Page 1

!

!

SERIES

MODEL

HOLDING DRAWERS

INTENDED FOR OTHER THAN

RETAIN THIS MANUAL FOR FUTURE REFERENCE

UNIT MUST BE KEPT CLEAR OF COMBUSTIBLES AT ALL TIMES

Do not store or use gasoline or other flammable vapors and liquids

Improper installation, adjustment, alteration, service or maintenance can cause property

damage, injury or death. Read the

installing or servicing this equipment.

Initial heating of unit may generate smoke or fumes and must be done in a well ventilated area. Overexposure to smoke

This equipment has been engineered to provide you with year

instructions in this manual and standard commercial kitchen practices

Installation, Operating and Maintenance Instructions thoroughly before

round dependable service when used according to the

P/N 70503000

APW WYOTT

1307 N Watters Rd STE 180

Allen

!

!

X*PERTTM

INSTALLATION

AND

OPERATING

INSTRUCTIONS

FOR YOUR SAFETY:

of this or any other appliance.

WARNING:

:

HDDi/HDDiS/HDXi

HOUSEHOLD USE

in the vicinity

or fumes may cause nausea or dizziness.

-

Phone: (972) 908-6100

Fax: (214) 565-0976

Toll Free: (800) 527-2100

Website: www.apwwyott.com

E-mail: info@apwwyott.com

1

, TX 75013

Rev A 12/13

Page 2

TABLE OF CONTENTS

SECTION ITEM PAGE

1. Owners Information........................................................................................... 2

General Information................................................................................... 2

General Operation Instructions................................................................. 2

Warranty Information................................................................................. 2

2. Important Safety Information.............................................................................. 3

3. Specifications..................................................................................................... 3

Electrical.................................................................................................... 3

Dimensions................................................................................................ 4

4. Operation........................................................................................................... 5

5. Cleaning............................................................................................................. 6

General Cleaning Instructions................................................................... 6

Daily Cleaning........................................................................................... 6

6. Troubleshooting................................................................................................. 6

7. Wiring Diagrams................................................................................................ 7

8. HDDi/HDXi/HDDiS Counter Exploded View....................................................... 9

HDDi/HDXi Counter Parts List…………………………….......................... 10

HDDiS Counter Parts List…………………………………........................... 12

9. HDDi/HDXi/HDDiS Built-In Exploded View....................................................... 14

HDDi/HDXi Built-In Parts List……………………………............................. 15

HDDiS Built-In Parts List………………..………......................................... 17

10. Warranty………………………………………………............................................ 20

1. OWNER’S INFORMATION

General Information:

1. Always clean equipment thoroughly before first use. (See general cleaning instructions).

2. Check rating label for your model designation and electrical rating.

3. For best results, use stainless steel countertops.

4. All dimensions in parenthesis in centimeters unless noted.

5. Legs are shipped unassembled. Legs must be screwed into base of unit.

General Operation Instructions:

1. All foodservice equipment should be operated by trained personnel.

2. Do not allow your customers to come in contact with any surface labeled “CAUTION HOT”.

3. Where applicable: Never pour cold water into dry heated units.

4. Never hold food below 150°F (66°C).

Warranty Information:

Reliability Backed By APW Wyott’s Warranty:

All APW Wyott Holding Drawers are backed by a one year parts and labor warranty, including On-Site Service calls

within 50 miles of authorized service technicians.

Service Information:

Service Hotline (800) 733-2203

2

Page 3

2. SAFETY INFORMATION

!

!

APW Wyott Holding Drawers are designed, built and sold for commercial use and should be operated by trained

personnel only. Clearly post all CAUTIONS, WARNINGS and OPERATING INSTRUCTIONS near each unit to insure

proper operation and to reduce the chance of personal injury and/or equipment damage.

Always disconnect power before servicing the Holding Drawer. Surfaces will remain hot after power has been turned

off. Allow unit to cool before cleaning or servicing. Never clean the Holding Drawer by immersing it in water. The

Holding Drawer is not protected against water jets; DO NOT CLEAN HOLDING DRAWER WITH A WATER JET.

Always clean equipment before first use.

3. SPECIFICATIONS

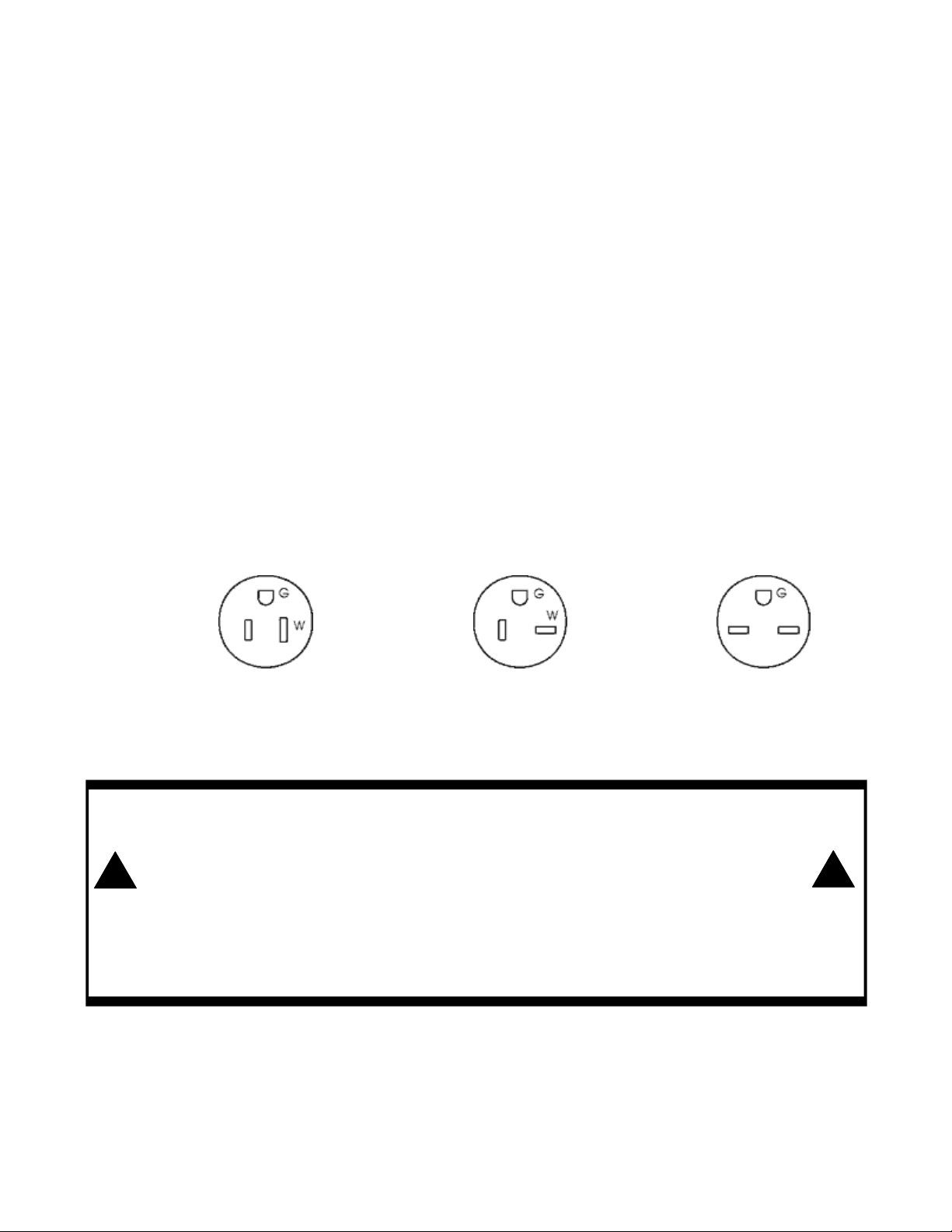

Cordset Configuration:

HDDi/HDDiS/HDXi-1-120 USES NEMA 5-15P HDDi/HDDiS/HDXi -3-120 USES NEMA 5-15P

HDDi/HDDiS/HDXi -1-208 USES NEMA 6-15P HDDi/HDDiS/HDXi -3-208 USES NEMA 6-15P

HDDi/HDDiS/HDXi -1-240 USES NEMA 6-15P HDDi/HDDiS/HDXi -3-240 USES NEMA 6-15P

HDDi/HDDiS/HDXi -2-120 USES NEMA 5-15P HDXi-4-120 USES NEMA 5-20P

HDDi/HDDiS/HDXi -2-208 USES NEMA 6-15P HDXi-4-208 USES NEMA 6-15P

HDDi/HDDiS/HDXi -2-240 USES NEMA 6-15P HDXi-4-240 USES NEMA 6-15P

NEMA 5-15P NEMA 5-20P NEMA 6-15P

If the supply cord is damaged, the manufacturer or an authorized service agent or a similarly qualified person must

replace it to avoid a hazard or voiding the warranty.

WARNING: ELECTRICAL SHOCK HAZARD. FAILURE TO FOLLOW THE INSTRUCTIONS IN THIS

MANUAL COULD RESULT IN SERIOUS INJURY OR DEATH.

•

Electrical Ground is required on this appliance.

•

DO NOT modify the power supply cord plug. If it does not fit into the outlet, have the proper outlet

installed by a qualified electrician.

•

DO NOT use an extension cord with this appliance.

•

Check with a qualified electrician if you are unsure as to whether the appliance is properly grounded.

3

Page 4

120

10-3/4x28

208

10-3/4x28

240

10-3/4x28

120

20x28

208

20x28

240

20x28

120

29-1/2x28

208

29-1/2x28

240

29-1/2x28

120

11-1/4

x20-1/2

208

11-1/4

x20-1/2

240

11-1/4

x20-1/2

120

20-3/4

x20-1/2

208

20-3/4

x20-1/2

240

20-3/4

x20-1/2

120

30

x20-1/2

208

30

x20-1/2

240

30

x20-1/2

120

10-3/4x28

208

10-3/4x28

240

10-3/4x28

120

20x28

208

20x28

240

20x28

120

29-1/2x28

208

29-1/2x28

240

29-1/2x28

120

208

240

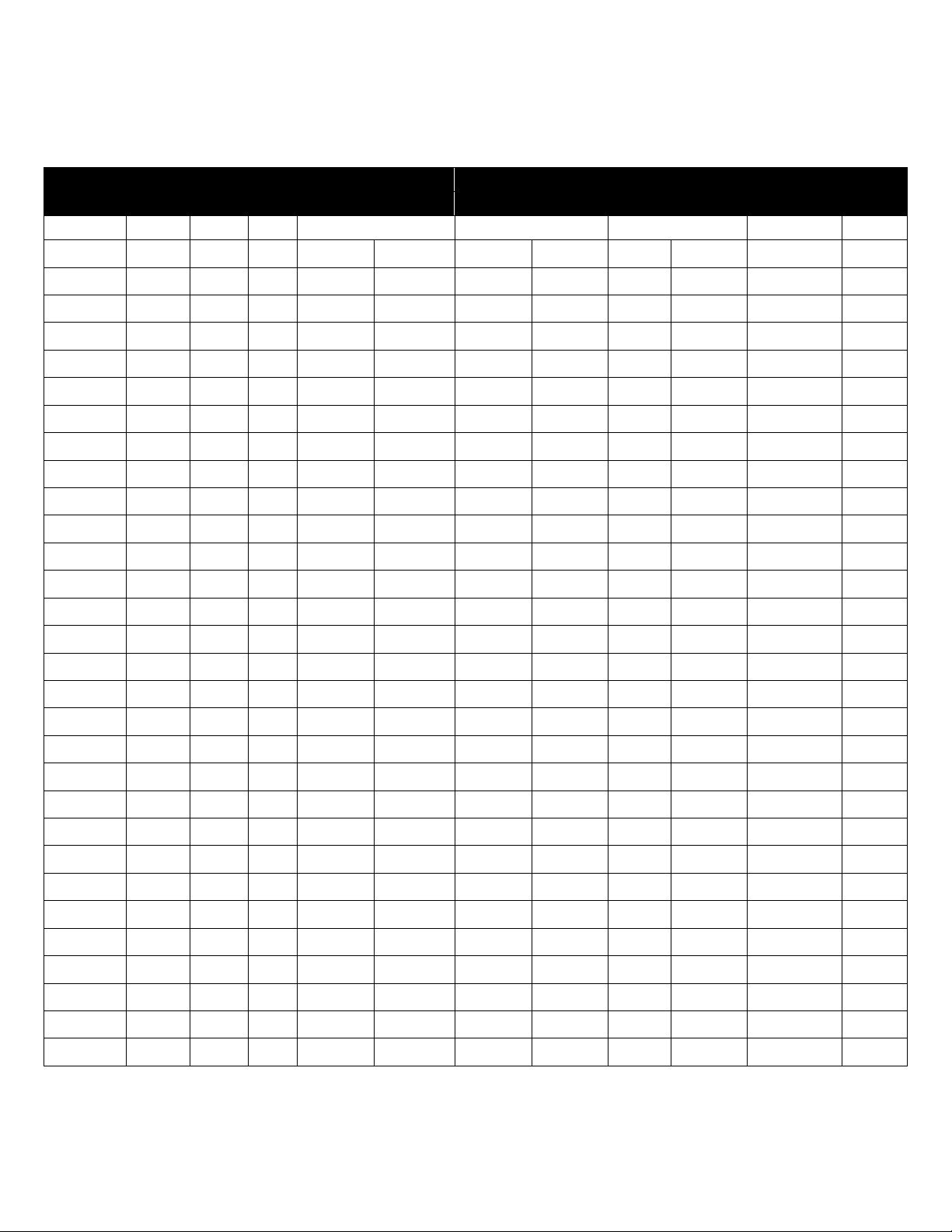

Overall Dimensions & Electrical Specifications

Model Volts, Power Amps Overall Height Overall Width Overall Depth Cutout Shipping

Number Hz Rating Counter Built-in Counter Built-in Counter Built-in Built-in Weight

HDDi-1-120

HDDi-1-208

HDDi-1-240

HDDi-2-120

HDDi-2-208

HDDi-2-240

HDDi-3-120

HDDi-3-208

HDDi-3-240

HDDiS-1-120

HDDiS-1-208

HDDiS-1-240

HDDiS-2-120

HDDiS-2-208

HDDiS-2-240

HDDiS-3-120

HDDiS-3-208

HDDiS-3-240

HDXi-1-120

HDXi-1-208

HDXi-1-240

HDXi-2-120

HDXi-2-208

HDXi-2-240

HDXi-3-120

HDXi-3-208

HDXi-3-240

HDXi-4-120*

HDXi-4-208*

HDXi-4-240*

V (Hz) Watts A in (mm) in (mm) in (mm) in (mm) lbs (kg)

(50/60)

(50/60)

(50/60)

(50/60)

(50/60)

(50/60)

(50/60)

(50/60)

(50/60)

(50/60)

(50/60)

(50/60)

(50/60)

(50/60)

(50/60)

(50/60)

(50/60)

(50/60)

(50/60)

(50/60)

(50/60)

(50/60)

(50/60)

(50/60)

(50/60)

(50/60)

(50/60)

(50/60)

(50/60)

(50/60)

450 3.75 14-7/8 (378) 10-3/8 (263) 27-3/4 (704) 27-3/4 (704) 21 (534) 20-5/8 (524)

450 2.16 14-7/8 (378) 10-3/8 (263) 27-3/4 (704) 27-3/4 (704) 21 (534) 20-5/8 (524)

450 1.88 14-7/8 (378) 10-3/8 (263) 27-3/4 (704) 27-3/4 (704) 21 (534) 20-5/8 (524)

900 7.50 24-1/4 (616) 19-3/4 (501) 27-3/4 (704) 27-3/4 (704) 21 (534) 20-5/8 (524)

900 4.33 24-1/4 (616) 19-3/4 (501) 27-3/4 (704) 27-3/4 (704) 21 (534) 20-5/8 (524)

900 3.75 24-1/4 (616) 19-3/4 (501) 27-3/4 (704) 27-3/4 (704) 21 (534) 20-5/8 (524)

1350 11.25 33-5/8 (852) 29-1/4 (740) 27-3/4 (704) 27-3/4 (704) 21 (534) 20-5/8 (524)

1350 6.49 33-5/8 (852) 29-1/4 (740) 27-3/4 (704) 27-3/4 (704) 21 (534) 20-5/8 (524)

1350 5.63 33-5/8 (852) 29-1/4 (740) 27-3/4 (704) 27-3/4 (704) 21 (534) 20-5/8 (524)

450 3.75 14-7/8 (378) 11-1/16 (281) 20-1/4 (515) 20-1/4 (515) 29 (737) 28-5/8 (727)

450 2.16 14-7/8 (378) 11-1/16 (281) 20-1/4 (515) 20-1/4 (515) 29 (737) 28-5/8 (727)

450 1.88 14-7/8 (378) 11-1/16 (281) 20-1/4 (515) 20-1/4 (515) 29 (737) 28-5/8 (727)

900 7.50 24-1/4 (616) 20-7/16 (519) 20-1/4 (515) 20-1/4 (515) 29 (737) 28-5/8 (727)

900 4.33 24-1/4 (616) 20-7/16 (519) 20-1/4 (515) 20-1/4 (515) 29 (737) 28-5/8 (727)

900 3.75 24-1/4 (616) 20-7/16 (519) 20-1/4 (515) 20-1/4 (515) 29 (737) 28-5/8 (727)

1350 11.25 33-5/8 (852) 29-13/16 (757) 20-1/4 (515) 20-1/4 (515) 29 (737) 28-5/8 (727)

1350 6.49 33-5/8 (852) 29-13/16 (757) 20-1/4 (515) 20-1/4 (515) 29 (737) 28-5/8 (727)

1350 5.63 33-5/8 (852) 29-13/16 (757) 20-1/4 (515) 20-1/4 (515) 29 (737) 28-5/8 (727)

450 3.75 14-7/8 (378) 10-3/8 (263) 27-3/4 (704) 27-3/4 (704) 21 (534) 20-5/8 (524)

450 2.16 14-7/8 (378) 10-3/8 (263) 27-3/4 (704) 27-3/4 (704) 21 (534) 20-5/8 (524)

450 1.88 14-7/8 (378) 10-3/8 (263) 27-3/4 (704) 27-3/4 (704) 21 (534) 20-5/8 (524)

900 7.50 24-1/4 (616) 19-3/4 (501) 27-3/4 (704) 27-3/4 (704) 21 (534) 20-5/8 (524)

900 4.33 24-1/4 (616) 19-3/4 (501) 27-3/4 (704) 27-3/4 (704) 21 (534) 20-5/8 (524)

900 3.75 24-1/4 (616) 19-3/4 (501) 27-3/4 (704) 27-3/4 (704) 21 (534) 20-5/8 (524)

1350 11.25 33-5/8 (852) 29-1/4 (740) 27-3/4 (704) 27-3/4 (704) 21 (534) 20-5/8 (524)

1350 6.49 33-5/8 (852) 29-1/4 (740) 27-3/4 (704) 27-3/4 (704) 21 (534) 20-5/8 (524)

1350 5.63 33-5/8 (852) 29-1/4 (740) 27-3/4 (704) 27-3/4 (704) 21 (534) 20-5/8 (524)

1800 15.00 45 (1092) N/A 27-3/4 (704) N/A 21 (534) N/A N/A 275 (125)

1800 8.65 45 (1092) N/A 27-3/4 (704) N/A 21 (534) N/A N/A 275 (125)

1800 7.50 45 (1092) N/A 27-3/4 (704) N/A 21 (534) N/A N/A 275 (125)

(273x711)

(273x711)

(273x711)

(508x711)

(508x711)

(508x711)

(749x711)

(749x711)

(749x711)

(286x521)

(286x521)

(286x521)

(527x521)

(527x521)

(527x521)

(762x521)

(762x521)

(762x521)

(273x711)

(273x711)

(273x711)

(508x711)

(508x711)

(508x711)

(749x711)

(749x711)

(749x711)

125 (57)

125 (57)

125 (57))

175 (79)

175 (79)

175 (79)

225 (102)

225 (102)

225 (102)

125 (57)

125 (57)

125 (57))

175 (79)

175 (79)

175 (79)

225 (102)

225 (102)

225 (102)

125 (57)

125 (57)

125 (57))

175 (79)

175 (79)

175 (79)

225 (102)

225 (102)

225 (102)

*MODELS COME STANDARD WITH 6” LEGS

4

Page 5

4. OPERATION

TEMPERATURE

1. Set thermostat control to 190°F and preheat each drawer for 30 minutes.

2. Place food product directly in stainless steel drawer pans or use any combination of full or fractional pans up to

6” (152mm) deep.

3. Set front vent to desired position for maintaining food product moisture.

4. Perforated pans may be used with damp towel or small amount of hot water in the drawer pan to prevent food

“dry out”.

CAUTION: Use no more than 1 quart (1 liter) for wet operation.

5. If too much moisture accumulates around drawer front or vent, reduce temperature setting or move vent to “dry”

position.

PRODUCT TEMPERATURE SETTING VENT

PRODUCT

Rolls, Bread 160°-180°F (71°-82° C) Moist

Vegetables 160°-180°F (71°-82° C) Moist

Meats 160°-180°F (71°-82° C) Moist

NOTE: Temperature and vent settings will require adjustment according to type and quantity of food, and number of

times drawer is opened during operation.

SETTING

VENT

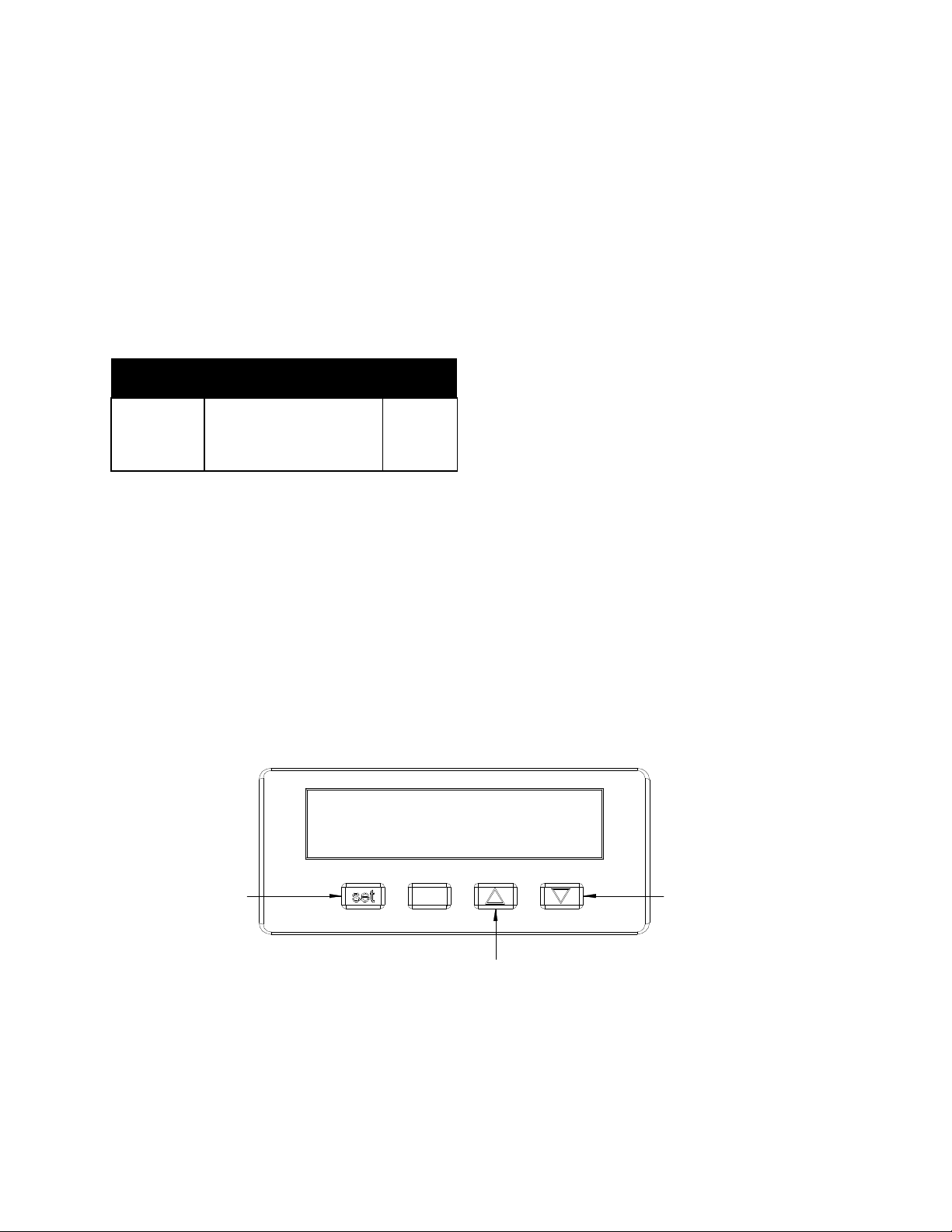

Digital Controller Operation (HDXi models only)

With unit plugged in and the rocker switch in the “ON” position, the digital controller will come on. When the controller

is on, the minimum set point value is preset to 100°F and the maximum set point is 300°F. To obtain the desired set

point, push the set key and release. You have two seconds to adjust the set temperature. Press the up or down

key to your desired setting. After setting desired temperature, release up or down key and press the set key. The

controller display should return to the measured temperature of the unit.

SET ARROW KEY

DOWN ARROW KEY

UP ARROW KEY

5

Page 6

5. CLEANING

General Cleaning Instructions:

1. NEVER clean any electrical unit by immersing it in water. Turn off before surface cleaning.

2. Always clean equipment thoroughly before first use. Clean unit daily. Use warm, soapy water. Mild cleansers

and PLASTIC scouring pads may be used to remove baked-on food and water scale.

3. Turn off electrical units before cleaning or servicing. All service should be performed by an APW authorized

service agency.

Daily Cleaning:

1. Follow General Cleaning instructions (above).

2. Remove any inset pans and drawer pans. Wash thoroughly in the sink or dishwasher.

3. Remove drawer: Remove pans and pan inserts. Extend drawer and lift up on the front to clear the drawer stop.

Lower drawer and lift over front cabinet bearing.

6. TROUBLESHOOTING GUIDE

Always ask and check the following:

1. Is the unit connected to a live power source of the proper voltage?

2. Check the circuit breaker.

3. Is power switch “ON” (HDXi models only)

4. Is the thermostat set to a temperature?

5. Is the Pilot light glowing?

6. Check the rating label. Is the unit connected to the correct power source?

6

Page 7

7. WIRING DIAGRAMS

HDDi/HDDiS WIRING DIAGRAMS

NOTE: Wire #’s 5 & 6 are not used in HDDi/HDDiS-1. Wire #’s 9 &10 are only used in HDDi/HDDiS-3

7

Page 8

8

Page 9

2

1

25

24

23

12

13

10

11

11

10

28

27

26

21

6

20

18

19

31

30

9

32

8

7

4

5

22

29

17

14

16

15

3

9

Page 10

PARTS LIST(QTY’S)

1

2

2

1

2

2

1

2

2

1

2

2

1

2

2

1

2

2

ITEM PN DESCRIPTION

1 70504805 HEATING ELEMENT, 120V 1 2 3 1 2 3

70504806 HEATING ELEMENT, 208V 1 2 3 1 2 3

70504807 HEATING ELEMENT, 240V 1 2 3 1 2 3

2 33936 TOP COVER 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1

3 33973 OUTER SIDE PANEL 2 2 2 2 2 2

33934 OUTER SIDE PANEL 2 2 2 2 2 2

33990 OUTER SIDE PANEL 2 2 2 2 2 2

4 33976 CONTROL PANEL 1 1 1

33952 CONTROL PANEL 1 1 1

33993 CONTROL PANEL 1 1 1

70502096 CONTROL PANEL 1 1 1

70502097 CONTROL PANEL 1 1 1

70502098 CONTROL PANEL 1 1 1

5 58269 CONTROL DECAL 1 1 1

58270 CONTROL DECAL 1 1 1

58271 CONTROL DECAL 1 1 1

58273 CONTROL DECAL 1 1 1

58274 CONTROL DECAL 1 1 1

58275 CONTROL DECAL 1 1 1

6 69145 THERMOMETER 1 1 1 2 2 2 3 3 3

70101034

70101035

70101026

7 69121 THERMOSTAT 1 1 1 2 2 2 3 3 3

8 56508 KNOB 1 1 1 2 2 2 3 3 3

9 1509600 PILOT LIGHT 1 1 1 2 2 2 3 3 3

10 33858 DRAWER SLIDE ROLLER 6 6 6 12 12 12 18 18 18 6 6 6 12 12 12 18

11 89013 MACHINE SCREW 6 6 6 12 12 12 18 18 18 6 6 6 12 12 12 18

12 8353200 RIVNUT 8 8 8 16 16 16 24 24 24 8 8 8 16 16 16 24

13 8945500 LOOP CLAMP S/S 1 1 1 2 2 2 3 3 3 1 1 1 2 2 2 3 3 3

14 30203 TERMINAL BLOCK 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1

15 60113 INSULATION 21X19X1 4 4 4 6 6 6 9 9 9 4 4 4 6 6 6 9 9 9

16 70502086 LEG SUPPORT BASE 4 4 4 6 6 6 9 9 9 4 4 4 6 6 6 9 9 9

DIGITAL CONTROLLER

120V 1 2 3

DIGITAL CONTROLLER

240V 1 1 2 2 3 3

TEMPERATURE PROBE

(120V/240V) 1 1 1 2 2 2 3 3 3

HDDi-1 HDDi-2 HDDi-3 HDXi-1 HDXi-2 HDXi-3

2

0

4

2

0

4

2

0

4

2

0

4

2

0

4

2

0

8

0

0

8

0

0

8

0

0

8

0

0

8

0

0

0

8

18 1

18 1

24 2

4

0

8

8

4

10

Page 11

PARTS LIST(QTY’S)

1

2

2

1

2

2

1

2

2

1

2

2

1

2

2

1

2

2

ITEM PN DESCRIPTION

17 87327

0-999-000

0-999-002

18 1532500 CORDSET 1 1 1 1 1 1

85645 CORDSET 1 1 1 1 1 1 1 1 1 1 1 1

19 89101 STRAIN RELEIF 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1

20 70502092 OUTER BACK PANEL 1 1 1 1 1 1

70502082 OUTER BACK PANEL 1 1 1 1 1 1

70502094 OUTER BACK PANEL 1 1 1 1 1 1

21 33930 TOP BRACE ASSY 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1

22 33975 RIGHT SIDE BRACE 1 1 1 1 1 1

33951 RIGHT SIDE BRACE 1 1 1 1 1 1

33992 RIGHT SIDE BRACE 1 1 1 1 1 1

23 70502072

24 70502073

25 70502077 STANDARD PAN 12X20 1 1 1 2 2 2 3 3 3 1 1 1 2 2 2 3 3 3

26 88987 SCREW, 1/4-20X3/4" 2 2 2 4 4 4 6 6 6 2 2 2 4 4 4 6 6 6

27 70502042 FLAT ROLLER BEARING 2 2 2 4 4 4 6 6 6 2 2 2 4 4 4 6 6 6

28 70502070

29 55611

30 8164100 SCREW, 10-24X1" 2 2 2 4 4 4 6 6 6 2 2 2 4 4 4 6 6 6

31 89070

32 70502060

N/A 70502045 WIRE SET 1 1 1 1 1 1

N/A 70502047 WIRE SET 1 1 1 1 1 1

N/A 70502049 WIRE SET 1 1 1 1 1 1

N/A 70503000 MANUAL 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1

LEG, STAINLESS 6"

(OPTIONAL) 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4

CASTER, 3"

(OPTIONALKIT OF 4) 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1

CASTER, 5"

(OPTIONAL KIT OF 4) 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1

RIGHT SIDE DRAWER

SLIDE 1 1 1 2 2 2 3 3 3 1 1 1 2 2 2 3 3 3

LEFT SIDE DRAWER

SLIDE 1 1 1 2 2 2 3 3 3 1 1 1 2 2 2 3 3 3

CENTER PAN SUPPORT

ASSY 1 1 1 2 2 2 3 3 3 1 1 1 2 2 2 3 3 3

HANDLE (ALSO NEED

30&31) 1 1 1 2 2 2 3 3 3 1 1 1 2 2 2 3 3 3

WASHER, #10 INTERNAL

TEETH 2 2 2 4 4 4 6 6 6 2 2 2 4 4 4 6 6 6

DRAWER ASSY

(INCLUDES 25-31) 1 1 1 2 2 2 3 3 3 1 1 1 2 2 2 3 3 3

HDDi-1 HDDi-2 HDDi-3 HDXi-1 HDXi-2 HDXi-3

2

0

4

2

0

4

2

0

4

2

0

4

2

0

4

2

0

8

0

0

8

0

0

8

0

0

8

0

0

8

0

0

0

8

4

0

11

Page 12

PARTS LIST(QTY’S)

ITEM PN DESCRIPTION

1 54114 HEATING ELEMENT, 120V 1 2 3 1 2 3

54115 HEATING ELEMENT, 208V 1 2 3 1 2 3

54116 HEATING ELEMENT, 240V 1 2 3 1 2 3

2 70501039 TOP COVER 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1

3 70501043 OUTER SIDE PANEL 2 2 2 2 2 2

70501017 OUTER SIDE PANEL 2 2 2 2 2 2

70501049 OUTER SIDE PANEL 2 2 2 2 2 2

4 33976 CONTROL PANEL 1 1 1

33952 CONTROL PANEL 1 1 1

33993 CONTROL PANEL 1 1 1

70502096 CONTROL PANEL 1 1 1

70502097 CONTROL PANEL 1 1 1

70502098 CONTROL PANEL 1 1 1

5 58269 CONTROL DECAL 1 1 1

58270 CONTROL DECAL 1 1 1

58271 CONTROL DECAL 1 1 1

58273 CONTROL DECAL 1 1 1

58274 CONTROL DECAL 1 1 1

58275 CONTROL DECAL 1 1 1

6 69145 THERMOMETER 1 1 1 2 2 2 3 3 3

70101034

70101035

70101026

7 69121 THERMOSTAT 1 1 1 2 2 2 3 3 3

8 56508 KNOB 1 1 1 2 2 2 3 3 3

9 1509600 PILOT LIGHT 1 1 1 2 2 2 3 3 3

10 33858 DRAWER SLIDE ROLLER 6 6 6 12 12 12 18 18 18 6 6 6 12 12 12 18 18 18

11 89013 MACHINE SCREW 6 6 6 12 12 12 18 18 18 6 6 6 12 12 12 18 18 18

12 8353200 RIVNUT 8 8 8 16 16 16 24 24 24 8 8 8 16 16 16 24 24 24

13 8945500 LOOP CLAMP S/S 1 1 1 2 2 2 3 3 3 1 1 1 2 2 2 3 3 3

14 30203 TERMINAL BLOCK 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1

15 60113 INSULATION 21X19X1 4 4 4 6 6 6 9 9 9 4 4 4 6 6 6 9 9 9

16 70501034 LEG SUPPORT BASE 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1

DIGITAL CONTROLLER

120V 1 2 3

DIGITAL CONTROLLER

240V 1 1 2 2 3 3

TEMPERATURE PROBE

(120V/240V) 1 1 1 2 2 2 3 3 3

HDDiS-1 HDDiS-2 HDDiS-3 HDXiS-1 HDXiS-2 HDXiS-3

1

2

2

1

2

2

1

2

2

1

2

2

1

2

2

1

2

0

4

2

0

4

2

0

4

2

0

4

2

0

0

8

0

0

8

0

0

8

0

0

8

0

0

4

8

0

2

2

0

0

8

2

4

0

12

Page 13

PARTS LIST(QYT’S)

ITEM PN DESCRIPTION

HDDiS-1 HDDiS-2 HDDiS-3 HDXiS-1 HDXiS-2 HDXiS-3

1

2

2

1

2

2

1

2

2

1

2

2

1

2

2

1

2

0

4

2

0

4

2

0

4

2

0

4

2

0

0

8

0

0

8

0

0

8

0

0

8

0

0

4

8

0

2

2

0

0

8

2

4

0

17 86295 LEG, BLACK 4” 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4

87327

0-999-000

0-999-002

18 1532500 CORDSET 1 1 1 1 1 1

85645 CORDSET 1 1 1 1 1 1 1 1 1 1 1 1

19 89101 STRAIN RELEIF 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1

20 70501047 OUTER BACK PANEL 1 1 1 1 1 1

70501027 OUTER BACK PANEL 1 1 1 1 1 1

70501055 OUTER BACK PANEL 1 1 1 1 1 1

21 70501057 TOP BRACE ASSY 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1

22 33975 RIGHT SIDE BRACE 1 1 1 1 1 1

33951 RIGHT SIDE BRACE 1 1 1 1 1 1

33992 RIGHT SIDE BRACE 1 1 1 1 1 1

23 70502072

24 70502073

25 70502077 STANDARD PAN 12X20 1 1 1 2 2 2 3 3 3 1 1 1 2 2 2 3 3 3

26 88987 SCREW, 1/4-20X3/4" 2 2 2 4 4 4 6 6 6 2 2 2 4 4 4 6 6 6

27 70502042 FLAT ROLLER BEARING 2 2 2 4 4 4 6 6 6 2 2 2 4 4 4 6 6 6

28 70501076

29 55613

30 8164100 SCREW, 10-24X1" 2 2 2 4 4 4 6 6 6 2 2 2 4 4 4 6 6 6

31 89070

32 70503200

N/A 70502045 WIRE SET 1 1 1 1 1 1

N/A 70502047 WIRE SET 1 1 1 1 1 1

N/A 70502049 WIRE SET 1 1 1 1 1 1

N/A 70503000 MANUAL 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1

LEG, STAINLESS 6"

(OPTIONAL) 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4

CASTER, 3" (OPTIONAL

KIT OF 4) 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1

CASTER, 5" (OPTIONAL

KIT OF 4) 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1

RIGHT SIDE DRAWER

SLIDE 1 1 1 2 2 2 3 3 3 1 1 1 2 2 2 3 3 3

LEFT SIDE DRAWER

SLIDE 1 1 1 2 2 2 3 3 3 1 1 1 2 2 2 3 3 3

CENTER PAN SUPPORT

ASSY 1 1 1 2 2 2 3 3 3 1 1 1 2 2 2 3 3 3

HANDLE (ALSO NEED

30&31) 1 1 1 2 2 2 3 3 3 1 1 1 2 2 2 3 3 3

WASHER, #10 INTERNAL

TEETH 2 2 2 4 4 4 6 6 6 2 2 2 4 4 4 6 6 6

DRAWER ASSY

(INCLUDES 25-31) 1 1 1 2 2 2 3 3 3 1 1 1 2 2 2 3 3 3

13

Page 14

2

1

12

21

23 24

13

25

31

30

11

10

28

10

11

26

27

1

29

16

19

6

7

9

8

22

4

5

14

15

20

3

14

Page 15

1

2

2

1

2

2

1

2

2

1

2

2

1

2

2

1

2

2

PARTS LIST(QTY’S)

ITEM PN DESCRIPTION

1 70504805 HEATING ELEMENT, 120V 1 2 3 1 2 3

70504806 HEATING ELEMENT, 208V 1 2 3 1 2 3

70504807 HEATING ELEMENT, 240V 1 2 3 1 2 3

2 70501039 TOP COVER 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1

3 70501043 OUTER SIDE PANEL 2 2 2 2 2 2

70501017 OUTER SIDE PANEL 2 2 2 2 2 2

70501049 OUTER SIDE PANEL 2 2 2 2 2 2

4 33976 CONTROL PANEL 1 1 1

33952 CONTROL PANEL 1 1 1

33993 CONTROL PANEL 1 1 1

70502096 CONTROL PANEL 1 1 1

70502097 CONTROL PANEL 1 1 1

70502098 CONTROL PANEL 1 1 1

5 58269 CONTROL DECAL 1 1 1

58270 CONTROL DECAL 1 1 1

58271 CONTROL DECAL 1 1 1

58273 CONTROL DECAL 1 1 1

58274 CONTROL DECAL 1 1 1

58275 CONTROL DECAL 1 1 1

6 69145 THERMOMETER 1 1 1 2 2 2 3 3 3

70101034 DIGITAL CONTROLLER 120V 1 2 3

70101035 DIGITAL CONTROLLER 240V 1 1 2 2 3 3

70101026

7 69121 THERMOSTAT 1 1 1 2 2 2 3 3 3

8 56508 KNOB 1 1 1 2 2 2 3 3 3

9 1509600 PILOT LIGHT 1 1 1 2 2 2 3 3 3

10 33858 DRAWER SLIDE ROLLER 6 6 6 12 12 12 18 18 18 6 6 6 12 12 12 18 18 18

11 89013 MACHINE SCREW 6 6 6 12 12 12 18 18 18 6 6 6 12 12 12 18 18 18

12 8353200 RIVNUT 8 8 8 16 16 16 24 24 24 8 8 8 16 16 16 24 24 24

13 8945500 LOOP CLAMP S/S 1 1 1 2 2 2 3 3 3 1 1 1 2 2 2 3 3 3

14 30203 TERMINAL BLOCK 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1

15 60113 INSULATION 21X19X1 4 4 4 6 6 6 9 9 9 4 4 4 6 6 6 9 9 9

16 33982 FRONT PLATE 1 1 1

TEMPERATURE PROBE

(120V/240V) 1 1 1 2 2 2 3 3 3

33963 FRONT PLATE

33999 FRONT PLATE

HDDi-1

BUILT-IN

2

0

0

8

4

0

HDDi-2

BUILT-IN

2

0

0

8

1 1 1

4

0

HDDi-3

BUILT-IN

2

0

0

8

1 1 1

4

0

HDXi-1

BUILT-IN

2

0

0

8

1 1 1

4

0

HDXi-2

BUILT-IN

2

0

0

8

1 1 1

4

0

HDXi-3

BUILT-IN

2

0

0

8

1 1 1

4

0

15

Page 16

PARTS LIST(QTY’S)

HDDi

-

1

HDDi

-

2

HDDi

-

3

HDXi

-

1

HDXi

-

2

HDXi

-

3

1

2

2

1

2

2

1

2

2

1

2

2

1

2

2

1

2

2

ITEM PN DESCRIPTION

19 84559 HOLE PLUG 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1

20 70501047 OUTER BACK PANEL 1 1 1 1 1 1

70501027 OUTER BACK PANEL 1 1 1 1 1 1

70501055 OUTER BACK PANEL 1 1 1 1 1 1

21 70501057 TOP BRACE ASSY 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1

22 33975 RIGHT SIDE BRACE 1 1 1 1 1 1

33951 RIGHT SIDE BRACE 1 1 1 1 1 1

33992 RIGHT SIDE BRACE 1 1 1 1 1 1

23 70501018 RIGHT SIDE DRAWER SLIDE 1 1 1 2 2 2 3 3 3 1 1 1 2 2 2 3 3 3

24 70501019 LEFT SIDE DRAWER SLIDE 1 1 1 2 2 2 3 3 3 1 1 1 2 2 2 3 3 3

25 70502077 STANDARD PAN 12X20 1 1 1 2 2 2 3 3 3 1 1 1 2 2 2 3 3 3

26 88987 SCREW, 1/4-20X3/4" 2 2 2 4 4 4 6 6 6 2 2 2 4 4 4 6 6 6

27 70502042 FLAT ROLLER BEARING 2 2 2 4 4 4 6 6 6 2 2 2 4 4 4 6 6 6

28 70501076 CENTER PAN SUPPORT ASSY 1 1 1 2 2 2 3 3 3 1 1 1 2 2 2 3 3 3

29 55613 HANDLE (ALSO NEED 30&31) 1 1 1 2 2 2 3 3 3 1 1 1 2 2 2 3 3 3

30 8164100 SCREW, 10-24X1" 2 2 2 4 4 4 6 6 6 2 2 2 4 4 4 6 6 6

31 89070

32 70503200

N/A 70502045 WIRE SET 1 1 1 1 1 1

N/A 70502047 WIRE SET 1 1 1 1 1 1

N/A 70502049 WIRE SET 1 1 1 1 1 1

N/A 70503000 MANUAL 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1

WASHER, #10 INTERNAL

TEETH 2 2 2 4 4 4 6 6 6 2 2 2 4 4 4 6 6 6

DRAWER ASSY (INCLUDES 25-

31) 1 1 1 2 2 2 3 3 3 1 1 1 2 2 2 3 3 3

BUILT-IN

2

0

0

8

4

0

BUILT-IN

2

0

BUILT-IN

0

4

2

8

0

0

BUILT-IN

0

4

8

2

0

0

0

4

2

8

0

0

BUILT-IN

0

8

4

0

BUILT-IN

2

0

0

8

4

0

16

Page 17

PARTS LIST(QTY’S)

HDDiS

-

1

HDDiS

-

2

HDDiS

-

3

HDXiS

-

1

HDXiS

-

2

HDXiS

-

3

1

2

2

1

2

1

2

2

ITEM PN DESCRIPTION

1 54114 HEATING ELEMENT, 120V 1 2 3 1 2 3

54115 HEATING ELEMENT, 208V 1 2 3 1 2 3

54116 HEATING ELEMENT, 240V 1 2 3 1 2 3

2 70501079 TOP COVER 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1

3

4 33976 CONTROL PANEL 1 1 1

5 58269 CONTROL DECAL 1 1 1

6 69145 THERMOMETER 1 1 1 2 2 2 3 3 3

7 69121 THERMOSTAT 1 1 1 2 2 2 3 3 3

8 56508 KNOB 1 1 1 2 2 2 3 3 3

9 1509600 PILOT LIGHT 1 1 1 2 2 2 3 3 3

10 33858 DRAWER SLIDE ROLLER 6 6 6 12 12 12 18 18 18 6 6 6 12 12 12 18 18 18

11 89013 MACHINE SCREW 6 6 6 12 12 12 18 18 18 6 6 6 12 12 12 18 18 18

12 8353200 RIVNUT 8 8 8 16 16 16 24 24 24 8 8 8 16 16 16 24 24 24

13 8945500 LOOP CLAMP S/S 1 1 1 2 2 2 3 3 3 1 1 1 2 2 2 3 3 3

14 30203 TERMINAL BLOCK 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1

15 60113 INSULATION 21X19X1 4 4 4 6 6 6 9 9 9 4 4 4 6 6 6 9 9 9

16 70501078 FRONT PLATE 1 1 1

70501081

70501082

70501091

70501092

70501086

70501087

33952 CONTROL PANEL 1 1 1

33993 CONTROL PANEL 1 1 1

70502096 CONTROL PANEL 1 1 1

70502097 CONTROL PANEL 1 1 1

70502098 CONTROL PANEL 1 1 1

58270 CONTROL DECAL 1 1 1

58271 CONTROL DECAL 1 1 1

58273 CONTROL DECAL 1 1 1

58274 CONTROL DECAL 1 1 1

58275 CONTROL DECAL 1 1 1

70101034 DIGITAL CONTROLLER 120V 1 2 3

70101035 DIGITAL CONTROLLER 240V 1 1 2 2 3 3

70101026

70501088 FRONT PLATE

70501084 FRONT PLATE

OUTER RIGHT SIDE PANEL

OUTER LEFT SIDE PANEL

OUTER RIGHT SIDE PANEL

OUTER LEFT SIDE PANEL

OUTER RIGHT SIDE PANEL

OUTER LEFT SIDE PANEL

TEMPERATURE PROBE

(120V/240V) 1 1 1 2 2 2 3 3 3

BUILT-IN

2

0

0

8

2 2 2 2 2 2

2 2 2 2 2 2

2 2 2 2 2 2

4

0

BUILT-IN

2

0

1 1 1

08 24

BUILT-IN

20 208 240 120 208 240 120 208 240 12

0

1 1 1

1 1 1

BUILT-IN

BUILT-IN

1 1 1

BUILT-IN

0

0

8

1 1 1

4

0

17

Page 18

PARTS LIST(QYT’S)

HDDiS

-

1

HDDiS

-

2

HDDiS

-

3

HDXiS

-

1

HDXiS

-

2

HDXiS

-

3

1

2

2

1

2

1

2

2

ITEM PN DESCRIPTION

19 84559 HOLE PLUG

20 70501080 OUTER BACK PANEL

70501090 OUTER BACK PANEL

70501085 OUTER BACK PANEL

21 70501057 TOP BRACE ASSY

22 33975 RIGHT SIDE BRACE

33951 RIGHT SIDE BRACE

33992 RIGHT SIDE BRACE

23 70502072 RIGHT SIDE DRAWER SLIDE

24 70502073 LEFT SIDE DRAWER SLIDE

25 70502077 STANDARD PAN 12X20

26 88987 SCREW, 1/4-20X3/4"

27 70502042 FLAT ROLLER BEARING

28 70501076 CENTER PAN SUPPORT ASSY

29 55613 HANDLE (ALSO NEED 30&31)

30 8164100 SCREW, 10-24X1"

31 89070

32 70503200

N/A 70502045 WIRE SET

N/A 70502047 WIRE SET

N/A 70502049 WIRE SET

N/A 70503000 MANUAL

WASHER, #10 INTERNAL

TEETH

DRAWER ASSY (INCLUDES 25-

31)

BUILT-IN

2

0

0

8

1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1

1 1 1 1 1 1

1 1 1 1 1 1

1 1 1 1 1 1

1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1

1 1 1 1 1 1

1 1 1 1 1 1

1 1 1 1 1 1

1 1 1 2 2 2 3 3 3 1 1 1 2 2 2 3 3 3

1 1 1 2 2 2 3 3 3 1 1 1 2 2 2 3 3 3

1 1 1 2 2 2 3 3 3 1 1 1 2 2 2 3 3 3

2 2 2 4 4 4 6 6 6 2 2 2 4 4 4 6 6 6

2 2 2 4 4 4 6 6 6 2 2 2 4 4 4 6 6 6

1 1 1 2 2 2 3 3 3 1 1 1 2 2 2 3 3 3

1 1 1 2 2 2 3 3 3 1 1 1 2 2 2 3 3 3

2 2 2 4 4 4 6 6 6 2 2 2 4 4 4 6 6 6

2 2 2 4 4 4 6 6 6 2 2 2 4 4 4 6 6 6

1 1 1 2 2 2 3 3 3 1 1 1 2 2 2 3 3 3

1 1 1 1 1 1

1 1 1 1 1 1

1 1 1 1 1 1

1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1

4

0

BUILT-IN

2

08 24

0

BUILT-IN

20 208 240 120 208 240 120 208 240 12

0

BUILT-IN

BUILT-IN

BUILT-IN

0

0

8

4

0

18

Page 19

IMPORTANT FOR FUTURE REFERENCE

Please complete this information and retain this manual for the life of the equipment. For

Warranty Service and/or Parts, this information is required.

______________ ______________ _______________

Model Number Serial Number Date Purchased

Notes:_____________________________________________________________

__________________________________________________________________

__________________________________________________________________

__________________________________________________________________

__________________________________________________________________

__________________________________________________________________

__________________________________________________________________

__________________________________________________________________

__________________________________________________________________

__________________________________________________________________

__________________________________________________________________

__________________________________________________________________

__________________________________________________________________

__________________________________________________________________

__________________________________________________________________

__________________________________________________________________

__________________________________________________________________

__________________________________________________________________

__________________________________________________________________

__________________________________________________________________

__________________________________________________________________

__________________________________________________________________

__________________________________________________________________

19

Page 20

20

Loading...

Loading...