Page 1

R

INSTALLATION

AND

OPERATING

INSTRUCTIONS

Models:

HFW-1, 1D

HFW-23, -23D

HFW-12, -12D

HOT FOOD WELLS TOP MOUNT, INSULATED

UNIT MUST BE KEPT CLEAR OF COMBUSTIBLES AT ALL TIMES

INTENDED FOR OTHER THAN HOUSEHOLD USE

RETAIN THIS MANUAL FOR FUTURE REFERENCE

WARNING: Improper installation, adjustment, alteration, service or maintenance can

cause property damage, injury or death. Read the Installation, Operating and

Maintenance Instructions thoroughly before installing or servicing this equipment.

Initial heating of unit may generate smoke or fumes and must be done in a well ventilated area.

Overexposure to smoke or fumes may cause nausea or dizziness.

This equipment has been engineered to provide you with year-round dependable service when used

according to the instructions in this manual and standard commercial kitchen practices.

Phone: +1 (214) 421-7366

Fax: +1 (214) 565-0976

Toll Free: +1 (800) 527-2100

Website: www.apwwyott.com

E-mail: info@apwwyott.com

SANITA TION

S

I

F

S

I

E

A

L

C

D

P/N 79967144 6/06

APW WYOTT

729 Third Avenue

Dallas, TX 75226

!!

1

Page 2

CONTENTS

OWNER’S INFORMATION.................................2 General Troubleshooting...............................3

General Installation.......................................2 SPECIFICATIONS...............................................3

General Operating Instructions.....................2 INSTALLATION...................................................4

Wet Set-Up (Units w/drains).........................2 PARTS LISTS w/EXPLODED VIEWS.................5

Dry Set-Up (Units w.o./drains)......................2 WIRING DIAGRAMS...........................................8

General Cleaning Instructions...................... 3 WARRANTY........................................................11

OWNER’S INFORMATION

General Installation:

1. Always clean equipment thoroughly before first use. (See general cleaning instructions.)

2. Check rating label for your model designation & electrical rating.

3. For best results, use stainless steel countertops.

4. All dimensions in parenthesis in centimeters, unless noted.

General Operating Instructions:

1. All food service equipment should be operated by trained personnel.

2. Do not allow your customers to come in contact with any surface labeled "CAUTION HOT."

3. Where applicable: Never pour cold water into dry heated units.

4. Where applicable, do not cook, warm or hold food directly in liner pans (well pans). Always use

steam table pans/insets, etc.

5. Never hold food below 150°F (66°C)

Wet set-up and operation procedures (units with drains):

1. Add hot water 120°-140°F (50°-60°C) to well pan:

! Four Thirds size units (12x27) use 5-1/2 qts. (1-1/3 gallon) (5.5 litre)

! Full size units (12x20) use: 3-3/4 qts. (15 cups) (3.5 litre)

! Two Thirds size units use 2-1/2 qts. (10 cups) (2.5 litre)

! Half size units use: 1-1/2 qts. (6 cups) (1.5 litre)

! One Third size units use: 3 cups (.7 litre)

! 4 Quart Round use 2 cups (.5 litre)

! 7 Quart Round use 3 cups (.7 litre)

! 11 Quart Round use 1-1/4 qt s. (5 cups) (1.4 litre)

2. Turn the thermostat control to "10" setting or if equipped with infinite controls to "?" or "Hi". Preheat

for approximately 30 minutes.

3. Place covered inset with preheated product into well.

4. Re-adjust control after another 30 minutes of operation to the "6" setting depending on the amount

and thickness of product.

5. Keep inset/steamtable pan(s) covered to maintain ideal serving temperature.

6. Do not let well run dry.

Dry set-up and operation procedures (units without drains):

1. Turn the thermostat control to "10" setting or if equipped with infinite controls to "7" or "Hi". Preheat

for approximately 30 minutes.

2. Place covered inset with preheated product into well.

3. Re-adjust control after another 30 minutes of operation to the "6" setting depending on the amount

and thickness of product.

4. Keep inset/steamtable pan(s) covered to maintain ideal serving temperature.

2

Page 3

General Cleaning Instructions:

1. NEVER clean any electrical unit by immersing it in water. T urn off before surface cleaning.

2. Always clean equipment thoroughly before first use. Clean unit daily. Use warm, soapy water

(except where noted on charts). Mild cleansers and PLASTIC scouring pads may be used to

remove baked-on food and water scale.

3. Turn off electrical units before cleaning or servicing. All service should be performed by an APW

Wyott authorized service agency.

General Troubleshooting:

1. Is the unit connected to a live power source?

2. Check circuit breaker.

3. Is power switch on & pilot light glowing?

4. Check rating label. Are you operating unit on proper voltage?

SPECIFICA TIONS

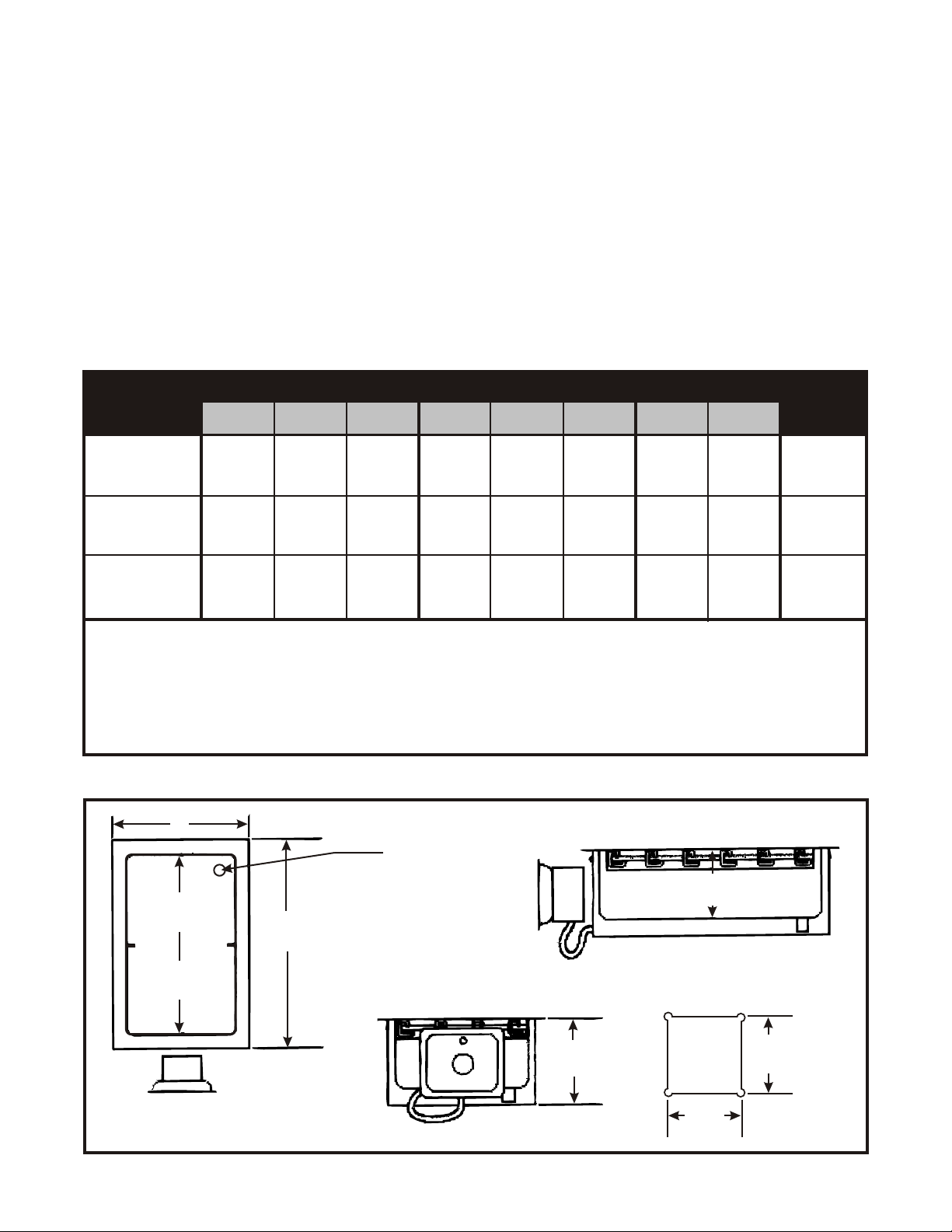

Description Outside Dimensions Inside Dimensions Cut-Out Shipping

(Model #) Weight L W H L W H D W

FullSize 23” 15” 7 3/4” 9 7/8” 11 7/8” 6 1/4” 21 3/4” 13 3/4” 25 lbs

(HFW-1) (54.4) (38.1) (19.7) (50.5) (30.2) (15.9) (55.2) (34.9) (11.4 kg)

2/3 Size 16” 15” 7 3/4” 13” 11 7/8” 6 1/4” 14 5/8” 13 3/4” 22 lbs

(HFW-23) (40.6) (38.1) (19.7) (33) (30.2) (15.9) (37.1) (34.9) (10 kg)

1/2 Size 12 ½” 15” 7 3/4” 9 1/2” 11 7/8” 6 1/4” 11 1/2” 13 3/4” 22 lbs

2

(HFW-12) (30.5) (38.1) (19.7) (24.1) (30.2) (15.9) (29.2) (34.9) (10 kg)

NOTE: T op Flange 1 9/16” (3.9cm) all 4 sides, 4 corners 1” (2.5 cm) radius. Standard thermostat has 36”

(91.4 cm) capillary effective length 26” (66 cm).

CONTROL SIZE: 5 5/16” W x 6 7/16” H (13.5 x 13.8)

CONTROL CUTOUT : 5 3/4” W x 6 1/4” H (14.6 x 15.8)

15”

DRAIN

11 7/8”

(30.2)

Outside

Length = O

(OPTIONAL)

0 = 23” (HFW-1)

16” (HFW-23)

12 1/2” (HFW-12)

8 1/4”

(15.9 cm)

Inside

Length = I

I = 19 7/8” (HFW-1)

13” (HFW-23)

9 1/2” (HFW-12)

Recessed Bezel Cut-Out

7 3/4”

(19.7 cm)

5 3/4”

(14.6)

3

6 1/4”

(15.9)

3/8” Dia.

(1.0)

Page 4

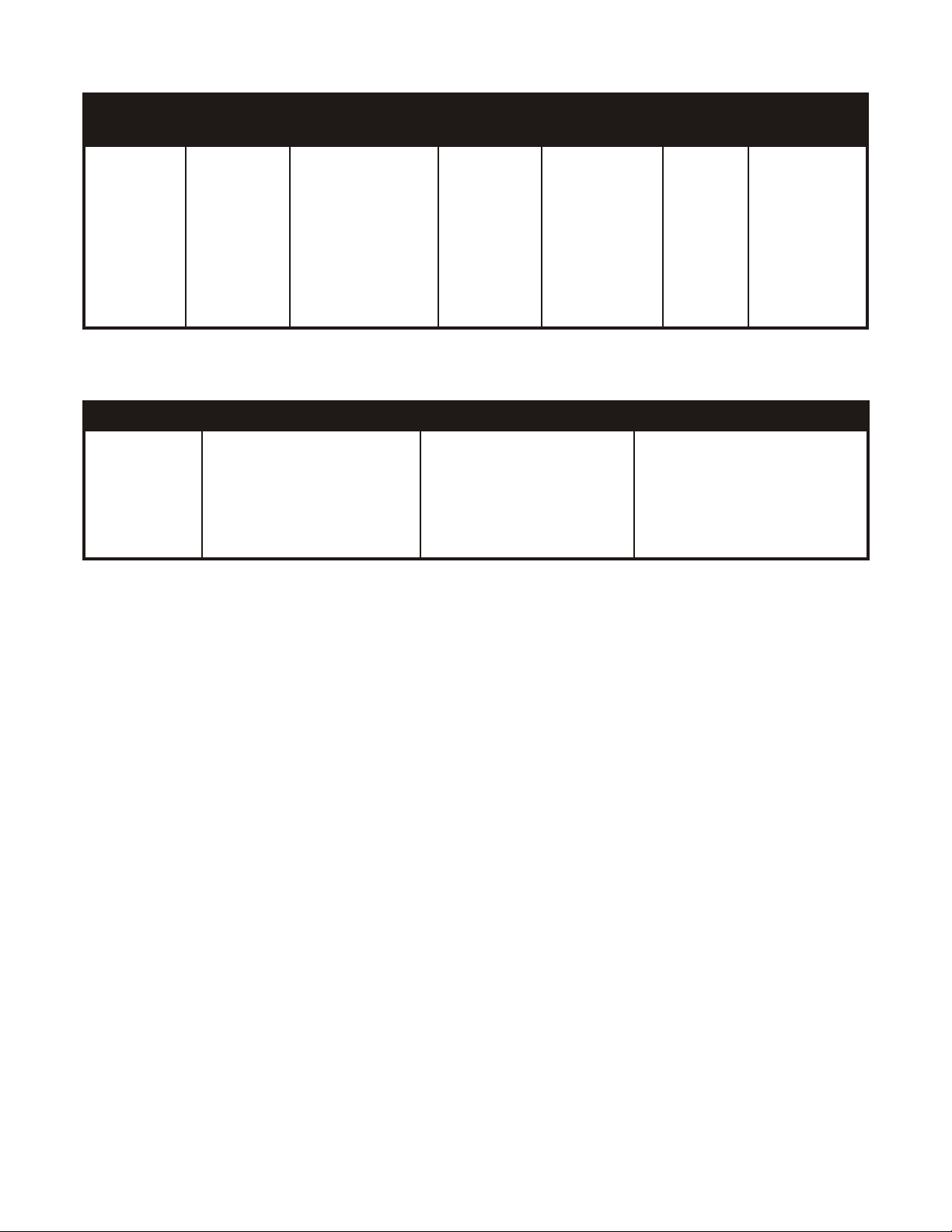

OPTION SPECIFICATIONS

Wood Mt

Kit Cut-Out

23 7/8” x 15 7/8”

(60.6 x 40.3)

16 5/8” x 15 7/8”

(42.2 x 40.3)

13 5/8” x 15 7/8”

(34.6 x 40.3)

Description

Full Size

(HFW-1)

2/3 Size

(HFW-23)

1/2 Size

2

(HFW-12)

Models

w/Drains

HFW-1D

HFW-23D

HFW-12D

Drain

Location

1 11/16” x 1 11/16”

(4.3 x 4.3) from

back right corner

Drain

Couplings

½ NPT

Stainless

1 1/2” (3.8)

long

Thermostat

72” (182.8)

Capillary

Effective

Length

62” (157.5)

Wood Mt

Kit No’s

56431

56460

56413

ELECTRICAL SPECIFICATIONS

Description

HFW-1 1500 Watts, 12.5 Amps 1660 Watts, 7.7 Amps 1200/1600 Watts, 5.7/6.7 Amps

HFW-23 800 Watts, 6.7 Amps

HFW-12 800 Watts, 6.7 Amps 500/660 Watts, 2.4/2.8 Amps

Rating at 120VAC, 1PH Rating at 208VAC, 1PH Rating at 208/240VAC, 1PH

INSTALLATION

Installation:

1. Follow applicable General Installation Instructions on page 2.

2. Make applicable Cut-Out per above table. CONNECTION NOTE: Unit is designed for installation in

stainless steel tops. Optional wood mounting kit available.

3. Apply putty tape (Provided) to the underside perimeter of the well rim outer edge.

4. Apply a 1/4" (.6 cm) bead of silicone sealant adjacent to the putty tape on the well flange.

5. Drop well into opening from the top and push down until entire parameter of rim is flush with the

counter surface.

6. From below the counter surface insert an 8" to 10" (20 cm to 25 cm) flat tip screwdriver into the

locking ring tab slots and twist in a clockwise motion to lock well in place.

7. Trim excess putty and sealant from around well rim.

8. Mount control to front panel using hardware. Maintain 4" clearance between well and front panel.

Connect power. Check power. Check nameplate for proper voltage. NOTE: Electrically connect

unit in compliance with local and NEC codes.

4

Page 5

Item P/N Description

HFW-1, 1D PARTS LIST & EXPLODED VIEW

Item P/N Description

10

11

12

13

14

15

16

17

18

19

20

1

2

3

4

5

6

7

8

9

56436

55304

56443

56442

56506

56322

55441

56370

56529

56530

56527

56528

56581

55341

55340

55343

55339

56586

56386

56387

56388

Pan & Wrapper W/Drain

Pan & Wrapper No Drain

Side Insulation

End Insulation

Reflector Plate

Element 120V-1500W

Element 208/240V-1200/1600W Control

Housing

Increase Decrease Plate

Indicator Light

Thermostat

Knob

Conduit Box

Flex Conduit

Anti Short Bushing

Conduit Connector 90°

Conduit Connector

Conduit Box Cover

Bottom Panel

Bottom Insulation

Hole Cover

MODEL P/N VOLTS WATTS

22

21

56542

22

56655

23

55872

24

56416

88961

89061

89068

89071

89059

89073

89120

HFW-1D 55440 208/240V 1200/1600W

HFW-1 55444 208/240V 1200/1600W

HFW-1D 55445 120V 1500W

HFW-1 56449 120V 1500W

FOR 72" THERMOSTAT ADD SUFFIX -72 TO MODEL & P/N

FOR UL KIT ADD SUFFIX -36UL OR -72UL TO MODEL & P/N

Dial Setting Plate

Drain Strainer

Permagum Package

Wire Set

Parts Not Shown

10-24 Green Hex Nut

10-24 Hex Nut

Flat Washer 5/16" X 3/4" X 1/16" #10 Flat

Washer

#10 External Lockwasher

#8 X 1/2" Sheet Metal Screw

Jiffy Clip

UL KIT

2

1

7

12

17

13

16

5

6

14

15

4

8

21

23

19

3

9

10

18

20

11

5

24

Page 6

Item P/N Description

56409

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

56459

56411

56412

55990

55695

55696

55960

56370

56529

56530

56527

56528

56372

56374

55341

55340

55343

55339

56405

56388

Pan & Wrapper (W/Drain)

Pan & Wrapper (No Drain)

Side Insulation

End Insulation

Element Cover

Element Clamp

Anti-rotation Clamp

Heating Element 120V-800W

Control Housing

Increase-decrease Plate

(Cap-Bulb T-Stat Models Only)

Indicator Light

Thermostat

Knob

Conduit Box

Conduit Box Cover

Flex Conduit

Anti-short Bushing

Conduit Connector 90°

Conduit Connector

Bottom Panel

Hole Cover

HFW-12, 12D PARTS LIST & EXPLODED VIEW

Item P/N Description

56542

22

23

24

25

26

27

28

56655

50817

56416

55872

89120

55258

89061

89068

89071

88961

89073

89059

Dial Setting Label

Drain Strainer

Heat Transfer Plate

Wire Set

Perma-Gum Package

#105 Jiffy Clip

Infinite Control Plate

Parts Not Shown

#10-24 Hex Nut

5/16 X 3/4 X 1/16 Flat Washer

#10 Flat Washer

#10-24 Green Hex Nut, Ground

#8 X 1/2 Hex Sheet Metal Screw

#10 External Lockwasher

MODEL P/N VOLTS WATTS

HFW-12D 56435 120V 800W

HFW-12 56439 120V 800W

FOR 72" THERMOSTAT ADD SUFFIX -72 TO MODEL & P/N

FOR UL KIT ADD SUFFIX -36UL OR -72UL TO MODEL & P/N

23

2

1

9

UL KIT

14

4

15

16

19

17

24

28

3

10

22

18

27

8

26

6

7

11

12

5

21

20

13

25

6

Page 7

Item P/N Description

56419

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

56403

56411

55990

55695

55696

55960

56370

56529

56530

56527

56528

56581

56586

55341

55340

55343

55339

56426

56388

56542

56655

Pan & Wrapper (W/Drain)

Pan & Wrapper (No Drain)

Insulation

Element Cover

Element Clamp

Anti-Rotation Clamp

Heating Element 120V-800W

Control Housing

Increase-Decrease Plate

(Cap-Bulb Thermostat Models Only)

Indicator Light

Thermostat

Knob, Thermostat

Conduit Box

Conduit Box Cover

Flex Conduit

Anti-short Bushing

Conduit Connector 90°

Conduit Connector

Bottom Panel

Hole Cover

Dial Setting Label

Drain Strainer

HFW-23, 23D PARTS LIST & EXPLODED VIEW

Item P/N Description

50817

23

24

25

26

27

28

29

30

55564

69107

55817

56416

55872

89120

55258

89061

89068

89071

88961

89073

89059

Heat Transfer Plate

Infinite Control

Limiting Thermostat

(Only w/Infinite Control)

Knob, Infinite Control

Wire Set

Perma-Gum Package

#105 Jiffy Clip

Infinite Control Plate

Parts Not Shown

#10-24 Hex Nut

5/16 X 3/4 X 1/16 Flat Washer

#10 Flat Washer

#10-24 Green Hex Nut, Ground

#8 X 1/2 Hex Sheet Metal Screw

#10 External Lockwasher

MODEL P/N VOLTS WATTS

HFW-23 (Thermostat) 56451 120V 800W

HFW-23D (Infinite Control) 56296 120V 800W

HFW-23D (Thermostat) 56450 120V 800W

FOR 72" THERMOSTAT ADD SUFFIX -72 TO MODEL & P/N

FOR UL KIT ADD SUFFIX -36UL OR -72UL TO MODEL & P/N

25

2

23

4

1

22

UL KIT

8

13

14

15

18

30

3

9

21

16

17

29

7

28

5

6

19

24

10

11

2612

27

20

7

Page 8

WIRING DIAGRAMS

HFW-1, HFW-1D

HEATING

ELEMENT

HEATING

ELEMENT

INDICATOR

LIGHT

INDICATOR

LIGHT

ROBERT SHAW

THERMOSTAT

H1

H2

RANCO

THERMOSTAT

H1

L1

L1

L2

H2

L2

HFW-12, HFW-12D, HFW-23, HFW-23D

THERMOSTAT CONFIGURATION

HEATING

ELEMENT

THERMOSTAT

INDICATOR

LIGHT

INDICATOR

HEATING

ELEMENT

HFW-23D

INFINITE CONTROL

LIGHT

L1

P

H1

LIMITING

THERMOSTAT

L2

H2

INFINITE

CONTROL

8

Page 9

Notes:

IMPORTANT FOR FUTURE REFERENCE

Please complete this information and retain this manual for the life of the equipment. For

Warranty Service and/or Parts, this information is required.

Model Number Serial Number Date Purchased

9

Page 10

Notes:

10

Page 11

APW WYOTT EQUIPMENT LIMITED WARRANTY

APW Wyott Foodservice Equipment Company warrants it's equipment against defects in materials and workmanship, subject to the

following conditions:

This warranty applies to the original owner only and is not assignable.

Should any product fail to function in its intended manner under normal use within the limits defined in this warranty, at the option of

APW Wyott such product will be repaired or replaced by APW Wyott or its Authorized Service Agency. APW Wyott will only be

responsible for charges incurred or service performed by its Authorized Service Agencies. The use of other than APW Wyott

Authorized Service Agencies will void this warranty and APW Wyott will not be responsible for such work or any charges associated

with same. The closest APW W yott Authorized Service Agent must be used.

This warranty covers products shipped into the 48 contiguous United States, Hawaii, metropolitan areas of Alaska and Canada. There

will be no labor coverage for equipment located on any island not connected by roadway to the mainland.

Warranty coverage on products used outside the 48 contiguous United States, Hawaii, and metropolitan areas of Alaska and Canada

may vary. Contact the international APW Wyott distributor , dealer, or service agency for details.

Time Period

One year for parts and one year for labor, effective from the date of purchase by the original owner. The Authorized Service Agency

may, at their option, require proof of purchase. Parts replaced under this warranty are warranted for the un-expired portion of the

original product warranty only.

Exceptions

In all cases, parts covered by extended warranty will be shipped FOB the factory after the first year.

Portable Carry In Products

Equipment weighing over 70 pounds or permanently installed will be serviced on-site as per the terms of this warranty. Equipment

weighing 70 pounds or under, and which is not permanently installed, i.e. with cord and plug, is considered portable and is subject to

the following warranty handling limitations. If portable equipment fails to operate in its intended manner on the first day of

connection, or use, at APW W yott's option or its Authorized Service Agency, it will be serviced on site or replaced.

From day two through the conclusion of this warranty period, portable units must be taken to or sent prepaid to the APW Wyott

Authorized Service Agency for in-warranty repairs. No mileage or travel charges are allowed on portable units after the first day of use.

If the customer wants on-site service, they may receive same by paying the travel and mileage charges. Exceptions to this rule: (1)

countertop warmers and cookers, which are covered under the Enhanced Warranty Program, and (2) toasters or rollergrills which have

in store service.

Exclusions

The following conditions are not covered by warranty:

If the equipment has been changed, altered, modified or repaired by other than an Authorized Service Agency during or after the

warranty period, then the manufacturer shall not be liable for any damages to any person or to any property, which may result from the

use of the equipment thereafter.

This warranty does not cover services performed at overtime or premium labor rates. Should service be required at times which

normally involve overtime or premium labor rates, the owner shall be charged for the difference between normal service rates and such

premium rates. APW W yott does not assume any liability for extended delays in replacing or repairing any items beyond its control.

In all cases, the use of other than APW W yott Authorized OEM Replacement Parts will void this warranty.

This equipment is intended for commercial use only. W arranty is void if equipment is installed in other than commercial application.

Water Quality Requirements

Water supply intended for a unit that has in excess of 3.0 grains of hardness per gallon (GPG) must be treated or softened before

being used. Water containing over 3.0 GPG will decrease the efficiency and reduce the operation life of the unit.

Note: Product failure caused by liming or sediment buildup is not covered under warranty.

“THE FOREGOING WARRANTY IS IN LIEU OF ANY AND ALL OTHER WARRANTIES EXPRESSED OR IMPLIED

INCLUDING ANY IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR PARTICULAR PURPOSES

AND CONSTITUTES THE ENTIRE LIABILITY OF APW WYOTT. IN NO EVENT DOES THE LIMITED W ARRANTY

EXTEND BEYOND THE TERMS STATED HEREIN.”

*Gas/Electric Cookline: Models GCB, GCRB, GF, GGM, GGT, CHP-H, EF, EG, EHP. Three (3) Year Warranty on all

component parts, except switches and thermostats. (2 additional years on parts only. No labor on second or third year .)

*Broiler Briquettes,

*Heat Strips: Models FD, FDL, FDD, FDDL. Two (2) Year Warranty on element only . No labor second year.

*Glass Windows, Doors, Seals, Rubber Seals, Light Bulbs:

*Equipment failure relating to improper installation, improper utility connection or supply and problems due to

ventilation.

*Equipment that has not been properly maintained, calibration of controls, adjustments, damage from improper cleaning

and water damage to controls.

*Equipment that has not been used in an appropriate manner, or has been subject to misuse or misapplication, neglect,

abuse, accident, alteration, negligence, damage during transit, delivery or installation, fire, flood, riot or act of god.

*Equipment that has the model number or serial number removed or altered.

Rock Grates, Cooking Grates, Burner Shields, Fireboxes: 90 Day Material Only. No Labor.

90 Day Material Only. No Labor.

9/05

11

Page 12

R

Phone: +1 (214) 421-7366

Fax: +1 (214) 565-0976

Toll Free: +1 (800) 527-2100

Website: www.apwwyott.com

E-mail: info@apwwyott.com

12

APW WYOTT

729 Third Avenue

Dallas, TX 75226

Loading...

Loading...