Page 1

AR767 H.P. Power - Jet Cleaner

Place

Stamp

Here

A.R. North America

Attn: Pressure Washer Warranty Department

140 - 81st Avenue NE

Fridley, MN 55432

OPERATING MAINTENANCE MANUAL

Warning: This manual must be read before

installation or use of the unit.

Important

Winter storage or long time

Notice:

storage. Drain all water out of the

pump. Flush the pressure washer

with a 50% antifreeze solution,

and relieve the pressure. Flush the

pressure washer before you use it

again to remove the antifreeze.

Page 2

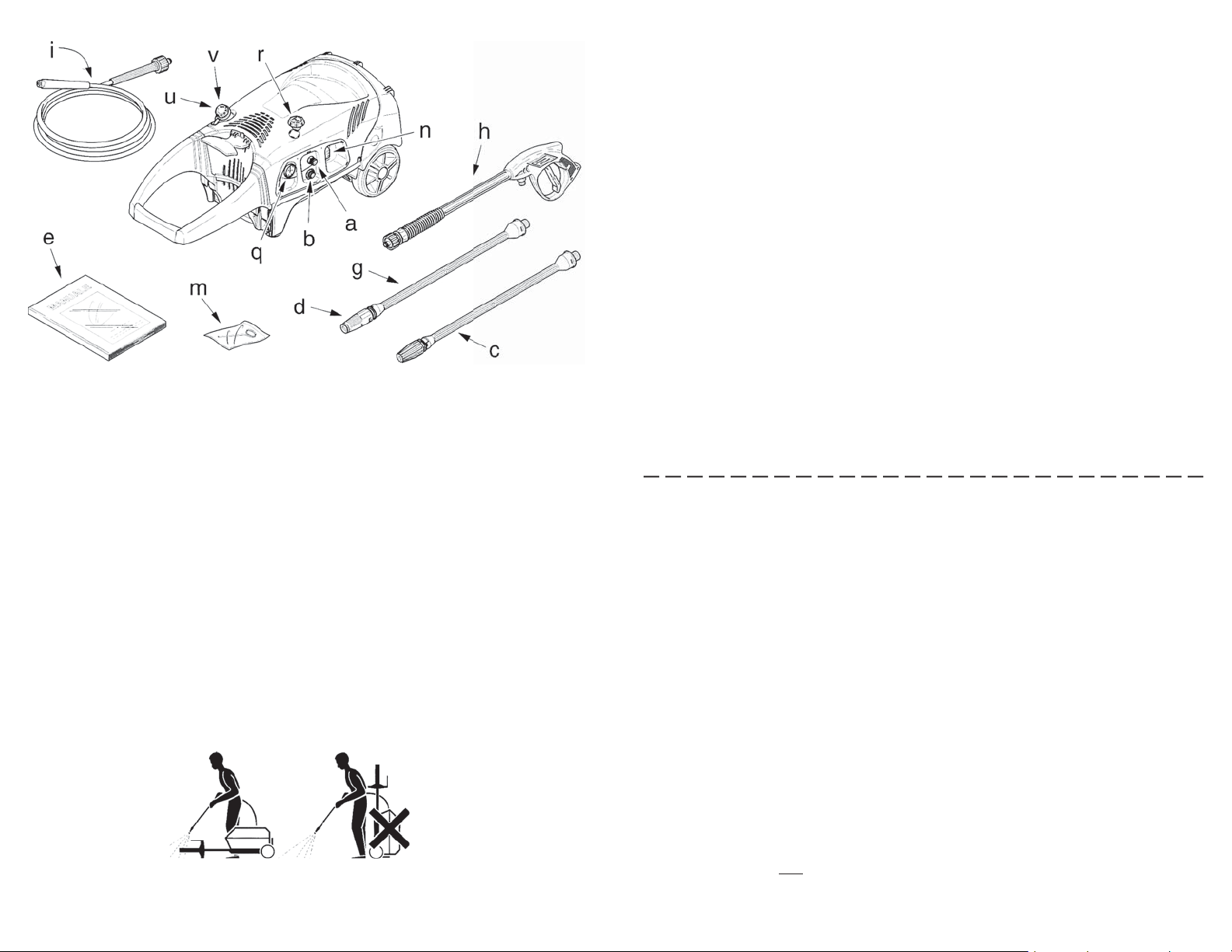

Key

a - Water outlet (OUTLET)

b - Water inlet with fi lter (INLET)

c - High pressure rotating nozzle kit (optional accessory)

d - Adjustable spray nozzle

e - Maintenance handbook

g - Lance

h - Gun with safety catch

i - High-pressure hose

m - Nozzle cleaning tool

n - Motor switch

q - Pressure gauge

r - Pressure regulator knob

u - Detergent tank plug

v - Detergent control knob

PRESSURE WASHER LIMITED WARRANTY

This product is under warranty to the original retail consumer against defects in

material and workmanship for a period of 1 (one) year on machine, 90 days on

gun and hose assembly, from the date of retail purchase and is not transferable.

Warranty covers replacement parts. This limited one year warranty applies

only to products used in consumer applications and does not apply to rental

or commercial applications.

WARRANTY RETURNS

Items returned for warranty consideration must have a Returned

Merchandise Authorization (RMA) number. All unauthorized returns

will be refused and shipped back to sender. Call 866-235-5112 Monday

through Friday 8:00 a.m. - 5:00 p.m (Central Standard Time). Or E-Mail to: info@

arnorthamerica.com 24 hours a day.

A.R. North America, Inc.

140 - 81st Avenue NE • Fridley, MN 55432

Attn: Pressure Washer Warranty Department

PRESSURE WASHER LIMITED WARRANTY CARD

Mr. Mrs. Ms. Miss

First Name: Initial: Last Name:

Address: (Number and Street) Apt. #:

City: State: Zip/Postal code:

-

Telephone: Date of Purchase: Purchase Price:

- -

Model Number: Serial Number:

Month Day Year

$ .00

(excluding tax)

Located on product package/box

Store Name:

Warranty void from Manufacture if this card is not returned.

All fi elds must be fi lled out for warranty.

Page 3

Notes

1. INTRODUCTION

The high pressure power-jet cleaner you have purchased is a

technologically advanced product designed by one of the leading European

manufactures of high-pressure pumps. To obtain the best performance

from your unit, read this booklet carefully and follow the instructions each

time you use the cleaner. We congratulate you on your choice and wish you

successful operation.

* Read and understand these instructions before operating the cleaner. Pay

particular attention to the safety symbols through out this manual. Failure

to comply with these instructions may result in personal injury or property

damage. DO NOT allow children to operate or play on or around this

equipment.

* Plug the cleaner into a properly grounded 3-prong outlet. Improper

grounding can result in electrical shock.

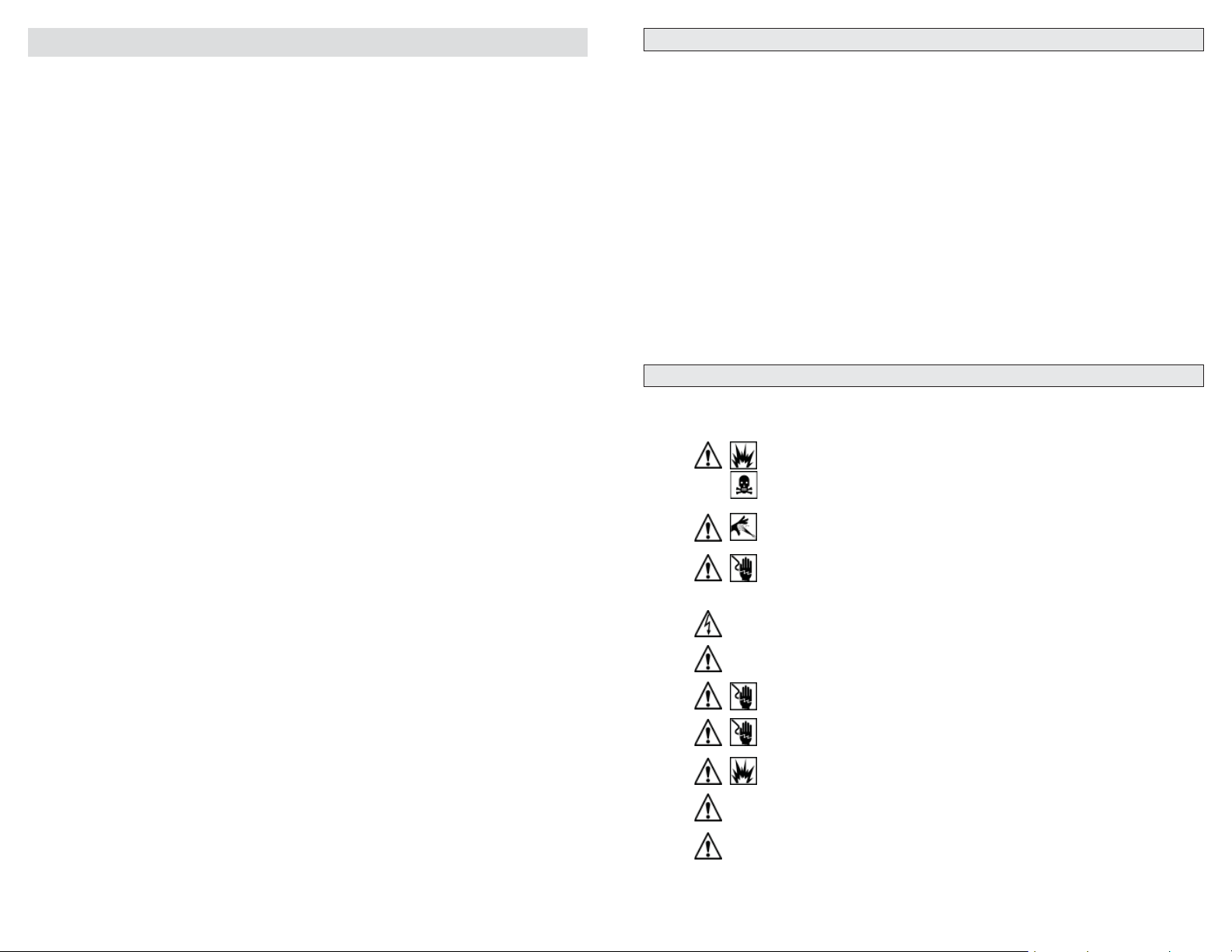

2. S

AFETY RULES

2.1 Safety “MUST NOTS”

2.1.1 DO NOT use the cleaner with fl ammable or toxic liquids,

or any products, which are not compatible with the correct

operation of the cleaner. EXPLOSION OR POISONNING

HAZARD.

2.1.2 DO NOT direct the water jet towards people or animals.

INJURY HAZARD.

2.1.3 DO NOT direct the water jet towards the unit itself,

electrical parts or towards other electrical equipment.

ELECTRICAL SHOCK HAZARD.

2.1.4 DO NOT use the cleaner outdoors if raining. SHORT CIRCUIT

HAZARD.

2.1.5 DO NOT allow children or incompetent persons to use the

cleaner. INJURY HAZARD.

2.1.6 DO NOT touch the plug and/or socket with wet hands.

ELECTRIC SHOCK HAZARD.

2.1.7 DO NOT use the cleaner if the electrical cable is damaged.

ELECTRIC SHOCK AND SHORT CIRCUIT HAZARD.

2.1.8 DO NOT use the cleaner if the high-pressure hose or spray

gun assembly is damaged. EXPLOSION HAZARD.

2.1.9 DO NOT jam or lock the spray gun trigger in the operating

position. ACCIDENT HAZARD.

2.1.10 Check that the data plates are affi xed to the cleaner, if not,

contact your dealer. Cleaners without plates must NOT be

used, as they are unidentifi able and potentially dangerous.

ACCIDENT HAZARD.

Page 4

2.1.11 DO NOT tamper with or alter the calibration of the safety

valve. EXPLOSION HAZARD.

2.1.12 DO NOT alter the original diameter of the spray head

nozzle. OVER PRESSURIZATION MAY OCCURE.

2.1.13 DO NOT leave the cleaner unattended. ACCIDENT HAZARD.

2.1.14 DO NOT move the cleaner by pulling on the electrical cable.

SHORT CIRCUIT HAZARD.

2.2 Safety “MUSTS”

2.2.1 All electrical circuits MUST BE PROTECTED against the water

jet. SHORT CIRCUIT HAZARD.

2.2.2 The cleaner MUST ONLY BE CONNECTED to a ground fault

system. ELECTRIC SHOCK HAZARD.

• Use of a safety residual current circuit-breaker (R.C.C.B.) will

provide additional protection for the operator. (30 mA)

2.2.3 The high pressure may cause materials to bounce off

surfaces at speeds; therefore protective clothing and safety

goggles MUST BE WORN. INJURY HAZARD.

2.2.4 Before working on the cleaner, REMOVE the electrical plug.

ACCIDENTAL START UP HAZARD.

2.2.5 Before pressing the trigger, GRIP the gun fi rmly to

counteract the recoil. INJURY HAZARD.

2.2.6 COMPLY WITH the requirements of the local water supply

company. According to DIN 1988, power-jet cleaners may

only be connected to the mains drinking water supply with

a backfl ow preventer valve with drain facility is installed in

the supply hose. CONTAMINATION HAZARD.

2.2.7 A qualifi ed technician MUST carry out maintenance and/or

repair of the electrical components. ACCIDENT HAZARD.

2.2.8 DISCHARGE residual pressure before disconnecting the

cleaner hose. Turn the water supply off and squeeze the

spray gun trigger. INJURY HAZARD.

2.2.9 Before each use. CHECK that all the screws are fully

tightened and that there are no broken or worn parts.

2.2.10 Only USE detergents, which will not corrode the coating

materials of the high- pressure hose/electrical cable and unit

components. EXPLOSION AND ELECTRIC SHOCK HAZARD.

2.2.11 ENSURE that all people or animals keep a minimum distance

of 16 yd. (15m) away. INJURY HAZARD.

Notes

Page 5

The pump does not operate at the prescribed pressure.

Sudden changes in pump pressure.

The motor buzzes but fails to start.

PROBLEMS

AND

R

EMEDIES

Nozzle worn. Replace nozzle.

Water fi lter clogged. Clean fi lter

Water supply pressure low. Turn on the water supply tap fully.

Air being sucked into the system.

Air in pump. Switch off the cleaner and operate the gun until

Adjustable nozzle Pull the spray adjuster back (+).

incorrectly positioned.

Water suction from external tank. Connect cleaner to the mains water supply.

Water temperature too high. Lower temperature.

Nozzle clogged. Disconnect power supply, discharge pressure and

clean with tool provided.

Worn seals. Have seals replaced by an authorized service center.

CAUSES

No electrical power. (§) Check that the plug is fi rmly in the socket and that

main power is present.

Supply voltage below required Check the voltage of the main supply line.

minimum.

Voltage loss due to use of extension

cord of inadequate cross-section or

excessive length.

High pressure cleaner in disuse for Contact nearest service center.

long time.

Problems with TSS device. Contact nearest service center.

High pressure system or pump Contact nearest service center.

hydraulic circuit not watertight.

------------------- Contact nearest service center.

(§) If the motor stops and fails to restart, wait 2 - 3 minutes before restarting. THERMAL CUTOUT TRIPPED. If this fault

occurs more than once, contact your service center.

More troubleshooting information on our website at www.arnorthamerica.com.

Motor does not start.

Water leakage.

Excess noise.

Oil leaks.

PROBLEM

TSS MODELS ONLY: Motor starts even though the trigger is released.

TSS MODELS ONLY: No water when lever is operated

Power cord damage.

(when supply hose is connected).

9

9

9

Check that hose fi ttings are tight.

99

9

a steady fl ow of water is obtained. The switch

cleaner back on.

9

9

9

9

9

9

9

9

9

9

Consult instructions regarding extension cords.

9

9

9

9

9

9

REMEDIES

Always use two hands when operating a pressure washer. This will assure

complete control of the equipment.

Always test the GFCI plug prior to using the cleaner.

Never test the pressure of the cleaner against any part of the body.

Use the trigger lock whenever the spray gun is not being used for cleaning.

Always seek emergency medical care immediately if any fl uid penetrates the

skin. A cut may be deeper and more serious than it appears.

3. G

ENERAL RULES

3.1.1 The USE and MAINTENANCE manual constitutes an essential

part of the cleaner equipment and should be kept in a

safe place for future reference. If you sell the cleaner, the

manual should be handed on to the new owner.

3.1.2 Before starting the cleaner, make sure that it is receiving

water correctly. Operating the cleaner without water could

damage the seals.

3.1.3 Do not disconnect the plug by pulling on the electrical cable.

3.1.4 If you are too far from the object you wish to clean, do not

move the cleaner nearer by pulling on the high pressure

hose; use the handle provided.

3.1.5 Protect the cleaner from freezing during the winter. Store in

a warm area.

3.1.6 Do not obstruct the ventilation grilles during operation.

3.1.7 The cross-section of any extension cord used must be

proportional to their length, i.e., the longer the extension

cord, the greater the cross-section; cables with a protection

level of “IPX5” must be used. See table A.

Table A

Voltage Volts Extension cable Extension cable

up to 25 m up to 50m

Motor

220 – 230240 Section3x1.5mm

100 – 115120 Section3x2.5mm

2

2

Section3x2.5mm

Section3x4mm

2

2

3.1.8 Position the cleaner AS NEAR AS POSSIBLE to the water

supply.

3.1.9 The packaging is easily recyclable, and must be disposed of

in compliance with the regulations in force in the country of

installation.

Page 6

3.1.10 Use the cleaner only with accessories and replacement

parts authorized by the manufacturer. The use of original

accessories and replacement parts will ensure safe, troublefree operation.

3.1.11 The cleaner must be used standing on a secure, stable

surface, positioned as shown.

3.2 Intended Use

3.2.1 The cleaner is intended only for the cleaning of vehicles,

machines, boats, buildings, etc., by the removal of stubborn

dirt using clean water and chemical detergents.

For domestic use only (single-phase motors only). Not for

professional use (for three-phase or industrial motors only),

and only for opration at temperatures above 32° F.

Compliant with EN 60335-2-79/A1 standard.

3.2.2 When using chemical detergents, only use biodegradable

types. We recommend HOBBY – FOAM detergent (#3206).

3.2.3 Only clean vehicle engines in areas in which suitable oil

traps are installed.

3.3 Safety Valve

AR767 - Motor

21

19

16

15

3

1

14

12

11

8

10

18

6

7

20

2

13

5

4

17

3.3.1 The safety valve also functions as a pressure-limiting valve.

When the gun trigger is released, the safety valve opens and

the water recirculates through the pump inlet. Never try to

adjust this valve.

4. I

NSTALLATION/ASSEMBLY

4.1 Fit the lance into the gun by rotating and pushing until the

two parts are completely locked.

4.2 Connect the gun to the high-pressure hose.

Pos. Code Description Qty.

1 1271950 Cable retainer 1

2 1260300 Fab 1

3 1260970 Seal ring 1

4 1260810 Screw TCTC M4x10 1

5 2360420 Capacitor 80uF 1

6 1265080 Gasket 1

7 1272030 Switch 1

8 1261560 Screw 3.9x16 4

10 1260341 Switch box 1

11 1260400 Gasket 1

12 1269100 Earth clamp 1

13 1466890 Cable 1

14 1269090 Cable retainer 1

15 1260950 Bearing 1

16 1260961 Motor shield 1

17 44075 Electric motor 1

18 1340280 Clamp 1

19 480621 Screw TE M5x25 4

20 1261570 Screw 3.9x9.5 4

21 1271660 Fan housing 1

Page 7

AR767 - Unloader

hose to the water (

OU

13

14

16

1

2

3

4

8

7

9

10

12

5

6

5

8

18

19

20

23

24

22

41

42

15

17

21

22

25

44

45

46

47

50

4.3 Connect the high-pressure hose to the water (OUTLET) on

the cleaner.

4.4 Connect the water supply hose.

(not supplied) to the water (INLET)

of the cleaner. The supply hose

must have an internal diameter of

26

27

39

28

35

34

36

38

51

37

The intake water temperature must NOT exceed 60° C

at least 13 mm (1/2 in.) and must

be reinforced. The water supply

must be at least equal to the cleaner

delivery capacity.

(122°F). The water supply pressure must NOT exceed 10

BAR (145 PSI).

4.4.1 CAUTION! The cleaner must only be used with clean water;

48

49

use of unfi ltered water or corrosive chemicals will damage

the cleaner.

4.5 Turn the motor switch to the “0” position.

Pos. Code Description Qty.

1 2500210 Knob extension 1

2 392840 Grub screw M6x16 1

3 1980300 Nut M6 1

4 2500400 Knob insert 1

5 1980220 Spring plate 2

6 1271070 Spring 1

7 1080041 Upper piston 1

8 1080070 Pin 2

9 1080401 Back-up ring 1

10 1080250 O-Ring Ø7.66x1.78 1

12 1980210 Piston guide 1

13 740290 O-Ring Ø14x1.78 1

14 800560 O-Ring Ø8.73x1.78 1

15 880830 O-Ring Ø15.54x2.62 1

16 1271170 Back-up ring 1

17 1080190 O-Ring Ø2.90x1.78 2

18 1271160 Lower piston 1

19 1980200 Valve seat 1

20 1470210 O-Ring Ø9x1 1

21 1540270 Screw 3/8” G - Brass 1

22 390080 O-Ring Ø11.91x2.62 2

23 1540510 Valve housing 1

24 1140450 O-Ring Ø20.24x2.62 1

25 1460430 O-Ring Ø4x2.5 1

26 1540170 Jet 1

27 1080091 Ball spring 1

28 394280 O-Ring Ø12.42x1.78 1

34 1560490 Hose tail 1

35 480480 O-Ring Ø4.48x1.78 1

36 1250280 Stainless steel ball 1

37 1560520 Spring 1

38 1540570 Fitting 3/8” G Ø2 1

39 1540300 Nut 1

41 1540280 By-pass housing 3/8” G 1

Pos. Code Description Qty.

42 1540630 O-Ring Ø23.47x2.62 1

44 880270 O-Ring Ø17.17x1.78 1

45 1540260 Screw

46 480440 O-Ring

47 1560600 Suction fi tting 1

48 1461470 Attachment for tap & gasket 3/4” G(F) 1

49 40126 Suction fi tting GHT 1

50 1340260 Water suction fi lter 1

51 1343160 Fitting 1/8” G 1

1/2” G 1

Ø17.13x2.62 1

Repair Kits

9(1)

22(2)

15(1)

10(1)

24(1)

16(1)

13(1)

17(2)

O-Rings

14(1)

20(1)

Kit 2812

25(1)

28(1)

35(1)

42(1)

44(1)

4.6 Check that the electrical supply voltage and frequency

(Volts/Hz) correspond those specifi ed on the cleaner data

plate. If the power supply is corect, you may now plug in

the cleaner.

The cleaner must only be connected to power sockets with

regulation earth connection. A differential safety breaker

(30mA) will increase the safety of operators.

CAUTION! The machine may cause electrical disturbances

when starting.

4.6.1 If the motor stops and fails to restart, wait 2 to 3 minutes

before restarting. THERMAL CUTOUT TRIPPED AND MUST

COOL BEFORE RESTARTING.

5. U

SE

5.1 Turn on the water supply tap FULLY.

5.2 Release the safety catch, then press

the trigger for a few seconds to

allow air to escape and to discharge

residual pressure in the pipes.

Page 8

5.3 Keeing the trigger pressed, push the switch

to start the motor.

Turn the pressure control knob to the desired

setting. (For models with this feature).

5.3.1 When re-starting the motor, always keep the spray gun

trigger compressed.

5.4 Using Detergent

5.4.2 CAUTION! liquid detergent must be sprayed at low

pressure. See 5.5 “Proper use of stnadard accessories”.

5.4.2 Fill the detergent tank to the level

indicated through the inlet.

5.4.3 Select LOW PRESSURE (see instructions);

the detergent will be sucked up and mixed

with the water, with the suction rate

regulated by the knob provided.

AR767 - Pump

22

12

5

3

89

88

21

22

91

21

23

90

11

10

9

8

7

44

46

47

48

45

25

24

26

27

21

22

32

31

33

28

93

43

49

29

35

50

51

64

36

41

42

5.4.4 Now distribute the detergent drawn in and

mixed with water.

5.5 Correct Use of standard accessories.

5.5.1 The cleaner is equipped with the adjustable nozzle, which

provides some important functions:

5.5.2 LOW PRESSURE operation (for suction and spraying of

detergent).

5.5.3. HIGH PRESSURE operation (for high pressure washing and

rinsing).

5.5.4 Jet adjustment from pencis to fan. (For models with this

feature).

5.6 Correct Use of the Rotary Nozzle (Where fi tted)

5.6.1 For increased washing power, use the rotary nozzle kit as

follows:

5.6.2 Turn off the high pressure cleaner.

Pos. Code Description Qty.

1 1260760 Screw TCEI M5x20 6

2 1269101 Rear cover 1

3 1260040 Gasket 1

5 1260780 Screw TCEI M5x25 4

7 1260190 Crankshaft 1

8 180400 Bearing 1

9 1260770 Circlip Øe25 1

10 1260790 Circlip Øi52 1

11 1260750 Seal ring 1

21 740290 O-Ring Ø14x1.78 3

22 1980740 Plug 3/8” G - Brass 3

23 1260460 Seal ring 3

24 1260420 O-Ring Ø26.70x1.78 3

25 1260440 C1 gasket 3

26 1260151 Piston guide Ø15 3

27 1271650 Gasket Ø15 3

28 1260141 Gasket support ring 3

29 1260121 Piston Ø15 3

31 820361 Plug 1/2” G - Brass 1

32 180101 O-Ring Ø17.5x2 1

33 1260021 Pump head 1

35 880830 O-Ring Ø15.54x2.62 6

36 1269050 Complete valve 6

41 960160 O-Ring Ø17.86x2.62 6

42 1260162 Valve plug 6

43 680570 Screw TCEI M6x60 6

44 1380520 Key 1

45 1260060 Aluminum con rod 3

46 1260080 Piston pin 3

47 1260070 Guiding piston 3

48 1260091 Spacer disc 3

49 480480 O-Ring Ø4.48x1.78 3

50 1260100 Piston washer 3

51 1260110 Stainless steel nut M8 3

Pos. Code Description Qty.

64 3226 Pressure gauge Ø40mm 1

88 1264010 Bearing 1

89 1264000 Internal ring 1

90 1260011 Pump housing 1

91 1269278 Pump head assembly 1

93 1381550 Washer Øi6.4 6

35(6)

23(3)

11

Repair Kits

36(6)

Valves

Kit 1864

3

Oil Seals

Kit 1865

21(3)

24(3)

32(1)

35(6)

41(6)

49(3)

50(3)

51(3)

28(3)

O-Rings

Kit 2040

49(3)

48(3)

29(3)

Pistons

Kit 2628

25(3)

24(3)

27(3)

Water Seals

Kit 1866

Page 9

AR767 - Body

g,

5.6.3 Unscrew the adjustable head and fi t the rotary nozzle onto

the lance.

5.6.4 Turn the high pressure cleaner back on.

5.7 Recommended Cleaning Procedure

7

See Pump

6

5

324

1

8

See Unloader

11 12

9 10

20

21

See Motor

Pos. Code Description Qty.

1 2500040 Blue casing 1

2 2500340 Closing plug 1

3 2500310 Knob 1

4 2500050 Hook 1

5 2500240 Cover 1

6 1680880 Washer 2

7 2500320 Driven gear Ø175 2

8 2500330 Detergent hose 1

9 2500100 Fixing plate 1

10 1260470 Screw TE M8x10 4

11 2100300 Screw 5x16 1

12 2600100 Gland 1

13 2100300 Screw 5x16 7

14 2500020 Handle 1

15 2500130 Rubber feet 2

16 880280 Screw TCEI M6x18 4

17 2180300 Washer Øi6.2 4

18 2500120 Wheels axle 1

19 2509001 Detergent tank assembly 1

20 2500010 Body 1

21 42113 Complete detergent plug 1

5.7.1 Dissolve dirt by applying detergent with the fan jet to the

14

dry surface.

On vertical surfaces, work from the bottom upwards. Leave

13

15

the detergent to act for 1 to 2 minutes, but do not allow to

dry out. Apply the high preesure jet, keeping the nozzle

at least 10 in. from the surface, working from the bottom

15

16

17

13

5.8 Storage

upwards. Avoid allowing the rinsing water to run on the

unwashed surfaces.

5.8.1 Switch off the cleaner.

13

7

18

5.8.2 Turn off the water supply tap.

5.8.3 After use, the detergent residues should be removed from

the tank.

5.8.4 Discharge residual pressure by pressing the trigger until no

19 6

5.8.5 Engage the gun safety catch.

more water comes out of the adjustable nozzle.

5.8.6 Remove the plug from the socket.

5.8.7 Operate the cleaner with non-corrosive/non-toxic antifreeze

before storing for the winter.

6 M

AINTENANCE

6.1 CAUTION! Before working on the cleaner, disconnect

the plug from the power supply

socket.

6.2 To ensure good performance,

check and clean the suction and

detergent fi lters after every 50

hours of operation.

6.3 Lont periods of disuse may lead to

the formation of lime scale deposits. Working through the

hole on the rear, or a 6 Allen key (6) for models with this

feature.

6.4 Clean the nozzle with the tool provided. Remove the lance

from the gun, remove any dirt from the nozzle hole and

rinse.

rinse.

Page 10

3

1

2

Loading...

Loading...