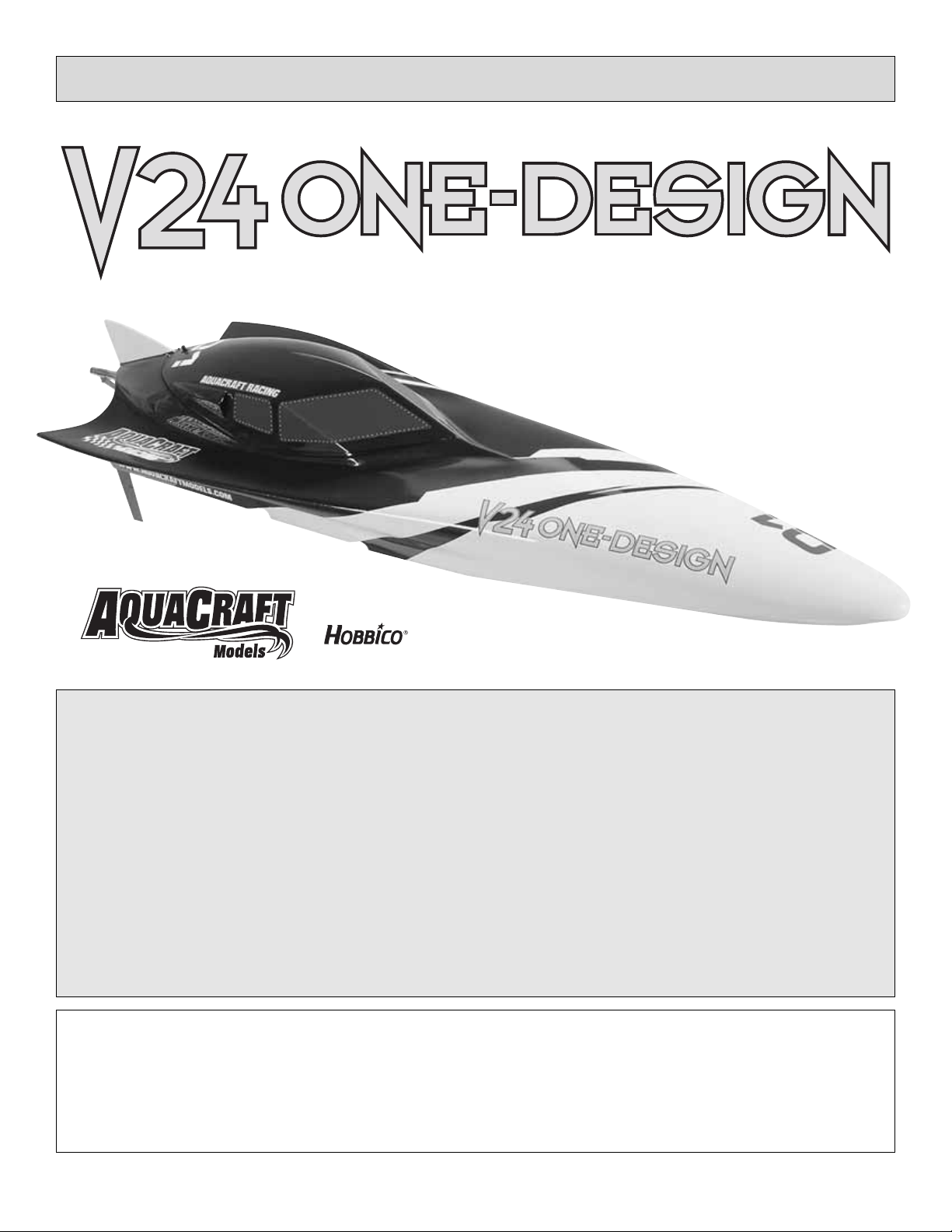

Page 1

Warranty

• AquaCraft™will warrant this kit* for 90 days after the purchase from defects in materials or workmanship. AquaCraft

will either repair or replace, at no charge, the incorrectly made part.

• Make sure you save the receipt or invoice you were given when you bought your model! It is your proof of purchase

and we must see it before we can honor the warranty.

• To return your V24 One-Design for repairs covered under warranty, you should send your boat to:

Hobby Services

3002 N. Apollo Drive, Suite 1

Champaign, Illinois 61822

Attn: Service Depar tment

Phone: (217) 398-0007 9:00 am - 5:00 pm Central Time M-F

E-mail:

hobbyservices@hobbico.com

*See engine warranty information on page 2

ASSEMBLY AND OPERATION MANUAL

™

™

Thank you for purchasing the V24 One-Design! We at AquaCraft know how e xciting a new R/C boat purchase can be and

we know you’re anxious to get started, but please take time to read these instructions carefully and completely before

attempting to operate your model. This manual contains the instructions you need to safely operate and maintain your

boat. As with any hobby, there is the possibility of injury.Arming yourself with knowledge is the best way to avoid injury.

If for any reason you think that this model is not f or y ou,return it to your local dealer immediately. PLEASE NOTE:

Your hobby dealer cannot accept a return on any model after the final assembly sequence has begun.

by

HCAZ1003 for HCAB40**Entire Contents © Copyright 2005

Page 2

Repair service is available anytime.

After the 90-day warranty, you can still have your V24 One-

Design repaired for a small charge by the experts at

AquaCraft’s authorized repair facility, Hobby Services, at

the address listed on the front page of this manual.

To speed up the repair process, please follow these instructions:

1. Under ALL circumstances return the ENTIRE system,

boat and radio.

2. Make sure the transmitter is turned off, all batteries

are removed and fuel is drained from the tank.

3. Send written instructions which include a list of all items

returned, a THOROUGH explanation of the problem, the

service needed and your phone number during the day. If

you expect the repair to be covered under warranty, be

sure to include a proof-of-purchase date (your store

receipt or purchase invoice).

4. Also be sure to send your full return address.

Your AquaCraft V24 One-Design features a powerful Fuji

™

24cc BT- Marine engine covered by Fuji Engines’ standard

3-Year Limited warranty.

SPECIFICATIONS:

Displacement: 23.9cc (1.45 cubic inch)

Horsepower: 3.0HP (2.18kw)

Ignition Style: Spring-Assisted Recoil Starter

RPM: 4000 - 12,000

Fuel: Gasoline/Oil mix

Weight: Approximately 1.4kg w/muffler (3.13 lbs)

Manufactured by FUJI IMVAC INC.

YOKOHAMA, 235-0005 JAPAN

Worldwide Distributor (except Japan): Hobbico, Inc.

Champaign, IL 61826 USA

www.fujiengines.com

Fuji Engines warrants this engine to be free from defects in

materials and workmanship for a period of three (3) years

from the date of purchase. During that period, Fuji Engines

will, at its option, repair or replace without service charge any

engine deemed defective due to those causes. You will be

required to provide proof of purchase date (receipt or invoice).

• This warranty does not cover damage caused by crash,

abuse, misuse, alteration or accident. Damage caused by

customer disassembly, tamper ing, use of substandard fuel,

use of incorrect accessories (spark plug, prop, etc.) or any

use of the engine for which it is not specifically intended will

automatically void the warranty of the engine. If there is

damage resulting from these causes within the stated

warranty period, Fuji Engines will, at its option, repair or

replace it for a service charge not greater than 50% of the

current retail list price. Be sure to include your daytime

telephone number and e-mail address in case we need to

contact you about your repair.

• Under no circumstances will the purchaser be entitled to

consequential or incidental damages.This warranty gives

you specific legal rights and you may also have other

rights, which vary from state to state.

• If you attempt to disassemble or repair this unit yourself, it

may void the warranty.

• The Fuji BT -24 Marineengine was designed for use in model

boats.Do not attempt to use it for any other purpose.

For service on your Fuji Engines product, either in or out of

warranty, send it post paid and insured to Hobby Services

(address on the front cover).

Along with your engine and proof of purchase date, please

include a complete written explanation detailing the problem(s)

and a phone number that you can be reached at during the

day. State your name and return address clearly. For repairs

not covered under warranty, you must specify whether you

wish the charges to be billed COD or if you wish to be notified

of the charges so you can send a check.

Outside USA and Canada, contact local importer for

warranty information.

All pictures, descriptions, and specifications found in this

instruction manual are subject to change without notice.

AquaCraft and Fuji Engines maintain no responsibility for

inadvertent errors in this manual.

• Adult supervision is strongly recommended! Children

should be warned about the dangers of playing in close

proximity to water.

• This boat is controlled by radio signals, which are

susceptible to possible interference from other R/C

transmitters, paging systems, or other electrical noise.

Before turning your radio transmitter and receiver on,

make sure no one else in the area is operating a radio on

the same frequency (channel).

SAFETY PRECAUTIONS

SPECIFICATION & DESCRIPTION CHANGES

FUJI ENGINES 3-YEAR LIMITED WARRANTY

FOR USA AND CANADA

REPAIR SERVICE

2

Page 3

• Use care to avoid touching the propeller anytime the

engine is running. Pay equally close attention to items

such as loose clothing, shirtsleeves, ties, scarves, long hair

or anything that may become entangled in the spinning

prop. If your fingers, hands, etc. come in contact with

the spinning propeller, you may be severely injured.

• The speed and mass of this boat can inflict property damage

and severe personal injury if a collision occurs. Never run

this boat in the presence of swimmers or where the

possibility of collision with people or property exists.

• Model engines generate considerable heat.Do not touch

any part of your engine until it has cooled. Touching

the muffler, cylinder head, or e xhaust header ma y result in

a serious burn.

• Gasoline is poisonous. Do not allow it to come into

contact with the eyes or mouth. Always store fuel in a

clearly marked container and out of the reach of children.

• Gasoline is highly flammable. Keep it away from open

flame, excessiv e heat, sources of sparks, or anything else

that might ignite it. Do not smoke or allow anyone else

to smoke in close proximity to open fuel containers.Make

sure that fuel lines are in good condition so that fuel will

not leak onto a hot engine causing a fire.

• Never operate your engine in an enclosed space. Model

engines, like automobile engines, exhaust deadly carbon

monoxide.Run your engine only in an open area.

• Use safety glasses when starting or running engines.

The propeller may throw loose material such as sand or

gravel into your face.

If the buyer is not prepared to accept the liability associated

with the use of this product, the buyer is advised to return

this kit immediately in new and unused condition to the

place of purchase.

The AquaCraft V24 One-Design can be made ready for the

water in just a few min utes.The following sizes of he x ke ys are

supplied with the V24:1.5mm, 2mm, 2.5mm, 3mm, and 4mm.

The following items are required to complete assembly:

❏ Adjustable Wrench

❏ Phillips Head Screwdriver

❏ Twelve (12) “AA”Batteries (SANP3500 x 4), eight (8) for

the transmitter, four (4) for the receiver

As with any hobby, it is a good idea to assemble a useful

collection of tools and accessories to bring along

anytime you head out to the pond. Here are some items

you will want to keep handy.

❏ #2 Phillips Screwdriver (HCAR1024)

❏ Hobbico Heavy Duty Diagonal Cutter 7" (HCAR0627)

❏ Pliers (HCAR0625)

❏ Hook & Loop Material (GPMQ4480)

❏ Hobby Knife (HCAR0109)

❏ Fuel Can (with 40:1 gas/oil mixture)

❏ Funnel

❏ Speed Grease Drive Cable Lubricant (HCAB3000) or

Heavy-Duty Marine Grade Cable Grease

❏ WD-40 (Spray-On Water Displacement Solution)

❏ Paper Towels

❏ Spray-On Glass Cleaner

❏ Zip-Ties (BUKC2477)

❏ Extra “AA” Batteries (SANP3510)

❏ Threadlocking Compound (GPMR6060)

❏ After Run Engine Oil (HCAP3000)

❏ Medium CA glue (GPMR6009) and Debonder (GPMR6039)

Other Useful Items to Have On Hand:

❏ Sunglasses

❏ Sun block

❏ Waders or rubber boots

❏ Cooler with plenty of ice and soda

❏ Folding table

❏ Lawn chairs

❏ First-Aid kit

❏ EZ-up or canopy for shelter

BOW:The front of the boat.

STERN: The back of the boat.

PORT: This is the left side of the boat when aboard and

facing the front (bow).An easy way to remember this is that

port and left both contain four letters.

STARBOARD:This is the right side of the boat when aboard

and facing the front (bow).

HULL: The body of the boat.

DECK: The top of the boat.

RUDDER: The hinged vertical plate mounted at the stern

that controls steering.

BOAT TERMINOLOGY

ITEMS REQUIRED FOR COMPLETION

AND OTHER USEFUL TOOLBOX ITEMS

3

Page 4

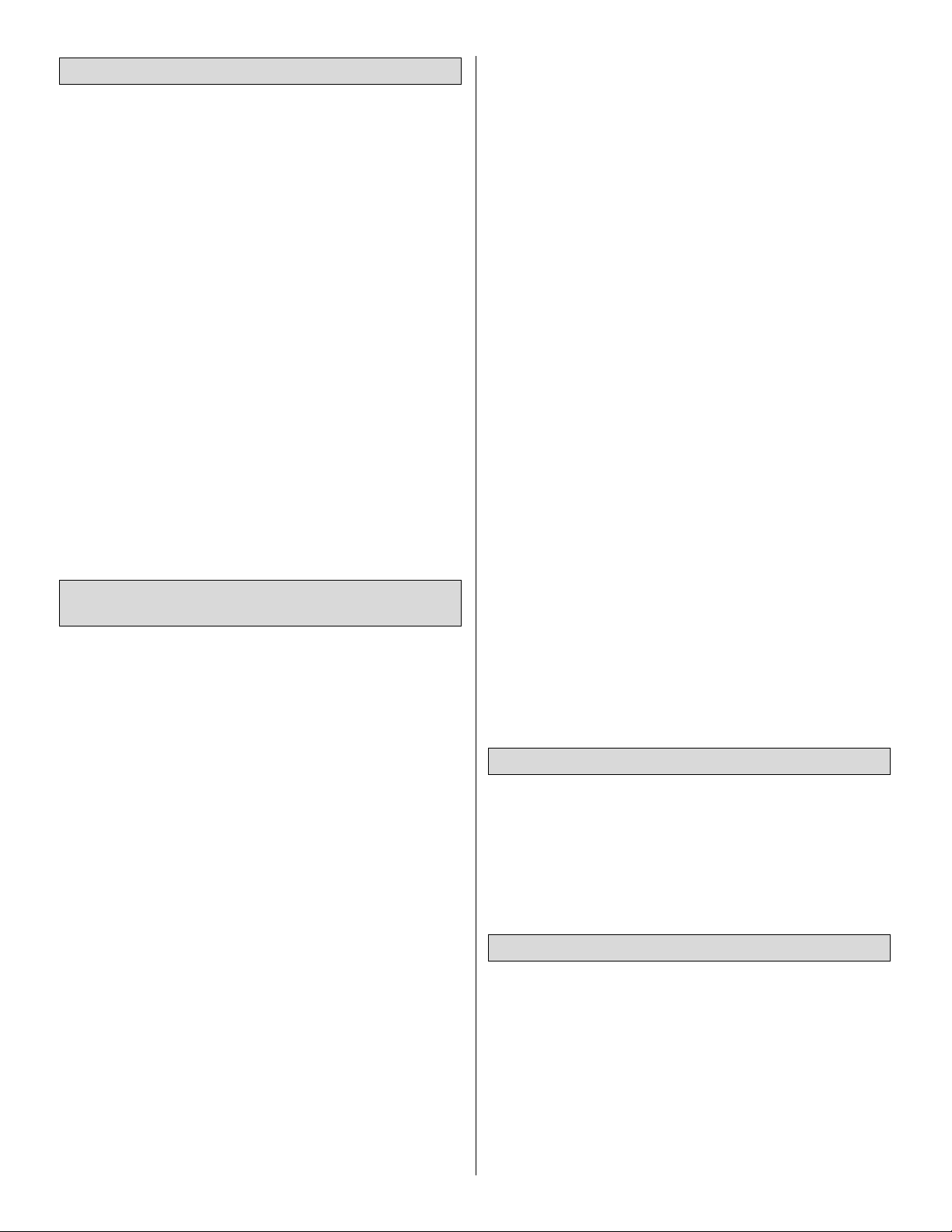

ASSEMBLE THE DISPLAY/WORK STAND

A display/work stand has been included with your V24 and

can be quickly assembled and disassembled.Simply join the

slots together as shown. If you prefer to keep the stand

assembled, you may glue the joints together with CA or

epoxy.This will also help to increase the stability of the stand.

Carefully place the V24 atop the display/work stand and

remove all remaining parts bags from the box. You may

wish to keep the box in order to more easily transport

and store your V24.

Decals have been provided for your V24. Simply cut

them out, peel and stick! See the photos on the box for

a decal placement example.

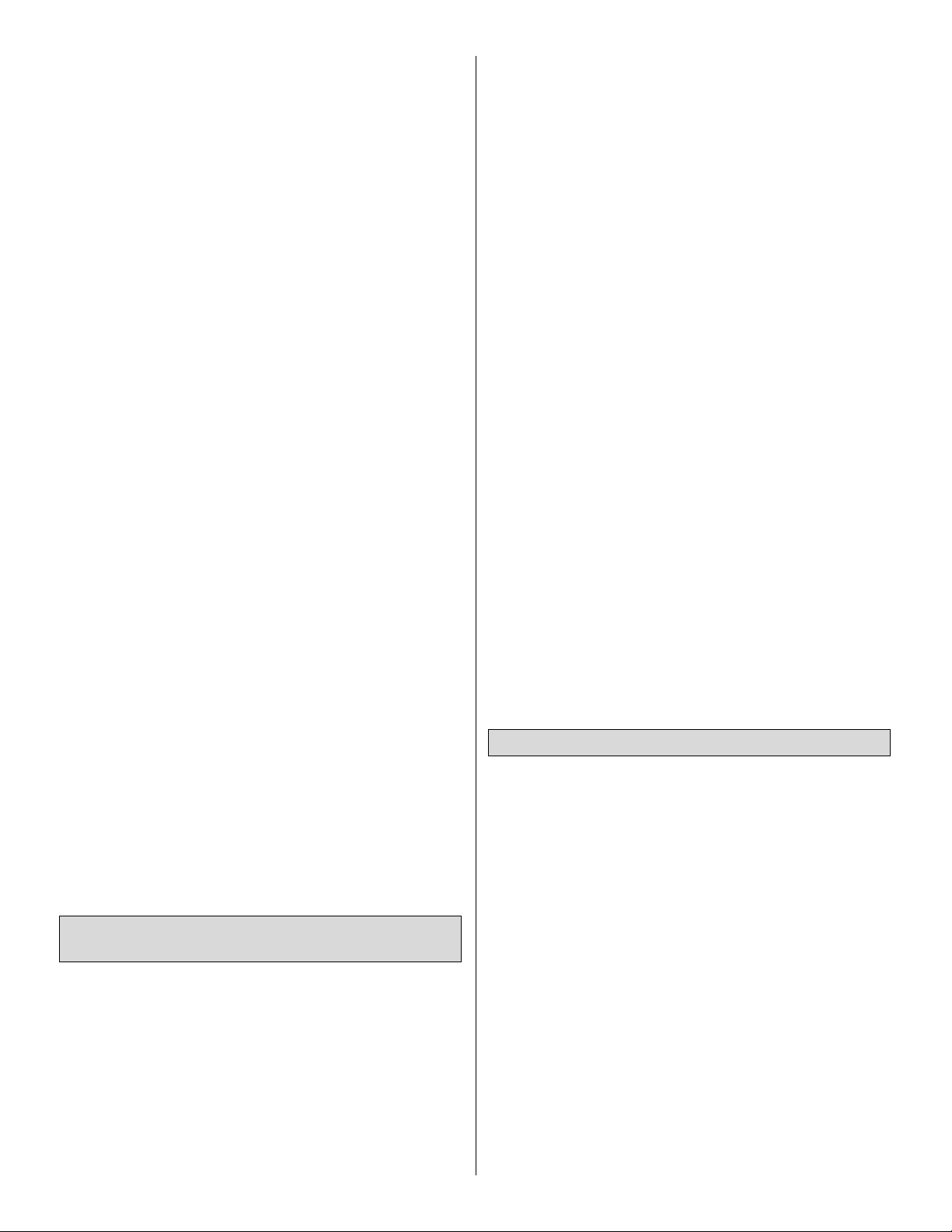

TRANSMITTER ASSEMBLY

Important Note: The transmitter is not water resistant

and should never come in contact with water.

❏ 1. Remove the transmitter antenna from the parts bag

and screw it into the top of the transmitter .To ensure that the

antenna is attached, lightly pull on the base of the antenna.

If it slides out, it is not installed properly.

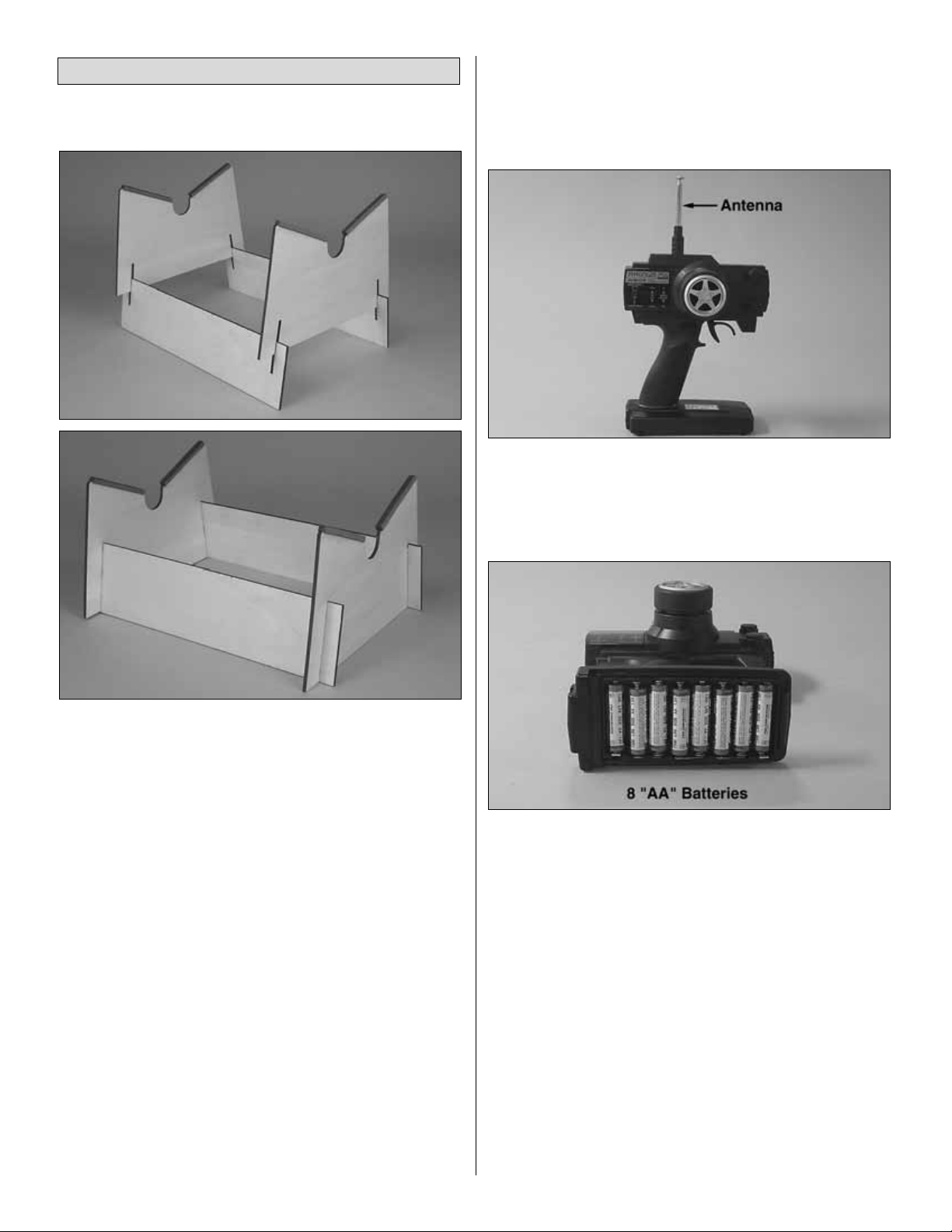

❏ 2.Slide off the battery door on the bottom of the transmitter.

Install 8 fresh “AA” batteries into the bottom of the transmitter

in the configuration molded into the battery holder.Reinstall the

battery door onto the bottom of the transmitter.

❏ 3.Turn the transmitter “ON”using the switch on the front.

The battery level indicator should show two green and one

red light. If the level shows only the red light, the batteries

are low and need to be replaced.

V24 ONE-DESIGN FINAL ASSEMBLY

4

Page 5

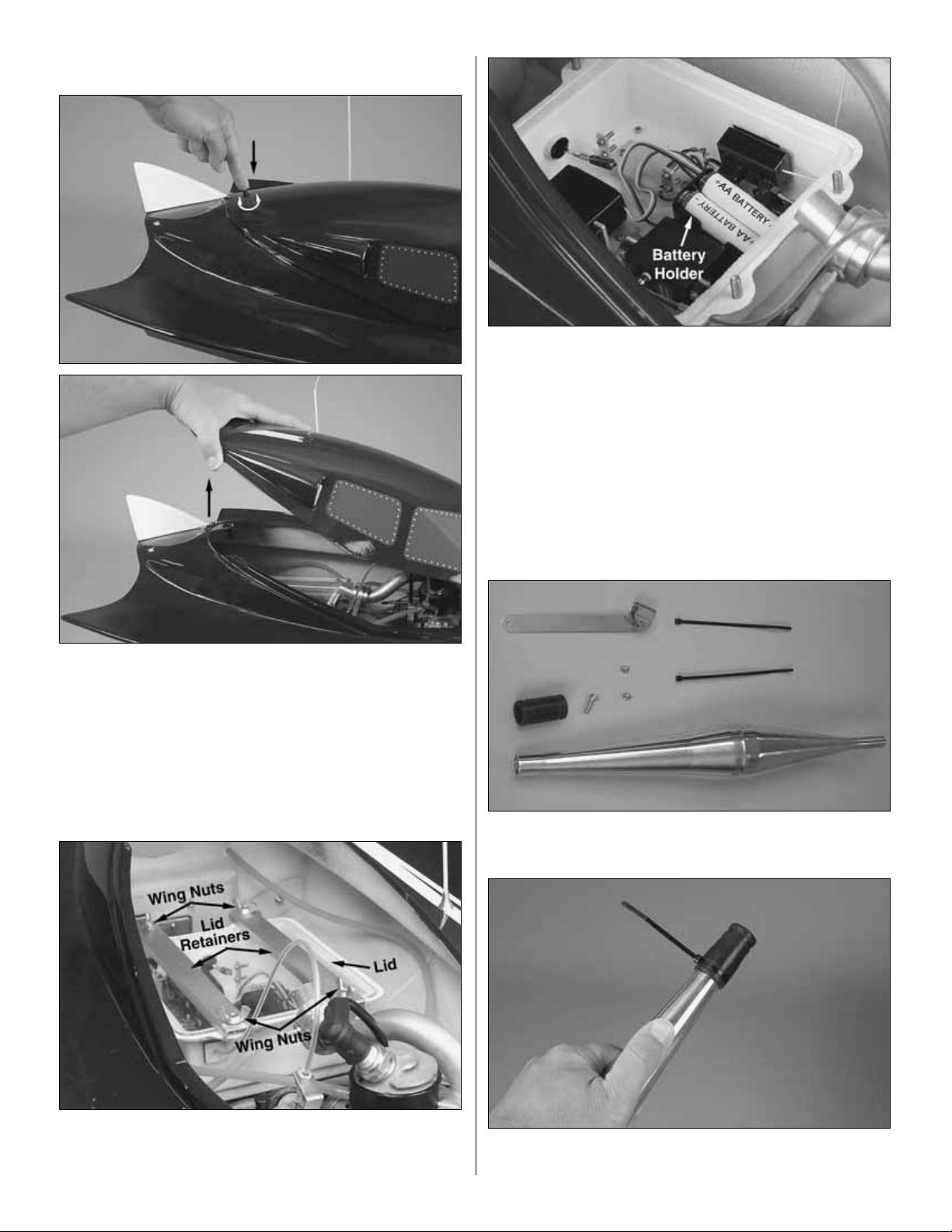

INSTALLATION OF RECEIVER BATTERIES

❏ 1. Locate the cowl lock button at the rear of the hatch.

Remove the hatch cover by depressing the button in a

twisting motion and then lifting as shown.

❏ 2. Remove the four (4) wing nuts and radio box lid

retainers as shown. This will allow you to remove the radio

box cover and access the receiver battery holder.

❏ 3. Place four (4) new “AA” batteries into the receiver

battery holder.Be sure to follow the polarity diagram molded

into the battery holder.

❏ 4. Replace the batter y holder inside the radio box. Make

sure that it will not interfere with any of the control linkages.

❏ 5. Replace the radio box cover and radio box lid

retainers. Secure them with the four (4) wing nuts.

INSTALLATION OF TUNED PIPE

❏ 1. Remove the tuned pipe, exhaust coupler, tuned pipe

brace, and (2) zip-ties from the accessory box.

❏ 2. Slide the exhaust coupler onto the large end of the

tuned pipe and secure it with one of the provided tie-straps.

5

Page 6

❏ 3. Slide the tuned pipe brace onto the small end of the

tuned pipe as shown.

❏ 4. Inser t the tuned pipe in through the exhaust outlet at

the rear of the boat until the exhaust coupler joins the tuned

pipe and exhaust manifold. Secure the exhaust coupler in

place with the remaining tie-strap as shown. Carefully cut

off the excess tie-strap end.

❏ 5. Place the tuned pipe brace onto the pipe brace mount

on the transom as shown and secure it with the 4mm nut.

❏ 6.Adjust the pipe so that it is not resting on the radio box

and insert the 4x15mm screw.Attach the 4mm nut.

INSTALLATION OF RUDDER

❏ 1.Locate the rudder from the accessory box.Remove the

3mm and 4mm nuts and the 4x15mm and 3x15mm screws.

❏ 2.Insert the rudder into the rudder control arm assembly as

shown. Replace the 4x15mm screw and 3x15mm screw and

secure them with the 4mm and 3mm nuts, respectively.

6

Page 7

❏ 3.Attach the water-cooling line to the rudder water pick-up

nipple as shown.

3-CHANNEL OPERATION

The V24 One-Design f eatures a variable strut unit that can be

adjusted manually or controlled by an optional third servo.

Installation of a third servo will require that you replace the

included radio gear with a 3-channel radio system.

As the boat is propelled forward and the speed increases,

the nose of the boat should lift out of the water slightly.

Adjusting the strut angle allows the propeller and engine to

work at maximum efficiency so the boat can reach faster

speeds (See Propeller Thrust Angle feature on page 12 and

3-Channel Operation feature on page 13).

CHECK THE RADIO SYSTEM:

• Standing behind the boat with both the transmitter and

receiver powered up , rotate the wheel to the left.The back

of the rudder should move towards the left. Move the

wheel to the right. The back of the rudder should move

towards the right. If this is not the case, simply move the

steering servo reverse switch to the other position.

• Squeeze the trigger on the transmitter; this should open the

throat of the carburetor. If this is not the case, simply move

the steering servo reverse switch to the other position.

The D/R knob located on the handle of the transmitter is the

steering rate adjustment. Turning the knob increases or

decreases the rudder movement.

SPARK PLUG

The recommended spark plug is a Champion RCJ-6Y. To

avoid improper operation or possib le engine damage, do not

use any other type of spark plugs. The plug gap should be

0.016" to 0.024" [0.4mm to 0.6mm]. If the plug gap is

incorrect, adjust it with a spark plug gapping tool, wash it

with gasoline and allow it to dry completely before you

reinstall the plug in the engine.

FUEL

Once the engine is broken in, use 40:1 (2.5% oil) fuel/oil

mix.Always use high quality oil intended for 2-cycle engines.

Prepare only the amount of gasoline needed.Aged gasoline

could damage the engine and cause it to overheat.

Use only low octane, alcohol-free gasoline. The carburetor

diaphragm will gradually deteriorate if you use gasoline with

alcohol.You will need to replace the diaphragm after about

80 hours of operation if you use gasoline with alcohol.

Fuel can go bad. Store your fuel out of the sunlight and in a

cool place. Bad fuel is one of the most difficult problems to

diagnose in engines. If you have tried everything you can

think of to remedy an engine that is not running correctly, try

using some fresh fuel.

OVERHEATING

One of the worst things you can do to your engine is

overheat it.The oil that lubricates the engine is carried in the

fuel. If your engine is set too lean, there will not be enough

oil in the engine to lubricate the internal parts. This will

cause premature wear in the engine and cause damage.

ENGINE ADJUSTMENTS

• Always make high and low-speed needle adjustments

while the engine is not running.

• Adjust the needle marked “H” for high-speed RPM. Adjust

the needle marked “L” for low-speed RPM.

NORMAL HIGH- AND LOW-SPEED NEEDLE SETTINGS:

It is not necessary to change the needle settings if the engine

runs smoothly. Normally only the “H” needle will need

adjustment from time to time and only by a small amount.

H: Open the needle 3/4 of a tur n from the closed position

(±1/4 of a turn in cold weather).

L: Open the needle 1-3/8 tur ns from the closed position

(±1/4 of a turn in cold weather).

Only adjust the high and low-speed needle within the

above range.

7

Page 8

IDLE ADJUSTMENT:

Important: Do not confuse the idle screw with the low-speed

needle “L”. The idle screw physically adjusts how much the

carburetor valve can close.The low-speed needle “L” adjusts

the gasoline to air mixture when the engine is running at low

RPM.If your engine appears to work correctly except that the

low RPM are not as low as you want them to be, then adjust

the idle screw. If your engine behaves erratically at low RPM,

then adjust the low-speed needle “L”. When adjusting, tur n

the screw about 1/8 of a turn each time.A dirty plug will make

it difficult to adjust the idle RPM. Follow the recommended

procedures if any of the following happens:

Problem:

• The engine hesitates when accelerated rapidly.

• The RPM increases at idling.

• The engine stops when the throttle is moved from high to low .

Solution:

Your low-speed needle “L” is too lean. Open it up

about 1/8 of a turn and try again.

Problem:

• The idle is not steady.

Solution:

Your low-speed needle “L” valve is too rich. Close

it 1/8 of a turn and try again.

HIGH-SPEED ADJUSTMENT:

The high-speed RPM and transition performance is adjusted

with the high-speed “H” needle valve. When adjusting, turn

the screw about 1/8 of a turn each time.The position of the

“H” needle will vary according to temperature and elevation.

If your engine is running smoothly then do not adjust this

needle valve.Follow the recommended procedures if any of

the following happens:

Problem:

• Engine stops at full throttle.

• Engine hesitates when accelerated rapidly.

• The engine will not come up to full RPM at full throttle.

Solution:

Your high-speed needle valve “H” is too lean.

Open it up 1/8 of a turn and try again.

Problem:

• Your engine does not reach full RPM.

• Carbon build-ups appear consistently on your spark plug.

Solution:

Your high-speed needle valve “H” is too rich.

Close it up 1/8 turn and try again.

To ensure long life and good performance from your Fuji BT-

24 Marine engine, you MUST break it in properly.To break-

in your BT-24 Marine, you need to run the engine for about

an hour with a fuel mixture that has a 25:1 (4% oil) fuel/oil

ratio. Patience is important here; the boat will run slowly

during the break-in process and the engine’s output power

will increase gradually over the first few tanks. Once the

engine is broken in and you begin running a 40:1 fuel/oil

mix, power will increase substantially.

• Do not adjust the high-speed needle on the carburetor to

break in the engine. If you do so, carbon will accumulate

in the spark plug and that will make ignition difficult.

• Do not run at full power for extended periods of time while

breaking in your engine.

• Make sure that the engine has adequate cooling.

Adjustments should be made on dry land with the boat

securely held in place.

BREAKING IN THE ENGINE

8

Page 9

There are several simple steps to starting the engine.It is a

good idea to have another person hold the boat in place

while you start the engine.

STARTING PROCEDURE:

IMPORTANT: The propeller will begin spinning as soon

as the engine starts! Be certain that the propeller is

unobstructed; failure to do so will damage the prop.

1. Carefully fill the fuel tank with the appropriate fuel/oil mix.

2.Turn on the transmitter and receiver (in that order).

3. Depress the priming bulb 2-3 times. This will begin the

flow of fuel into the carburetor.

4. NOTE: The engine was removed from the boat for

photographic purposes. You do not need to remove the

engine to open/close the choke. Close the choke on the

carburetor and pull the handle of the recoil starter until you

hear some initial firing sounds.DO NOT PULL THE RECOIL

HANDLE OUT ANY MORE THAN 25 INCHES; DOING SO

MAY DAMAGE THE RECOIL STARTER.

5. Quickly open the choke and pull the handle of the recoil

starter until the engine starts. THE PROPELLER WILL

BEGIN SPINNING AS SOON AS THE ENGINE STARTS!

6. After starting, let the engine idle for 15-20 seconds.Open

and close the throttle slowly until the engine runs smoothly

at idle and at full throttle. Acceleration should also be

smooth. DO NOT RUN THE ENGINE FOR EXTENDED

PERIODS OF TIME WITHOUT SUFFICIENT COOLING!

7.If your engine does not start, repeat the starting procedure.

8.With the engine started, put the hatch cover back in place.

Press the cowl lock and twist to secure it. BE CAREFUL

NOT T O TOUCH THE SPINNING PROP!

IMPORTANT: Unlike full scale boats, model boats race in a

clockwise circuit and it is the nature of model race boats to

make right turns more easily than left turns. If you absolutely

have to turn left, do so at very slow speed and allow yourself

plenty of room.

ST ARTING THE ENGINE

AND LAUNCH PROCEDURE

9

Page 10

9. Gently place the boat in water that is at least 8" deep and

free of obstacles (weeds, rocks, stic ks, duc ks , muskrats , etc.).

Be sure to stay clear of the spinning prop during the launch.

10. Slowly advance the throttle and note if the boat has a

tendency to turn right or left. Adjust the steering trim knob on

your transmitter until the boat runs in a straight line when the

steering wheel is at neutral.

11. When finished running, use the kill switch to stop the

engine and turn off the receiver and transmitter (in that order).

If the V24 pulls sharply to the right when accelerating, add

weight to the portside near the radio box. You will need to

experiment in order to determine most effective placement.

If the engine fails to start, refer to the TR OUBLESHOO TING

CHART on page 8.

HOW TO STOP YOUR ENGINE

For safety purposes, your V24 comes equipped with a kill

switch that can completely disable the engine until you are

ready to start it.

PLEASE READ these valuable running tips as well as the

“Safety Precautions” at the beginning of this manual

BEFORE Running the V-24 to ensure a successful and

safe run.

• NEVER attempt to swim after a stalled or capsized boat!

Wait patiently for the wind currents to return the boat to

shore or use a tennis ball attached to the end of a fishing

rod to retrieve a stalled or capsized boat.

• NEVER threaten wildlife with any R/C vehicle! This is the

quickest wa y to get R/C boating banned from y our favorite

local pond.

• It is dangerous to operate any R/C vehicle at any time that

there is not sufficient light.

• R/C models produce vibrations which

will

cause screws,

nuts, bolts, etc, on y our model to become loose over time.

It is important to make sure that all hardware is

secure before operating your model.

• Before running your V24, it is a good idea to check the

water-cooling system to make sure all tubes are

properly connected and unblocked.

• Do not attempt to stop the engine by throwing anything

into the path of the propeller or by grabbing the driveshaft.

• The edges of the propeller are very sharp and can cut

you very badly if you are not careful. At no time should

you ever attempt to stop the prop with your hand. In the

event that weeds become entangled in the propeller, stop

the engine before attempting to remove them.

• IMPORTANT: If, for whatever reason your boat takes on a

large amount of water causing the radio equipment to get

wet, you must do the following immediately: Remove the

battery pack and radio equipment from the boat.Allow the

components to air dry completely before reassembling.

Reinstall the components and check for proper operation

before running the boat again.

• If your engine should ever become submerged, remove

the spark plug and pull the handle of the recoil starter

several times until all water has been expelled from the

engine. Once you are positive that all water has been

removed from the engine and the spark plug is completely

dry, reinstall the plug and perform the starting procedure.

This may take several attempts.

• Always use a balanced prop. An unbalanced prop will

cause high levels of vibration that may be harmful to your

driveshaft and engine.

• Be sure to keep your driveshaft well lubricated. Failure to

do so may cause vibrations that can be harmful to the

engine. Re-lubricate your driveshaft frequently (See

Driveshaft Maintenance

on page 11).

• Do not use silicone fuel line because gasoline will ruin it.

Use vinyl or neoprene rubber fuel line instead.

• Use an in-line fuel filter intended for use with gasoline

engines. Metal filters intended for glow engines are too

coarse and will not screen out finer particles.

• CAUTION!The engine will be hot! Allow it to cool for a f ew

minutes before restarting.

• Total r un time of the V24 is approximately 25-35 minutes

(assuming you begin with a full tank of fuel). When you

notice an increase in power, it means the fuel tank is

nearly empty and it’s time to head for shore. As soon as

the boat reaches shore, stop the engine by pushing

forward on the kill switch. Open the hatch and turn off the

receiver and transmitter (in that order).

10

Page 11

• CAUTION: Windy conditions cause rough water that will

affect the performance of your V24 and increase the

chances of capsizing.

• Your V24 may take on water when running in rough

conditions and when making tight turns. Keep a roll of

paper towels handy and dry out the hull interior after every

run. Check for leaks if you notice excessive amounts of

water in the hull.

THE WAITING GAME

If your V24 should happen to stall, water currents will slowly

carry it to shore. The bad news is that the boat could be

carried to the opposite shore. When surveying areas to run

your V24, keep v ariables in mind such as wind direction, size

of the lake, etc. It is not advisable to run R/C boats on any

free-flowing bodies of water such as creeks or rivers.

HELPFUL TIP:

Use a fishing rod with at least 15lb line and

a tennis ball tied to the end to retrieve a stalled boat.

BASIC MAINTENANCE

When you are through operating your boat for the day, be

sure to perform these basic maintenance procedures. This

will prolong the life of the V24 and help to ensure troub le-free

running.Make sure that the engine kill switch is set to the

“OFF” position before performing any maintenance.

• Remove the hatch cover.

• Open the radio box.

• Soak up any excess water with a paper towel.

• Remove the driveshaft and wipe aw ay as much grease as

you can.Spray the driveshaft down with WD-40 and place

it in a plastic bag until you are ready to operate the boat

again (See Driveshaft Maintenance feature below).

• Wipe down the entire boat with spray-on glass cleaner

and a paper towel.

DRIVESHAFT MAINTENANCE

The flexible driveshaft is the most abused component of a

gas boat. IT IS CRUCIAL that you remove the drive shaft

and lubricate it with Speed Grease Driveline Cable Lubricant

(HCAB3000) or some type of heavy-duty marine grade

cable grease at the beginning of each daily session and

again every couple of tanks. This exercise will require a

1.5mm hex driver.Make sure that the engine kill switch is

set to the “OFF” position during this procedure.

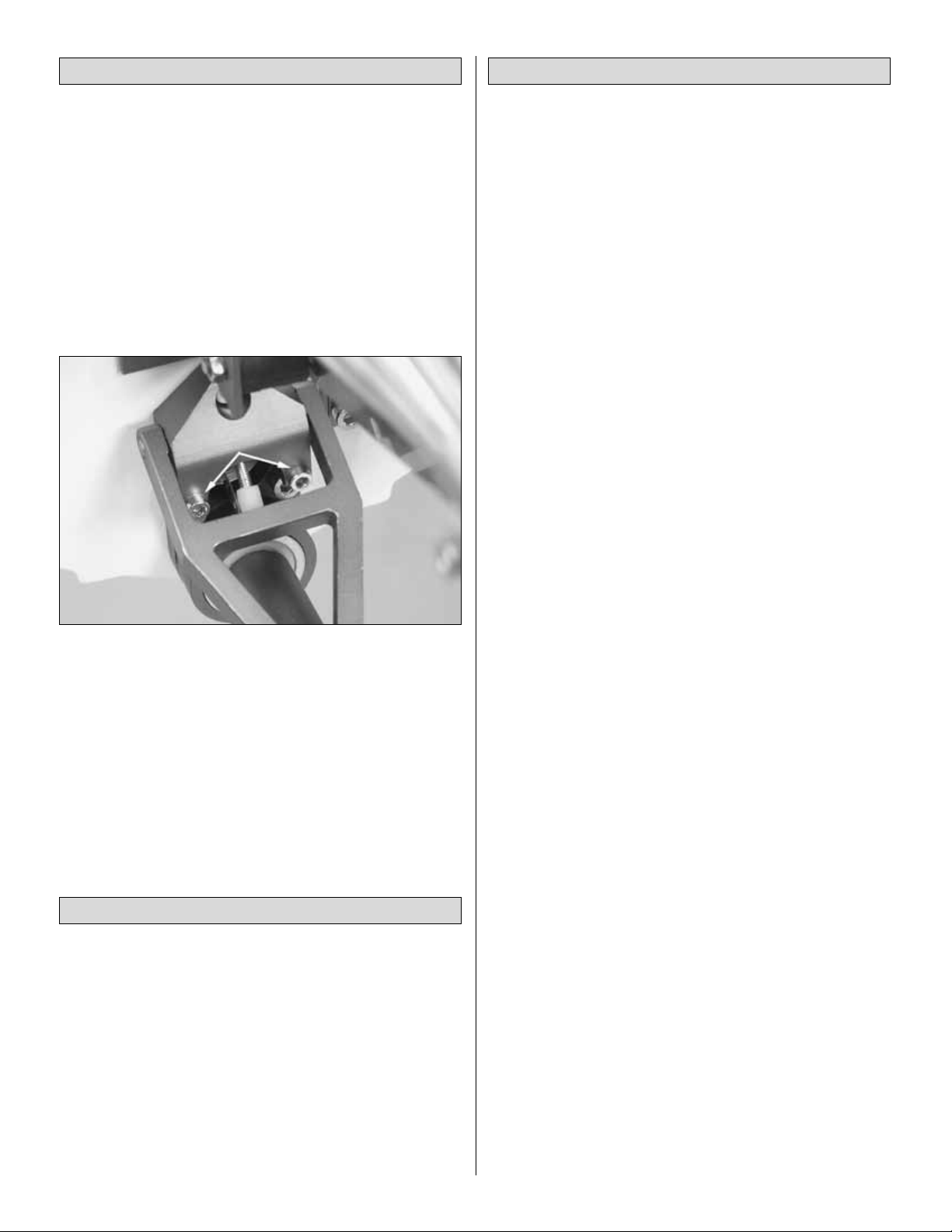

1. Usa a 1.5mm hex key to loosen the 3x3mm set screw

located on the strut assembly, and slide the retainer pin out

as shown.

2.Gently pull the driveshaft out and wipe off any excess grease

with a clean rag.

3.Apply Speed Grease Driveline Cable Lubricant (HCAB3000)

or heavy-duty marine grade cable grease to the driveshaft and

reinsert it into the stuffing box.Slowly rotate the driveshaft while

gently pushing it back into place.

4. Slide the retainer pin back in place and retighten the

3x3mm set screw on the strut assembly, making sure that

the set screw rests on the flat spot of the retainer pin.

MAINT AINING THE V24

11

Page 12

ENGINE MAINTENANCE:

Ways To Ensure A Long Life For Your Engine.

• Keep your engine clean. Dirt will act as insulation on an

engine and prevent it from shedding heat easily.

• Do not over-lean your engine.

• Do not run your engine without a propeller.

• Do not overheat the engine.This goes along with keeping

it clean and not over-leaning the engine.

• Avoid using old fuel in the engine. Always run all of the

fuel out of the engine. After r unning for the day, use afterrun oil and work it into the engine by pulling the pullstarter 2-3 times.

• Store your engine someplace where it will not be

subjected to extreme temperature changes.

• Before transporting your model, remove all of the gasoline

from the tank and lines.

• If you are not planning to run your engine for more than a

month, drain the fuel tank and remove any fuel from inside

the carburetor. Do this by running the engine at idle until it

quits by running out of fuel. Keeping gasoline inside the

carburetor over an e xtended period of time will damage the

diaphragm valve and clog passages inside the carburetor.

RADIO BOX MAINTENANCE

• Line the forward interior of the radio box with paper towel

prior to running to absorb moisture.

• Place the receiver in a rubber balloon to provide added

protection from moisture.

• Use a water-resistant tape to seal the radio box lid to the

radio box.

• When finished running, open the radio box and soak up any

moisture that may hav e made its wa y into the compartment.

• Should moisture gain access to the radio box, all

connections should be dried thoroughly. Hobbico “Duster”

Compressed Air (HCAR5500) will provide a blast of air

capable of blowing moisture out of connectors.

HULL MAINTENANCE

• After running, the exterior of the hull should be cleaned.

Common household cleaners can be utilized for cleaning.

Areas exposed to fuel/engine exhaust residue should be

thoroughly cleaned. Agents in the fuel/exhaust residue can

attack the finish if allowed to remain on the surf ace ov er time.

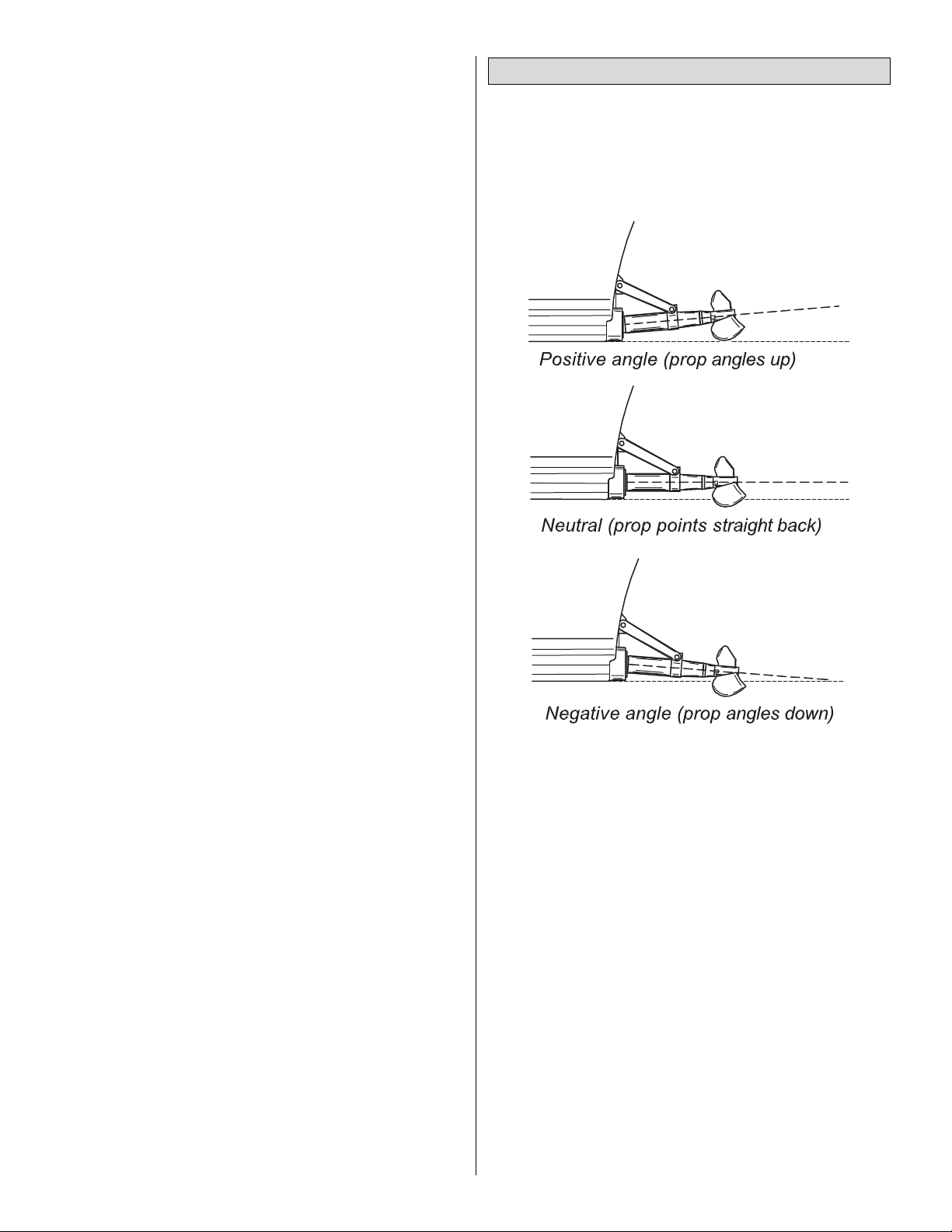

As an initial starting point, try running the V24 with a neutral

propeller thrust angle (See Figures 1-3 above).This can be

checked by placing a straight edge along the bottom of the

hull and checking its relation to the prop shaft.

Neutral Propeller Thrust: Provides thrust without letting the

thrust affect the ride attitude of the hull (the bow’s tendency

to ride up or down).

Positive Propeller Thrust: Causes a “bow upward” ride

attitude.A “bow upward”ride attitude will increase speed but

as it does, handling becomes more sensitive.

Negative Propeller Thrust: Causes the hull to r ide “stuck

down” (flat on the water). This reduces speed and may

cause the boat to submerge in a turn.

Be sure to retighten all the screws upon establishing the

desired thrust angle.

PROPELLER THRUST ANGLE INFORMATION

12

Page 13

The optional third channel will allow you to adjust the strut

and prop angle while the boat is in motion. This option is

used mainly by serious racers who need to fine-tune their

struts during a race. Once the proper thrust angle is

achieved manually by the average modeler, it is unlikely that

it would be used very often. In other words, a 3-channel

radio is not essential to have fun with this boat!

The procedure requires a 3-channel radio system (of

course!), an additional servo (preferably high torque), and

removing the two 3x10mm hex head screws that keep the

strut stationery (See photo below).

Once the two 3x10mm hex head screws ha ve been remo ved,

the strut assembly linkage is able to move freely. Simply

attach the strut linkage to the arm of your third servo and you

are ready for some serious racing!

IMPORT ANT SAFETY TIPS: It is recommended that you use

a 5-cell rechargeable receiver battery pack if you decide to

use the third channel option. However, since gasoline fumes

can build up inside the hull, you should NEVER attempt to

charge a battery pack while it is in the boat.

To avoid damage to the engine and flexible driveshaft,

balancing metal propellers is highly recommended. Balancing

a propeller requires the use of a balancing device such as the

Top Flite®Pow er Point®balancer (TOPQ5700), metal files, and

400 grit wet/dry sandpaper. The front, rounded side of the

propeller is the surface from which material is removed.Follow

the curvature of the propeller surface. Continue checking the

propeller on the balancer until the propeller is balanced. 400

grit wet/dry sandpaper will provide a smooth finish.

NOTE:While polishing a propeller improves its appearance,

it does not improve performance.

Although it is very enjoyable to run the V24 by yourself, the

real fun and excitement of R/C boating is experienced when

you get involved in racing. Racing against other boats is

much different than running your boat alone. The following

suggestions will hopefully provide helpful strategies when

racing a model boat.

A good set-up for running alone may not be the best for

racing. Race water conditions create challenges different

from running alone and water conditions constantly change

during a race. Five or six boats racing against one another

will create rough water on the race course. To compete

successfully, it may be necessary to “tighten” the ride

characteristics. This can be accomplished by lowering the

depth of the propeller or adding additional weight to the front

of the boat.

Wakes caused by other boats can upset the balance and

ride characteristics of even a well trimmed model boat.

When running down the straight-aways, don’t follow in

another boat’s wake.Wakes generated by other boats while

entering and negotiating a corner are especially dangerous.

Cutting across a wake when entering a corner can cause

the boat to “hook” (spin to the inside) and stall.

Racing other boats through a corner may be a competitor’s

greatest challenge, especially the first corner after the start

of a race.The boat entering the cor ner first has the task of

holding its position (often called “holding your lane”) through

the corner. The following boats must then attempt to hold

their lanes, too.Changing lanes and crossing a wake to gain

a position in a turn can result in “hooking” and elimination

from that race. Executing a good start in the inside lane is

one key to successful racing.

Avoid beating yourself.In any type of racing, there are some

situations you can control and other situations that you

cannot control. The ability to set the needle-valve on the

engine so it runs the entire race without stopping, checking

the linkages, fasteners, fuel tubing, amount of fuel, glow

plug, and radio system are conditions/situations that can be

dealt with prior to the start of a race. During the race, making

a good start and driving defensively are controllable actions.

By focusing on tasks and actions that can be controlled,

successful racing outcomes can be achieved.

RACING

BALANCE THE PROPELLER

3-CHANNEL OPERATION

13

Page 14

NATIONAL MODEL BOATING ORGANIZATIONS

There are three national model boating organizations in the

United States and Canada:

APBA or American Power Boat Association (RC Boat Category)

www.apba-rcboating.com

IMPBA or International Model Power Boat Association

www.impba.net

NAMBA or North American Model Boat Association

www.namba.com

Each of these organizations has its own rules governing

model boat racing, sanctioned events and recognized

records. Organized model boat racing is offered at both

regional and national levels .Location of clubs, race dates and

locations, membership applications, and other information

can be obtained through their respective websites.

All three offer both stock and modified engine classes for hulls

like the V24. Participation by those new to the hobby of model

boating is possible through club events.

Here are some more good sources of information regarding

all aspects of model boat operation:

International Waters Jim’s RC Boat Dock

www.intlwaters.com www.jrcbd.com

Of course, racing does not have to be an organized and

sanctioned competition to be fun. Small informal races can be

very exciting without the stress that comes with formal events.

SUGGESTIONS FOR SETTING UP

A SIMPLE RACECOURSE

• Make 2 to 4 simple and inexpensive “marker buoys”with

empty milk jugs, string, and heavy objects for anchors,

similar to the above sketch.

•For “drag racing”place the buoys similar to the abov e sketch.

• For “oval racing” place the buoys similar to the above

sketch. NOTE: The above patterns are not based on

official standards. You may set up racecourses any way

you desire, using your imagination to make the races

more interesting. Usually, smaller courses will provide

more action and excitement.

• The length of the races can be determined by a set number

of laps around the buoys (for example, the first boat to

complete 5 laps is the winner); or by time (for example,

whoever is leading at the end of two min utes is the winner).

GOOD LUCK AND GREAT BOATING!

14

GALLON-SIZE

PLASTIC MILK JUG

NYLON STRING

(ENOUGH TO REACH BOTTOM)

BOLT, ROCK OR HEAVY

OBJECT FOR ANCHOR

Page 15

To order replacement par ts for the AquaCraft V24, use the

order numbers from the lists below. Replacement par ts are

available only as listed and can be purchased from hobby

shops or through mail order/ Internet order firms. Hardware

items (screws, nuts, bolts) are also available from these

outlets.If you need assistance locating a dealer to purchase

parts, visit www.hobbico.com and click on “Where to buy”. If

this kit is missing parts, contact Hobbico Product Support.

ORDER # ITEM

HCAB6464 Fiberglass Cowl w/cowl lock

HCAB6902 Gas Boat Fuel Tank, 24oz.

HCAB7859 Flex Cable w/prop shaft, 1/4"

HCAB7862 Stuffing Tube

HCAB7863 Engine Flex Cable Collet

HCAG5101 Exhaust Header

HCAG5911 Tuned Pipe, 23cc - 30cc Gas

HCAB8200 Tuned Pipe Suppor t Brace

HCAB6502 Gas Engine Isolation Mount, 23-30cc

HCAB8605 Radio Box, Fiberglass w/Lid

HCAB9011 Servo Linkages w/connects

HCAB7865 Drive Dog w/screw,washer, 1/4"

HCAZ1003 Instr uction Manual

HCAB6314 Decal Sheet

HCAB7866 On-board Adjustable Surface Drive, 1/4"

HCAB7864 Prop Shaft for Adjustable Surface Drive

HCAG4736 Gas Exhaust Coupler w/tiewraps

HCAB7008 Push Button Cowl Locks (2)

HCAB8606 Radio Box Waterproof Tape

HCAG6010 Gas Engine Toggle Kill Switch

HCAB8708 Machined Aluminum Rudder, Blue alum

HCAB8709 Rudder Support Assembly, Blue alum

HCAB8710 Aluminum Rudder Control Arm

HCAB9260 Water Line nipples, std

HCAB9043 Adj.Trim Tabs w/water pick up

HCAB7761 Propeller, Balanced/Sharp 65mm Stainless

HCAG5110 Water Cool Header Jacket

HCAG5111 Water Cool Exhaust Flange for Fuji engine

HCAB6700 Water-proof Switch Boot w/ON-OFF Plate

HCAB6701 Radio Box Water Seal Boot (2)

HCAB7008 Push-button Cowl Locks (2)

HCAB8604 Antenna Tube w/ Cap

HCAB6702 Receiver Water-Proof Balloon (2)

HCAB8603 Radio Box Foam

HCAB8606 Radio Box Water-Proof Tape

HCAB3000 Speed Grease Driveline Cable Lube

Crankcase

Key # Part # Description

16......FJIG3830..................................Crankcase Assembly

17......FJIG6300........................................Oil Seal TB12227

18......FJIG3080 .................................Ball Bearing 6001 C3

19......FJIG3920......................................Crankcase Gasket

20*.....FJIG7310.................................Gear Shaft Shim 0.10

20*.....FJIG7311.................................Gear Shaft Shim 0.15

20*.....FJIG7312.................................Gear Shaft Shim 0.20

20*.....FJIG7313.................................Gear Shaft Shim 0.30

21......FJIG5315 ................................Ignition Coil Complete

24......FJIG0020.................................Magneto Rotor 60mm

25......FJIG0020.......................................................Adapter

28......FJIG8220...............................Hex Hole Bolt 4x18WS

32......FJIG8290 ..................................Hex Hole Bolt 5x18S

Engine

Key # Part # Description

1........FJIG5480..........................................Insulator Gasket

2........FJIG5515 ...............................................Insulator Set

3........FJIG8305 .................................Hex Hole Bolt 5x22/S

4........FJIG8645 ....................................Small Washer 5mm

5........FJIG3110 ......................................Carburetor Gasket

6........FJIG8340.....................................Hex Hole Bolt 5x50

7........FJIG8605 ..............................................Washer 5mm

8........FJIG8645 ....................................Small Washer 5mm

9........FJIG3230............................................Carburetor Set

ORDERING REPLACEMENT PARTS

15

Page 16

Recoil Starter

Key # Part # Description

0........FJIG7130.......................Recoil Start Body Assembly

1........FJIG7134 ............................................Starter Handle

2........FJIG7131.......................Recoil Star t Body Complete

3........FJIG7132................................................Recoil Rope

4........FJIG7133 ..............................................Recoil Spr ing

6........FJIG7135................................................Spring Case

8........FJIG7136...............................................Sarter Pulley

9........FJIG8606...............................Special Washer 5.2x15

10......FJIG7164 ...................................Tapping Screw 5x14

15......FJIG7137................................................Star ter Base

16......FJIG7162 ................................Tapping Screw 4.5x14

17......FJIG8190...............................Hex Hole Bolt 4x12WS

20......FJIG7138 .............................Starter Pulley Assembly

Cylinder/Piston/Crankshaft

Key # Part # Description

1........FJIG7470 ....................................Spark Plug RCJ-6Y

2........FJIG4441................................................Cylinder Set

3........FJIG8290..........................................Hex Bolt 5x18/S

4........FJIG4291..........................................Cylinder Gasket

5........FJIG6635 .................................................Piston Ring

6........FJIG6361 ...................................................Piston Set

7........FJIG6419 ...................................................Piston Pin

8........FJIG6509 ........................................Piston Pin Circlip

9........FJIG8719...............................Water Jacket Complete

10......FJIG7160...................................................Screw 3x8

11......FJIG4019..................................Crankshaft Complete

12......FJIG6149..............................Needle Bear ing 1.4x8.5

13......FJIG7660..............................................Woodruff Key

14......FJIG6260 ........................................................O-Ring

15......FJIG7500 ..........................Spark Plug Cap Assembly

Carburetor

Key # Part # Description

2........FJIG5460 ................................................Inlet Screen

3........FJIG6930.................................................Pump Body

4........FJIG7170 ...................................................Set Screw

5........FJIG7060..............................................Pump Gasket

6........FJIG7020 ........................................Pump Diaphragm

7........FJIG4610......................................Diaphragm Gasket

8........FJIG5760 ........................Metering Diaphragm Comp

9........FJIG3020..........................................Air Purge Comp

10......FJIG4520........................................Diaphragm Cover

11......FJIG6210 ..............................................Pr iming Body

12......FJIG8525................................................Valve Spring

13......FJIG6240...............................................Needle Valv e

15......FJIG7540.................................................Valve Hinge

16......FJIG5130...................................Hinge Pin Set Screw

17......FJIG5100....................................................Hinge Pin

18......FJIG5220........................................Idle Adjust Screw

19......FJIG5285 .......................................Idle Adjust Spring

27......FJIG7161 ...................................................Set Screw

28......FJIG5070..............................High/Low Adjust Spring

29......FJIG5590.......................................Low Adjust Screw

30......FJIG5040 ......................................High Adjust Spr ing

31......FJIG4940 ......................................High Adjust Screw

Loading...

Loading...