Page 1

R

Ease*Extreme

INSTALLATION

AND

OPERATING

INSTRUCTIONS

HOLDING DRAWERS

INTENDED FOR OTHER THAN HOUSEHOLD USE

RETAIN THIS MANUAL FOR FUTURE REFERENCE

UNIT MUST BE KEPT CLEAR OF COMBUSTIBLES AT ALL TIMES

TM

Model: HDX

FOR YOUR SAFETY: Do not store or use gasoline or other flammable vapors and

liquids in the vicinity of this or anyother appliance.

WARNING: Improper installation, adjustment, alteration, service or maintenance can

cause property damage, injury or death. Read the Installation, Operating and

Maintenance Instructions thoroughly before installing or servicing thisequipment.

Initial heating of unit may generate smoke or fumes and must be done in a well ventilated area.

Overexposure to smoke or fumes may cause nausea or dizziness.

This equipment has been engineered to provide you with year-round dependable service when used

according to the instructions in this manual and standard commercial kitchen practices.

ANSI/NSF4

P/N 70504626 9/05

Phone:

Fax: (214) 565-0976

Toll Free: (800) 527-2100

Website: www.apwwyott.com

E-mail: info@apwwyott.com

(214) 421-7366

APW WYOTT

729 Third Avenue

Dallas, TX 75226

!!

!!

1

Page 2

SECTION

ITEM

TABLE OF CONTENTS

PAGE

1

2

3

4

5

6

7

8

9

Owners Information

General Information......................................................................................

General Operation Instructions.....................................................................

Warranty Information....................................................................................

Important Safety Information

Specifications

Electrical.......................................................................................................

Dimensions...................................................................................................

Operation

Operating Instructions...................................................................................

Parts Lists

HDX-1 Parts List w/Exploded View...............................................................

HDX-2 Parts List w/Exploded View...............................................................

HDX-3 Parts List w/Exploded View................................................................

HDX-4 Parts List w/Exploded View...............................................................

Wiring Diagrams

Cleaning

General Cleaning Instructions......................................................................

Daily Cleaning...............................................................................................

Troubleshooting

Warranty

.........................................................................................................

.................................................................................................................

................................................................................................................

..................................................................................................................

.................................................................................................................

..............................................................................................

.....................................................................................................

.....................................................................................................

.................................................................................

2

2

2

2

3

3

3

3

5

5

6

6

8

10

12

14

18

18

18

18

20

1. OWNER’S INFORMATION

GeneralInformation:

1. Alwaysclean equipment thoroughly beforefirst use. (See general cleaning instructions).

2. Checkrating label foryour model designationand electrical rating.

3. Forbest results, use stainlesssteel countertops.

4. Alldimensions in parenthesisincentimeters unless noted.

5. Legsare shipped unassembled. Legs must be screwed into base of unit.

GeneralOperation Instructions:

1. Allfoodservice equipment should be operated by trained personnel.

2. Donot allow your customers to come in contact with any surface labeledCAUTION HOT.

3. Whereapplicable: Never pour cold water into dry heated units.

4. Neverhold food below150°F (66°C).

WarrantyInformation:

ReliabilityBacked ByAPW WyottsWarranty:

All APW Wyott Holding Drawers are backed by a one year parts and labor warranty, including On-Site

Servicecalls within 50 miles of authorizedservice technicians.

ServiceInformation:

ServiceHotline (800) 733-2203

2

Page 3

2. SAFETY INFORMATION

APW Wyott Holding Drawers are designed, built and sold for commercial use and should be operated by

trained personnel only. Clearly post all CAUTIONS, WARNINGS and OPERATING INSTRUCTIONS near

eachunit to insure proper operation andto reduce the chance of personal injury and/or equipmentdamage.

Always disconnect power before servicing the Holding Drawer. Surfaces will remain hot after power has

been turned off. Allow unit to cool before cleaning or servicing. Never clean the Holding Drawer by

immersing it in water. The Holding Drawer is not protected against water jets; DO NOT CLEAN HOLDING

DRAWERWITHAWATER JET.Alwayscleanequipment before first use.

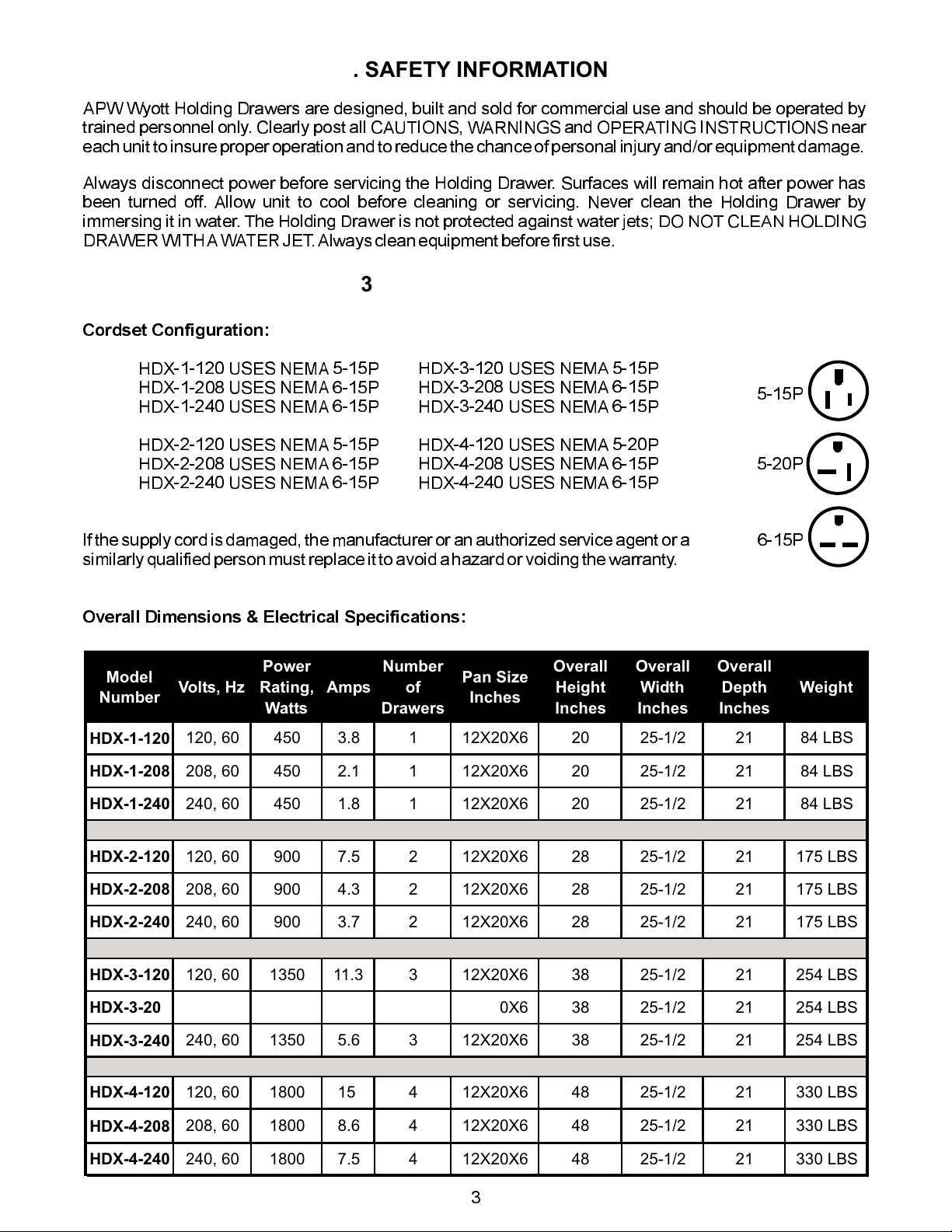

3. SPECIFICATIONS

Cordset Configuration:

HDX-1-120 USES NEMA 5-15P

HDX-1-208 USES NEMA 6-15P

HDX-1-240 USES NEMA 6-15P

HDX-2-120 USES NEMA 5-15P

HDX-2-208 USES NEMA 6-15P

HDX-2-240 USES NEMA 6-15P

HDX-3-120 USES NEMA 5-15P

HDX-3-208 USES NEMA 6-15P

HDX-3-240 USES NEMA 6-15P

HDX-4-120 USES NEMA 5-20P

HDX-4-208 USES NEMA 6-15P

HDX-4-240 USES NEMA 6-15P

If the supply cord is damaged, the manufacturer or an authorized service agent or a

similarlyqualified person must replace it to avoid a hazardor voiding the warranty.

Overall Dimensions & Electrical Specifications:

Model

Number

HDX-1-120

HDX-1-208

HDX-1-240

Power

Volts, Hz

120, 60 450 3.8 1 12X20X6 20 25-1/2 21 84 LBS

208, 60 450 2.1 1 12X20X6 20 25-1/2 21 84 LBS

240, 60 450 1.8 1 12X20X6 20 25-1/2 21 84 LBS

Rating,

Watts

Amps

Number

of

Drawers

Pan Size

Inches

Overall

Height

Inches

Overall

Width

Inches

5-15P

5-20P

6-15P

Overall

Depth

Inches

Weight

HDX-2-120

HDX-2-208

HDX-2-240

HDX-3-120

HDX-3-208

HDX-3-240

HDX-4-120

HDX-4-208

HDX-4-240

120, 60 900 7.5 2 12X20X6 28 25-1/2 21 175 LBS

208, 60 900 4.3 2 12X20X6 28 25-1/2 21 175 LBS

240, 60 900 3.7 2 12X20X6 28 25-1/2 21 175 LBS

120, 60 1350 11.3 3 12X20X6 38 25-1/2 21 254 LBS

208, 60 1350 6.5 3 12X20X6 38 25-1/2 21 254 LBS

240, 60 1350 5.6 3 12X20X6 38 25-1/2 21 254 LBS

120, 60

208, 60 1800 8.6 4 12X20X6 48 25-1/2 21 330 LBS

240, 60 1800 7.5 4 12X20X6 48 25-1/2 21 330 LBS

1800 15 4 12X20X6 48 25-1/2 21 330 LBS

3

Page 4

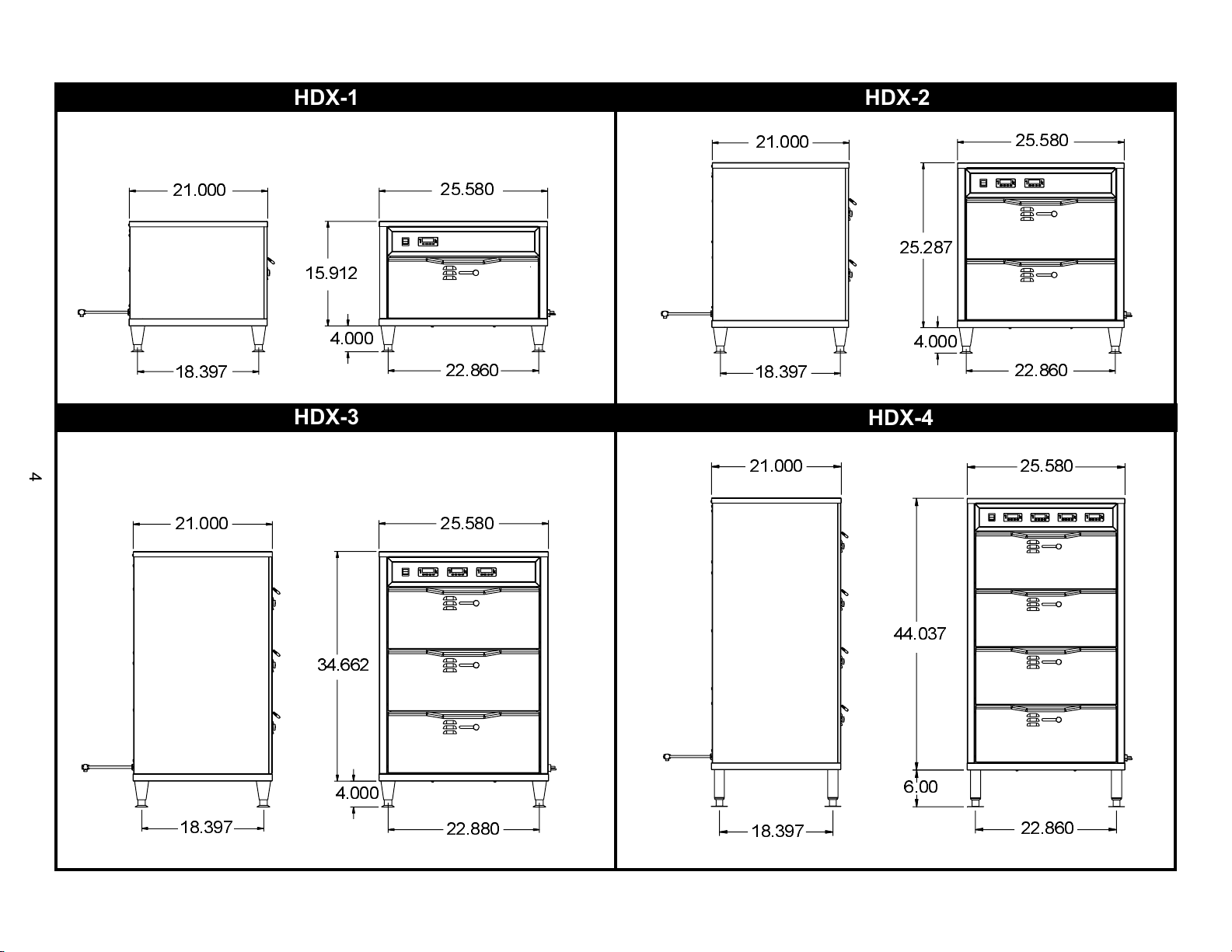

HDX-1 HDX-2

21.000

18.397

21.000

15.912

4.000

HDX-3

25.580

22.860

25.580

21.000

18.397

21.000

25.580

25.287

4.000

22.860

HDX-4

25.580

18.397

34.662

4.000

22.880

18.397

44.037

6.00

22.860

Page 5

WARNING:

INSTRUCTIONS IN THIS MANUAL COULD RESULT IN SERIOUS INJURY OR

!

DEATH.

ElectricalGround is required on this appliance.

Do not modify the power supply cord plug. If it does not fit into the outlet, have

theproper outlet installedby a qualified electrician

Donot use an extension cord with this appliance.

Check with a qualified electrician if you are unsure as to whether the appliance

is properly grounded.

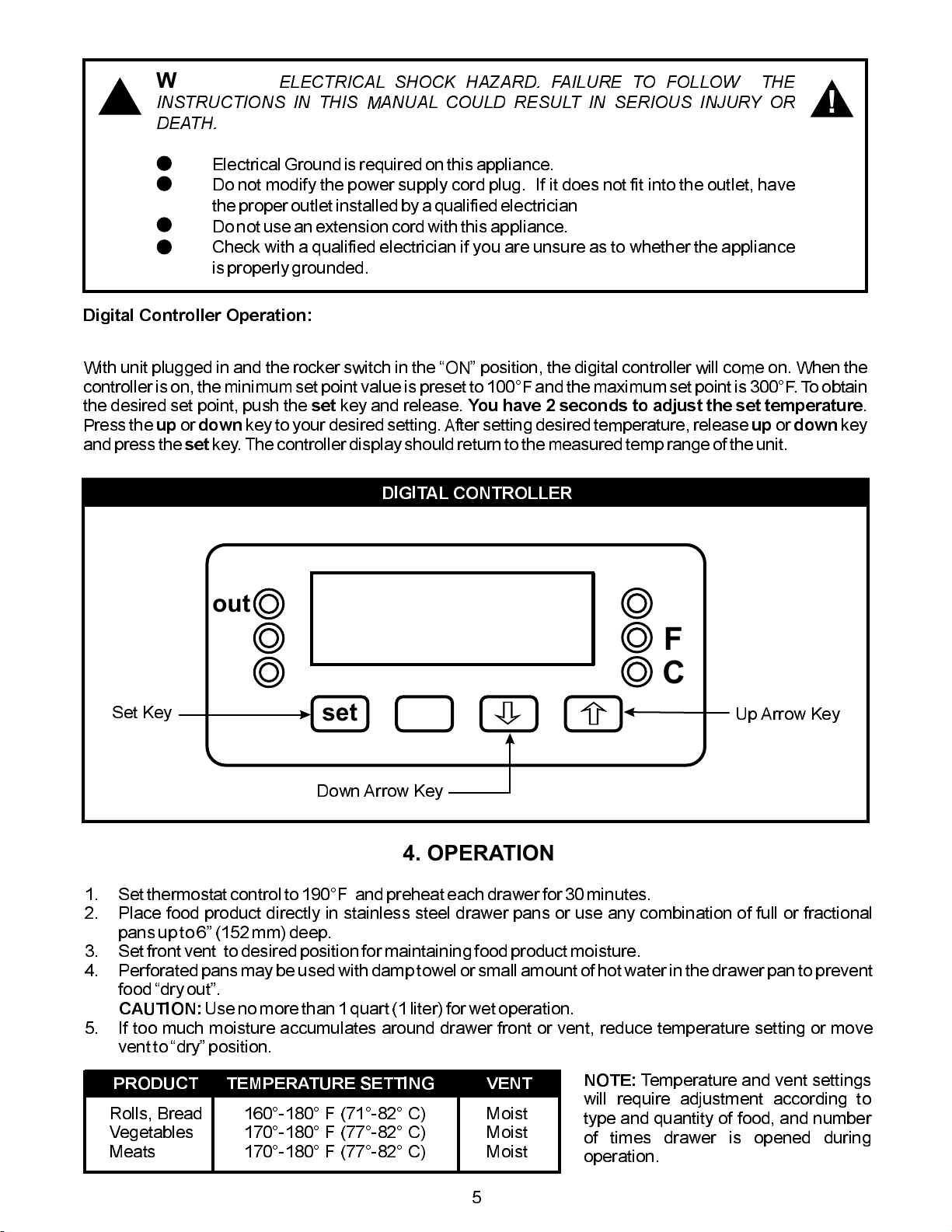

Digital Controller Operation:

With unit plugged in and the rocker switch in the ON position, the digital controller will come on. When the

controller is on, the minimum set point value is preset to 100°F and the maximum set point is 300°F. Toobtain

the desired set point, push the key and release. .

Press the or key to your desired setting. After setting desired temperature, release or key

and press the key.Thecontroller display should return to the measured temp range of the unit.

up down up down

set

ELECTRICAL SHOCK HAZARD. FAILURE TO FOLLOW THE

!

set You have 2 seconds to adjust the set temperature

DIGITAL CONTROLLER

out

F

C

Set Key

set

Down Arrow Key

4. OPERATION

1. Setthermostatcontrol to 190°F and preheat eachdrawer for 30 minutes.

2. Place food product directly in stainless steel drawer pans or use any combination of full or fractional

pansup to 6 (152 mm) deep.

3. Setfront vent todesired position for maintainingfood product moisture.

4. Perforatedpans may be used with damp towel or small amount of hot water in the drawer pan to prevent

fooddry out.

CAUTION:

5. If too much moisture accumulates around drawer front or vent, reduce temperature setting or move

ventto dry position.

Useno more than 1 quart (1 liter) for wet operation.

Up Arrow Key

PRODUCT TEMPERATURE SETTING VENT

Rolls, Bread

Vegetables

Meats

160°-180° F (71°-82° C)

170°-180° F (77°-82° C)

170°-180° F (77°-82° C)

Moist

Moist

Moist

5

NOTE:

will require adjustment according to

type and quantity of food, and number

of times drawer is opened during

operation.

Temperature and vent settings

Page 6

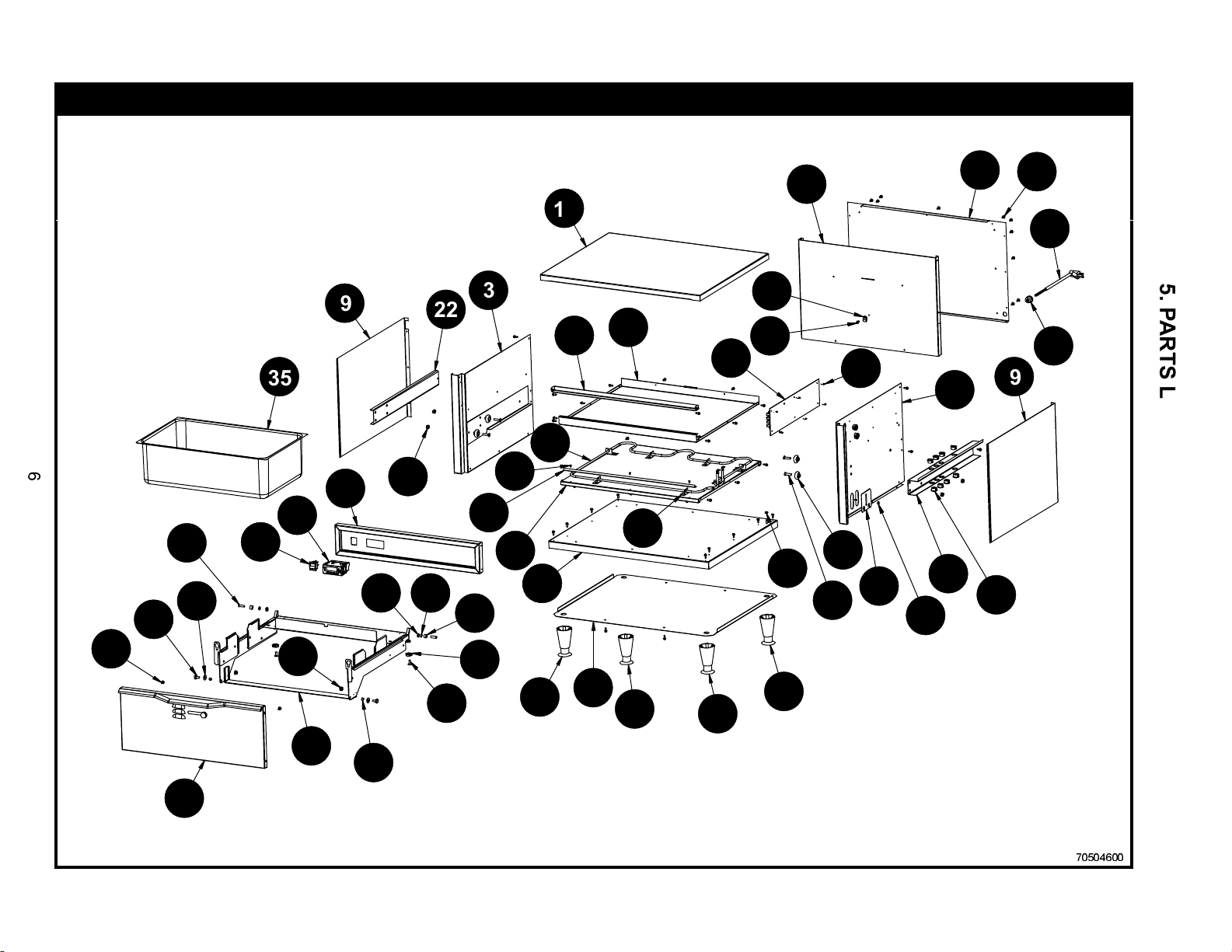

HDX-1 EXPLODED VIEW

48

48

2

41

41

2

45

45

2

20

20

1

40

40

2

23

23

1

35

35

1

19

19

1

13

13

6

38

38

1

9

9

2

17

17

1

47

47

39

39

2

8

2

21

21

1

8

1

2

1

7

7

28

28

1

18

49

16

27

27

1

16

4

1

25

25

6

11

11

4

32

32

12

12

4

1

33

33

1

10

10

1

3

3

22

22

13

13

6

46

46

2

2

43

43

1

1

36

36

17

34

34

1

4

4

1

44

44

2

42

42

2

2

1

1

1

16

16

4

29

29

1

6

6

1

15

15

1

5

5

1

14

16

16

4

18

26

26

1

14

7

16

16

4

24

24

10

31

31

15

37

37

1

5. PARTS LISTS W/EXPLODED VIEWS

30

30

1

9

9

2

70504600

Page 7

HDX-1 PARTS LIST

ITEM

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

PART NUMBER

70504101

70504601

70504605

70504100

70504087

70504089

70504608

70504609

70504607

70504096

33858

88892

88893

32404

70504127

86295

DESCRIPTION

WELD ASSY, BASE BOTTOM

W/ASS'Y, RIGHT SIDE PANEL

W/ASS'Y, LEFT SIDE PANEL

W/ASS'Y, BOTTOM SHELF

SHELF, TOP

BRACE TOP

PANEL, INNER BACK

PANEL, OUTER BACK

PANEL, OUTER RIGHT SIDE

COVER, TOP

ROLLER, DRAWER SLIDE

SCREW, 1/4-20x1 FLAT HEAD SS

NUT, 1/4-20 NYLON INSERT

BRACKET, ELEMENT

BOTTOM COVER

LEG, 4"-BLACK

QUAN

1

1

1

1

1

1

1

1

2

1

4

4

6

7

1

4

ITEM

26

27

28

29

30

31

32

33

34

35

36

37

38

39

PART NUMBER

70504624

88961

70504812

70504805

70504806

70504807

89111

88889

70504625

89063

70504815

33018

56521

55970

70504121

70504817

DESCRIPTION

S/A, COMPONENT PARTS

NUT, HEX 10-24, GREEN

P CLIP

HDX ELEMENT, 120V

HDX ELEMENT, 208V

HDX ELEMENT, 240V

BUSHING, STRAIN RELIEF SR-7W-2

SCREW #8 X 1/2 AB SMS PHL TRUSS

ELEMENT, COVER

NUT, HEX 8-32

DRIP, L-BRACKET

PAN, SPECIAL 600 DRAWER

RIVET POP SS-42-D

CORD, 120 VOLT 15A

W/ASSY, DRAWER HOUSING

STAINLESS STEEL, BUSHING

QUAN

1

1

1

1

1

1

1

15

1

1

1

1

17

1

1

2

17

18

19

20

21

22

23

24

25

70504040

89073

70101025

70101031

70504107

70504618

70502041

89491

89207

88989

CONTROL PANEL

SCREW, #8 X 1/2 HEX

TEMP. CONTROLLER,

TEMP. CONTROLLER,

DIGITAL 208-240V

DIGITAL 115V

S/ASSY, DRAWER FACE

BRACKET, STIFFNER

BRACKET, STIFFNER

SWITCH, ROCKER

HEYCO BUSHING .750 P/N 2093

STANDOFF, #4-40, MALE /FEMALE

1

49

1

1

1

1

1

1

10

6

40

41

42

43

44

45

46

47

48

87441

89003

70502042

70502028

88852

88894

89076

89163

87074

WASHER .250 id x .47/64 od x .065 thk

BOLT,1/4-20 X 1/2" SS HEX

FLAT BEARING W/ HOLE

SCREW, 1/4-20x FLAT HEAD SS

BUSHING, SLIDE

STUD PRESS THREADED

WASHER, LOCK 1/4 INTERNAL

NUT, JAM HEX 1/4-20 N.P. SS

PIN, HANGER

2

2

2

2

2

2

2

2

2

Page 8

22

22

2

44

44

4

41

41

4

47

47

4

22

22

HDX-2 EXPLODED VIEW

36

36

17

21

21

28

28

1

2

1

16

16

17

17

8

4

1

1

1

21

21

68

68

27

27

34

34

2

9

9

1

6

30

30

2

10

10

1

35

35

2

23

26

26

18

23

2

11

11

13

13

12

2

12

12

1

2

45

45

4

50

50

4

3

3

1

38

38

8

8

1

7

7

1

33

33

2

4

4

1

37

37

34

6

6

1

5

5

1

15

15

1

2

16

16

4

16

16

4

14

16

16

4

2

2

1

31

31

18

18

8

14

14

29

29

11

11

2

20

20

2

25

25

1

49

49

4

2

40

40

2

40

40

2

43

43

4

19

19

1

46

46

42

42

4

4

24

24

48

48

4

39

32

32

1

39

1

70504200

Page 9

HDX-2 PARTS LIST

ITEM

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

PART NUMBER

70504101

70504102

70504103

70504801

70504100

32417

70504087

70504089

70504091

70504090

70504094

70504096

88893

32404

70504127

86295

33266

33265

70504814

33858

88892

70504017

70101025

70101031

89073

70504107

70504618

70502041

DESCRIPTION

WELD ASSY, BASE BOTTOM

W/ASS'Y, RIGHT SIDE PANEL

W/ASS'Y, LEFT SIDE PANEL

SHELF, MIDDLE

W/ASS'Y, BOTTOM SHELF

COVER, SHELF

SHELF, TOP

BRACE TOP

PANEL, INNER BACK

PANEL, OUTER BACK

PANEL, OUTER RIGHT SIDE

COVER, TOP

NUT, 1/4-20 NYLON INSERT

BRACKET, ELEMENT

BOTTOM COVER

LEG, 4"-BLACK (Standard)

Swivel Caster (Front of Unit) Optional

Rigid Caster (Rear of Unit) Optional

Leg, 6" (Optional)

ROLLER, DRAWER SLIDE

SCREW, 1/4-20x1 FLAT HEAD SS

CONTROL PANEL

TEMP. CONTROLLER,

TEMP. CONTROLLER,

DIGITAL

DIGITAL

208-240V

115V

SCREW, #8 X 1/2 HEX

S/ASSY, DRAWER FACE

BRACKET, STIFFNER

BRACKET, STIFFNER

QUAN

1

1

1

1

1

1

1

1

1

1

2

1

12

14

1

4

2

2

4

8

8

1

2

2

68

2

2

2

ITEM

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

PART NUMBER

89491

89207

88989

70504623

88961

70504812

70504805

70504806

70504807

89111

70504815

70504625

89063

88889

56521

33018

55970

70504121

70504817

87441

89003

87074

70502042

70502028

88852

88894

89076

89163

DESCRIPTION

SWITCH, ROCKER

HEYCO BUSHING .750 P/N 2093

STANDOFF, #4-40, MALE /FEMALE

S/A, COMPONENT PARTS

NUT, HEX 10-24, GREEN

P CLIP

HDX ELEMENT, 120V

HDX ELEMENT, 208V

HDX ELEMENT, 240V

BUSHING, STRAIN RELIEF SR-7W-2

DRIP, L-BRACKET

ELEMENT, COVER

NUT, HEX 8-32

SCREW #8 X 1/2 AB SMS PHL TRUSS

RIVET POP SS-42-D

PAN, SPECIAL 600 DRAWER

CORD, 120 VOLT 15A

W/ASSY, DRAWER HOUSING

STAINLESS STEEL, BUSHING

WASHER .250 id x .47/64 od x .065 thk

BOLT,1/4-20 X 1/2" SS HEX

PIN, HANGER

FLAT BEARING W/ HOLE

SCREW, 1/4-20x FLAT HEAD SS

BUSHING, SLIDE

STUD PRESS THREADED

WASHER, LOCK 1/4 INTERNAL

NUT, JAM HEX 1/4-20 N.P. SS

QUAN

1

18

6

1

1

2

2

2

2

1

2

2

2

17

34

2

1

2

4

4

4

4

4

4

4

4

4

4

Page 10

11

11

2

HDX-3 EXPLODED VIEW

12

12

24

24

3

3

3

1

8

8

1

31

31

3

1

10

10

1

32

32

1

36

36

17

39

39

1

9

9

1

30

30

3

26

26

6

28

7

28

1

7

1

19

2

2

1

19

74

23

23

3

22

22

3

40

40

41

41

6

20

20

21

21

25

25

1

3

15

15

18

42

42

6

1

3

37

37

3

50

50

43

43

6

44

44

6

6

49

49

6

45

45

6

46

46

6

47

47

6

37

37

48

48

6

3

37

37

3

4

16

16

21

4

2

18

18

4

5

5

1

1

1

1

35

35

3

19

19

74

18

18

4

18

18

4

14

14

12

18

18

4

6

6

2

13

29

38

38

51

13

12

29

1

17

11

15

15

18

11

2

70504300

27

27

34

34

3

27

33

33

3

17

1

Page 11

HDX-3 PARTS LIST

ITEM

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

PART NUMBER

70504101

70504304

70504307

70504801

70504100

32417

70504087

70504089

70504311

70504309

70504310

70504096

33858

88892

88893

32404

70504127

86295

33266

33265

70504814

89073

70504041

70101025

70101031

70504107

70504618

70502041

DESCRIPTION

WELD ASSY, BASE BOTTOM

W/ASS'Y, RIGHT SIDE PANEL

W/ASS'Y, LEFT SIDE PANEL

SHELF, MIDDLE

W/ASS'Y, BOTTOM SHELF

COVER, SHELF

SHELF, TOP

BRACE TOP

PANEL, INNER BACK

PANEL, OUTER BACK

PANEL, OUTER RIGHT SIDE

COVER, TOP

ROLLER, DRAWER SLIDE

SCREW, 1/4-20x1 FLAT HEAD SS

NUT, 1/4-20 NYLON INSERT

BRACKET, ELEMENT

BOTTOM COVER

LEG, 4"-BLACK (Standard)

Swivel Caster (Front of Unit) Optional

Rigid Caster (Rear of Unit) Optional

Leg, 6" (Optional)

SCREW, #8 X 1/2 HEX

CONTROL PANEL

TEMP. CONTROLLER,

TEMP. CONTROLLER,

S/ASSY, DRAWER FACE

BRACKET, STIFFNER

BRACKET, STIFFNER

208-240V

115V

QUAN

1

1

1

2

1

2

1

1

1

1

2

1

12

12

18

21

1

4

2

2

4

74

1

3

3

3

3

3

ITEM

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

PART NUMBER

89491

88989

89207

70504622

88961

70504812

70504805

70504806

70504807

89111

70504625

89063

70504815

88889

33018

56521

55970

70504121

87074

70504817

87441

89003

70502042

70502028

88852

88894

89076

89163

DESCRIPTION

SWITCH, ROCKER

STANDOFF, #4-40, MALE /FEMALE

HEYCO BUSHING .750 P/N 2093

S/A, COMPONENT PARTS

NUT, HEX 10-24, GREEN

P CLIP

HDX ELEMENT, 120V

HDX ELEMENT, 208V

HDX ELEMENT, 240V

BUSHING, STRAIN RELIEF SR-7W-2

ELEMENT, COVER

NUT, HEX 8-32

DRIP, L-BRACKET

SCREW #8 X 1/2 AB SMS PHL TRUSS

PAN, SPECIAL 600 DRAWER

RIVET POP SS-42-D

CORD, 120 VOLT 15A

W/ASSY, DRAWER HOUSING

PIN, HANGER

STAINLESS STEEL, BUSHING

WASHER .250 id x .47/64 od x .065 thk

BOLT,1/4-20 X 1/2" SS HEX

FLAT BEARING W/ HOLE

SCREW, 1/4-20x FLAT HEAD SS

BUSHING, SLIDE

STUD PRESS THREADED

WASHER, LOCK 1/4 INTERNAL

NUT, JAM HEX 1/4-20 N.P. SS

QUAN

1

6

27

1

1

3

3

3

3

1

3

3

3

17

3

51

1

3

6

6

6

6

6

6

6

6

6

6

Page 12

HDX-4 EXPLODED VIEW

36

36

19

40

21

21

4

40

4

34

34

4

15

15

24

9

9

1

20

20

88

11

11

2

29

29

4

10

10

39

39

31

31

1

1

1

12

7

7

1

4

4

3

30

30

4

37

37

68

6

6

3

35

17

8

8

35

4

17

1

32

32

4

12

1

1

16

16

28

23

23

4

11

11

2

18

19

18

4

44

44

8

49

15

24

47

48

48

49

8

1

38

38

4

38

8

46

46

38

4

38

38

4

8

38

38

4

45

45

15

47

8

8

19

24

24

1

4

43

43

8

41

41

8

42

42

8

50

50

8

3

3

1

27

27

28

5

28

5

1

1

14

1

25

25

35

14

16

13

26

26

6

22

22

2

2

1

33

33

4

13

16

1

1

1

32

32

4

70504400

Page 13

HDX-4 PARTS LIST

ITEM

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

PART NUMBER

70504101

70504401

70504403

70504801

70504100

32417

70504087

70504089

70504406

70504407

70504405

70504096

33858

88892

88893

32404

70504127

70504043

70101025

70101031

89073

70504107

70504618

70502041

89491

89207

88989

70504621

DESCRIPTION

WELD ASSY, BASE BOTTOM

W/ASS'Y, RIGHT SIDE PANEL

W/ASS'Y, LEFT SIDE PANEL

SHELF, MIDDLE

W/ASS'Y, BOTTOM SHELF

COVER, SHELF

SHELF, TOP

BRACE TOP

PANEL, INNER BACK

PANEL, OUTER BACK

PANEL, OUTER RIGHT SIDE

COVER, TOP

ROLLER, DRAWER SLIDE

SCREW, 1/4-20x1 FLAT HEAD SS

NUT, 1/4-20 NYLON INSERT

BRACKET, ELEMENT

BOTTOM COVER

CONTROL PANEL

TEMP. CONTROLLER,

TEMP. CONTROLLER,

DIGITAL 208-240V

DIGITAL 115V

SCREW, #8 X 1/2 HEX

S/ASSY, DRAWER FACE

BRACKET, STIFFNER

BRACKET, STIFFNER

SWITCH, ROCKER

HEYCO BUSHING .750 P/N 2093

#4-40 MALE/FEMALE STANDOFF

S/A, COMPONENT PARTS

QUAN

1

1

1

3

1

3

1

1

1

1

2

1

16

16

24

28

1

1

4

4

88

4

4

4

1

35

6

1

ITEM

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

PART NUMBER

88961

70504812

70504805

70504806

70504807

89111

70504814

33266

33265

70504625

89063

70504815

88889

56521

33018

55970

70504121

87074

70502042

70502028

70504817

87441

89003

88852

88894

89076

89163

DESCRIPTION

NUT, HEX 10-24, GREEN

P CLIP

HDX ELEMENT, 120V

HDX ELEMENT, 208V

HDX ELEMENT, 240V

BUSHING, STRAIN RELIEF SR-7W-2

6" ADJUSTABLE LEG (Standard)

Swivel Caster (Front of Unit) Optional

Rigid Caster (Rear of Unit) Optional

ELEMENT, COVER

NUT, HEX 8-32

DRIP, L-BRACKET

SCREW #8 X 1/2 AB SMS PHL TRUSS

RIVET POP SS-42-D

PAN, SPECIAL 600 DRAWER

CORD, 120 VOLT 15A

W/ASSY, DRAWER HOUSING

PIN, HANGER

FLAT BEARING W/ HOLE

SCREW, 1/4-20x FLAT HEAD SS

STAINLESS STEEL, BUSHING

WASHER .250 id x .47/64 od x .065 thk

BOLT,1/4-20 X 1/2" SS HEX

BUSHING, SLIDE

STUD PRESS THREADED

WASHER, LOCK 1/4 INTERNAL

NUT, JAM HEX 1/4-20 N.P. SS

QUAN

1

4

4

4

4

1

4

2

2

4

4

4

19

68

4

1

4

8

8

8

8

8

8

8

8

8

8

Page 14

6. WIRING DIAGRAMS

HDX-1 (120, 208 &240V)

RELAY 1 NEUTRAL POWER

ELEMENT

120V, 208 &

240 - 450W

12

9

3

8

5

10

PROBE

TYP FOR ALL CONTROLS

CONTROL 1

YELLOW

RED

4

2

1

11

GND

L2

L1

6

7

14

14

13

SWITCH

Page 15

HDX-2 (120, 208 &240V)

ELEMENT

120V, 208 &

240 - 450W

RELAY 1

3

17

8

RELAY 2

13

1

NEUTRAL POWER

6

22

16

22

24

12

18

11

21

21

23

14

CONTROL 2

15

20

CONTROL 1

2

ELEMENT

120V, 208 &

240 - 450W

7

19

PROBE

TYP FOR ALL CONTROLS

GND

YELLOW

RED

5

4

L2

L1

15

10

SWITCH

9

Page 16

RELAY 1

12

HDX-3 (120, 208 &240V)

RELAY 2

RELAY 3

NEUTRAL

22

22

24

26

POWER

21

21

3

17

ELEMENT

120V, 208 &

240 - 450W

ELEMENT

120V, 208 &

240 - 450W

13

11

25

8

3

6

29

31

CONTROL 3

1

30

16

14

23

CONTROL 2

7

2

20

15

18

CONTROL 1

ELEMENT

120V, 208 &

240 - 450W

27

16

PROBE

28

GND

L2

L1

19

YELLOW

RED

TYP FOR ALL CONTROLS

10

5

SWITCH

4

9

Page 17

RELAY 1

RELAY 2

HDX-4 (120, 208 &240V)

RELAY 3

RELAY 4

NEUTRAL

6

22

24

22

POWER

34

21

12

17

3

13

ELEMENT

120V, 208 &

240 - 450W

ELEMENT

120V, 208 &

240 - 450W

3

25

3

11

26

8

36

37

38

CONTROL 4

1

35

29

23

CONTROL 3

7

2

31

30

14

16

CONTROL 2

ELEMENT

120V, 208 &

240 - 450W

ELEMENT

120V, 208 &

240 - 450W

27

32

28

33

17

15

20

18

CONTROL 1

19

YELLOW

PROBE

TYP FOR ALL CONTROLS

GND

RED

5

L2

L1

10

SWITCH

4

9

Page 18

7. CLEANING

General Cleaning Instructions:

1. NEVER clean any electrical unit by immersing it in water.Turnoffbeforesurfacecleaning.

2. Always clean equipment thoroughly before first use. Clean unit daily. Except where noted on charts:

Use warm, soapy water.Mild cleansers and PLASTIC scouring pads may be used to remove baked-on

foodand water scale.

3. Turn off electrical units before cleaning or servicing. All service should be performed by an APW

authorizedservice agency.

DailyCleaning:

1. Follow General Cleaninginstructions (above).

2. Remove any inset pans and drawerpans. Washthoroughlyin the sink or dishwasher.

3. Remove drawers: Remove pans and pan inserts. Extend drawer and lift up on the front to clear the

drawerstop. Lower drawer and pull straightout.

8. TROUBLESHOOTING GUIDE

Alwaysask and checkthe following:

1. Is the unit connected to a live power source of the proper voltage?

2. Check the circuit breaker.

3. Is power switch ON and pilot light glowing?

4. Check the rating label. Is the unit connectedto the correct power source?

18

Page 19

Notes:

IMPORTANT FOR FUTURE REFERENCE

Please complete this information and retain this manual for the life of the equipment. For

WarrantyServiceand/orParts,this information is required.

ModelNumber SerialNumber DatePurchased

19

Page 20

9. APW WYOTT EQUIPMENT LIMITED WARRANTY

APW Wyott Foodservice Equipment Company warrants it's equipment against defects in materials and workmanship, subject to the

following conditions:

This warranty appliestotheoriginal owner only and is notassignable.

Should any product fail to function in its intended manner under normal use within the limits defined in this warranty, at the option of

APW Wyott such product will be repaired or replaced by APW Wyott or its Authorized Service Agency. APW Wyott will only be

responsible for charges incurred or service performed by its Authorized Service Agencies. The use of other than APW Wyott

Authorized Service Agencies will void this warranty and APW Wyott will not be responsible for such work or any charges associated

with same. The closestAPW WyottAuthorized Service Agent must be used.

This warranty covers products shipped into the 48 contiguous United States, Hawaii, metropolitan areas of Alaska and Canada. There

will be no labor coverage for equipment located on any island not connected by roadway to the mainland.

Warranty coverage on products used outside the 48 contiguous United States, Hawaii, and metropolitan areas of Alaska and Canada

may vary. Contact the international APWWyottdistributor, dealer, or service agency for details.

TimePeriod

One year for parts and one year for labor, effective from the date of purchase by the original owner. The Authorized Service Agency

may, at their option, require proof of purchase. Parts replaced under this warranty are warranted for the un-expired portion of the

original product warranty only.

Exceptions

Inall cases, parts covered byextended warranty will be shipped FOB the factory after the first year.

Portable Carry In Products

Equipment weighing over 70 pounds or permanently installed will be serviced on-site as per the terms of this warranty. Equipment

weighing 70 pounds or under, and which is not permanently installed, i.e. with cord and plug, is considered portable and is subject to

the following warranty handling limitations. If portable equipment fails to operate in its intended manner on the first day of

connection, or use, atAPW Wyott'soption or its Authorized ServiceAgency,it will beserviced on site orreplaced.

From day two through the conclusion of this warranty period, portable units must be taken to or sent prepaid to the APW Wyott

Authorized ServiceAgency for in-warranty repairs. No mileage or travel charges are allowed on portable units after the first day ofuse.

If the customer wants on-site service, they may receive same by paying the travel and mileage charges. Exceptions to this rule: (1)

countertop warmers and cookers, which are covered under the Enhanced WarrantyProgram, and (2) toasters or rollergrills which have

instore service.

Exclusions

The following conditions are not covered by warranty:

If the equipment has been changed, altered, modified or repaired by other than an Authorized Service Agency during or after the

warranty period, then the manufacturer shall not be liable for any damages to any person or to any property,which may result from the

use of the equipment thereafter.

This warranty does not cover services performed at overtime or premium labor rates. Should service be required at times which

normally involve overtime or premium labor rates, the owner shall becharged for the difference between normal service rates and such

premium rates.APWWyott does not assume any liability for extended delays in replacing or repairing any items beyond its control.

Inall cases, the useof other thanAPW WyottAuthorized OEM Replacement Parts will void this warranty.

This equipment is intended for commercial use only.Warranty isvoid if equipment is installed in other than commercial application.

WaterQuality Requirements

Water supply intended for a unit that has in excess of 3.0 grains of hardness per gallon (GPG) must be treated or softened before

being used. Water containing over 3.0 GPG will decrease the efficiency and reduce the operation life of the unit.

Note: Product failure caused by liming or sediment buildup is not covered under warranty.

THE FOREGOING WARRANTY IS IN LIEU OF ANY AND ALL OTHER WARRANTIES EXPRESSED OR IMPLIED

INCLUDING ANY IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR PARTICULAR PURPOSES

AND CONSTITUTES THE ENTIRE LIABILITY OFAPW WYOTT. IN NO EVENT DOES THE LIMITED WARRANTY

EXTEND BEYOND THE TERMS STATED HEREIN.

*Gas/Electric Cookline:

component parts, except switches and thermostats. (2 additional years on parts only.No labor on second or third year.)

*BroilerBriquettes,

*Heat Strips:

*GlassWindows, Doors, Seals, Rubber Seals, Light Bulbs:

*Equipment failure relating to improper installation, improper utility connection or supply and problems due to

ventilation.

*Equipment that has not been properly maintained, calibration of controls, adjustments, damage from improper cleaning

and water damage to controls.

*Equipment that has not been used in an appropriate manner, or has been subject to misuse or misapplication, neglect,

abuse, accident, alteration, negligence, damage during transit, delivery or installation, fire, flood, riotor act of god.

*Equipment that has the model number or serial number removed or altered.

Models FD,FDL, FDD, FDDL. Two (2) Year Warrantyon element only. No labor second year.

Models GCB, GCRB, GF, GGM, GGT, CHP-H, EF, EG, EHP.Three (3) Year Warranty on all

RockGrates, Cooking Grates,Burner Shields,Fireboxes:

90Day Material Only. No Labor.

90Day Material Only.NoLabor.

9/05

20

Loading...

Loading...