Page 1

by

Aqua

Aqua

Metrix

Water Analytics

Model EX80 Series

Magmeter Flow Sensor

Features

• Low-ow performance and

accuracy superior to any

mechanical ow sensor

• No moving parts to wear out

• Dedicated ttings for simplicity

• Retainer clip automatically sets

correct depth

• Meter extends only about 1/8 of

pipe diameter, minimizing potential

for clogging with debris

• Easy to install and easy to maintain

Description

EX80 series insertion electromagnetic ow meters are designed for use with

conductive liquids in 1 to 12” pipe. A choice of materials (stainless steel,

brass, and PVC) allows the meter to adapt to a range of temperature, pressure, and corrosive environments. Conductivity values of 20 µS/cm are sufcient to enable the magmeter to operate which makes it suitable for all but

the ultrapure environment.

The EX80 is highly suitable for difcult applications with changing viscosities

and pulsating ows, such as air-driven diaphragm pumps. With no moving

parts, these meters can be used in “dirty” applications where debris would

foul a mechanical meter. Like all meters, when used in chemical injection

applications, they should be installed upstream of the chemical line (or far

enough downstream to allow complete mixing of uids before the meter).

Designed for modularity and versatility, the EX80-Series has a current-sinking pulse output that can be combined with the Shark controller or Shark TX

transmitter for the application. When used with the Shark the output signal

can be fed direct, with no other conditioning required.

EX80 series xed depth insertion meters require special ttings. Factory

installation in the tting ensures correct depth placement in the pipe. The

EX80 series meter can be ordered in a low power model that can run on an

external battery with solar panel. A hot tap version, reverse ow output and

immersibility are all available. Contact Water Analytics for information on

these and other options.

Applications

• Waste water ow

• Water Treatment systems

• Irrigation

• Groundwater remediation

• Chemical Mixing

• Process cooling systems

• Neutralizaton Systems

• Process ow control

• Filtration systems

by

Toll free - 855-747-7623

wwww.WaterAnalytics.net

Metrix

Water Analytics

100 School Street

Andover, MA 01810

978-749-9949

Page 2

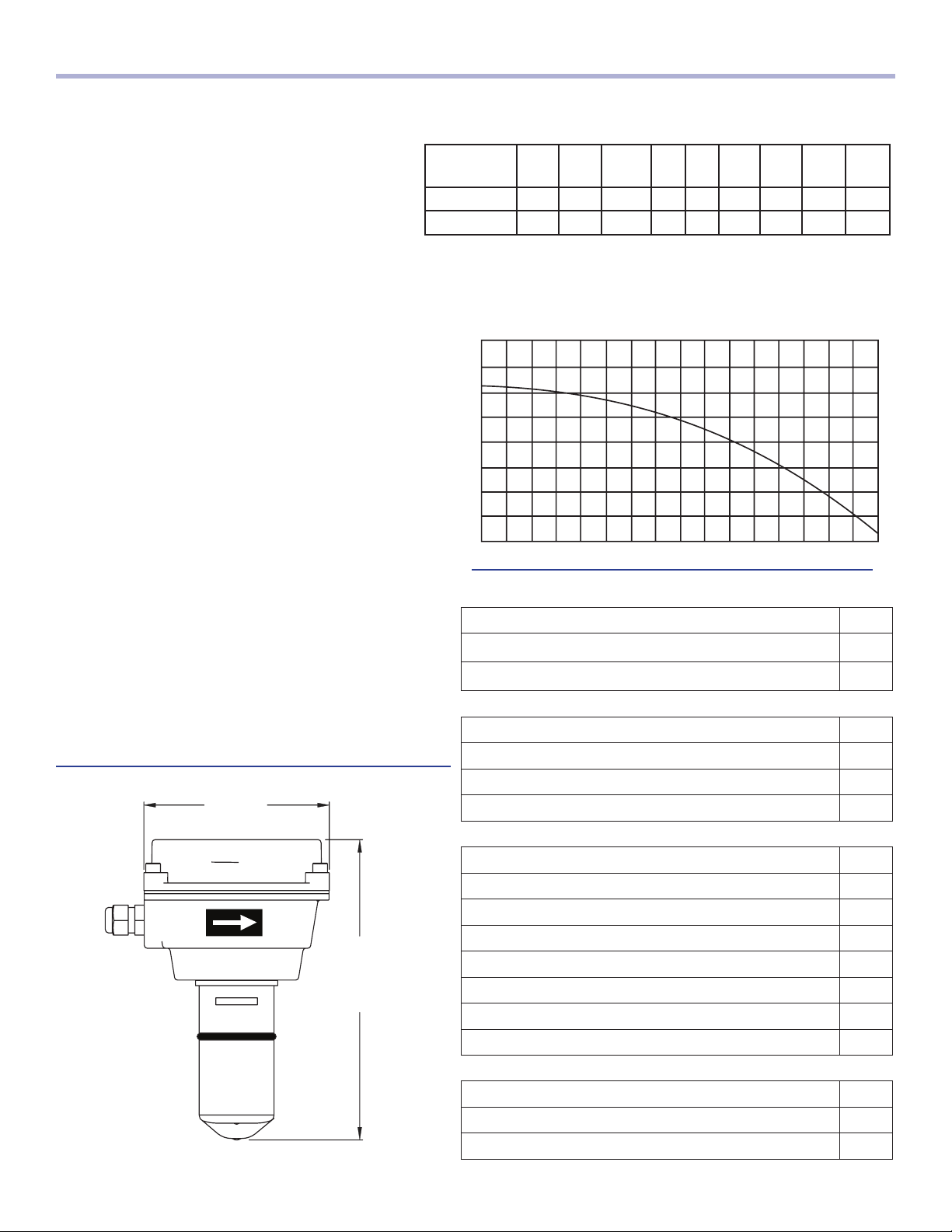

Model EX80 Series Magmeter Flow Sensors Technical Data

3.95”3.95”

2.80”

(TOP OF TEE)

EX81 5.85”

EX82 6.85”

EX83 7.85”

Pipe Size 1 to 12”

Materials

Shaft/Fitting 316 SS or Brass or PVC

Electrodes Hastalloy

Housing Cast powder-coated aluminum

Electrode Cap PVDF (Kynar)

O-Ring EPDM (Viton optional)

Power

Full Power 12 - 25 VDC, 250 mA

Low Power 12 - 25 VDC, 40 mA average w

250 mA peaks

Flow Rate 0.28 - 20 ft/sec (0.08 - 6.09 m/

sec)

Temperature

Ambient Temp 0˚ to 160˚ F (-17˚ to 72˚ C)

Fixed Temp:

Brass or SS

Fluid Temp: PVC 32˚ to 130˚ F (0˚ to 55˚ C) @ 0

Pressure

Brass / SS 200 psi (13.8 bar)

PVC 150 psi (10 bar) @ 75˚ F

Maximum conductivity

Calibratin Accuracy

Output Square wave pulse, opto-isolat-

Empty Pipe Detection

Maximum Current 20 mA

32˚ to 200˚ F (0˚ to 93˚ C)

psi

20 µS/cm

+/- 1% of full scale

ed, 550 Hz @ 20 ft/sec

Software, defaults to zero ow

Dimensions

Flow Range (GPM)

Nominal

Pipe Size

Min

Max

60º7 0º 80º9 0º 100º 110º 120º 130º 140º

200

150

P.S.I.

100

50

1” 1.5 2” 3” 4” 6” 8” 10” 12”

0.69 1.5 2.7 6.2 11 25 43 68 99

49 110 196 440 783 1760 3130 4900 7050

PVC/Polypro Working Pressure vs. Temperature

Order Information

Sensor Style

Impeller sensor ( 1/2” - 3”)

Impeller sensor ( 4” - 6”)

Impeller sensor ( 12”)

Sensor Material

PVC

Stainless Steel

Polypropylene

Brass

Mounting Style

1/2” Tee tting

3/4” Tee tting

1” Tee tting

1.5” Tee tting

2” Tee tting

3” Saddle/Weldolet tting

4” Saddle/Weldolet tting

6” Saddle/Weldolet tting

Mounting Tee Material

PVC

304 Stainless Steel (available only for 0.5” - 2”)

Bronze (Not available for 6” pipes)

81

82

83

P

S

Y

B

050

075

100

150

200

300

400

600

P

S

B

www.WaterAnalytics.net 978-749-9949 Toll free - 855-747-7623 (855-pHProbe)

Loading...

Loading...