Page 1

www.aquacraftmodels.com

m

™

• Never attempt to swim after a stalled R/C boat.

• Never operate your R/C boat while standing in the water.

• Never operate your R/C boat in the presence of swimmers.

• Always use a Personal Flotation Device (PFD) when boarding and operating your retrieval craft, i.e. Jon

boat or duck boat. NOTE: Because of the sharp running hardware included with this R/C boat, we do not

recommend a rubber blow up raft.

• R/C boat running hardware is very sharp. Be very careful when working on and around the metal parts.

• While the motor is running pay close attention to the propeller. Do not come in contact with the propeller at

any time the engine is running or serious injury will result.

• AquaCraft products are to be used by ages 14 and over.

WARNING:

www.aquacraftmodels.com

ww.aquacraftmodels.co

™

Page 2

ITEMS INCLUDED

1

2

5

6

7

3

4

1. VS1 Hull and Cowl

2. Throttle Outer Pushrod Tube

3. Throttle Cable (Gold)

4. Rudder Cable (Silver)

5. Screw Bag

6. Antenna Tube

WARRANTY

AquaCraft will warrant your VS1 for 90 days after the purchase from

defects in materials or workmanship of original manufacture. AquaCraft,

at their option, will repair or replace at no charge, the incorrectly made

part. This warranty does not cover damage caused by crash, abuse,

misuse, alteration or accident. To return your boat for repairs you need

to provide proof of purchase. Your store receipt or product invoice will

suffi ce. IN NO EVENT SHALL THE PURCHASER BE ENTITLED TO

ANY INCIDENTAL, SPECIAL, INDIRECT OR CONSEQUENTIAL

DAMAGES, WHETHER RESULTING FROM THE USE, MISUSE OR

INABILITY TO USE THE PRODUCT OR FROM DEFECTS IN THE

PRODUCT. This warranty gives you specifi c legal rights and you may

also have other rights, which vary from state to state. (Outside USA

and Canada, contact local importer for warranty information.)

Hobby Services

3002 N. Apollo Drive, Suite 1

Champaign, Illinois 61822

Attn: Service Department

Phone: (217) 398-0007 9:00 am - 5:00 pm Central Time M-F

E-mail: hobbyservices@hobbico.com

10

11

8

9

7. On/Off Switch Pushrod

8. Fuel Tank

9. Radio Box Cover

10. Hardware Bag

11. Tank Mount Bag

Decal Sheet

STANDARD REPAIR SERVICE

After the 90-day warranty has run out you can still have your VS1

repaired for a service fee by the experts at AquaCraft.™ To speed up

the repair process, please follow these four simple steps:

Important Note: For standard repair service you must specify

whether you wish the charges to be billed COD or if you wish to be

notifi ed of the charges so you can send a check.

1. Please return the ENTIRE system, boat and radio.

2. Make sure batteries are removed from the transmitter.

3. Send written instructions which include a list of all items returned,

a THOROUGH explanation of the problem or problems of the

service needed. Be sure to include your return address and

daytime phone number. If you have access to e-mail please provide

us with your e-mail address to help speed communication.

4. Send to the address above.

2

Page 3

INTRODUCTION

SPECIFICATIONS

Thank you for purchasing the AquaCraft™ VS1! We want

the time you spend with your new R/C boat to be fun and

successful so please fully read the manual. If for any reason

you think this R/C model is not for you, return it to your local

hobby dealer immediately. Your hobby dealer cannot accept

returns on any model after final assembly or after your boat

has been operated.

SAFETY PRECAUTIONS

• Never, ever, attempt to swim after a stalled R/C boat.

Do not get in the water for any reason to retrieve your

boat. To aid you in retrieving a stalled R/C boat, set up a

fi shing reel with a tennis ball tied to the end of the line.

Or better yet, get yourself a small boat so you can row

out and pick up your R/C boat. Remember to use a PFD

any time you enter your retrieval craft.

• AquaCraft products are to be used by ages 14 and over.

• Do not touch the propeller anytime the motor is running.

Pay equally close attention to items such as loose clothing,

shirtsleeves, ties, scarves, long hair or anything that may

become entangled in the spinning prop. If your fi ngers,

hands, etc., come in contact with the spinning propeller,

you may be severely injured.

• The speed and mass of this boat can infl ict property

damage and severe personal injury if a collision occurs.

Never run this boat in the presence of swimmers or where

the possibility of collision with people or property exists.

• Glow engines produce heat. Do not touch any part of your

motor until it has cooled.

VS1 SPECIFICATIONS:

Hull Length: 28" (710mm)

Overall Length: 34-1/4" (870mm)

Width: 11-1/2" (290mm)

Height: 5-1/2" (140mm)

Weight (less fuel): 4lbs, 2oz

VS1 FEATURES:

ARR Pro-built construction

Race-winning heritage

Lightweight wood, foam and ABS construction

High-gloss, fuel resistant, natural wood fi nish

Water-resistant radio box

Molded waterproof radio box cable output

8 oz. molded plastic fuel tank

Pull-pull steering system

BOAT TERMINOLOGY

TUNNEL HULL: Is a style of boat that traps air between two

sponsons to gain lift.

BOW: The front of the boat.

TRANSOM: Aft most structure on the back of the boat.

PORT: This is the left side of the boat when aboard and

facing the front (bow). An easy way to remember this is that

port and left both contain four letters.

STARBOARD: This is the right side of the boat when aboard

and facing the front (bow).

HULL: The body of the boat.

DECK: The top of the hull.

COWL or CANOPY: Removable ABS top.

SPONSON: Left or right structure this type of boat rides on.

KEELSON: The inner side of the sponsons.

SKEG: The rudder blade on your outboard that extends

below the propeller shaft.

• This boat is controlled by radio signals, which are susceptible

to possible interference from other R/C transmitters, paging

systems, or other electrical noise. Before turning your radio

transmitter and receiver on, make sure no one else in the

area is operating a radio on the same frequency (channel).

• In the event that weeds become entangled in the propeller,

stop the motor before attempting to remove them.

• If your VS1 should happen to stall, water currents will slowly

carry it to shore. The bad news is that the boat could be

carried to the opposite shore. When surveying areas to run

your boat, keep variables in mind such as wind direction, size

of the lake, etc. It is not advisable to run R/C boats on any

free-fl owing bodies of water such as creeks or rivers.

MANUAL SPECIFICATION AND

DESCRIPTION CHANGES

All pictures, descriptions, and specifi cations found in this

instruction manual are subject to change without notice.

AquaCraft maintains no responsibility for inadvertent errors

in this manual.

3

3

Page 4

PARTS NEEDED TO

COMPLETE YOUR VS1

RADIO SYSTEM:

• Futaba

Harness (FUTK2020) OR Futaba 4PK 2.4GHz Transmitter,

Receiver and Switch Harness (FUTK4900)

• Steering Servo, Futaba S3305 (FUTM0045), OR Futaba

S9405 (FUTM0098)

• Throttle Servo, Futaba S3115 (FUTM0415) OR Futaba

S3201 (FUTM0034)

• Receiver pack, DuraTrax® 5-cell 6V NiMH (DTXM2011)

• Futaba Receiver Pack Wall Charger (FUTM1705)

• 8AA batteries (transmitter) (3PM Only)

• Boat stand

ENGINE:

• O.S.® 21XM Marine Outboard Engine (OSMG1721)

or equivalent

®

3PM 2.4GHz Transmitter, Receiver and Switch

ACCESSORIES NEEDED TO

OPERATE YOUR VS1

• TorqMaster™ Electric Starter (HCAP3200)

• 30% Boat Fuel (ODOP3130, Quart) or 50% Boat Fuel

(ODOP3150, Quart)

• Hot Shot™ 2 Glow Igniter (HCAP2520)

• Hand Crank Fuel Pump (HCAP3015)

• Fuel Line (AQUB6903)

• Fuel Filter (GPMQ4150)

• Glow Plug Wrench (GPMP2000)

• AquaCraft GrimRacer™ Pro Radio Box Tape (AQUB9514)

• AquaCraft GrimRacer Speed Grease (AQUB9500)

OPTIONAL PERFORMANCE PROPS

• AquaCraft GrimRacer 40x52/3 Metal 3-blade Prop

(AQUB9720)

• AquaCraft GrimRacer 40x53 Metal Prop (AQUB9715)

EXTRA SUPPLIES

As with any hobby, it is a good idea to assemble a useful

collection of tools and accessories to bring along when

you head to the pond. Here are some items you will want to

keep handy:

Extra “AA” batteries

Extra glow plugs

Spare prop

Small standard screwdriver

Hobby knife

Hex wrenches

Waders or rubber boots

Paper towels

Spray-on cleaner

Sunglasses

Sun block

Folding table

Lawn chair

First-Aid kit

Cooler with plenty of ice and water

Canopy or shelter

TOOLS NEEDED TO COMPLETE

YOUR MODEL

• Soldering Iron

• Solder

• Small Phillips Screwdriver

• 5-64 Hex Wrench

• Needle Nose Pliers

• Hand Drill

• Drill Bits

• Silicone Sealer

• Masking Tape

• 12-Minute Epoxy

• Denatured Alcohol

• Paper Towels

• Rotary Tool with Cut-Off Wheel

• Side Cutters

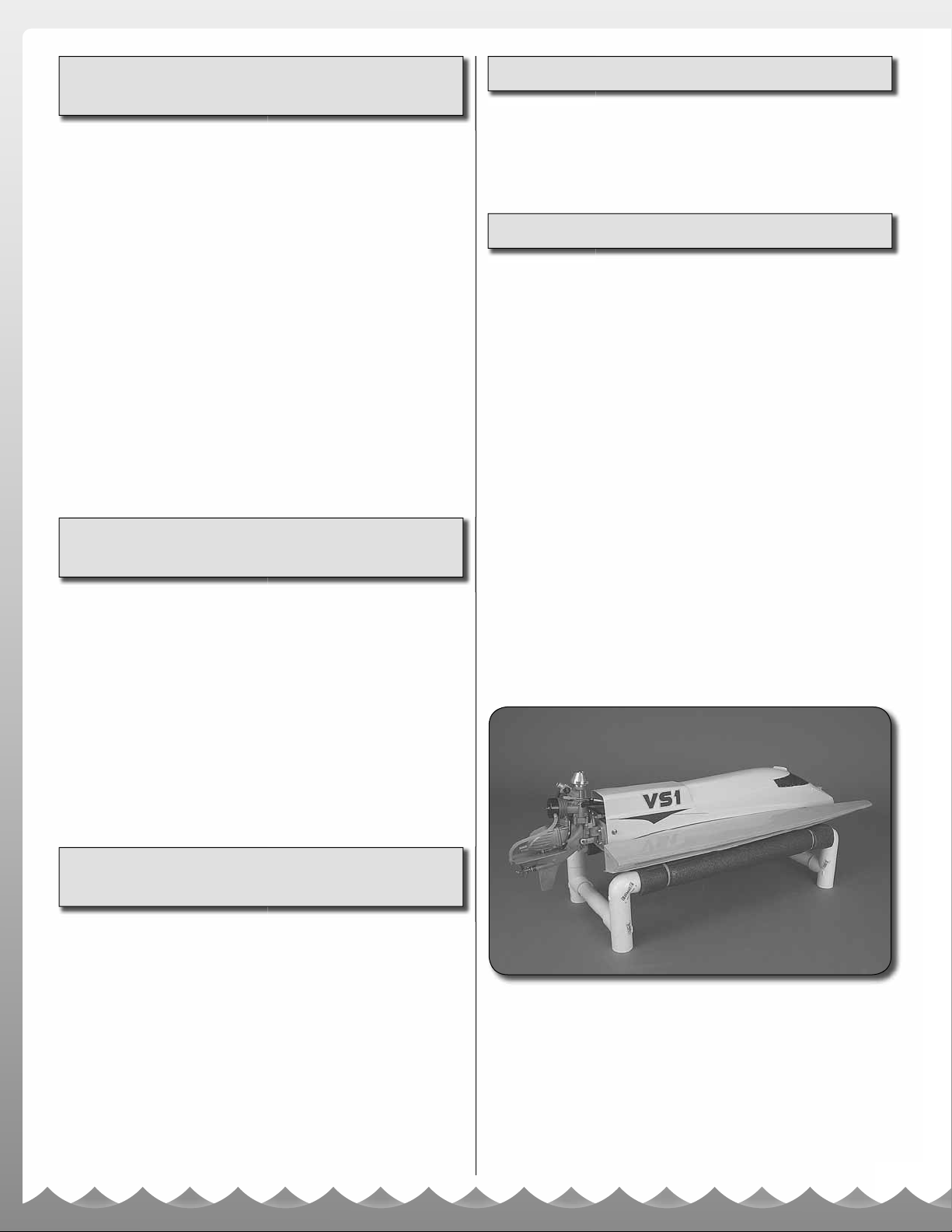

Your VS1 does not include a boat stand. You can build one

out of wood or make one from PVC tubing that you buy from

your local home store.

4

4

Page 5

ASSEMBLY

INSPECT THE HULL

1. Check the hull for any open gaps in the seams. We have

done our best to make sure the seams are closed, but it is

still necessary to check it over. I like to use the tip of a hobby

knife to probe around the seams. If you suspect a seam

might be open or allow water to enter the structure you need

to seal it. It is best to do this with 12 minute epoxy. Mix a small

amount of epoxy and work it into the seam using a razor

blade or small acid brush. Keep some denatured alcohol and

paper towel handy to wipe away any excess epoxy. It is also

a good time to look for any exposed wood and seal it from

the water, including the wood parts of the cowl.

and a long, fl at sanding block. Keep the bottom edges sharp

and re-seal any exposed wood. TAKE YOUR TIME! The

fi nished sponsons must be parallel to each other and fl at.

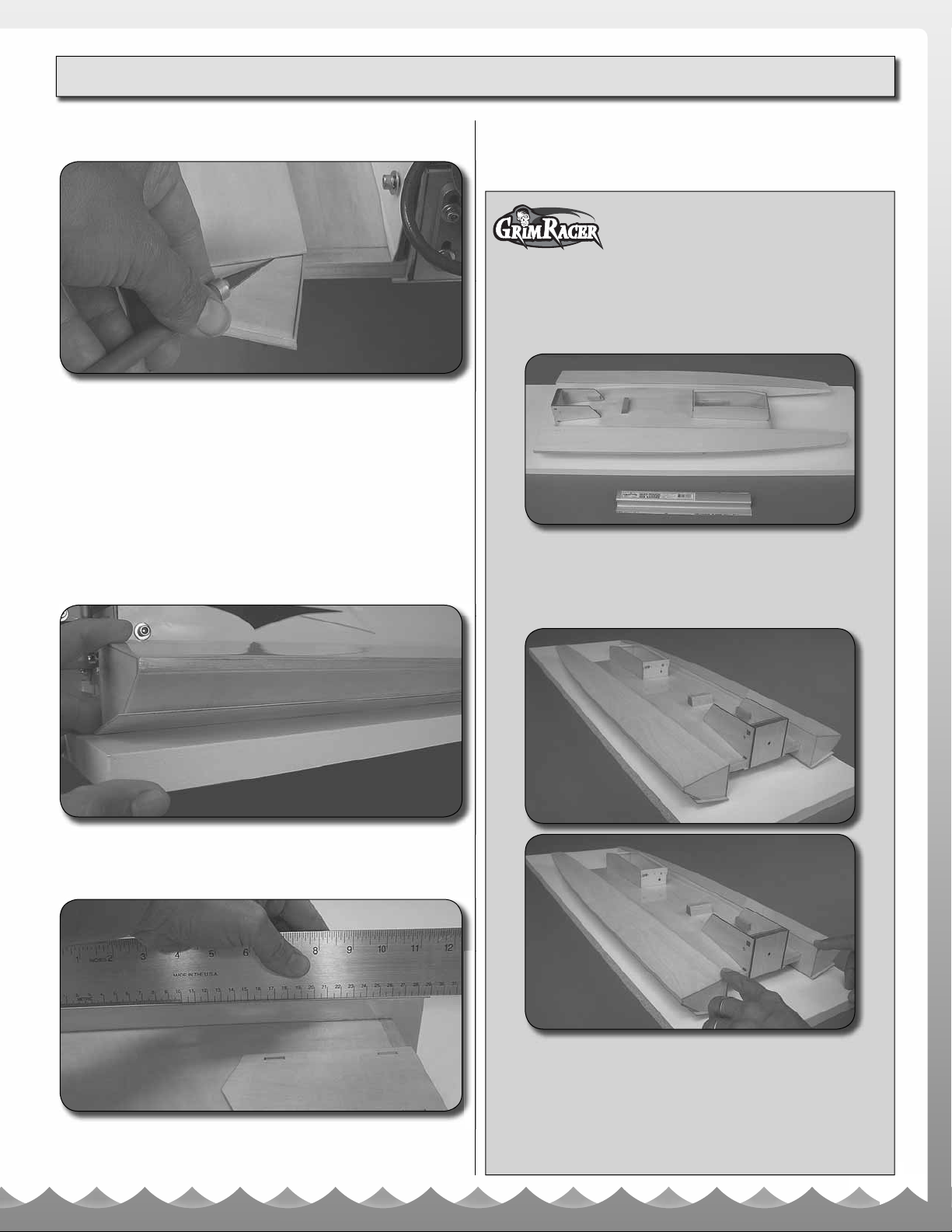

Grimracer says: Blueprinting is the

process of straightening and/or matching

parts. When we talk about blueprinting

the bottom of your VS1, we are mostly talking about the

bottom of the sponsons. Your VS1, like other hand built

performance boats, will likely need to be trued (blueprinted)

get maximum performance.

To do this, you are going to need an 11" sanding bar with 80

grit sandpaper as well as 220 grit sandpaper; a fl at surface

from which to base your progress; as well as some sealer to

re-seal any areas of clear coat you might sand through.

2. Place the boat on a fl at surface and check the alignment

of the sponsons. Your sponsons should be parallel to each

other and touch the fl at surface at the same time.

3. Place a straightedge on the bottom of each sponson (ride

pad). Make sure the last 10"-11" are fl at. If not, you can

“blueprint” them - or make them identical - using sandpaper

To begin, set the boat on your fl at surface and put fi nger

pressure on the top back sides of the sponsons. We need to

do this to see if the two sponsons are parallel to each other.

If the boat rocks from side to side AT ALL, it’s best to match

them. Also take a look down the length of each sponson.

The sponsons work best if they are dead fl at from the back

of the sponsons to around 11" forward of that point.

5

Page 6

If your boat’s sponsons are not parallel to each other, you

will have to decide which sponson needs to be changed. I

like to pick the sponson that is lower in back and work this

sponson forward to match the other.

Load your sanding block with 80 grit sandpaper and place

it on the lower sponson. Start removing material off the

sponson, making sure you keep the sanding block fl at.

Check your progress often and work slowly. Be careful not

to round off any of the edges on the bottom of the boat.

They need to remain sharp.

DRILLING THE TRANSOM FOR THE ENGINE

Parts list and tools needed for this step:

Engine mount template (back cover of this manual)

Hand drill 3/32” drill 5/32” drill

Masking tape Toothpick Epoxy

Carefully cut the engine mount template out from the back

of this manual. Position it on the back of the transom using

tape to hold it in place. Using a 3/32" drill bit, drill the On-Off

hole location as well as pre-drill the holes for the motor mount

bolts. Switch to the larger 5/32" bit and re-drill the four motor

mount bolt locations. Remove the pattern and do your best to

seal the holes using epoxy and a toothpick. After the epoxy

has cured it’s a good idea to pass the appropriate drill bit back

through the holes to clean out any excess epoxy buildup.

Once you have the two sponsons parallel it’s time to move

on, making sure the sponson bottoms are fl at. You will

have noticed that the sponson that you just sanded had

some low spots; if you did not get all the low spots out do

your best to remove them, making sure you do not change

the sponsons’ angle. Once that sponson is completely fl at,

sand the other sponson bottom fl at as well. Finish up with

some 220 grit sand paper.

After you have both sponsons parallel to each other and

the bottoms are dead fl at, you will have to reseal the bare

wood. I like to use clear catalyzed auto paint but a good

fi nishing epoxy works well, too. Note: Avoid laminating

epoxies for this process.

After the sealer is cured, scrape the sponson bottoms fl at

with a single edge razor blade. If you need to apply more

sealer do so now. When that is cured, repeat the scraping

process and fi nish by scuffi ng the sponson bottoms with a

red scratch pad.

INSTALLING THE CABLE OUTPUT, SERVO

TRAY AND SERVOS

List of parts and tools needed to complete this step

(Collect the parts and supplies you need and let’s get

started. This step goes quite fast.):

Output (VS1 Kit)

Eight 2 x 8mm wood screws (VS1 Kit)

Servo Tray (VS1 Kit)

Throttle servo Steering servo Switch harness

Hand drill 1/16" drill bit 5/64" drill bit

Small tube of silicone sealer

4. Test fi t the cowl and make sure there is foam fl otation in

the front. Again check for any exposed wood and seal it at

this time if needed.

1. Place a small amount of silicone sealer onto the back of

the output and screw it into place on the back of the radio

6

6

Page 7

box using four of the 2 x 8mm wood screws. Be careful not to

get any silicone sealer into the small holes in the output that

the cables pass through and do not over tighten the screws.

2. Next take a 5/64" drill bit and carefully over drill the small

hole that passes through the fi nger lever of the on/off switch.

ASSEMBLING THE PULL-PULL WHEEL

This step requires the following kit parts and tools:

35mm pull-pull wheel (VS1 Kit)

Five 2 x 6mm machine screws (VS1 Kit)

Five 2mm machine nuts (VS1 Kit)

.049" pull-pull silver cable (VS1 Kit)

35 mm servo wheel (FUTM2000, comes with most standard

size Futaba servos)

Hand drill

5/64" drill bit

3. Install the switch harness onto the servo tray, making sure

that the switch is positioned on the starboard side of the tray

and that the off position of the switch is towards the back of

the boat. For safety reasons you want to have your switch

“PUSH” to turn the boat on. Slip the servo tray into the radio

box. Use four of the provided 2 x 8mm wood screws to hold

the tray in place. Install the rubber grommets and eyelets

(eyelets slide in from the bottom) onto the servos and place

the servos into the proper openings. Do your best to center

the servos in the opening so the sides of the servos do not

touch the edge of the wood. Using a 1/16" drill, pre-drill

the holes in the servo tray for the servo attaching screws.

Screw the servos in place using the screws provided with

the servos, being careful not to over tighten. Make sure you

have the output shaft positioned towards the front of the boat

on the steering servo and the output shaft to the port side on

the throttle servo.

1. Place the Futaba 35mm servo wheel over the top of the

pull-pull wheel. From the bottom side drill fi ve matching holes

into the Futaba servo wheel that coincide with the fi ve bolt

holes in the pull-pull wheel.

2. Test fi t, and bolt the two parts together using the provided

M2 screws and nuts. Do not fully tighten the parts as we are

just checking the alignment of the holes you drilled. Remove

the screws from the assembly and install the pull-pull cable. To

do this grab the cable and make a small loop in the center of it.

Slip the loop into the recess in the pull-pull wheel as shown.

7

Page 8

3. Carefully reinstall the Futaba servo wheel back over the

top of the pull-pull wheel and reinstall the screws and nuts.

You can place a small dab of thread lock on the screws

before tightening them down. Also, it is not a bad idea to use

a small amount of epoxy in the area the cables cross over

each other to keep them from slipping during operation.

INSTALLING THE ON/OFF PUSHROD WIRE

This step requires:

On/Off rod wire .069" dia. 16" long (VS1 Kit)

3/32" collar with M3 set screw (VS1 Kit)

Needle nose pliers

1.5mm hex wrench

1. Slip the wire through the on/off hole in the output of the

radio box. You are going to want to do this by inserting the

wire from the inside of the box through the cable output.

Temporarily remove the steering servo and 4 screws that

hold the servo tray into the box. Slip the tray forward but do

not remove it. Slide the bent end into the hole you enlarged

into the switch.

2. Carefully slide the servo tray back into position, taking

note the on/off pushrod wire needs to exit the transom you

drilled earlier. The wire will fl ex around the tank mount block.

Install the small lock collar on the end of the wire to complete

this step.

Grimracer says: One way to protect

your on/off switch from accidentally

being turned on or off is by clipping the

wire to just 1" long after it exits the radio box. This shorter

inside switch position requires you to unscrew the cowl

before and after each run but makes the on/off switch less

susceptible to accidental bumping.

In the future if you decide you would like to move the switch

back out through the transom, this can easily be done by

saving your cut-off length of wire and binding the two wires

together using a 5/32" locking collar (not included).

8

Page 9

INSTALLING THE ENGINE

Parts and tools you are going to need:

Engine

Four 6-32 x 1" Socket head bolts (VS1 Kit)

Four #6 washers (VS1 Kit)

Metal backing plate (VS1 Kit)

7/64" hex wrench

ASSEMBLING THE FUEL TANK MOUNT

1. Take a few moments to study the parts layout in the picture.

You will notice that one end of the base plate has holes in

it and the other end does not. The upright with the shorter

bottom legs glues to the end of the base plate without the

holes. The part fi t is tight; if needed, fi le or sand the slots a

bit larger for more clearance.

Place the motor against the transom. Set the metal backing

plate inside the motor box. Using the 6-32 bolts and washers,

bolt the motor to the transom. The metal backing plate is

tapped to the correct size so there is no need for lock nuts.

At this time there is no need to adjust the height of the motor;

we will get to that during the “Hull Tuning Tips” section (page

15) of this manual.

2. Using 12-minute epoxy, glue the center spine to the

base plate.

3. Epoxy the rear (short) upright into the slots in the back of

the base plate.

9

Page 10

4. Next, epoxy the front (longer) upright into the base.

INSTALLING THE FUEL TANK

Parts and tools you are going to need:

Pre-built mount (VS1 Kit)

Four 2 x 10mm wood screws (VS1 Kit)

Small Phillips screwdriver

Fuel tank (VS1 Kit)

O-rings (VS1 Kit)

Fuel line

5. To help strengthen the area that the O-rings attach to, it is

a good idea to place a few drops of thin CA on the hook end

of the uprights.

6. The completed mount.

1. Align the fuel tank mount’s front tabs in front of the forward

mounting block. Screw the mount in place using the four

2 x 10mm wood screws provided.

2. Carefully slip fuel line onto each fi tting on the fuel tank.

Place the fuel cell in the mount cradles and secure with the

included O-rings. If you like, you can cut the fuel line to length.

When doing so, make sure you have enough line length to

place the lower fuel line to the carburetor and the upper line

to the muffl er pressure. Note: Please use a fuel fi lter from the

tank to the engine carburetor.

10

Page 11

INSTALLING THE STEERING CABLE SYSTEM

Parts and tools you are going to need:

Assembled pull-pull wheel Safety glasses/goggles

Two clevises (VS1 Kit) Soldering iron

Two 2-56 nuts (VS1 Kit) Solder

Two threaded couplers (VS1 Kit)

Two 1/4" lengths of fuel line (VS1 Kit)

Rotary tool w/cutoff wheel

1. Position the pull-pull wheel so that the Futaba wheel is

facing up and the cable is towards the back of the boat. Slide

the cable through the small holes in the back of the output.

Place the pull-pull wheel on the steering servo and align the

wheel so the cable is centered on the servo.

4. Using a rotary tool and safety glasses, cut the cable on

the marks. Install the end of the cables into the threaded

couplers and solder them together. Repeat this on the other

side. Slip the short lengths of fuel tube up over the clevis.

This will help keep the ends from popping off in the event of

a blow off or rollover.

Grimracer says: When installed, the

cables will touch the fuel tank mount.

This is OK and will not cause any binding

in the system.

2. Screw the nuts onto the threaded couplers, then the

couplers onto the clevises to the point where you have an

even amount of threaded portion showing both front and

back. It’s a good idea to install the short length of fuel line

onto the clevis at this time so as not to forget.

3. Clip the clevises to the outermost holes on the engine’s tiller

arm. Make sure the servo wheel and tiller are centered. Then,

place a mark on the cable so you know where to cut it.

This is also a good time to place a small amount of cable

grease on the steering cables and on/off wire where they

exit the output guide.

11

Page 12

INSTALLING THE THROTTLE CABLE

Parts and tools you are going to need:

Outer white sheath (VS1 Kit)

Inner metal cable (VS1 Kit)

Four metal clevises (VS1 Kit)

Four threaded couplers (VS1 Kit)

Four 1/4" lengths of fuel line (VS1 Kit)

1/2" length of fuel line (VS1 Kit)

Two zip ties (VS1 Kit)

Rotary tool with cut off wheel

Soldering iron

Solder

Side cutters

Small Phillips screwdriver

2. Cut the outer white sheath to 16" long. Slip the 1/2" length

of fuel tubing onto the large protruding barrel of the output.

Then, slide the white sheath inside the output. Secure the

white sheath to the output by using the two provided zip ties.

1. Using a pair of side cutters prepare the throttle servo horn

by clipping away three of the four protrusions. I like to keep

things neat so I sand away any sharp edges that the side

cutters leave.

3. Insert the other end of the white sheath into the cable

clamp that comes with your motor and tighten.

4. Solder the metal clevis to one end of the steel cable;

slide the cable into the outer sheath from the radio box side.

Attach the metal clevis to the servo horn and position the

horn parallel with the servo.

12

Page 13

5. Next slide the short length of fuel line over the clevis so

as not to forget it. Temporarily slide the clevis over the metal

cable and attach to the throttle arm of the motor. Position the

throttle arm so the carburetor barrel is half open.

POWER UP AND FINAL SET UP

Parts and tools you are going to need:

Small Phillips screwdriver

Clear plastic radio box cover (VS1 Kit)

Antenna mount and tube (VS1 Kit)

Hand drill

1/4" drill bit

Silicone sealer

1. If you have installed the servo horn screws, remove them

at this time. Pull the servo horns off the servo output shafts

and power up the radio. Allow the servos to center. If you

are using a multiple memory radio system, select a model

and rename your model VS1. Reinstall the servo horns and

check the directions and centering of the servos. Adjust the

throttle linkage so that you can fully open and fully close the

carburetor. Remember, you MUST be able to stop the engine

with the radio system or you could risk a disqualifi cation (DQ)

in one of your heats.

6. Place the threaded coupler along side the clevis and mark

the approximate location to cut the cable. Using a rotary

tool and cut off wheel cut the cable at the mark. Solder the

threaded coupler to the cable and install the clevis.

2. Pick a location in the top of the clear plastic radio box

cover and drill a 1/4" hole through it. Using a small amount

of silicone sealer place it around the base of the antenna

mount and bolt in place. You can fi nger tighten the nut on

the back side or use a 10mm wrench, but be careful to not

overtighten the nut.

3. If you are using the latest 2.4GHz technology, you can

shorten the antenna tube that exits the radio box by cutting it

down. Caution: Do not cut the antenna wire from the receiver.

Also, if you are using 2.4GHz you can just let the antenna fold

back as you slide the cowl in place. If you are using 75MHz

technology, you are going to have to drill a corresponding

hole in the top of the cowl to allow the antenna to protrude

through the top.

13

Page 14

TAPING THE RADIO BOX LID

3. Finish by taping the sides. Check again to make sure

you’ve pressed all the tape fi rmly in place, and you’re done.

Remember: After running the boat, pull up the tape to remove

the lid and unplug the battery from the switch.

PAINTING TIPS

1. Start at the back of the radio box. Place tape so that half is

on the clear plastic top and the rest hangs over the side. Fold

the corners down, then press down fi rmly on the top and the

back side of the box.

SAFETY FIRST!

1. Always use a dust mask when sanding and a respirator

when painting.

2. It is required to have access to a proper spray booth or

outside ventilation.

3. You must wear protective gloves when painting and

working with chemicals.

4. If you are not willing to follow the above steps, do not

proceed with painting your boat.

To save weight the main hull and sponsons are best not

painted. However, to make the boat easier to see on the

water and to help protect the cowl from the elements, you

can paint it. Here are a few tips on painting your cowl. I will

list out a quick and easy way to paint the cowl as well as a

more professional way to paint the cowl.

QUICK AND EASY

Quick and easy paint supplies:

White Primer, Top Flite® LustreKote® (TOPR7527)

Color Paint, Top Flite LustreKote (TOPR7502 – TOPR7518)

Clear Top Coat, Top Flite LustreKote (TOPR7501)

Stick (to hold cowl when applying paint)

Double-sided tape

Isopropyl alcohol

Lint-free cloth

2. Repeat at the front of the box.

1. Follow the recommended usage on the paint cans for

proper application.

2. Prep your cowl by installing a paint fi xture of some type. I

like to use a 36" length of 3/4" square dowel (paint stick).

14

Page 15

3. Wipe the cowl down with isopropyl alcohol to remove any

fi ngerprints or other oils. Allow the alcohol to completely

evaporate.

4. Prime the cowl using LustreKote white primer.

5. Paint the cowl with the LustreKote color of your choice.

6. Clear coat the cowl using LustreKote clear top coat.

7. Add some decals and you’re set to go!

Sounds simple and it is. This is a great way to add a personal

touch to your VS1!

PROFESSIONAL FINISH:

Supplies you will need:

Spray equipment (i.e. compressor, spray gun)

Stick (to hold cowl when applying paint)

Double sided tape

Ta c k ra g

Lint free cloth

Fine line masking tape

Painter’s masking tape

Sandpaper (320 wet/dry)

Red scratch pad

Two part automotive primer/surfacer

Two part automotive color (your choice/s)

Two part automotive clear top coat

Let’s get started! Prep your cowl by installing a paint fi xture

of some type. I like to use a 36" length of 3/4" square dowel

(paint stick). You can get a length of wood like this at either

your local hobby shop or your local home store. Take some

double-sided tape and place a 10" to 12" length of it onto the

stick. Remove the backing and attach the stick to the inside

of the cowl. The longer stick makes a great handle to turn the

cowl as you paint.

Prep the cowl by wiping it down with a lint-free cloth and

isopropyl alcohol. Allow the alcohol to completely evaporate

before going any further. Using the red scratch pad scuff

the cowl to remove the gloss. Clean again with the isopropyl

alcohol and allow time to dry. Do not touch the cowl after

this step. Mix up some primer using the mixing ratios that

come with the primer. Prime the cowl starting with a light tack

coat followed by a slightly heaver coat. No need to go to a

full wet coat when using primer, as we are not going for the

ultimate fi nish but rather good adhesion. After the primer has

dried, inspect for any imperfections. Use the 320 sandpaper

on a sanding block to fl atten any high spots or imperfections.

Re-spray any areas that need to be touched up.

After the primer is fully dry, mix and spray the color. With

the color, you are looking for good adhesion and uniformity.

Begin by spraying a light tack coat. After the solvents have

fl ashed off apply another tack coat, wait just a few minutes

and apply a full wet coat. Be careful to avoid any runs in the

paint. After the color coat has fully cured, you can add details

like painting the windshield area or any fancy designs you

might like to try. I like to paint my windshield a medium gray

with a black anti-glare fade near the top. I also like to add

more than one color. Grimracer Says: Odd numbers of base

colors look better than an even number of colors. In other

words, 3 colors look better than 2 or 4.

After the color coats have cured, mix up your clear coat.

Spray the fi rst coat on using a light to medium coat. Wait for

the paint to fl ash off and apply another medium weight coat.

After you have that medium coat applied, wait approximately

5 minutes and apply a full wet coat. Be careful to avoid runs

in the clear. Move the cowl around in the light to look for any

dry spray or runs, adjust or add more paint if needed. If you

take your time you will be rewarded with a very long lasting,

tough and great looking paint job for years to come.

LAUNCH PROCEDURE

Before running the engine, read the instruction manual that

came with your engine.

1. Turn the transmitter on and then the receiver, in that order.

2. Start the engine. It is important to note, the propeller will

start spinning as you start the engine. Be sure to keep

clear of the propeller.

3. Once the engine is running and you are safely at the water’s

edge, launch the boat with a slight forward motion, applying

a slight amount of throttle as you release the boat.

4. Advance the throttle, taking note of the forward track of

the boat. Use the steering trim adjustment knob on your

transmitter to adjust the track of the boat.

5. When you are ready to bring the boat in, drive it parallel to

shore and push back on the trigger to stop the engine. Never

bring your boat to shore by driving it straight at you. Always

drive parallel to shore, stop the motor and then retrieve the

boat. This way if for some reason your engine does not kill

you can still go around and make another attempt.

ENGINE MAINTENANCE

When you are done running your VS1 for the day it is

important to properly maintain the engine.

1. Remove any fuel from the tank.

2. Remove the glow plug from the engine.

3. Open the carburetor.

4. Fill the carburetor with after run oil.

5. Place a rag over the head of the engine and apply short

bursts to the starting cone with your electric starter to coat

the inside of the engine. Repeat this step a few more times.

6. Reinstall the glow plug.

7. Remove the stub shaft from the lower unit and slide out

the cable. Re-grease the cable and reinstall.

When you are ready to run the boat again, remove the plug

and turn the engine over with the starter. Try to remove as

much oil as you can before restarting your motor.

15

Page 16

CARE AND MAINTENANCE

• If you should happen to drip or spill fuel on the fi nish of your

VS1, carefully wipe it off as soon as you can. Some fuels,

especially high nitro fuels and some with special oil additives,

can damage your boat’s fi nish.

• Open the radio box and unplug the battery from the switch

harness. Leave the lid off the radio box over night to make

sure any water that might have entered can evaporate.

• Clean the exterior of the boat and check the mounting

hardware.

• After a few runs and things have had a chance to settle you

are going to have to re-tighten the pull-pull cables leading

to the motor. There is no need to overtighten the cables.

I have found that even a fair amount of slack cannot be

detected when the boat is running.

• If you should happen to fl ip your VS1 you are going to need

to remove any water that might have entered the engine.

We recommend removing the glow plug and turn the engine

over a few times by hand to remove water. After most of

the water has been removed, leave the glow plug out and

turn the engine over with the electric starter to expel the

rest of the water. Make sure you hold a rag over the glow

plug hole. NOTE: Be careful to keep your rag and fi ngers

away from the spinning prop. Re-install the glow plug and

start the engine. It is best to start the engine after you have

fl ipped the boat to make sure ALL THE WATER IS OUT OF

THE ENGINE. It is also a good idea to inspect the radio box

to make sure no water entered the radio compartment.

HULL TUNING TIPS

The major tuning areas of your VS1 are:

• Propeller shaft (stub shaft) height

• Propeller shaft (stub shaft) angle

• Hinge Pin Angle

• Center of Gravity (C.G.)

• Propeller

Let’s start with propeller shaft height. To simplify, what we

are trying to do with propeller shaft height is to raise the

propeller to a height that gives us the greatest speed with the

least loss in stability. Let’s expand on this.

To measure the height of the shaft most racers use a set

up board. A typical tunnel hull set up board can be a simple

piece of shelf board with a slot cut into one end so the user

can reference the height of the prop to the bottom riding

surface of the sponsons.

Adjusting the shaft height plays a huge part in the speed

as well as the handling of the boat. Typically adjusting the

propeller higher makes the boat run faster but at a greater

risk of blowing off the water (fl ipping over backwards). It

also can cause loss of steering in the corners if set too high.

Lowering the shaft has the opposite effect and makes the

boat more stable but considerably slower. It is also important

to note that having the shaft too low can cause the boat to

stuff or tuck under when going around the corner. Setting

the shaft (prop height) is a very important part of tuning your

boat. It is also good to note that even 1/16" higher or lower

can make or break a good running tunnel boat.

Propeller Shaft Angle: Changing the propeller shaft angle

causes the bow of the boat to either run higher or lower

depending on the angle. What we are trying to accomplish

by changing the shaft angle is to loosen up the boat on the

water to make it go as fast as possible. More positive (+)

shaft angle lifts the bow, causing the boat’s tunnel to capture

more air, hence less drag and more speed. The risk of having

too much positive shaft angle is the possibility of blowing the

boat off the water. Too much negative (–) and the boat will

run too wet. Typical modern R/C tunnel boats run with about

1/2° of negative (–) shaft angle.

Hinge Pin Angle: Not all outboard engine mounting systems

allow you to change the hinge pin angle separately from the

stub shaft angle. It is worth noting, however, that outboard

engines that do have a distinct advantage over the ones that

don’t. Let me explain. When the servo swings your engine

left or right, the stub shaft follows the arc that the hinge

pin has been set at. If you have a positive hinge pin angle,

your stub shaft swings in a positive, neutral, positive motion

( + 0 + ). If your hinge pin angle is set negative, your stub

shaft swings in a negative, neutral, negative motion ( – 0 – ).

It’s important to note this, as the more positive angle the

hinge is set at the higher the bow raises in the corners and

the opposite regarding negative pin angle. These can be a

huge tuning advantage for the way you drive. To adjust the

hinge pin angle you must shim either the top or the bottom of

the engine mount plate from the transom. Also: You are going

to want to avoid engine mounts that set the hinge pin past the

back of the sponsons. Having the pin in front of the sponson

we call under steer and behind the back of the sponsons over

steer. The VS1 likes the pin in the under steer position.

Center Of Gravity (C.G.): The center of gravity “balance” of

your boat is just as important as other adjustments you make.

Adding or removing weight from the front of the boat ultimately

decides the stability of the boat as it fl ies over the top of the

water. The further forward you have the C.G., the more speed

the hull can handle, but like other adjustments to your boat

it comes with a price. As a model tunnel boat operates, the

boat’s ride can become disrupted. Any “acting forces” (i.e. wind,

waves, drag and or acceleration/deceleration) can cause the

boat to lose its balance. A properly set C.G. gives you the best

overall balance regarding all those changing conditions.

Propeller: First and foremost you need to balance or use

a balanced propeller. Not only will this provide the best

performance but it is necessary to avoid damaging your

engine. You can learn more about how to balance your

propeller at www.aquacraftmodels.com

16

Page 17

The propeller is probably the most important aspect of how

fast your boat goes and or how well it handles. A poor handing,

slow boat can become an instant winner just by using the

right propeller. As a rule of thumb, non-lifting propellers are

best suited for your tunnel hull. Some lifting propellers can

work but typically need to be “re-worked” to make work well

on a Tunnel Hull. For the best overall performance stick with

a low lift propeller like the AquaCraft GrimRacer 40x53 or

AquaCraft GrimRacer 40x52/3. Testing your propeller is best

done with a stop watch. The most important reading is the

time the boat takes to go from buoy one (1) to buoy three

(3) IMPBA and buoys one (1) through fi ve (5) NAMBA. The

second most important time to capture is overall lap speed.

Your boat may sound or look faster with a prop change

but don’t let that fool you. Course timing is the best way to

determine what if any changes your prop change as made.

Rudder Defl ection: Your VS1 needs very little rudder

defl ection to make it around a corner. Obviously your boat will

turn tighter with more rudder defection but the truth is this can

upset the boat in the corners. It is best to have just enough

rudder defl ection to make a nice sweeping corner PLUS just

a tad tighter. To set the amount of rudder defl ection, run your

boat on the race course at half throttle. Adjust the steering

dual rate until the boat makes a nice sweeping corner a few

feet off the buoys. Next: Run the boat at top speed (remember

to lift off the throttle just a little going into the corner) and

drive the course. Add in more dual rate until the boat runs

the course smooth and fast. Give a few more clicks on the

dual rate adjustment. The extra movement might be needed

to get you out of danger in the middle of a race.

VS1 BASIC SETUP PARAMETERS:

Motor Height: .200" Center of the prop shaft to

the bottom of the sponsons

Propeller Thrust Angle: .5° Negative

Hinge Pin Angle: Parallel to the transom

C.G. Range: 7.5" (27%) to 8.6" (31%) from

the back of the sponsons

Prop: 40x52/3 (AQUB9720)

Rudder Defl ection: 1-3/4" left – 1-3/4" right

DRIVING AND RACING TIPS FROM

12-TIME NATIONAL AND

WORLD RACING CHAMPION

MIKE "GRIMRACER" ZABOROWSKI

Your VS1 makes a fantastic Sport Class racing boat. The

VS1 was designed ultra light to take full advantage of low

power stock style motors. The VS1 is fully capable of wining

races against boats with a lot more power.

Grimracer says, “Don’t just drive your VS1 around, drive

your VS1 around something!” To reach the full potential

this boat has to offer, you need to get it on the water running

around the race course. Running your boat on the race

course allows you to build depth perception as well as get to

know the needs of the boat.

The VS1 responds best if you drive it as if you were driving

a car or any other type of wheeled vehicle. Your lap times

will go down if you lift off the throttle and set the boat as you

enter the corner and accelerate out. Driving “white knuckled”

you will likely not be paying attention to your entry point,

losing valuable seconds off your lap time.

If the pond you test at has an elevated driver’s platform,

make sure you stand on it even during testing. Also stand

in multiple locations. This way if you do not get your favorite

spot on race day you will not be surprised by what you

experience. It is also good to take a quick look at the water

and race course before you launch the boat for your heat. If

you see a buoy out of place or an obstacle in the water it’s

best to identify it before you launch the boat.

Starting and launching the boat later in clock time is far

better than starting and launching at the beginning. If your

clock time is 2:30 like most, be warned, if you go out early

you are adding to the seconds your boat can get into trouble.

During the race it’s best to be on the water ONLY as long as

you need to be.

Also have your caller show you the back of the boat before

he or she launches it. Move your rudder back and forth and

make SURE it is working before the boat is launched.

The VS1 was designed for the use of “stock” or “sport”

outboard motors. The ultra light weight of the VS1 and long

fl at section on the sponson bottoms take full advantage of

the lower power stock motors have. We do not recommend

the use of a modifi ed (piped engine) on this hull.

17

Page 18

Precision Prop Balancer

Precision Prop Balancer

ORDERING REPLACEMENT PARTS

To order replacement parts for the AquaCraft VS1 use the

order numbers in the replacement parts list that follows.

Replacement parts can be purchased from your local hobby

shop or by mail order. If you need assistance locating a

dealer to purchase parts, visit www.hobbico.com and click

on “Where to buy”. If you are missing parts, contact Hobbico

Product Support at:

Phone: 217-398-8970

Fax: 217-398-7721

E-mail: productsupport@hobbico.com

REPLACEMENT PART NUMBERS

AQUB9535 GrimRacer Tunnel Hull Fuel Tank 8oz

AQUB6899 Fuel Tank Hold Down O-Rings

AQUB7768 Pull-Pull Cable Tunnel Hull

AQUB8611 Radio Box Lid VS1

AQUB8610 Radio Box Output Guide VS1

AQUB9536 GrimRacer Pull-Pull Wheel Assembly 35mm

AQUB9537 GrimRacer Antenna Mount Assembly

AQUB6506 Engine Mounting Plate VS1

AQUB6226 Cowling

AQUB6898 Fuel Tank Mount

AQUB6328 Decal Sheet

AQUB9538 GrimRacer 8-32x1/2 Cowl Thumb Screw

GPMQ3790 Steel Clevis 2-56

GPMQ3830 2-56Threaded Coupler

GPMQ3702 Throttle Cable

GPMQ3300 2-56 Nut

GPMQ3404 #6 Flat Washer

GPMQ3038 6-32x1 Socket Head Cap Screw

™

Precision Prop Balancer

Precision Prop Balancer

To maximize performance — and minimize damage to

on-board electronics and parts —balance your props with

the GrimRacer Precision Prop Balancer. It’s easy to use.

Three thumb screws provide perfect level adjustment, and

a precise bubble level is built into the one-piece extruded

aluminum base. The balancer includes balancing shafts for

1/8” (3.2 mm), 3/16” (4.8 mm) and 1/4” (6.4 mm) bore prop

hubs. Propeller not included. AQUB9575

Below are some great web sites to help you in your R/C

boating quest.

www.aquacraftmodels.com

www.futaba-rc.com

www.osengines.com

www.odonnellracing.com

www.intlwaters.com

www.rcuniverse.com

www.rcgroups.com

www.metimeproductions.com

GrimRacer™ Speed Grease™ Cable Lube

This waterproof blue lubricant — with specially formulated,

“non sling” properties — reduces friction and wear on the

cable and direct drive systems in electric and nitro boats.

AQUB9500

GrimRacer™ Pro Radio Box Tape

Like champion racer Michael “Grimracer”

Zaborowski, use this 3/4” wide, clear

electrical 3M tape to seal your boat’s

radio box water-tight. AQUB9514

18

Page 19

™

Precision cast from Copper-Beryllium-Titanium!

Precision cast from Copper-Beryllium-Titanium!

Give your VS1 an added burst of speed — as easily as bolting on a high-quality copper-beryllium-titanium GrimRacer metal

prop! Racer-designed and USA-made, these are the most accurately cast metal props available. Ultra-clean casting and true

center-bore hubs place each prop near its balance point right out of the package. You can fi ne-tune them using less effort

than stainless steel props require — and they hold their shape better for balancing, sharpening, and changing pitch.

Stock # Description Type Diameter Pitch Bore Octura Equivalent Prather Equivalent

AQUB9715 40 x 53 2-Blade 40mm 53mm 3/16" 440 215

AQUB9720 40 x 52/3 3-Blade 40mm 52mm 3/16" 440 220

ENGINE MOUNT TEMPLATE

Cut Line

Drill four 5/32" holes

for motor mount bolts

Drill one 3/32" hole for

ON/OFF switch wire

Switch

Hole

19

Page 20

COPYRIGHT © 2008

COPYRIGHT © 2008

AQUB0006MNL v1.0

AQUB0006MNL v1.0

Loading...

Loading...