AV8

Programmer\). Follow the instructions on-s creen.

Operation procedure

! Open the AV8 Programmer utility by double clicking

the desktop icon, or from the Programs list within the

Start menu

! Switch off all the power amps connected to the AV8

! Switch off the AV8

! Connect th e RS232 lead from th e PC to the RS232

control port on the AV8

! From within the AV8 Progr ammer software:

o Select the new software file to be uploaded

using the ‘Open file’ button

o Select the Com port you are using

! Put the AV8 into program mode:

o Press and hold the program button on th e back

of the AV8 (located with the video output

connections)

o Turn the AV8 on with the progra m button still

pressed

o Wait 5 seconds and then release the program

button. The display will remain completely

blank and no LEDs will light.

! From within the AV8 Progr ammer software:

o Click ‘Program’

The PC will now upload the software and display the

following information:

Connecting: 0 to 100%

Programming: 0 to 100%

Verifying: 0 to 100%

This process will take up to four minutes. When the

software has been uploaded the message ‘Status:

SUCCESS’ will be displayed.

! Turn the AV8 off and unplug the RS232 lead

! Wait 10 seconds before turning the AV8 back on

If, after programming the AV8 the unit displays

“Populating EEPROM” when first turned on, it will be

necessary to reset the user configurations within the unit.

This is d ependent on the degree of the software c hanges

and will not always be necessary.

AV8 Loader (Preset Backup)

The AV8 Loader utility allows the unit settings to be either

downloaded from or uploaded to the AV8. The following

equipment will be required:

! IBM PC compatible computer running Windows 98

or later

! Software – ARCAM AV8 Loader utility (included

on the AV8 CD -ROM)

! Lead – RS232 9-way female D type to 9-way female

D type (null modem)

Installation procedure

The AV8 Loader utility can be run directly from the CDROM, or you can copy the entire ‘Preset Backup Utility’

folder to your ha rd dri ve (e.g. C:\ Progra m Files \ Arca m \

Preset Backup Utility).

Operation procedure

To run the AV8 Loader program:

! Connect th e RS232 lead from t he PC to the RS232

control connector on the AV8

! Switch off all the power amps connected to the AV8

! Run the AV8 Loader program:

o Click on ‘Start’ and select ‘Run…’ from the

pop-up menu

o In the box, type ‘D:\ Preset Backup Utility \

AV8Loader_GUI.exe’ or the location of the file

on the hard drive if no t using the CD-ROM

o Click ‘OK’

! Select the Com port you are using:

o Select ‘File -> Settings…’

o Select the Com port you are using from the

drop down menu

o Close the window

To download the settings from the AV8 to the PC:

! Create a new backup file:

o Select ‘File -> New…’

o Locate a suitable place to save the backup file

(e.g. C:\ Program Fi les \ Arcam \)

o Enter a name for the file in the ‘File name’ box

(e.g. AV8.epr). Note the ‘.epr’ name extension

o Click ‘Save’

! Download the AV8 s ettings:

o Select ‘Transfer -> Download From AV8…’

The AV8 Loader utility will then download the

configuration from the AV8 and save it using the filename

you gave. Once the setup is read from the AV8 it is

automatically stored as a “working file”.

To upload a configuration to the AV8 from the PC:

! Locate th e backup file you wish to upload:

o Select ‘File -> Open…’

o Locate the folder where the backup file is saved

o Select the name of the ‘.epr’ file you wish to

upload

o Click ‘Open’

! Upload the AV8 settings:

o Select ‘Transfer -> Upload To AV8…’

The AV8 automatically resets after the configuration has

been uploaded.

Build

Sequence

Contents

!

How to assemble the

AV8

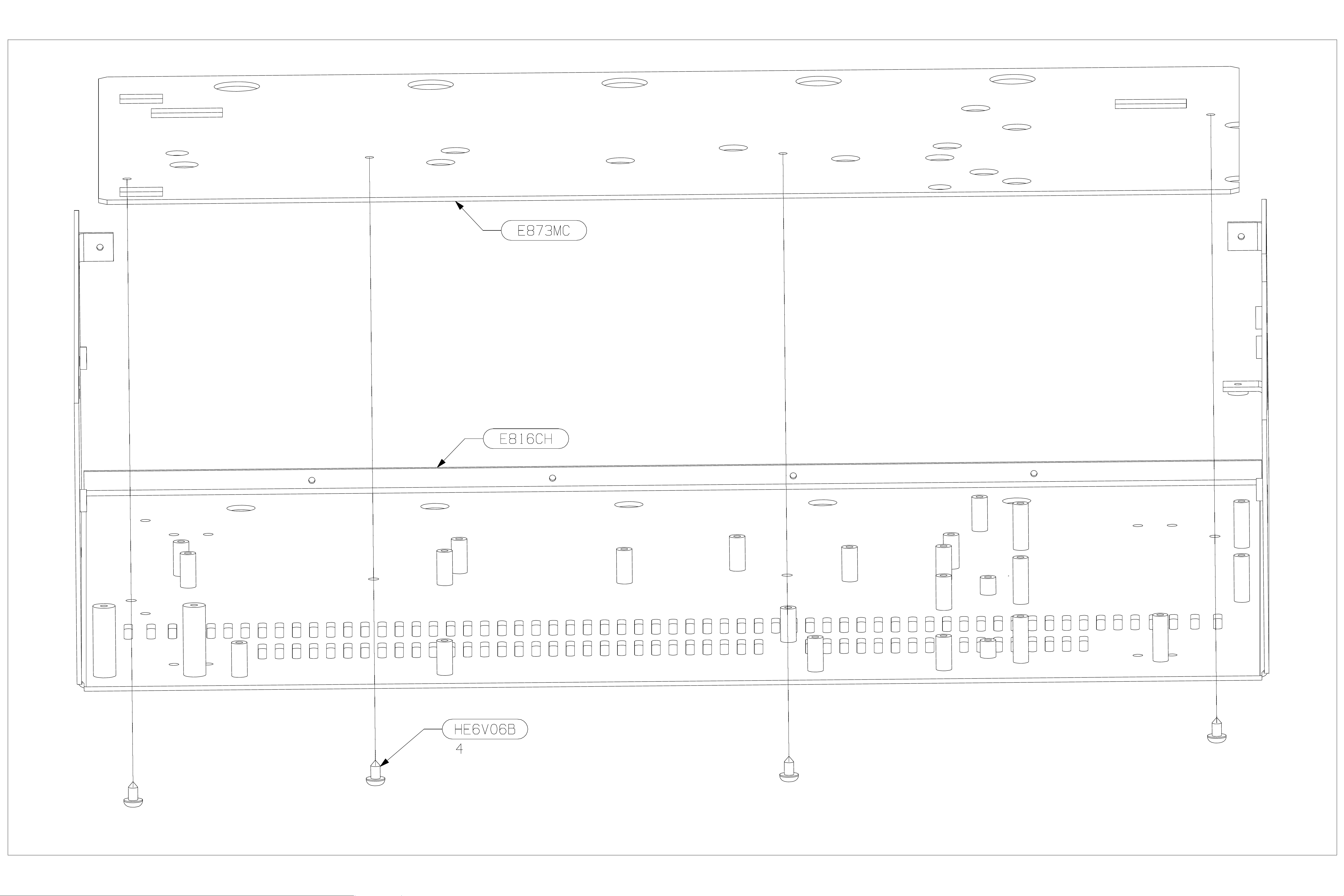

1. Assemble the damping plate to chassis floor. Screw

through from underneath the chassis and thoroughly degrease the

chassis floor before assembling the damping plate. See FIG1.

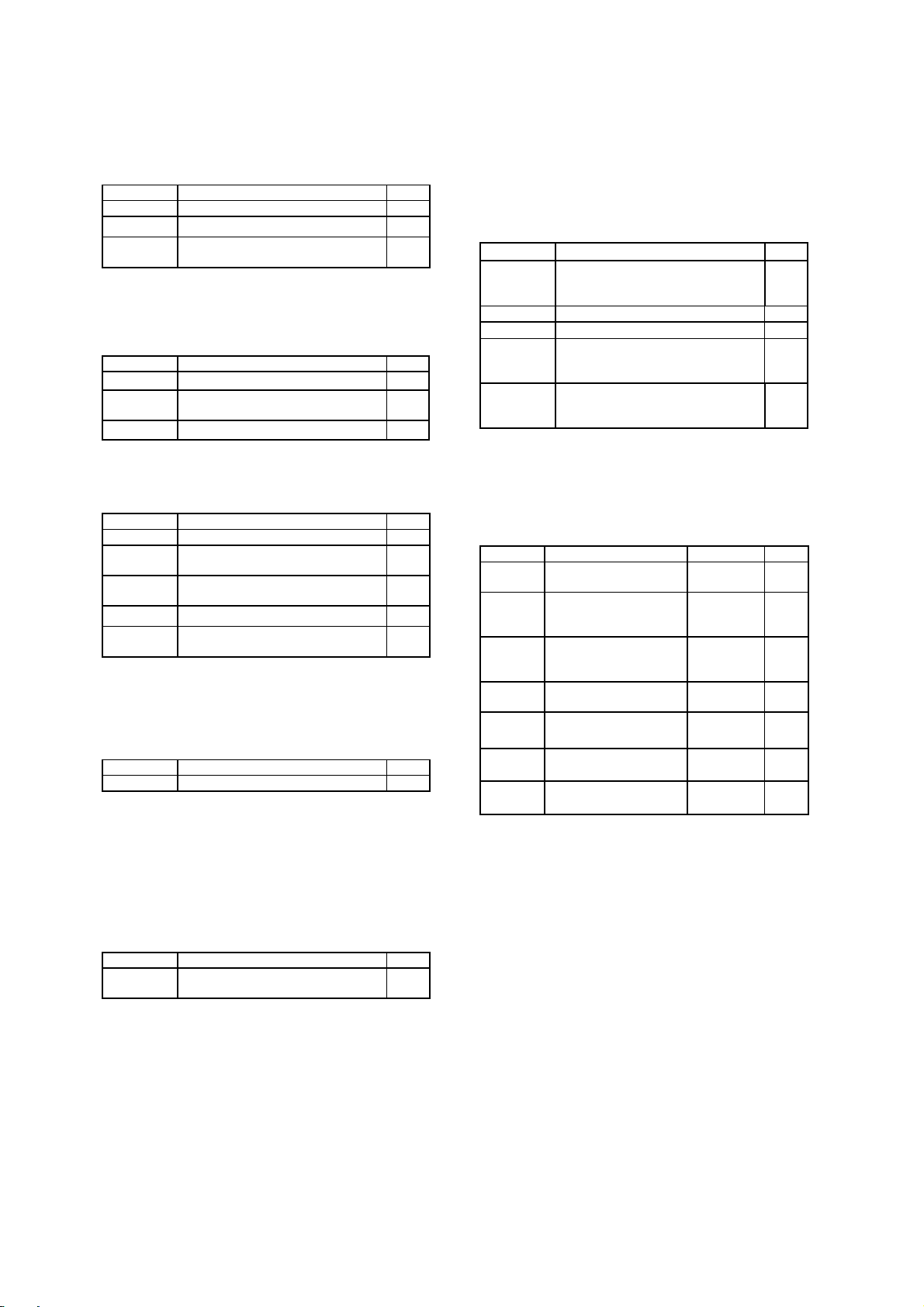

Part No. Description Qty

E816CH Chassis 1

E873MC Damping Plate 1

HE6V06B Self-tapping No6x6mm Pan Torx-Slot

Steel Zinc-Plate Black

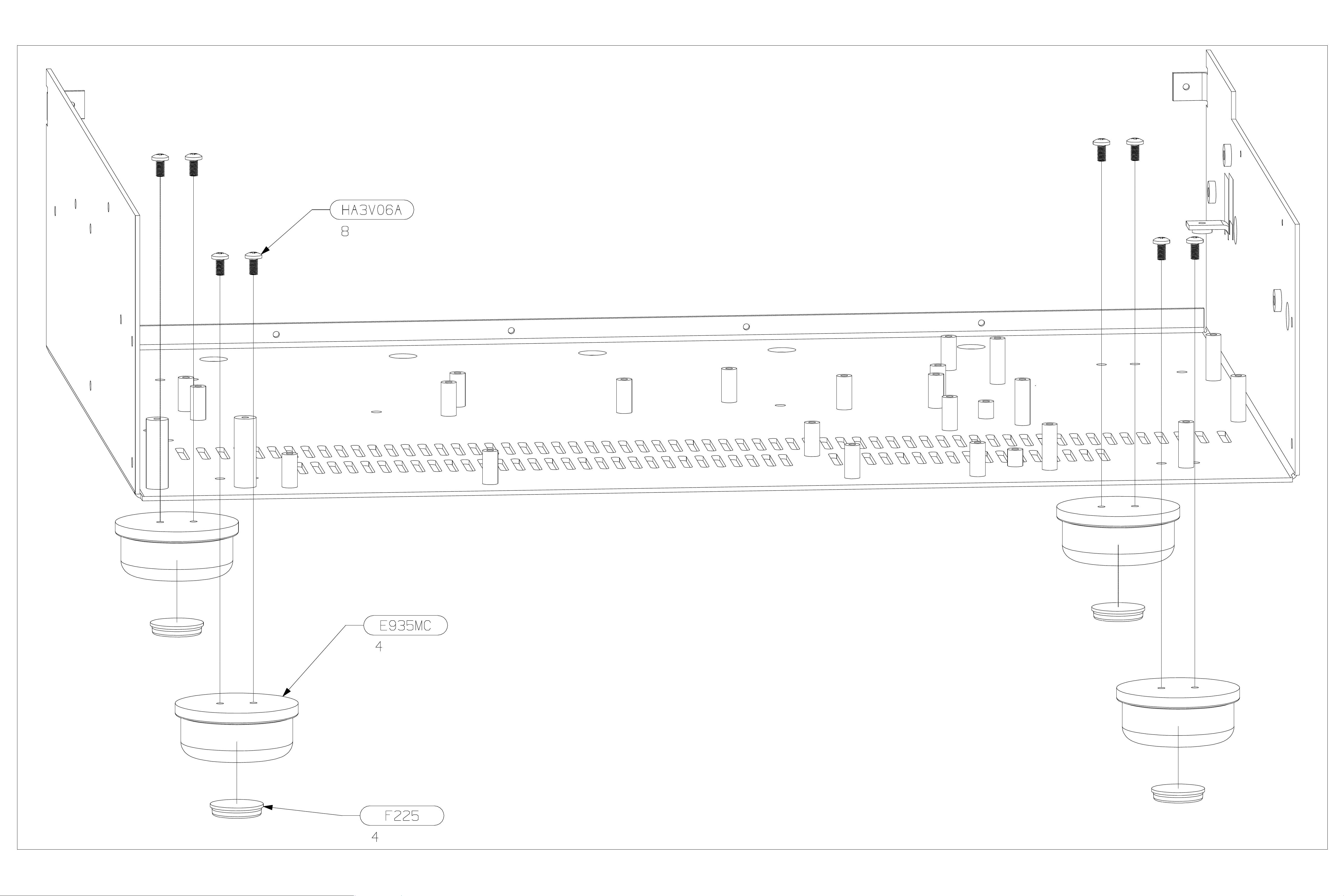

2. Assemble the feet to the chassis. Screw through the

chassis floor into the foot. Stick the bumpon foot onto the base of

turned foot. See FIG2.

Part No. Description Qty

E935MC Turned Foot 4

HA3V06A Screw Machine M3x6mm Pan Torx

Steel Zinc-Plate Clear

F225 Black ‘Bumpon’ Foot 4

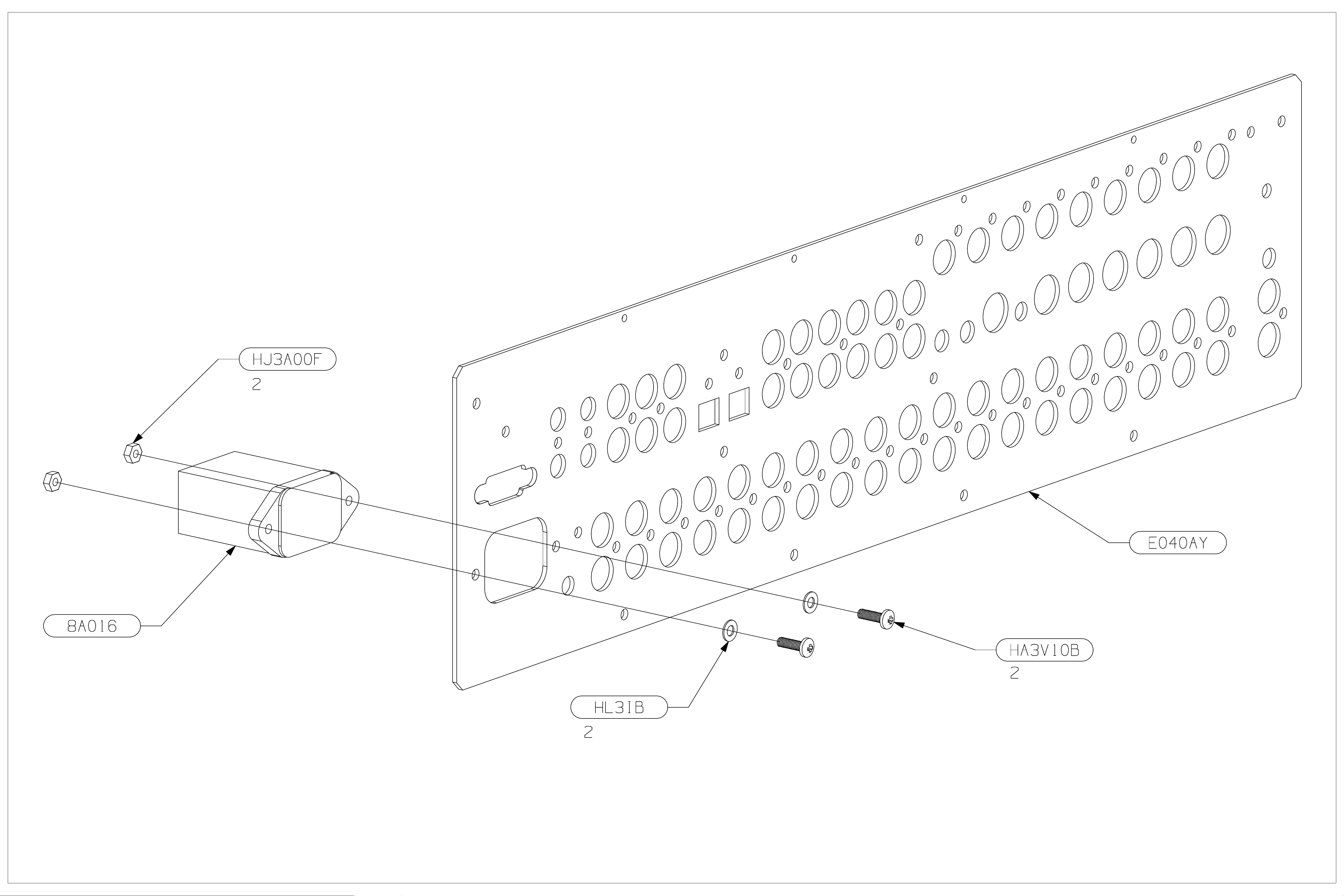

3. Assemble the power socket to rear panel before

assembling the rear panel to the chassis. See FIG3.

Part No. Description Qty

E040AY Rear Panel Assembly 1

8A016 8A016 IEC Inlet with EMI Filter

YB10T1

HA3V10B Screw Machine M3x10mm Pan Torx-

Slot Steel Zinc-Plate Black

HJ3A00F Nut Nyloc M3 Steel Zinc-Plate Clear 2

HL3IB Washer Internal Shakeproof M 3 Steel

Zinc-Plate Black

4. Assemble power loom to IEC power inlet before

assembling the rear panel to the chassis. The live connection is

the right hand spade as viewed from behind (spade terminals)

with the earth spade at the top.

Part No. Description Qty

L939CA AV8 power loom 1

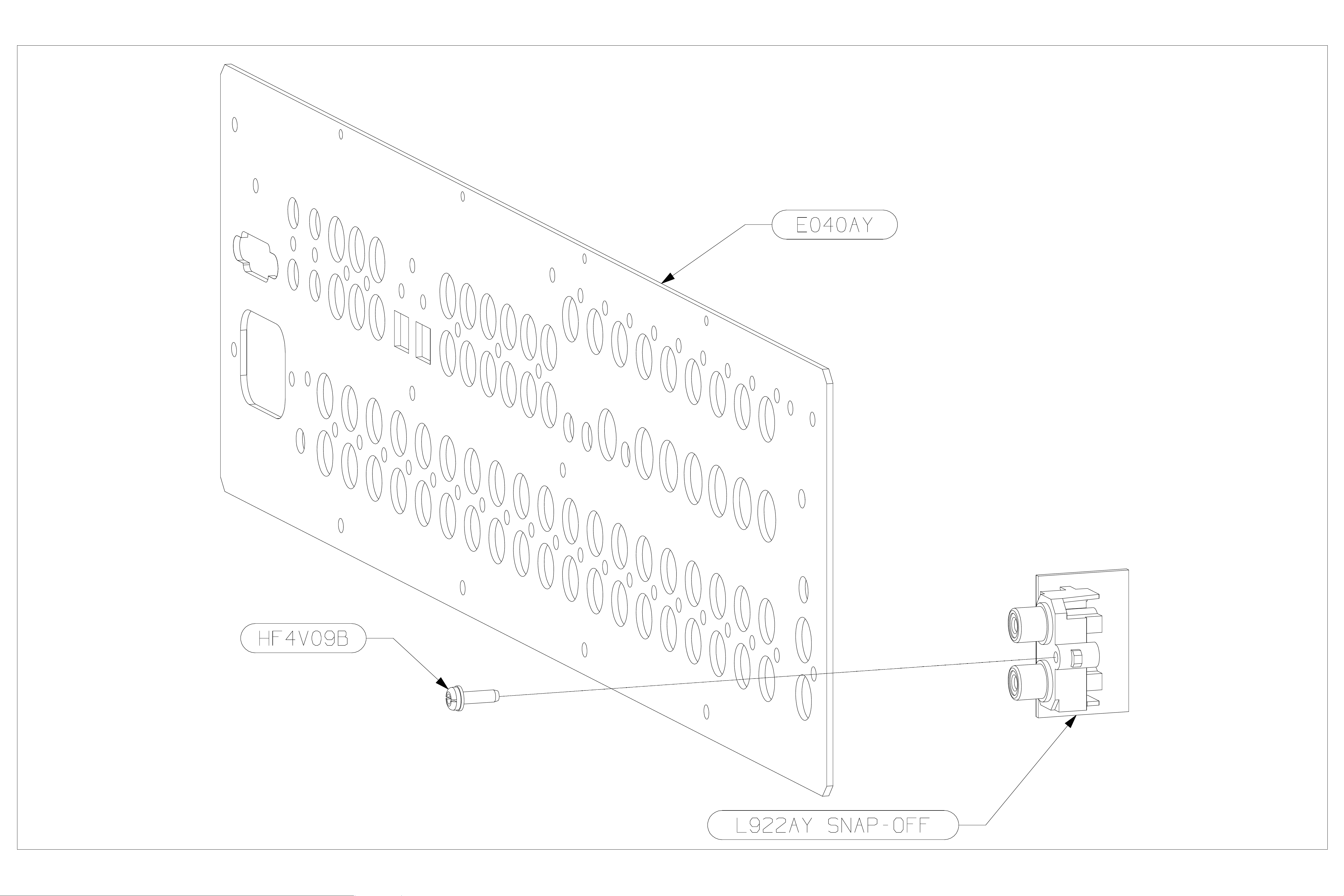

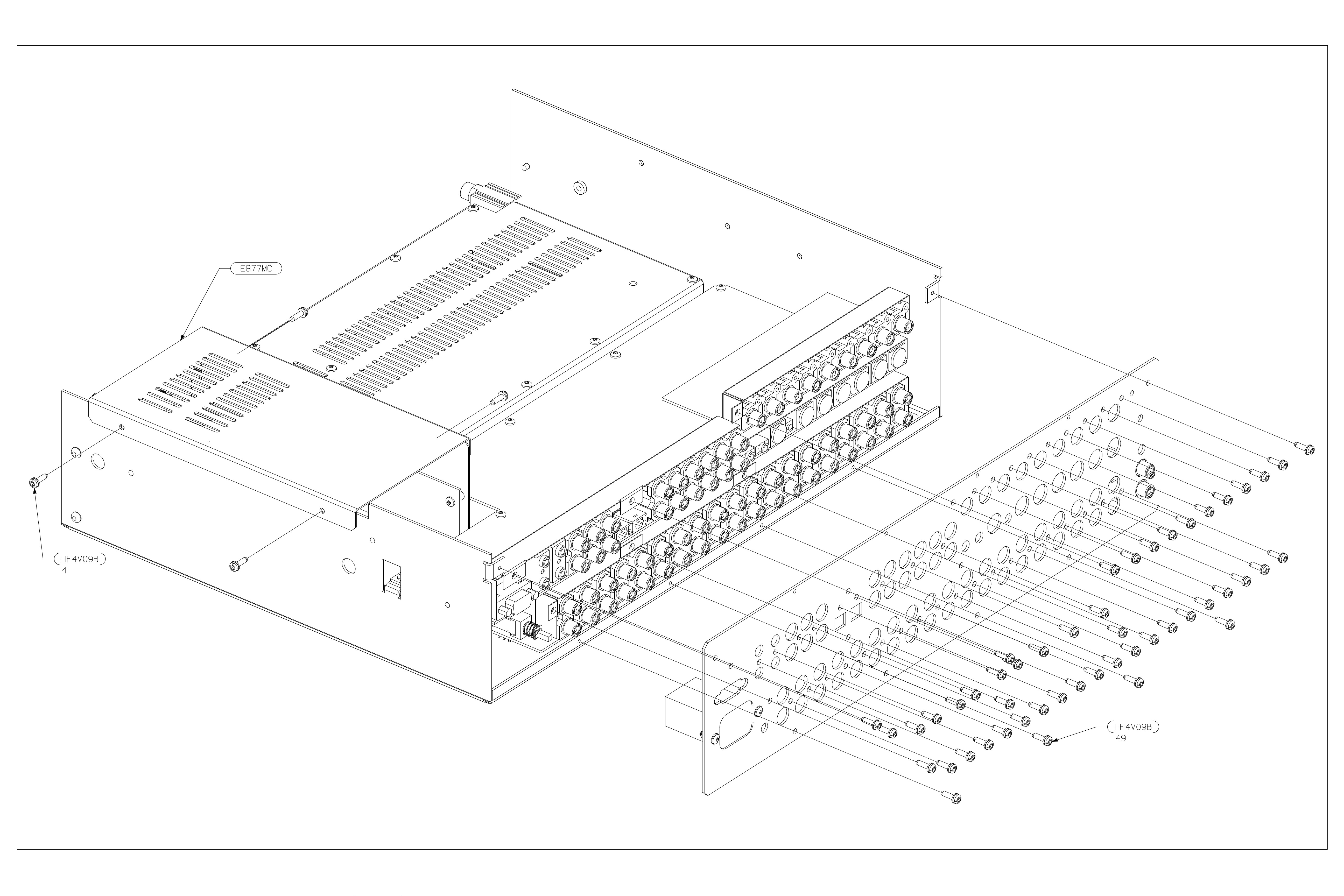

5. N.B. If a phono card is to be fitted then you do not fit

the “Aux” snap-off board at this stage, move to step 6. See step

23 for fitting the Phono upgrade kit.

Fit the “Aux” input snap-off board (snap-off from Audio board,

L921AY) to the rear panel before assembling the rear panel to the

chassis. See FIG4.

Part No. Description Qty

HF4V09B Screw Self-Tapping-SEMS No4x9mm

Pan Torx-Slot Steel Zinc-Plate Black

4

8

1

2

2

1

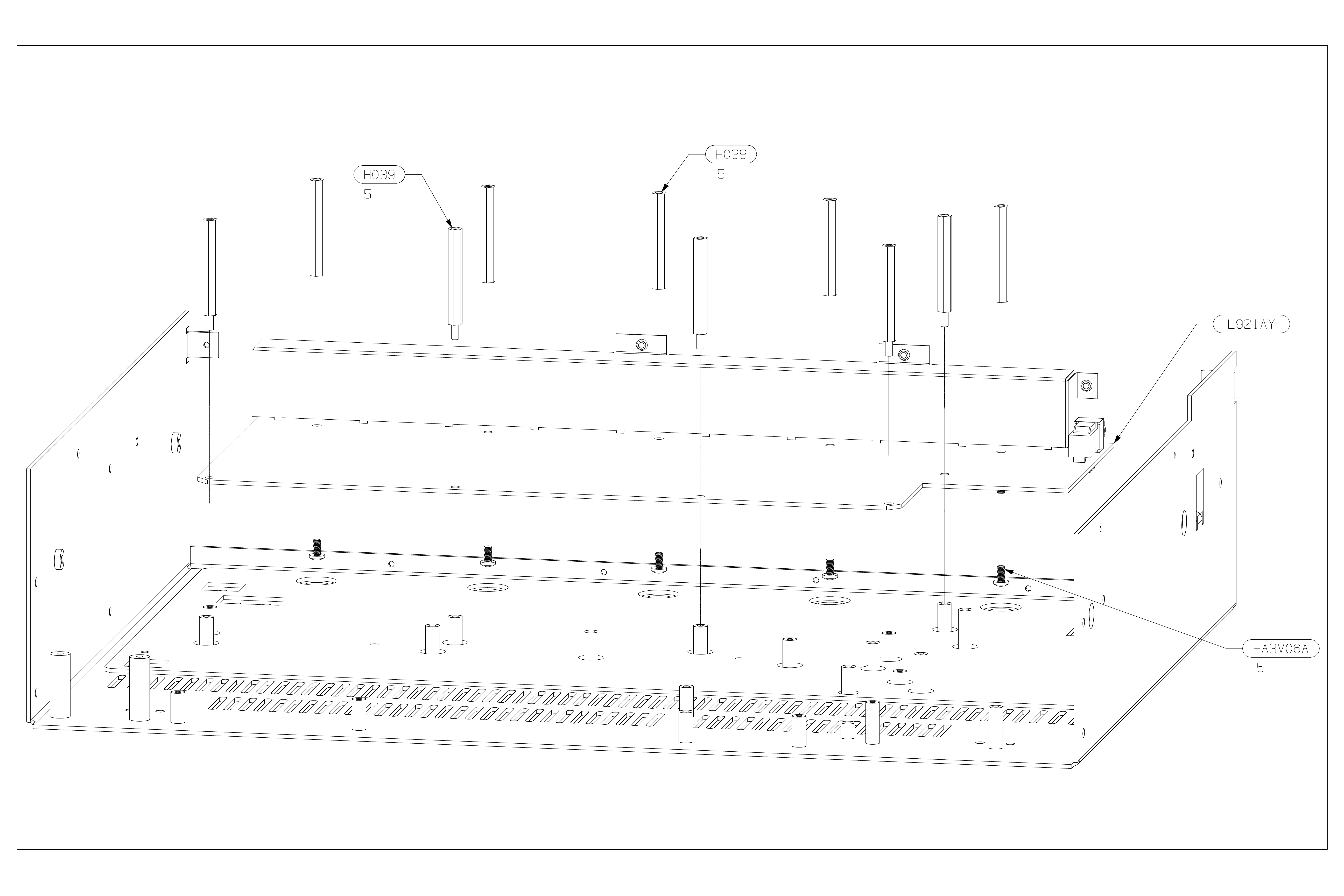

6. Assemble 5x H038 to audio board, L921AY, using 5x

HA3V06A in the holes running along the EMC can, only then fit

the board into the chassis with the other 5x H039 pillars (do no t fit

rear panel). Loosely screw all the pillars through the pcb into the

chassis, once these pillars are in place tighten them all.

See FIG5.

Part No. Description Qty

HF4V09B Screw Self-Tapping-SEMS No4x9mm

H038 38 ff pillars 5

H039 38 mf pillars 5

HA3V06A Screw Machine M3x6mm Pan Torx

HF4V09B Screw Self-Tapping-SEMS No4x9mm

NB. Screws in italics are to be used when rear pane l is fitted in

step 18.

7. Once the audio board is in place, fit the following

cables to the audio board. Ensure the cables, especially the flex

foil, are the correct way round.

Part No. Description Reference Qty

L925CA 8-way AMP CT from

L927CA 6-way AMP CT from

L930CA 5-way AMP CT from

L922CA 22-way foil cable from

L933CA 5-way AMP CT from

L923CA 8-way AMP CT from

L923CA 8-way AMP CT from

Pan Torx-Slot Steel Zinc-Plate Black

(into EMC shield)

Steel Zinc-Plate Clear (from

underneath)

Pan Torx-Slot Steel Zinc-Plate Black

(into sockets)

SK901 1

audio to snap-off 280mm

SK801 1

audio to horiz power

100mm

SK917 1

headphone to audio

250mm

SK916 1

digital to audio 100m m

SK915 1

digital to audio 100m m

SK913 1

digital to audio 120m m

SK914 1

digital to audio 120m m

3

5

19

FIG1

FIG2

FIG3

FIG4

FIG5

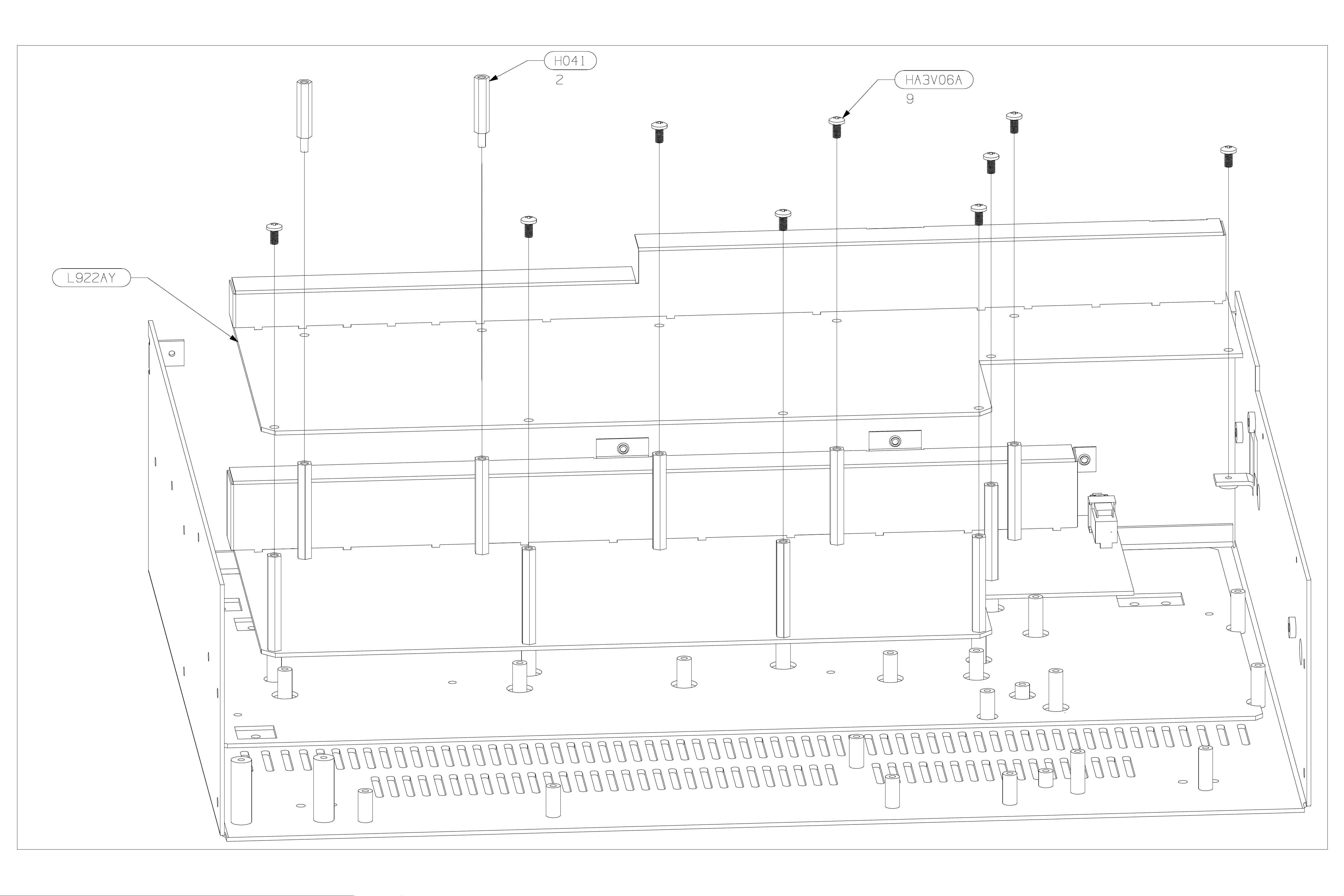

8. Fit the video board (L922AY – main board) to the

chassis (do not fit rear panel yet). Ensure the board is pushed to

the back of the chassis before tightening down the board. Use

the H041 pillars in the two holes closest to the S-video

connectors (right hand side nearest the EMC screen as viewed

from the connector side). See FIG6.

Part No. Description Qty

HF4V09B Screw Self-Tapping-SEMS No4x9mm

H041 22 mf pillars 2

HA3V06A Screw Machine M3x6mm Pan Torx

HF4V09B Screw Self-Tapping-SEMS No4x9mm

cables to the video board:

Part No. Description Reference Qty

L922CA 22-way foil cable from

L925CA 8-way AMP CT from

L931CA 30-way foil cable from

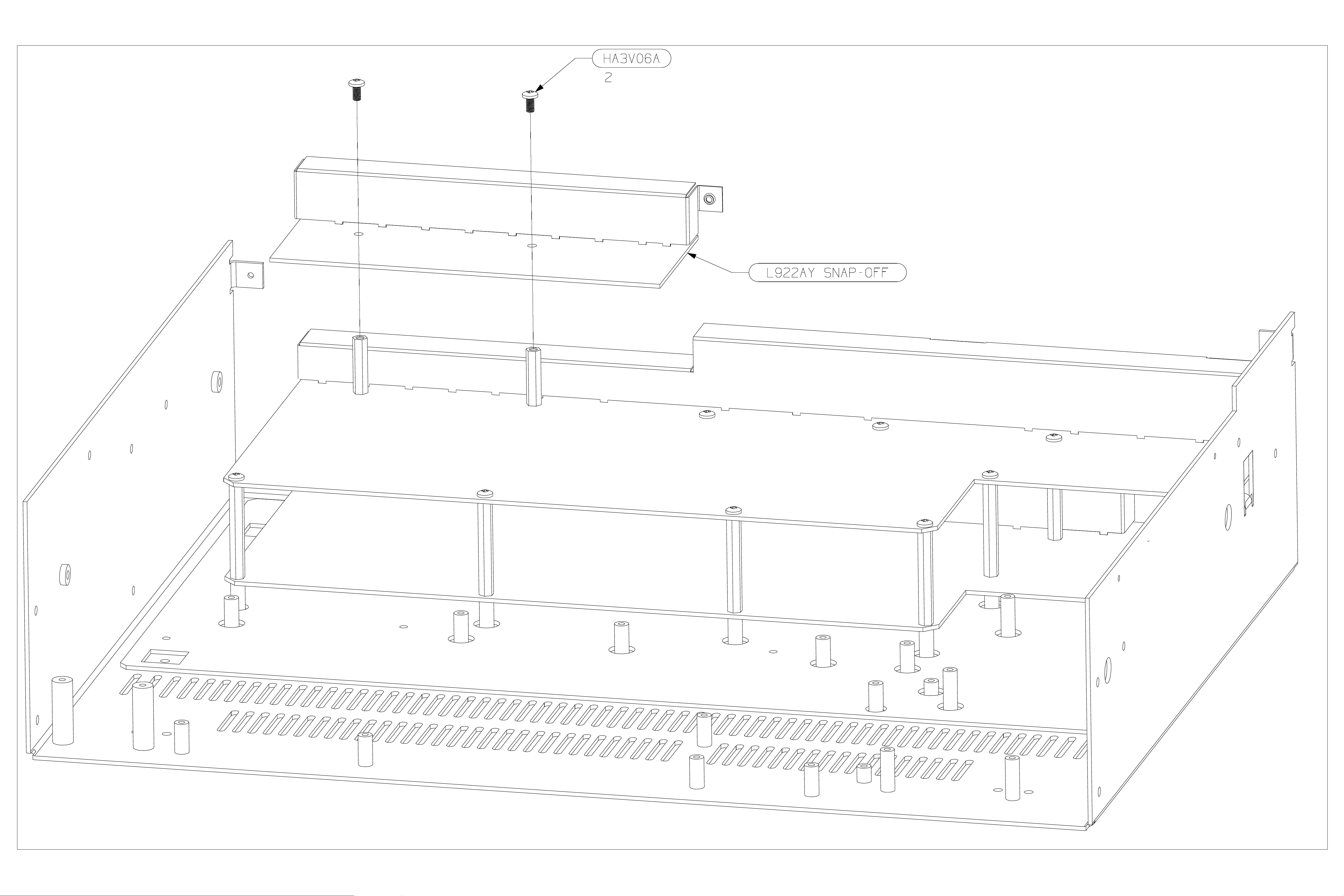

9. Fit the top video board (L922AY – sub board) to

chassis (do not fit rear panel). See FIG7.

Part No. Description Qty

HF4V09B Screw Self-Tapping-SEMS No4x9mm

HA3V06A Screw Machine M3x6mm Pan Torx

HF4V09B Screw Self-Tapping-SEMS No4x9mm

Connect L922CA from the video board (SK700) to the top-video

board (SK209)

10. Fit the power can using 2x HA3V06A into standoffs.

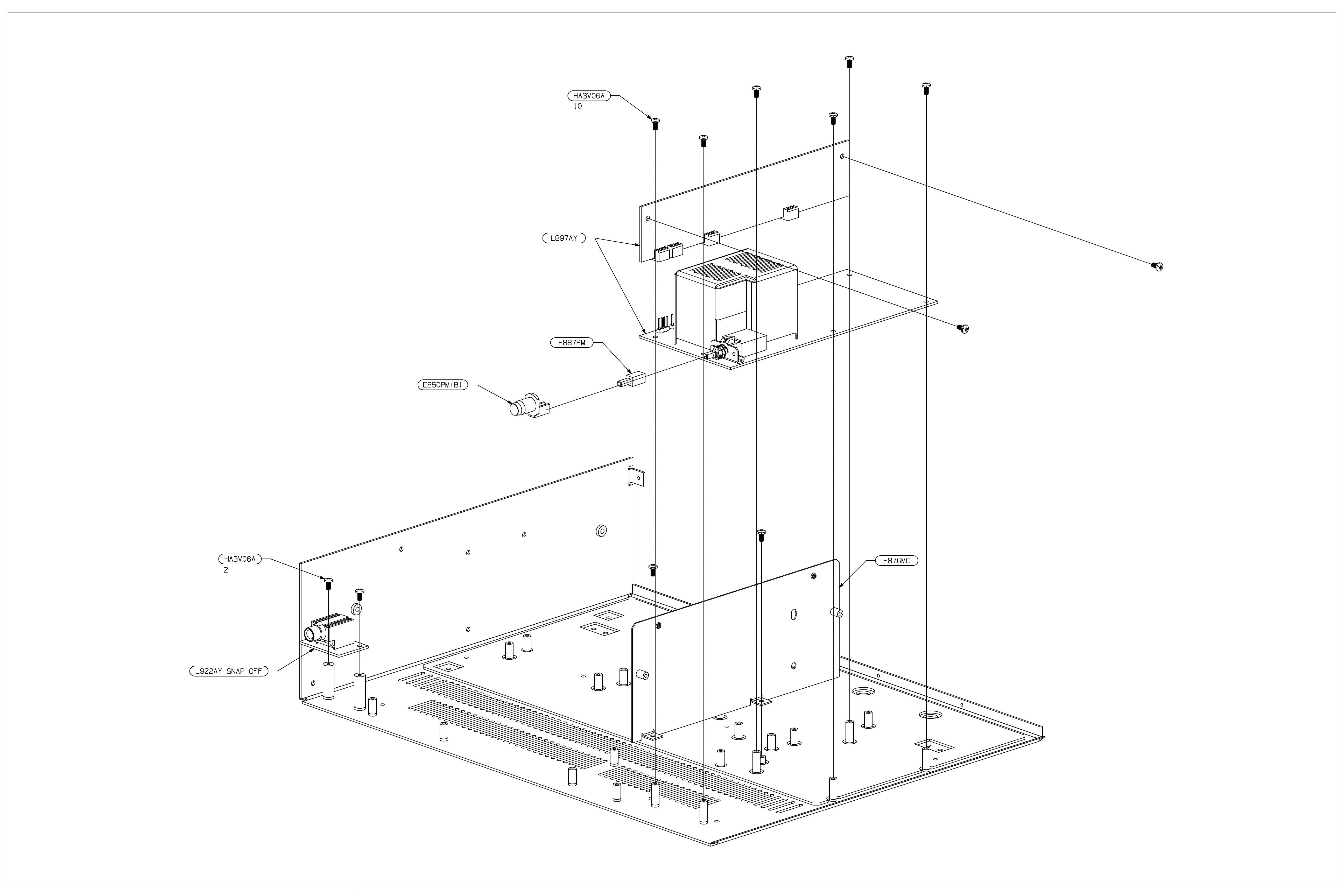

See FIG8.

Part No. Description Qty

E876MC Power Can 1

HA3V06A Screw Machine M3x6mm Pan Torx

Pan Torx-Slot Steel Zinc-Plate Black

(into EMC shield)

Steel Zinc-Plate Clear thro’ video PCB

into standoffs

Pan Torx-Slot Steel Zinc-Plate Black

(thro’ RP into sockets)

Once the video board is in place, fit the following

SK700 1

top video to video

100mm

SK1000 1

video to horiz power

280mm

SK702 1

digital to video 190mm

Pan Torx-Slot Steel Zinc-Plate Black

(into EMC shield)

Steel Zinc-Plate Clear through top

video PCB into standoffs

Pan Torx-Slot Steel Zinc-Plate Black

(thro’ RP into sockets)

Steel Zinc-Plate Clear into s tandoffs

2

9

9

1

2

9

2

11. Fit the horizontal power PCB (L897AY – snap-off

part 2) using 6x HA3V06A screws into standoffs. Refer to FIG8.

Once the pcb is in place, fit the cables below.

Part No. Description Reference Qty

HA3V06A Screw Machine

M3x6mm Pan Torx

Steel Zinc-Plate Clear

into standoffs

L925CA 8-way AMP CT from

horiz power to digital

280mm

L926CA 7-way AMP CT from

horiz power to digital

350mm

L928CA 6-way AMP CT from

horiz power to digital

540mm

L925CA 8-way AMP CT from

horiz power to phase

lock loop 280m m

Connect the following cables using the reference table below:

Part No. From To

L927CA Audio / SK801 Horizontal power /

L925CA Video / SK1000 Horizontal power /

N.B. The Video cable L925CA has an excess of length so that the

video board may be removed but still remain connected when the

unit is serviced. A cable tie should be used to hold this excess

when the board is installed.

12. Fit the mains power button to the power switch, with

the button to the top. Refer to FIG8.

Part No. Description Qty

E887PM DiVA power button adapter 1

E850PM FMJ mains button (silver)

E850PMB FM J m ains button (black)

13. Fit the vertical power PCB. Once the pcb is in place,

fit the cable specified below.

Part No. Description Reference Qty

HA3V06A Screw Machine

M3x6mm Pan Torx

Steel Zinc-Plate Clear

into standoffs

L929CA 4-way AMP CT from

digital to vertical

power 220mm

14. Fit the headphone PCB (snap-off from video board).

Fit with socket facing to the front. Refer to FIG8.

Part No. Description Qty

HA3V06A Screw Machine M3x6mm Pan Torx

Steel Zinc-Plate Clear into s tandoffs

Connect L930CA from audio board (SK917) to the headphone

board (SKP1).

6

SK5 1

SK7 1

SK2 1

SK4 1

SK3

SK5

1

2

SK8 1

2

FIG6

FIG7

FIG8

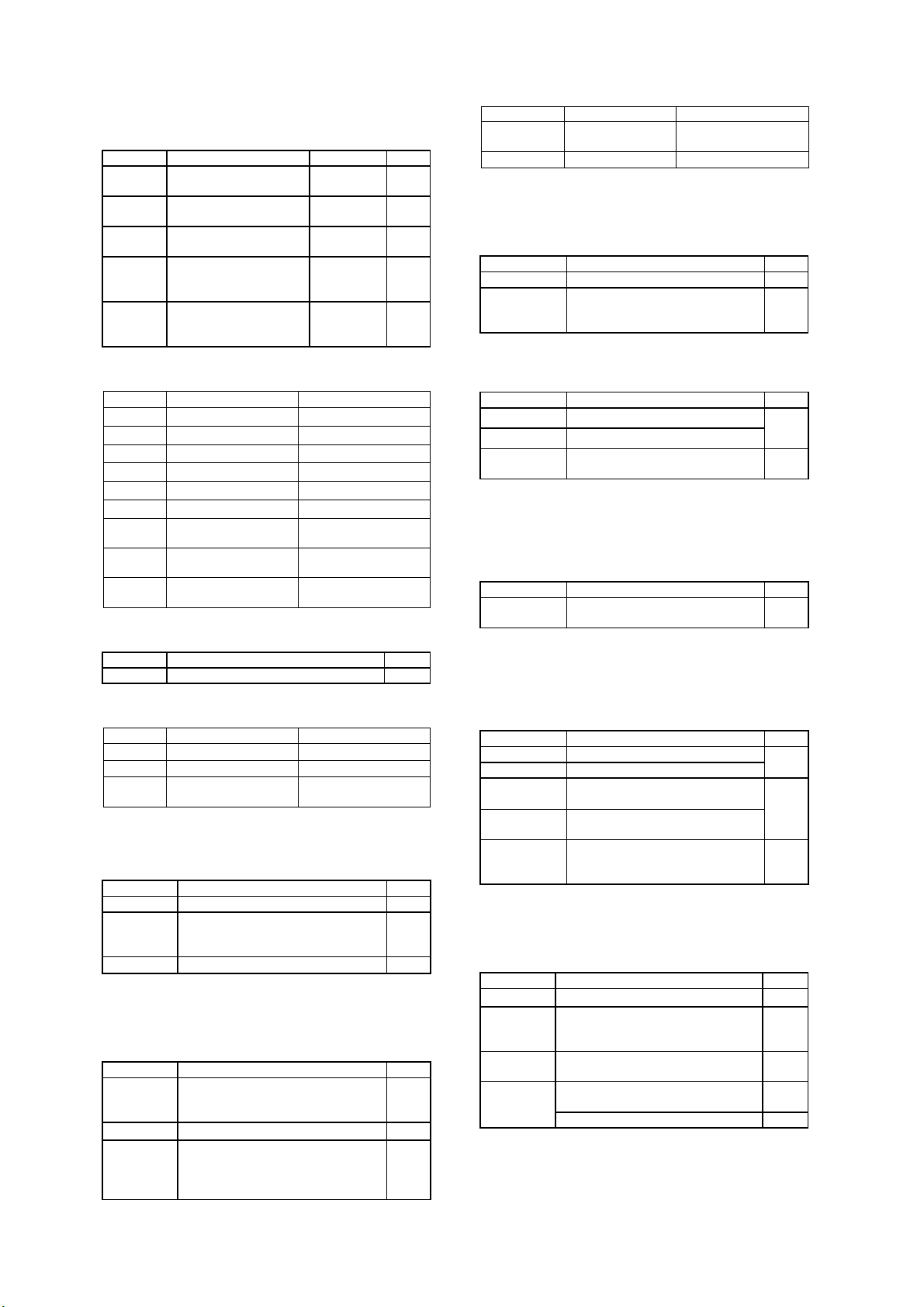

15. Fit the digital PCB (L896AY) such that the notch in

the board is by the headphone board. Once the pcb is in place, fit

the cables below. See FIG9.

Part No. Description Reference Qty

H039 M3x38mm mf pillars

into standoffs

H030 M3x18mm mf pillars

into standoffs

L931CA 30-way foil cable from

digital to display 190mm

L923CA 8-way AMP CT from

digital to phase lock loop

120mm

L933CA 5-way AMP CT from

digital to phase lock loop

100mm

Connect the cable assemblies listed below.

Part No. From To

L923CA Audio / SK914 Digital / SK102

L923CA Audio / SK913 Digital / SK103

L933CA Audio / SK915 Digital / SK100

L922CA Audio / SK916 Digital / SK902

L931CA Video / SK702 Digital / SK900

L929CA Vertical Power / SK8 Digital / SK1002

L925CA Horizontal Power /

SK6

L926CA Horizontal Power /

SK7

L928CA Horizontal Power /

SK2

16. Fit the phase lock loop PCB (L948AY). See FIG9.

Part No. Description Qty

H030 M3x18mm mf pillars into standoffs 4

Connect the cable assemblies listed below.

Part No. From To

L923CA Digital / SK903 Phase lock loop / SK1

L933CA Digital / SK801 Phase lock loop / SK3

L925CA Horizontal Power /

SK4

17. Clip 2 F219 cable clips into top of EMC shield. Then

using the cable clips as handles fit EMC digital PCB shield.

Refer to FIG9.

Part No. Description Qty

E919MC Digital EMC Shield 1

HA3V06A Screw Machine M3x6mm Pan Torx

Steel Zinc-Plate Clear into s tandoffs

thro’ EMC shield into pillars

F219 Twist Lock cable clip 2

18. Assemble the rear panel to the chassis using all the

screws in italics on previous pages. Fit the power can lid over

the chassis and the vertical can wall with vents directly above the

EMC can on the power board. See FIG10.

Part No. Descrip tion Qty

HF4V09B Screw Self-Tapping-SEMS No4x9mm

Pan Torx-Slot Steel Zinc-Plate Black

(rear chassis return)

E877MC Power Can Lid 1

HF4V09B Screw Self-Tapping-SEMS No4x9mm

Pan Torx-Slot Steel Zinc-Plate Black

(2 into power can wall and 2 into

chassis wall)

7

4

SK901 1

SK903 1

SK801 1

Digital / SK1001

Digital / SK1003

Digital / SK1000

Phase lock loop / SK2

11

6

4

Connect the cable assemblies listed below.

Part No. From To

L939CA IEC Inlet Horizontal Power /

L925CA Audio / SK901 Aux snap-off / SK927

19. Assemble the phono can assembly to the chassis (3

screws) and the rear panel (1 screw) making sure the cable loom

fits into notch in top of the phono can. See FIG11.

Part No. Description Qty

E041AY Phono Can Assembly 1

HF4V09B Screw Self-Tapping-SEMS

20. Assemble the display PCB to the fascia assembly

Part No. Description Qty

E919AY Fascia Assembly (silver)

E919AYB Fascia Assembly (black)

HA3V06A Screw Machine M 3x6m m Pan Torx

21. Assemble the fascia assembly and the display PCB to

the chassis. Check the operation of mains button at this stage.

Keep the foil bent upwards. Connect the flexfoil after the fascia

assembly is fitted to the chassis.

Part No. Description Qty

HE6V06B Self Tapping No6x6mm Pan Torx-

Connect L931CA from the digital board (SK901) to the display

board (SK100).

22. Assemble the cover plate to the chassis

Part No. Description Qty

E826CP Cover Plate (Silver)

E826CPB Cover Plate (black)

HA4V06S

HA4V06B Screw Machine M4x6mm Pan Torx

HF4V09B Screw Self-Tapping-SEMS

23. Fit the Phono Board Upgrade Kit, using L870AY

board and the following parts. See FIG12 for assembly

instructions.

Part No. Descrip tion Qty

H031 20 ff pillars 3

HF4V09B Screw Self-Tapping-SEMS

HA3V06A Screw Machine M3x6mm Pan Torx

No4x9mm Pan Torx-Slot Steel

Zinc-Plate Black

Steel Zinc-Plate Clear into s tandoffs

Slot Steel Zinc-Plate Black

Screw Machine M4x6mm Pan Torx

St Steel Nickel

St Steel Black

No4x9mm Pan Torx-Slot Steel

Zinc-Plate Black

No4x9mm Pan Torx-Slot Steel ZincPlate Black into rear panel

Steel Zinc-Plate Clear into pillars

8-way AMP CT from phono (SK2) to

audio (SK901) 280mm

8-way connector 2

SK1

4

1

14

4

1

4

4

1

6

1 L925CA

FIG9

FIG10

FIG11

FIG12

Phono

Board

L870

Contents

!

Circuit description

!

Component overlay

!

Parts list

!

Circuit diagrams

AV8 Phono Board

Circuit Description

Refer to circuit diagram L870 sheet 1

The phono board is a simple single stage RIAA amplifier

and consists of two channels of high gain amplification,

and the ability to switch between moving magnet (MM)

and moving coil (M C) settings.

PSU

The unit derives its +

fitted into with only local decoupling capacitors on board.

Interface

The unit connects to the host unit via a 8 way connector.

Amplification

The left channel h as designators beginnin g with 100, and

the right with 200. For the purposes of this description the

left channel will be described, as the right channel is the

same in all respects.

The amplifier is a small signal class A voltage feedback

amplifier with switch able gain. The input consists of an

actively loaded differential pair of very low noise PNP

transistors (TR106, TR107). These transistors are very

specific and should only be replaced with identical parts

with the E grade high gain. TR100 and TR101 form a

current source for the pair, which sets the qu iescent current

for the entire amplifier. The active load consists of TR110

and TR111, which forms part of the differential current

mirror with TR112, TR113 & TR114. This differential

stage also h as an active load (TR102 & TR10 3) to keep

gain to a maximum.

Both of these di fferential stages are design ed to have as

much gain as p ossible to enable the sing le stage design.

The RIAA respon se is achieved in th e feedback network:

C101, C110, C111, C112, C119, C120 and R115, R112.

C115 is used to correct between MM and MC gains as the

amplifier is non-inverting.

SW100 switches between MM and MC. Two poles of the

switch change between the different loading required for

each type of the cartridge: R108 & C109 for MM and

added in parallel for MC R104 & C108. The other two

poles chan ge the feedbac k resister valu e to alter th e gain:

R105 for MM and added in parallel for MC R123.

The DC offset is c ontrolled by a non-i nverting s ervo built

around IC100. The amount of servo current is different for

each gain setting via R111 (MM) and R124 (MC) so that

the low frequency high pass point remains the same for

both settings. However the high pass point for the circuit

is set by C113. This gives a warp filter, stops DC start-up

thumps from upsetting DC coupled circuitry and an

approximation of the RIAA/IEC curve (-2dB @ 20Hz)

The output is class A buffered by a d ual mirror follower

(TR104, TR105, TR108, TR109). The quiescent current is

set by D100 and R118 and R119.

Closed loop st ability is achieved with C16, C117, gi ving

symmetrical slewing capability.

15V regulated rails from the unit it is

L870 Phono Board Parts List Issue 2.0

Designator Part Description

C1 2A410 CERD 100N 63V -20% +80% RA

C100 2N622 ELST 22U 63V

C101 2D210 PPRO 1N0 5% 63V RA

C102 2P710AS ELEC 100U 25V SILMIC

C103 2P710AS ELEC 100U 25V SILMIC

C104 2K410 PEST 100N 63V 10%

C105 2K410 PEST 100N 63V 10%

C106 2K410 PEST 100N 63V 10%

C107 2K410 PEST 100N 63V 10%

C108 2D147W PPRO W 470P 63V 5% RA

C109 2D110W PPRO W 100P 63V 5% RA

C110 2D247N PPRO 4N7 63V 5% RA

C111 2D310 PPRO 10N 63V 1% AXIAL

C112 2D310 PPRO 10N 63V 1% AXIAL

C113 2K510 CAP MKS2 1U0 16V 10%

C115 2D213N PPRO 1N3 63V 5% RA

C116 2D147W PPRO W 470P 63V 5% RA

C117 2D147W PPRO W 470P 63V 5% RA

C118 2U610 ELST NON POLAR 10UF 35V

C119 2D110N PPRO 100P 63V 5% RA

C120 2D210 PPRO 1N0 5% 63V RA

C200 2N622 ELST 22U 63V

C201 2D210 PPRO 1N0 5% 63V RA

C202 2P710AS ELEC 100U 25V SILMIC

C203 2P710AS ELEC 100U 25V SILMIC

C204 2K410 PEST 100N 63V 10%

C205 2K410 PEST 100N 63V 10%

C206 2K410 PEST 100N 63V 10%

C207 2K410 PEST 100N 63V 10%

C208 2D147W PPRO W 470P 63V 5% RA

C209 2D110W PPRO W 100P 63V 5% RA

C210 2D247N PPRO 4N7 63V 5% RA

C211 2D310 PPRO 10N 63V 1% AXIAL

C212 2D310 PPRO 10N 63V 1% AXIAL

C213 2K510 CAP MKS2 1U0 16V 10%

C215 2D213N PPRO 1N3 63V 5% RA

C216 2D147W PPRO W 470P 63V 5% RA

C217 2D147W PPRO W 470P 63V 5% RA

C218 2U610 ELST NON POLAR 10UF 35V

C219 2D110N PPRO 100P 63V 5% RA

C220 2D210 PPRO 1N0 5% 63V RA

D100 3A4148 SSDIODE 1N4148 75V

D101 3A4148 SSDIODE 1N4148 75V

D102 3A4148 SSDIODE 1N4148 75V

D200 3A4148 SSDIODE 1N4148 75V

D201 3A4148 SSDIODE 1N4148 75V

D202 3A4148 SSDIODE 1N4148 75V

IC100 5B071 IC FET OPAMP TL071

IC200 5B071 IC FET OPAMP TL071

PCB1 L870PB_2 PRINTED CIRCUIT BOARD

R100 1H133 RES MF W4 1% 330R

R101 1H110 RES MF W4 1% 100R

R102 1H110 RES MF W4 1% 100R

R104 1H110 RES MF W4 1% 100R

R105 1H110 RES MF W4 1% 100R

R106 1H110 RES MF W4 1% 100R

R108 1H347 RES MF W4 1% 47K

R109 1H312 RES MF W4 1% 12K

R110 1H312 RES MF W4 1% 12K

R111 1H356 RES MF W4 1% 56K

R112 1H410 RES MF W4 1% 100K

R113 1H410 RES MF W4 1% 100K

R114 1H410 RES MF W4 1% 100K

R115 1H315 RES MF W4 1% 15K

R116 1H522 RES MF W4 1% 2M2

Loading...

Loading...