Page 1

INSTALLATION INSTRUCTIONS

BUILDERS’ CHOICE FRAMED

Shower Height Neo Angle Swing Door

Model: L061

Rev. 09.20.13

Page 2

MAINTENANCE: Two primary materials are used to manufacture your new Aquatic enclosure:

tempered glass and anodized aluminum. To assure a long lasting finish on the enclosure, wipe it down

with a towel after each use. Never use a scouring agent to clean the aluminum.

For occasional, more concentrated cleaning efforts, we find that Lysol Bathroom Cleaner

works extremely well. Be sure that any over spray falling on the aluminum frame is rinsed thoroughly and

dried. Many over-the-counter cleaners, if applied to t

and cause permanent damage, even though their directions indicate safe use on shower doors.

INSTALLATION NOTES: Unpack your unit carefully and inspect for freight damage. Lay out and

identify all parts using the instruction sheets as a reference. Before discarding the carton, check to see that

no small hardware parts have fallen to the bottom of the box. If any parts are damaged or missing, refer

to the descriptions noted in the instructions when contacting your deal

Handle the glass panels carefully and protect the edges. Safety tempered glass is very resistant to

breakage, but the sharp corners of the panels can damage tile and floor surfaces.

Please wear safety glasses whenever drilling or cutting. When drilling holes in the ceramic tile or marble,

use a center punch and hammer to carefully break the surface glaze so the drill can start without skidding.

To install your Aquatic shower door you will need the following: tape measure, level, #2 Phillips

screwdriver, 3/16” wrench, drill, 1/8” and 3/16” drill bits, hacksaw, pencil, and caulking (clear silicone

recommended). Optional tools include a miter box for cutting parts to length, files, center punch, and

masking tape.

he aluminum and left on, will harm the metal finish

er for replacements.

NOTE: Tempered glass cannot be cut.

Although safety tempered glass is very resistant to breakage, the glass can still

break if unequal pressure is placed on it during installation. Use caution. In addition, the sharp corners of the panels can damage tile and floor surfaces, so it is best

to handle the glass panels carefully and protect the edges.

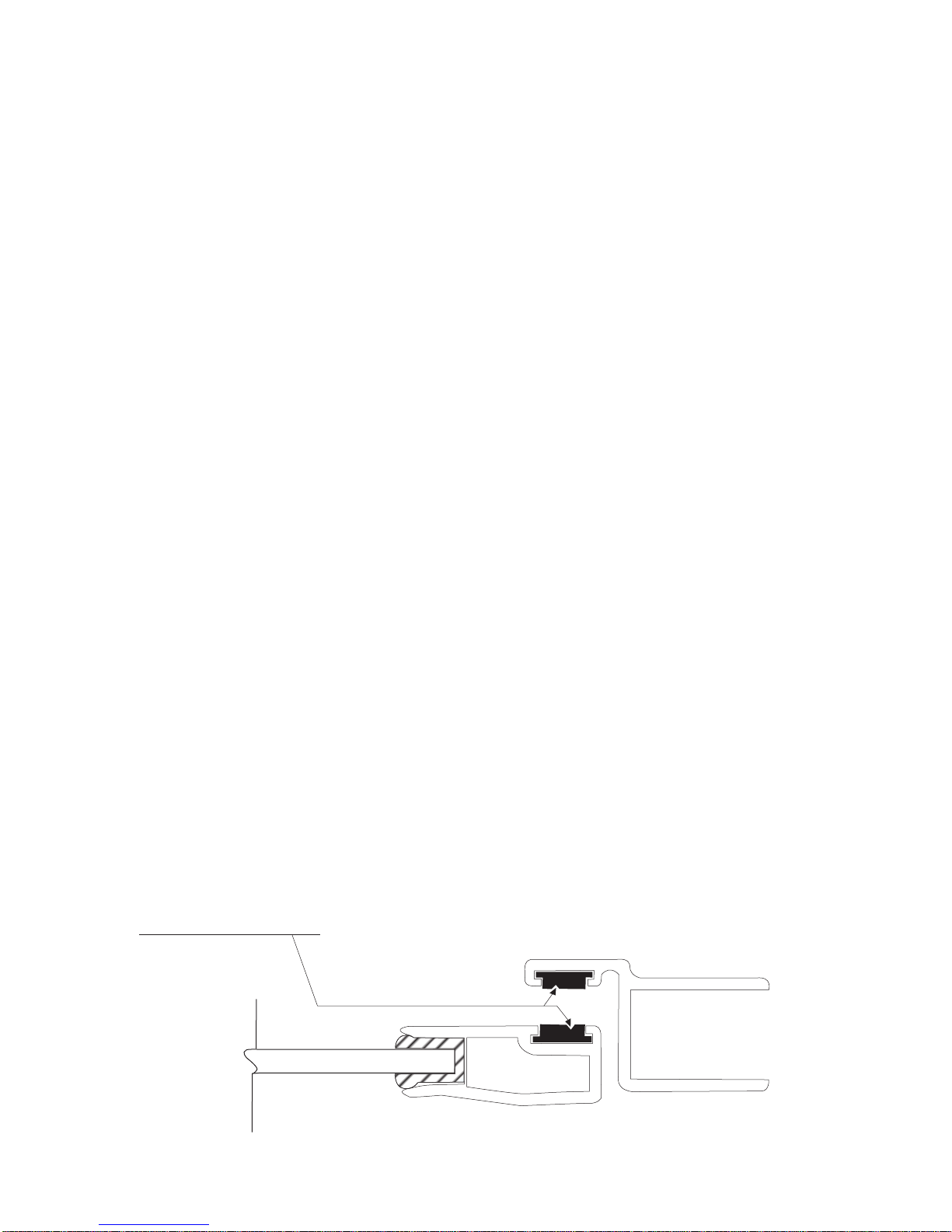

INDENTIFICATION GROOVE

NOTE : Each magnetic strip has an indentification groove on the exposed

surface. For proper alignment, the grooves should be opposite

each other (see detail).

Identification Groove

Page 2 of 9

Page 3

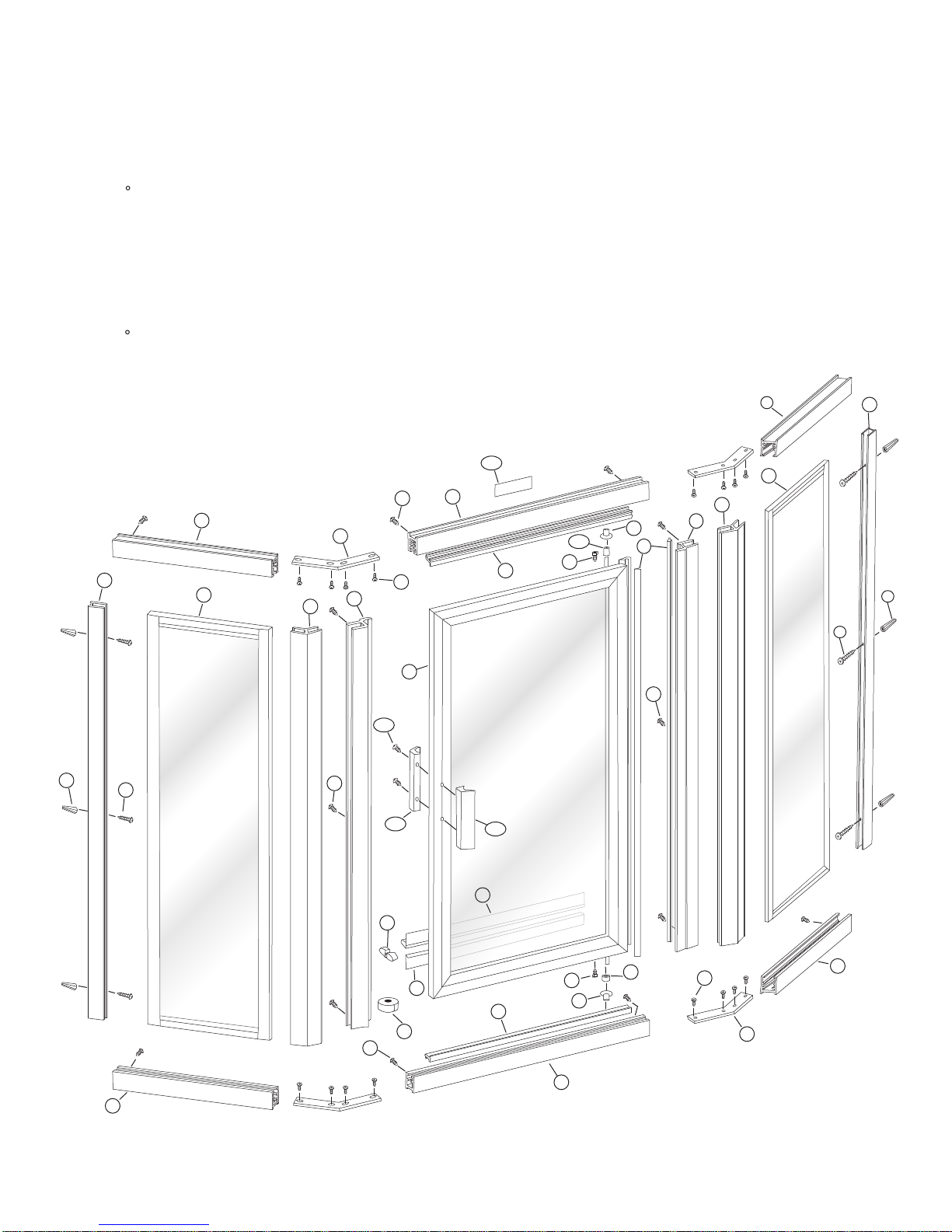

Parts List

Page 3 of 9

A. 3 Curb Sectons

B. 4 135 Anchor Plates

C. 30 #8 x 1/4” Truss Head Screws

D. 3 Header Sections

E. 2 Wall Jambs

F. 6 Plastic Wall Anchors

G. 6 #8 x 1 1/2” Truss Head Screws

H. 2 Pre-Glazed Side Panels

J. 2 135 Posts

D

E

H

K. 2 Clear Vinyl Jamb Seals

L. 1 Glazed Door Panel

M. 1 Pivot Jamb

N. 1 Strike Jamb (Magnetic)

P. 2 Snap-in Fillers

R. 1 Drip Rail

S. 2 Drip Plugs

T. 1 Tapered Drip Vinyl

V. 1 Roll Double Stick Taped

C

B

C

N

J

D

W. 2 #10 x 7/16” Sq. Head Set Screws

X. 1 Nylon Spacer

Y. 2 Nylon Pivot Bushings

AA. 1 Security Washer

BB. 1 Interior Door Handle

CC. 1 Exterior Door Handle

DD. 2 #6 x 1 1/4” Round Head Screws

EE. 1 Aquatic Decal

D

EE

AA

P

W

Y

K

M

H

J

E

F

G

L

C

DD

F

G

A

J

BB

S

T

V

C

CC

R

W

P

Y

A

X

C

B

A

Page 4

The Aquatic Shower

1

NOTE: If the curb and header sections come

2

The curb should sit near the centerline of the sill.

nd

3

Enclosure is completely reversible and may be installed

pivot-left or pivot-right. For maximum waterproofing, the

pivot jamb should be opposite the shower head. Using the

diagram, determine the correct position for the door in

your particular Quick-N-Stall installation. This

instruction sheet depicts a pivot-right installation.

CAUTION: For safety reasons, the door panel must

always open outward.

pre-assembled, skip to Step #3.

Assemble the three curb sections [A] (with weep slots) by

sliding a 135° anchor plate [B] into the mitered ends and

forcing the sections together. The weep slots in the curb

must be to the inside. Screw four #8 x 1/4” truss head

screws [C] through the slots in the anchor plates into the

curbs. As you tighten the screws, be sure the mitered

ends are forced tightly together. To increase the rigidity

mitered joint, drill 1/8” holes into the curb through

of the

the round holes in the anchor and install two more #8 x

1/4” screws.

Assemble the three header sections [D] in the same

manner and set the assembly aside.

PIVOT-RIGHT

(HINGE-RIGHT)

ANCHOR

MITERED

CURB END

PLATE

PIVOT-LEFT

(HINGE-LEFT)

#8 x 1/4”

SCREWS

MITERED

CURB END

If required, use a file to round the lower ends of the curb

assembly to fit the shower sill properly.

Using a 3/16” drill bit, drill the interior face of the curb

assembly on both ends as shown. These holes may be

predrilled from the factory.

Reposition the curb assembly on the shower sill and mark

its position with a pencil line along the interior a

exterior base.

CURB

ASSEMBLY

MEASURE

SHOWER

SILL

INTERIOR

3/8”

1/4”

3/16” DIA

Page 4 of 9

Page 5

Place the two wall jambs [E] into the ends of the

curb assembly [A]. Plumb the jambs and mark the hole

4

Wipe the shower walls and sill, curb assembly

5

NOTE: Panels with obscure or etched glass

b

6

Page 5 of 9

locations on the wall. Masking tape may be used to hold

the curb in place during this operation. Remove all parts

and drill the walls for mounting hardware.

For tile or marble walls, drill six 3/16” diameter holes

and insert the plastic wall anchors [F]. Attachments to

fiberglass or acrylic units can be made in two ways. If

reinforcement is built into the wall of the unit, drill six

1/8” diameter holes to install mounting screws directly

into the reinforcement. If walls are not reinforced, drill

3/16” holes and install plastic wall anchors or Molly bolts

(Molly bolts not supplied by Aquatic).

[A] and wall jambs [E] with a clean, dry cloth to remove

any dust or debris. Apply a 1/4” bead of caulk along the

inside of both of the pencil lines marked in Step #3.

Carefully replace the curb assembly in the exact position

marked. Caulk the inside of the curb ends where they

meet the wall. Caulk around the anchor plates [B], screws

[C], and the insides of the mitered joints.

Replace both wall jambs and attach to the walls with six

#8 x 1 1/

2” truss head screws [G].

#8 x 1/2”

SCREW

WALL

JAMB

WALL

JAMB

CURB

WEEP SLOT

CAULK

CURB

WEEP SLOT

TO INTERIOR

should be installed with the rough surface of the glass to

the exterior of the unit.

Snap one of the side panels [H] into the curb [A] next to

the wall jamb [E]. Slide the panel over into the wall

jamb. Press a 135° post [J] into the curb. Slide the side

panel across until it is centered between the wall jam

and post. Use masking tape to hold the post in position

temporarily.

Repeat for the other side panel and 135° post.

PANEL

SNAP-IN

GLASS

VINYL

PANEL RAIL

CURB

WALL

JAMB

PANEL

SIDE RAIL

PANEL

GLASS

135

POST

Page 6

Using a 3/16” drill bit, drill the interior face of the header

assembly on both ends as shown. These holes may be

predrilled from the factory.

Press the header assembly [D] over the wall

jambs [E], the 135° posts [J] and the pre-glazed panels.

Check the posts for plumb. Adjust as required by varying

the overlap of the header over the wall jambs. You may

need to trim the ends of the header where it meets the

wall. The minimum horizontal dimension for the door

opening is the door panel width (see the graphic in Step

#9) plus 1/2”, maximum is the door panel width plus

1 3/4”.

Using the holes in the ends of the header and curb as a

guide, drill four 1/8” holes into the wall jambs. Drill 1/8”

holes thru the header and curb into each 135° post as

shown, then enlarge the outer holes with a 3/16” drill for

clearance on the self-tapping screws. Secure the header

and curb to the wall jambs and posts with eight #8 x 1/4”

truss head screws [C].

8

Strip two clear vinyl jamb seals [K] into the door

panel [L] splash guard and the pivot jamb [M] and trim

flush at both ends. Both vinyls should be turned to trap

water from the shower head. Secure the vinyls with a

small quantity of glue or caulk at each end or by carefully

crimping the vinyl pocket. Set the door panel aside.

Press the pivot jamb and strike jamb [N] (with magnetic

strip) over the two 135° posts [J]. Refer to Step #1 for the

proper handling of the door.

NOTE: The magnetic strip on the strike jamb must face

the exterior and the clear vinyl jamb seal on the pivot

jamb must face inward.

9

MEASURE AT TOP OF

Page 6 of 9

JAMBS AND POSTS

HEADER

ASSEMBLY

HEADER

ASSEMBLY

INTERIOR

1/4”

3/16” DIA.

3/8”

135

POST

STRIKE

JAMB

GLAZED

DOOR

PANEL

OPENING

135

POST

CURB

ASSEMBLY

INTERIOR

MAGNETIC

VINYL

PIVOT

JAMB

DOOR PANEL WIDTH

1/4”

1/4”

JAMB

SEAL

SPLASH

GAURD

WALL

JAMB

PRE-GLAZED

PANEL

PIVOT

JAMB

JAMB

SEAL

Page 7

Aquatic

Page 7 of 9

Page 8

Insert the two nylon pivot bushings [Y] into

the pivot holes in the head and curb fillers [P].

Lift the door panel [L] and insert the top pivot pin into

the pivot bushing in the header filler. Hold the door

vertical and insert the bottom pivot pin into the pivot

bushing in the curb filler. It may be necessary to

remove the header retaining screws and raise the header

slightly to install the door.

When the door has been set into place, snap the security

washer [AA] over the top pivot pin to hold the upper

pivot bushing in place and prevent accidental

dislodging of the door.

13

The drip rail [R] is pre-cut from the factory.

Clean the bottom rail and the drip rail thoroughly with

rubbing alcohol to ensure proper adhesion. Unroll the

double stick tape [V] and carefully apply it to the back

of the drip rail (do not peel the tape backing yet).

Insert the tapered drip vinyl [T] into the drip rail.

Position the drip rail flush with the bottom and pivot

side of the door panel [L], then raise the strike side

until the bottom edge of the drip vinyl is parallel to the

curb [A]. Mark the location of each end of the drip rail.

14

Adjust the drip vinyl [T] by sliding it left or

right until it almost touches the curb. Trim the vinyl

(flush with the pivot end and notch 1/4” longer than the

drip rail as shown on the strike end).

The drip plug [S] is supplied with a left and right hand

plug together. Break the right and left drip plug apart

and insert the appropriate plug into the high (strike)

side of the drip rail. Discard the unused drip plug. Peel

off the tape backing and carefully press the drip rail [R]

to the door in the marked position.

NOTE: Cleaners with alcohol content can dissolve

the adhesive that attaches the drip rail. To prevent

this possibility, place a small bead of clear sealant at

the top of the drip rail where it is attached to the

bottom rail.

15

HEADER

Page 8 of 9

SAFETY

WASHER

PIVOT

SIDE

DOOR

PANEL

NYLON

SPACER

SNAP-IN

FILLER

DRIP

RAIL

DRIP

VINYL

PIVOT

BUSHING

CURB

TAPE

BOTTOM

RAIL

(ALIGN)

11/16”

STRIKE

SIDE

1/4”

TAPERED

DRIP VINYL

BREAK

APART

1/16”

DRIP RAIL

DRIP

PLUG

DRIP

VINYL

Page 9

Attach the interior door handle [BB] and the

exterior door handle [CC] to the door panel [L] with

16

Carefully caulk the interior jamb-to-wall and

17

Peel off the backing on the Aquatic decal

18

Note: Do not caulk over weep holes

Page 9 of 9

two #6-32 x 1 1/4” round head screws [DD].

Close the door and check the clearance with the strike

jamb [N]. If necessary, loosen the set screws [W] on

the top and bottom slide bars and adjust the door panel

to align the strike magnets. When the door panel is

properly aligned, tighten the set screws securely.

MAGNETIC

VINYL

STRIKE

JAMB

1/8”

(2) HANDLE

SCREWS

IDENTIFICATION

GROOVES

EXTERIOR

HANDLE

INTERIOR

HANDLE

INTERIOR

HANDLE

STRIKE

RAIL

DOOR

PANEL

EXTERIOR

HANDLE

curb-to-base joints. Caulk the small gaps at the corners

CAULK

of the side panels (see arrow on illustration) to prevent

water infiltration. For appearance, you may wish to

caulk the exterior joints as well.

We recommend you wait twenty-four hours before the

first shower to allow the caulking to cure properly.

INTERIOR FACE

OF HEADER

[EE] and apply to the inside surface of the header.

DECAL

Loading...

Loading...