Page 1

501923

INSTRUCTION SHEET

INSTRUCTIONS FOR SEALING APPLETON “ES” SERIES SEALING HUBS FOR USE WITH

APPLETON KWIKO

®

, KWIKO A™ AND CROUSE-HINDS CHICO A

• The National Electric Code in Article 501, Section 501-5, Class I, DIV. 1 and 2, requires that seals be installed in specific

locations.

• This is to prevent the passage of gasses, vapors or flames through the conduit from one portion of the electrical installations

to another portion.

• Appleton Sealing Hubs are U/L Listed for use in hazardous locations with “Kwiko, Kwiko A compound or Crouse-Hinds Chico

compound only. These compounds when used properly mixed and poured, hardens into a dense and strong mass which is

insoluble with water. It is not attacked by petroleum products and is not soften by heat.

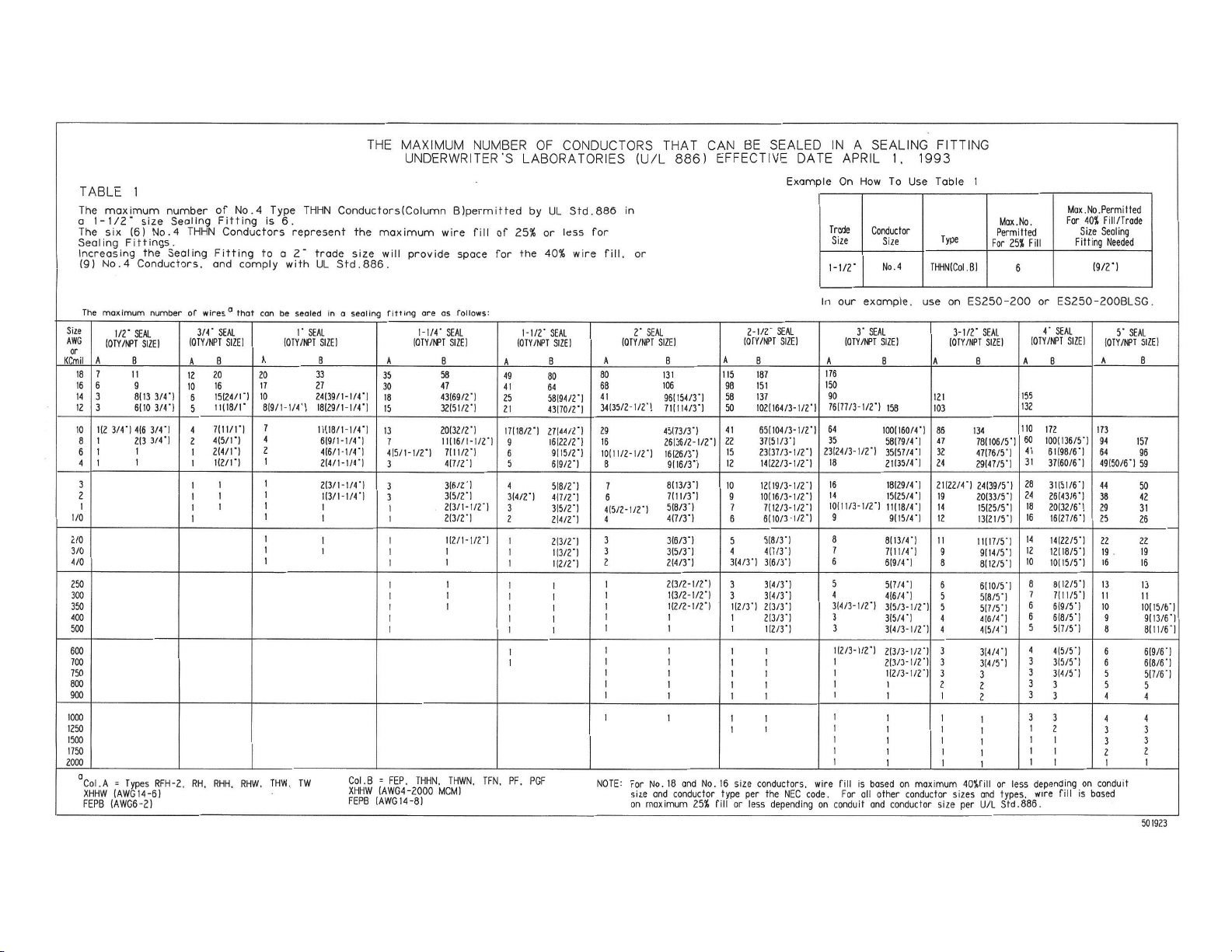

• Appleton ES Sealing Hubs are used to seal vertical conduit risers in Class I, Division 1 and 2 hazardous (classified) locations

as defined by the National Electrical Code (NEC). These sealing hubs may be installed vertically in a NPT threaded hub as

shown in Figure 1 or with a STG steel ring and gasket assembly through slip hole in metal enclosure wall as shown in Figure 2.

WARNING: Electrical power must be turned Off before and during installation and maintenance.

• Failure to follow safety instructions may cause ignition of hazardous atmospheres resulting in serious personal

injury and / or property damage.

1. Install sealing hub securely in enclosure

opening and pull conductors through.

2. DAMMING: Separate each conductor

and pack fiber filler into hub behind

conductors and around each conductor.

• These conductors must not touch each

other nor touch the sealing fitting wall.

• Clean fiber shreds away from walls or

conductors to prevent them from causing

flame and / or leakage of gasses. Finished

Mineral Fiber

Filler “Asbestos

-Free”

dam must be as shown in Fig. 1 & 2.

3. MIxing: Prepare sealing compound

using a completely clean mixing vessel

in each batch. Shake the sealing cement

thoroughly in all directions. Mix sealing

cement with correct proportion of clean

water as noted below.

“Asbestos-

APPLETON Kwiko CEMENT. Add 3

fluid ounces of water to 1 lb. of cement

equivalent to 1 part water to 3 parts

cement by volume for a minimum of

5 minutes or until an even pouring

consistency is obtained.

Free”

Sealing Cement

Be sure to read the

mixing instructions

on the Sealing

cement can.

Appleton Kwiko A and CROUSE-HINDS Chico A

CEMENT. Add one (1) part water to two (2) parts cement

by volume. Use cold water, warm water increases setting

CAUTION: Temperature / Cure Time

Appleton Kwiko Cement must not be mixed and poured at

temperature below 35°F (1.7°C). Cement compound curing time varies

with temperatures. Examples are: 35°F (1.7°C) - 24 hrs., At 68°F

(20°C) - 4 hrs.

CAUTION: For Group B installations, compound must be allowed 72

hours to cure at full strength before energizing system.

APPLETON Kwiko A and CROUSE HINDS Chico A CEMENT

FOR APPLICATIONS INVOLVING GROUP C AND D

CAUTION: Sealing compound to be mixed ONLY at temperatures

above 35°F (1.7°C) and ONLY poured into fittings that have been

brought to a temperature above 35°F (1.7°C). Seals must NOT be

exposed to temperatures below 35oF (1.7°C) for at least 8 hours.

CAUTION: Sealing compound to be mixed ONLY at temperatures

above 40°F (4.4°C) and ONLY poured into fittings that

brought to a temperature above 40°F (4.4°C).

exposed to tempertures below 400F (4.40C) for at least 72 hours.

CAUTION: Refer to Table 1 to determine the maximum number and

size of conductors allowed in a seal.

FOR ALL APPLICATIONS

4. Pour sealing cement into hub until flush with top as shown

in Figures 1 and 2, below.

5. For guidance in mixing sealing compound see Table below.

These cements are NOT INSULATING COMPOUNDS and

•

MUST NOT be used for such purposes.

speed. Add water and stir immediately and thoroughly.

• DO NOT mix more than can be poured in 15 minutes

after adding w

HUB CATALOG NUMBERS

WITH OUT

SEALING GASKET

ES100-50

ES100-75

ES150-100

ES200-125

ES200-150

ES250-200

ES400-300

ES500-400

ES600-500

ater.

WITH

SEALING GASKET

ES100-50BLSG

ES100-75BLSG

ES150-100BLSG

ES200-125BLSG

ES200-150BLSG

ES250-200BLSG

ES400-300BLSG

ES500-400BLSG

ES600-500BLSG

VOLUME OF

SEAL CAVITY

33.70 cu inches

91.23 cu inches

143.73 cu inches

INTERNAL

.74 cu inches

.76 cu inches

3.10 cu inches

4.69 cu inches

4.69 cu inches

9.38 cu inches

KEEP CONDUCTORS

IN CENTER OF

ENCLOSURE

HUB

‘ES’ SEALING

Class I and II, Div. 1 and 2

‘ES’ HUB

HUB

FIGURE 1

SEALING

COMPOUND

FLUSH WITH TOP

5 THREADS

MINIMUM

ENGAGED

FIBER

FILLER

®

SEALING CEMENT

Seals must NOT be

FIGURE 2

KEEP

CONDUCTORS

IN CENTER OF

‘ES’ HUB

CONDUIT

LOCKNUT

FLAT WALL

ENCLOSURE

‘ES’ SEALING

HUB

FLUSH WITH TOP

Class I and II, Div. 2 Only

have been

SEALING

COMPOUND

STEEL RING

AND GASKET

ASSEMBLY

FIBER

FILLER

Rev. D • 7/17/96

Page 2

Loading...

Loading...