Page 1

Warranty

• AquaCraft

™

will warrant this motor for 90 days after the purchase from defects in materials or

workmanship. AquaCraft will either repair or replace, at no charge, the incorrectly made part.

• Make sure you save the receipt or invoice you were given when you bought your motor! It is your

proof of purchase and we must see it before we can honor the warranty.

• To return your EP1 for repairs covered under warranty you should send your motor to:

Hobby Services

3002 N Apollo Drive Suite 1

Champaign, IL 61822

Attn: Service Department

Phone: (217) 398-0007 9:00 am - 5:00 pm Central Time M-F

E-mail: hobb

yservices@hobbico.com

HCAZ3023 for HCAB7861Entire Contents © Copyright 2004

ASSEMBLY AND OPERATION MANUAL

™

EP1™Electric

Outboard Motor

Page 2

Thank you for purchasing the AquaCraft EP1! We at AquaCraft

know how exciting a new hobby purchase can be and we know

you’re anxious to get started, but please take time to read these

instructions carefully and completely before attempting to

operate your motor. This manual contains the instructions you

need to safely operate and maintain your motor. As with any

hobby, there is the possibility of injury. Arming yourself with

knowledge is the best way to avoid injury.

PLEASE NOTE: Your hobby dealer cannot accept a return on

the EP1 outboard unit after it has been used.

All pictures, descriptions, and specifications found in this

instruction manual are subject to change without notice.

AquaCraft maintains no responsibility for inadvertent errors in

this manual.

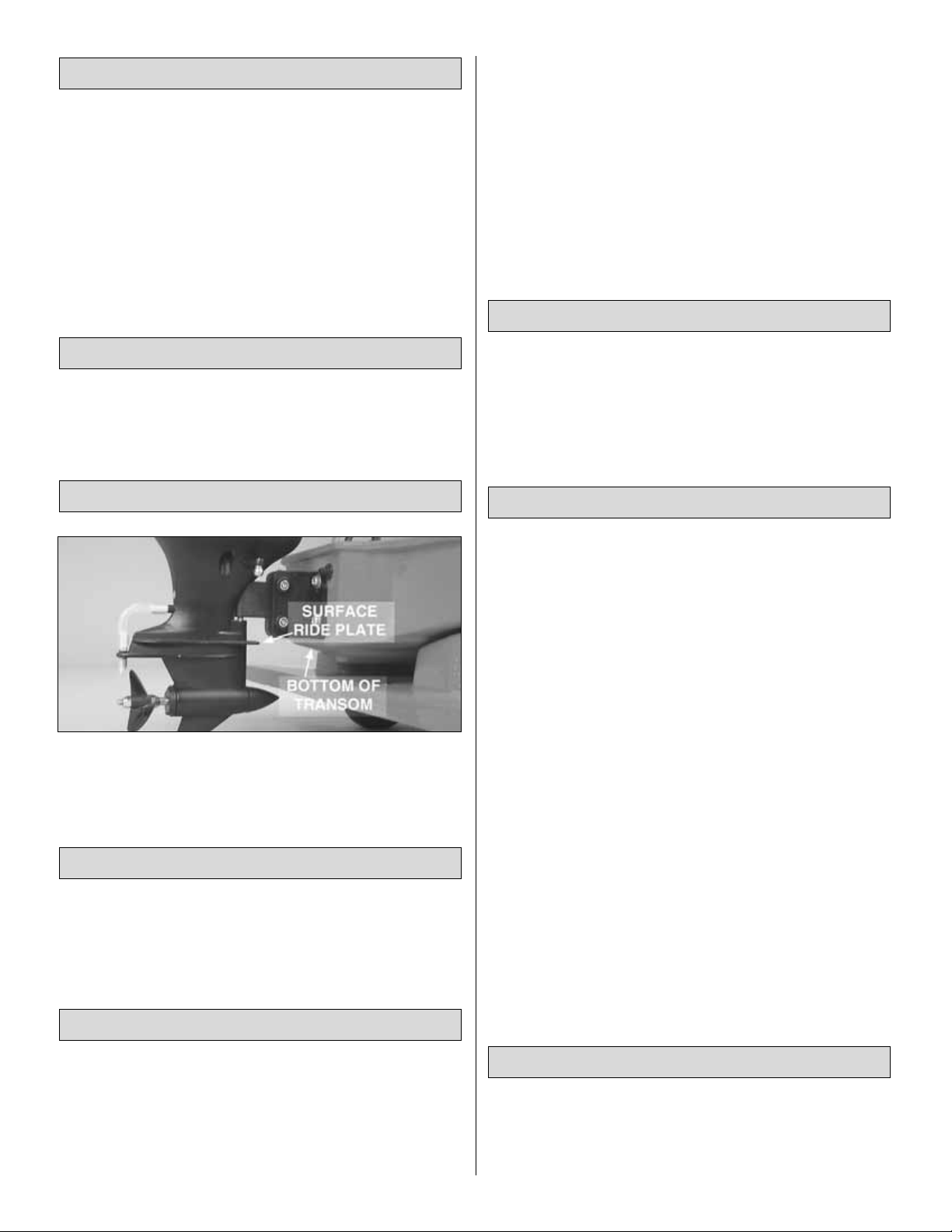

A template has been provided for you on page 3 of this

manual. This will help to accurately place the mounting holes.

Mount the outboard unit in the center of the rear of the boat

and so that the surface ride plate is even with the bottom of

the transom as shown.

The steering control arms of the EP1 outboard unit have been

outfitted with 4.8mm balls, but will accept clevis or Z-bend

links as well. You can attach to either control arm or both but

it is best, of course, to do whichever makes your boat perform

to its fullest potential.

When you are through operating your boat for the day, be sure

to perform these basic maintenance procedures. This will

prolong the life of the EP1 Outboard motor and help to ensure

trouble-free running. Be sure to turn the power “OFF” to

your boat and transmitter before performing any

maintenance.

• Flip your boat over and shake any excess water from the

motor compartment.

• Locate and remove the “end cap” (see “Exploded View”

on page 4) at the base of the outboard by turning it

counterclockwise. This will allow you to release any

water trapped in the gear housing. The “bullet” at the

front of the outboard unit is also removed by

counterclockwise rotation. This allows access to the front

shaft bearing.

• Make sure the propeller and drive dog are free of moss.

After every 10-12 hours of leisurely run time or after a day of

competition, it is a good idea to disassemble and re-lubricate

the gears, shafts, and bearings of the outboard unit with fairly

heavy-duty grease (not oil). Be sure to wipe away any old

grease but DO NOT use any de-greasing agents. Refer to the

“Exploded View” on the back cover for an assembly diagram.

You can increase the performance of the AquaCraft EP1 by

adjusting the ride height or the thrust angle of the propeller.

Making slight adjustments can make major differences, so it is

a good idea to keep a record of any adjustments you make

and how they affect performance. In addition to these

adjustments, performance may also be affected by the weight

distribution of your onboard radio gear, speed control, battery

pack(s), etc…

GO FASTER

The EP1 comes equipped with a 27-turn stock motor but can

be upgraded by replacing it with almost any 550-can size

motor. Be sure to consult the instructions for your speed

control unit to determine motor upgrade limits.

1. After clipping or de-soldering the red (+) and black (-)

motor wires, simply remove the two 3 x 8mm hex head

screws on the underside of the motor compartment and gently

lift out the stock motor. Be sure to remove the water-cooling

coil and jacket from the stock motor and place it on the

upgrade motor before installation.

2. Solder the red (+) and black (-) motor wires to the proper

wiring lugs and attach the upgrade motor to the outboard unit

with the two 3 x 8mm hex head screws.

PLEASE READ BEFORE running the EP1 on your model:

• NEVER attempt to swim after a stalled or capsized boat!

Wait patiently for the wind currents to return the boat to

SAFETY PRECAUTIONS

GETTING MORE OUT OF YOUR EP1

REGULAR MAINTENANCE

BASIC MAINTENANCE

STEERING LINKAGE

EP1 INSTALLATION

SPECIFICATION & DESCRIPTION CHANGES

INTRODUCTION

2

Page 3

shore or use a tennis ball attached to the end of a fishing

rod to retrieve a stalled or capsized boat.

• It is dangerous to operate any R/C model at any time that

there is not sufficient light.

• R/C models produce vibrations which will cause screws,

nuts, bolts, etc, on your model to become loose over

time. It is important to make sure that all hardware is

secure before operating your model.

• The edges of the propeller are very sharp and can cut your

fingers if you are not careful. At no time should you ever

attempt to stop the prop with your hand. In the event that

weeds become entangled in the propeller, turn the EP1’s

power “OFF” before attempting to remove them.

• Total run time of the EP1 can vary depending upon what

battery pack and ESC combination you are using. When

you notice a decrease in power or sluggish steering

response, it means the battery pack is nearly drained and

it’s time to head for shore. As soon as the boat reaches

shore, turn off the power to the boat’s receiver and

transmitter (in that order).

• CAUTION: Your motor and battery may be hot! Allow

them to cool for a few minutes before attempting to

remove the battery pack.

• Adult supervision is strongly recommended! Children

should be warned about the dangers of playing in close

proximity to water.

• R/C boats are controlled by radio signals, which are

susceptible to possible interference from other R/C

transmitters, paging systems, or other electrical noise.

Before turning your radio transmitter and receiver on,

make sure no one else in the area is operating a radio on

the same frequency (channel).

• Do not touch the propeller anytime the electronics are

turned “ON.” Pay close attention to items such as loose

clothing, shirt sleeves, ties, scarves, long hair or any

loose objects that may come in contact with the spinning

propeller. If your fingers, hands, etc. come in contact

with the spinning propeller, you may be severely injured.

• The speed and mass of R/C boats can inflict property

damage and severe personal injury if a collision occurs.

Never run an R/C boat in the presence of swimmers or

where the possibility of collision with people, wildlife, or

property exists.

• Electric motors can generate considerable heat. Do not

touch any part of your motor until it has cooled.

Touching the motor immediately after running the boat

may result in a serious burn.

If the buyer is not prepared to accept the liability associated

with the use of this product, the buyer is advised to return

the EP1 immediately in new and unused condition to the

place of purchase.

To order replacement parts for the AquaCraft EP1, use the order

numbers in the Replacement Parts List that follows. Replacement

parts are available only as listed and can be purchased from

hobby shops or mail order/Internet order firms. Hardware items

(screws, nuts, bolts) are also available from these outlets. If you

need assistance locating a dealer to purchase parts, visit

www .hobbico.com and click on “Where to buy.” If this kit is

missing parts, contact Hobbico Product Support.

Replacement Parts List

Order # Item Description

HCAB7861 EP1 Outboard Motor Unit *This is the part number

for the entire unit.

HCAB6457 Outboard Upper Cover #1

HCAB7857 Outboard Lower Unit #2

HCAB7750 Propeller Set #16,17,18,19 x2

HCAB7856 Ball Bearings #G x4

HCAB3479 Motor #3

HCAB7858 Motor Coupler & Gasket #6, A, #7

HCAB8100 Transom Mount #22, C x2, D x2

HCAB7801

Linkage Ball Studs & Linkages

#23 x2, E x2, F x2

HCAZ3023 Instruction Manual

Hardware Listing

A. 3 x 3mm Set Screw

B. 3 x 8mm Hex Head Screw

C. 3 x 16mm Hex Head Screw

D. 3mm Nylon Insert Locknut

E. 2mm Nut

F. 2 x 8mm Screw

G. 5 x 10mm Ball Bearing

OUTBOARD MOTOR TEMPLATE

ORDERING REPLACEMENT PARTS

3

Page 4

EXPLODED VIEWS

Loading...

Loading...