APW Wyott HTG-2436i Installation Manual

INSTALLATIONANDOPERATINGINSTRUCTIONS

Thermostatic Heavy Duty Gas Griddles

MODELS: HTG-2424i, HTG-2436i, HTG-2448i, HTG-2460i, HTG-2472i

(US & Canadian units are convertible and are assembled for Natural Gas)

(European units are not convertible and assembled for the appropriate Gas)

IMPORTANT FOR FUTURE REFERENCE

Please complete this information and retain this manual for the life of the equipment. For Warranty

Service and/or Parts, this information is required.

Model Number Serial Number Date Purchased

FOR YOUR SAFETY: Do not store or use gasoline or other flammable vapors and liquids

in the vicinity of this or any other appliance.

WARNING: Improper installation, adjustment, alteration, service or maintenance can

cause property damage, injury or death. Read the installation, operating and maintenance

instructions thoroughly before installing, or servicing this equipment.

WARNING: Instructions must be posted in a prominent location. All safety precautions

must be taken in the event the user smells gas. Safety information can be obtained from

your local gas supplier

P/N 8822231 09/24/13

APW Wyott MANUFACTURING

DALLAS: CHEYENNE:

1307 N. Watters Rd #180 • Allen, TX • 75013 1938 Wyott Dr • Cheyenne, WY • 82007

Local: (972) 908-6100 Local: (307) 634-5801

Toll Free: (800) 431-2745 Toll Free: (800) 752-0863

Parts/Service Fax: (214) 565-0976 Parts/Service Fax: (214) 565-0976

1

TABLE OF CONTENTS

ITEM PAGE ITEM PAGE

Safety Precautions ............................................ 3 Cleaning/Maintenance .......................................... 11

General Installation Instructions ........................ 4 Service/Repair ...................................................... 11

Specifications & Dimensions ............................. 5 Troubleshooting Guide ......................................... 12

Conversion ........................................................ 8 Replacement Parts Lists & Exploded Views ......... 13

Lighting Instructions .......................................... 9 Warranty ............................................................... 19

Operating Instructions ....................................... 10

LOCATION OF DATA PLATE

The data plate is located on the right side panel.

CAUTION: These models are designed, built, and sold for commercial use. If these

models are positioned so the general public can use the equipment, make sure that

cautions, warnings, and operating instructions are clearly posted near each unit so that

anyone using the equipment will use it correctly and not injure themselves or harm the

equipment.

WARNING: Improper installation, adjustment, alteration, service or maintenance can

cause property damage, injury or death. Read the installation, operating and maintenance

instructions thoroughly before installing or servicing this equipment.

WARNING: For your safety do not store or use gasoline or other flammable vapors and

liquids in the vicinity of this or any other appliance. Keep the area free and clear of

combustibles. (See ANZI Z83. 14B, 1991).

NOTICE: Instructions to be followed if anyone smells gas should be posted in a prominent

place. These may be obtained from the gas supplier.

GAS PRESSURE

The appliance and it’s individual shutoff valve (to be supplied by user) must be disconnected from the gas

supply piping system during any pressure testing of that system at test pressures in excess of ½ psi (3.45 kPa).

The appliance must be isolated from the gas supply piping system by closing it’s individual manual shut-off

valve during any pressure testing of the gas supply piping system at test pressures equal to or less than ½ psi

(3.45 kPa).

Congratulations on your purchase of APW Wyott commercial cooking or refrigeration equipment. APW Wyott

takes pride in the design and quality of our products. When used as intended and with proper care and

maintenance, you will experience years of reliable operation from this equipment. To ensure best results, it is

important that you read and follow the instructions in this manual carefully.

WARNING: A factory authorized agent should handle all maintenance and repair. Before

doing any maintenance or repair, contact APW Wyott.

2

IMMEDIATELY INSPECT FOR SHIPPING DAMAGE

All containers should be examined for damage before and during unloading. The freight carrier has assumed

responsibility for its safe transit and delivery. If equipment is received damaged, either apparent or concealed, a

claim must be made with the delivering carrier.

A) Apparent damage or loss must be noted on the freight bill at the time of delivery. It must then be signed by

the carrier representative (Driver). If this is not done, the carrier may refuse the claim. The carrier can

supply the necessary forms.

B) Concealed damage or loss if not apparent until after equipment is uncrated, a request for inspection must

be made to the carrier within 15 days. The carrier should arrange an inspection. Be certain to hold all

contents and packaging material.

Installation and start-up should be performed by a qualified installer who thoroughly read, understands and

follows these instructions.

If you have questions concerning the installation, operation, maintenance or service of this product, write

Technical Service Department APW Wyott Manufacturing., Inc, 1938 Wyott Dr. Cheyenne, WY 82007.

SAFETY PRECAUTIONS

Before installing and operating this equipment be sure everyone involved in its operation is fully trained an d is

aware of all precautions. Accidents & problems can result by a failure to follow fundamental rules and

precautions.

The following words and symbols, found in this manual, alert you to hazards to the operator, service personnel

or the equipment. The words are defined as follows:

DANGER: This symbol warns of imminent hazard which will result in serious injury or

death.

WARNING: This symbol refers to a potential hazard or unsafe practice, which could result

in serious injury or death.

CAUTION: This symbol refers to a potential hazard or unsafe practice, which may result

in minor or moderate injury or product or property damage.

NOTICE: This symbol refers to information that needs special attention or must be fully

understood even though not dangerous.

NOTICE: This product is intended for commercial use only. Not for household use.

CAUTION: These models are designed, built, and sold for commercial use. If these

models are positioned so the general public can use the equipment make sure that

cautions, warnings, and operating instructions are clearly posted near each unit so that

anyone using the equipment will use it correctly and not injure themselves or harm the

equipment.

WARNING: Improper installation, operation, service or maintenance can cause property

damage, injury or death. Read and understand these instructions thoroughly before

positioning, installing, maintaining or servicing this equipment.

3

WARNING: Keep the appliance free & clear of all combustible substances. If gas odor is

detected at any time, immediately shut unit down at the main shutoff valve. Do not permit

any open flames in the area of the appliance. Immediately contact an authorized Service

Agency or your local Gas Supplier for service.

WARNING: Do not obstruct either the air inlet (underneath unit) or the ventilation air

(back of unit). Provisions must be provided to provide an adequate air supply to the

griddle.

NOTICE: Local codes regarding installation vary greatly from one area to another. The

National Fire Protection Association, Inc., states in its NFPA96 latest edition that local

codes are "Authority Having Jurisdiction" when it comes to requirement for installation of

equipment. Therefore, installation should comply with all local codes.

GENERAL INSTALLATION INSTRUCTIONS

Ensure gas supply and gas type, as shown on unit nameplate agree.

Unit installation must conform with the National Fuel Gas Code, ANSI Z223.1/NFPA 54, the National Gas

Installation Code, CSA-B149.1, or the Propane Installation Code, CSA-B149.2 as applicable and in accordance

with local codes.

Screw legs into the permanently fastened nuts on the four corners of the unit and tighten by hand. Level the

unit by turning the adjustment screw at the bottom of each leg. Do not slide unit with legs mounted, lift if

necessary to move unit.

Pipe threading compound must be resistant to the action of liquefied petroleum gases.

Caution: DO NOT use an open flame to check for leaks. Check all gas piping for leaks with a soap and water

solution before operating unit.

THESE UNITS ARE SUITABLE FOR INSTALLATION ON NON-COMBUSTIBLE SURFACES ONLY.

Noncombustible clearances:

0" sides (0 mm) 0" rear (0 mm) 4" floor (102mm)

Do not obstruct the flow of combustion and ventilation air, under the unit by the legs or behind the unit by the

flue.

Adequate clearance for air openings into the combustion chamber is required. Do not place objects between

the bottom of the unit and the counter top.

There must be adequate clearance for removal of the front panel. All major parts except the burners are

removable thru the front if the gas line is disconnected.

Unit must have adequate clearances for servicing. (Sides = 0", Rear = 0", Floor = 4").

European Community Installation Instructions:

"THIS APPLIANCE MUST BE FITTED BY A COMPETENT PERSON. IN THE UK, CORGI REGISTERED

INSTALLERS (INCLUDING THE REGIONS OF BRITISH GAS) UNDERTAKE TO WORK TO SAFE AND

SATISFACTORY STANDARDS. THIS APPLIANCE MUST BE INSTALLED IN ACCORDANCE WITH THE

GAS SAFETY (INSTALLATION AND USE) REGULATIONS AND THE RELEVANT BUILDING REGULATIONS

/ IEE. REGULATIONS. DETAILED RECOMMENDATIONS ARE CONTAINED IN THE FOLLOWING BRITISH

STANDARD CODES OF PRACTICE - BS 6172, BS 5440 PART 2, BS 6891"

"THIS APPLIANCE MUST BE INSTALLED IN ACCORDANCE WITH THE RULES IN FORCE"

4

"MUST BE INSTALLED IN A WELL VENTILATED AREA. Ventilation requirements ie. B.S. 5440."

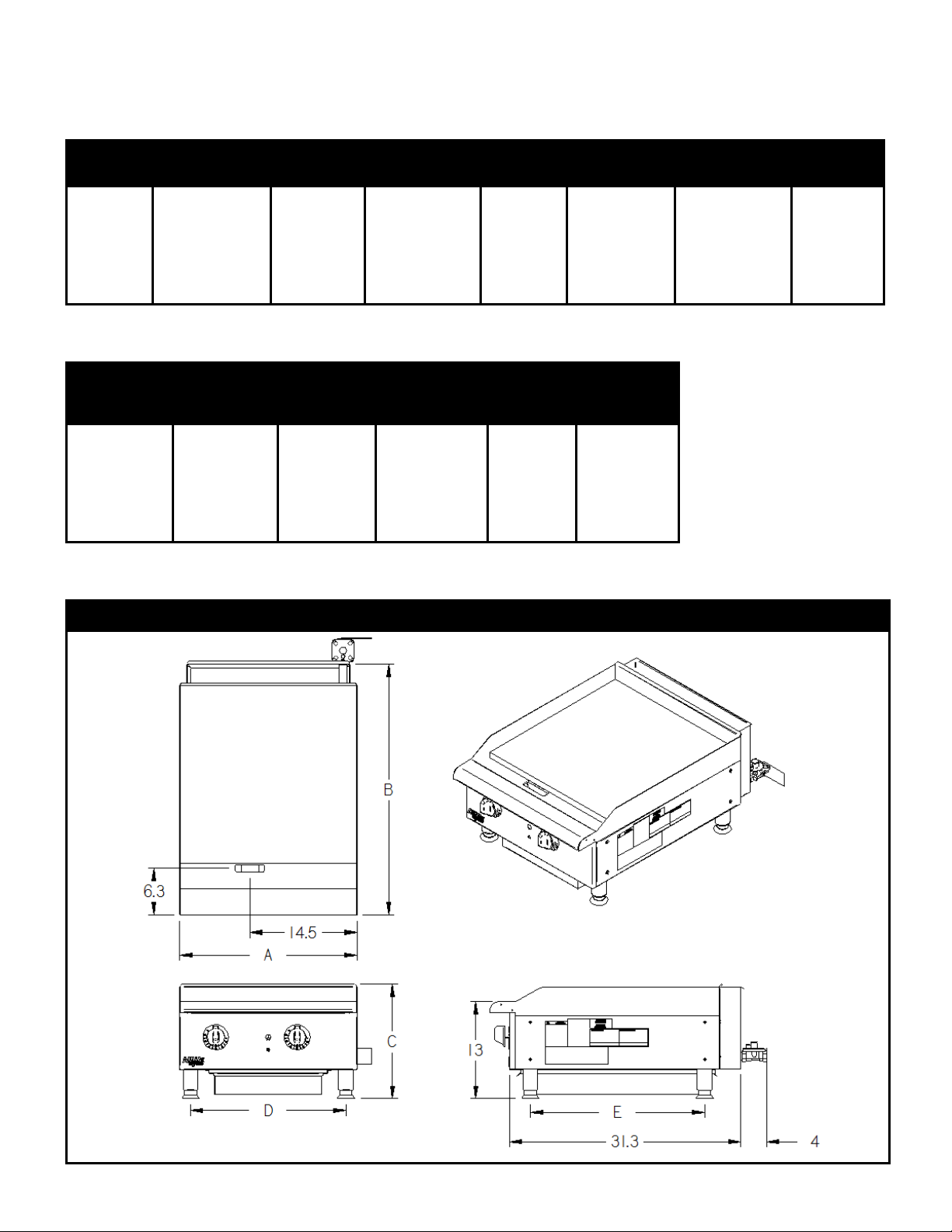

SPECIFICATIONS AND GRIDDLE SURFACE DIMENSIONS

MODEL

HTG-2424i

HTG-2436i

HTG-2448i

HTG-2460i

HTG-2472i

WIDTH

IN. (MM)

23.844" (605.6) 24" (609.6)

35.844" (910.4) 24" (609.6)

47.844" (1215.2) 24" (609.6)

59.844" (1520.0) 24" (609.6)

71.844" (1824.8) 24" (609.6)

Griddle Dimensions

DEPTH

IN. (MM)

HEIGHT

IN. (MM)

15.437" (392.1)

15.437" (392.1)

15.437" (392.1)

15.437" (392.1)

15.437" (392.1)

# OF

BURNERS

2

32,000 (9.78) 64,000 (18.8) 5 (12.4)

3

32,000 (9.78) 96,000 (28.1) 5 (12.4)

4

32,000 (9.78) 128,000 (37.5) 5 (12.4)

5

32,000 (9.78) 160,000 (46.9) 5 (12.4)

6

32,000 (9.78) 192,000 (56.3) 5 (12.4)

BTU/kW PER

BURNER

TOTAL

BTU/kW HOUR

W.C.

IN.('Mbar')

MODEL

HTG-2424i 24" (609.6) 33.3" (846) 15.5" (392.1)

HTG-2436i 36" (914.4) 33.3" (846) 15.5" (392.1)

HTG-2448i 48" (1219.2) 33.3" (846) 15.5" (392.1)

HTG-2460i 60" (1524.0) 33.3" (846) 15.5" (392.1)

HTG-2472i 72" (1828.8) 33.3" (846) 15.5" (392.1)

WIDTH

(A)

DEPTH

(B)

HEIGHT

(C)

SPECIFICATIONS – HEAVY DUTY GAS GRIDDLE: HTG-2424i

LEG

SPACING

(D)

21.0”(533)

33.0”(838)

45.0”(1143)

57.0”(1448)

69.0”(1753)

LEG

SPACING

(E)

23.6” (600)

23.6 “ (600)

23.6” (600)

23.6” (600)

23.6” (600)

5

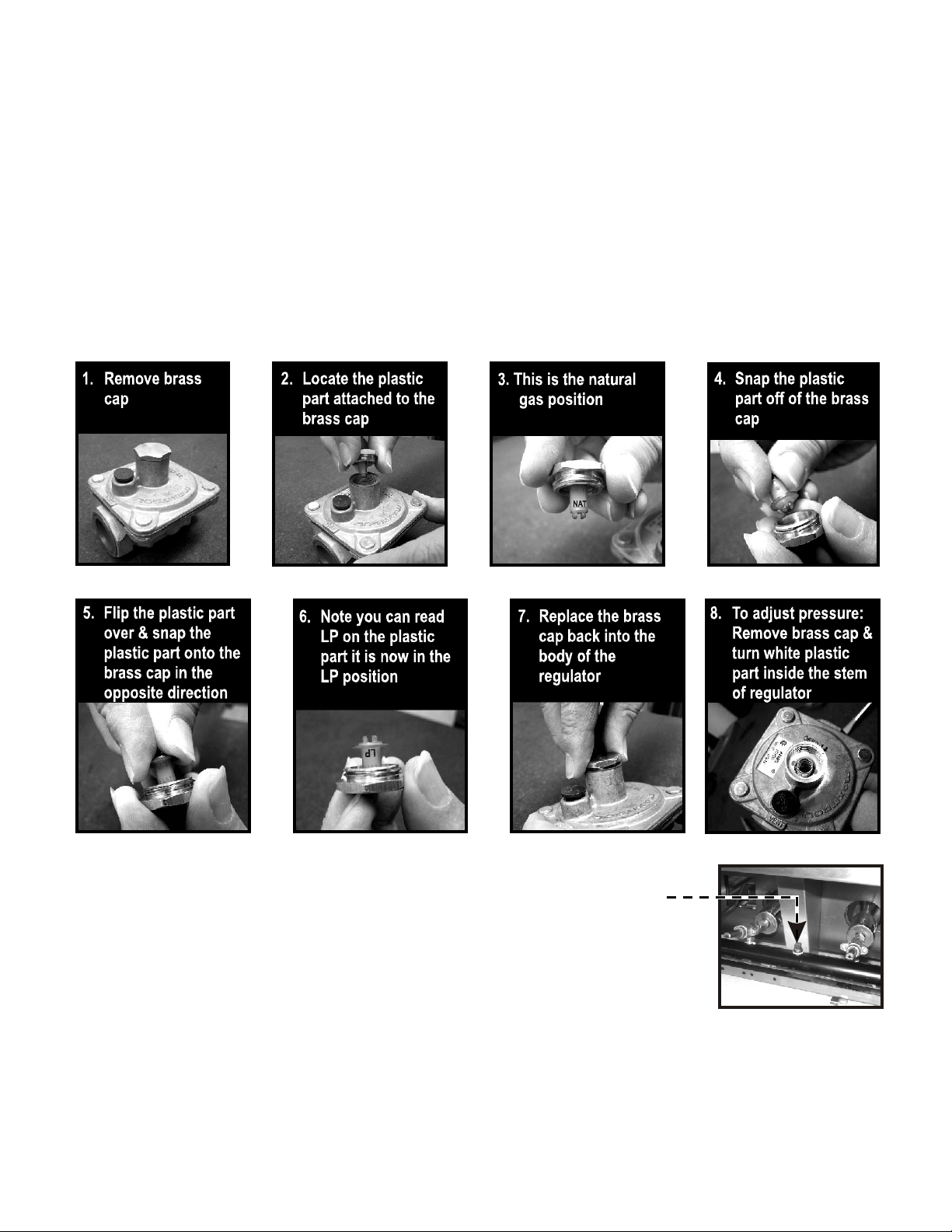

CONVERSION

Instructions are for conversion from Natural Gas to Propane (L.P.) on all models HTG.

The conversion should be done before connecting the unit to the gas supply.

Units are shipped from the factory equipped for use on natural gas. Orifices necessary for LP (propane) are

provided in a bag tied to the valve on the front panel.

1. Remove the knobs and front panel.

2. Remove the orifice fittings from the valve. Change the orifices to the size recommended for propane

(L.P.).

3. Replace the orifice fittings into the valve.

To change the regulator:

Connect the regulator to the unit, connect gas and check for leaks. WARNING: Do not use an open flame

to check for leaks.

Check the system pressure. With the front p anel remo ved remo ve the pl ug

from the manifold.

Place a fitting in the plug opening and connect a manometer.

For Natural gas the pressure in the manifold should be 5" water column or

12.4 millibar. For LP the pressure in the manifold should be 10" water Column of

24.9 millibar.

To adjust the pressure remove the brass cap and turn the white plastic part inside the stem of the regulator.

See picture regulator 8.

Take a wide straight screw driver and place it in the two notches shown in pi cture regulator 7 turn clockwise

to increase pressure and counter-clockwise to reduce pressure. See picture regulator 8.

Once the pressure has been adjusted replace the brass cap.

Note the blue cap on the regulator, this is the vent there are openings below the top rim. NEVER bloc k

these openings your regulator will fail to operate correctly. On at least a monthly basis blow off any dust or

6

Loading...

Loading...