Page 1

EDS Factory Sealed Tumbler Switches

CONTROLS: NEC/CEC EXPLOSIONPROOF CONTROL STATIONS AND SWITCHES

© June 2017

Explosionproof, Dust-Ignitionproof

UNILETS™ for Use with Threaded Metal Conduit.

NEC/CEC:

Class I, Division 1 and 2, Groups B, C, D

Class II, Division 1 and 2, Groups E, F, G

Class III

NEMA 3, 7 BCD, 9EFG

Applications

• Designed to prevent arcing of enclosed switches in ignitable

atmospheres during connect and disconnect operation of

lighting and light power loads.

• For use in classied areas where ignitable vapors, gases or

highly combustible dusts are present.

• For installation in:

— Chemical plants

— Petrochemical plants

— Reneries

— Other process industries

Features

• Enclosures have external mounting lugs for ease of mounting.

• Smooth, rounded integral bushing in each hub protects

conductor insulation.

• Enclosures furnished with internal ground screw.

• 20 Amp and 30 Amp units available for use with 120-277 Vac.

• Factory sealed switches are designed to a UL Standard so

that any arcing devices are contained within an explosionproof

labyrinth switch (standard switch and sealing chamber on

select models). Tumbler switch devices are approved for

installation without additional external sealing ttings.

• 1/2” and 3/4” 1-gang units suitable for Class I, Group B, in

addition to Class I, Groups C and D; Class II, Groups E, F and

G; and Class III.

• 20 Amp 4-way and all 30 Amp models utilize a switch enclosed

in separate sealing chamber. Smooth double-face, accurately

ground surfaces on sealing chamber ange mate with cover

and body to provide positive ame-tight construction.

• Sealing chamber has prewired factory sealed pigtail leads to

switch.

• Corrosion resistant, strong stainless steel hex head cap screws

attach cover/body/sealing chamber assembly for approved

ame-tight construction.

• Threaded stainless steel operating handle provides positive

Corrosion resistant operation.

• Choice of front-operating or side rocker arm handle—each may

be locked in ON or OFF position.

Standard Materials

• Body and cover: malleable iron

• Sealing chamber (on select models): copperfree (4/10 of 1%

max.) aluminum

• Handle: nylon 6/6

• Optional nameplate mounting bracket: corrosion resistant

stainless steel

Standard Finishes

• Tumbler switches: triple-coat—(1) zinc electroplate,

(2) chromate, and (3) epoxy powder coat

Front Operated Rocker Arm Operated

Illustrated Features

Handles may be locked in ON or OFF position

Separate sealing chamber and switch construction.

Used on 20 Amp 4-way and all 30 Amp models.

Explosionproof Labyrith Switch

Used on all 20 Amp models excluding 4-way.

Indicates items which are suitable for Class I, Group B, as well as Class I, Groups C and D; Class II, Groups E, F, G; and Class III. See product selection pages

for suitable items.

69

Page 2

EDS Factory Sealed Tumbler Switches

CONTROLS: NEC/CEC EXPLOSIONPROOF CONTROL STATIONS AND SWITCHES

© June 2017

Explosionproof, Dust-Ignitionproof

UNILETS™ for Use with Threaded Metal Conduit.

NEC/CEC:

Class I, Division 1 and 2, Groups B, C, D

Class II, Division 1 and 2, Groups E, F, G

Class III

NEMA 3, 7 BCD, 9EFG

Options

• 1- or 2-gang copperfree (4/10 of 1% max.) aluminum bodies

and covers available. Add sufx – A.

• NPBRKT nameplate mounting bracket to make circuit

description/identication easy.

— Pre-drilled holes in bottom of bracket allow direct mounting

to control stations with existing cover bolts.

— Pre-drilled holes in middle of bracket allow mounting of

customer’s circuit identication nameplate; epoxy glue may

also be used for mounting (phenolic nameplate not included).

— Bracket eliminates costly eld installation of drilling and

tapping to accommodate circuit identication nameplate.

— Brackets t side-by-side on 2-, 3- and 4-gang boxes and

3-devices.

Standard Materials

• Body and cover: malleable iron

NEC/CEC Certifications and Compliances

• UL Standards: UL 894, UL 1203

• UL Listed: E10523, E81751

• cUL Listed: E81751, E810523

Ordering Information for ”Custom” Units

• Devices, covers and bodies may be ordered separately so that

a different EDS chamber/switch assembly may be used in each

gang.

• Order components separately as follows:

(1) select mounting body catalog number,

(2) select cover catalog number with desired switch operation

(1-pole, 2-pole, 3-way or 4-way).

How to Order Hub Arrangements

• Simply send sketch indicating sizes and locations for brazed

hubs on body or bodies selected from catalog listings. Orient

sketch so that cover opening faces front and mounting lugs

face upward and downward (box wall opposite cover should be

referred to as the back of box).

Bodies and Hubs Available

• Tumbler switches may be ordered in single thru ve gang deep

malleable iron blank bodies with brazed hubs as specied at

any location.

• Tumbler switches may be ordered with tandem malleable iron

boxes with additional brazed hubs as specied.

• Standard malleable iron single and 2-gang tumbler switches

may be ordered with additional brazed hubs as specied.

• Single and 2-gang tumbler switches may be ordered with

aluminum boxes with additional brazed hubs as specied.

Related Products

• For classied-location push button, pilot light and selector

switch control stations, see EFD/EFDB and EDS Control

Stations and Pilot Lights.

Indicates items which are suitable for Class I, Group B, as well as Class I, Groups C and D; Class II, Groups E, F, G; and Class III. See product selection pages

for suitable items.

Aluminum rocker arm cover is not available.

70

Page 3

EDS Factory Sealed Tumbler Switches

CONTROLS: NEC/CEC EXPLOSIONPROOF CONTROL STATIONS AND SWITCHES

© June 2017

Explosionproof, Dust-Ignitionproof

Malleable Iron Body and Cover. Furnished with Internal Ground Screw.

NEC/CEC:

Class I, Division 1, Groups B, C, D

Class I, Division 2, Groups B, C, D

Class II, Division 1 and 2, Groups E, F, G

Class III

NEMA 3, 7CD, 9EFG

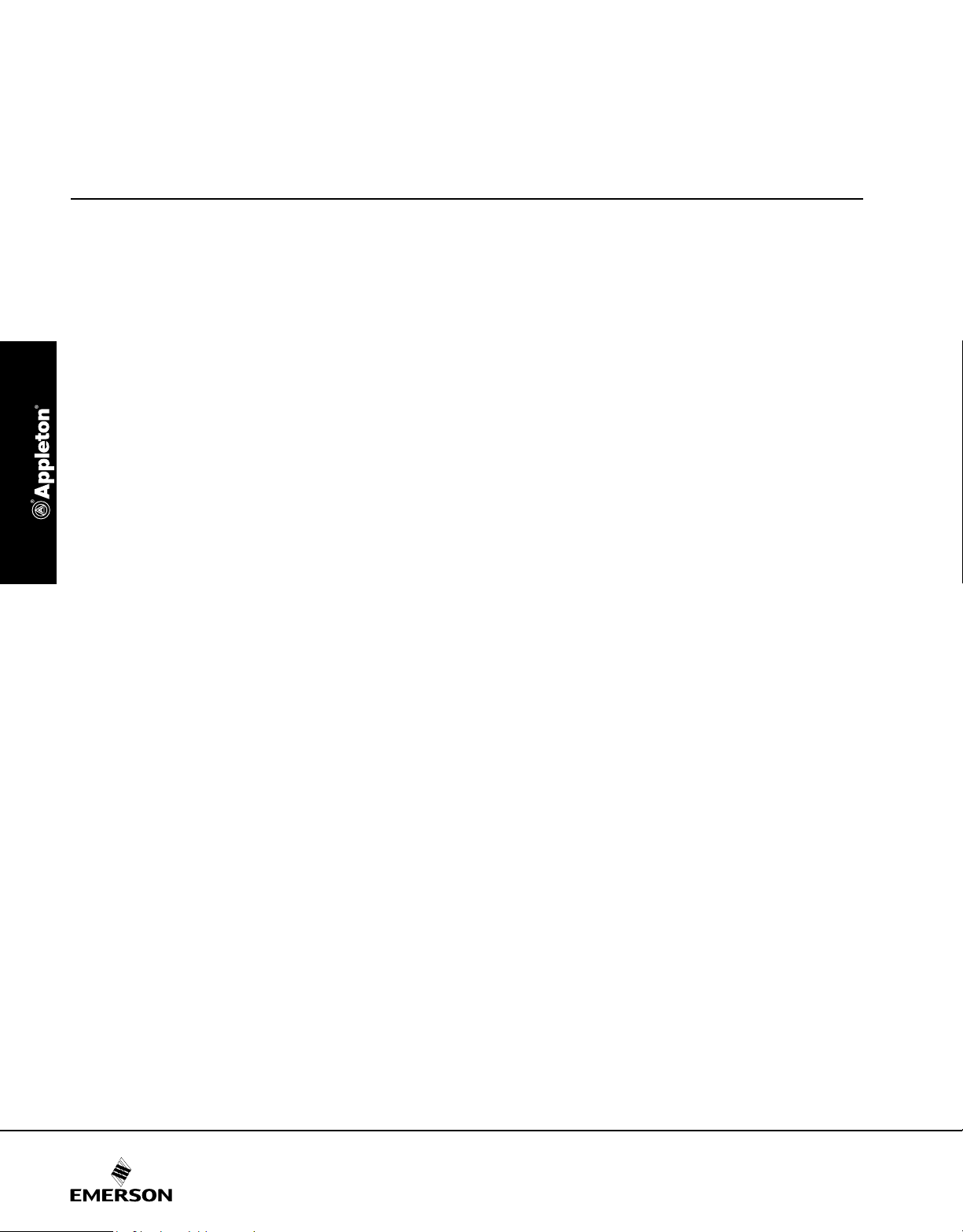

1-Gang — Front Operated

Dead-End

Feed-Thru

2-Gang — Front Operated

Dead-End

Hub Size

(Inches)

20 Amp — 120-277 Vac

1/2 1-Pole EDS150-F1 EDSC150-F1

1/2 2-Pole EDS150-F2 EDSC150-F2

1/2 3-Way EDS150-F3W EDSC150-F3W

1/2 4-Way EDS150-F4W EDSC150-F4W

3/4 1-Pole EDS175-F1 EDSC175-F1

3/4 2-Pole EDS175-F2 EDSC175-F2

3/4 3-Way EDS175-F3W EDSC175F3W

3/4 4-Way EDS175-F4W EDSC175F4W

1 1-Pole EDS110-F1 EDSC110-F1

1 2-Pole EDS110-F2 EDSC110-F2

1 3-Way EDS110-F3W EDSC110-F3W

1 4-Way EDS110-F4W EDSC110-F4W

30 Amp — 120-277 Vac

3/4 1-Pole EDS175-F13 EDSC175-F13

3/4 2-Pole EDS175-F23 EDSC175-F23

3/4 3-Way EDS175-F3W3 EDSC175-F3W3

1 1-Pole EDS110-F13 EDSC110-F13

1 2-Pole EDS110-F23 EDSC110-F23

1 3-Way EDS110-F3W3 EDSC110-F3W3

20 Amp — 120-277 Vac

1/2 1-Pole EDS250-F1 EDSC250-F1

1/2 2-Pole — EDSC250-F2

1/2 3-Way — EDSC250-F3W

1/2 4-Way — EDSC250-F4W

3/4 1-Pole EDS275-F1 EDSC275-F1

3/4 2-Pole — EDSC275-F2

3/4 3-Way EDS275-F3W EDSC275-F3W

3/4 4-Way — EDSC275-F4W

1 1-Pole EDS210-F1 EDSC210-F1

1 2-Pole EDS210-F2 EDSC210-F2

1 3-Way EDS210-F3W EDSC210-F3W

1 4-Way EDS210-F4W EDSC210-F4W

Switch Dead-End Feed-Thru

Catalog Number

Feed-Thru

For aluminum backbox and cover, add suffix -A.

20 Amp — 1 HP at 120 Vac and 2 HP at 240 Vac.

30 Amp — 2 HP at 120 Vac or 240 Vac.

Contains standard switch and sealing chamber.

Shaded area indicates items suitable for Class I, Group B, as well as Class I, Groups C and D; Class II, Groups E, F, G; and Class III.

71

Page 4

EDS Factory Sealed Tumbler Switches

CONTROLS: NEC/CEC EXPLOSIONPROOF CONTROL STATIONS AND SWITCHES

© June 2017

Explosionproof, Dust-Ignitionproof

Malleable Iron Body and Cover. Furnished with Internal Ground Screw.

NEC/CEC:

Class I, Division 1, Groups B, C, D

Class I, Division 2, Groups B, C, D

Class II, Division 1 and 2, Groups E, F, G

Class III

NEMA 3, 7 BCD, 9EFG

Hub Size

(Inches)

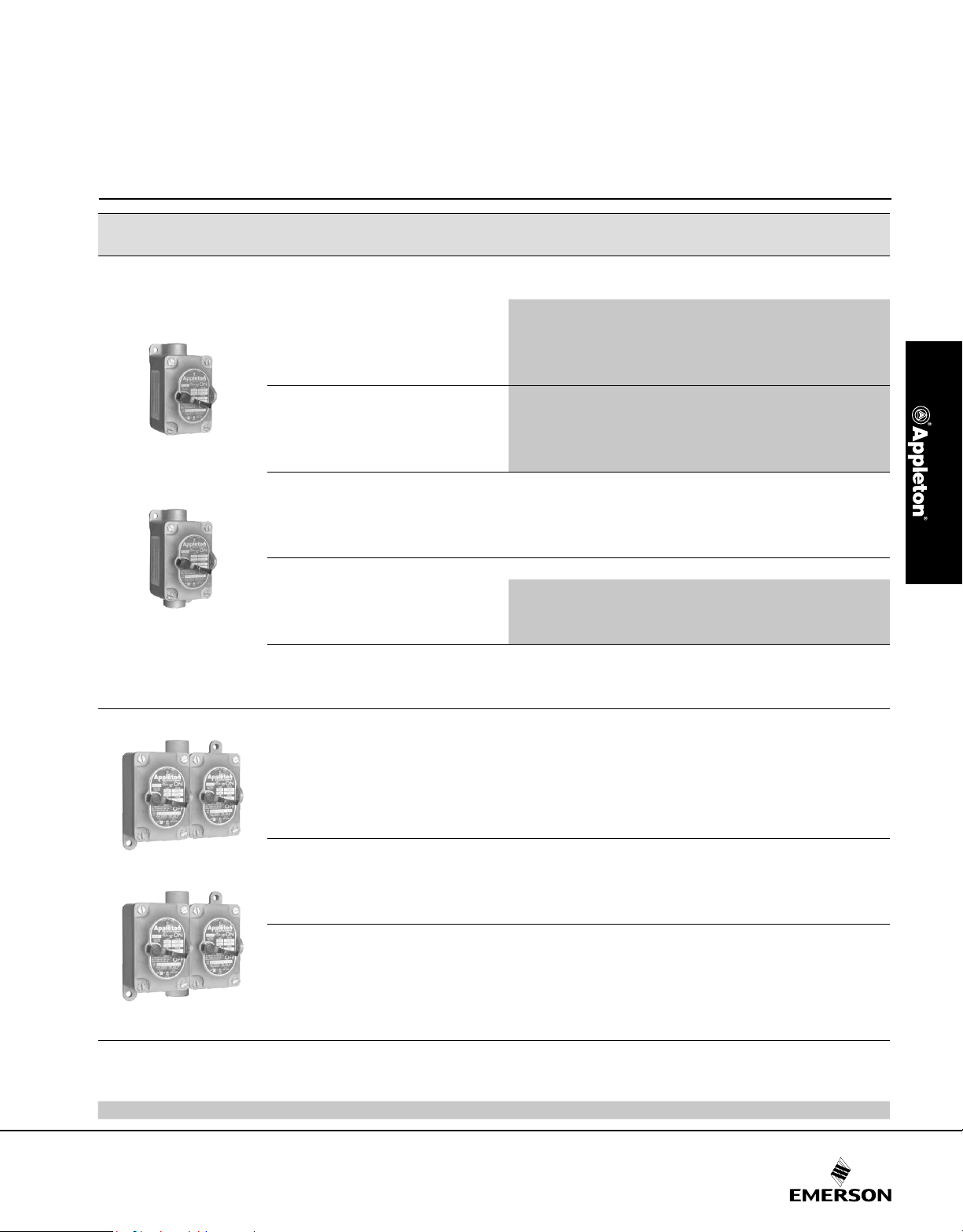

1-Gang — Rocker Arm Operated

20 Amp — 120-277 Vac

1/2 1-Pole EDS150-R1 EDSC150-R1

1/2 2-Pole EDS150-R2 EDSC150-R2

1/2 3-Way EDS150-R3W EDSC150-R3W

1/2 4-Way

3/4 1-Pole EDS175-R1 EDSC175-R1

3/4 2-Pole EDS175-R2 EDSC175-R2

3/4 3-Way EDS175-R3W EDSC175-R3W

Dead-End

Feed-Thru

2-Gang — Rocker Arm Operated

Dead-End

Feed-Thru

For aluminum backbox, add suffix -A.

20 Amp — 1 HP at 120 Vac and 2 HP at 240 Vac.

30 Amp — 2 HP at 120 Vac or 240 Vac.

Contains standard switch and sealing chamber.

Shaded area indicates items suitable for Class I, Group B, as well as Class I, Groups C and D; Class II, Groups E, F, G; and Class III.

3/4 4-Way

1 1-Pole EDS110-R1 EDSC110-R1

1 2-Pole EDS110-R2 EDSC110-R2

1 3-Way EDS110-R3W EDSC110-R3W

1 4-Way

30 Amp — 120-277 Vac

3/4 1-Pole

3/4 2-Pole

3/4 3-Way

1 1-Pole

1 2-Pole

1 3-Way

20 Amp — 120-277 Vac

1/2 1-Pole EDS250-R1 EDSC250-R1

1/2 2-Pole — EDSC250-R2

1/2 3-Way — EDSC250-R3W

1/2 4-Way —

3/4 1-Pole EDS275-R1 EDSC275-R1

3/4 2-Pole — EDSC275-R2

3/4 3-Way EDS275-R3W EDSC275-R3W

3/4 4-Way —

1 1-Pole EDS210-R1 EDSC210-R1

1 2-Pole EDS210-R2 EDSC210-R2

1 3-Way EDS210-R3W EDSC210-R3W

1 4-Way

Switch Dead-End Feed-Thru

EDS150-R4W EDSC150-R4W

EDS175-R4W EDSC175-R4W

EDS110-R4W EDSC110-R4W

EDS175-R13 EDSC175-R13

EDS175-R23 EDSC175-R23

EDS175-R3W3 EDSC175-R3W3

EDS110-R13 EDSC110-R13

EDS110-R23 EDSC110-R23

EDS110-R3W3 EDSC110-R3W3

EDS210-R4W EDSC210-R4W

Catalog Number

EDSC250-R4W

EDSC275-R4W

72

Page 5

EDS Factory Sealed Tumbler Switches

CONTROLS: NEC/CEC EXPLOSIONPROOF CONTROL STATIONS AND SWITCHES

© June 2017

Explosionproof, Dust-Ignitionproof

Malleable Iron Body and Cover. Furnished with Internal Ground Screw.

NEC/CEC:

Class I, Division 1 and 2, Groups C, D

Class II, Division 1 and 2, Groups E, F, G

Class III

NEMA 3, 7CD, 9EFG

Factory Assembled Switch Assembly

20 Amp, 120-277 Vac 30 Amp, 120-277 Vac

Switch Type

1-Pole

2-Pole

3-Way

4-Way

Front Cover

1-Pole

2-Pole

3-Way

4-Way

Rocker Cover/Chamber

1-Pole LAB21 —

2-Pole LAB22 —

3-Way LAB23W —

Malleable Iron Aluminum Malleable Iron Aluminum

EDKF21-Q EDKF21-AQ EDKF31-Q EDKF31-AQ

EDKF22-Q EDKF22-AQ EDKF32-Q EDKF32-AQ

EDKF23W-Q EDKF23W-AQ EDKF33W-Q EDKF33W-AQ

EDKF24W-Q EDKF24W-AQ

EDK-R21-Q EDK-R31-Q

EDK-R22-Q EDK-R32-Q

EDK-R23W-Q EDK-R33W-Q

EDK-R24W-Q

Catalog Number

— —

—

Factory Sealed Switch Only

Nameplate Mounting Bracket

Description Catalog Number

Bracket with blank silver/black nameplate for EFDB series NPBRKT-EFDB

To order bracket with control station, add suffix –NPBRKT to end of catalog number.

To order engraved nameplates, add desired markings after catalog number. Maximum

of 2 lines with 12 characters (including spaces) per line.

Note: Mount bracket between cover screws and cover. Do not mount bracket between ground joint flame path between

cover and backbox.

20 Amp Switches 1 HP at 120 Vac and 2 HP at 240 Vac.

30 Amp Switches 2 HP at 120 Vac or 240 Vac.

Contains Factory Sealed Switch; no sealing chamber.

With sealing chamber.

73

Page 6

EFD Factory Sealed Tumbler Switches

CONTROLS: NEC/CEC EXPLOSIONPROOF CONTROL STATIONS AND SWITCHES

© June 2017

Furnished with Internal Ground Screw.

NEC/CEC:

Class I, Division 1 and 2, Groups C, D

Class II, Division 1 and 2, Groups E, F, G

Class III

NEMA 7CD, 9EFG

Mounting Bodies

Type

1-Gang

Dead-End

Feed-Thru

2-Gang

Dead-End

Feed-Thru

Tandem

Dead-End

Feed-Thru

Hub Size

(Inches)

1/2 EFD150NLQ EFD150ANLQ

3/4 EFD175NLQ EFD175ANLQ

1 EFD110NLQ EFD110ANLQ

1/2 EFDC150NLQ EFDC150ANLQ

3/4 EFDC175NLQ EFDC175ANLQ

1 EFDC110NLQ EFDC110ANLQ

1/2 EFD250NLQ EFD250ANLQ

3/4 EFD275NLQ EFD275ANLQ

1 EFD210NLQ EFD210ANLQ

1/2 EFDC250NLQ EFDC250ANLQ

3/4 EFDC275NLQ EFDC275ANLQ

1 EFDC210NLQ EFDC210ANLQ

1/2 EFDT50NLQ —

3/4 EFDT75NLQ —

1 EFDT10NLQ —

1/2 EFDCT50NLQ —

3/4 EFDCT75NLQ —

1 EFDCT10NLQ —

Malleable Iron Aluminum

Catalog Number

Blank Bodies for Brazed Hubs

Construct complete catalog numbers per EFD Cast Device Boxes Ordering Information on following

page. Hubs will be located in center of walls and evenly spaced unless otherwise specified. Where

spacings are critical, submit sketch showing exact spacing requirements.

1-Gang EFD1NL

2-Gang EFD2NL

3-Gang EFD3NL

4-Gang EFD4NL

5-Gang EFD5NL

For tandem bodies, external seals must be installed within 1.5 meters (5 feet) of each conduit entrance for Class I, Groups C and D.

74

Page 7

EDS Factory Sealed Tumbler Switches

CONTROLS: NEC/CEC EXPLOSIONPROOF CONTROL STATIONS AND SWITCHES

© June 2017

Blank Bodies for Brazed Threaded Hubs

Single, Two, Three, Four and Five Gang Boxes. Brazed Threaded Hubs for Rigid Conduit, 1/2” thru 1”; Brazed Union Hubs, 1/2” thru 1”.

NEC/CEC:

Class I, Division 1 and 2, Groups C, D

Class II, Division 1 and 2, Groups E, F, G

Class III

NEMA 7CD, 9EFG

Cast Device Box Ordering Information

Determine catalog number as follows:

(1) Select EFD device box catalog number;

(2) Select ”Standard Hub Arrangement

Diagram” number; and

(3) Select symbols that represent hub

sizes from ”Symbol Table.” (Use ”0”

where no hub is required, and separate

the various divisions of the complete

catalog number by dashes.)

Example

The blank body device box selected is

EFD3NL and the hub arrangement is

diagram #8. Hub ”a” is to be 3/4” brazed

threaded; hub ”b”, 1” brazed threaded;

hub ”c”, 3/4” brazed threaded; hub ”d”,

no hub is required; and hub ”e”, 1” brazed

union.

The complete catalog number will be:

EFD–3NL–8–23203E

Standard Hub Arrangement Diagrams

Hub ”a” is always TOP of box

2-, 3-, 4- and 5-Gang (Front View)

If a ”Standard Hub Arrangement” is not

suitable for the application, or when hubs

are to be more accurately spaced, submit

sketch locating hubs (1) from centerlines

of walls and (2) from outside back of box

(or from mounting lug surface if lugs are

supplied).

All hubs will be located in centerlines of

walls and evenly spaced unless

otherwise specified.

Symbol Table

Hub Size

(Inches)

Blank 0 0

1/2 1 1E

3/4 2 2E

1 3 3E

Brazed

Threaded Hub

Symbol

Brazed Union

Hub Symbol

1-Gang (Front View)

75

Page 8

EDS Factory Sealed Tumbler Switches

CONTROLS: NEC/CEC EXPLOSIONPROOF CONTROL STATIONS AND SWITCHES

© June 2017

NEC/CEC:

Class I, Division 1, Groups B, C, D

Class I, Division 2, Groups B, C, D

Class II, Division 1 and 2, Groups E, F, G

Class III

NEMA 3, 7 BCD, 9EFG

Dimensions in Millimeters (Inches)

Front Operated Tumbler Switches

Front — 1-Gang Side Front — 2-Gang

Hub Size

(Inches)

1/2 and 3/4 136.7 (5.38) 155.7 (6.13) 19.8 (0.78)

1 139.7 (5.50) 160.3 (6.31) 23.9 (0.94)

Rocker Arm Operated Tumbler Switches

Front — 1-Gang Side Front — 2-Gang

Dimensions in Millimeters (Inches)

A B C

Hub Size

(Inches)

Indicates items which are suitable for Class I, Group B, as well as Class I, Groups C and D; Class II, Groups E, F, G; and Class III. See product selection pages

for suitable items.

1/2 and 3/4 136.7 (5.38) 155.7 (6.13) 19.8 (0.78)

1 139.7 (5.50) 160.3 (6.31) 23.9 (0.94)

A B C

Dimensions in Millimeters (Inches)

76

Page 9

EDS Factory Sealed Tumbler Switches

CONTROLS: NEC/CEC EXPLOSIONPROOF CONTROL STATIONS AND SWITCHES

© June 2017

NEC/CEC:

Class I, Division 1, Groups B, C, D

Class I, Division 2, Groups B, C, D

Class II, Division 1 and 2, Groups E, F, G

Class III

NEMA 3, 7 BCD, 9EFG

Dimensions in Millimeters (Inches)

Tandem

Front - Dead-End Front — Feed-Thru Side

NPBRKT Nameplate Mounting Bracket

Secure bracket under

cover screws of box.

Torque cover screws

to 35” - lbs.

Indicates items which are suitable for Class I, Group B, as well as Class I, Groups C and D; Class II, Groups E, F, G; and Class III. See product selection pages

for suitable items.

77

Loading...

Loading...