AquaStar 38B LP, 38B NG User Manual

INSTALLATION AND OPERATING INSTRUCTIONS FOR AUTOMATIC

INSTANTANEOUS TYPE WATER HEATERS FOR USE WITH NATURAL AND

LIQUEFIED PETROLEUM GAS

MODEL 38B LP and NG (Non Modulating)

Suitable for water (potable) heating and space heating

Intended for low flow domestic hot water applications with steady cold water inlet temperatures

WARNING

If the information in this manual is not followed exactly ,

a fire or explosion may result causing property

damage, personal injury or death.

FOR YOUR SAFETY

Do not store or use gasoline or other flammable,

combustible or corrosive vapors and liquids in the

vicinity of this or any other appliance.

WHAT TO DO IF YOU SMELL GAS

- Do not try to light any appliance.

- Do not touch any electrical switch; do not use any

phone in your building.

- Immediately call your gas supplier from a neighbor’s

phone. Follow the gas supplier’s instructions.

- If you cannot reach your gas supplier, call the fire

department.

WARNING: Improper installation, adjustment,

alteration, service or maintenance can cause injury

or property damage. Refer to this manual. For

assistance or additional information consult a

qualified installer, service agency or the gas supplier .

Upon completion of the installation, these instructions

should be handed to the user of the appliance for

future reference.

6 720 605 293 PT 862 (12.98)

- Installation and service must be performed by a

qualified installer, service agency or the gas supplier .

T ABLE OF CONTENTS

Specifications .................................................... Page 2

Rules for safe operation .................................... Page 4

Locating the Heater ........................................... Page 4

Combustion Air Requirements........................... Page 4

Mounting the Heater ..........................................Page 5

Venting the Heater............................................. Page 5

Gas Connections ............................................... Page 6

Water Connections............................................ Page 6

Safety before lighting the pilot............................ Page 7

Lighting instructions........................................... Page 8

Setting water temperature ................................. Page 8

Maintenance & Service...................................... Page 9

Trouble Shooting ............................................. Page 10

Diagram of AquaStar ....................................... Page 13

Components and Parts List ............................. Page 14

This well engineered, gas water heater has all the features a water heater should have:

It operates on the principle of heating water instantaneously

“on demand”. When a hot water faucet is opened, cold

water flows through the coils of the heat exchanger in the

Aquastar. This same flow opens the gas valve, and the

burners are ignited by the pilot flame. The heat exchanger

coils absorb the heat generated by the burners and transfer heat to the water. When the hot water faucet is shut

off, the gas valve automatically closes and the burners

turn off. Your hot water faucet is an ignition key to turn on

the water heater, giving you control over your hot water

energy use. Each time you turn off your hot water faucet,

you also shut off the water heater .

AquaStar 38B LP and 38B NG Specifications

Gas Input max.: 40,000 Btu/hr

min.: 20,000 Btu/hr

Water Connection 1/2” Thread fitting

H x W x D 25 3/8” x 10 5/8” x 9 1/8"

Vent 4”

Gas Connection 1/2” NPT thread

Min. Water Pressure 13 Psi at 1.3 GPM

FEA TURES

- High Quality Materials for Long Working Life.

- Copper heating coils for endless supply of hot water.

- Safety thermocouple at pilot burner.

- Automatic overheating protection shut-off sensor .

- Stainless steel burners with stabilized blue flame.

- Built-in corrosion resistant draft inducer.

- Compact space saver: mounts on a wall with two hooks.

- Easily removable one-piece cover.

- Easy one person installation.

- Adjustable water flow restrictor to ensure that water flow

demand will not exceed the heating capacity of the

heater.

- Easy pilot flame lighting with push button piezo ignition.

Max. Water Pressure 150 Psi

Shipping Weight 20 LB

Net Weight 18 LB

0.5 GPM at 90° rise

1.3 GPM at 45° rise

Min. Water Flow 1/2 gal/min

LP GAS Pressure inlet. min. 1 1” W.C.

max. 14” W.C.*

LP GAS Manifold pressure 9.0” W.C.**

Natural Gas Pressure inlet min.: 7” W.C.

max.: 14” W.C.*

Natural Gas Manifold Pressure 5.2 W.C.**

* Inlet gas pressure must not exceed this value

** For purposes of input adjustment

UNP ACKING THE AQUASTAR HEATER

This heater is packed securely . The box includes two water connection fittings, a gas pressure regulator, two hooks for

hanging the heater, this manual, a personal letter, a warranty statement and a warranty registration card. Do not lose

this manual, as there is a charge for replacement. Please complete and return the enclosed warranty registration card.

2

If you are using the AquaStar for combined space heating and potable water heating

schematic diagram below)

, all piping and other components connected to the system must

(see

be suitable for potable water, (b) toxic chemicals such as those commonly used for boiler

treatment to prevent corrosion and freezing must not be introduced into the system, and

(c) if the space heating requires water temperatures higher than those required for domestic, potable water, a mixing valve or other similar device must be provided to reduce

scald hazard potential, (d) maximum system water temperature must not exceed 140°F

(60°C). DO NOT CONVERT AN EXISTING, CLOSED HOT WATER HEATING SYSTEM TO A

COMBINA TION SPACE AND POTABLE WATER HEATING SYSTEM USING THE AQUASTAR

OR ANY OTHER HEA T SOURCE.

Open loop potable water and combination space heating system*

* T o be used with a tank, check local codes. May not be permitted in some jurisdictions.

Notes

1. Maximum operating temperature of 38B: 140°F

2. Maximum heating capacity: 40°F rise 20°F rise

AquaStar 38B - 30,000 BTU/hr 15,000 BTU/hr

3. System shown is electric storage tank with recirculating supply drawn from the tapping for the lower heating element.

4. Schematic is for illustration and example only and must not be used for actual installation without appropriate

engineering and technical advice from a professional properly licensed in the locality where the installation is made.

3

GENERAL RULES TO FOLLOW

FOR SAFE OPERA TION

1. You should follow these instructions when you install

your heater. In the United States: The installation must

conform with local codes or, in the absence of local codes,

the National Fuel Gas Code ANSI Z223.1/NFP A 54.

In Canada: The Installation should conform with CGA

B149.(1,2) INSTALLATION CODES and /or local

installation codes.

2. Carefully plan where you install the heater. Correct

combustion air supply and flue pipe installation are very

important. If not installed correctly , fatal accidents can be

caused by lack of air, carbon monoxide poisoning or fire.

3. The place where you install the heater must have

enough ventilation. The National Fire Codes do not allow

water heater installation in bathrooms, bedrooms or any

occupied rooms normally kept closed. See the section

below on locating the heater.

The heater may still operate even when improperly vented.

It will, however, be less efficient and could eventually

damage the heater. It could even result in human sickness

or death due to oxygen deprivation and carbon monoxide

poisoning. Follow the guidelines below:

1. Place your heater as close to a vent or chimney as

possible.

2. National building codes require that you do not install

this appliance in bathrooms, bedrooms, unvented closet

or any occupied rooms normally kept closed.

3. Simultaneous operation of other appliances such as

exhaust fans, ventilation systems clothes dryers, fireplaces

or wood stoves could create a vacuum effect in your home

which could cause dangerous combustion by-products to

spill back into your home rather than venting to the outside

through the flue. Confirm that your Aquastar is venting

properly when all these other appliances are running. See

section on venting.

4. You must vent your heater. See section on Vent Pipe

Connections, Page 4.

5. The appliance must be disconnected from the gas

supply piping system during any pressure testing at

pressures in excess of 1/2 Psig (3.5 kPa).

The appliance must be isolated from the gas supply piping

system by closing its individual manual shutoff valve during

any pressure testing of the gas supply piping system at

test pressures equal to or less than 1/2 Psig (3.5Kpa).

The appliance and its gas connection must be leak tested

before placing the appliance in operation.

6. Keep water heater area clear and free from

combustibles and flammable liquids. Do not locate the

heater over any material which might burn.

7. Correct gas pressure is critical for the optimum

operation of this heater (see specifications on page 2).

Gas piping must be sized to provide the required pressure

at the maximum output of the heater, while all the other

gas appliances are in operation. Check with your local gas

supplier, and see the section on connecting the gas supply .

8. Should overheating occur or the gas supply fail to shut

off, turn off the gas supply at the manual gas shut off valve

on the gas line.

9. Do not use this appliance if any part has been

underwater. Immediately call a qualified service technician

to inspect the appliance and to replace any part of the

control system and any gas control which has been

underwater.

PROPER LOCA TION FOR INST ALLING YOUR

HEA TER

Carefully select the location of your new heater. For your

safety and for proper heater operation, you must provide

an abundant supply of combustion air and a proper venting

installation.

4

Do not obstruct the flow of combustion and ventilation

air to the appliance. If installed near a clothes dryer it is

very important that the dryer be properly vented. Failure

to properly vent a dryer could result in a gradual

accumulation of lint on the water heater fin coils and

burners, leading to a dangerous condition of venting

blockage and poor unsafe combustion.

4. Y our hot water lines should be kept short to save energy .

It is always best to have hot water lines insulated. Having

a floor drain or sink nearby is handy in case you need to

drain water from your heater.

WARNING: The water in this water heater is cold and

always remains cold exept for the times that hot water is

being used DO NOT INST ALL IN AN AREA WHERE IT

COULD FREEZE.

This heater is neither designed for nor approved for

outside installation.

WARNING: Flammable materials, gasoline,

pressurized containers, or any other items or articles

that are potentially fire hazards must NOT be placed

on or adjacent to the heater. The appliance area must

be kept free of all combustible materials, gasoline and

other flammable vapors and liquids.

COMBUSTION AIR REQUIREMENT

Observe the following instructions concerning combustion

air.

Appliances located in unconfined spaces:

a) An unconfined space is one whose volume is greater

than 50 cubic feet per 1000 Btu per hour of the combined

rating of all appliances installed in the space. That would

be 2000 cubic feet for the AquaStar 38B alone.

b) In unconfined spaces in buildings of conventional frame,

masonry, or metal construction, infiltration is normally

adequate to provide air for combustion, ventilation, and

dilution of flue gasses.

Appliances located in confined spaces:) The confined

space must be provided with two permanent openings,

one commencing within 12 inches of the top and one

commencing within 12 inches of the bottom of the

enclosure. Each opening must have a minimum free area

of one square inch per:

- 1000 Btu/hr if all air is taken from inside the building.

- 2000 Btu/hr if all air is taken from the outside by horizontal

ducts.

- 4000 Btu/hr if all air is taken from the outside by direct

openings or vertical ducts.

Louvers, grills and screens have a blocking effect. If the

effective free area is not known, increase the sizes of your

openings by 75% if your louvers are wood and by 30% if

your louvers are metal. Refer to the National Fuel Gas

Code for complete information. In buildings of tight

construction all air should be taken from outside. That

would be 2000 cubic feet for the Aquastar 38B alone.

CLEARANCES

The Aquastar 38 B is design certified for installation on a

combustible wall and for installation in an alcove or closet

with the minimum clearances to combustible and non combustible construction listed below

A. Top 12 inches ( 305 mm)

B. Front 4 inches (102mm)

C. Back 0 inches

D. Sides 4 inch (102mm)

E. Bottom 12 inches (306 mm)

Clearance from vent is dependent upon the clearance

rating of the venting material used. For example: type B-1

vent is approved for 1 inch clearance, B-2 vent for 2 inch,

etc.

Note: Minimum clearance to combustible materials should

not be less than 6" for single wall flue pipe. Note that this

clearance can be reduced if combustible material are

protected as per table VI of the National fuel Gas Code or

if Type B gas vent is used.

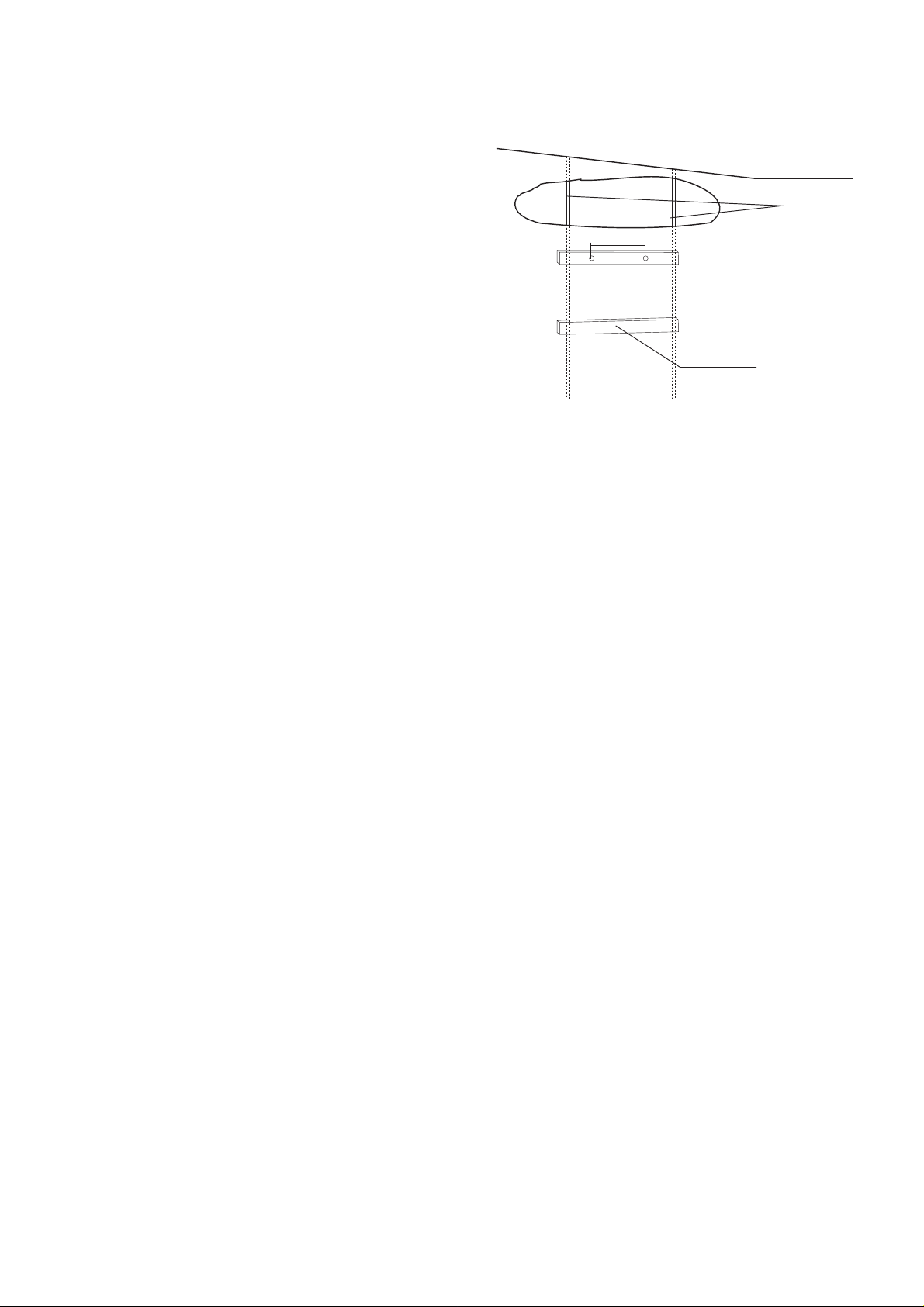

MOUNTING INST ALLA TION

The Aquastar 38 B is design certified for mounting on a

wall.

Do not install this appliance on a carpeted wall or over

floor covering which is combustible, such as carpet. The

heater must be mounted on a wall using appropriate

anchoring materials. If wall is a stud wall sheathed with

plasterboard, it is recommended that support board(s),

either 1x4’s or 1/2" (minimum) plywood first be

attached across a pair of studs and then the heater

should be attached to the support boards. See Fig 1.

Expansion and contraction of piping due to changing water

temperature in the pipes imparts movement to the heater

which, if mounted directly to a brittle, friable board, such

as plasterboard, can cause failure of mounting.

Before installing the unit, be certain you have the correct

heater for your type of Gas – Propane or Natural Gas.

Identification labels are found on the shipping box, and on

the rating plate which is located on the right side panel of

the cover. Also, each burner orifice is stamped with a number (79 for LPG and 120 for Natural Gas).

WALL STUDS

5 ½”

SUPPORT BOARD

1” X 4”

SPACE BOARD

Fig. 1 - Mounting the Heater

VENTING

Vent pipe connection. WARNING: Do not reduce the

vent pipe size.

This appliance must be vented to the outside following all

local ordinances and specifications for installing a gas

appliance vent or chimney. The venting system must be

designed and constructed so as to develop a positive flow

adequate to remove flue gasses to the outdoors. Minimum

vent size must be 4". Minimum height must be 6 feet,

provided there are no elbows. Termination of vent

must be 2 feet above any obstruction within a 10 foot

radius. Consult your gas utility or National Fuel Gas

Code if vent will have elbows or share venting with

another appliance. The vent connector should have

as much vertical rise as possible (minimum 12”) before

any horizontal run. The appliance must be located as

close as practicable to a chimney or vent. The vent pipe

sections must be secured to each other with sheet metal

screws. Keep in mind the minimum clearance from the

top of your heater. Remember also that single wall vent

pipe connectors require a 6 inch clearance from

combustibles. National Fuel Gas Code specifies double

wall — Type “B” — vent pipe be used in cold climates and

for gas vents running through attics. We consider double

wall vent pipe preferable in all circumstances. Any vent

section greater than 45 degrees from vertical is considered

horizontal. Horizontal sections of vent connectors must

slope upwards at least 1/4 inch for every foot of its

horizontal length. Keep the horizontal section short and

avoid too many elbows.

5

Loading...

Loading...