Page 1

INSTALLATION AND OPERATING INSTRUCTIONS

HEAVY DUTY ELECTRIC FRYERS

Models: HEF-15S, HEF-30T

INTENDED FOR OTHER THAN HOUSEHOLD USE

RETAIN THIS MANUAL FOR FUTURE REFERENCE

OVEN MUST BE KEPT CLEAR OF COMBUSTIBLES AT ALL TIMES

FOR YOUR SAFETY

Do not store or use gasoline or other flammable vapors and liquids in the

vicinity of this or any other appliance.

WARNING

Improper installation, adjustment, alteration, service or maintenance can

cause property damage, injury or death. Read the Installation, Operating and

Maintenance Instructions thoroughly before installing or servicing this

equipment.

WARNING

Initial heating of oven may generate smoke or fumes and must be done in a

well-ventilated area. Overexposure to smoke or fumes may cause nausea or

dizziness.

This equipment has been engineered to provide you with year round dependable service when used

according to the instructions in this manual and standard commercial kitchen practices.

U

L

EPH

P/N 8814621 9-09

APW WYOTT Foodservice Equipment Company

P.O. Box 1829

Cheyenne, WY 82003

(307) 634-5801 Phone

(307) 637-8071 Fax

(800) 752-0863 Toll Free

www.apwwyott.com

1

Page 2

TABLE OF CONTENTS

SECTION ITEM PAGE

1 Safety Precautions ....................................2

2 General Instructions ..................................4

3 Description ................................................4

4 Installation .................................................4

5 Thermostat Calibration..............................5

6 Operating ..................................................5

7 Maintenance..............................................6

APW Wyott takes pride in the design and quality of our products. When used as intended and with proper

care and maintenance, you will experience years of reliable operation from this equipment. To ensure best

results, it is important that you read and follow the instructions in this manual carefully. Installation and startup should be performed by a qualified installer who thoroughly read, understands and follows these

instruction.

If you have questions concerning the installation, operation, maintenance or service of this product, write

Technical Service Department APW Wyott Foodservice Equipment Company, P.O. Box 1829, Cheyenne,

WY 82003.

SECTION ITEM PAGE

8 Cleaning ....................................................6

9 Specifications ............................................7

10 Wiring Diagrams........................................8

11 Troubleshooting Guide.............................10

12 Suggested Temperature & Times.............11

13 Replacement Parts ..................................11

14 Warranty...................................................17

1. SAFETY PRECAUTIONS

Before installing and operating this equipment be sure everyone involved in its operation is fully trained

and is aware of all precautions. Accidents & problems can result by a failure to follow fundamental rules

and precautions.

The following words and symbols, found in this manual, alert you to hazards to the operator, service

personnel or the equipment. The words are defined as follows:

DANGER: This symbol warns of imminent hazard which will result in serious injury or death.

WARNING: This symbol refers to a potential hazard or unsafe practice, which could result in

serious injury or death.

CAUTION: This symbol refers to a potential hazard or unsafe practice, which may result in minor or

moderate injury or product or property damage.

NOTICE: This symbol refers to information that needs special attention or must be fully understood

even though not dangerous.

XXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXX

CAUTION: These models are designed, built, and sold for commercial use. If these models are

positioned so the general public can use the equipment make sure that cautions, warnings, and

operating instructions are clearly posted near each unit so that anyone using the equipment will use

it correctly and not injure themselves or harm the equipment.

WARNING: Check the data plate on this unit before installation. Connect the unit only to the voltage

and frequency listed on the data plate. Connect only to 1 or 3 phase as listed on the data plate.

WARNING: Electrical and grounding connections must comply with the applicable portions of the

national electrical code and/or other local electrical codes.

WARNING: Disconnect device from electrical power supply and place a Tag Out-Lockout on the

power plug, indicating that you are working on the circuit.

2

Page 3

WARNING: Install per the spacing requirements listed in the installation section of this manual. We

strongly recommend having a competent professional install the equipment. A licensed electrician

should make the electrical connections and connect power to the unit. Local codes should always

be used when connecting these units to electrical power. In the absence of local codes, use the

latest version of the National Electrical Code.

WARNING: This device should be safely and adequately grounded in accordance with local codes,

or in the absence of local codes, with the National Electrical code, ANSI/NFPA 70, Latest Edition to

protect the user from electrical shock. It requires a grounded system and a dedicated circuit,

protected by a fuse or circuit breaker of proper size and rating. Canadian installation must comply

with the Canadian Electrical Code, CSAC22.2, as applicable.

CAUTION: Do not set the fryer with its back flat against the wall. It will not operate properly unless

there is at least 3” breathing space behind fryer.

WARNING: A factory authorized agent should handle all maintenance and repair. Before doing any

maintenance or repair, contact APW Wyott.

WARNING: Never clean any electrical unit by immersing it in water. Turn off before cleaning

surface.

WARNING: An earthing cable must connect the appliance to all other units in the complete

installation and from there to an independent earth connection.

NOTICE: The unit when installed, must be electrically grounded and comply with local codes, or in

the absence of local codes, with the national electrical code ANSI/NFPA70- latest edition. Canadian

installation must comply with CSA-STANDARD C.22.2 Number 0 M1982 General RequirementsCanadian Electrical Code Part II, 109-M1981- Commercial Cooking Appliances.

WARNING: SHOCK HAZARD - De-energize all power to equipment before cleaning the

equipment.

NOTICE: This product is intended for commercial use only. Not for household use.

NOTICE: Local codes regarding installation vary greatly from one area to another. The National

Fire Protection Association, Inc. states in its NFPA96 latest edition that local codes are “Authority

Having Jurisdiction” when it comes to requirement for installation of equipment. Therefore,

installation should comply with all local codes.

CAUTION: This product when stacked, has more than one power supply connection point.

Disconnect all power supplies before servicing.

CAUTION: Suitable for installation on combustible floor when installed with legs or casters

provided.

WARNING: SHOCK HAZARD - Do not open any panels that require the use of tools.

IMPORTANT FOR FUTURE REFERENCE

Please complete this information and retain this manual for the life of the equipment. For

Warranty Service and/or Parts, this information is required.

Model Number Serial Number Date Purchased

IMMEDIATELY INSPECT FOR SHIPPING DAMAGE

All containers should be examined for damage before and during unloading. The freight carrier has

assumed responsibility for its safe transit and delivery. If equipment is received damaged, either apparent

or concealed, a claim must be made with the delivering carrier.

3

Page 4

A) Apparent damage or loss must be noted on the freight bill at the time of delivery. It must then be signed

by the carrier representative (Driver). If this is not done, the carrier may refuse the claim. The carrier

can supply the necessary forms.

B) Concealed damage or loss if not apparent until after equipment is un-crated, a request for inspection

must be made to the carrier within 15 days. The carrier should arrange an inspection. Be certain to hold

all contents and packaging material.

Installation and start-up should be performed by a qualified installer who thoroughly read, understands and

follows these instructions.

2. GENERAL INFORMATION

General Installation:

1. Always clean equipment thoroughly before first use (see “General Cleaning Instructions”).

2. Check rating label for your model designation & electrical rating.

3. For best results, use stainless steel countertops.

4. Attach legs to unit.

General Operation Instructions:

1. All food service equipment should be operated by trained personnel.

2. Do not allow your customers to come in contact with any surface labeled “CAUTION HOT”.

3. Where applicable, never pour cold water into dry heated units.

4. NEVER hold food below 140°F.

General Cleaning Instructions:

1. Refer to section 8, page 6.

General Troubleshooting:

Always ask and check:

1. Is the unit connected to a live power source?

2. Check circuit breaker.

3. Is power switch “ON” and pilot light glowing?

4. Check rating label. Are you operating unit on proper voltage?

If the above checks out and you still have problems, call an APW/Wyott authorized service agency.

3. DESCRIPTION

Electric Fryers:

These electric units are designed for countertop operation. They are used for producing evenly cooked,

perfectly fried products.

4. INSTALLATION

1. Follow General Installation Instructions on previous page.

Screw legs into the permanently fastened nuts on the four corners of the unit and tighten by hand.

Level the fryer by turning the adjustment screw at the bottom of each leg. Do not slide unit with legs

mounted, lift if necessary to move unit.

For testing, see the wiring diagrams in this manual for the rated amperages.

NOTE: These values are nominal ratings. Field wire connections must be capable of withstanding

anticipated surges.

CAUTION: Installing personnel should be guided by National Electrical Code NFPA

Number 70 (Latest Edition), and applicable local codes.

4

Page 5

5. THERMOSTAT CALIBRATION

Checking Thermostat Calibration:

The fryer thermostat is carefully calibrated at the factory so that dial settings match actual frying

compound temperatures. Field re-calibration is seldom necessary unless the unit has been mishandled in

transit or abused. Re-calibration should not be resorted to unless considerable experience with cooking

results definitely proves that the control isn’t maintaining the temperature to which the dial is set.

1. To check compound frying temperatures when recalibrating, use a precision test instrument, or a

good grade mercury thermometer. Fill the tank

half way between the MAX and MIN marks on the

tank.

2. Frying compound temperature should be checked

at the center of the tank, approximately 1" to 1 ½"

below surface of frying compound.

3. Turn the dial of the thermostat being checked to

the 350°F mark.

4. Allow temperature to stabilize, or until the

thermostat cycles to “OFF” three times after

starting with cold frying compound. With power

“ON”, read highest and lowest frying compound

temperature, as thermostat cycles through at

least two cycles. Average the reading.

5. Thermostat should be re-calibrated if temperature

reading is not within 10 degrees of the control

knob setting (350°F +/- 15°F). If re-calibration is

required, continue with steps 6, 7, 8 and 9.

6. Remove control knob by grasping outer edge and pulling straight out, without twisting or turning.

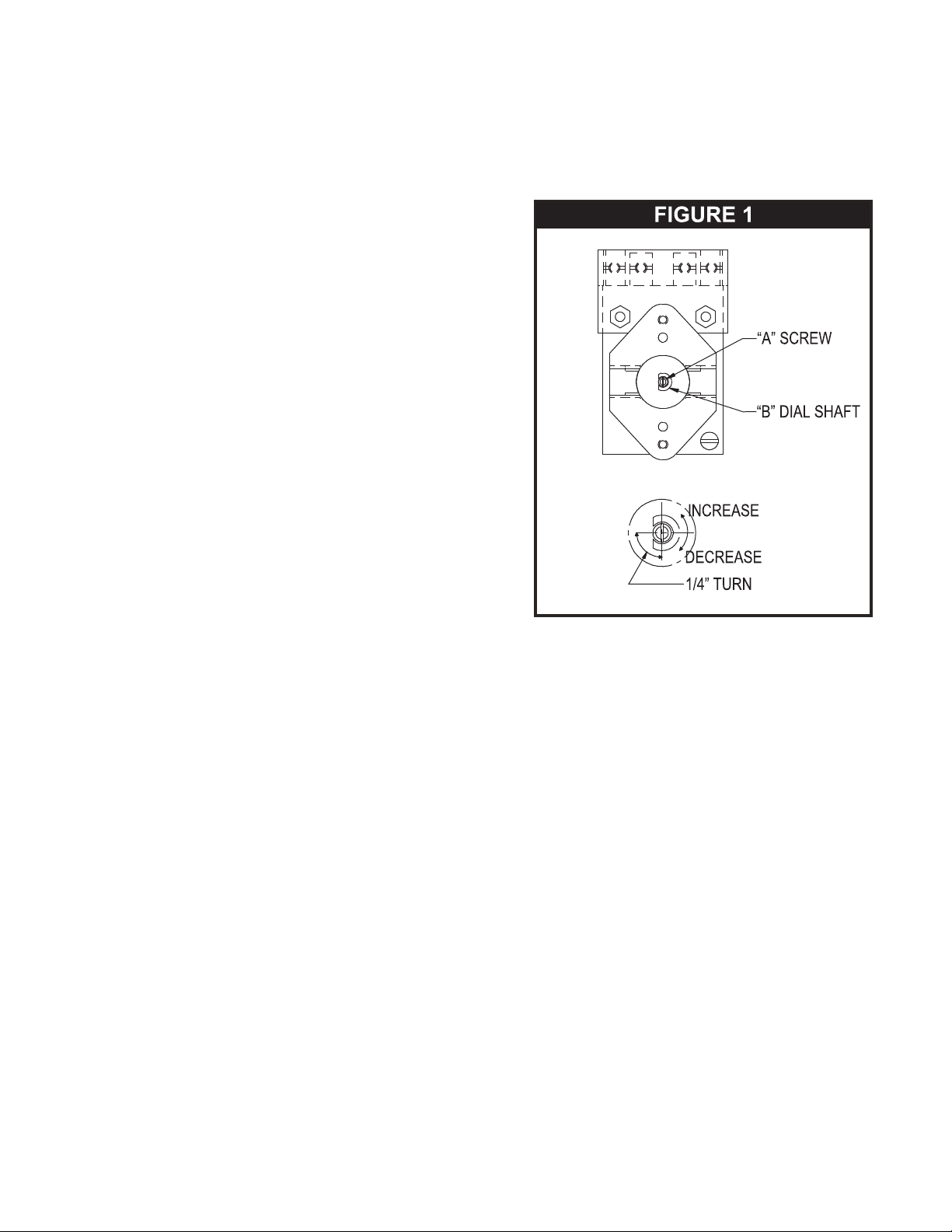

7. Hold thermostat dial shaft “B” (Figure 1) stationary with pliers, and with a screwdriver, turn screw “A”

clockwise to obtain a lower temperature; or counter-clockwise for higher temperature. Each ¼ turn

(90° rotation) of screw “A” represents 18°F.

8. Replace thermostat control knob.

9. Recheck thermostat as in Steps 4 and 5 above. If the fat temperature is not within 20 degrees of dial

setting (350°F +/- 20°F), it means that the sensing element is inoperative and the thermostatic control

should be replaced.

6. OPERATING

Removing Fry Tanks (Fry tanks equipped with drain are not to be removed):

1. Remove fry baskets.

2. Carefully grasp the element handle. CAUTION: May be hot. Pull out the head lock on the left of the

head. On the EF-30NT there is also a head lock on the right side of the right head.

3. Lift the element handle while at the same time, pulling the head lock. This will permit lifting the

elements to just above frying compound level in tank. The element can be left in this position for

draining frying compound.

4. Again, lift the element handle while pulling the head lock, until the elements lock themselves at a

higher position.

5. Firmly grasp both handles of fry tank and lift it out. After replacing the fry tank, simply pull the head lock;

and at the same time, pull down the element handle until the elements rest on fry tank bottom.

6. Both the lifting out and lowering of elements can be done in one swing, without stopping at the

intermediate position.

5

Page 6

7. MAINTENANCE

Filling Fry Tank:

1. Fill the fry tank half way between the MAX and MIN marks on the tank with approximately 15 lbs. of

liquid or melted frying compound. Do not fill past the MAX.

NOTE: This fryer is not equipped with a melt cycle option. Air holes caused when packing solid frying

compound into the fryer can cause hot spots on the heating element sheath, resulting in momentary

overheating of some of the frying compound and premature frying compound breakdown. It can also

damage the heating elements. If it is necessary to use solid frying compound, it must be melted

before adding to fry tank.

Turn the thermostat to the desired frying temperature. The yellow “HEAT ON” light will stay on until the

temperature set on the thermostat is reached, then the light cycles off. The fryer is now ready to

begin frying. After a load has been fried, do not lower the next load into the frying compound until the

“HEAT ON” light cycles off.

2. Do not let the frying compound level drop below the MIN mark on the tank. For proper operation of the

fryer and good frying results, the frying compound level should be maintained.

3. Use a quality frying compound.

4. Filter the frying compound frequently, at least once a day.

5. Skim out food particles frequently with the strainer/skimmer.

6. Add at least 15% (of fry tank capacity) of fresh frying compound daily, (more if possible) without

overloading the tank. If 15% of the frying compound is not used during frying, remove some of the

frying compound for other use (gravy, griddle frying, etc.) to permit adding fresh frying compound.

7. Do not overload the fry baskets. Approximately half-full or even less is correct. If foods are taking

longer to fry than the chart shows, or are not browning, over-loading is a probable cause.

8. Prepare the food properly.

9. Keep salt out of the frying compound. Do not salt foods with the basket above the kettle.

10. Assure a good thermostat operation.

11. Keep the fry tank and elements clean.

8. CLEANING

1. The frequency of cleaning should depend on the load conditions. Set a definite cleaning schedule

corresponding to how hard the kettle is used. Cleaning should be done at least once a week.

A. Turn the thermostat to “OFF” and allow unit to cool down.

B. Lift the elements to drain position. Wire brush or scrape elements to remove any solids adhering

to the elements.

C. Raise the elements. Lift out fry tank. Strain the frying compound into a clean container.

D. Replace empty fry tank, lower elements to rest inside the tank.

E. Add water to the “MAX” mark on tank.

F. Add any good grade of cleaner, following cleaning instructions.

CAUTION: Use only non-abrasive cleaners. Abrasive cleaners could scratch the finish of your

unit, marring it’s appearance and making it susceptible to dirt accumulation. Do Not use steel wool,

other abrasive cleaners or cleaners/sanitizers containing chlorine, iodine, ammonia or bromine

chemicals as these will deteriorate the stainless steel and glass material and shorten the life of the

unit.

G. Turn the thermostat to 250°F and let the heating unit bring the solution to a boil.

H. Boil long enough to loosen or dissolve all varnish or carbon deposits, approximately 30 minutes.

I. Turn the unit off and lift out the elements to drain position.

J. If necessary, clean the thermostat bulbs using a long-handled fiber or plastic brush and mild soap

solution.

K. Rinse with clean water to remove all cleaning mixture.

L. Lift out the fry tank and drain. Repeat steps J & K with fry tank.

M. Rinse the inside of the tank with 2 cups of vinegar.

N. Rinse with clean water until the vinegar odor is gone. The fry tank must be thoroughly rinsed,

since even a trace of cleaner left inside the tank will ruin frying compound.

O. Dry thoroughly. Replace the tank and lower the elements.

6

Page 7

P. Shut the unit off and cover tank until ready for further use.

Q. Thin films of oil subjected to frying temperatures quickly form into a gummy consistency. In order

to avoid these gum formations, keep all other surfaces of the unit clean by polishing stainless steel

surfaces with a damp cloth. To remove discolorations or oil film, a non-abrasive cleaner may be

used.

CAUTION: Use only non-abrasive cleaners. Abrasive cleaners could scratch the finish of your

unit, marring it’s appearance and making it susceptible to dirt accumulation. Do Not use steel wool,

other cleaners/sanitizers containing chlorine, iodine, ammonia or bromine abrasive cleaners or

chemicals as these will deteriorate the stainless steel and glass material and shorten the life of the

unit.

9. SPECIFICATIONS

24

31-1/32

HEF-15S

HEF-30T

Dimensions

Width Depth Height

12 31.4 17.5 5700 208 27.4

12 31.4 17.5 5700 230 24.8

12 31.4 17.5 5700 240 23.8

24 31.4 17.5 11400 208 54.8

24 31.4 17.5 11400 230 49.6

24 31.4 17.5 11400 240 47.5

Electrical Info.

Watts Volts Amps

20-15/16

17-9/16

9-3/32

13-1/16

23-19/325-11/32

7

Page 8

Wire sizes listed above are for reference only. Check local

codes or the National Electrical Code for sizes to be used.

MODEL # VOLTS WATTS AMPS WIRE VOLTS WATTS AMPS WIRE

CHECK DATA PLATE & CONNECT TO 208 OR 240V AS INDICATED.

EF30-NT 240 11400 47.6 6 208 8560 41.2 6

10. WIRING DIAGRAMS

THIS UNIT TO BE CONNECTED TO 1O ONLY

CHECK DATA PLATE & CONNECT TO 208 OR 240V AS INDICATED.

THIS UNIT TO BE CONNECTED TO 1O ONLY

Wire sizes listed above are for reference only. Check local

codes or the National Electrical Code for sizes to be used.

MODEL # VOLTS WATTS AMPS WIRE VOLTS WATTS AMPS WIRE

EF15-N 240 5700 23.8 12 208 4280 20.6 12

EF15-N-208 - - - - 208 5700 27.5 10

8

Page 9

EF30-NT 240 11400 47.6 6 208 8560 41.2 6

MODEL # VOLTS WATTS AMPS WIRE VOLTS WATTS AMPS WIRE

CHECK DATA PLATE & CONNECT TO 208 OR 240V AS INDICATED. CHECK DATA PLATE & CONNECT TO 208 OR 240V AS INDICATED.

THIS APPLIANCE HAS MORE THAN ONE POWER

SUPPLY CONNECTION POINT. DISCONNECT ALL

Wire sizes listed above are for reference only. Check local

codes or the National Electrical Code for sizes to be used.

EF30-NT 240 11400 23.8 & 23.8 12 208 8560 20.6 & 20.6 12

MODEL # VOLTS WATTS AMPS WIRE VOLTS WATTS AMPS WIRE

THIS UNIT TO BE CONNECTED TO 1O ONLY THIS UNIT TO BE CONNECTED TO 1O ONLY

POWER SUPPLIES BEFORE SERVICING.

9

Page 10

Inadequate cleaning of fry tank.

X

after cooking.

Keeping food in frying compound

Excessive crumbs in fry tank

Inadequate filtering of frying compound.

Cooking time too short.

X

X

X

X X

X

X

X

(Either initially or after excessive use)

Poor quality of frying compound

Drip-back from exhaust stack.

X

X

X

X

quality.

Food being fried may be of poor

Frying in foam.

XX

X

X

X

X

X

(Due to salt or other foreign material)

Contamination of frying compound.

X

X

X

X

X

X

X

X

XXX

X

X

X

Possible Cause

11. TROUBLESHOOTING GUIDE

Improper preparation of food.

X

turnover.

Inadequate frying compound

fried.

High moisture content in food being

Improper draining of food after frying.

X

XX

X X

X

X

Overloading the fry tank.

X

(Check thermostat)

Frying temperature too low.

high/overheating. (Check thermostat)

Frying temperature too

X

X X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

Problem

Excessive and premature

Greasy food/excessive frying

foaming.

10

“Objectionable” odor or flavor

compound absorption.

“Objectionable” flavor of fried

of frying compound.

Excessive smoking of frying

food.

Excessive darkening of frying

compound.

compound.

Frying compound won’t hold

Food crust color not brown.

Rapid breakdown of frying

heat.

compound.

Page 11

12. SUGGESTED TEMPERATURES & TIMES

FOOD

CONTROL

SETTING

(FAHRENHEIT)

TIME IN

MINUTES

DOUGHNUTS

Cake Type 375° 1 ½ - 2

Yeast Raised 375° 2 - 2 ½

MEAT

Cutlets (Less than 1/2” thick) 350° 5 - 8

Chicken Fried Steak 350° 5 - 8

Chops (Very lean) 350° 5 - 8

MISCELLANEOUS

Chinese Noodles 375° 1 - 2

Croquettes 350° 2 - 3

French Toast 350° 2 - 3

Glazed Cinnamon Apples 300° 5 - 10

French Fried Sandwiches 350° 1 - 2

POULTRY

Chicken (Large pieces) 325° 10 - 15

Chicken (Small pieces) 350° 7 - 10

Chicken (Pre-cooked) 325°-350° 3 - 5

Turkey (Small pieces) 325° 9 - 10

FOOD

CONTROL

SETTING

(FAHRENHEIT)

TIME IN

MINUTES

SEAFOOD

Fish Cakes 350° 2 - 3

Clams 350° 1 - 3

Fillets (Small) 350° 3 - 5

Oysters 350° 2 - 5

Scallops 350° 3 - 5

Shrimp 350° 4 - 6

Smelts 350° 4 - 6

VEGETABLES

Egg Plant 350° 5 - 7

Onion Rings 350° 3 - 5

Potatoes

(1/2” Strips, one-operation) 350° 6 - 9

Potatoes (Blanch) 350° 4 - 6

Potatoes (Brown) 350° 2 - 3

Potatoes (Julienne) 350° 3 - 5

Item

1

2

3

4

5

6

7

8

P/N

218100-95

1439729

13801-00

81300-00

1515300

14876-00

8705504

2125502

13. REPLACEMENT PARTS

CONTROL HEAD (Models: HEF-15S & HEF-30T)

2

12

Description

Control Head, Elec. Fryer W/A

Heating Unit Assembly

Switch, Hi-limit

8-32 X 3/8 Type T

Ind Light, rect, amb, 250v, 2/tabs

Thermostat

Knob, Thermostat

Grommet Split

13

9

7

14

Quan

1

1

1

2

1

1

1

2

10

8

15

5

11

6

Item

9 64285901 4

10

11

12

13

14

15

16 8455700

P/N

8944100

8837018

8108300

8500600

8402900

8103400

Description

Clamp Bulb

Clip Lead

Label Reset

Screw, Pan Head 6-32 X 1/2

Washer, Lock #6 S/S

Nut, Hex, 6-32 S/S

Screw, Mach, 6-32 X 1/4" Lg.

Nut, PAL 5/8-18

1

3

16

4

Quan

4

1

4

4

4

2

2

11

Page 12

DETAIL A

HEF-15S

16

1

17

1

18

25

1

21

1

9

37

28

1

26

1

20

1

1

A

15

4

9

37

14

1

1

1

9

27

1

24

8

37

1

2

1

5

4

1

23

1

32

2

9

4

1

9

19

37

1

6

37

1

3

1

7

2

30

1

10

11

12

1

2

31

1

33

1

22

1

13

1

2

Item Item

P/N P/N

Description Description

1 21828025 BODY, FRYER HD 1

2 21810065 "SUPPORT, HEAD WELD ASSEMBLY LS" 1

3 21810075 "HEAD SUPPORT OUTSIDE WELD ASSY" 1

4 21810085 HEAD SUPPORT INSIDE 1

5 8415500 WING NUT 10-32 S/S 4

6 89670-00 "BUSHING, SNAP HEYCO .5"" I.D." 1

7 3101230 BASKET, ½ SIZE 2

8 21810096 COVER HEAD 1

9 8170700 SCREW, 10-32x1/2, TYPE AB 37

10 21810023 BRACKET HANDLE 1

11 21810022 ELEMENT HANDLE 1

12 8141400 8-32 x ½ MS 2

13 84104-00 NUT,HEX, 8-32 S/S 2

14 21828034 BACK, BOTTOM W/A 1

15 8633700 "LEG, HEAVY DUTY 2"" DIA. W/ FOOT FLANGE" 4

16 8422400 #10-24 HX NUT GRN 1

17 8158800 MS RD HD PH 10-24 X ½ 1

Quan Quan

18 5161000 CONNECTOR CABLE ROMEX 1

19 21828018 PANEL, FRONT HEF-15 1

20 21828038 BAFFLE, INTERIOR 1

21 21810040 DOOR ELECTRIC FRYER 1

22 8832600 LABEL, SERVICE HOTLINE 1

23 43813103 LABEL, WRNG, HOT SURFC 1

24 43813149 "LABEL, WRN HOT SURF (FRNCH)" 1

25 21810018 LABEL, DIAGRAM 1

26 8861000 LABEL, SPEC 1

27 8824200 LABEL, BUTTON POSITION 1

28 64416801 LABEL, 90 DEG C 1

29 2901051 "CARTON, RSC 39.25X19.87X20.18" 1

30 21810010 FAT CONTAINER AY 1

31 8825300 DECAL, LEG 1

32 8460900 NUT, PUSH 1/8" 2

33 2065847 LOGO, APW WYOTT CASTED 1

12

Page 13

HEF-30T

17

1

18

DETAIL A

28

1

23

1

31

1

19

1

29

1

10

51

16

4

15

1

A

22

2

1

4

5

2

30

1

2

1

1

9

10

2

51

7

1

3

1

6

6

12

2

13

4

11

2

14

4

8

2

21

2

27

2

26

2

1

1

Item Item

P/N P/N

Description Description

1 21828226 BODY, W/A 1

2 21810065 "SUPPORT, HEAD WELD ASSEMBLY LS" 1

3 21810265 "SUPPORT, HEAD WELD ASSEMBLY RS" 1

4 21810275 "HEAD SUPPOR, OUTSIDE ASSY." 1

5 21810285 "HEAD SUPPORT, INSIDE ASSY." 1

6 8415500 WING NUT 10-32 S/S 6

7 89785-00 BUSHING, 1" SNAP, HEYCO 1

8 21810010 FAT CONTAINER AY 2

9 21810096 COVER HEAD 2

10 8170700 SCREW, 10-32 x 1/2, TYPE AB 51

Quan Quan

19 5161000 CONNECTOR CABLE ROMEX 1

20 21828218 PANEL, FRONT EF-30NT HD 1

21 31012-32 BASKET, FULL SIZE, 30H 2

22 21828038 BAFFLE, INTERIOR 2

23 21810040 DOOR ELECTRIC FRYER 1

24 2065847 LOGO, APW WYOTT CASTED 1

25 8832600 LABEL, SERVICE HOTLINE 1

26 43813103 LABEL, WRNG, HOT SURFC 2

27 43813149 "LABEL, WRN HOT SURF(FRNCH)" 2

28 21810218 "LABEL, DIAGRAM EL. TWIN FRYER

11 21810023 BRACKET HANDLE 2

12 21810022 ELEMENT HANDLE 2

13 8141400 8-32 x ½ MS 4

14 84104-00 NUT, HEX, 8-32 S/S 4

15 21828134 "BACK AND BOTTOM WELDMENT W/O DRAIN" 1

16 8633700 "LEG, HEAVY DUTY 2"" DIA. W/FOOT FLANGE" 4

17 8422400 #10-24 HX NUT GRN 1

18 8158800 MS RD HD PH 10-24 X ½ 1

29 8861000 LABEL, SPEC 1

30 8824200 LABEL, BUTTON POSITION 2

31 64416801 LABEL, 90 DEG C 1

32 29087-42 SKID, 44 X 32 FOR 42" MERCHANDISER 1

33 29088-42 CARTON, HSC 43.25 X 30.25 X 33.25 275 DW 1

34 8825300 DECAL, LEG 1

35 8460900 NUT, PUSH 1/8" 2

35

2

20

10

1

51

24

25

1

34

1

1

208/240V UNITS" 1

13

Page 14

HEF-15S (CE)

24

1

23

1

17

1

16

1

18

1

19

1

25

2

13

4

DETAIL A

20

1

A

22

1

32

1

26

1

9

37

35

1

33

1

12

4

15

4

9

34

1

8

37

1

2

1

5

4

9

4

1

6

37

1

3

1

7

2

9

37

14

1

1

1

31

1

30

1

Item Item

P/N P/N

Description Description

1 21828025 BODY, FRYER HD 1

2 21810065 "SUPPORT, HEAD WELD ASSEMBLY LS" 1

3 21810075 "HEAD SUPPORT OUTSIDE WELD ASSY" 1

4 21810085 HEAD SUPPORT INSIDE 1

5 8415500 WING NUT 10-32 S/S 4

6 89670-00 "BUSHING, SNAP HEYCO .5"" I.D." 1

7 3101230 BASKET, ½ SIZE 2

8 21810096 COVER HEAD 1

9 8170700 SCREW, 10-32x1/2, TYPE AB 37

10 21810023 BRACKET HANDLE 1

11 21810022 ELEMENT HANDLE 1

12 8141400 8-32 x ½ MS 4

13 84104-00 NUT,HEX, 8-32 S/S 4

14 21828035 BACK, BOTTOM W/A 1

15 8633700 "LEG, HEAVY DUTY 2"" DIA.

W/ FOOT FLANGE" 4

16 11141-00 LUG, SOLDERLESS 1

17 8422400 #10-24 HX NUT GRN 1

18 88370-01 LABEL, GROUND MARKER 1

19 8158800 MS RD HD PH 10-24 X ½ 1

Quan Quan

20 5161000 CONNECTOR CABLE ROMEX 1

21 21828019 PANEL, FRONT HEF-15 1

22 21828038 BAFFLE, INTERIOR 1

23 1302100 RELAY, SOLID STATE 1

24 21810042 CAPACITOR, ASSY 1

25 8103400 "SCREW, MACH, 6-32 X 1/4"" LG." 2

26 21810040 DOOR ELECTRIC FRYER 1

27 2065847 LOGO, APWWYOTT CASTED 1

28 1305612 SWITCH, ROCKER 20 AMP 1

29 8832600 LABEL, SERVICE HOTLINE 1

30 43813103 LABEL, WRNG, HOT SURFC 1

31 43813149 "LABEL, WRN HOT SURF(FRNCH)" 1

32 21810017 "LABEL, DIAGRAM EL. 15LB CE UNITS" 1

33 8861000 LABEL, SPEC 1

34 8824200 LABEL, BUTTON POSITION 1

35 64416801 LABEL, 90 DEG C 1

36 2901051 "CARTON, RSC39.25X19.87X20.18" 1

37 21810010 FAT CONTAINER AY 1

38 8825300 DECAL, LEG 1

39 8460900 NUT, PUSH 1/8" 2

37

1

10

11

12

1

4

28

1

38

1

39

2

9

21

37

1

27

1

29

1

13

1

4

14

Page 15

14

8

31

4

DETAIL A

21

1

13

8

40

1

10

50

16

4

HEF-30T (CE w/DRAIN)

18

1

17

1

19

1

20

1

30

2

29

2

32

1

43

1

35

1

39

1

A

15

1

24

2

25

2

26

2

42

2

28

1

2

1

6

6

27

2

45

2

41

2

38237

5

4

1

1

1

1

49

2

2

9

7

2

1

10

22

50

1

3

1

12

2

13

8

11

2

14

8

8

2

23

2

44

2

34

2

48

1

33

1

36

1

Item Item

P/N P/N

Description Description

1 21828226 BODY, W/A 1

2 21810065 SUPPORT, HEAD WELD ASSEMBLY LS 1

3 21810265 SUPPORT, HEAD WELD ASSEMBLY RS 1

4 21810275 HEAD SUPPOR, OUTSIDE ASSY. 1

5 21810285 HEAD SUPPORT, INSIDE ASSY. 1

6 8415500 WING NUT 10-32 S/S 6

7 89785-00 BUSHING, 1" SNAP, HEYCO 1

8 21828210 2

9 21810096 COVER HEAD 2

10 8170700 SCREW, 10-32x1/2, TYPE AB 50

11 21810023 BRACKET HANDLE 2

12 21810022 ELEMENT HANDLE 2

13 8141400 8-32 x ½ MS 8

14 84104-00 NUT,HEX, 8-32 S/S 8

15 21828235 BACK AND BOTTOM WELDMENT 1

16 8633700 LEG, HEAVY DUTY 2" DIA. W/ FOOT FLANGE 4

17 11141-00 LUG, SOLDERLESS 1

18 8422400 #10-24 HX NUT GRN 1

19 88370-01 LABEL, GROUND MARKER 1

20 8158800 MS RD HD PH 10-24 X ½ 1

21 5161000 CONNECTOR CABLE ROMEX 1

22 21828219 PANEL, FRONT EF-30NT HD 1

23 31012-32 BASKET, FULL SIZE, 30H 2

24 2092627 NIPPLE, 3/4 SCH. 40 X 2" 2

25 2092611 ELBOW, 3/4 BLACK PIPE 2

26 2092628 PIPE, 3/4 SCH. 40 2

Quan Quan

27 2099900 VALVE, BALL, Ø3/4 2

28 21828238 BAFFLE, INTERIOR EF-30NT HD 1

29 1302100 RELAY, SOLID STATE 2

30 21810042 CAPACITOR, ASSY 2

31 8103400 SCREW, MACH, 6-32 X 1/4" LG. 4

32 21810040 DOOR ELECTRIC FRYER 1

33 2065847 LOGO, APWWYOTT CASTED 1

34 1305612 SWITCH, ROCKER 20 AMP 2

35 89673-00 BUSHING, 3/4 SNAP 1

36 8832600 LABEL, SERVICE HOTLINE 1

37 43813103 LABEL, WRNG, HOT SURFC 2

38 43813149 LABEL, WRN HOT SURF (FRNCH) 2

39 21810216 "LABEL, DIAGRAM EL. TWINFRYER

40 8861000 LABEL, SPEC 1

41 8824200 LABEL, BUTTON POSITION 2

42 21828215 DRAIN SUPPORT 2

43 64416801 LABEL, 90 DEG C 1

44 21828211 GASKET, GREASE PAN 2

45 217730-04 DRAIN TUBE 2

46 29087-42 "SKID, 44 X 32 FOR 42""MERCHANDISER" 1

47 29088-42 "CARTON, HSC 43.25 X30.25 X 33.25

48 8825300 DECAL, LEG 1

49 8460900 NUT, PUSH 1/8" 2

CE UNITS" 1

275 DW" 1

15

Page 16

NOTES:

16

Page 17

14. APW WYOTT EQUIPMENT LIMITED WARRANTY

APW Wyott Food service Equipment Company warrants it's equipment against defects in materials and workmanship, subject to the

following conditions:

This warranty applies to the original owner only and is not assignable.

Should any product fail to function in its intended manner under normal use within the limits defined in this warranty, at the option of

APW Wyott such product will be repaired or replaced by APW Wyott or its Authorized Service Agency. APW Wyott will only be

responsible for charges incurred or service performed by its Authorized Service Agencies. The use of other than APW Wyott Authorized

Service Agencies will void this warranty and APW Wyott will not be responsible for such work or any charges associated with same.

The closest APW Wyott Authorized Service Agent must be used.

This warranty covers products shipped into the 48 contiguous United States, Hawaii, metropolitan areas of Alaska and Canada. There

will be no labor coverage for equipment located on any island not connected by roadway to the mainland.

Warranty coverage on products used outside the 48 contiguous United States, Hawaii, and metropolitan areas of Alaska and Canada

may vary. Contact the international APW Wyott distributor, dealer, or service agency for details.

Time Period

One year for parts and one year for labor, effective from the date of purchase by the original owner. The Authorized Service Agency may,

at their option, require proof of purchase. Parts replaced under this warranty are warranted for the un-expired portion of the original

product warranty only.

Exceptions

In all cases, parts covered by extended warranty will be shipped FOB the factory after the first year.

Portable Carry In Products

Equipment weighing over 70 pounds or permanently installed will be serviced on-site as per the terms of this warranty. Equipment

weighing 70 pounds or under, and which is not permanently installed, i.e. with cord and plug, is considered portable and is subject to the

following warranty handling limitations. If portable equipment fails to operate in its intended manner on the first day of connection, or

use, at APW Wyott's option or its Authorized Service Agency, it will be serviced on site or replaced.

From day two through the conclusion of this warranty period, portable units must be taken to or sent prepaid to the APW Wyott

Authorized Service Agency for in-warranty repairs. No mileage or travel charges are allowed on portable units after the first day of use.

If the customer wants on-site service, they may receive same by paying the travel and mileage charges. Exceptions to this rule:

(1) countertop warmers and cookers, which are covered under the Enhanced Warranty Program, and (2) toasters or rollergrills which

have in store service.

Exclusions

The following conditions are not covered by warranty:

If the equipment has been changed, altered, modified or repaired by other than an Authorized Service Agency during or after the

warranty period, then the manufacturer shall not be liable for any damages to any person or to any property, which may result from the

use of the equipment thereafter.

This warranty does not cover services performed at overtime or premium labor rates. Should service be required at times which

normally involve overtime or premium labor rates, the owner shall be charged for the difference between normal service rates and such

premium rates. APW Wyott does not assume any liability for extended delays in replacing or repairing any items beyond its control.

In all cases, the use of other than APW Wyott Authorized OEM Replacement Parts will void this warranty.

This equipment is intended for commercial use only. Warranty is void if equipment is installed in other than commercial application.

Water Quality Requirements

Water supply intended for a unit that has in excess of 3.0 grains of hardness per gallon (GPG) must be treated or softened before

being used. Water containing over 3.0 GPG will decrease the efficiency and reduce the operation life of the unit.

Note: Product failure caused by liming or sediment buildup is not covered under warranty.

"THE FOREGOING WARRANTY IS IN LIEU OF ANY AND ALL OTHER WARRANTIES EXPRESSED OR IMPLIED

INCLUDING ANY IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR PARTICULAR PURPOSES

AND CONSTITUTES THE ENTIRE LIABILITY OF APW WYOTT. IN NO EVENT DOES THE LIMITED WARRANTY

EXTEND BEYOND THE TERMS STATED HEREIN."

*Gas/Electric Cookline: Models HCB, HCRB, HMG, HTG, HHP, HHPS, GCB, GCRB, GF, GGM, GGT, CHP-H, EF, EG,

EHP. Three (3) Year Warranty on all component parts, except switches and thermostats. (2 additional years on parts only.

No labor on second or third year.)

*Broiler Briquettes, Rock Grates, Cooking Grates, Burner Shields, Fireboxes: 90 Day Material Only. No Labor.

*Heat Strips: Models FD, FDL, FDD, FDDL. Two (2)YearWarranty on element only. No labor second year.

*Glass Windows, Doors, Seals, Rubber Seals, Light Bulbs: 90 Day Material Only. No Labor.

*Equipment failure relating to improper installation, improper utility connection or supply and problems due to ventilation.

*Equipment that has not been properly maintained, calibration of controls, adjustments, damage from improper cleaning

and water damage to controls.

*Equipment that has not been used in an appropriate manner, or has been subject to misuse or misapplication, neglect, abuse,

accident, alteration, negligence, damage during transit, delivery or installation, fire, flood, riot or act of god.

*Equipment that has the model number or serial number removed or altered.

9/05

17

Loading...

Loading...