Aquametrix SHARK-120, SHARK-240 User Manual

S H A R K

SHARK MULTI-PARAMETER CONTROLLER

& ANALYZER USER’S MANUAL

Rev 3

AquaMetrix Inc. |

Tel: (800) |

742-1413 |

1245 Maple Hill Ct., Unit 7 |

(905) |

954-0841 |

Newmarket, ON |

Fax: (905) |

954-0415 |

Canada, L3Y 9E8 |

www.aquametrix.com |

|

MULTI-PARAMETER CONTROLLER & ANALYZER USER’S MANUAL

S H A R K

Table of Contents

Subject |

Page No. |

|||

Introduction |

|

|

1 |

|

Section 1 - Specifications |

2 |

|

||

Section 2 - Installation |

3 - 5 |

|||

Section 3 - Electrical Connections & Setup |

6 - 14 |

|||

Differential Probe connection & setup |

7 |

|

||

Combination Probe connection & setup |

8 |

|

||

Conductivity Cell (Contacting style) connection & setup |

9 |

|

||

Paddle Wheel Flow Sensor connection & setup |

10 |

|

||

Relay connections |

11 |

|

||

Relay A & B setup |

12 |

|

||

Alarm relay setup |

13 |

|

||

Manual test mode & Relay override |

14 |

|

||

4-20mA Isolated Outputs Channel 1 & Channel 2 |

15 |

|

||

Service & Fuse Replacements |

16 |

|

||

Section 4 - Using the SHARK in pH Mode |

17 |

|

||

LCD Menu |

18 |

- 44 |

||

LED Menu |

45 |

- 46 |

||

Section 5 - Using the SHARK in ORP Mode |

47 |

|

||

LCD Menu |

48 |

- 73 |

||

LED Menu |

74 |

|

||

Section 6 - Using the SHARK in Conductivity Mode |

75 |

|

||

LCD Menu |

76 |

- 102 |

||

LED Menu |

103 |

|||

Section 7 - Using the SHARK in Flow Mode |

104 |

|||

LCD Menu |

105 - 128 |

|||

Appendix A - Probe Configuration Table |

129 |

Return Policy and Warranty Plan |

130 |

MULTI-PARAMETER CONTROLLER & ANALYZER USER’S MANUAL

S H A R K

Introduction

The SHARK multi-parameter controller is a microprocessor based controller capable of measuring one of the following parameters, pH, ORP, conductivity or flow.

When shipped from the factory, the SHARK is not set to measure any one parameter. When the SHARK is powered up for the first time, it will display the meter selection screen where the meter type must be selected. (refer to section 4.6 Meter Selection)

This meter selection screen will only be displayed when the SHARK is powered up for the first time.

After the user selects a meter type the SHARK will remain set to that meter type until it is changed with the meter selection menu function in the Utilities menu.

To return the SHARK to its factory settings, the user must re-select the current meter type from the meter selection menu function. This will override all set-points and return all settings back to the factory settings.

The SHARK User’s menu has been divided into five main categories

-Calibration, used to calibrate the SHARK with the selected sensor

-Utilities, Used to manually control or override the outputs.

-Setup, used to configure the SHARKs many options

-Diagnostics, used to troubleshoot any problems with the SHARK

-Outputs, used to configure the SHARK’s outputs.

There are two displays on the SHARK. A bright LED numeric display with bar graph on the outside front panel, and a 2-line, 16-character LCD display on the inside. The LED readout on the outside panel can be seen several yards away. The distinctive,colorcoded bar graph will immediately indicate if you are within the process parameters that you set (green), if the control relays are on (yellow) and if you are in alarm condition (red). This makes diagnosing pump and alarm malfunctions easy. All configuration and control functions are performed on the LCD menu on the inside front panel.

A universal mounting kit is included for surface,panel and pipe-mount applications. The 1/4 DIN enclosure makes panel-mount cutouts and engineering simple.

SHARK is packaged in a rugged NEMA 4X polycarbonate enclosure making it ideally suited for heavy-duty applications such as industrial wastewater neutralization, municipal water and wastewater, pulp and paper, and process control.

Introduction |

Page 1 |

MULTI-PARAMETER CONTROLLER & ANALYZER USER’S MANUAL

S H A R K

Section I - Specifications

|

|

pH |

ORP |

|

|

Conductivity |

|

|

Flow |

||

Display |

Front Panel: 4 x 7 segment 1/2”LED display, 1 LED indicator 0n-line,7 LED Bar Graph |

|

|

|

|||||||

Inside Panel: 2 x 16 alpha-numeric LCD display |

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

||||

Power Requirements |

120Vac (±10%) 50/60Hz (less than 12VA) or 240Vac (±10%) 50/60Hz (less than 12VA) |

|

|||||||||

|

|

|

|

|

|

MΩ/cm3 |

0 to 19.99 |

|

0.01 |

|

Flow: 0 to 9999 with selectable |

|

|

|

|

|

|

|

|

flow rate units |

|||

|

|

|

|

|

|

|

0 to 2.000 |

|

0.01 |

|

|

|

|

|

|

|

|

|

|

|

Volume: 0 to 9999 with Auto Range |

||

Measuring Range |

pH: |

0.01 to 14.00 |

ORP: -1999 to +1999mV |

|

|

uS/cm3 |

0 to 20.00 |

|

0.1 |

|

Flow rate units:Gallons (GP),Cubic |

|

|

|

(Dependent on sensor) |

|

|

|

|

|

|

||

|

|

|

|

|

0 to 200.0 |

|

0.1 |

|

|||

|

|

|

|

|

|

|

|

||||

|

Temp: |

0 to 100°C or |

Temp: 0 to 100°C or |

|

|

|

|

|

Feet (CF),Liters (LP),Cubic Meters |

||

|

|

|

|

|

|

|

|

||||

|

|

|

0 to 2000 |

|

1.0 |

|

|||||

|

|

32° to +212°F |

32° to +212°F |

|

|

|

|

|

(CM),custom by entering factor |

||

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

mS/cm3 |

0 to 20.00 |

|

10 |

|

related to Gallons |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

0 to 200.0 |

|

50 |

|

Time units:Seconds (S), |

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Temp: 0 to 100°C or 32° to +212°F |

Minutes (M),Hours (H) |

|||||

|

|

|

|

|

Automatic or Manual |

|

|

|

|||

Temperature |

Automatic or Manual |

Not required |

|

User selectable temperature |

Not required |

||||||

Compensation |

0 to 100°C (32° to +212°F) |

|

compensation slope 0.0 to 10.0%/°C. |

||||||||

|

|

|

|

|

0 to 100°C (32° to +212°F) |

|

|||||

Temperature Unit |

°C or °F |

|

|

|

|

|

|

|

|

|

Not required |

Temperature Sensor |

User selectable: 300Ω NTC Thermistor, 3000Ω NTC Thermistor or Pt. 1000 RTD |

|

|

Not required |

|||||||

Calibration Modes |

Auto-Calibration |

Manual Calibration |

|

|

Dry Calibration |

|

|

|

|||

Manual Calibration |

|

|

Sample Calibration |

|

|

K factor Input |

|||||

Temperature Calibration |

|

|

|

|

|||||||

|

Temperature Calibration |

|

|

Temperature Calibration |

|

||||||

|

|

|

|

|

|||||||

Ambient Conditions |

Temperature: -20°C to +60°C or -4°F to +140°F Humidity: 0 to 90% RH (non-condensing) |

|

|||||||||

Menu Access |

Auto-Calibration, Manual |

Manual-Calibration, |

|

|

Manual Calibration |

|

|

|

|||

Calibration,Temperature |

|

|

|

|

Not available |

||||||

Front Panel |

Temperature Display |

|

|

Temperature Display |

|

|

|||||

Display |

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

Menu Access Inside Panel |

Full Access to all parameters of operations menu |

|

|

|

|

|

|

|

|||

Sensor to SHARK |

Differential Sensor: 3000 ft |

|

|

|

300 ft |

|

|

2000 ft |

|||

Distance |

Combination Sensor: 10 ft |

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|||

|

Two Control Relays, 10A / NO, 5A / NC @ 240VAC or 28VDC. |

|

|

|

|||||||

|

Mode: Process control, Adjustable parameters: process direction,(rising or falling) on-set-point, off set-point, |

||||||||||

Relay Outputs |

(0 to 100% of full scale), cycle timer (on / off, 0 to 600 seconds), failsafe (on / off). |

|

|

|

|||||||

One Alarm Relay, 10A / NO, 5A / NC @ 240VAC or 28VDC. |

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

||||

|

Mode: High / Low Alarm, Adjustable parameters: Low on / Low off set-point (0 to 100% of full scale, low on must be less than |

||||||||||

|

low off), High On / High Off set-point (0 to 100% of full scale, High on must be greater than High off). |

||||||||||

|

4 to 20mA Channel 1 |

|

|

|

|

|

|

|

|

|

|

Analog Outputs |

Isolated Output, Range expand 0 - 100% of full scale (min segment 10% of full scale), max. load 800Ω |

||||||||||

4 to 20mA Channel 2 |

|

|

|

|

|

|

|

|

|

||

|

Isolated Output, Range expand 0 - 100% of full scale (min segment 10% of full scale), max. load 800Ω |

||||||||||

|

Can be set to track temperature if sensor is equipped with a temperature sensor |

|

|

|

|||||||

Memory Back-up |

All user settings are retained indefinitely in memory (EEPROM) |

|

|

|

|||||||

Mechanical |

Enclosure: NEMA 4X, 1/4 DIN, polycarbonate enclosure with four 1/2”conduit holes |

|

|

|

|||||||

Mounting: Universal Mounting kit for surface, pipe and panel mount, is included |

|

|

|

||||||||

|

|

|

|

||||||||

Sensor Input |

Probe: -600 to +600mV |

Probe: -1999 to +1999mV |

|

|

Cell: 0 to 9999Ω |

|

|

Paddle: 0 to 2000Hz |

|||

Temp. Sensor: 0 to 9999Ω |

Temp. Sensor: 0 to 9999Ω |

|

|

Temp. Sensor: 0 to 9999Ω |

|||||||

|

|

|

|

||||||||

Invalid Entries |

Invalid entries cannot be stored |

|

|

|

|

|

|

|

|||

Manual Test Mode |

Process value can be simulated with arrow keys to verify correct setup of outputs |

|

|

|

|||||||

Manual Relay Override |

Relays can be set to on / off / auto, to verify correct wiring of auxiliary devices, or to manually adjust process |

||||||||||

Output Hold |

All outputs are placed on hold when SHARK is in Menu mode |

|

|

|

|||||||

|

Recall data from last calibration, calibration mode, |

|

|

Recall data from last |

|

|

|

||||

|

|

|

calibration, calibration buffer |

|

|||||||

|

1st & 2nd accepted buffer value and probe mV output, |

|

|

|

|||||||

Calibration Data |

|

|

accepted value, and cell |

Recall store K factor. |

|||||||

calibration temperature, calibration slope, and probe |

|

|

|||||||||

|

|

|

resistance, calibration |

|

|

|

|||||

|

efficiency |

|

|

|

|

|

|

||||

|

|

|

|

temperature |

|

|

|

||||

|

|

|

|

|

|

|

|

|

|||

Auto Return |

User selectable auto return if SHARK is left in menu mode or if relays are left in manual override mode for more than 10 min. |

||||||||||

Display Damping |

User can select rate at which SHARK updates display. Enables display damping of unstable process |

||||||||||

Net Weight |

2.2lbs (1kg) |

|

|

|

|

|

|

|

|

|

|

Approvals |

ULC (pending) |

|

|

|

|

|

|

|

|

|

|

Section I - Specifications |

Page 2 |

MULTI-PARAMETER CONTROLLER & ANALYZER USER’S MANUAL

S H A R K

Section 2 - Installation

2.1 Unpacking

Save the shipping carton and packing material in case the instrument needs to be stored or returned. Inspect the instrument and packing material for shipping damage and report any problems immediately.

2.2 Location

Locate the controller/analyzer close to the sensor. The list below gives typical maximum distances for various sensors. Refer to the sensor specifications for exact information.

• Aquametrix Differential PH Probe |

3000 ft (914 meters) |

• Aquametrix Combination PH Probe |

10 ft (3 meters) |

• Aquametrix Conductivity Probe |

300 ft (91 meters) |

• Aquametrix Flow sensor |

2000 ft (610 meters) |

2.3 Mounting

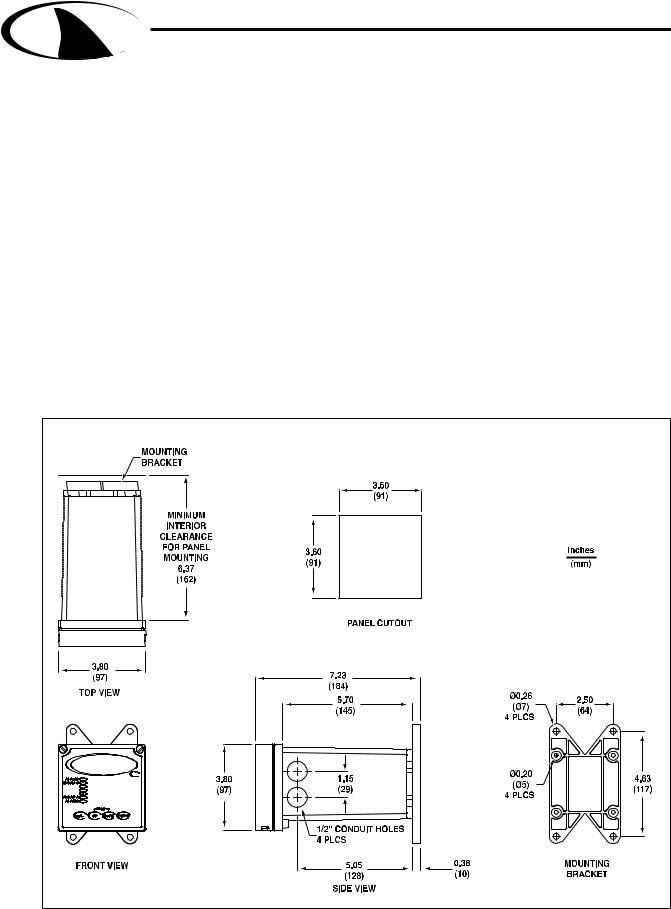

Fig 2.1 Controller dimensions |

Dwg# N106-127 |

Section 2 - Installation |

Page 3 |

MULTI-PARAMETER CONTROLLER & ANALYZER USER’S MANUAL

S H A R K

Section 2 - Installation

Panel Mount – The Shark can be |

Figure 2.2 Panel Mount |

|

panel mounted to a panel using the |

EXTERNAL PANEL |

|

hardware kit provided. The panel |

||

GASKET QTY.1 |

||

cutout dimensions are shown in fig. |

PANEL |

|

(CUSTOMER SUPPLIED) |

||

2.1. |

||

UNIVERSAL MOUNTING |

||

|

BRACKET |

|

|

QTY.1 |

|

|

|

SCREW |

|

|

|

10-24 X 1/2" |

|

|

|

QTY.4 |

|

|

|

SCREW |

|

|

|

1/4-20 X 6" |

|

|

UNIVERSAL |

QTY.4 |

|

|

MOUNTING |

|

|

|

CLAMP QTY.2 |

|

|

|

|

NUT |

|

|

|

1/4-20 |

|

|

|

QTY.4 |

|

|

Dwg# N105-100 |

|

Pipe Mount – The Shark |

Fig. 2.3 |

Vertical Pipe Mount |

|

can also be mounted to a |

|

|

|

horizontal or vertical pipe |

|

|

MIN. PIPE DIA. |

with: |

|

|

1" PIPE (NOMINAL) |

|

|

MAX. PIPE DIA. |

|

|

|

|

2" PIPE (NOMINAL) |

• a minimum outside |

|

|

|

diameter of 1.30” (33mm) |

|

|

|

(for example 1” CPVC |

|

|

UNIVERSAL MOUNTING |

|

|

BRACKET |

|

pipe) |

|

|

QTY.1 |

|

|

|

|

• and a maximum of |

|

|

|

2.375” (60mm) (for |

|

|

|

example 2” CPVC pipe) |

|

|

NUT |

|

|

|

|

|

|

|

10-24 |

|

|

|

QTY.4 |

|

|

|

SCREW |

|

|

|

10-24 X 3-1/2" |

|

|

|

QTY.4 |

|

Dwg# N105-100 |

|

|

Section 2 - Installation |

Page 4 |

MULTI-PARAMETER CONTROLLER & ANALYZER USER’S MANUAL

S H A R K

Section 2 - Installation

Figure 2.4 Horizontal Pipe Mount

MIN. PIPE DIA. 1" PIPE (NOMINAL) MAX. PIPE DIA. 2" PIPE (NOMINAL)

|

|

NUT |

|

|

10-24 |

|

|

QTY.4 |

|

|

SCREW |

|

|

10-24 X 3-1/2" |

|

|

QTY.4 |

|

|

UNIVERSAL MOUNTING |

|

|

BRACKET |

|

|

QTY.1 |

Dwg# N105-100 |

|

|

Surface Mount – The Shark can be |

Figure 2.5 |

Surface Mount |

surface mounted using the hardware |

|

|

kit provided with the unit. |

|

|

|

|

UNIVERSAL MOUNTING |

|

|

BRACKET |

|

|

QTY.1 |

|

|

SCREW |

|

|

10-24 X 1/2" |

|

|

QTY.4 |

|

|

HOLES Ø1/4" |

|

|

FOR MOUNTING SCREWS |

|

|

QTY.4 |

|

|

(CUSTOMER SUPPLIED) |

|

Dwg# N105-100 |

|

Section 2 - Installation |

Page 5 |

MULTI-PARAMETER CONTROLLER & ANALYZER USER’S MANUAL

S H A R K

Section 3 - Electrical Connections and Setup

3.1 Conduit Connections

The Shark has four 1/2” conduit holes, 2 on each side of the enclosure as shown on fig. 2.1. The unit is shipped with these holes plugged with liquid tight conduit seals. These must be left in unused holes to maintain the NEMA 4X integrity. Use approved conduit hubs to connect the conduit, connect these to the conduit before connecting to the enclosure.

Wire Specification: Size and fuse wire accroding to local electrical code. Maximum current not to exceed 10A when used to power auxillary decvices powered via internal connections.

3.2 A.C. Power Connections

Caution: This instrument uses 120 or 240 50/60 Hz AC power. Opening the enclosure door exposes you to potentially hazardous line power voltage which might be present on the terminals of plug P3 and P4. Always remove line power before working in this area. If the relay contacts on P4 are powered from a seperate source from the line power on P3, be sure to disconnect that power before proceeding. The Shark flip out door contains only low voltage and is safe to handle.

The Shark is available in two power models.

The Shark-240 is designed to operate at 240 VAC. The Shark-120 is designed to operate at 120 VAC.

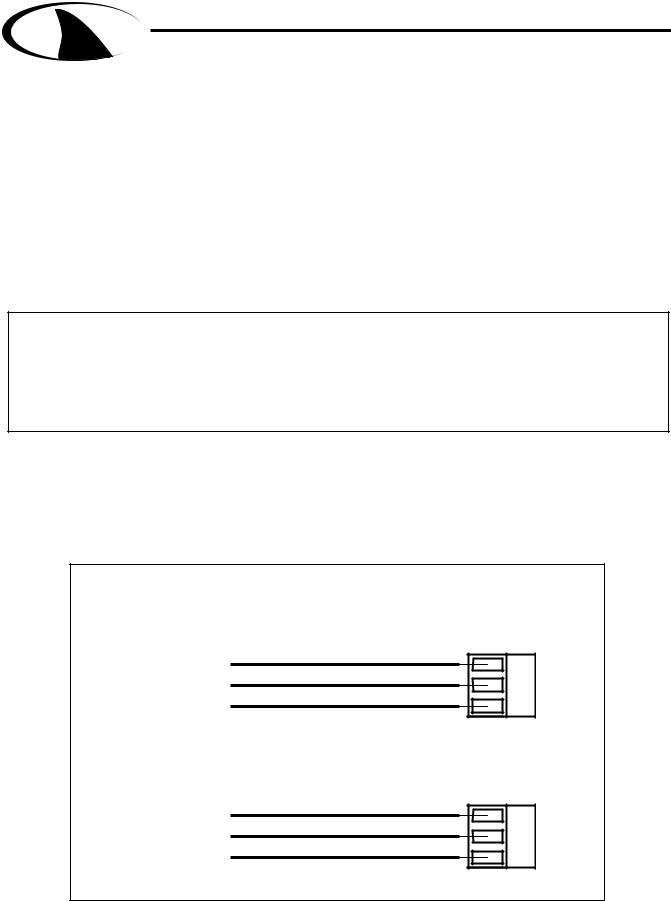

To connect power to the Shark, remove the terminal block plug P3 and connect the wiring as shown below.

Figure 3.1 A.C. Power Connections

AC POWER CONNECTIONS FOR 120 VAC

SHARK-120

NEUTRAL LINE GROUND

G L N

AC POWER CONNECTIONS FOR 240 VAC SHARK-240

LINE

LINE

GROUND

P3

G L L

P3

Dwg# N104-33

Section 3 - Electrical Connections and Setup |

Page 6 |

MULTI-PARAMETER CONTROLLER & ANALYZER USER’S MANUAL

S H A R K

Section 3 - Electrical Connections and Setup

3.3 pH and ORP Differential Probe connections and setup

The drawing shows the connections for the Aquametrix Differential (5 wire) probe. The cable should be run in a conduit separate from AC power wires, and via a separate conduit hole.

Note: Leave 4” to 6” slack for all wires connected to the terminals of P6. Slack required so that wires do not interfere with opening or closing of the front door.

If the cable of the differential probe is cut, the blue

wire is not used.

CAUTION:

Always remove line power before unplugging or plugging in the P6 connector

Figure 3.2 Connections for Differential (5 wire) pH or ORP probe |

|||||||||||||

|

|

GREEN (2) |

|

|

|

|

|

|

|

||||

|

|

|

|

RED (3) |

|

|

|

|

|

|

|

||

|

|

|

|

|

BLACK (4) |

|

|

|

|

|

|||

|

|

|

|

|

|

YELLOW (5) |

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

WHITE (10) |

|

||

|

|

|

|

|

|

|

|

|

|

|

SHIELD (8) |

|

|

P6 |

1 |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

9 |

10 |

11 12 |

13 14 15 16 |

17 |

|

|

|

|

|

|

|

|

|

|

|

|

|

DIFFERENTIAL |

Dwg# N104-34 |

|

|

|

|

|

|

|

|

|

|

|

|

pH or ORP PROBE |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Once connected, step through the LCD menus to select the probe in the order shown. The first two steps may be skipped if the meter is already configured for pH or ORP and a Differential Probe.

When using a pH probe, it is important to ensure that the Shark is reading the probe temperature correctly for accurate temperature compensation. The ORP probe does not require temperature compensation, although the Shark can display process temperature measured by the probe. The factory temperature calibration is usually accurate enough that no adjustments are necessary.

METER SELECTION

PROBE SELECT

MANUAL CAL PH

7.15pH 25.0C

SELECT pH SEC. 4.6 or ORP SEC. 5.5

(IF NECESSARY)

SELECT DIFFERENTIAL PROBE pH SEC. 4.7 or ORP SEC. 5.6 (IF NECESSARY)

MANUAL CALIBRATE pH PROBE SEC. 4.1

or ORP PROBE SEC. 5.1

RUN MODE

Section 3 - Electrical Connections and Setup |

Page 7 |

MULTI-PARAMETER CONTROLLER & ANALYZER USER’S MANUAL

S H A R K

Section 3 - Electrical Connections and Setup

3.4 pH or ORP Combination Probe connections and setup

The drawing shows the connections for the Aquametrix Combination probe. The cable should be run in a conduit separate from AC power wires, and via a separate conduit hole. The cable length should not exceed 10 feet (3 meters).

The 2 wire version has no |

Fig. 3.3 Connections for the 2 and 4 wire Combination Probe |

|

||||||||

|

|

|

|

|

||||||

temperature |

sensor |

and is |

|

|

|

GREEN (4) |

|

|||

connected via a coaxial wire. |

|

|

|

WHITE (5) |

|

|||||

COAX CENTER (3) |

|

|

|

|

||||||

In a pH meter, |

the |

user |

|

|

|

These wires are only |

||||

should |

set |

the |

T |

COMP |

COAX SHIELD (4) |

|

|

JUMPER 2-4 MUST BE |

present with 4-wire |

|

|

|

combination probe. |

||||||||

|

|

|

|

|

|

|

|

|

|

|

OVERRIDE |

menu |

to |

ON |

|

|

|

INSTALLED FOR |

|

||

|

|

|

COMBINATION PROBE |

|

||||||

(Section 4.11) and adjust the |

|

|

|

|

||||||

|

|

|

(CUSTOMER SUPPLIED) |

|

||||||

temperature |

setting |

to |

the |

|

|

|

|

|

||

actual probe temperature. |

|

|

|

|

|

|||||

In an ORP meter, the user |

|

|

|

|

|

|||||

should set the T.DISP OVER- |

|

|

|

|

|

|||||

RIDE to ON (Section 5.10) to |

P6 1 |

2 3 |

4 5 6 7 8 |

9 10 11 12 13 14 15 16 17 |

|

|||||

blank the temperature reading |

|

|

|

|

|

|||||

on the display. |

|

|

|

|

|

|

|

|

||

The 4 wire version has two |

|

|

|

|

|

|||||

additional wires for the probe |

|

|

|

|

|

|||||

internal |

temperature |

sensor. |

|

|

|

|

|

|||

Ensure that the T COMP |

|

|

|

|

|

|||||

OVERRIDE |

or |

T.DISP |

|

|

|

|

|

|||

OVERRIDE is OFF. |

|

|

|

|

|

|

|

|||

Note: Leave 4” to 6” slack for |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

all wires connected to the ter- |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

minals of P6. Slack required |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

COMBINATION |

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||

so wires do not interfere with |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

pH or ORP PROBE |

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

opening/closing of front door. |

Dwg# N104-35 |

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||

|

|

|

|

|

|

|

Once connected, step throught the LCD menus to select the probe in the order |

|||||||||||||||||||

|

|

CAUTION: |

|

|

|

|||||||||||||||||||||

|

|

|

|

|

shown. The first two steps may be skipped if the meter is already configured for |

|||||||||||||||||||||

|

|

Always remove line |

|

|||||||||||||||||||||||

|

|

|

a Combination Probe. If a two wire pH probe is used, which has no temperature |

|||||||||||||||||||||||

|

|

power before unplugging |

|

|||||||||||||||||||||||

|

|

|

sensor, ensure that the Temp. Comp. Override is set to same temperature as |

|||||||||||||||||||||||

|

|

or plugging in the P6 |

|

|||||||||||||||||||||||

|

|

|

the buffer before calibrating. If a two wire ORP probe is used, you can blank the |

|||||||||||||||||||||||

|

|

connector |

|

|

|

|||||||||||||||||||||

|

|

|

|

|

Temp display with the T DISP OVERRIDE menu. |

|

|

|

|

|

||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

pH |

|

|

|

|

|

|

|

|

|

|

|

ORP |

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

SELECT PH METER |

|

|

|

|

|

|

|

|

|

|

|

SELECT ORP METER |

|

|

|

|

|

||||

|

METER SELECTION |

|

|

|

|

|

|

|

|

|

METER SELECTION |

|

|

|

|

|

|

|||||||||

|

|

SEC. 4.6 |

|

|

|

|

|

|

|

|

|

SEC. 5.5 |

|

|

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

SELECT COMBINATION PROBE |

|

|

|

|

SELECT COMBINATION PROBE |

||||||||||||||||

|

PROBE SELECT |

|

|

PROBE SELECT |

|

|||||||||||||||||||||

|

|

SEC. 4.7 |

|

|

|

|

|

|

|

|

|

SEC. 5.8 |

|

|

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

TWO WIRE PROBE WITH NO TEMP SENSOR |

|

|

|

TWO WIRE PROBE WITH NO TEMP SENSOR |

||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||

|

|

|

|

|

MANUAL CALIBRATE |

|

|

|

|

|

|

|

|

|

|

|

MANUAL CALIBRATE |

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

MANUAL CAL PH |

|

|

T.COMP OVERRIDE |

|

MANUAL CAL PH |

|

T.DISP OVERRIDE |

|

|||||||||||||||||

|

|

|

|

|

PH PROBE |

|

|

|

|

|

|

|

|

|

|

|

ORP PROBE |

|

|

|

|

|

||||

|

|

|

|

|

SEC. 4.1 |

|

|

MANUAL PROBE |

|

|

|

|

SEC. 5.1 |

DISABLE TEMPERATURE |

||||||||||||

|

|

|

|

|

|

|

TEMPERATURE SETUP |

|

|

|

|

DISPLAY |

||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||

|

|

7.15pH 25.0C |

|

RUN MODE |

|

|

SEC 4.10 |

|

7.15pH 25.0C |

|

RUN MODE |

SEC 5.10 |

||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Section 3 - Electrical Connections and Setup |

Page 8 |

MULTI-PARAMETER CONTROLLER & ANALYZER USER’S MANUAL

S H A R K

Section 3 - Electrical Connections and Setup

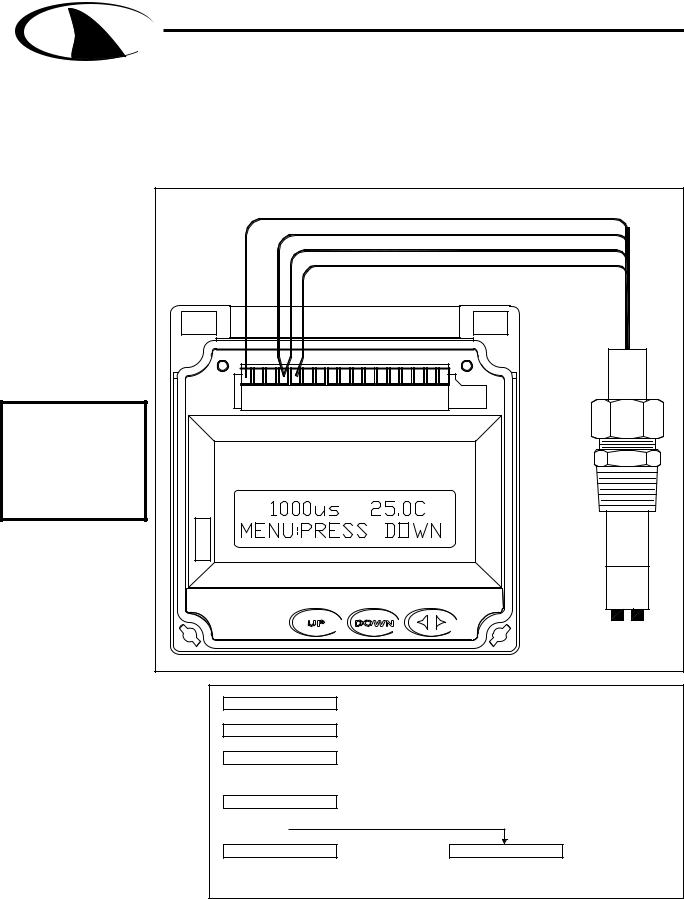

3.5 Conductivity Cell (Contacting style) connections and setup

The drawing shows the connections for the Aquametrix Conductivity Cells (Contacting style). The cable should be run in a conduit seperate from the AC power wires, and via a seperate conduit hole. The cell cable length should not exceed 300ft. (91 meters).

Note: Leave 4” to 6” slack for all wires connected to the terminals of P6. Slack required so that wires do not interfere with opening or closing of the front door.

CAUTION:

Always remove line power before unplugging or plugging in the P6 connector

Figure 3.4 Connections for Conductivity Cells |

|

|

|||||||||||

|

|

|

|

WHITE (CELL) (1) |

|

|

|

|

|||||

|

|

|

|

|

|

BLACK (CELL) (4) |

|

|

|||||

|

|

|

|

|

|

|

|

|

RED (TEMP. SENSOR) (4) |

|

|||

|

|

|

|

|

|

|

|

|

|

GREEN (TEMP. SENSOR) (5) |

|||

P6 |

1 |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

9 |

10 |

11 12 |

13 14 15 16 |

17 |

|

|

|

|

|

|

|

|

|

|

|

|

|

CONTACTING |

|

|

|

|

|

|

|

|

|

|

|

|

|

CONDUCTIVITY |

Dwg# N104-36 |

|

|

|

|

|

|

|

|

|

|

|

|

CELL |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Once connnected, step through the LCD menus to select the cell in the order shown. The TEMP COMP CURVE setup default is 1.8%/deg C. This is acceptable for most process applications. If your process is significantly different from this, change the setting in the TEMP COMP CURVE menu.

METER SELECTION

COND RANGE

TEMP SENSOR

TEMP COMP CURVE

OR

SELECT COND METER

SEC. 6.6

SELECT CONDUCTIVITY RANGE SEC. 6.7

ENSURE SENSOR IS CORRECT TYPE

3Kohm NTC (thermistor)

1Kohm RTD

SEC 6.9

SET TEMPERATURE COMPENSATION FOR PROCESS

SEC. 6.13

CALIBRATE WITH

MANUAL CAL COND REFERENCE SOLUTIONS DRY CAL COND

SEC 6.1

1000uS |

25.0C |

RUN MODE |

CALIBRATE WITH FACTORY SPECIFIED CELL CONSTANT SEC 6.2

Section 3 - Electrical Connections and Setup |

Page 9 |

MULTI-PARAMETER CONTROLLER & ANALYZER USER’S MANUAL

S H A R K

Section 3 - Electrical Connections and Setup

3.6 Paddle Wheel Flow Sensor connections and setup

The drawing shows the connnections for a typical paddle wheel flow sensor. The cable to the sensor should not exceed 2000’ (600 meters).

The Shark controller also supports the use of an external “flow switch”. When the flow switch input is grounded, either through a dry contact or solid state input, the flow display will be held at zero. This is useful to ensure the flow reading remains locked at zero when conditions require it. The flow will start reading again when the input is opened. If the flow switch function is not desired, simply leave it disconnected and the flow meter will read as normal.

Figure 3.5 Connections for Flow Sensor |

SHIELD |

|

|

|

|

|

|

|

|

+12V (6) |

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

SIGNAL + (14) |

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

SIGNAL - (GND) (15) |

|

||||

|

|

|

|

(FLOW SWITCH INPUT) (13) |

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

GND (15) |

|

|

|

9ma |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

+12V O.C. |

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

DRY |

|

|

OR |

|

OPEN |

|

|

|

|

|||

P6 1 |

2 3 |

4 5 6 7 8 9 10 11 12 13 14 15 16 |

17 |

|

|

CONTACT |

|

|

|

COLLECTOR |

|

|

|

|||||

CLOSING THE FLOW SWITCH INPUT |

|

|

FLOW SENSOR |

|||||||||||||||

|

|

|

|

TO GROUND WILL ZERO THE FLOW DISPLAY |

EXTERNAL POWERED |

|||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

SHIELD |

SIGNAL + (14) |

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

SIGNAL - (15) |

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

SHIELD (15) |

||

|

|

|

|

1 |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

9 |

10 |

11 12 |

13 14 15 16 |

17 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

FLOW SENSOR |

Dwg# N104-37 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

SELF POWERED |

Note: Leave 4” to 6” slack for all wires connected to the terminals of P6. Slack required so that wires do not interfere with opening or closing of the front door.

CAUTION:

Always remove line power before unplugging or plugging in the P6 connector

Once connected, step through the LCD menus to select the sensor in the order shown. The Sensor K factor (pulses per U.S. Gallon) is usually printed on the side of the sensor or on a label attached to the sensor cable.

METER SELECTION |

SELECT FLOW METER |

|

SEC. 7.4 |

||

|

||

|

ENTER FLOW SENSOR |

|

K FACTOR |

||

CALIBRATION FACTOR |

||

|

||

|

SEC. 7.1 |

|

|

SETUP OF UNITS |

|

UNITS OF VOLUME |

||

OF VOLUME |

||

|

||

|

SEC 7.5 |

|

|

SETUP OF UNITS |

|

UNITS OF TIME |

||

OF TIME |

||

|

||

|

SEC. 7.6 |

|

|

RESET TOTALIZER |

|

TOTALIZER RESET |

||

TO ZERO |

||

|

SEC 7.0 |

TOTAL |

0 |

RUN MODE |

Section 3 - Electrical Connections and Setup |

Page 10 |

MULTI-PARAMETER CONTROLLER & ANALYZER USER’S MANUAL

S H A R K

Section 3 - Electrical Connections and Setup

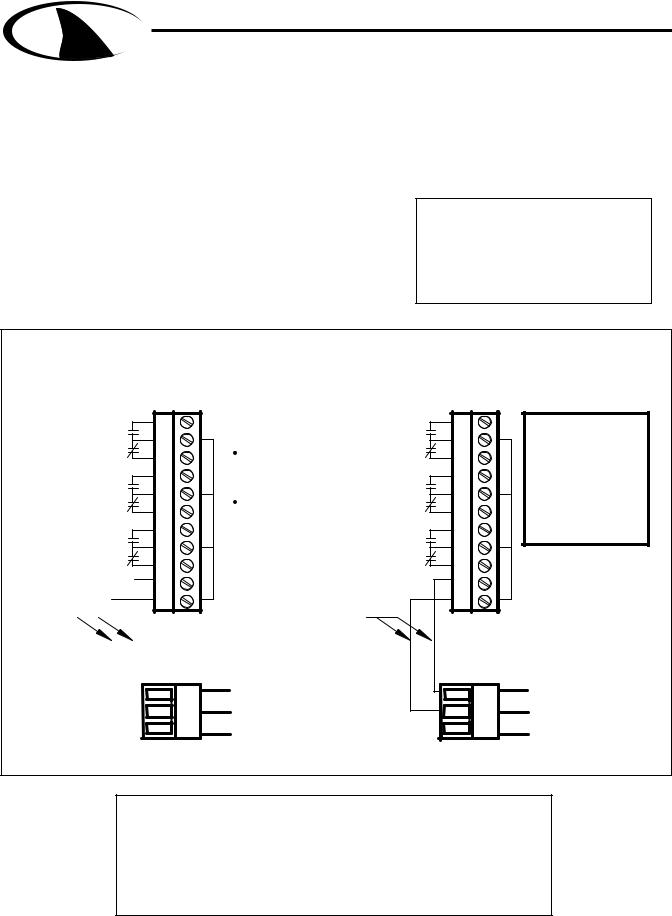

3.7 Relay connections

The Shark controller has three internal relays. Relays A and B are for control, the Alarm Relay can be configured for alarm functions or as an additional control relay.

The connections to the relays are shown in the drawing. Note that the AC power is internally connected to the relay terminal plug P4. This is used to provide 120V or 240V AC power for the relay contacts.

Wire Specification: Size and fuse wire accroding to local electrical code. Wire size not to exceed 14 AWG.

WARNING

DISCONNECT POWER FROM CONTROLLER AND LOADS WHILE CONNECTING TO THE RELAY OUTPUT TERMINAL PLUG.

Figure 3.6 Connections for Relay A, B and Alarm |

|

RELAY CONNECTIONS FOR 120VAC |

RELAY CONNECTIONS FOR 240vac |

SHARK-120 |

SHARK-240 |

|

N.0 |

RELAY |

||

|

|

|

||

|

N.C. |

A |

||

|

|

|

||

|

N.C. |

RELAY |

||

|

N.O. |

|

|

|

|

|

|

B |

|

|

N.C. |

ALARM |

||

|

N.O. |

|

|

|

Internal |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

connections |

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Dwg# N104-38

21 22 23 24 25 26 27 28 29 30 31

P4

N L GNDG

P3

|

W A R N I N G |

N.0 |

A RELAY |

|

PIN 21 must be |

N.C. |

|

|

connected to relays |

|

|

|

for power. |

N.C. |

RELAY |

|

PIN 22 cannot be |

||

|

|

N.O. |

|

|

connected to the |

|

B |

|

|

|

|

|

relays. |

N.C. |

ALARM |

|

|

||

|

|

N.O. |

|

NEUTRAL OUT (22) |

|

|

|

LINE OUT (21)

Internal connections

NEUTRAL

LINE

GROUND

21 22 23 24 25 26 27 28 29 30 31

P4

L L GNDG

P3

W A R N I N G

PIN 21 must be connected to relays for power.

PIN 21 must be connected to relays for power.

PIN 22 cannot be connected to the relays.

PIN 22 cannot be connected to the relays.

LINE OUT (22)

LINE OUT (21)

LINE

LINE

GROUND

Caution:

The contacts are rated at 10 amp N.O. and 5 amp N.C. Do not exceed this rating. When switching larger currents, use an auxillary relay switched by the controller relay to extend the controller relay life. If the relays are controlling an inductive load, use appropriate transient suppression at the load.

Section 3 - Electrical Connections and Setup |

Page 11 |

MULTI-PARAMETER CONTROLLER & ANALYZER USER’S MANUAL

S H A R K

Section 3 - Electrical Connections and Setup

3.8 RELAY A and B Setup

(LCD MENU SECTIONS - pH: 4.18 & 4.19, ORP: 5.17 & 5.18,

Conductivity: 6.18 & 6.19, Flow: 7.15 & 7.16)

Relay A & Relay B on the SHARK are SPDT dry contact relays. They are configurable to operate in response to rising or falling process values. Each relay has independently adjustable on and off setpoints, cycle times, and fail-safe options.

The operator would use the control relays if the device to be controlled is a simple on/off device. For example a pump, solenoid valve, fan, or an indicating light.

The control relays have 6 user configurable settings:

DIRECTION: The relay can be set to control either a rising or falling process. If for example the relay is set to control a falling process, the ON set-point must be set lower than the OFF set-point. If the relay is set to control a falling process the SHARK will not allow the RELAY OFF set point to be set lower than the RELAY ON set-point. This rule will also apply to a rising process.

RELAY ON set-point: This is the process value at which the relay will energize. This value can be set anywhere between 0-100% of the range.

RELAY OFF set-point: This is the process value at which the relay will de-energize. Depending on the direction for which the relay is configured, the RELAY OFF set-point will only be setable in a limited range.

CYCLE ON time: To obtain a tighter process control, and limit over-shoot, the control relay can be set with the cycling feature. This feature, if enabled, will cause the control relay to cycle when the process is between the RELAY ON set-point and RELAY OFF set-point. The cycle on time is the amount of time in seconds that the relay will be energized. It can be set between 0 and 600 seconds.

CYCLE OFF time: The CYCLE OFF time is the amount of time in seconds that the relay will be deenergized, it can be set between 0 and 600 seconds. To disable the cycling feature set the cycle off time to 0.

OVERFEED TIMER: The overfeed timer is designed to help safeguard against a process or instrumentation error causing one of the control relays to remain energized for extended periods of time.

When enabled, the overfeed timer will time out if the control RELAY OFF set point is not reached inside the overfeed time out. The control relays will de-energize, the alarm relay will energize and an LED will flash at the front.

FAILSAFE: The FAILSAFE feature is designed to reverse the normal action of the control relay.

When the relay is set to FAILSAFE OFF the relay will operate as a normal relay. When the relay is de-energized the NO contacts are open and the NC contacts are closed. Thus the device connected via the NO contacts will be off. When the relay becomes energized the device will be on.

When the relay is set to FAILSAFE ON, the normal action of the relay is reversed. Thus the NO contacts act as the NC contact and the NC act as the NO. The device connected to the NC contacts will be energized when the RELAY ON set-point is reached. The relay will be de-energized but because it is acting in reverse the device will be energized. When the RELAY OFF set-point is reached the relay will energize and the device connected to the NC contact will de-energize.

The purpose of the Fail Safe option is to have the device turned on in the event of a power interruption.

The factory default for FAILSAFE is OFF.

Section 3 - Electrical Connections and Setup |

Page 12 |

MULTI-PARAMETER CONTROLLER & ANALYZER USER’S MANUAL

S H A R K

Section 3 - Electrical Connections and Setup

3.9 ALARM RELAY Setup

(LCD MENU SECTIONS - pH: 4.20, ORP: 5.19, Conductivity: 6.20, Flow: 7.17)

The third relay (Relay C) is used as an alarm relay. The alarm relay on the SHARK is a SPDT dry contact relay.

This relay will respond to both a rising and falling process. The alarm relay will act as a low alarm (falling process) and a high alarm (rising process). Both relays will have independently adjustable on and off set-points. The ALARM ON set-points will always be set before the ALARM OFF set-points. The shark will not let the user input a value below the ALARM ON set-point. The same rule holds true for the high alarm.

The control relays have 5 user configurable settings:

ALARM LOW ON set-point: This is the low process value that will cause the relay to energize. This value can be set anywhere between 0-100% of the range.

ALARM LOW OFF set-point: This is the value that the process must reach in order to de-energize the alarm relay after it has dropped below the ALARM LOW ON set-point. This value must be higher than the ALARM LOW ON set-point.

ALARM HIGH ON set-point: This is the process value that will cause the relay to energize. This value can be set anywhere between 0-100% of the range.

ALARM HIGH OFF set-point: This is the value that the process must reach in order to de-energize the alarm relay after it has increased over the ALARM HIGH ON set-point. This value must be lower than the ALARM HIGH ON set-point.

FAILSAFE: This option can be turned on or off. It reverses the normal action of the relay. (see description under control relay)

ALARM SET-POINT ERROR: If the ALARM LOW ON set-point is set higher than the factory default ALARM LOW OFF set-point, when the user advances from the ALARM LOW ON set-point to the ALARM LOW OFF set-point the shark will adjust the ALARM LOW OFF set-point to be equal to the ALARM LOW ON set-point. If the user then tries to decrease the ALARM LOW OFF set-point the Shark will display the ALARM LOW ALARM setup error screen.

This screen will be displayed for 10 seconds, then return back to the setup screen that was previously displayed. If the user presses the down key again the error message will be displayed again for 10 seconds. The user must accept the LOW OFF set-point, equal to, or greater than the LOW ON set-point.

The same conditions apply to the ALARM HIGH set-points. Except the ALARM HIGH OFF setpoint must be lower than the ALARM HIGH ON set-point. If the user tries to increase the ALARM HIGH OFF set-point higher than the ALARM HIGH ON set-point the High Alarm setup error screen will be displayed.

ALARM RELAY DISABLE: If the user sets the ALARM LOW ON set-point and the ALARM LOW OFF set-point equal to 0% of the range. It will disable the low alarm relay.

If the user sets the ALARM HIGH ON set-point and the ALARM HIGH OFF set-point equal to 100% of the range. It will disable the high alarm relay.

Section 3 - Electrical Connections and Setup |

Page 13 |

MULTI-PARAMETER CONTROLLER & ANALYZER USER’S MANUAL

S H A R K

Section 3 - Electrical Connections and Setup

3.10 MANUAL TEST MODE

(LCD MENU SECTIONS - pH: 4.4, ORP: 5.3, Conductivity: 6.4, Flow: 7.2)

Once the relays are configured, the setup can be tested using Manual Test Mode to simulate process changes.

MANUAL TEST MODE is used to simulate a process reading in order to verify the correct response of the outputs. When in the MANUAL TEST MODE, the relays and outputs are no longer placed on hold as they are when in the rest of the menu. The relays and outputs will react to the simulated change in process as if the Shark was in RUN MODE.

Note that when the user exits the MANUAL TEST

MODE, the relays and outputs will remain in the

MANUAL TEST MODE state until the user enters

RUN MODE.

3.11 RELAY OVERRIDE

(LCD MENU SECTION - pH: 4.5, ORP: 5.4, Conductivity: 6.5, Flow: 7.3)

Relay Override is used to manually override the state of the relays. The user is able to set the operating mode of the relay as AUTO/ON/OFF (the default and RUN MODE states are AUTO).

This feature can be used to energize or de-energize the relays to manually correct the process, or to shut down an ancillary device to perform maintenance. When in the RELAY OVERRIDE mode, the relays are no longer placed on hold as they are when in the other menus.

Note that if the RELAY AUTO RETURN is set to "ON", the controller will place all the relay settings back to AUTO 10 minutes after the Shark returns to the run mode..

Section 3 - Electrical Connections and Setup |

Page 14 |

MULTI-PARAMETER CONTROLLER & ANALYZER USER’S MANUAL

S H A R K

Section 3 - Electrical Connections and Setup

3.12 4-20 mA Isolated Outputs

Channel 1 and Channel 2

(LCD MENU SECTIONS - pH: 4.21 & 4.22, ORP: 5.20 & 5.21,

Conductivity: 6.21 & 6.22, Flow: 7.18 & 7.19)

The Shark Controller has two 4 to 20mA outputs, electrically isolated from each other and ground. Either output can source current into a maximum of 800 ohms.

Channel 1 (the primary output) is located on the flip out door, terminal plug P6. Channel 1 is dedicated to track the process and has fully independent and fully adjustable 4 & 20 mA output setpoints. This will enable the operator to span the output over the desired range.

Channel 2 (the secondary output) is located in the enclosure terminal plug P1. Channel 2 can be selected to track the process value or temperature and has fully independent and adjustable 4 & 20 mA output setpoints.

Both Channel 1 and 2 can be precisely trimmed through the LCD menu for precision applications.

The drawing shows the connections for both outputs.

Wire Specification: 22 AWG 7/30, insulation 0.010”

Figure 3.7 Connections for the 4-20mA outputs

|

|

|

|

|

|

|

|

|

|

|

|

51 |

|

|

|

30 31 |

|

|

|

|

|

|

|

5453 52 |

|

||

|

|

|

28 29 |

|

|

|

|

|

|

|

5756 55 |

|

|

|

|

|

25 26 27 |

|

|

|

|

|

|

|

61 60 59 58 |

Secondary Output |

|

|

|

|

24 |

|

|

|

|

|

|

|

63 62 |

CH2 4-20mA + |

|

|

|

|

23 |

|

|

|

|

|

|

|

64 |

CH2 4-20mA - |

|

|

|

|

21 22 |

|

|

|

|

|

|

|

67 66 65 |

||

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

P4 |

|

|

|

P3 |

|

P1 |

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

Primary Output |

|

|

|

|

|

|

|

|

|

|

|

|

|

CH1 4-20mA + |

|

|

|

|

|

|

|

|

|

|

|

|

|

CH1 4-20mA - |

P6 |

1 |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

9 |

10 |

11 12 |

13 14 15 16 |

17 |

Dwg# N104-39 |

|

|

|

|

|

|

|

|

|

|

|

|

|

Note: Leave 4” to 6” slack for all wires connected to the terminals of P6. Slack required so that wires do not interfere with opening or closing of the front door.

Section 3 - Electrical Connections and Setup |

Page 15 |

MULTI-PARAMETER CONTROLLER & ANALYZER USER’S MANUAL

S H A R K

Section 3 - Electrical Connections and Setup

3.13 Service

SHARK SERVICE TO BE PERFORMED BY QUALIFIED PERSONNEL ONLY.

3.14 Fuse Replacement

WARNING:

DISCONNECT LINE POWER TO THE UNIT

TO AVOID THE POSSIBILITY

OF ELECTRICAL SHOCK.

1.Proceed after disconnecting line power from the instrument.

2.Open the front panel by rotating the quarter-turn fasteners, using a flat blade screwdriver, to expose the relay board.

3.The fuse, F1, is located in the middle of the relay board, directly above the three terminal connectors.

4.Remove the open fuse and replace it only with a fuse of the same type and rating. REFER TO THE FUSE RATING TABLES BELOW.

5.Close the front panel and secure using the quarter-turn fasteners.

6.Restore power to the unit.

Figure 3.8 Fuse Location

21 22 23 24 25 26 27 28 29 30 31

P4

FUSE

P3

67 66 65 64 63 62 61 60 59 58 57 56 55 54 53 52 51

67 66 65 64 63 62 61 60 59 58 57 56 55 54 53 52 51

P1

P6 |

1 |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

9 |

10 |

11 12 |

13 14 15 16 |

17 |

Dwg# N104-40

Fuse Rating Table for 120 volt operation

Fuse Type: Slo-Blo Fuse Ratings: 250 |

|

fuse 5 x 20mm |

VAC, 100mA |

Fuse Rating Table for 240 volt operation

Fuse Type: Slo-Blo Fuse Ratings: 250 |

|

fuse 5 x 20mm |

VAC, 50mA |

Section 3 - Electrical Connections and Setup |

Page 16 |

MULTI-PARAMETER CONTROLLER & ANALYZER USER’S MANUAL

S H A R K

Section 4 - Using the SHARK in pH Mode

4 DIGIT, 7 SEGMENT LED DISPLAY

1/4" TURN SCREWS |

DISPLAYS PROCESS VALUE IN RUN MODE. |

|

DISPLAYS CALIBRATION DATA IN |

|

CALIBRATION MODE. |

RELAY C (ALARM RELAY) |

|

STATUS LED's (RED) |

|

BOTTOM LED WILL ILLUMINATE |

|

WHEN ALARM RELAY IS |

|

ENERGIZED BECAUSE OF LOW |

|

ALARM CONDITION. |

|

TOP LED WILL ILLUMINATE WHEN |

|

ALARM RELAY IS ENERGIZED |

|

BECAUSE OF HIGH ALARM |

|

CONDITION. |

|

BAR GRAPH LED's (GREEN) |

|

LINEAR INDICATOR OF PROCESS |

|

VALUE. |

|

(REFER TO SECTION 4.13) |

|

CALIBRATION FROM THE

FRONT PANEL

RUN LED (GREEN)

LED WILL BE ILLUMINATED WHEN

SHARK IS IN THE RUN MODE.

WILL BE OFF WHEN SHARK IS IN

THE MENU MODE.

OVERFEED LED (RED)

LED WILL FLASH WHEN THE

OVERFEED TIMER IS ACTIVATED.

AUXILLARY LED's

AUXILLARY LED's

NOT USED IN pH MODE.

UNIT LABEL

LABEL TO INDICATE UNIT OF

MEASURE SHARK IS

CONFIGURED FOR.

RELAY B STATUS LED (YELLOW)

LED WILL BE ILLUMINATED WHEN

RELAY B IS ENERGIZED.

RELAY A STATUS LED (YELLOW)

LED WILL BE ILLUMINATED WHEN

RELAY A IS ENERGIZED.

TEMPERATURE DISPLAY

WHEN THE 'UP' AND 'DOWN' ARROW

KEYS ARE PRESSED

SIMULTANEOUSLY, THE LED WILL

DISPLAY THE CURRENT PROCESS

TEMPERATURE FOR 5 SECONDS.

4 PUSH BUTTONS USED TO |

|

|

|

|

FRONT PANEL |

|

THIS FEATURE WILL BE DISABLED IF |

||||||||

CALIBRATE THE SHARK FROM THE |

|

|

|

|

|

THE 'TEMPERATURE COMPENSATION |

|||||||||

FRONT PANEL. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

OVERRIDE' IS TURNED ON IN THE |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

SETUP MENU. |

|

(REFER TO SECTIONS 4.22 & 4.23) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

IN THIS CASE THE LED WILL DISPLAY |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

---- IN PLACE OF THE |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

TEMPERATURE. |

REMOVABLE TERMINAL BLOCK |

P6 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

CONNECTORS |

1 |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

9 |

10 |

11 12 |

13 14 15 16 |

17 |

NOTE |

|

"SNAP-ON" CONNECTORS FOR EASY |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

WIRING OF YOUR pH SENSOR AND |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

WHEN THE SHARK IS TAKEN INTO |

PRIMARY 4-20mA OUTPUT. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

MENU MODE VIA THE INSIDE LCD |

(REFER TO SECTIONS 3.3, 3.4 & 3.12) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

SCREEN, THE FRONT 7-SEGMENT LED |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

WILL DISPLAY ----. THE STATUS & |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

BAR GRAPH LED's WILL BE TURNED |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

OFF. THE 4 PUSH BUTTONS ON THE |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

FRONT WILL NOT RESPOND. |

2 LINE, 16 CHARACTER |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

LCD DISPLAY |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

MAIN MENU INTERFACE |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

SCREEN |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

SIMPLE THREE-BUTTON INTERFACE |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

FOR FAST & EASY SETUP |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

(REFER TO SECTIONS 4.0 TO 4.21) |

INSIDE PANEL

Section 4 - Using the SHARK in pH Mode |

Page 17 |

MULTI-PARAMETER CONTROLLER & ANALYZER USER’S MANUAL

S H A R K

pH - Menu Overview 4.0

7.15pH 25.0C |

RUN MODE |

CALIBRATION |

|

UTILITIES

SETUP

DIAGNOSTICS

OUTPUTS

EXIT

FIRMWARE REV

PROBE SELECT

TEMP UNIT

TEMP SENSOR

AUTO RETURN

T.COMP OVERRIDE

DISPLAY DAMPING

BAR GRAPH O/R

EXIT

DISPLAY

FIRMWAVE REVISION SEC. 4.15

MANUAL CAL PH

AUTO CAL PH

TEMP CALIBRATION

EXIT

SELECT TYPE OF |

MANUAL TEST MODE |

|

|

||

pH PROBE |

|

|

SEC. 4.8 |

RELAY OVERRIDE |

|

SELECT DEG C OR DEG F |

||

|

||

SEC 4.9 |

|

|

SELECT TYPE OF |

METER SELECTION |

|

|

||

TEMP SENSOR |

|

|

SEC 4.10 |

RESET OVERFD TMR |

|

ENABLE TIME OUT |

||

|

||

FROM MENU |

|

|

SEC. 4.11 |

EXIT |

|

TEMPERATURE SETUP FOR |

||

|

||

PROBE W/O TEMP. SENSOR |

|

|

SEC 4.12 |

|

SETUP DISPLAY AND

OUTPUT RESPONSE TIME

SEC 4.13

SETUP RESOLUTION

OF FRONT PANEL BAR GRAPH

SEC 4.14

CALIBRATION DATA |

DISPLAY PREVIOUS |

|

CALIBRATION DATA |

||

|

||

|

SEC 4.16 |

|

SENSOR INPUT |

DISPLAY UNCALIBRATED |

|

PROBE DATA |

||

|

||

|

SEC 4.17 |

MANUAL CALIBRATE pH PROBE

SEC. 4.1

AUTO CALIBRATE pH PROBE

SEC. 4.2

CALIBRATE TEMP. SENSOR IN pH PROBE SEC. 4.3

SIMULATE PROCESS VERIFY OUTPUTS SEC. 4.4

MANUALLY OVERRIDE RELAYS

SEC. 4.5

SELECT TYPE OF METER SEC. 4.6

RESETS RELAY OVERFEED TIMER SEC. 4.7

|

EXIT |

|

|

RELAY A |

SETUP |

|

|

RELAY A |

|

|

|

|

|

|

|

|

SEC 4.18 |

|

|

RELAY B |

SETUP |

|

|

RELAY B |

|

|

|

|

|

|

|

|

SEC 4.19 |

|

|

ALARM RELAY |

SETUP |

|

|

ALARM RELAY |

|

|

|

|

|

|

|

|

SEC 4.20 |

|

|

4-20mA CH1 |

SETUP |

|

|

4-20 mA CH 1 OUTPUT |

|

|

|

|

|

|

|

|

SEC 4.21 |

|

|

4-20mA CH2 |

SETUP |

|

|

4-20 mA CH. 2 OUTPUT |

|

|

|

|

|

|

|

|

SEC 4.22 |

NOTE |

|

EXIT |

|

|

|

PRESS THE |

AND |

KEYS |

|

|

TOGETHER TO GO IMMEDIATELY BACK TO |

||

|

|

RUN MODE |

|

pH - Menu Overview 4.0 |

Page 18 |

MULTI-PARAMETER CONTROLLER & ANALYZER USER’S MANUAL

S H A R K

pH - Calibration Menu - Manual Calibrate 4.1

7.15pH 25.0C |

RUN MODE |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Place the probe in the first buffer solution, be |

|

||||

CALIBRATION |

MANUAL CAL PH |

|

IF BUFFER1 READY |

|

sure to clean and rinse the Probe first with D.I. |

|

||||

|

|

|

PRESS 'DOWN' |

|

water and then insert it in the 7.00 buffer. |

|

|

|||

|

|

|

|

Press |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

RUNNING MANU CAL |

The controller will read the pH value, |

|

|

|

|||

|

|

|

averaging a number of results to get a |

|

|

|||||

|

|

|

BUFFER1 WAIT... |

|

|

|

||||

|

|

|

|

stable calibration value. |

|

|

|

|

||

|

|

|

|

|

Please wait for the controller to complete |

|

|

|||

|

|

|

|

|

the measurement |

|

|

|

|

|

|

|

|

MANUAL CAL PH |

|

When complete, the controller will report |

|

|

|||

|

|

|

BUFFER1 |

7.3 5 > |

the measured value |

|

|

|

|

|

|

|

|

Use the |

and |

keys to adjust |

|

|

|||

|

|

|

UP |

|

|

|

||||

|

|

|

|

the reading until it agrees with the actual |

|

|

||||

|

|

|

|

|

|

|

||||

|

|

|

|

|

buffer pH value |

|

|

|

|

|

|

|

|

MANUAL CAL PH |

|

Then press |

to move the |

|

|

||

|

|

|

BUFFER1 |

7.0 0 > |

cursor to the RH position |

|

|

|

||

|

|

|

MANUAL CAL PH |

|

Then press |

to store the value and move |

|

|||

|

|

|

BUFFER1 |

7.00 > |

|

|||||

|

|

|

to BUFFER2 |

|

|

|

|

|

||

This example shows a MANUAL |

|

|

|

|

Place the probe in the second buffer. |

|

|

|

||

|

|

|

|

Be sure to clean and rinse the Probe first with |

|

|||||

calibration with buffers of 7pH & 4pH. |

|

IF BUFFER2 READY |

|

|

||||||

|

|

D.I. water and then insert it in the 4.00 buffer. |

|

|||||||

|

|

|

|

|

||||||

|

|

|

PRESS 'DOWN' |

|

|

|||||

When performing a manual |

|

|

|

Press |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

calibration, any two known buffer |

|

|

|

|

|

|

|

|

|

|

solutions can be used. |

|

|

RUNNING MANU CAL |

The controller will read the pH value, |

|

|

|

|||

|

|

|

averaging a number of results to get a |

|

|

|||||

|

|

|

BUFFER2 WAIT... |

|

stable calibration value. |

|

|

|

|

|

|

|

|

|

|

Please wait for the controller to complete |

|

|

|||

|

|

|

|

|

the measurement |

|

|

|

|

|

|

|

|

MANUAL CAL PH |

|

When complete, the controller will report |

|

|

|||

|

|

|

BUFFER2 |

4.4 0 > |

the measured value |

|

|

|

|

|

|

|

|

UP |

|

Use the |

and |

keys to adjust |

|

|

|

|

|

|

|

|

the reading until it agrees with the actual |

|

|

|||

|

|

|

|

|

buffer pH value |

|

|

|

|

|

|

|

|

MANUAL CAL PH |

|

Then press |

to move the |

|

|

||

|

|

|

BUFFER2 |

4.0 0 > |

cursor to the RH position |

|

|

|

||

|

|

|

|

|

|

|

|

|

||

|

|

|

MANUAL CAL PH |

|

Then press |

to store the value and |

|

|

||

|

|

|

BUFFER2 |

4.00 > |

complete the Manual Calibration |

|

|

|

||

|

|

|

|

|

|

|

|

|

||

|

|

|

SLOPE 61.22MV/PH |

|

After 5 seconds, the controller will |

|

|

|

||

|

|

|

|

compute the slope of the calibration, the |

|

|

||||

|

|

|

EFF 95% 24.8C |

|

estimated probe efficiency and the probe |

|

|

|||

|

|

|

|

|

temperature. |

|

|

|

|

|

|

|

|

|

|

If the calibration is OK, use the |

key |

|

|

||

|

|

|

|

|

to move the cursor over the Y text and |

|

|

|||

|

|

|

|

|

press the down key. |

|

|

|

|

|

|

If the calibration did not appear to be |

MANUAL CAL PH |

|

MANUAL CAL PH |

|

|

Press |

to store the calibration |

||

|

correct, press the |

key |

STORE? |

Y N |

STORE? |

Y |

N |

data and return back to the Manual |

||

|

which will return back to the Manual |

Cal menu so the user can select |

||||||||

|

|

|

|

|

|

|

||||

|

Cal menu. |

|

|

|

|

|

|

|

another function. |

|

NOTE

PRESS THE  AND

AND  KEYS

KEYS

TOGETHER TO GO IMMEDIATELY BACK TO

RUN MODE

pH - Calibration Menu - Manual Calibrate 4.1 |

Page 19 |

MULTI-PARAMETER CONTROLLER & ANALYZER USER’S MANUAL

S H A R K

pH - Calibration Menu - Auto Calibrate 4.2

7.15pH 25.0C |

RUN MODE |

|

|

|

|

|

CALIBRATION |

|

MANUAL CAL PH |

|

|

|

|

|

|

AUTO CAL PH |

IF BUFFER1 READY |

|

Place the probe in the first buffer solution, |

|

|

|

|

be sure to clean and rinse the Probe first |

|||

|

|

|

PRESS 'DOWN' |

|

with D.I. water and then insert it in the 7.00 |

|

|

|

|

|

buffer. |

|

|

|

|

|

|

|

|

|

|

|

|

RUNNING AUTO CAL |

|

Press |

|

|

|

|

|

The controller will read the pH value, |

||

|

|

|

BUFFER1 WAIT... |

|

||

|

|

|

|

averaging a number of results to get a |

||

|

|

|

|

|

||

|

|

|

|

|

stable calibration value. |

|

|

|

|

|

|

Please wait for the controller to complete |

|

|

If an errors occurs, the controller will indicate a |

|

|

the measurement |

|

|

|

|

|

|

|

||

|

"BUFFER ERROR" alarm. This could be caused by |

|

|

|

||

|

- using a defective buffer |

|

|

|

|

|

|

- incorrect probe wiring |

|

|

BUFFER ERROR |

|

|

|

- defective probe |

|

|

CONTINUE |

> |

|

|

Press |

to return to the Auto cal menu, try to |

|

|||

|

|

|

|

|||

|

correct the problem and calibrate again, or go to the |

|

|

|

||

|

diagnotics menus to test the probe |

|

|

|

|

|

|

see Section 4.17 |

|

|

|

|

|

|

|

|

AUTO CAL PH |

|

When complete, the controller will report |

|

|

|

|

BUFFER1 |

7.00 > |

the measured value |

|

|

|

|

|

|

||

|

This example shows an AUTO |

|

|

Press the |

key to move to Buffer 2 |

|

|

calibration with buffers of 7pH & 4pH. |

|

|

|

|

|

|

When performing an auto calibration, |

|

|

Place the probe in the second buffer |

||

|

any two standard buffers of 4.00, 7.00 |

|

|

|||

|

|

|

solution.Be sure to clean and rinse the |

|||

|

or 10.00 pH can be used. The buffers |

IF BUFFER2 READY |

|

|||

|

|