Page 1

SHARK

TRANSMITTER USER’S MANUAL

TX

& SHARK

TXP

MULTI-PARAMETER

N116-35 Rev 3

AquaMetrix Inc.

1245 Maple Hill Ct., Unit 7

Newmarket, ON

Canada, L3Y 9E8

A57-24

Tel: (800) 742-1413

(905) 954-0841

Fax: (905) 954-0415

www.aquametrix.com

Page 2

MULTI-PARAMETER TRANSMITTER USER’S MANUAL

Table of Contents

Subject Page No.

Introduction 1

Section 1 - Specifications 2

Section 2 - Installation 3 - 5

Section 3 - Electrical Connections & Setup 6 - 11

Differential Probe connection & setup 7

Combination Probe connection & setup 8

Conductivity Cell (Contacting style) connection & setup 9

Paddle Wheel Flow Sensor connection & setup 10

4-20mA Isolated Output 11

Section 4 - Using the Transmitter in pH Mode 12

LCD Menu 13 - 28

Section 5 - Using the Transmitter in ORP Mode 29

LCD Menu 30 - 44

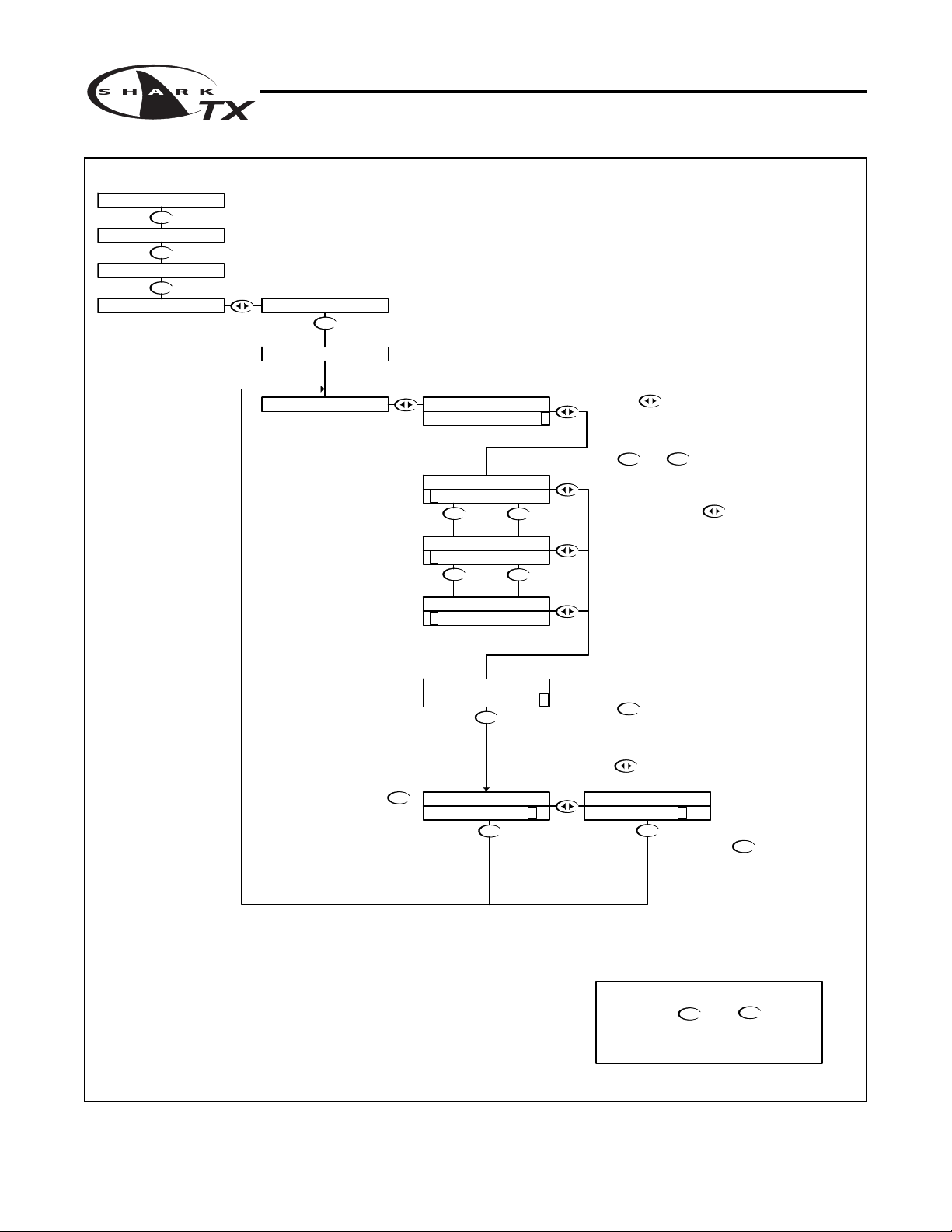

Section 6 - Using the Transmitter in Conductivity Mode 45

LCD Menu 46 - 62

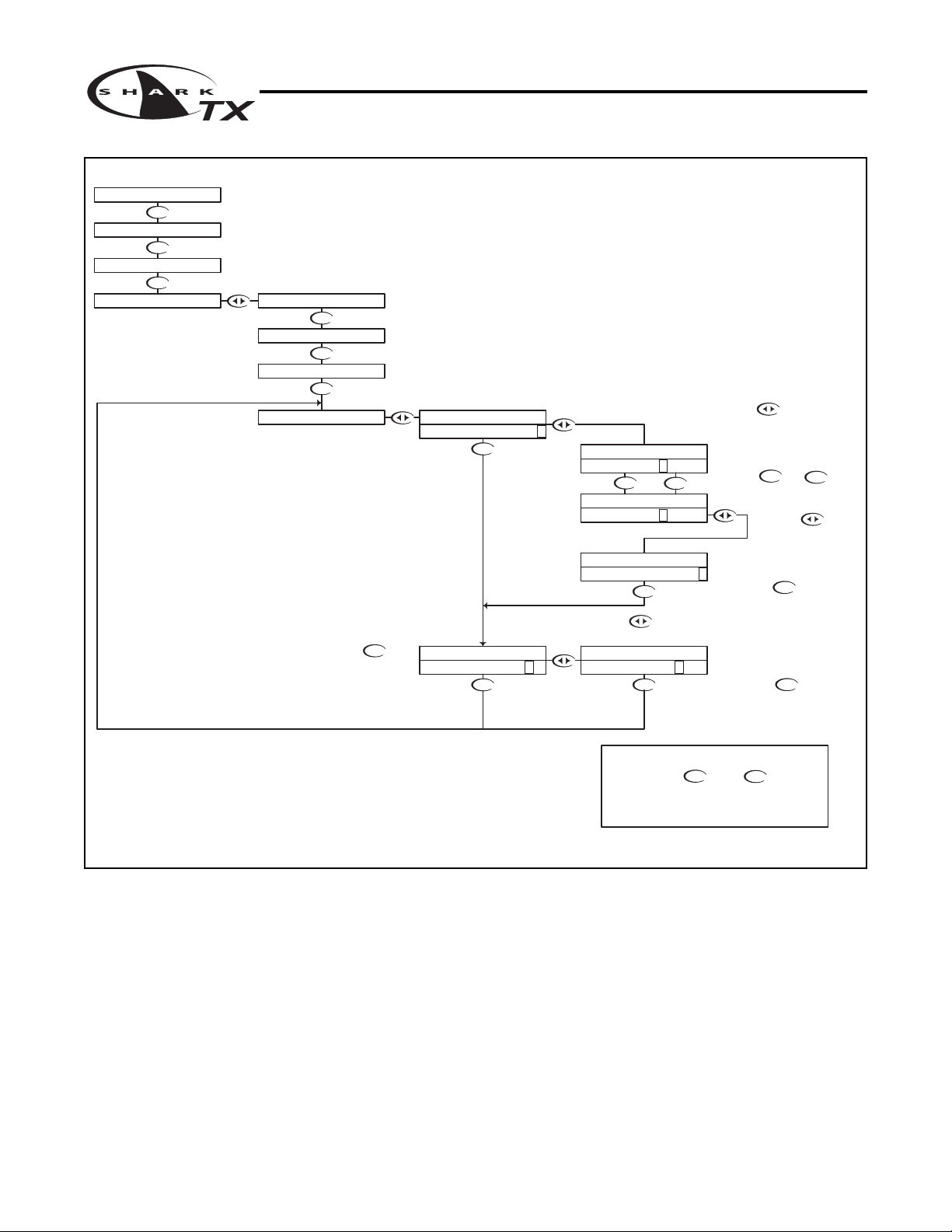

Section 7 - Using the Transmitter in Flow Mode 63

LCD Menu 64 - 78

Appendix A - Probe Configuration Table 79

Return Policy & Warranty Plan 80

Page 3

MULTI-PARAMETER TRANSMITTER USER’S MANUAL

Introduction

The SHARKTX & SHARKTXP multi-parameter transmitter is a microprocessor based

transmitter capable of measuring one of the following parameters, pH, ORP, conductivity or flow.

When shipped from the factory, the Shark is not set to measure any one parameter.

When the Shark is powered up for the first time, it will display the meter selection

screen where the meter type must be selected. (refer to section 4.5 Meter Selection)

This meter selection screen will only be displayed when the Shark is powered up for the

first time.

After the user selects a meter type the Shark will remain set to that meter type until it is

changed with the meter selection menu function in the Utilities menu.

To return the Shark to its factory settings, the user must re-select the current meter type

from the meter selection menu function. This will override all set-points and return all

settings back to the factory settings.

The Shark Users menu has been divided into five main categories

- Calibration, used to calibrate the Shark with the selected sensor

- Utilities, used to manually control or override the outputs.

- Setup, used to configure the Sharks many options

- Diagnostics, used to troubleshoot problems with the Shark or sensor

- Outputs, used to configure the Shark’s 4 to 20mA output.

SHARK

TX is packaged in a rugged NEMA 4X polycarbonate enclosure with a universal

mounting kit for surface, panel and pipe-mount applications. This enclosure is perfect for

stand-alone or panel-mount operation.

SHARK

TXP enclosure is also polycarbonate with a NEMA 4X front panel. Panel mount,

and DIN rail mounting hardware are supplied.

Introduction Page 1

Page 4

MULTI-PARAMETER TRANSMITTER USER’S MANUAL

Section I - Specifications

pH ORP Conductivity Flow

Display 2 x 16 alpha-numeric LCD display

Power Requirements 4 to 20mA, Loop Powered, 16 to 32 VDC

MΩ/cm30 to 19.99 0.01

0 to 2.000 0.01

0 to 20.00 0.1

3

0 to 200.0 0.1

0 to 5000 1.0

0 to 20.00 10

3

0 to 200.0 50

Measuring Range

pH: 0.01 to 14.00 ORP: -1999 to +1999mV

(Dependent on sensor)

uS/cm

Temp: 0 to 100°C or Temp: 0 to 100°C or

32° to +212°F 32° to +212°F (

mS/cm

Temp: 0 to 100°C or 32° to +212°F

Automatic or Manual

Temperature Automatic or Manual

Compensation 0 - 100°C (32° to +212°F)

Not r

equired

User selectable temperature

compensation slope 0.0 to 10.0%/°C.

0 to 100°C (32° to +212°F)

Temperature Unit °C or °F Not required

Temperature Sensor User selectable: 300Ω NTC Thermistor, 3000Ω NTC Thermistor or Pt. 1000 RTD Not required

Auto-Calibration

Calibration Modes Manual Calibration

Temperature Calibration Temperature Calibration

Manual Calibration

T

emperature Calibration

Dry Calibration

Sample Calibration K factor Input

Ambient Conditions Temperature:-20°C to +60°C or -4°F to +140°F Humidity: 0 to 90% RH (non-condensing)

Sensor to Transmitter Differential Sensor: 3000 ft

Distance Combination Sensor: 10 ft

Analog Output

4 to 20mA

Isolated Output, Range expand 0 to 100% of full scale (min segment 10% of full scale), max. load 800Ω

300 ft

Memory Back-up All user settings are retained indefinitely in memory (EEPROM)

SHARK

TX Enclosure: NEMA 4X,1/4 DIN, polycarbonate enclosure with two 1/2” conduit holes

SHARK

Mechanical

TXP Enclosure: NEMA 4X front panel, 1/4 DIN, polycarbonate

SHARK

TX Mounting: Universal Mounting kit for surface,pipe and panel mount included

SHARKTXP Mounting: Panel and DIN rail mount included

Sensor Input

Probe: -600 to +600mV Probe:-1999 to +1999mV Cell: 0 to 9999Ω

Temp. Sensor:0 to 9999Ω Temp. Sensor: 0 to 9999Ω Temp. Sensor:0 to 9999Ω

Invalid Entries Invalid entries cannot be stored

Manual Test Mode Process value can be simulated with arrow keys to verify correct setup of output

Output Hold 4 to 20mA output is placed on hold when the transmitter is in Menu mode

Recall data from last

Calibration Data

Recall data from last calibration, calibration mode,

1st & 2nd accepted buffer value and probe mV output,

calibration temperature, calibration slope, and probe

efficiency

calibration, calibration buffer

accepted v

alue, and cell Recall store K factor.

resistance, calibration

temperature

Auto Return User selectable auto return if the transmitter is left in menu mode for more than 10 min.

Display Damping User can select rate at which the transmitter updates display.Enables display damping of unstable process

Net Weight SHARK

TX: 0.71 lbs (0.32 kg)

SHARKTXP: 0.25 lbs (0.12 kg)

Approvals ULC (pending)

Flow: 0 to 9999 with

flow rate units

Volume: 0 - 999 with Auto Range

Flow rate units: Gallons (GP), Cubic

Feet (CF), Liters (LP), Cubic Meters

CM), custom by entering factor

related to Gallons

Time units: Seconds (S), Minutes (M)

Hours (H)

Not required

2000 ft

P

addle: 0 to 2000Hz

selectable

Section I - Specifications Page 2

Page 5

MULTI-PARAMETER TRANSMITTER USER’S MANUAL

Section 2 - Installation

2.1 Unpacking

Save the shipping carton and packing material in case the instrument needs to be stored or

returned. Inspect the instrument and packing material for shipping damage and report any

problems immediately.

2.2 Location

Locate the tr

ansmitter close to the sensor. The list below gives typical maximum distances for

various sensors. Refer to the sensor specifications for exact information.

• Aquametrix Differential PH Probe 3000 ft (914 meters)

• Aquametrix Combination PH Probe 10 ft (3 meters)

• Aquametrix Conductivity Probe 300 ft (91 meters)

• Aquametrix Flow sensor 2000 ft (610 meters)

2.3 Mounting

Fig 2.1 SHARKTX Transmitter dimensions

Dwg# N106-128

Section 2 - Installation Page 3

Page 6

MULTI-PARAMETER TRANSMITTER USER’S MANUAL

EXTERNAL

PANEL GASKET

QTY.1

SCREW

4-40 X 3/4"

QTY.4

NUT

4-40

QTY.4

PANEL

(CUSTOMER SUPPLIED)

PANEL

(CUSTOMER SUPPLIED)

EXTERNAL PANEL

GASKET QTY.1

SCREW

1/4-20 X 2-1/2"

QTY.4

NUT

1/4-20

QTY.4

UNIVERSAL

MOUNTING

CLAMP QTY.2

SCREW

10-24 X 1/2"

QTY.4

UNIVERSAL MOUNTING

BRACKET

QTY.1

Section 2 - Installation

Fig 2.2 SHARKTXP Transmitter dimensions

Dwg# N106-129

Panel Mount – The transmitters can be panel mounted to a panel using the hardware kit

provided. The panel cutout dimensions are shown in fig. 2.1 and 2.2.

Figure 2.3 Panel Mount

Dwg# N105-101 & N105-104

Section 2 - Installation Page 4

Page 7

MULTI-PARAMETER TRANSMITTER USER’S MANUAL

MIN. PIPE DIA.

1" PIPE (NOMINAL)

MAX. PIPE DIA.

2" PIPE (NOMINAL)

NUT

10-24

QTY.4

SCREW

10-24 X 3-1/2"

QTY.4

UNIVERSAL MOUNTING

BRACKET

QTY.1

MIN. PIPE DIA.

1" PIPE (NOMINAL)

MAX. PIPE DIA.

2" PIPE (NOMINAL)

SCREW

10-24 X 3-1/2"

QTY.4

NUT

10-24

QTY.4

UNIVERSAL MOUNTING

BRACKET

QTY.1

UNIVERSAL MOUNTING

BRACKET

QTY.1

SCREW

10-24 X 1/2"

QTY.4

HOLES Ø1/4"

FOR MOUNTING SCREWS

QTY.4

(CUSTOMER SUPPLIED)

TS35 DIN RAIL MOUNT

(CUSTOMER SUPPLIED)

TS32 DIN RAIL MOUNT

(CUSTOMER SUPPLIED)

Section 2 - Installation

Surface Mount – The SHARKTX can be surface

mounted using the hardware kit provided with the unit.

Pipe Mount – The SHARK

TX can be mounted to a

horizontal or vertical pipe with:

• a minimum outside diameter of 1.30” (33mm) (for

example 1” CPVC pipe)

• and a maximum of 2.375” (60mm) (for example 2”

CPVC pipe)

DIN Rail Mount – The SHARK

TXP can be DIN rail

mounted or panel mounted. See figure 2.3 & figure 2.7.

Fig. 2.5 Vertical Pipe Mount

Figure 2.6 Horizontal Pipe Mount

Figure 2.4 Surface Mount

Dwg# N105-101

Dwg# N105-101

Dwg# N105-101

Figure 2.7 DIN Rail Mount

Dwg# N105-104

Section 2 - Installation Page 5

Page 8

3.1 Conduit Connections

MULTI-PARAMETER TRANSMITTER USER’S MANUAL

Section 3 - Electrical Connections and Setup

The SHARK

TX

has two 1/2” conduit holes at the bottom of the enclosure as shown on fig. 2.1. The

unit is shipped with these holes plugged with liquid tight conduit seals. These must be left in unused

holes to maintain the NEMA 4X integrity. Use approved conduit hubs to connect the conduit, connect

these to the conduit before connecting to the enclosure.

3.2 Power Connections

Figure 3.1 Connections

Dwg# N104-41

Section 3 - Electrical Connections and Setup Page 6

Page 9

MULTI-PARAMETER TRANSMITTER USER’S MANUAL

Section 3 - Electrical Connections and Setup

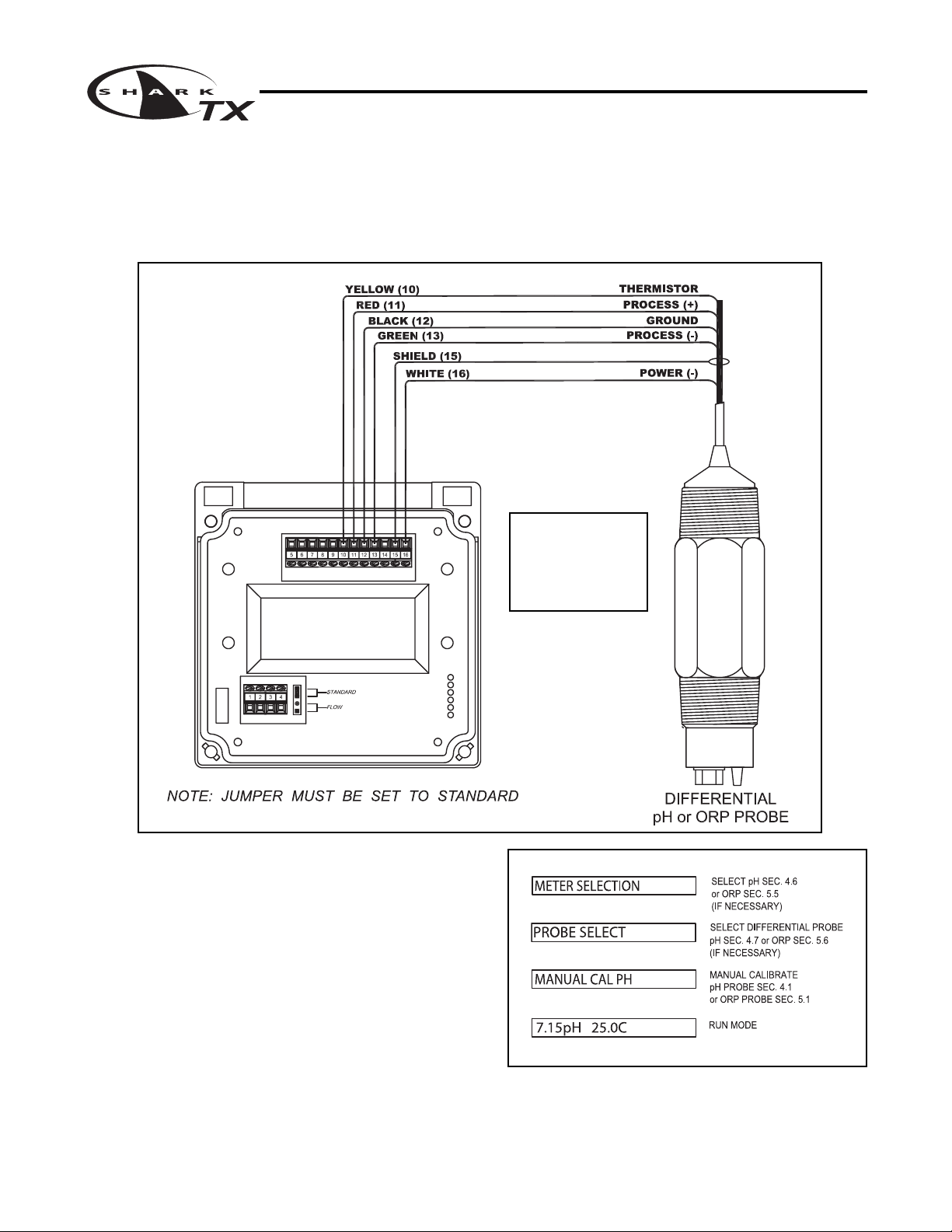

3.3 pH and ORP Differential Probe connections and setup

The drawing shows the connections for the Aquametrix Differential (5 wire) probe. The cable

should be run in a conduit separate from AC power wires, and via a separate conduit hole.

Figure 3.2 Connections for Differential (5 wire) pH or ORP probe

CAUTION:

Always disconnect

the loop power

before wiring or

unwiring a sensor

Dwg# N104-42

Once connected, step through the LCD menus to

select the probe in the order shown. The first two

steps may be skipped if the meter is already configured for pH or ORP and a Differential Probe.

When using a pH probe, it is important to ensure

that the transmitter is reading the probe temperature correctly for accurate temperature compensation. The ORP probe does not require temperature

compensation, although the transmitter can display process temperature measured by the probe.

The factory temperature calibration is usually

accurate enough that no adjustments are necessary.

Section 3 - Electrical Connections and Setup Page 7

Page 10

MULTI-PARAMETER TRANSMITTER USER’S MANUAL

Section 3 - Electrical Connections and Setup

3.4 pH or ORP Combination Probe connections and setup

The drawing shows the connections for the Aquametrix Combination probe. The cable should be run

in a conduit separate from AC power wires, and via a separate conduit hole. The cable length should

not exceed 10 feet (3 meters).

The 2 wire version has

no temperature sensor

and is connected via a

coaxial wire.

In a pH meter, the user

should set the T COMP

OVERRIDE menu to ON

(Section 4.10) and adjust

the temperature setting to

the actual probe temperature.

In an ORP meter, the

user should set the

T.DISP OVERRIDE to

ON (Section 5.9) to blank

the temperature reading

on the display.

The 4 wire version has

two additional wires for

the probe internal temperature sensor. Ensure

that the T COMP OVER-

RIDE or T.DISP OVERRIDE is OFF.

Fig. 3.3 Connections for the 2 and 4 wire Combination Probe

CAUTION:

Always disconnect

the loop power

before wiring or

unwiring a sensor

Dwg# N104-43

Once connected, step through the LCD menus to select the probe in the order shown. The first two steps

may be skipped if the meter is already configured for a Combination Probe. If a two wire pH probe is

used, which has no temperature sensor, ensure that the Temp. Comp. Override is set to same temperature as the buffer before calibrating. If a two wire ORP probe is used, you can blank the Temp display

with the T DISP OVERRIDE menu.

Section 3 - Electrical Connections and Setup Page 8

Page 11

MULTI-PARAMETER TRANSMITTER USER’S MANUAL

Section 3 - Electrical Connections and Setup

3.5 Conductivity Cell (Contacting style) connections and setup

The drawing shows the connections for the Aquametrix Conductivity Cells (Contacting style). The cable

should be run in a conduit seperate from the AC power wires, and via a seperate conduit hole. The cell

cable length should not exceed 300ft. (91 meters).

Figure 3.4 Connections for Conductivity Cells

CAUTION:

Always disconnect

the loop power

before wiring or

unwiring a sensor

Dwg# N104-44

Once connnected, step

through the LCD menus to

select the cell in the order

shown. The TEMP COMP

CURVE setup default is

1.8%/deg C. This is acceptable for most process applications. If your process is

significantly different from

this, change the setting in

the TEMP COMP CURVE

menu.

Section 3 - Electrical Connections and Setup Page 9

Page 12

MULTI-PARAMETER TRANSMITTER USER’S MANUAL

Section 3 - Electrical Connections and Setup

3.6 Paddle Wheel Flow Sensor connections and setup

The drawing shows the connnections for a typical paddle wheel flow sensor. The cable to the

sensor should not exceed 2000’ (600 meters).

Figure 3.5 Connections for Flow Sensor

Dwg# N104-45

CAUTION:

Always disconnect

the loop power

before wiring or

unwiring a sensor

Once connected, step through

the LCD menus to select the

sensor in the order shown. The

Sensor K factor (pulses per U.S.

Gallon) is usually printed on the

side of the sensor or on a label

attached to the sensor cable.

Section 3 - Electrical Connections and Setup Page 10

Page 13

MULTI-PARAMETER TRANSMITTER USER’S MANUAL

Section 3 - Electrical Connections and Setup

3.10 MANUAL TEST MODE

(LCD MENU SECTIONS - pH: 4.4, ORP: 5.3, Conductivity: 6.4, Flow: 7.2)

The setup can be tested using Manual Test Mode to simulate process changes.

MANUAL TEST MODE is used to simulate a process reading in order to verify the correct

response of the output.

3.11 4-20 mA Isolated Output

(LCD MENU SECTIONS - pH: 4.15, ORP: 5.14, Conductivity: 6.16, Flow: 7.14)

The Transmitter has a single 4 to 20mA output, electrically isolated from the ground. The output

can source current into a resistive load. Maximum resistance depends on supply voltage.

Drawing on page 6 (Fig. 3.1)

The output is dedicated to track the process and has fully independent and fully adjustable 4 &

20 mA output setpoints. This will enable the operator to span the output over the desired range.

The output can be precisely trimmed through the LCD menu for precision applications.

The drawing on page 6 (Fig. 3.1) shows the connections for the output.

Wire Specification

: 22 AWG 7/30, insulation 0.010”

Section 3 - Electrical Connections and Setup Page 11

Page 14

MULTI-PARAMETER TRANSMITTER USER’S MANUAL

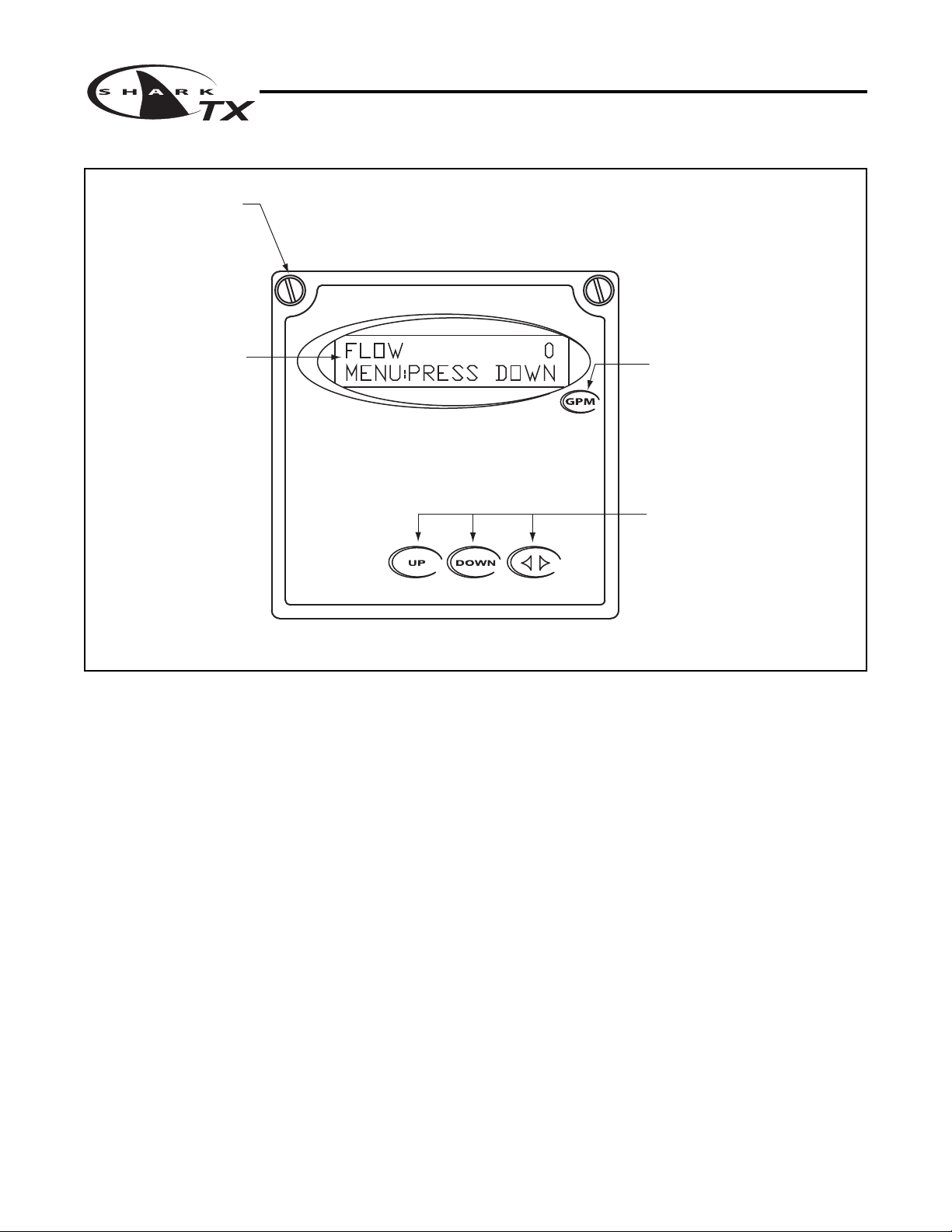

SIMPLE THREE-BUTTON INTERFACE

FOR FAST & EASY SETUP

(REFER TO SECTIONS 4.0 TO 4.15)

2 LINE, 16 CHARACTER

LCD DISPLAY

MAIN MENU INTERFACE

SCREEN

1/4" TURN SCREWS

(FOR SHARKTX ONLY)

UNIT LABEL

LABEL TO INDICATE UNIT OF

MEASURE SHARK IS

CONFIGURED FOR.

Section 4 - Using the Transmitter in pH Mode

Section 4 - Using the Transmitter in pH Mode Page 12

Page 15

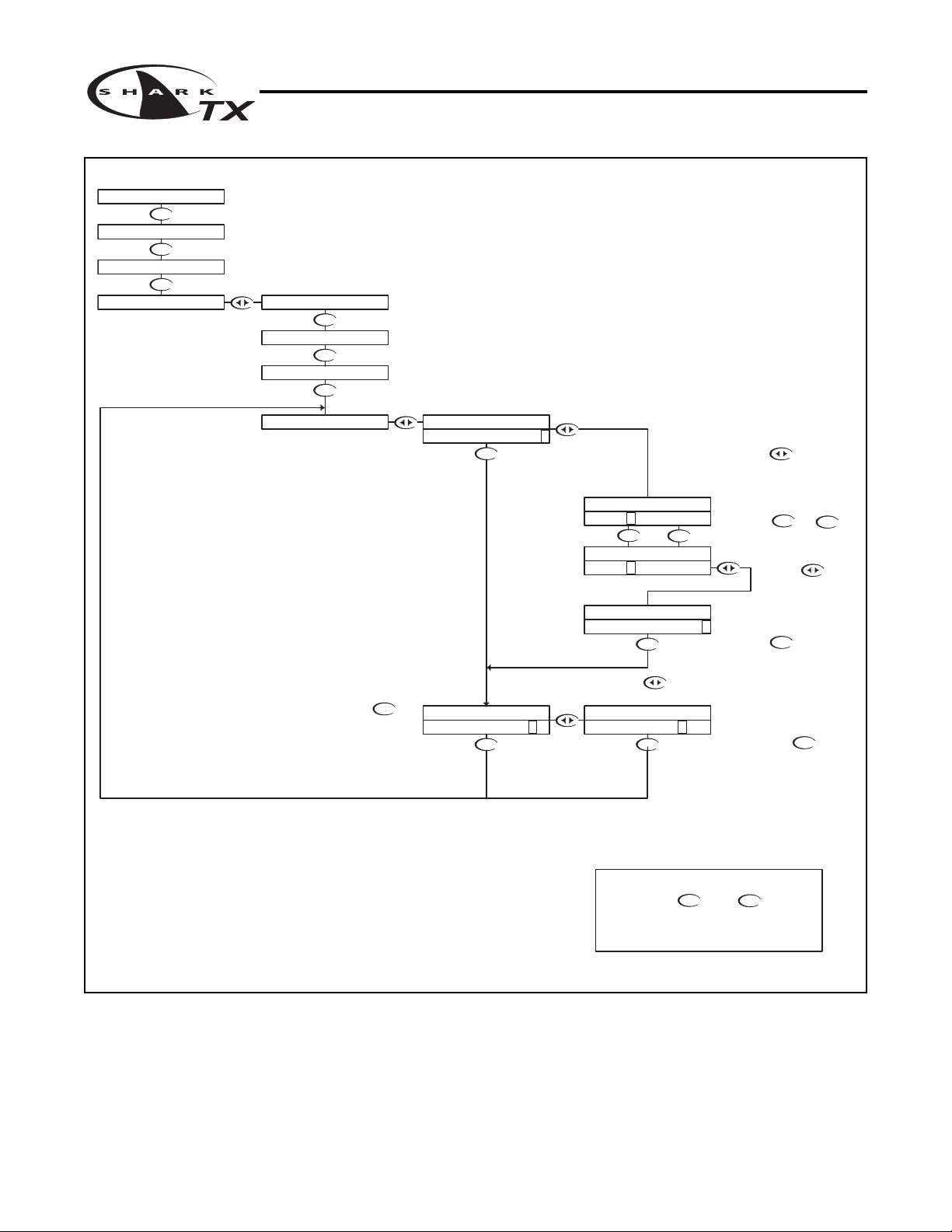

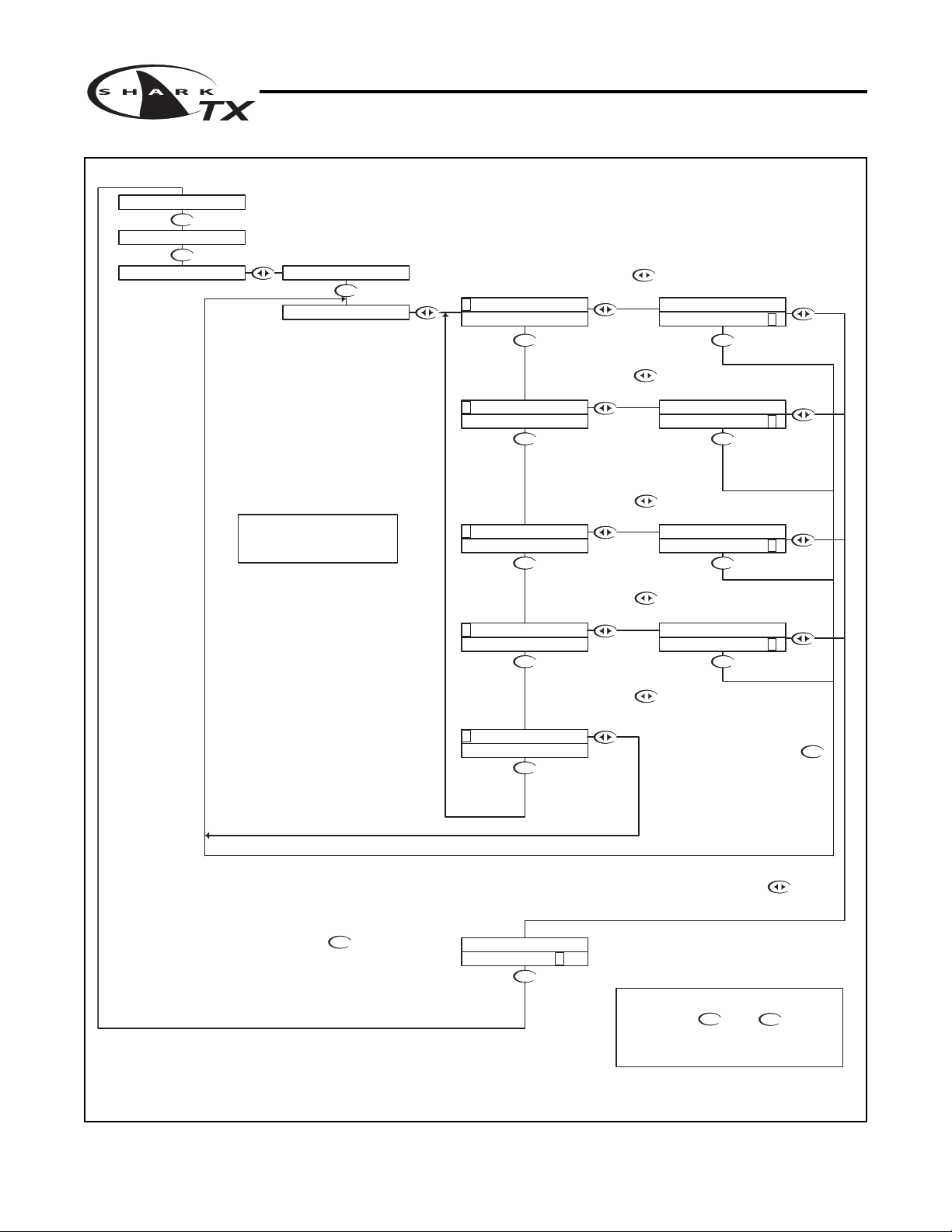

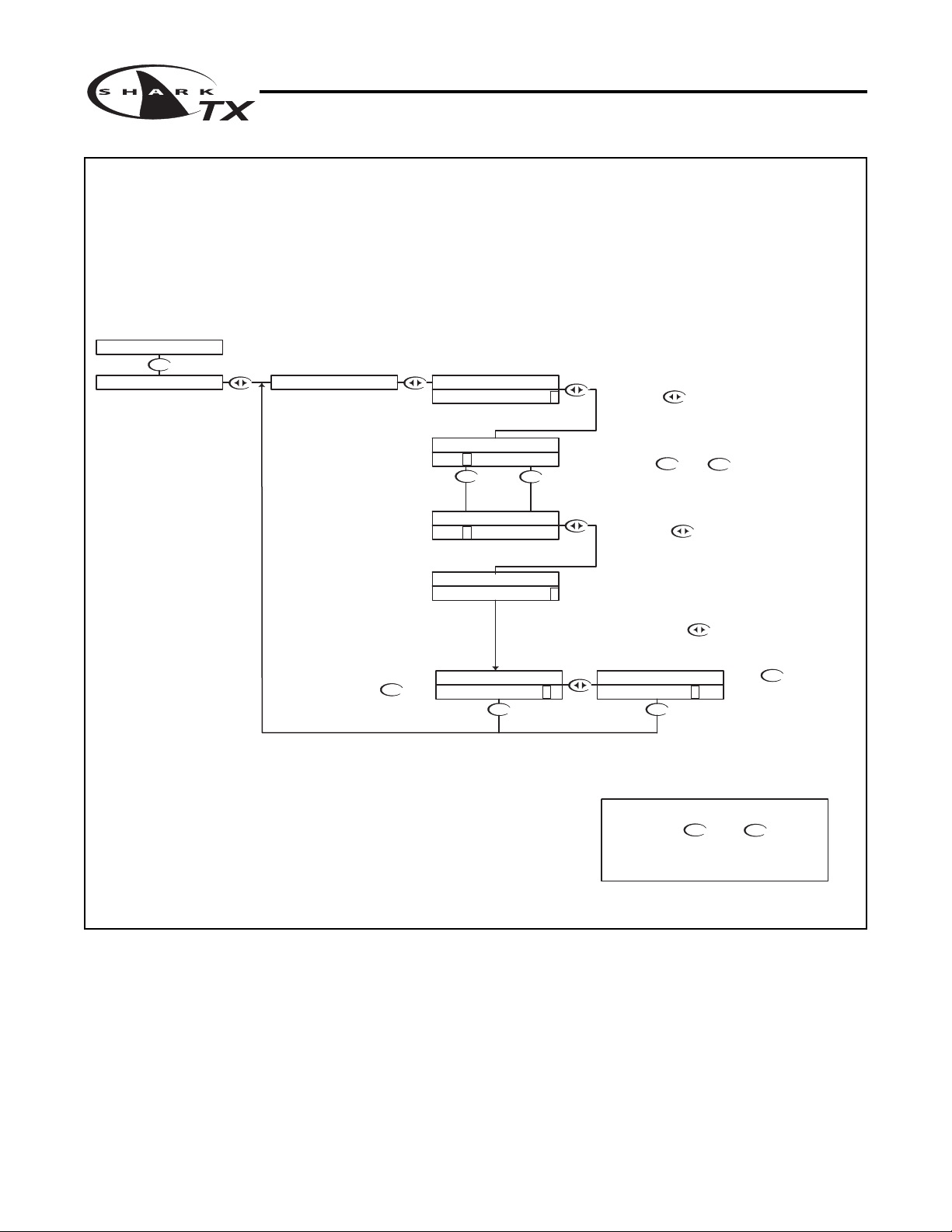

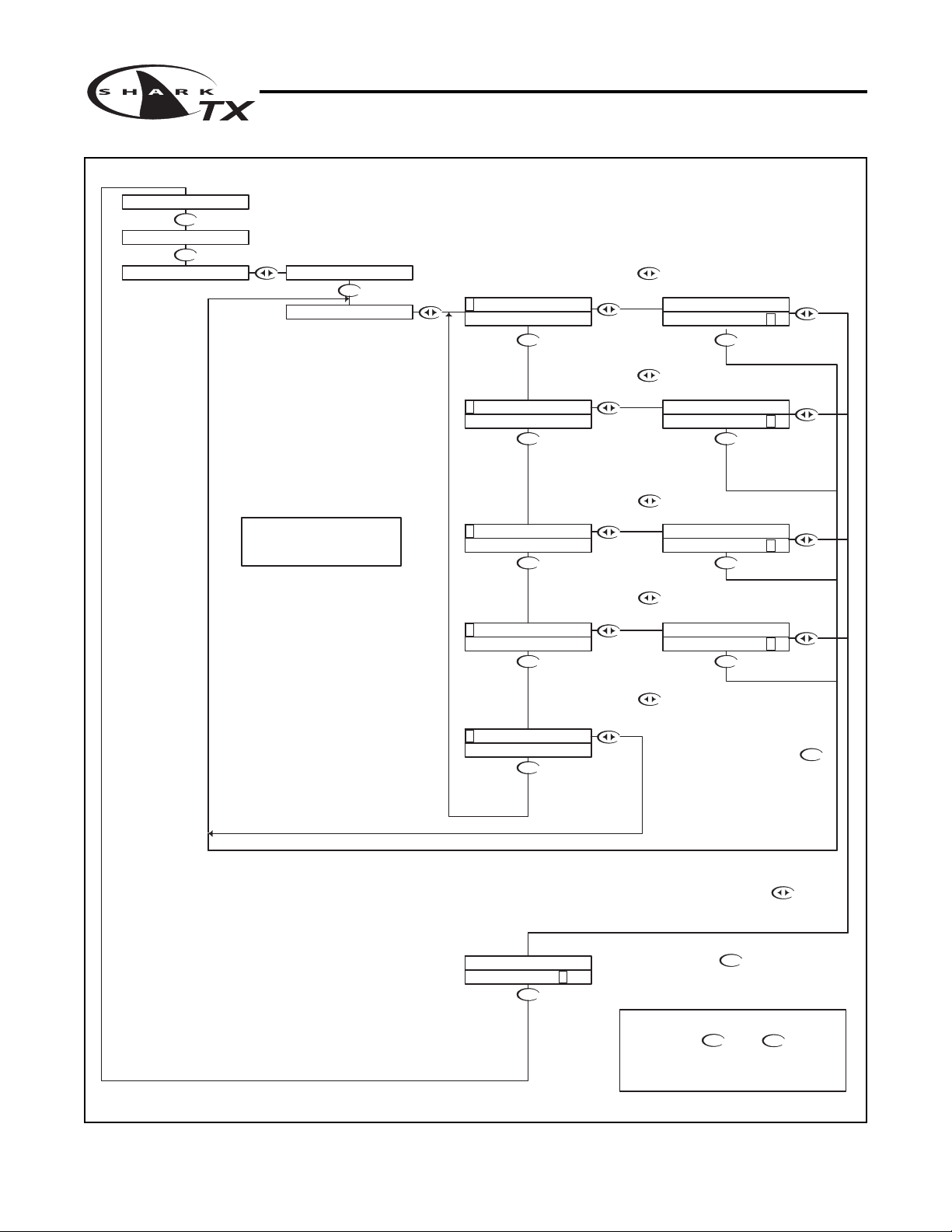

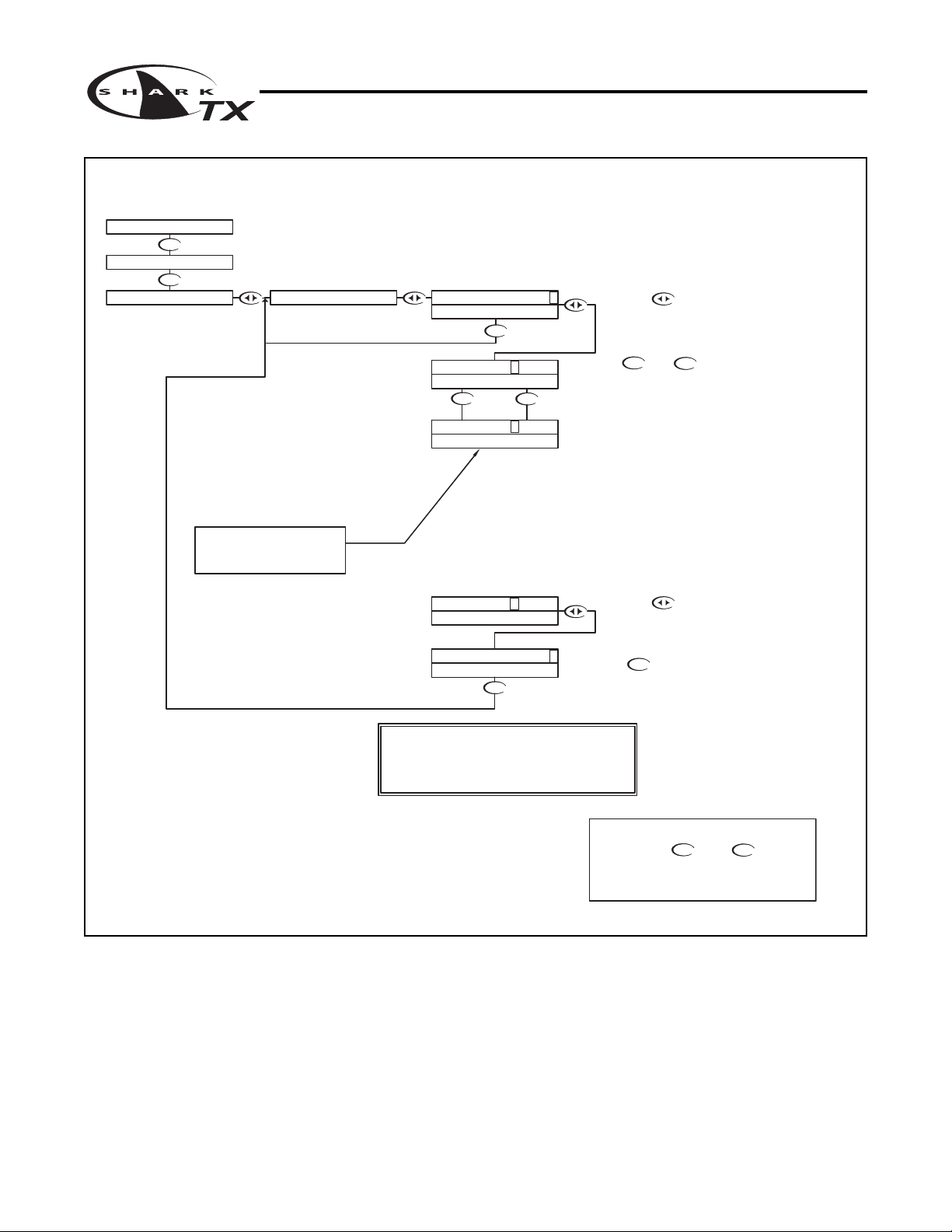

MULTI-PARAMETER TRANSMITTER USER’S MANUAL

DOWN

DOWN

DOWN

DOWN

DOWN

DOWN

DOWN

DOWN

DOWN

DOWN

DOWN

DOWNDOWN

DOWNDOWN

DOWN

DOWN

DOWNDOWN

DOWN

DOWN

DOWN

DOWN

DOWN

DOWN

DOWN

DOWNDOWN

SELECT DEG C OR DEG F

ENABLE TIME OUT

PROBE WITHOUT TEMP. SENSOR

TEMPERATURE SETUP FOR

SETUP DISPLAY AND

OUTPUT RESPONSE TIME

SELECT TYPE OF

FROM MENU

DISPLAY

FIRMWAVE REVISION

SEC. 4.12

DISPLAY PREVIOUS

CALIBRATION DATA

SEC 4.13

DISPLAY UNCALIBRATED

PROBE DATA

SEC 4.14

SEC. 4.9

SEC 4.10

SEC 4.11

SEC. 4.6

SEC 4.7

SELECT TYPE OF

TEMP SENSOR

SEC 4.8

pH PROBE

RUN MODE

SEC. 4.3

UP

NOTE

PRESS THE AND KEYS

TOGETHER TO GO IMMEDIATELY BACK TO

RUN MODE

DOWN

SELECT TYPE

OF METER

SEC. 4.5

VERIFY OUTPUTS

SIMULATE PROCESS

SEC. 4.4

AUTO CALIBRATE

MANUAL CALIBRATE

SENSOR IN pH PROBE

CALIBRATE TEMP.

pH PROBE

SEC. 4.1

pH PROBE

SEC. 4.2

DIAGNOSTICS

EXIT

SENSOR INPUT

CALIBRATION DATA

FIRMWARE REV

EXIT

DISPLAY DAMPING

T.COMP OVERRIDE

EXIT

AUTO RETURN

TEMP UNIT

TEMP SENSOR

PROBE SELECT

7.15pH 25.0C

UTILITIES

SETUP

CALIBRATION

MANUAL TEST MODE

METER SELECTION

EXIT

EXIT

TEMP CALIBRATION

MANUAL CAL pH

AUTO CAL pH

DOWN

DOWN

DOWN

4-20 mA OUTPUT

SETUP

SEC 4.15

EXIT

4-20mA

OUTPUT

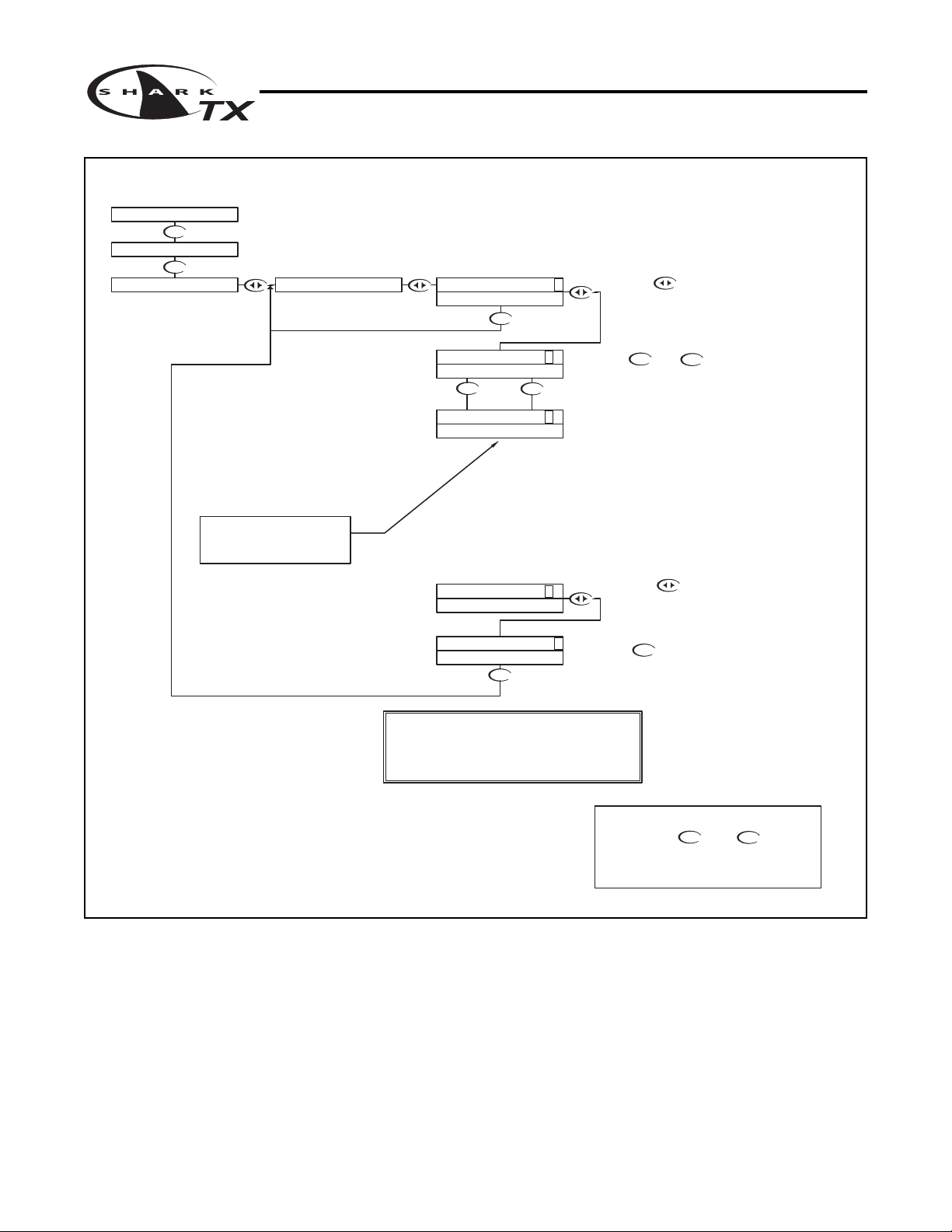

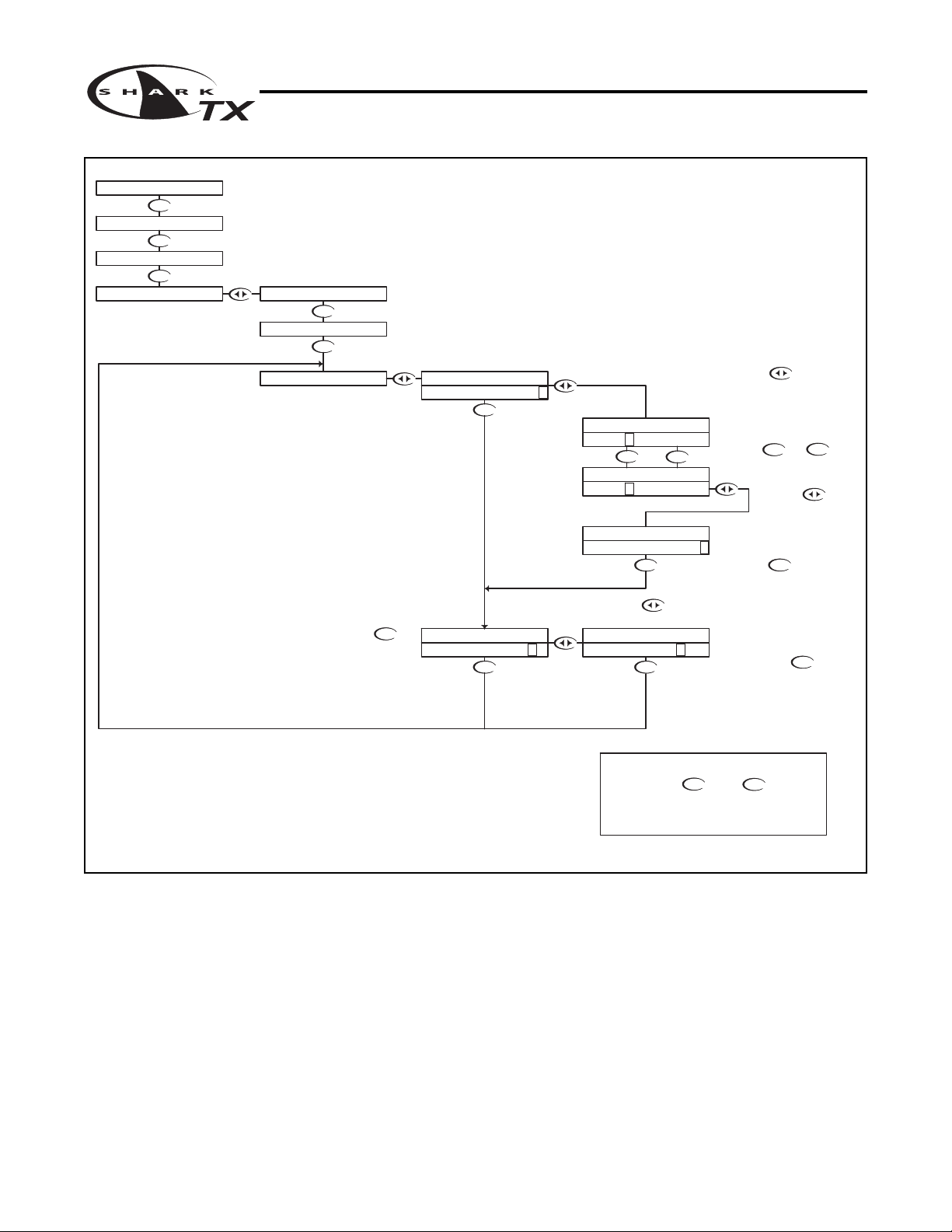

pH - Menu Overview 4.0

pH - Menu Overview 4.0 Page 13

Page 16

MULTI-PARAMETER TRANSMITTER USER’S MANUAL

DOWN

DOWN

DOWN

UP DOWN

DOWN

DOWN

UP DOWN

DOWN

DOWN

DOWN

DOWN

DOWN

DOWN

UP

DOWN

DOWN

UP

DOWN

DOWN

Please wait for the controller to complete

the measurement

After 5 seconds, the controller will

compute the slope of the calibration, the

estimated probe efficiency and the probe

temperature.

Then press to store the value and

complete the Manual Calibration

Then press to store the value and move

to BUFFER2

Use the and keys to adjust

the reading until it agrees with the actual

buffer pH value

When complete, the controller will report

the measured value

The controller will read the pH value,

averaging a number of results to get a

stable calibration value.

Place the probe in the second buffer.

Be sure to clean and rinse the Probe first with

D.I. water and then insert it in the 4.00 buffer.

Press

Use the and keys to adjust

the reading until it agrees with the actual

buffer pH value

When complete, the controller will report

the measured value

Please wait for the controller to complete

the measurement

The controller will read the pH value,

averaging a number of results to get a

stable calibration value.

Place the probe in the first buffer solution, be

sure to clean and rinse the Probe first with D.I.

water and then insert it in the 7.00 buffer.

Press

If the calibration is OK, use the key

to move the cursor over the Y text and

press the down key.

If the calibration did not appear to be

correct, press the key

which will return back to the Manual

Cal menu.

RUN MODE

UP

NOTE

PRESS THE AND KEYS

TOGETHER TO GO IMMEDIATELY BACK TO

RUN MODE

DOWN

Press to store the calibration

data and return back to the Manual

Cal menu so the user can select

another function.

Then press to move the

cursor to the RH position

Then press to move the

cursor to the RH position

STORE? Y N STORE? Y N

IF BUFFER1 READYCALIBRATION MANUAL CAL pH

MANUAL CAL pH

MANUAL CAL pH

BUFFER2 4.00 >

SLOPE 61.22MV/pH

EFF 95% 24.8C

BUFFER1 7.00 >

MANUAL CAL pH

BUFFER2 4.4 0 >

MANUAL CAL pH

BUFFER2 4.0 0 >

BUFFER2 WAIT...

RUNNING MANU CAL

IF BUFFER2 READY

PRESS 'DOWN'

MANUAL CAL pH

MANUAL CAL pH

BUFFER1 7.0 0 >

RUNNING MANU CAL

BUFFER1 WAIT...

PRESS 'DOWN'

BUFFER1 7.3 5 >

MANUAL CAL pH

7.15pH 25.0C

MANUAL CAL pH

This example shows a MANUAL

calibration with buffers of 7pH & 4pH.

When performing a manual

calibration, any two known buffer

solutions can be used.

pH - Calibration Menu - Manual Calibrate 4.1

pH - Calibration Menu - Manual Calibrate 4.1 Page 14

Page 17

MULTI-PARAMETER TRANSMITTER USER’S MANUAL

DOWN

DOWN DOWN

DOWN

DOWN

DOWN

DOWN

DOWN

DOWN

DOWN

DOWN

DOWN

If an erros occurs, the controller will indicate a

"BUFFER ERROR" alarm. This could be caused by

- using a defective buffer

- incorrect probe wiring

- defective probe

Press to return to the Auto cal menu, try to

correct the problem and calibrate again, or go to the

diagnotics menus to test the probe

see Section 4.16

If an erros occurs, the controller will indicate a

"BUFFER ERROR" alarm. This could be caused by

- using the same buffer twice

- using a defective buffer

- incorrect probe wiring

- defective probe

Press to return to the Auto cal menu, try to

correct the problem and calibrate again, or go to the

diagnotics menus to test the probe

If the calibration did not appear to

be correct, press the key

which will return back to the Auto cal

menu.

UP

NOTE

PRESS THE AND KEYS

TOGETHER TO GO IMMEDIATELY BACK TO

RUN MODE

DOWN

This will store the calibration

data and return back to the

Auto cal setup so the user

can select another function.

If the calibration is OK, use the key to

move the cursor over the Y text and press the

down key.

After 5 seconds, the controller will

compute the slope of the calibration, the

estimated probe efficiency and the probe

temperature.

When complete, the controller will report the

measured value

When complete, the controller will report

the measured value

Press the key to move to Buffer 2

Please wait for the controller to complete

the measurement

The controller will read the pH value,

averaging a number of results to get a

stable calibration value.

Place the probe in the second buffer

solution.Be sure to clean and rinse the

Probe first with D.I. water and then insert

it in the 4.00 buffer.

Press the key

Please wait for the controller to complete

the measurement

The controller will read the pH value,

averaging a number of results to get a

stable calibration value.

Place the probe in the first buffer solution,

be sure to clean and rinse the Probe first

with D.I. water and then insert it in the 7.00

buffer.

Press

RUN MODE

AUTO CAL pH

STORE? Y N

STORE? Y N

AUTO CAL pH

AUTO CAL pH

EFF 95% 24.8C

SLOPE 61.22MV/pH

BUFFER2 4.00 >

AUTO CAL pH

AUTO CAL pH

BUFFER ERROR

CONTINUE >

RUNNING AUTO CAL

BUFFER2 WAIT...

BUFFER1 7.00 >

PRESS 'DOWN'

IF BUFFER2 READY

BUFFER ERROR

CONTINUE >

PRESS 'DOWN'

IF BUFFER1 READY

RUNNING AUTO CAL

BUFFER1 WAIT...

CALIBRATION

7.15pH 25.0C

MANUAL CAL pH

This example shows an AUTO

calibration with buffers of 7pH & 4pH.

When performing an auto calibration,

any two standard buffers of 4.00, 7.00

or 10.00 pH can be used. The buffers

will be automatically recognized if the

probe measures them within +/- 1 pH

of their nominal value.

pH - Calibration Menu - Auto Calibrate 4.2

pH - Calibration Menu - Auto Calibrate 4.2 Page 15

Page 18

MULTI-PARAMETER TRANSMITTER USER’S MANUAL

DOWN

DOWN DOWN

DOWNUP

DOWN

DOWN

DOWN

UP

DOWN

DOWN

DOWN

DOWN

DOWN

If the Temperature Compensation Override is set to ON

(see section 4.11), the Shark cannot calibrate the

temperature sensor. This display will appear to alert the

user to the condition.

If the calibration does not appear to

be correct, press the key

which will return back to the Temp

Calibration menu.

UP

NOTE

PRESS THE AND KEYS

TOGETHER TO GO IMMEDIATELY BACK TO

RUN MODE

DOWN

This will store the calibration data

and return back to the Temp

Calibration setup so the user can

select another function.

Use the and to adjust

the reading until it agrees with the

known temperature of the probe

Press the key to accept the

reading and move to the store function

"T FACTOR SHIFTED" will be

displayed for 5 seconds to indicate that

the temperature sensor has been

calibrated.

The Shark will then move to the store

function.

The controller displays the current probe

temperature.

If this incorrect, the controller can be

adjusted to compensate.

Press the key once

which will move the cursor

back to the RH side of

temperature display.

Press the key once which will move

the cursor over the least sign. digit of the

temperature display.

RUN MODE

AUTO CAL pH

STORE? Y N

TEMP CALIBRATION

STORE? Y N

TEMP CALIBRATION

TEMP CALIBRATION

25.0C >

T FACTOR SHIFTED

25. 0 C >

TEMP CALIBRATION

TEMP CALIBRATION

TEMP CALIBRATION

TEMP CALIBRATION

22. 4 C >

22.4C >

TEMP CALIBRATION

TEMP O/R ON >

7.15pH 25.0C

CALIBRATION MANUAL CAL pH

pH - Calibration Menu - Temperature Calibration 4.3

pH - Calibration Menu - Temperature Calibration 4.3 Page 16

Page 19

DOWN

DOWN

DOWN

UP DOWN

DOWN

UP

DOWN

Manual Test Mode is used to simulate a process reading

in order to verify the correct response of the output.

When in the Manual Test Mode, the output IS no longer

placed on hold as it is when in the rest of the menu.

NOTE:

When the user exits the Manual Test Mode, the 4-20mA

output will remain in the Test Mode state until the operator

enters the run mode. The output will then revert back to

the previous On-line state.

The 4-20 mA output will track

the change in process value

RUN MODE

UP

NOTE

PRESS THE AND KEYS

TOGETHER TO GO IMMEDIATELY BACK TO

RUN MODE

DOWN

Press the key once to

move the cursor to the RH side

of the display

The 4 to 20 mA output will follow the process

value change.

Press the key to return to the

MANUAL TEST MODE menu

Use the and keys to change

the simulated process value.

Press the key once which will

move the cursor over the least digit of the

simulated process value.

TEST 7.0 0 >

TEST 7.00 >

7.15pH 25.0C

CALIBRATION

UTILITIES

19.0mA

19.0mA

TEST 13.1 5 >

TEST 13.15 >

MANUAL TEST MODE

12.0mA

12.0mA

19.0mA

TEST 13.1 5 >

DOWN

MULTI-PARAMETER TRANSMITTER USER’S MANUAL

pH - Utilities Menu - Manual Test Mode 4.4

pH - Utilities Menu - Manual Test Mode 4.4 Page 17

Page 20

MULTI-PARAMETER TRANSMITTER USER’S MANUAL

DOWNDOWN

DOWN

DOWN

DOWN

DOWN

DOWN

DOWN

DOWN

DOWN

DOWN

DOWN

DOWN DOWN

DOWN

If you do not wish to initialize to this

type of meter after all, then press

key to return back to the Meter

Selection menu

Then press

The controller will initialize itself for a

specific meter

If you do wish to initialize to this

type of meter, press the

key to highlight the Y character

UP

NOTE

PRESS THE AND KEYS

TOGETHER TO GO IMMEDIATELY BACK TO

RUN MODE

DOWN

Press the key to Exit and

return to the Utilities menu

RUN MODE

Press the key to initialize the

controller as a Flow meter

Press the key to initialize the

controller as a Conductivity meter

The Meter Selection menu is used to select the meter type that the

controller is configured for, either pH, ORP, Conductivity or FLow.

Once selected, the controller will initialize itself for the selected meter's

functionality and move to run mode.

Press the key to initialize the

controller as an ORP meter

Press the key to initialize the

controller as a pH meter.

INITIALIZE? Y N

INITIALIZE? Y N

INITIALIZE? Y N

INITIALIZE? Y N

INITIALIZE? Y N

PH

PH

E XIT

MANUAL TEST MODE

7.15pH 25.0C

UTILITIES

CALIBRATION

METER SELECTION

C ONDUCTIVITY

FLOW

EXIT

F LOW

CONDUCTIVITY

O RP

CONDUCTIVITY

FLOW

ORP

P H

ORP

PH

To reset the controller back to all

the factory default values, reselect

the current meter type

pH - Utilities Menu - Meter Selection 4.5

pH - Utilities Menu - Meter Selection 4.5 Page 18

Page 21

MULTI-PARAMETER TRANSMITTER USER’S MANUAL

DOWN

DOWN

DOWN

DOWN

DOWN

DOWN

UP DOWN

DOWN

DOWN

DOWN

UP

DOWN

Then press the key to store the

selection and return to the PROBE

SELECT Menu.

With "N" selected, pressing the

key will NOT store the selection, but

simply return to the PROBE SELECT

Menu. This function is useful if you

wish to view the current selection

without making any changes.

Not stored

Stored

Or press the key to highlight

the Y character.

Note:

If using the 2 wire Combination Probe (which

doesn't have a temperature sensor), T COMP

OVERRIDE must be set to ON, and the actual

probe temperature set through the T COMP

OVERRIDE menu.

(see sec. 4.11)

PROBE SELECT will allow the user to select

whether the probe is a 2 or 4 wire

combination probe, or a 5 wire differential

probe.

RUN MODE

UP

NOTE

PRESS THE AND KEYS

TOGETHER TO GO IMMEDIATELY BACK TO

RUN MODE

DOWN

Use the or keys to scroll through

the probe types available.

In this case, the user can select

- the 2 or 4 wire combination probe

- the 5 wire differential probe

Press the key to accept the

setting and move to the store function

Press the key once

which will move the cursor

back to the RH side of the

display.

Once the correct probe type is selected,

move to the store function to save the

selection

Press the key once

which will move the cursor

over the first character of the

probe type.

STORE? Y N STORE? Y N

PROBE SELECT PROBE SELECT

7.15pH 25.0C

UTILITIES

SETUP

CALIBRATION

PROBE SELECT

COMBINATION >

C OMBINATION

PROBE SELECT

D IFFERENTIAL

PROBE SELECT

PROBE SELECT PROBE SELECT

DIFFERENTIAL >

Note: Refer to Appendix A - Probe

Configuration Table

pH - Setup Menu - Probe Select 4.6

pH - Setup Menu - Probe Select 4.6 Page 19

Page 22

MULTI-PARAMETER TRANSMITTER USER’S MANUAL

DOWN

DOWN

DOWN

DOWN

DOWN

DOWN

DOWN

DOWN

DOWN

UP DOWN

DOWN

UP

DOWN

With "N" selected, pressing the

key will NOT store the selection, but

simply return to the TEMP UNIT

Selection Menu. This function is useful if

you wish to view the current selection

without making any changes.

RUN MODE

Or press the key to highlight

UP

NOTE

PRESS THE AND KEYS

TOGETHER TO GO IMMEDIATELY BACK TO

RUN MODE

DOWN

Then press the key to store the

selection and return to the TEMP UNIT

Selection Menu.

Not stored

Stored

the Y character.

Use the or to select C or F

Press the key to accept the

change and move to the store function

Press the key once

which will move the cursor

over the unit type, C or F.

Press the key once

which will move the cursor

back to the RH side of the

display.

TEMP UNIT allows the user to select either

Degrees Centigrade or Fahrenheit units for

display

7.15pH 25.0C

CALIBRATION

UTILITIES

SETUP

TEMP UNIT

PROBE SELECT

STORE? Y N

STORE? Y N

TEMP UNIT TEMP UNIT

DEG

REE

C >

DEGREE F >

TEMP UNIT

DEGREE F >

DEG

REE

C >

TEMP UNIT

TEMP UNIT

TEMP UNIT

pH - Setup Menu -Temp Unit 4.7

pH - Setup Menu - Temp Unit 4.7 Page 20

Page 23

MULTI-PARAMETER TRANSMITTER USER’S MANUAL

DOWN

DOWN

DOWN

DOWN

DOWN

DOWN

DOWN

DOWN

DOWN

UP

UP

DOWN

DOWN

DOWN

UP

DOWN

the Y character.

Or press the key to highlight

With "N" selected, pressing the

key will NOT store the selection, but

simply return to the TEMP SENSOR

Selection Menu. This function is useful if

you wish to view the current selection

without making any changes.

Not stored

UP

NOTE

PRESS THE AND KEYS

TOGETHER TO GO IMMEDIATELY BACK TO

RUN MODE

DOWN

Press the key to accept the

change and move to the store function

Then press the key to store the

selection and return to the TEMP

SENSOR Selection Menu.

Stored

TEMP SENSOR allows the user to select the

type of temperature sensor used the in the

probe.

The factory default for pH is a 300 NTC

Thermistor. The user can also select a 3000

NTC Thermistor or a 1000 RTD.

RUN MODE

Use the or to select the

sensor type

Once the correct Sensor has

been selected press the

key once which will move the

cursor back to the RH side of

the display.

Press the key once

which will move the cursor

over to the sensor type.

7.15pH 25.0C

SETUP

UTILITIES

CALIBRATION

STORE? Y N

STORE? Y N

TEMP SENSOR

300 NTC >

3 000 NTC >

TEMP SENSOR

Ω

TEMP SENSOR

TEMP UNIT

TEMP SENSOR

1 000 RTD >

TEMP SENSOR

TEMP SENSOR

3 00 NTC >

TEMP SENSOR

Ω

Ω

300 NTC >

TEMP SENSOR

PROBE SELECT

Ω

Ω

Ω

Ω

pH - Setup Menu - Temp. Sensor 4.8

pH - Setup Menu - Temp. Sensor 4.8 Page 21

Page 24

MULTI-PARAMETER TRANSMITTER USER’S MANUAL

DOWN

DOWN

DOWN

DOWN

Not stored

DOWN

Stored

DOWN

DOWN

DOWN

DOWN

DOWN

DOWN

DOWN

DOWN

UP DOWN

DOWN

UP

UP

NOTE

PRESS THE AND KEYS

TOGETHER TO GO IMMEDIATELY BACK TO

RUN MODE

DOWN

With "N" selected, pressing the

key will NOT store the selection, but

simply return to the AUTO RETURN

Selection Menu. This function is useful if

you wish to view the current selection

without making any changes.

Then press the key to

store the selection and return

to the Auto Return Selection

Menu.

Press the key to

accept the change and move

to the STORE function

Or press the key to highlight

the Y character.

RUN MODE

To change the MENU

RETURN setting,

Press the key once

which will move the cursor to

the ON or OFF text

Use the or

keys to select either ON or

OFF.

Press the key

once which will move

the cursor back to the

RH side of the display.

MENU ON will cause the controller to exit the menu and

revert back to the online run mode after 10 minutes with no

buttons pressed. This feature ensures that if a user forgets

to return back to run mode, the controller will not be left in

an offline state. If for some reason, the user would like to

remain in the menu mode for extended periods of time, the

AUTO RETURN function can be set to "OFF".

AUTO RETURN is used to select what conditions will

cause the controller to time-out of the operations

menu

7.15pH 25.0C

SETUP

UTILITIES

CALIBRATION

STORE? Y N

STORE? Y N

AUTO RETURN AUTO RETURN

AUTO RETURNAUTO RETURN

MENU ON >

TEMP SENSOR

TEMP UNIT

PROBE SELECTION

AUTO RETURN

MENU OFF >

AUTO RETURN

AUTO RETURN

MENU O FF >

MENU O N >

pH - Setup Menu - Auto Return 4.9

pH - Setup Menu - Auto Return 4.9 Page 22

Page 25

MULTI-PARAMETER TRANSMITTER USER’S MANUAL

UP

DOWN

UP

DOWN

DOWN

DOWN

DOWN DOWN

DOWN

DOWNUP

DOWN

DOWN

DOWN

DOWN

DOWN

DOWN

DOWN

DOWN

DOWN

DOWNUP

DOWN

DOWN

DOWN

Use the or keys to

select either ON or OFF.

Press the key to accept the

change and move to the Temperature

Entry function

Press the key once

which will move the cursor

back to the RH side of the

display.

Press the key once

which will move the cursor

over the least significant digit

of the temperature display.

Use the and to

adjust the reading until it agrees

with the known temperature of the

probe or process

Press the key to accept the

reading and move to the store function

Press the key once

which will move the cursor

back to the RH side of

temperature display.

The user can now enter the actual

probe or process temperature

Then press the key to store the

selection and return to the T. COMP

OVERRIDE Menu.

UP

NOTE

PRESS THE AND KEYS

TOGETHER TO GO IMMEDIATELY BACK TO

RUN MODE

DOWN

With "N" selected, pressing the

key will NOT store the selection, but

simply return to the T. Comp Override

Menu. This function is useful if you wish

to view the current selection without

making any changes.

If you wish to save the setting, press the

key to highlight the Y character

Not stored

Stored

RUN MODE

Press the key once

which will move the cursor to

the ON or OFF text

Temperature Compensation Override is used to manually set

the actual probe or process temperature. This is useful if the

probe does not have a temperature sensor or if the process

temperature is constant. When the override is enabled, the

controller will use the selected temperature when performing

temperature compensation calculations.

T.COMP OVERRIDE

STORE? Y N

STORE? Y N

TEMP 35. 7 C >

TEMP 35.7C >

T.COMP OVERRIDE

T.COMP OVERRIDE T.COMP OVERRIDE

TEMP 25. 4 C >

T.COMP OVERRIDE

T.COMP OVERRIDE

TEMP 25.4C >

AUTO RETURN

T.COMP OVERRIDE

CALIBRATION

UTILITIES

SETUP

7.15pH 25.0C

TEMP UNIT

TEMP SENSOR

PROBE SELECTION

COMPENSATE O FF >

COMPENSATE O N >

T.COMP OVERRIDE

T.COMP OVERRIDE

COMPENSATE O N >

T.COMP OVERRIDE

COMPENSATE OFF >

T.COMP OVERRIDE

pH - Setup Menu - T.Comp Override 4.10

pH - Setup Menu - T.Comp Override 4.10 Page 23

Page 26

MULTI-PARAMETER TRANSMITTER USER’S MANUAL

DOWN

DOWN

DOWN

DOWN

DOWN

DOWN

DOWN

DOWN

DOWN

DOWN

DOWN

DOWN

DOWN

DOWN

UP

DOWNUP

DOWN

UP

NOTE

PRESS THE AND KEYS

TOGETHER TO GO IMMEDIATELY BACK TO

RUN MODE

DOWN

The Display Damping menu allows the user to adjust

the rate at which the display and the output is

updated. This allows the user to dampen out

unstable process readings.

The damping can be set from 0 seconds to 10

seconds. (default value is 0 sec.)

With "N" selected, pressing the

key will NOT store the selection, but

simply return to the Display Damping

Menu. This function is useful if you wish

to view the current selection without

making any changes.

Not stored

RUN MODE

Use the and to adjust

the damping time, the default

setting is 0 seconds.

The setting can be adjusted from 0

to 10 seconds.

Then press the key to store the

selection and return to the Display

Damping Menu.

Stored

If you wish to save the setting, press the

key to highlight the Y character

Press the key once

which will move the cursor back

to the RH side of the display.

Press the key to accept the

setting and move to the store function

Press the key once

which will move the cursor

over the seconds digit

STORE? Y N

UPDATE 10 SEC >

UPDATE 0 SEC >

DISPLAY DAMPING

UPDATE 1 0 SEC >

DISPLAY DAMPING

DISPLAY DAMPING

DISPLAY DAMPING

STORE? Y N

DISPLAY DAMPING

7.15pH 25.0C

CALIBRATION

SETUP

UTILITIES

DISPLAY DAMPING

AUTO RETURN

T.COMP OVERRIDE

DISPLAY DAMPING

UPDATE 0SEC >

TEMP UNIT

PROBE SELECTION

DOWN

TEMP SENSOR

pH - Setup Menu - Display Damping 4.11

pH - Setup Menu - Display Damping 4.11 Page 24

Page 27

MULTI-PARAMETER TRANSMITTER USER’S MANUAL

DOWN

DOWN

DOWN

DOWN

DOWN

The FIRMWARE REV menu allows the user to see what revision of

the firmware is currently installed in the controller. This is a Read

Only menu item.

RUN MODE

UP

NOTE

PRESS THE AND KEYS

TOGETHER TO GO IMMEDIATELY BACK TO

RUN MODE

DOWN

7.15pH 25.0C

DIAGNOSTICS

SETUP

UTILITIES

CALIBRATION

FIRMWARE REV. FIRMWARE REV.

1.00 >

pH - Diagnostics Menu - Firmware Rev 4.12

pH - Diagnostics Menu - Firmware Rev 4.12 Page 25

Page 28

MULTI-PARAMETER TRANSMITTER USER’S MANUAL

DOWN

DOWN

DOWN

DOWN

DOWN

DOWN

DOWN

DOWN

DOWN

DOWN

DOWN

DOWN

The Calibration Data menu is a series of read only screens which

allow the user to view the data collected during the last calibration.

RUN MODE

Press to view the first

Calibration Data screen.

UP

NOTE

PRESS THE AND KEYS

TOGETHER TO GO IMMEDIATELY BACK TO

RUN MODE

DOWN

1st POINT PH = 7.00

INPUT FROM PROBE = - 19 mV

Calculated efficiency based on 2

point calibration = 91 %

Calculated slope based on 2

point calibration = 59.16 mV/pH

Probe Temperature at which

calibration was performed = 19.4°C

2nd POINT PH = 4.00

INPUT FROM PROBE = + 143 mV

Calibration Mode

2 point calibration

Press to view the next

Calibration Data screen.

EFF 91% >

59.16MV/PH >

CALIBRATION DATA

CAL TEMP 19.4C >

CALIBRATION DATA

2P 4.00/ 143 >

CALIBRATION DATA

1P 7.00/ -19 >

MODE 2PT >

CALIBRATION DATA

7.15pH 25.0C

DIAGNOSTICS

CALIBRATION

UTILITIES

SETUP

CAL EFFICIENCY

CAL SLOPE

CALIBRATION DATA

FIRMWARE REV.

pH - Diagnostics Menu - Calibration Data 4.13

pH - Diagnostics Menu - Calibration Data 4.13 Page 26

Page 29

MULTI-PARAMETER TRANSMITTER USER’S MANUAL

DOWN

DOWN

DOWN

DOWN

DOWN

DOWN

DOWN

UP

NOTE

PRESS THE AND KEYS

TOGETHER TO GO IMMEDIATELY BACK TO

RUN MODE

DOWN

The Sensor Input Menu allows the user to view real time, uncompensated

process data from the probe.

This is a Read only menu item.

The top line shows the mV input from the probe

The bottom line shows the actual value of the

temperature sensor in ohms.

Press to view the

Sensor Input data.

CALIBRATION DATA

SETUP

DIAGNOSTICS

SENSOR INPUT

FIRMWARE REV.

7.15pH 25.0C

UTILITIES

CALIBRATION

TEMP 331Ω >

PROBE -18mV

RUN MODE

pH - Diagnostics Menu - Sensor Input 4.14

Troubleshooting a pH probe using the sensor input

Sensor input displays the uncompensated sensor input data. The pH probe values are displayed in mV (millivolts). The temperature sensor value is displayed in Ω (ohm).

Connect the pH probe as per Probe Configuration Table in Appendix A.

1. Place the probe in buffer 7pH (allow temperature to stabilize)

• Probe should read 0mV [±50mV]

• Temperature should read 300Ω [±50Ω] @ 25°C

• Record both of these numbers.

2. Place the probe in buffer 4pH

• Probe should read +160mV more than probe value at 7pH

• Temperature should read the same as in 7pH

3. Place the probe in buffer 10pH

• Probe should read -160mV less then probe value at 7pH

• Temperature should read the same as in 7pH

pH - Diagnostics Menu - Sensor Input 4.14 Page 27

Page 30

MULTI-PARAMETER TRANSMITTER USER’S MANUAL

DOWN

DOWN

DOWN

DOWN

DOWN

DOWN

UP

DOWN

DOWN

DOWN

DOWN

DOWN

DOWN

DOWN

DOWN

DOWN

UP DOWN

UP DOWN

DOWN

DOWN

UP DOWN

DOWN

DOWNUP

DOWNUP

DOWN

DOWN

UP

Press the key once

which will move the cursor

back to the RH side of the

display.

Or press the

key to highlight

the Y character

Then press the key to store the

selection and return to the OUTPUT

menu

Not stored

Stored

Press the key to accept the

setting and move to the next setting

UP

NOTE

PRESS THE AND KEYS

TOGETHER TO GO IMMEDIATELY BACK TO

RUN MODE

DOWN

The TUNE fuction allows the user to precisely

adjust the 4-20 ma output to compensate for

any errors in the output circuitry. Normally,

fine tuning the 4-20mA output is not

necessary.

To make the adjustment, place an accurate

current meter in series with the 4-20 mA

output, with the appropriate loads connected.

When the TUNE menu is selected, the

controller puts 20 mA out the terminals. Use

the or keys to adjust the 20mA

output to get exactly 20.

The TUNE value can be adjusted over the

range from 0 to 1000, these are unitless

numbers used for tuning purposes only.

RUN MODE

With "N" selected, pressing the

key will NOT store the selection, but

simply return to the OUTPUT Menu. This

function is useful if you wish to view the

current selection without making any

changes.

The example below shows the 4-20 mA set to 4mA =7.00pH and 20mA = 14pH.

The output would then span 4 to 20 mA for a pH swing of 7.0 to 14.0.

Note that the span can reversed, in that 4 mA can be set to a high pH value, and 20

mA can be set to a low pH value, effectively reversing the control direction.

Use the and

keys to change the setting

If you wish to change the setting,

press the key once which will move the cursor

to the first character of the value to be changed

Press the key to accept the

setting and move to the next setting

Use the and

keys to change the setting

If you wish to change the setting,

press the key once which will move the cursor

to the first character of the value to be changed

If you wish to change the setting,

press the key once which will move the cursor

to the first character of the value to be changed

Use the and

keys to change the setting

Press the key to accept the

setting and move to the next

setting

Press the key once

which will move the cursor

back to the RH side of the

display.

Press the key once

which will move the cursor back

to the RH side of the display.

The Transmitter has a single 4-20mA output, electrically

isolated from the ground. The output can source current into a

maximum of 800 ohms. See Section 3.9 for wiring diagram.

The channel has a fully adjustable 4 & 20 mA output

adjustments. This will enable the operator to span the output

over the desired range.

STORE? Y N

STORE? Y N

4-20mA PROC

20mA TUNE 54 0 >

4-20mA PROC

20mA TUNE 54 0 >

4-20mA PROC

OUTPUT

CALIBRATION

DIAGNOSTICS

UTILITIES

SETUP

7.15pH 25.0C

4-20mA

20mA TUNE 512 >

4-20mA PROC

4-20mA PROC

20mA OUT 14.00 >

20mA TUNE 51 2 >

4-20mA PROC

4-20mA PROC

20mA OUT 14.0 0 >

20mA OUT 14.00 >

20mA OUT 14.0 0 >

4-20mA PROC

4-20mA PROC

4-20mA PROC

4-20mA PROC

4mA OUT 0.00 >

4-20mA PROC

4-20mA PROC

4mA OUT 7.00 >

4mA OUT 7.0 0 >

4-20mA PROC

4mA OUT 0.0 0 >

pH - Output Menu - 4-20mA Output 4.15

pH - Output Menu - 4-20mA Output 4.15 Page 28

Page 31

MULTI-PARAMETER TRANSMITTER USER’S MANUAL

SIMPLE THREE-BUTTON INTERFACE

FOR FAST & EASY SETUP

(REFER TO SECTIONS 5.0 TO 5.13)

2 LINE, 16 CHARACTER

LCD DISPLAY

MAIN MENU INTERFACE

SCREEN

1/4" TURN SCREWS

(FOR SHARKTX ONLY)

UNIT LABEL

LABEL TO INDICATE UNIT OF

MEASURE SHARK IS

CONFIGURED FOR.

Section 5 - Using the Transmitter in ORP Mode

Section 5 - Using the Transmitter in ORP Mode Page 29

Page 32

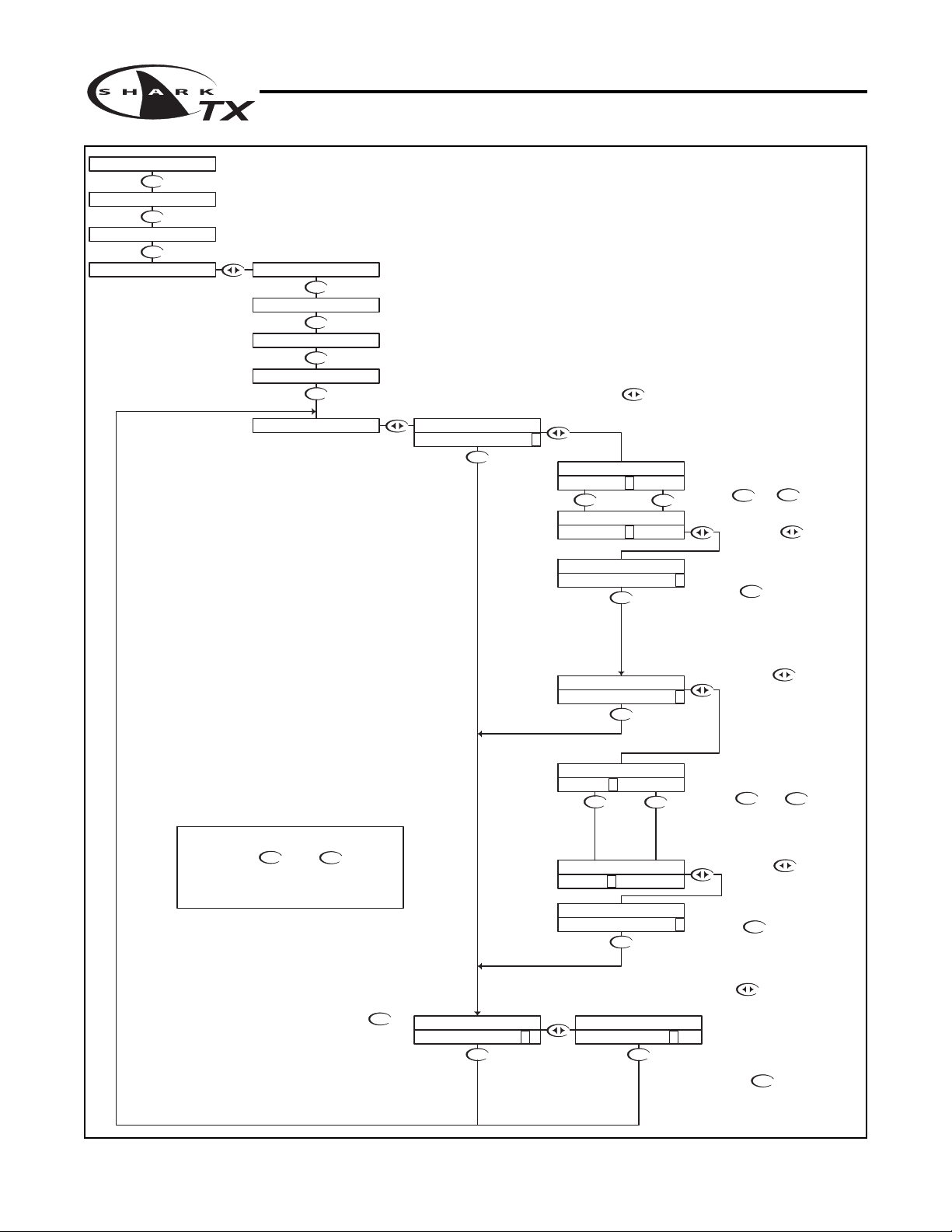

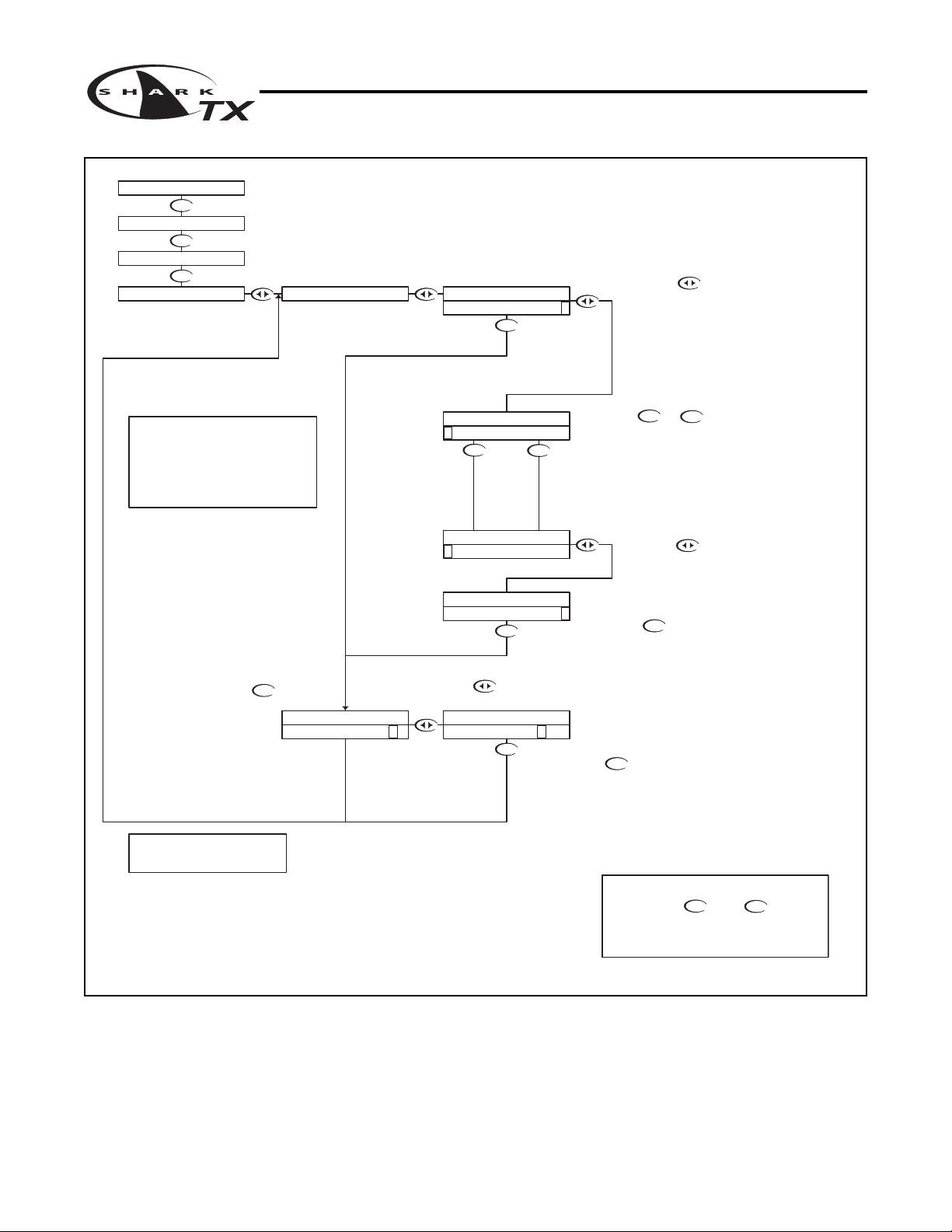

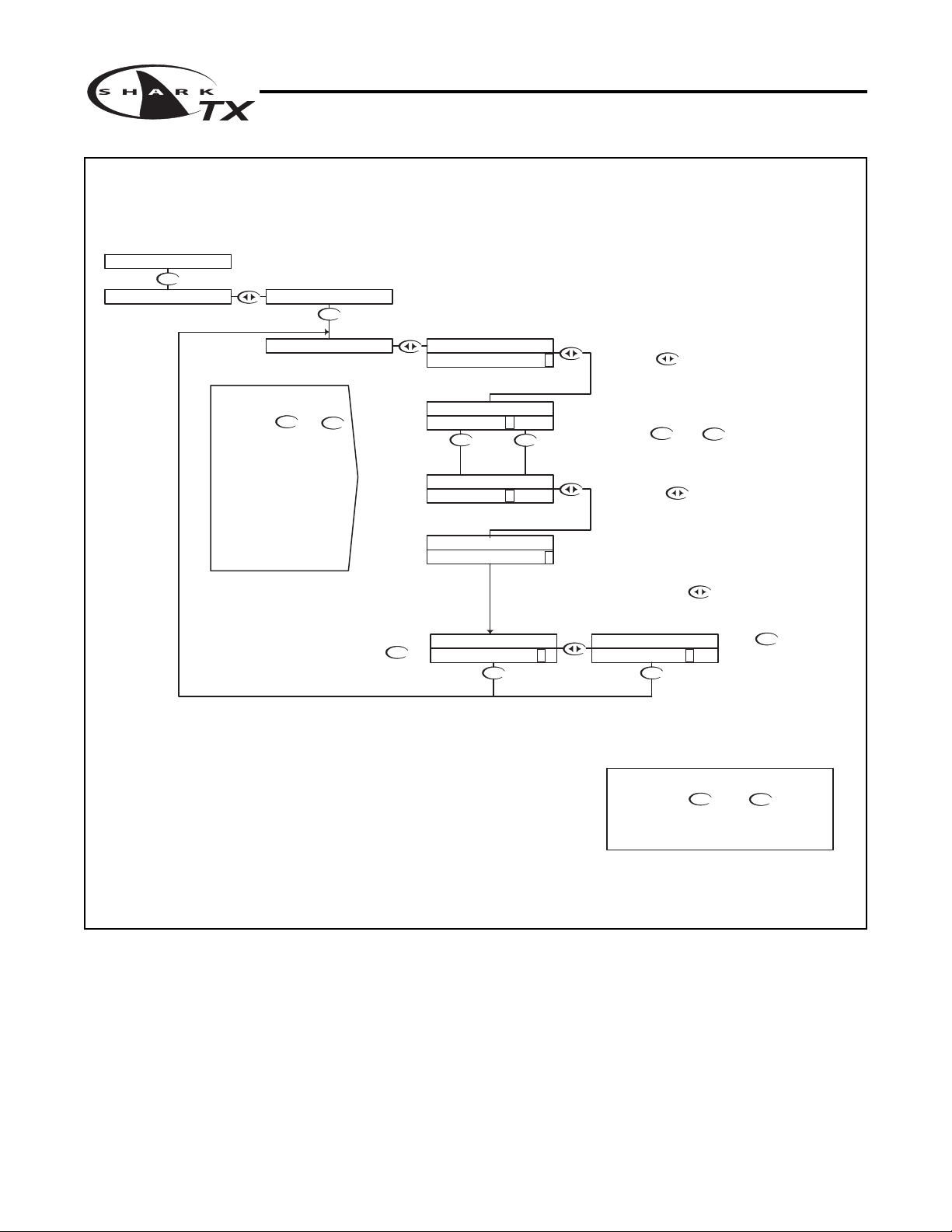

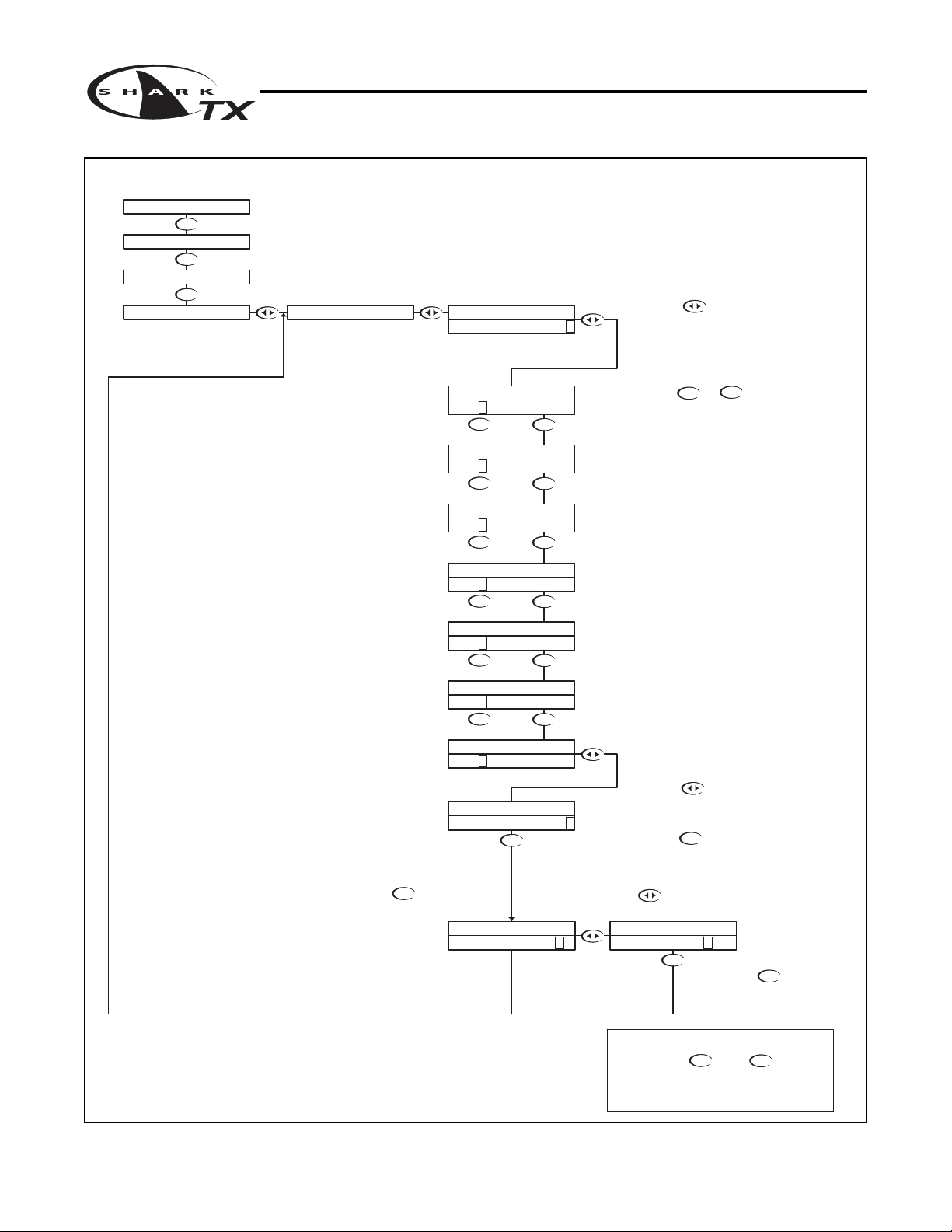

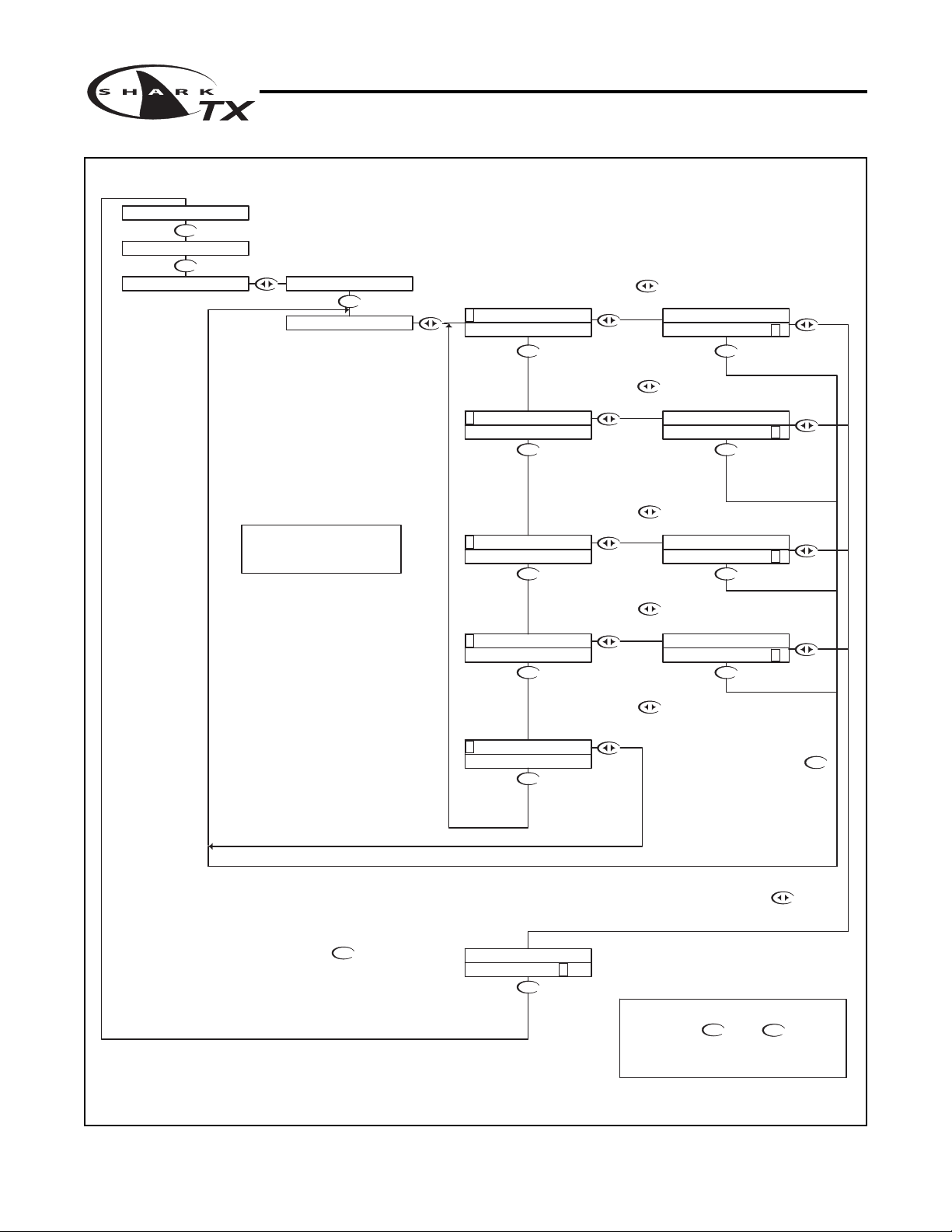

MULTI-PARAMETER TRANSMITTER USER’S MANUAL

DOWN

DOWN

DOWN

DOWN

DOWN

DOWN

DOWN

DOWN

DOWN

DOWN

DOWN

DOWN

DOWNDOWN

DOWN

DOWN

DOWNDOWN

DOWN

DOWN

DOWN

DOWN

DOWN

DOWN

DOWN

SELECT DEG C OR DEG F

ENABLE TIME OUT

ON LCD AND LED DISPLAYS

DISABLE TEMPERATURE DISPLAY

SETUP DISPLAY AND

OUTPUT RESPONSE TIME

SELECT TYPE OF

FROM MENU

DISPLAY

FIRMWAVE REVISION

SEC. 5.11

DISPLAY PREVIOUS

CALIBRATION DATA

SEC 5.12

DISPLAY UNCALIBRATED

PROBE DATA

SEC 5.13

SEC. 5.8

SELECT TYPE OF

TEMP SENSOR

SEC. 5.7

SEC 5.9

SEC 5.10

SEC. 5.5

SEC 5.6

ORP PROBE

RUN MODE

SEC. 5.2

UP

NOTE

PRESS THE AND KEYS

TOGETHER TO GO IMMEDIATELY BACK TO

RUN MODE

DOWN

SELECT TYPE

OF METER

SEC. 5.4

VERIFY OUTPUTS

SIMULATE PROCESS

SEC. 5.3

MANUAL CALIBRATE

SENSOR IN ORP PROBE

CALIBRATE TEMP.

ORP PROBE

SEC. 5.1

DIAGNOSTICS

EXIT

SENSOR INPUT

CALIBRATION DATA

FIRMWARE REV

EXIT

DISPLAY DAMPING

T. DISP OVERRIDE

EXIT

AUTO RETURN

TEMP SENSOR

TEMP UNIT

PROBE SELECT

500mV 25.0C

UTILITIES

SETUP

CALIBRATION

MANUAL TEST MODE

METER SELECTION

EXIT

EXIT

TEMP CALIBRATION

MANUAL CAL ORP

DOWN

DOWN

DOWN

4-20 mA OUTPUT

SETUP

SEC 5.14

EXIT

4-20mA

OUTPUT

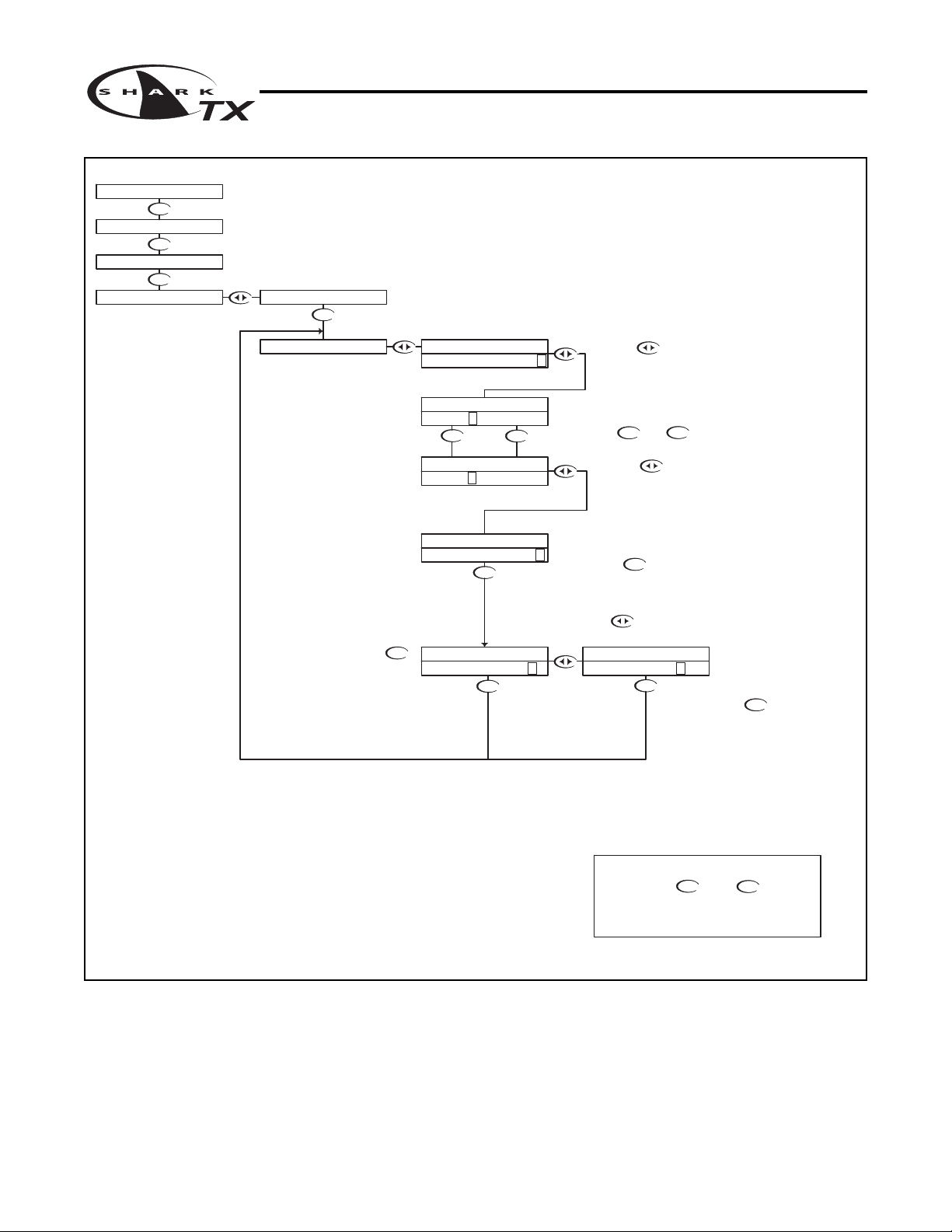

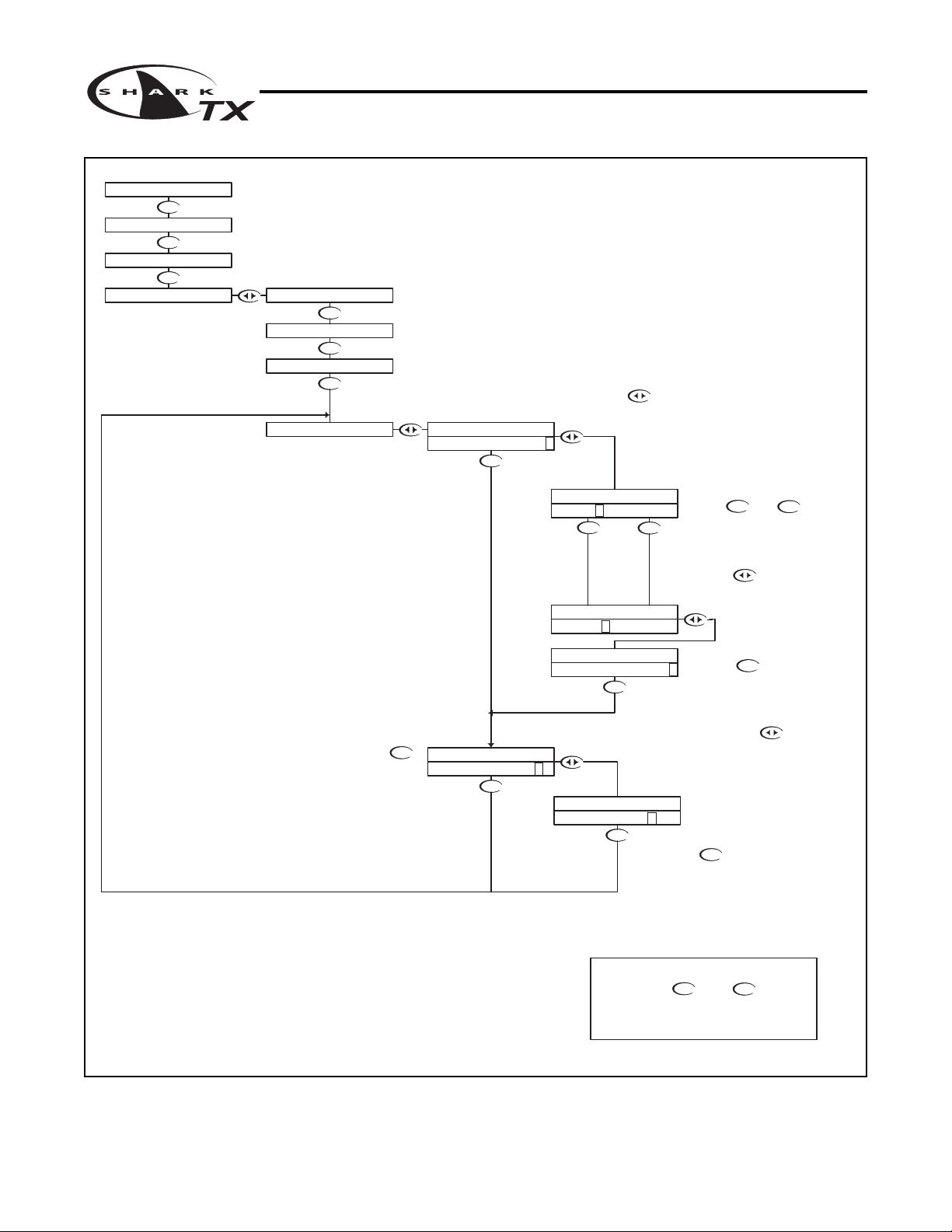

ORP - Menu Overview 5.0

ORP - Menu Overview 5.0 Page 30

Page 33

MULTI-PARAMETER TRANSMITTER USER’S MANUAL

DOWN

UP

DOWN

DOWN

DOWN

DOWN

UP

DOWN

DOWN

DOWN

DOWN

DOWN

UP

NOTE

PRESS THE AND KEYS

TOGETHER TO GO IMMEDIATELY BACK TO

RUN MODE

DOWN

Press to store the

calibration data and return

back to the Manual Cal menu

so the user can select another

function.

Place the probe in the buffer solution, be sure

to clean and rinse the Probe first with D.I.

water and then insert it in the mV buffer.

Press

If the calibration did not appear

to be correct, press the

key which will return back to the

Manual Cal menu.

The controller will display the mV value and the

probe temperature for 5 seconds.

If the T.DISPLAY O/R is enabled, the display will

show.

If the calibration is OK, use the

key to move the cursor over the Y

text and press the down key.

Then press to move

the cursor to the RH position

Use the and keys to

adjust the reading until it agrees with

the actual buffer mV value

When complete, the controller will

report the measured value

Please wait for the controller to

complete the measurement

The controller will read the mV value, averaging a

number of results to get a stable calibration value.

RUN MODE

IF BUFFER READYCALIBRATION MANUAL CAL ORP

STORE? Y N

STORE? Y N

TEMP 25.0C

BUFFER 600mV

MANUAL CAL ORP

BUFFER 600 >

RUNNING MANU CAL

BUFFER WAIT...

PRESS ©DOWN©

BUFFER 50 0 >

MANUAL CAL ORP

BUFFER 60 0 >

MANUAL CAL ORP

MANUAL CAL ORP

TEMP O/R ON

MANUAL CAL ORP

500mV 25.0C

ORP - Calibration Menu - Manual Calibrate 5.1

ORP - Calibration Menu - Manual Calibrate 5.1 Page 31

Page 34

MULTI-PARAMETER TRANSMITTER USER’S MANUAL

DOWN

DOWN DOWN

DOWNUP

DOWN

DOWN

UP

DOWN

DOWN

DOWN

DOWN

DOWN

If the Temperature Display Override is set to ON (see

section 5.10), the Shark cannot calibrate the temperature

sensor. This display will appear to alert the user to the

condition.

If the calibration did not appear to

be correct, press the key

which will return back to the Temp

Calibration menu.

UP

NOTE

PRESS THE AND KEYS

TOGETHER TO GO IMMEDIATELY BACK TO

RUN MODE

DOWN

This will store the calibration data

and return back to the Temp

Calibration setup so the user can

select another function.

Use the and to adjust

the reading until it agrees with the

known temperature of the probe

Press the key to accept the

reading and move to the store function

"T FACTOR SHIFTED" will be

displayed for 5 seconds to indicate that

the temperature sensor has been

calibrated.

The Shark will then move to the store

function.

The controller displays the current probe

temperature.

If this incorrect, the controller can be

adjusted to compensate.

Press the key once

which will move the cursor

back to the RH side of

temperature display.

Press the key once which will move

the cursor over the least sign. digit of the

temperature display.

RUN MODE

STORE? Y N

TEMP CALIBRATION

STORE? Y N

TEMP CALIBRATION

TEMP CALIBRATION

25.0C >

T FACTOR SHIFTED

25. 0 C >

TEMP CALIBRATION

TEMP CALIBRATION

TEMP CALIBRATION

TEMP CALIBRATION

22. 4 C >

22.4C >

TEMP CALIBRATION

TEMP O/R ON >

500mV 25.0C

CALIBRATION MANUAL CAL ORP

ORP - Calibration Menu - Temp. Calibration 5.2

ORP - Calibration Menu - Temp. Calibration 5.2 Page 32

Page 35

DOWN

DOWN

DOWN

UP DOWN

DOWN

UP

DOWN

Manual Test Mode is used to simulate a process reading

in order to verify the correct response of the output.

When in the Manual Test Mode, the outputs is no longer

placed on hold as it is when in the rest of the menu.

The range is 0 to +1000mV.

NOTE:

When the user exits the Manual Test Mode, the 4-20mA

output will remain in the Test Mode state until the operator

enters the run mode. The output will then revert back to

the previous On-line state.

The 4-20 mA output will track

the change in process value

RUN MODE

UP

NOTE

PRESS THE AND KEYS

TOGETHER TO GO IMMEDIATELY BACK TO

RUN MODE

DOWN

Press the key once to

move the cursor to the RH side

of the display

The 4-20 mA output will follow the process

value change.

Press the key to return to the

MANUAL TEST MODE menu

Use the and keys to change

the simulated process value.

Press the key once which will

move the cursor over the least digit of the

simulated process value.

TEST 50 0 >

TEST 500 >

500mV 25.0C

CALIBRATION

UTILITIES

12.0mA

12.0mA

TEST 50 0 >

TEST 500 >

MANUAL TEST MODE

12.0mA

12.0mA

16.8mA

TEST 80 0 >

DOWN

MULTI-PARAMETER TRANSMITTER USER’S MANUAL

ORP - Utilities Menu - Manual Test Mode 5.3

ORP - Utilities Menu - Manual Test Mode 5.3 Page 33

Page 36

MULTI-PARAMETER TRANSMITTER USER’S MANUAL

DOWNDOWN

DOWN

DOWN

DOWN

DOWN

DOWN

DOWN

DOWN

DOWN

DOWN

DOWN

DOWN DOWN

DOWN

If you do not wish to initialize to this

type of meter after all, then press

key to return back to the Meter

Selection menu

Then press

The controller will initialize itself for a

specific meter

If you do wish to initialize to this

type of meter, press the

key to highlight the Y character

UP

NOTE

PRESS THE AND KEYS

TOGETHER TO GO IMMEDIATELY BACK TO

RUN MODE

DOWN

Press the key to Exit and

return to the Utilities menu

RUN MODE

Press the key to initialize the

controller as a Flow meter

Press the key to initialize the

controller as a Conductivity meter

The Meter Selection menu is used to select the meter type that the

controller is configured for, either pH, ORP, Conductivity or FLow.

Once selected, the controller will initialize itself for the selected meter's

functionality and move to run mode.

Press the key to initialize the

controller as an ORP meter

Press the key to initialize the

controller as a pH meter.

INITIALIZE? Y N

INITIALIZE? Y N

INITIALIZE? Y N

INITIALIZE? Y N

INITIALIZE? Y N

ORP

PH

E XIT

MANUAL TEST MODE

500mV 25.0C

UTILITIES

CALIBRATION

METER SELECTION

C ONDUCTIVITY

FLOW

EXIT

F LOW

CONDUCTIVITY

O RP

CONDUCTIVITY

FLOW

ORP

P H

ORP

PH

To reset the controller back to all

the factory default values, reselect

the current meter type

ORP - Utilities Menu - Meter Selection 5.4

ORP - Utilities Menu - Meter Selection 5.4 Page 34

Page 37

MULTI-PARAMETER TRANSMITTER USER’S MANUAL

DOWN

DOWN

DOWN

DOWN

DOWN

DOWN

UP DOWN

DOWN

DOWN

DOWN

UP

DOWN

Then press the key to store the

selection and return to the PROBE

SELECT Menu.

With "N" selected, pressing the

key will NOT store the selection, but

simply return to the PROBE SELECT

Menu. This function is useful if you

wish to view the current selection

without making any changes.

Not stored

Stored

Or press the key to highlight

the Y character.

Note:

If using the 2 wire Combination Probe (which

doesn't have a temperature sensor), T DISP

OVERRIDE must be set to ON, and the actual

probe temperature set through the T DISP

OVERRIDE menu.

(see sec. 5.10)

PROBE SELECT will allow the user to select

whether the probe is a 2 or 4 wire

combination probe, or a 5 wire differential

probe.

RUN MODE

UP

NOTE

PRESS THE AND KEYS

TOGETHER TO GO IMMEDIATELY BACK TO

RUN MODE

DOWN

Use the or keys to scroll through

the probe styles available.

In this case, the user can select

- the 2 or 4 wire combination probe

- the 5 wire differential probe

Press the key to accept the

setting and move to the store function

Press the key once

which will move the cursor

back to the RH side of the

display.

Once the correct style probe is selected,

move to the store function to save the

selection

Press the key once

which will move the cursor

over the first character of the

probe type.

STORE? Y N STORE? Y N

PROBE SELECT PROBE SELECT

500mV 25.0C

UTILITIES

SETUP

CALIBRATION

PROBE SELECT

COMBINATION >

C OMBINATION

PROBE SELECT

D IFFERENTIAL

PROBE SELECT

PROBE SELECT PROBE SELECT

DIFFERENTIAL >

Note: Refer to Appendix A - Probe

Configuration Table

ORP - Setup Menu - Probe Select 5.5

ORP - Setup Menu - Probe Select 5.5 Page 35

Page 38

MULTI-PARAMETER TRANSMITTER USER’S MANUAL

DOWN

DOWN

DOWN

DOWN

DOWN

DOWN

DOWN

DOWN

DOWN

UP DOWN

DOWN

UP

DOWN

With "N" selected, pressing the

key will NOT store the selection, but

simply return to the TEMP UNIT

Selection Menu. This function is useful if

you wish to view the current selection

without making any changes.

RUN MODE

Or press the key to highlight

UP

NOTE

PRESS THE AND KEYS

TOGETHER TO GO IMMEDIATELY BACK TO

RUN MODE

DOWN

Then press the key to store the

selection and return to the TEMP UNIT

Selection Menu.

Not stored

Stored

the Y character.

Use the or to select C or F

Press the key to accept the

change and move to the store function

Press the key once

which will move the cursor

over the unit type, C or F.

Press the key once

which will move the cursor

back to the RH side of the

display.

TEMP UNIT allows the user to select either

Degrees Centigrade or Fahrenheit units for

display

500mV 25.0C

CALIBRATION

UTILITIES

SETUP

TEMP UNIT

PROBE SELECT

STORE? Y N

STORE? Y N

TEMP UNIT TEMP UNIT

DEGREE C >

DEGREE F >

TEMP UNIT

DEGREE F >

DEGREE C >

TEMP UNIT

TEMP UNIT

TEMP UNIT

ORP - Setup Menu - Temp. Unit 5.6

ORP - Setup Menu - Temp. Unit 5.6 Page 36

Page 39

MULTI-PARAMETER TRANSMITTER USER’S MANUAL

DOWN

DOWN

DOWN

DOWN

DOWN

DOWN

DOWN

DOWN

DOWN

UP

UP

DOWN

DOWN

DOWN

UP

DOWN

the Y character.

Or press the key to highlight

With "N" selected, pressing the

key will NOT store the selection, but

simply return to the TEMP SENSOR

Selection Menu. This function is useful if

you wish to view the current selection

without making any changes.

Not stored

UP

NOTE

PRESS THE AND KEYS

TOGETHER TO GO IMMEDIATELY BACK TO

RUN MODE

DOWN

Press the key to accept the

change and move to the store function

Then press the key to store the

selection and return to the TEMP

SENSOR Selection Menu.

Stored

TEMP SENSOR allows the user to select the

type of temperature sensor used in the probe.

The factory default for ORP is a 300 NTC

Thermistor. The user can also select a 3000

NTC Thermistor or a 1000 RTD.

RUN MODE

Use the or to select the

sensor type

Once the correct Sensor has

been selected press the

key once which will move the

cursor back to the RH side of

the display.

Press the key once

which will move the cursor

over to the sensor type.

500mV 25.0C

SETUP

UTILITIES

CALIBRATION

STORE? Y N

STORE? Y N

TEMP SENSOR

300 NTC >

3 000 NTC >

TEMP SENSOR

Ω

TEMP SENSOR

TEMP UNIT

TEMP SENSOR

1 000 RTD >

TEMP SENSOR

TEMP SENSOR

3 00 NTC >

TEMP SENSOR

Ω

Ω

300 NTC >

TEMP SENSOR

PROBE SELECT

ORP - Setup Menu - Temp. Sensor 5.7

ORP - Setup Menu - Temp. Sensor 5.7 Page 37

Page 40

MULTI-PARAMETER TRANSMITTER USER’S MANUAL

DOWN

DOWN

DOWN

DOWN

Not stored

DOWN

Stored

DOWN

DOWN

DOWN

DOWN

DOWN

DOWN

DOWN

DOWN

UP DOWN

DOWN

UP

UP

NOTE

PRESS THE AND KEYS

TOGETHER TO GO IMMEDIATELY BACK TO

RUN MODE

DOWN

With "N" selected, pressing the

key will NOT store the selection, but

simply return to the AUTO RETURN

Selection Menu. This function is useful if

you wish to view the current selection

without making any changes.

Then press the key to

store the selection and return

to the Auto Return Selection

Menu.

Press the key to

accept the change and move

to the STORE function

Or press the key to highlight

the Y character.

RUN MODE

To change the MENU

RETURN setting,

Press the key once

which will move the cursor to

the ON or OFF text

Use the or

keys to select either ON or

OFF.

Press the key

once which will move

the cursor back to the

RH side of the display.

MENU ON will cause the controller to exit the menu and

revert back to the online run mode after 10 minutes with no

buttons pressed. This feature ensures that if a user forgets

to return back to run mode, the controller will not be left in

an offline state. If for some reason, the user would like to

remain in the menu mode for extended periods of time, the

AUTO RETURN function can be set to "OFF".

AUTO RETURN is used to select what conditions will

cause the controller to time-out of the operations

menu

500mV 25.0C

SETUP

UTILITIES

CALIBRATION

STORE? Y N

STORE? Y N

AUTO RETURN AUTO RETURN

AUTO RETURNAUTO RETURN

MENU ON >

TEMP UNIT

TEMP SENSOR

PROBE SELECTION

AUTO RETURN

MENU OFF >

AUTO RETURN

AUTO RETURN

MENU O FF >

MENU O N >

ORP - Setup Menu - Auto Return 5.8

ORP - Setup Menu - Auto Return 5.8 Page 38

Page 41

MULTI-PARAMETER TRANSMITTER USER’S MANUAL

UP

DOWN

DOWN

DOWN

DOWN DOWN

DOWN

DOWN

DOWN

DOWN

DOWN

DOWN

DOWN

DOWN

DOWNUP

DOWN

DOWN

Use the or keys to

select either ON or OFF.

Press the key to accept the

change and move to the store function

Press the key once

which will move the cursor

back to the RH side of the

display.

Then press the key to store the

selection and return to the T. DISP

OVERRIDE Menu.

UP

NOTE

PRESS THE AND KEYS

TOGETHER TO GO IMMEDIATELY BACK TO

RUN MODE

DOWN

With "N" selected, pressing the

key will NOT store the selection, but

simply return to the T. Disp. Override

Menu. This function is useful if you wish

to view the current selection without

making any changes.

If you wish to save the setting, press the

key to highlight the Y character

Not stored

Stored

RUN MODE

Press the key once

which will move the cursor to

the ON or OFF text

T. Display Override is used to blank the Temperature Display

on the LCD menu and place 4 dots on the LED menu when

Temp display is requested.This is to ensure the user isn't

shown a temperature value that isn't valid.

STORE? Y N STORE? Y N

T.COMP OVERRIDE T.COMP OVERRIDE

AUTO RETURN

T. DISP OVERRIDE

CALIBRATION

UTILITIES

SETUP

500mV 25.0C

TEMP UNIT

TEMP SENSOR

PROBE SELECTION

OVERRIDE O FF >

OVERRIDE O N >

T. DISP OVERRIDE

T. DISP OVERRIDE

OVERRIDE ON >

T. DISP OVERRIDE

OVERRIDE OFF >

T. DISP OVERRIDE

ORP - Setup Menu - Temp. Display Override 5.9

ORP - Setup Menu - Temp. Display Override 5.9 Page 39

Page 42

MULTI-PARAMETER TRANSMITTER USER’S MANUAL

DOWN

DOWN

DOWN

DOWN

DOWN

DOWN

DOWN

DOWN

DOWN

DOWN

DOWN

DOWN

DOWN

DOWN

DOWN

UP

DOWNUP

DOWN

UP

NOTE

PRESS THE AND KEYS

TOGETHER TO GO IMMEDIATELY BACK TO

RUN MODE

DOWN

The Display Damping menu allows the user to adjust

the rate at which the display and the output is

updated. This allows the user to dampen out

unstable process readings.

The damping can be set from 0 seconds to 10

seconds. (default value is 0 sec.)

With "N" selected, pressing the

key will NOT store the selection, but

simply return to the Display Damping

Menu. This function is useful if you wish

to view the current selection without

making any changes.

Not stored

RUN MODE

Use the and to adjust

the damping time, the default

setting is 0 seconds.

The setting can be adjusted from 0

to 10 seconds.

Then press the key to store the

selection and return to the Display

Damping Menu.

Stored

If you wish to save the setting, press the

key to highlight the Y character

Press the key once

which will move the cursor back

to the RH side of the display.

Press the key to accept the

setting and move to the store function

Press the key once

which will move the cursor

over the seconds digit

STORE? Y N

UPDATE 10 SEC >

UPDATE 0 SEC >

DISPLAY DAMPING

UPDATE 1 0 SEC >

DISPLAY DAMPING

DISPLAY DAMPING

DISPLAY DAMPING

STORE? Y N

DISPLAY DAMPING

500mV 25.0C

CALIBRATION

SETUP

UTILITIES

DISPLAY DAMPING

TEMP SENSOR

AUTO RETURN

T. DISP OVERRIDE

DISPLAY DAMPING

UPDATE 0SEC >

TEMP UNIT

PROBE SELECTION

ORP - Setup Menu - Display Damping 5.10

ORP - Setup Menu - Display Damping 5.10 Page 40

Page 43

MULTI-PARAMETER TRANSMITTER USER’S MANUAL

DOWN

DOWN

DOWN

DOWN

DOWN

The FIRMWARE REV menu allows the user to see what revision of

the firmware is currently installed in the controller. This is a Read

Only menu item.

RUN MODE

UP

NOTE

PRESS THE AND KEYS

TOGETHER TO GO IMMEDIATELY BACK TO

RUN MODE

DOWN

500mV 25.0C

DIAGNOSTICS

SETUP

UTILITIES

CALIBRATION

FIRMWARE REV. FIRMWARE REV.

1.00 >

ORP - Diagnostics Menu - Firmware Rev 5.11

ORP - Diagnostics Menu - Firmware Rev 5.11 Page 41

Page 44

MULTI-PARAMETER TRANSMITTER USER’S MANUAL

DOWN

DOWN

DOWN

DOWN

DOWN

DOWN

DOWN

DOWN

DOWN

UP

NOTE

PRESS THE AND KEYS

TOGETHER TO GO IMMEDIATELY BACK TO

RUN MODE

DOWN

The Calibration Data menu is a series of read only screens which

allow the user to view the data collected during the last calibration.

RUN MODE

If the Temperature Display

Override is ON (Section 5.10),

the display will show

Press to view the first

Calibration Data screen.

1st POINT 600mV

Probe Temperature at which

calibration was performed = 19.4 C

Calibration Mode

1 point calibration

Press to view the next

Calibration Data screen.

CALIBRATION

UTILITIES

DIAGNOSTICS

SETUP

500mV 25.0C

CALIBRATION DATA

TEMP O/R ON

CAL TEMP 19.4C >

CALIBRATION DATA

CALIBRATION DATA

MODE 1PT >

CALIBRATION DATACALIBRATION DATA

FIRMWARE REV.

600mV >

ORP - Diagnostics Menu - Calibration Data 5.12

ORP - Diagnostics Menu - Calibration Data 5.12 Page 42

Page 45

MULTI-PARAMETER TRANSMITTER USER’S MANUAL

DOWN

DOWN

DOWN

DOWN

DOWN

DOWN

DOWN

UP

NOTE

PRESS THE AND KEYS

TOGETHER TO GO IMMEDIATELY BACK TO

RUN MODE

DOWN

The Sensor Input Menu allows the user to view real time, uncompensated

process data from the probe.

This is a Read only menu item.

The top line shows the mV input from the probe

The bottom line shows the actual value of the

temperature sensor in ohms.

Press to view the

Sensor Input data.

CALIBRATION DATA

SETUP

DIAGNOSTICS

SENSOR INPUT

FIRMWARE REV.

500mV 25.0C

UTILITIES

CALIBRATION

TEMP 331Ω >

PROBE 500mV

If the Probe is not equiped with a

Temperature Sensing Device,

and Temperature Display

Override is ON (Section 5.10),

the display will show

PROBE 500mV

TEMP O/R ON

RUN MODE

ORP - Diagnostics Menu - Sensor Input 5.13

ORP - Diagnostics Menu - Sensor Input 5.13 Page 43

Page 46

MULTI-PARAMETER TRANSMITTER USER’S MANUAL

DOWN

DOWN

DOWN

DOWN

DOWN

DOWN

UP

DOWN

DOWN

DOWN

DOWN

DOWN

DOWN

DOWN

DOWN

DOWN

UP DOWN

UP DOWN

DOWN

DOWN

UP DOWN

DOWN

DOWNUP

DOWNUP

DOWN

DOWN

UP

Press the key once

which will move the cursor

back to the RH side of the

display.

Or press the

key to highlight

the Y character

Then press the key to store the

selection and return to the OUTPUT

menu

Not stored

Stored

Press the key to accept the

setting and move to the next setting

UP

NOTE

PRESS THE AND KEYS

TOGETHER TO GO IMMEDIATELY BACK TO

RUN MODE

DOWN

The TUNE fuction allows the user to precisely

adjust the 4-20 ma output to compensate for

any errors in the output circuitry. Normally,

fine tuning the 4-20mA output is not

necessary.

To make the adjustment, place an accurate

current meter in series with the 4-20 mA

output, with the appropriate loads connected.

When the TUNE menu is selected, the

controller puts 20 mA out the terminals. Use

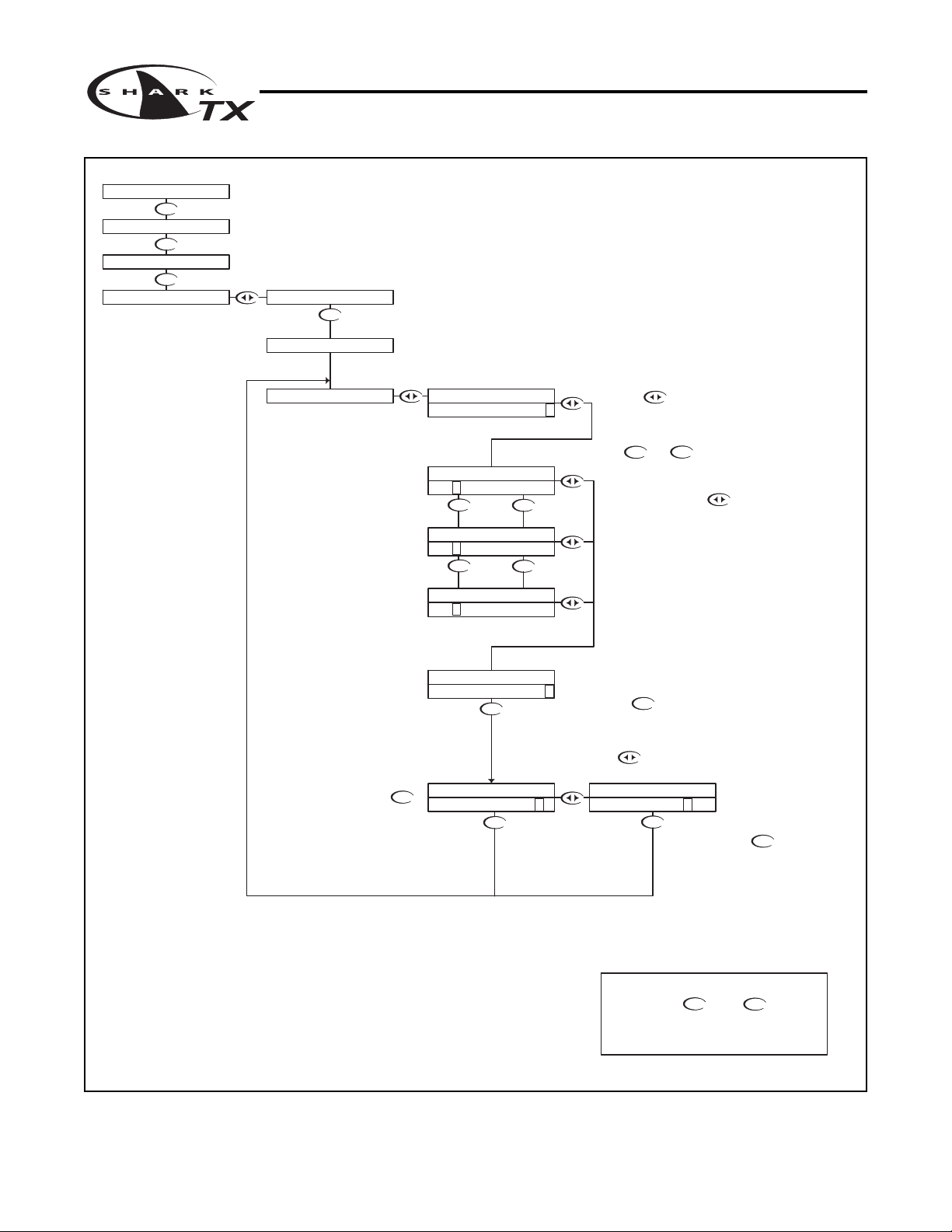

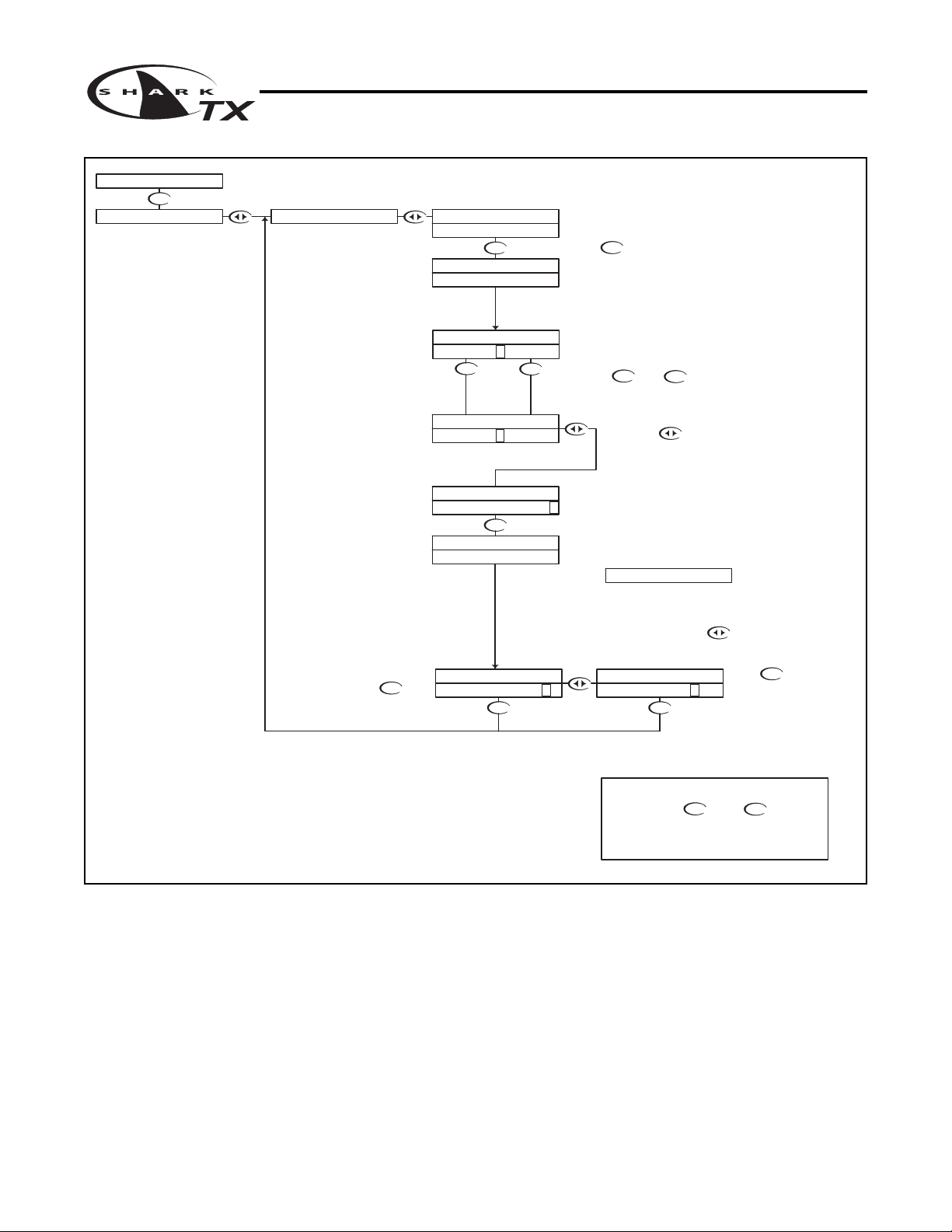

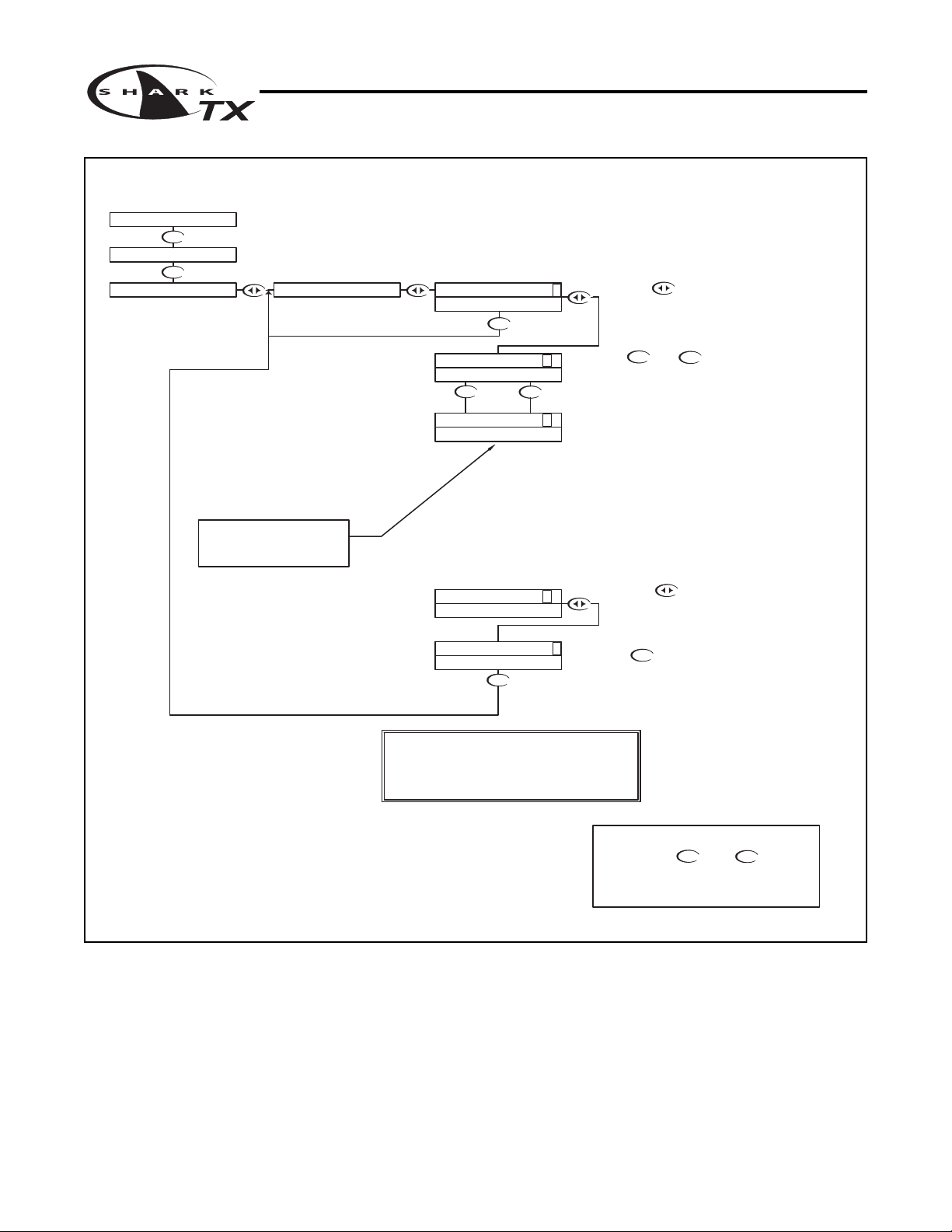

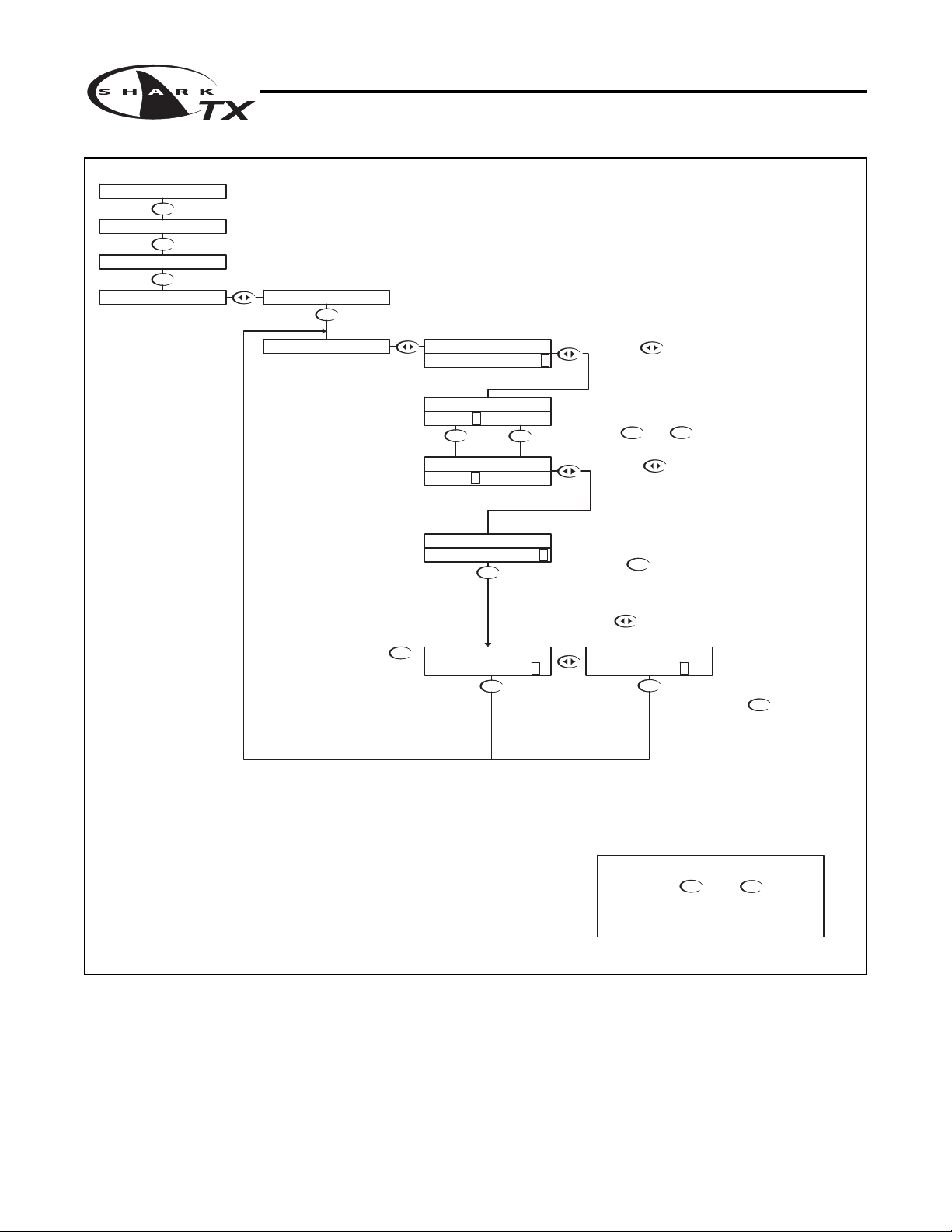

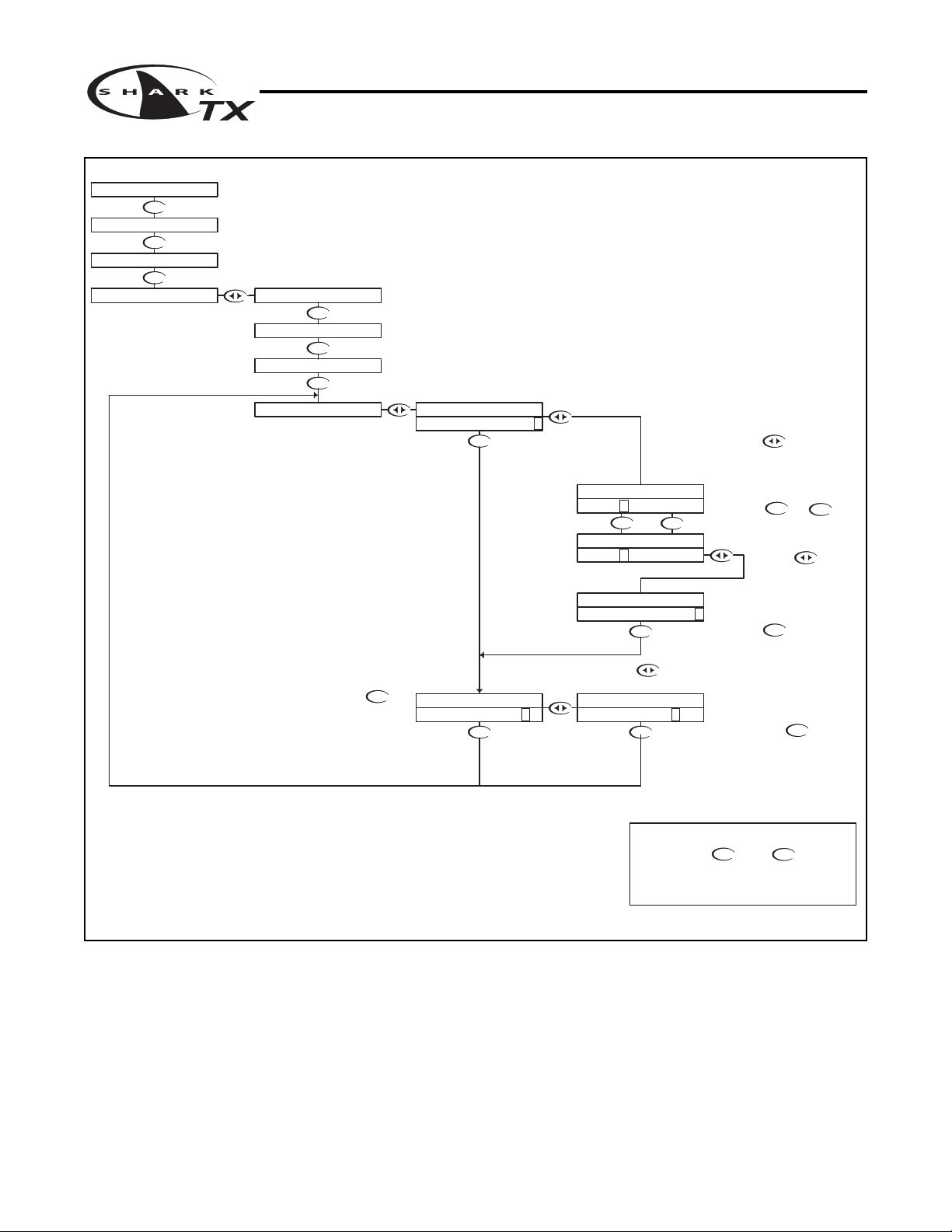

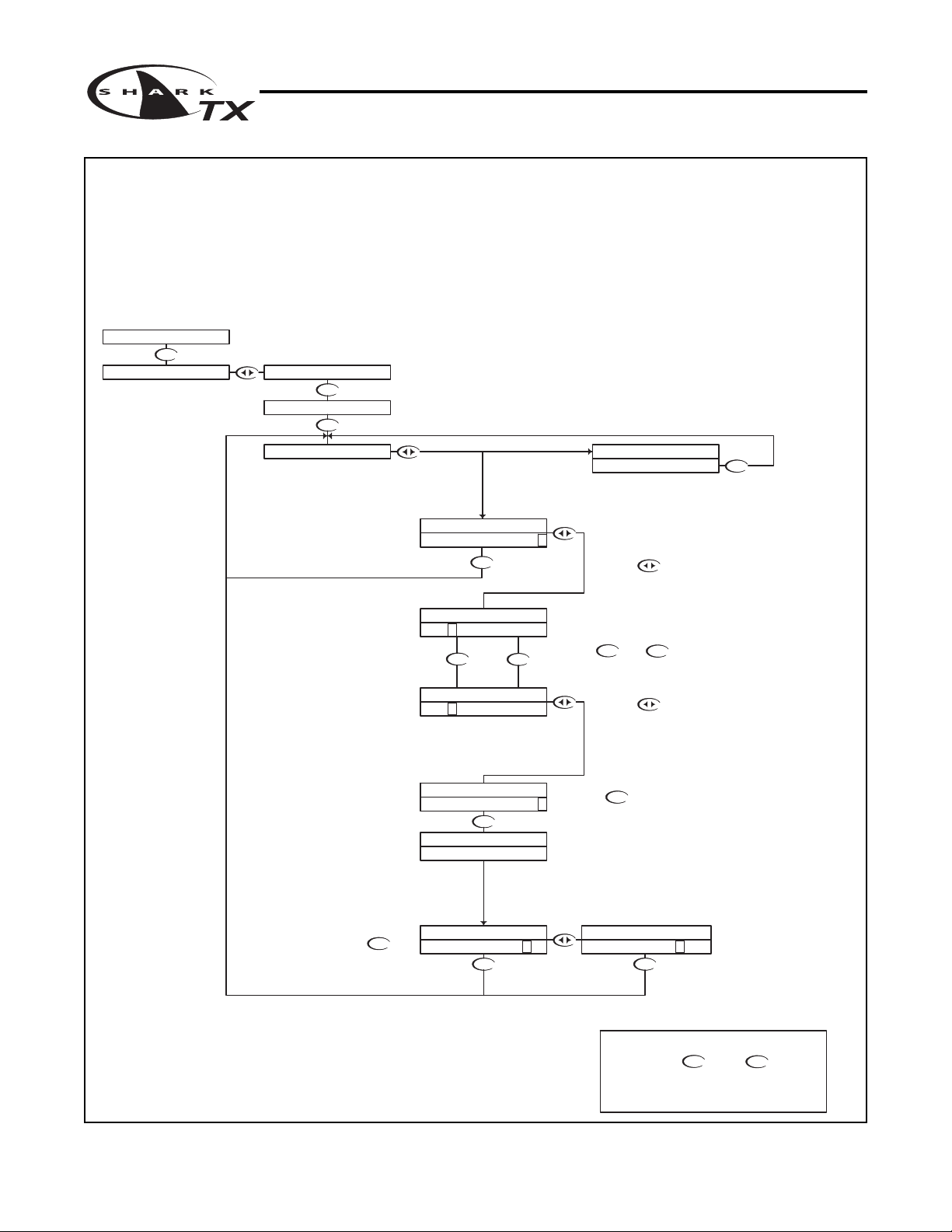

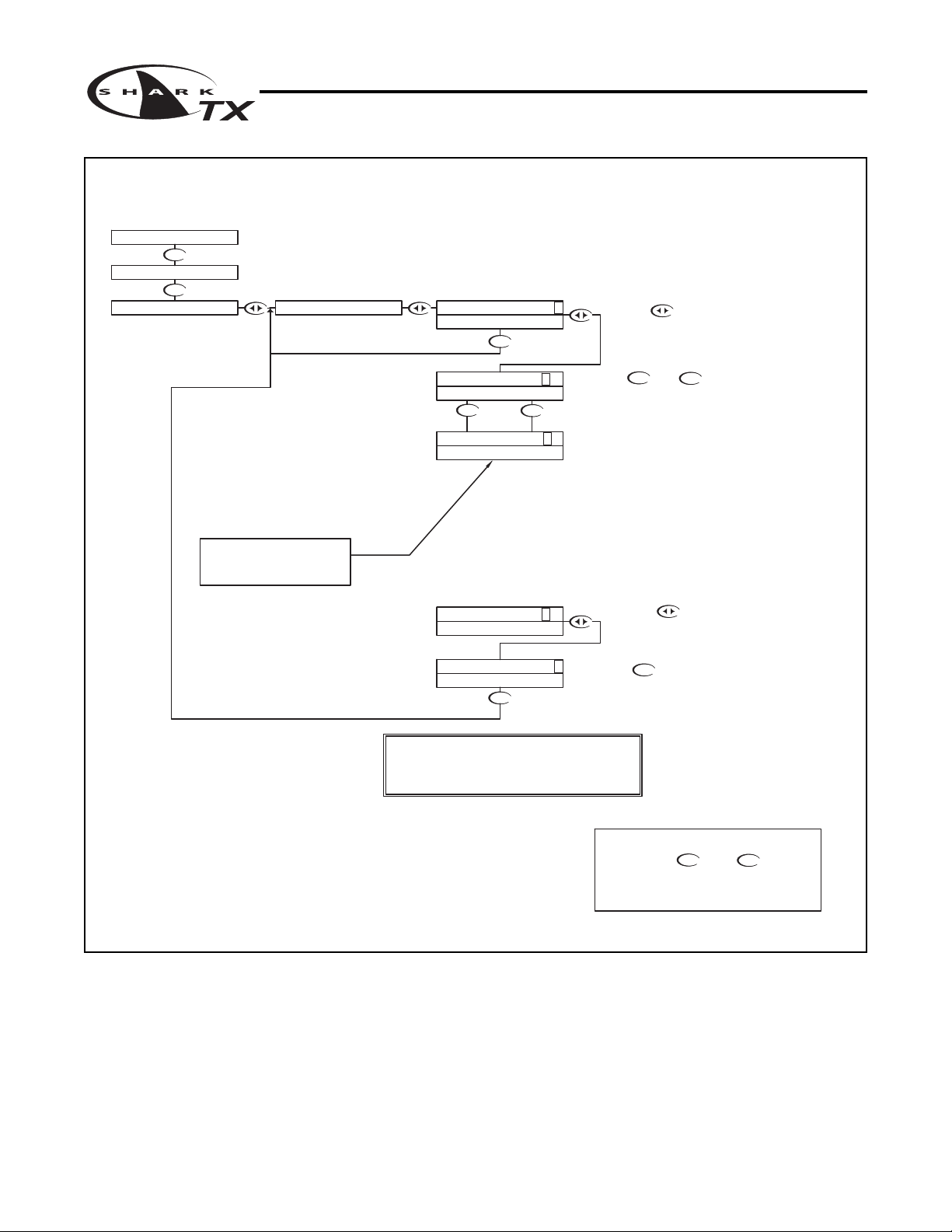

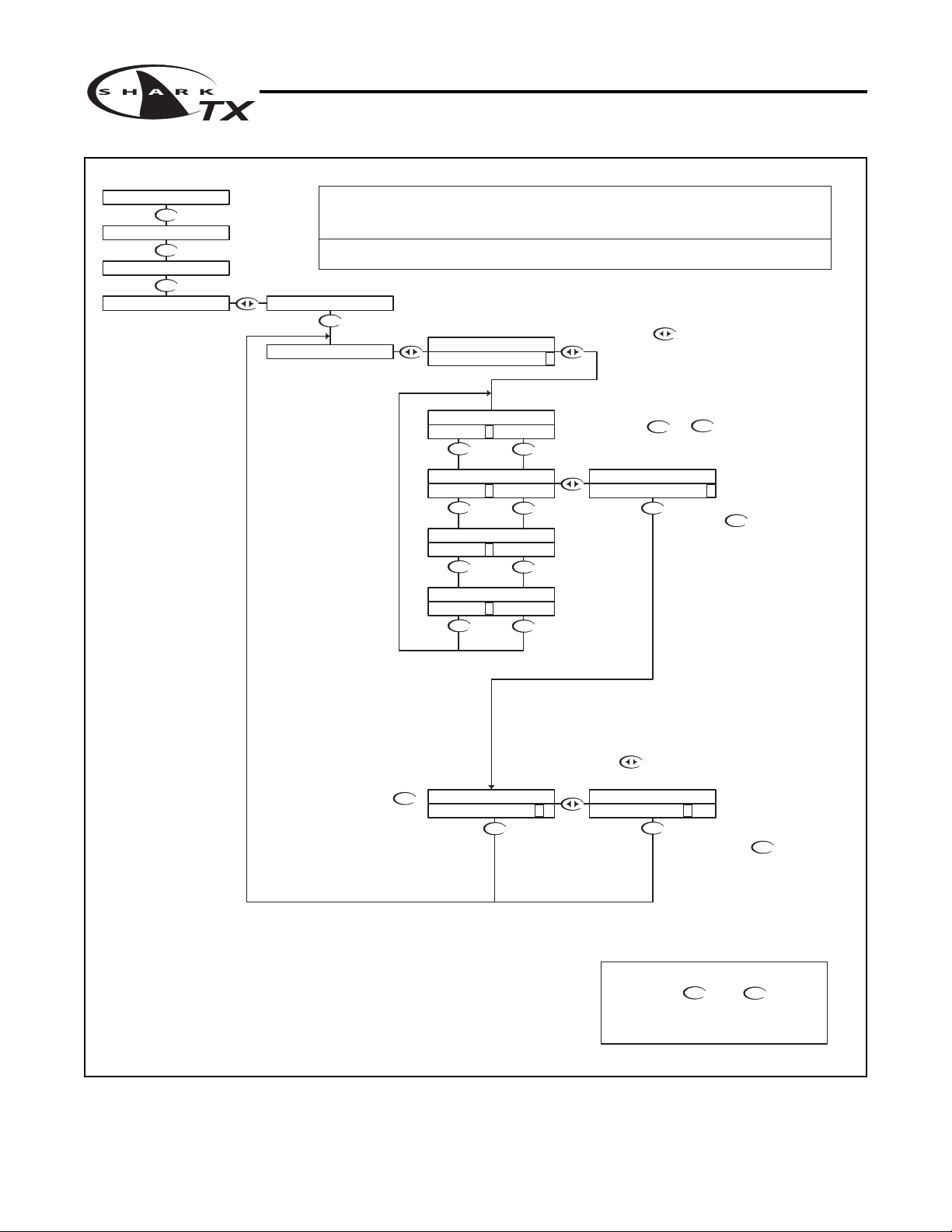

the or keys to adjust the 20mA