Page 1

INSTALLATION

AND

OPERATING

INSTRUCTIONS

HOLDING DRAWERS

INTENDED FOR OTHER THAN HOUSEHOLD USE

RETAIN THIS MANUAL FOR FUTURE REFERENCE

UNIT MUST BE KEPT CLEAR OF COMBUSTIBLES AT ALL TIMES

R

Model: HDD / HDDS

FOR YOUR SAFETY: Do not store or use gasoline or other flammable vapors and

liquids in the vicinity of this or any otherappliance.

WARNING: Improper installation, adjustment, alteration, service or maintenance can

cause property damage, injury or death. Read the Installation, Operating and

Maintenance Instructions thoroughlybefore installing or servicing this equipment.

This equipment has been engineered to provide you with year-round dependable service when used

according to the instructions in this manual and standard commercial kitchen practices.

ANSI/NSF4

P/N 70505000 9/05

Phone: +1

Fax: +1 (214) 565-0976

Toll Free: +1 (800) 527-2100

Website: www.apwwyott.com

E-mail: info@apwwyott.com

(214) 421-7366

APW WYOTT

729 Third Avenue

Dallas, TX 75226

!!

!!

1

Page 2

TABLE OF CONTENTS

SECTION

1

2

3

4

ITEM

Owners Information

General Information......................................................................................

General Operation Instructions.....................................................................

Warranty Information....................................................................................

Important Safety Information

Specifications

Electrical.......................................................................................................

Dimensions...................................................................................................

Operation

Operating Instructions...................................................................................

.........................................................................................................

.................................................................................................................

..............................................................................................

.................................................................................

PAGE

3

3

3

3

3

3

3

4

5

5

5

6

7

8

9

Cleaning

Troubleshooting

Wiring Diagram

Parts Lists & Exploded Views

Warranty

...................................................................................................................

General Cleaning Instructions.......................................................................

Daily Cleaning...............................................................................................

......................................................................................................

........................................................................................................

................................................................................

HDD-B...........................................................................................................

HDD-L or C....................................................................................................

HDDS-B.........................................................................................................

HDDS-L or C..................................................................................................

...................................................................................................................

5

5

5

5

6

7

7

8

9

10

11

2

Page 3

1. OWNER’S INFORMATION

General Information:

1. Alwaysclean equipment thoroughlybefore first use. (See general cleaning instructions).

2. Checkrating label for yourmodel designation and electrical rating.

3. Forbest results, usestainless steel countertops.

4. Alldimensions in parenthesisin centimeters unlessnoted.

General Operation Instructions:

1. Allfoodservice equipment shouldbe operated by trained personnel.

2. Donot allow your customersto come in contactwith any surfacelabeled CAUTION HOT.

3. Whereapplicable: Never pourcold water into dry heated units.

4. Where applicable: Do not cook, warm or hold food directly in liner pans (well pans). Always use

steamtablepans/insets,etc.

5. Neverhold perishable food below 150°F (66°C).

Warranty Information:

Reliability Backed ByAPW Wyott’s Warranty:

All APW Wyott Holding Drawers are backed by a one year parts and labor warranty, including On-Site

Servicecalls within 50 milesof authorized service technicians.

Service Information:

ServiceHotline (800) 733-2203

2. SAFETY INFORMATION

APW Wyott Holding Drawers are designed, built and sold for commercial use and should be operated by

trained personnel only. Clearly post all CAUTIONS, WARNINGSand OPERATING INSTRUCTIONS near

eachunit to insure properoperation and to reducethe chance of personalinjury and/or equipmentdamage.

Always disconnect power before servicing the Holding Drawer. Surfaces will remain hot after power has

been turned off. Allow unit to cool before cleaning or servicing. Never clean the Holding Drawer by

immersing it in water. The Holding Drawer is not protected against water jets; DO NOT CLEAN HOLDING

DRAWERWITHAWATERJET.Always clean equipment before first use.

3. SPECIFICATIONS

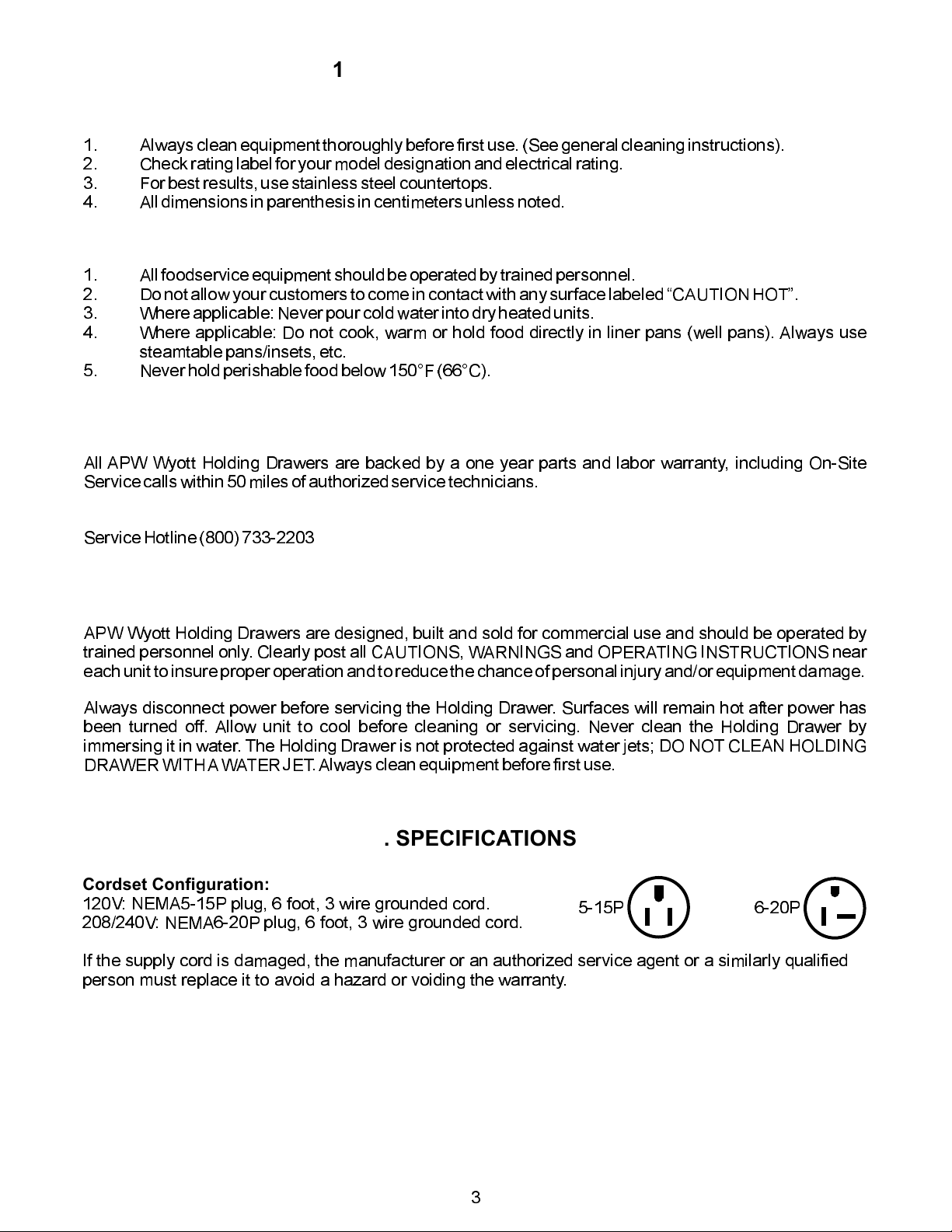

Cordset Configuration:

120V: NEMA5-15P plug, 6 foot, 3 wire grounded cord.

208/240V: NEMA6-20P plug, 6 foot, 3 wire grounded cord.

If the supply cord is damaged, the manufacturer or an authorized service agent or a similarly qualified

person must replace it to avoid a hazard or voiding the warranty.

5-15P 6-20P

3

Page 4

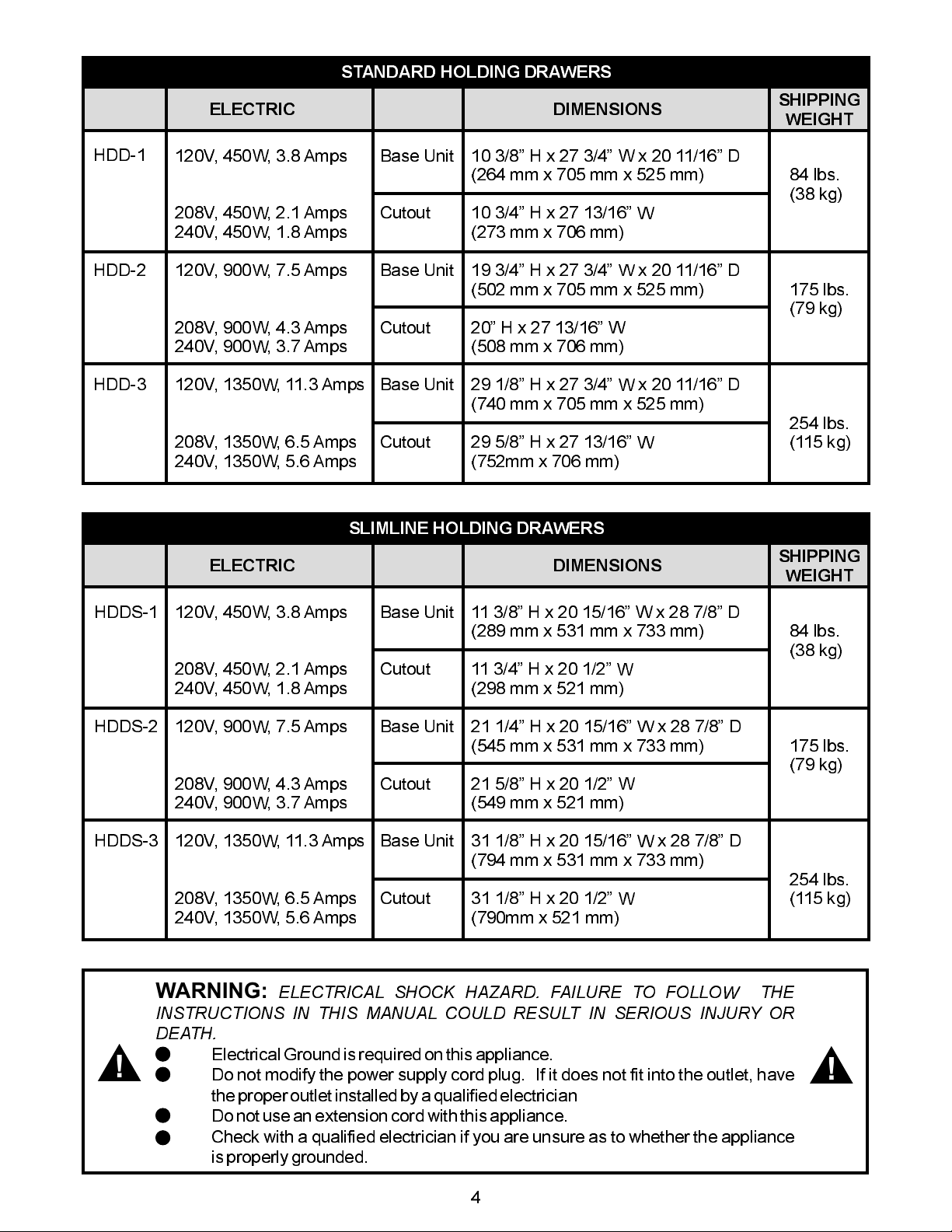

STANDARD HOLDING DRAWERS

HDD-1

HDD-2

HDD-3

ELECTRIC

120V, 450W, 3.8 Amps

208V, 450W, 2.1 Amps

240V, 450W, 1.8 Amps

120V, 900W, 7.5 Amps

208V, 900W, 4.3 Amps

240V, 900W, 3.7 Amps

120V, 1350W, 11.3 Amps

208V, 1350W, 6.5 Amps

240V, 1350W, 5.6 Amps

SLIMLINE HOLDING DRAWERS

Base Unit

Cutout

Base Unit

Cutout

Base Unit

Cutout

DIMENSIONS

10 3/8 H x 27 3/4 W x 20 11/16 D

(264 mm x 705 mm x 525 mm)

10 3/4 H x 27 13/16 W

(273 mm x 706 mm)

19 3/4 H x 27 3/4 W x 20 11/16 D

(502 mm x 705 mm x 525 mm)

20 H x 27 13/16 W

(508 mm x 706 mm)

29 1/8 H x 27 3/4 W x 20 11/16 D

(740 mm x 705 mm x 525 mm)

29 5/8 H x 27 13/16 W

(752mm x 706 mm)

SHIPPING

WEIGHT

84 lbs.

(38 kg)

175 lbs.

(79 kg)

254 lbs.

(115 kg)

HDDS-1

HDDS-2

HDDS-3

!

ELECTRIC

120V, 450W, 3.8 Amps

208V, 450W, 2.1 Amps

240V, 450W, 1.8 Amps

120V, 900W, 7.5 Amps

208V, 900W, 4.3 Amps

240V, 900W, 3.7 Amps

120V, 1350W, 11.3 Amps

208V, 1350W, 6.5 Amps

240V, 1350W, 5.6 Amps

WARNING:

INSTRUCTIONS IN THIS MANUAL COULD RESULT IN SERIOUS INJURY OR

DEATH.

ElectricalGround is requiredon this appliance.

Do not modify the power supply cord plug. If it does not fit into the outlet, have

theproper outlet installedby a qualified electrician

Donot use an extensioncord with this appliance.

Check with a qualified electrician if you are unsure as to whether the appliance

is properly grounded.

ELECTRICAL SHOCK HAZARD. FAILURE TO FOLLOW THE

Base Unit

Cutout

Base Unit

Cutout

Base Unit

Cutout

11 3/8 H x 20 15/16 W x 28 7/8 D

(289 mm x 531 mm x 733 mm)

11 3/4 H x 20 1/2 W

(298 mm x 521 mm)

21 1/4 H x 20 15/16 W x 28 7/8 D

(545 mm x 531 mm x 733 mm)

21 5/8 H x 20 1/2 W

(549 mm x 521 mm)

31 1/8 H x 20 15/16 W x 28 7/8 D

(794 mm x 531 mm x 733 mm)

31 1/8 H x 20 1/2 W

(790mm x 521 mm)

DIMENSIONS

SHIPPING

WEIGHT

84 lbs.

(38 kg)

175 lbs.

(79 kg)

254 lbs.

(115 kg)

!

4

Page 5

4. OPERATION

1. Initial heating ofunit may generatesmoke or fumes andmust be donein a wellventilated area.

2. Setthermostat control knob to desired settingand preheat each drawerfor 30 minutes.

3. Place food product directly in stainless steel drawer pans or use any combination of full or fractional

pansup to 6 (152mm) deep.

4. Setfront vent knob to desired position for maintainingfood product moisture.

5. Perforatedpans may be used with damp towel or smallamount of hot water in the drawer pan to prevent

fooddry out.

CAUTION:

6. If too much moisture accumulates around drawer front or vent, reduce temperature setting or move

ventknob to dry position.

Useno more than 1 quart (1 liter) for wet operation.

PRODUCT TEMPERATURE SETTING VENT

Rolls, Bread

Vegetables

Meats

160°-180° F (71°-82° C)

170°-180° F (77°-82° C)

170°-180° F (77°-82° C)

Moist

Moist

Moist

NOTE:

will require adjustment according to

type and quantity of food, and number

of times drawer is opened during

operation.

Temperature and vent settings

5. CLEANING

General Cleaning Instructions:

1. NEVERclean any electrical unit by immersing it in water.Turnoff before surface cleaning.

2. Always clean equipment thoroughly before first use. Clean unit daily. Except where noted on charts:

Use warm, soapy water.Mild cleansers and PLASTIC scouring pads may be used to remove baked-on

foodand water scale.

3. Turn off electrical units before cleaning or servicing. All service should be performed by an APW

authorizedservice agency.

DailyCleaning:

1. FollowGeneral Cleaning instructions(above).

2. Removeany inset pansand drawer pans.Wash thoroughly in the sink or dishwasher.

3. Remove drawers: Remove pans and pan inserts. Extend drawer and lift up on the front to clear the

drawerstop. Lower drawer and pull straight out.

6. TROUBLESHOOTING GUIDE

Alwaysask and check the following:

1. Is the unit connected to a live power source of the proper voltage?

2. Checkthe circuit breaker.

3. Is power switch ON andpilot light glowing?

4. Checkthe rating label. Isthe unit connected tothe correct power source?

5

Page 6

Element

Element

7. WIRING DIAGRAM

Pilot Light

Thermostat

Pilot Light

Thermostat

Element

Pilot Light

L2

Thermostat

L1

6

Page 7

8. PARTS LISTS & EXPLODED VIEWS

ITEM P/N DESCRIPTION

HDD-B PARTS LIST

ITEM P/N DESCRIPTION

1

2

3

4

N/S

N/S

7

8

9

10

11

12

13

14

15

16

17

18

N/A

56505

33976

33952

33993

69120

60113

32490

32491

33359

89145

32438

32437

32439

33962

33980

33960

33997

33981

33961

33998

88852

33932

33933

56530

69145

33938

33944

Rating Label

Thermostat Knob

HDD1B Control Panel

HDD2B Control Panel

HDD3B Control Panel

Thermostat

Insulation

HDD1B Wire Set

HDD2B Wire Set

HDD3B Wire Set

Terminal Block

HDD1B Body Assembly

HDD2B Body Assembly

HDD3B Body Assembly

Top Cover

HDD1B Side Outer Cover Right

HDD2B Side Outer Cover Right

HDD3B Side Outer Cover Right

HDD1B Side Outer Cover Left

HDD2B Side Outer Cover Left

HDD3B Side Outer Cover Left

Bushing, Bronze

Left Drawer Slide

Right Drawer Slide

Indicator Light

Thermometer

Drawer Housing Assembly

Drawer Face Assembly

19

20

21

22

23

24

25

26

27

28

N/S

N/S

N/S

N/S

N/S

N/S

N/S

N/S

N/S

N/S

N/S

89167

33154

33018

33397

33156

54111

54112

54113

33982

33963

33999

33908

33909

33910

88851

89026 Cap Nut

33858

88961

89071

89076

89163

88909

89140

88894

89073

88892

88893

Drawer Vent Knob

Drawer Handle Strip

Drawer Pan

Thermostat & Thermometer Bracket

Element Bracket

120V Heating Element

208V Heating Element

240V Heating Element

HDD1B Front Plate

HDD2B Front Plate

HDD3B Front Plate

HDD3B Front Poly Panel

HDD2B Front Poly Panel

HDD1B Front Poly Panel

Press Stud

Roller, Drawer Slide

Green Ground Nut

#10 Flat Washer

1/4 Internal Star Washer

1/4-20 SS Jam Nut

8-18 X 1/2 Sheet Metal Screw

Cable Tie

1/4-20 X 7/8 Press Stud

8 X 1/2 Screw

1/4-20X1FlatHead SS

1/4-20 Nylon Insert Locknut

13

20

21

18

25

HDD-B EXPLODED VIEW

9

16

23

8

11

2

24

17

22

12

7

27

28

19

14

26

4

3

15

10

7

Page 8

ITEM P/N DESCRIPTION

1

2

3

4

N/S

N/S

7

8

9

10

11

12

13

14

15

16

17

18

19

N/A

56505

33976

33952

33993

69120

60113

33357

33358

33359

33907

32425

32403

32431

33936

33973

33934

33990

33906

88852

32406

32411

56530

69145

70502023

70502030

89167

Rating Label

Thermostat Knob

HDD1B Control Panel

HDD2B Control Panel

HDD3B Control Panel

Thermostat

Insulation

HDD1 Wire Set

HDD2 Wire Set

HDD3 Wire Set

Caster Swival Locking (Opt)

HDD1 Body Assembly

HDD2 Body Assembly

HDD3 Body Assembly

Top Cover

HDD1 Side Outer Cover Panel

HDD2 Side Outer Cover Panel

HDD3 Side Outer Cover Panel

Caster Fixed (Opt)

Bushing, Bronze

Left Drawer Slide

Right Drawer Slide

Indicator Light

Thermometer

Drawer Housing Assembly

Drawer Face Assembly

Drawer Vent Knob

HDD-L or C PARTS LIST

ITEM P/N DESCRIPTION

20

21

22

23

24

N/S

26

27

28

29

30

N/S

N/S

N/S

N/S

N/S

N/S

N/S

N/S

N/S

N/S

N/S

32483

33018

55970

32404

54111

54112

54113

32402

86295

33909

33910

33908

33948

88851

89026

33858

88961

89071

89076

89163

88909

89140

88894

89073

88892

88893

Drawer Handle Strip

Drawer Pan

Cordset 16/3 SJTO

Element Bracket

120V Heating Element

208V Heating Element

240V Heating Element

Element Bracket Large

Legs 4" Black (Std)

HDD1B Front Poly Panel

HDD2B Front Poly Panel

HDD3B Front Poly Panel

Bottom Panel

Press Stud

Cap Nut

Roller, Drawer Slide

Green Ground Nut

#10 Flat Washer

1/4 Internal Star Washer

1/4-20 SS Jam Nut

8-18 X 1/2 Sheet Metal Screw

Cable Tie

1/4-20 X 7/8 Press Stud

8 X 1/2 Screw

1/4-20X1FlatHead SS

1/4-20 Nylon Insert Locknut

21

20

13

18

HDD-L or C EXPLODED VIEW

16

9

8

23

2

24

17

12

29

30

19

14

15

27

28

4

3

22

10

26

7

11

8

Page 9

ITEM P/N

DESCRIPTION

HDDS-B PARTS LIST

ITEM P/N DESCRIPTION

1

2

3

4

N/S

N/S

7

8

9

10

11

12

13

14

15

16

N/A

56505

33351

33387

33331

69120

60113

32490

32491

33359

89145

32477

32474

32480

33301

33302

33309

33316

33304

33311

33318

88852

32443

32448

56530

69145 Thermometer

Rating Label

Thermostat Knob

HDDS1B Control Panel

HDDS2B Control Panel

HDDS3B Control Panel

Thermostat

Insulation

HDDS1B Wire Set

HDDS2B Wire Set

HDDS3B Wire Set

Terminal Block

HDDS1B Body Assembly

HDDS2B Body Assembly

HDDS3B Body Assembly

Top Cover

HDDS1B Side Outer Cover Panel

HDDS2B Side Outer Cover Panel

HDDS3B Side Outer Cover Panel

HDDS1B Front Plate

HDDS2B Front Plate

HDDS3B Front Plate

Bushing, Bronze

Left Drawer Slide

Right Drawer Slide

Indicator Light

17

18

19

20

21

22

N/S

24

25

26

27

N/S

N/S

N/S

N/S

N/S

N/S

N/S

N/S

N/S

N/S

N/S

32456

33366

89167

32483

33018

32404

32402

54114

54115

54116

58168

58169

58170

88851

89026

33858

88961

89071

89076

89163

88909

89140

88894

89073

88892

88893

Drawer Housing Assembly

Drawer Face Assembly

Drawer Vent Knob

Drawer Handle Strip

Drawer Pan

Element Bracket

Element Bracket Large

120V Heating Element

208V Heating Element

240V Heating Element

HDDS1B Front Panel Poly

HDDS2B Front Panel Poly

HDDS3B Front Panel Poly

Press Stud

Cap Nut

Roller, Drawer Slide

Green Ground Nut

#10 Flat Washer

1/4 Internal Star Washer

1/4-20 SS Jam Nut

8-18 X 1/2 Sheet Metal Screw

Cable Tie

1/4-20 X 7/8 Press Stud

8 X 1/2 Screw

1/4-20 X 1 Flat Head SS

1/4-20 Nylon Insert Locknut

13

20

21

HDDS-B EXPLODED VIEW

9

22

8

24

17

12

16

25

4

15

2

3

7

18

19

14

26

27

11

10

9

Page 10

ITEM P/N

DESCRIPTION

HDDS-L or C PARTS LIST

ITEM P/N DESCRIPTION

1

2

3

4

N/S

N/S

7

8

9

10

11

12

13

14

15

16

17

18

19

N/A

56505

33351

33387

33331

69120

60113

33357

33358

33359

33907

32462

32441

32468

33360

33352

33392

33332

33906

88852

32443

32448

56530

69145

32456

33366

89167

Rating Label

Thermostat Knob

HDDS1 Control Panel

HDDS2 Control Panel

HDDS3 Control Panel

Thermostat

Insulation

HDDS1 Wire Set

HDDS2 Wire Set

HDDS3 Wire Set

Caster Swivel Locking (Opt)

HDDS1 Body Assembly

HDDS2 Body Assembly

HDDS3 Body Assembly

Top Cover

HDDS1 Side Outer Cover Panel

HDDS2 Side Outer Cover Panel

HDDS3 Side Outer Cover Panel

Caster Fixed (Opt)

Bushing, Bronze

Left Drawer Slide

Right Drawer Slide

Indicator Light

Thermometer

Drawer Housing Assembly

Drawer Face Assembly

Drawer Vent Knob

20

21

22

23

24

25

26

27

28

29

30

N/S

N/S

N/S

N/S

N/S

N/S

N/S

N/S

N/S

N/S

N/S

32483

33018

89101

32402

54114

54115

54116

86295

55970

85645

32404

58168

58169

58170

88851

89026

33858

88961

89071

89076

89163

88909

89140

88893

88894

89073

88892

Drawer Handle Strip

Drawer Pan

Strain Relief, Bushing .625DD

Element Bracket Large

120V Heating Element

208V Heating Element

240V Heating Element

Legs 4" Black (Std)

Cordset 16/3 SJTO

Cordset 16/3 SJTO

Element Bracket

HDDS1B Front Panel Poly

HDDS2B Front Panel Poly

HDDS3B Front Panel Poly

Press Stud

Cap Nut

Roller, Drawer Slide

Green Ground Nut

#10 Flat Washer

1/4 Internal Star Washer

1/4-20 SS Jam Nut

8-18 X 1/2 Sheet Metal Screw

Cable Tie

1/4-20 Nylon Insert Locknut

1/4-20 X 7/8 Press Stud

8 X 1/2 Screw

1/4-20 X 1 Flat Head SS

13

20

18

21

19

14

30

29

15

9

12

HDDS-L or C EXPLODED VIEW

24

8

27

16

17

3

4

28

2

7

22

23

26

10

11

25

10

Page 11

9. APW WYOTT EQUIPMENT LIMITED WARRANTY

APW Wyott Foodservice Equipment Company warrants it'sequipment against defects in materials and workmanship, subject to the

following conditions:

This warranty applies to the original owner only and is not assignable.

Should any product fail to function in its intended manner under normal use within the limits defined in this warranty, at the option of

APW Wyott such product will be repaired or replaced by APW Wyott or its Authorized Service Agency. APW Wyott will only be

responsible for charges incurred or service performed by its Authorized Service Agencies. The use of other than APW Wyott

Authorized Service Agencies will void this warranty and APW Wyott will not be responsible for such work or any charges associated

with same. The closestAPWWyottAuthorized Service Agent must be used.

This warranty covers products shipped into the 48 contiguous United States, Hawaii, metropolitan areas ofAlaska and Canada. There

will be no labor coverage for equipment located on any island not connected by roadway to the mainland.

Warranty coverage on products used outside the 48 contiguous United States, Hawaii, and metropolitan areas of Alaska and Canada

may vary.ContacttheinternationalAPWWyottdistributor,dealer,or service agency for details.

TimePeriod

One year for parts and one year for labor, effective from the date of purchase by the original owner. The Authorized ServiceAgency

may, at their option, require proof of purchase. Parts replaced under this warranty are warranted for the un-expired portion of the

original product warranty only.

Exceptions

Inall cases, parts covered by extended warranty will be shipped FOB the factory after thefirst year.

Portable Carry In Products

Equipment weighing over 70 pounds or permanently installed will be serviced on-site as per the terms of this warranty. Equipment

weighing 70 pounds or under, and which is not permanently installed, i.e. with cord and plug, is considered portable and is subject to

the following warranty handling limitations. If portable equipment fails to operate in its intended manner on the first day of

connection, or use, at APWWyott'soptionoritsAuthorizedServiceAgency,it will beserviced on site or replaced.

From day two through the conclusion of this warranty period, portable units must be taken to or sent prepaid to the APW Wyott

Authorized Service Agency for in-warranty repairs. No mileage or travel charges are allowed on portable units after the first day of use.

If the customer wants on-site service, they may receive same by paying the travel and mileage charges. Exceptions to this rule: (1)

countertop warmers and cookers, which are covered under the Enhanced WarrantyProgram, and (2) toasters or rollergrills which have

instore service.

Exclusions

The following conditions are not covered by warranty:

If the equipment has been changed, altered, modified or repaired by other than an Authorized Service Agency during or after the

warranty period, then the manufacturer shall not be liable for any damages to any person or to any property, which may result from the

use of the equipment thereafter.

This warranty does not cover services performed at overtime or premium labor rates. Should service be required at times which

normally involve overtime or premium labor rates, the owner shall be charged for the difference between normal service rates and such

premium rates.APWWyottdoesnotassumeanyliability for extended delays in replacing or repairing any items beyond its control.

Inall cases, the use of other than APW WyottAuthorized OEM Replacement Parts will void this warranty.

This equipment is intended for commercial use only.Warrantyisvoidifequipment is installed in other than commercial application.

WaterQualityRequirements

Water supply intended for a unit that has in excess of 3.0 grains of hardness per gallon (GPG) must be treated or softened before

being used. Water containing over 3.0 GPG will decrease the efficiency and reduce the operation life of the unit.

Note: Product failure caused by liming or sediment buildup is not covered under warranty.

THE FOREGOING WARRANTY IS IN LIEU OFANYAND ALL OTHER WARRANTIES EXPRESSED OR IMPLIED

INCLUDING ANY IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR PARTICULAR PURPOSES

AND CONSTITUTES THE ENTIRE LIABILITY OF APW WYOTT. IN NO EVENT DOES THE LIMITED WARRANTY

EXTEND BEYOND THE TERMS STATED HEREIN.

*Gas/Electric Cookline:

component parts, except switches and thermostats. (2 additional years on parts only. No labor on second orthird year.)

*BroilerBriquettes,

*Heat Strips:

*GlassWindows, Doors, Seals, Rubber Seals, Light Bulbs:

*Equipment failure relating to improper installation, improper utility connection or supply and problems due to

ventilation.

*Equipment that has not been properly maintained, calibration of controls, adjustments, damage from improper cleaning

and water damage to controls.

*Equipment that has not been used in an appropriate manner, or has been subject to misuse or misapplication, neglect,

abuse, accident, alteration, negligence, damage during transit, delivery or installation, fire, flood, riot or act of god.

*Equipment that has the model number or serial number removed or altered.

Models FD, FDL, FDD, FDDL. Two(2)YearWarranty onelement only. No labor second year.

Models GCB, GCRB, GF, GGM, GGT, CHP-H, EF, EG, EHP. Three (3) Year Warranty on all

RockGrates,CookingGrates, BurnerShields,Fireboxes:

90Day Material Only. No Labor.

90DayMaterialOnly.NoLabor.

9/05

11

Page 12

Phone: +1

Fax: +1 (214) 565-0976

Toll Free: +1 (800) 527-2100

Website: www.apwwyott.com

E-mail: info@apwwyott.com

(214) 421-7366

APW WYOTT

729 Third Avenue

Dallas, TX 75226

12

Loading...

Loading...