Page 1

K

Service Source

PLW SC/NT/NTR/LS

Personal LaserWriter SC, Personal LaserWriter NT,

Personal LaserWriter NTR, Personal LaserWriter LS,

Personal LaserWriter LS/L

Page 2

K

Service Source

Basics

PLW SC/NT/NTR/LS

Page 3

Basics Product Information - 1

Product Information

The printers covered in this manual are

• Personal LaserWriter SC

• Personal LaserWriter NT

• Personal LaserWriter NTR

• Personal LaserWriter LS

• Personal LaserWriter LS/L

Compatibility

Not all parts are compatible among the five models. Refer to

Illustrated Parts for compatibility cross references.

The cassette feeder tray and its associated parts are optional

on the LS, LS/L, and NTR models.

Page 4

Basics Paper Paths - 2

Paper Paths

There are four paper paths in the Personal LaserWriter.

Paper is fed from the cassette or multipurpose tray and

delivered to the face-down or face-up delivery trays.

Note:

Face signifies image side. Default delivery is face-

down at the top of the printer.

Page 5

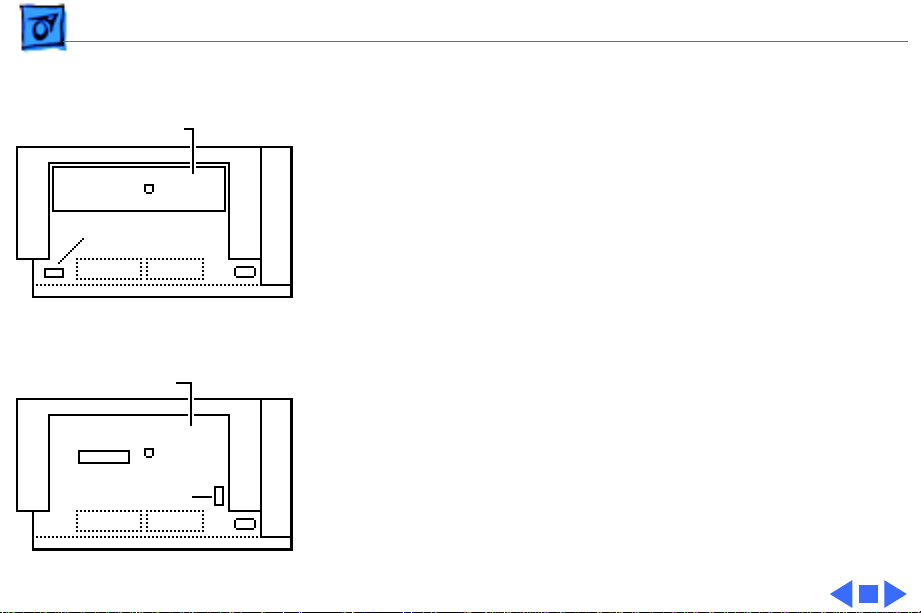

Basics LS–LS/L Identification - 3

LS–LS/L Identification

I/O Board Bracket

Power Switch

Personal LaserWriter LS

Solid Rear Cover

Power Switch

Personal LaserWriter LS/L

The LS/L is a cost-reduced version of the LS but is sold and

packaged under the same LS name. Parts are not necessarily

interchangeable between the two models.

External distinguishing characteristics:

• LS: The power switch is on the left rear of printer; the

rear cover has an opening for an I/O board bracket and

displays the family number M2000.

• LS/L: The power switch is on the right rear of printer;

the rear cover is solid plastic and displays the family

number M2002.

Page 6

Basics Sensing System Theory - 4

Sensing System Theory

PS502

PS13

PS12

PS501

PS11

PS901

There are six sensors in the

Personal LaserWriter: four

paper sensors and two

printer-open sensors. Each

consists of an actuator, a Ushaped photo interrupter,

and circuitry that communicates with the controller.

If the actuator is present

inside the U, the circuit

closes; if it is absent, the

circuit opens. In ready state

the appropriate circuit is

closed.

Page 7

Basics Sensing System Theory - 5

Paper sensors are actuated

as an arm or lever swings

against movement of paper.

Printer-open sensors are

PS11

PS12

actuated as the user shuts a

door or cover.

Illustrations on the

following cards show each

sensor as it would appear in

PS501

PS502

PS13

PS901

print ready state. Some

peripheral elements are

deleted for clarity.

Page 8

PLW SC/NT/NTR/LS Basics - 6

Actuator Tab on

Toner Cartridge

Photo Interrupter

PS11

Toner Cartridge Sensor

Actuator: Toner cartridge shutter flips into

position as front door closes.

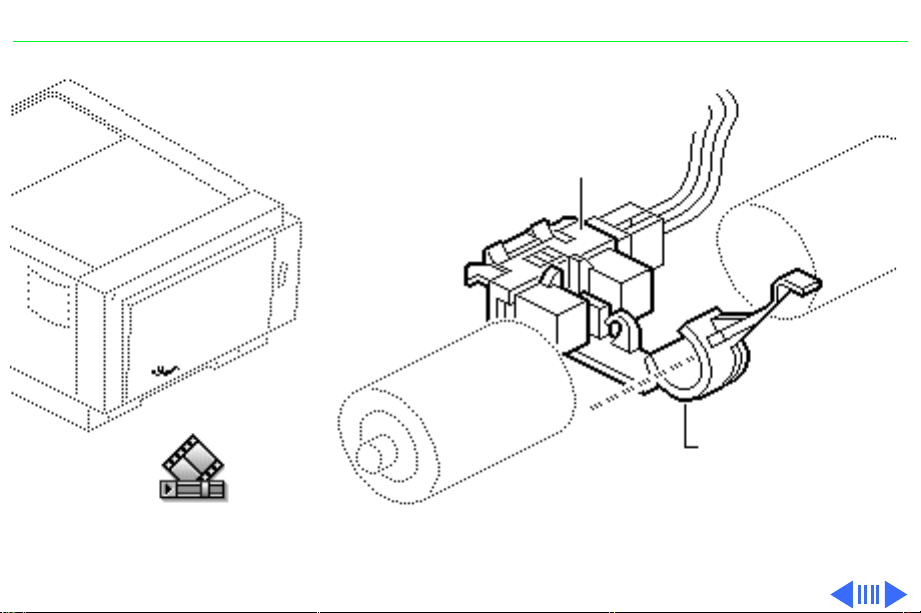

Page 9

PLW SC/NT/NTR/LS Basics - 7

Photo

Interrupter

PS12

Delivery Unit Paper Sensor

Actuator: Sensing lever housed in fuser

assembly is tripped by paper exiting fuser.

Paper-Sensing Lever

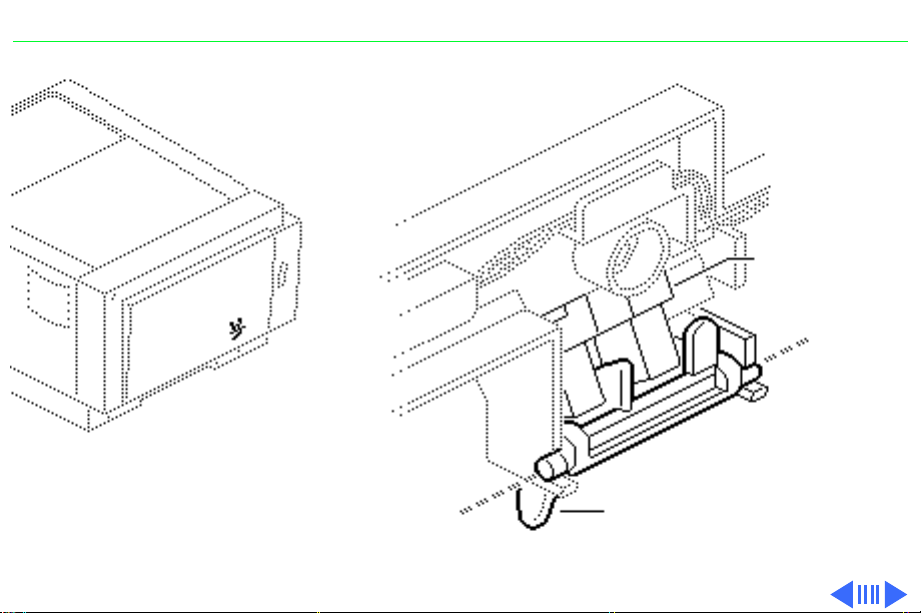

Page 10

PLW SC/NT/NTR/LS Basics - 8

Photo

Interrupter

Paper-Sensing Lever

PS13

Pickup Unit Paper Sensor

Actuator: Sensing lever in feeder assembly

is tripped by paper entering feed cycle.

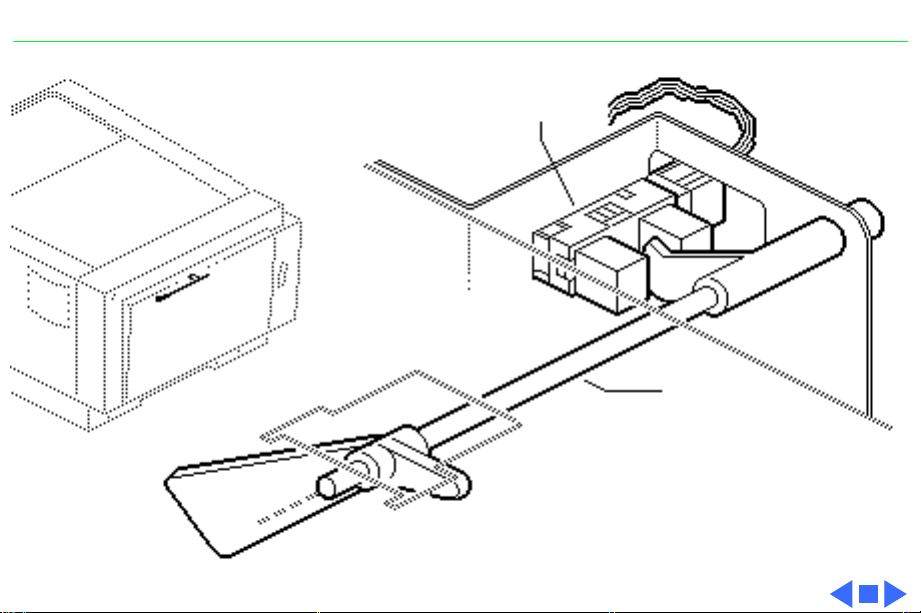

Page 11

PLW SC/NT/NTR/LS Basics - 9

Photo

Interrupter

PS501

Multipurpose Tray Sensor

Actuator: Sensing lever in multipurpose cable

assembly is tripped by manually fed paper.

Paper-Sensing Lever

(Shown in tripped position)

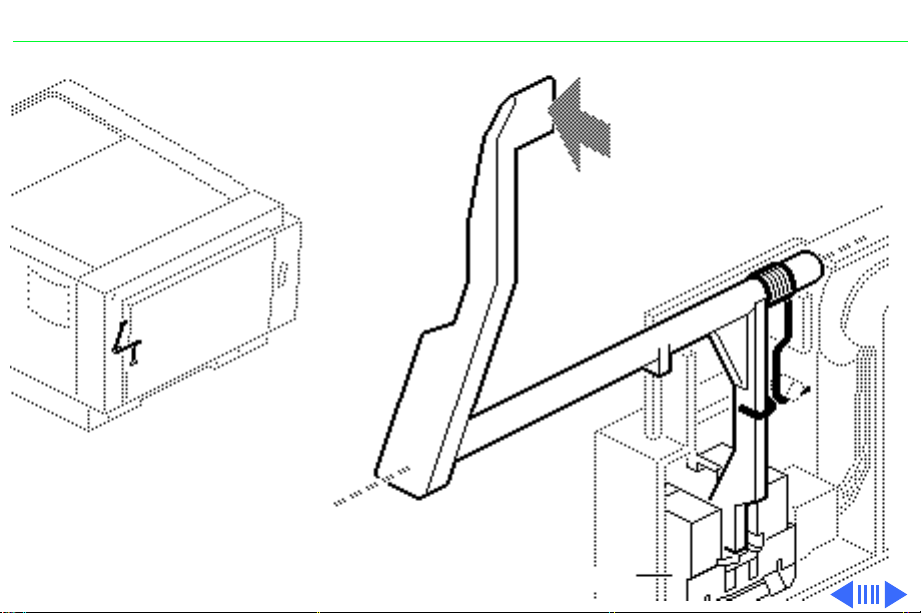

Page 12

PLW SC/NT/NTR/LS Basics - 10

Cover

Sensing

Arm

PS502

Face-Up Cover Sensor

Actuator: Sensing arm is tripped

by the closing of the face-up ocver.

Photo Interrupter

Page 13

PLW SC/NT/NTR/LS Basics - 11

Photo

Interrupter

PaperSensing Arm

PS901

Paper Cassette Sensor

Actuator: Sensing arm is tripped by the

insertion of loaded cassette tray.

Page 14

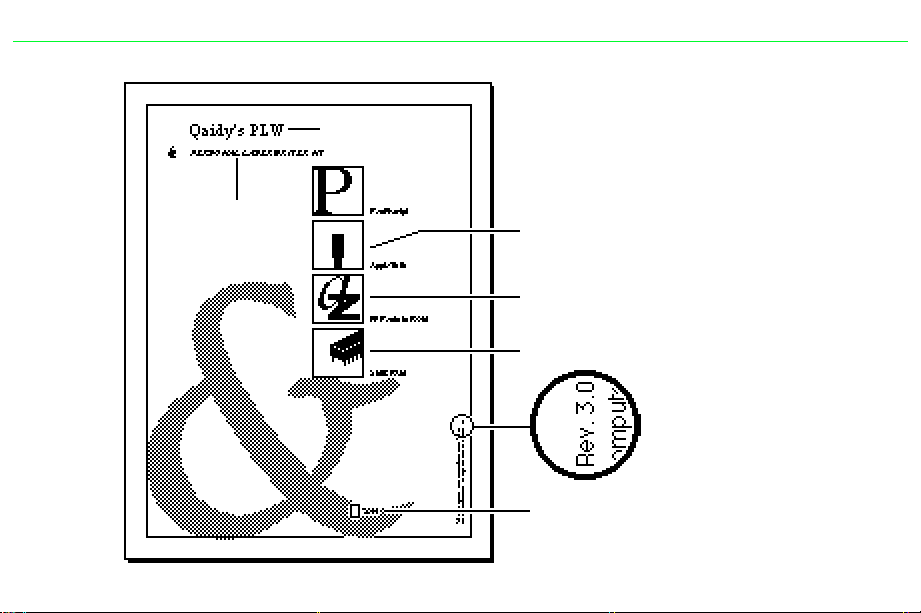

Basics Startup Test Pages - 12

Startup Test Pages

The Personal LaserWriter

SC, NT, and NTR generate a

startup test page 2 – 3

minutes after you switch on

the printer. The LS and LS/

L do not produce such a page.

In the NT and NTR the

startup test page also shows

unit-specific configuration

information. The following

pages describe each element

of the startup test pages.

Page 15

PLW SC/NT/NTR/LS Basics - 13

Ê

Printer Name

I/O Board

Type

NT/NTR Startup Test Page

Communication Protocol

RS-232 serial or AppleTalk

Fonts in ROM

Installed RAM

Version of ROM installed

Number of pages the I/O

board has produced

Page 16

Basics Startup Test Pages - 14

The Personal LaserWriter

SC test page consists of a line

matrix. The printer

generates a test page only if

you set its SCSI address to 7

prior to switching on the

printer. It continues to

print until it is out of paper.

Note:

Be sure to set the SCSI

address back before

resuming printing.

SC Startup Test Page

Page 17

Basics Service Test Page - 15

Service Test Page

Successful printing of a

service test page confirms

print engine operation.

There are three variations

in how you run a service test

page, depending on the

model you are servicing.

Each involves using a pencil

or similar dowel-shaped

tool to depress the service

test button on the DC

controller board (or serial

controller on the LS/L).

Service Test Page

Page 18

Basics Service Test Page - 16

SC, NT, NTR

First remove the I/O board.

You can then access the test

button through the 1/4inch diameter opening in

the I/O shield.

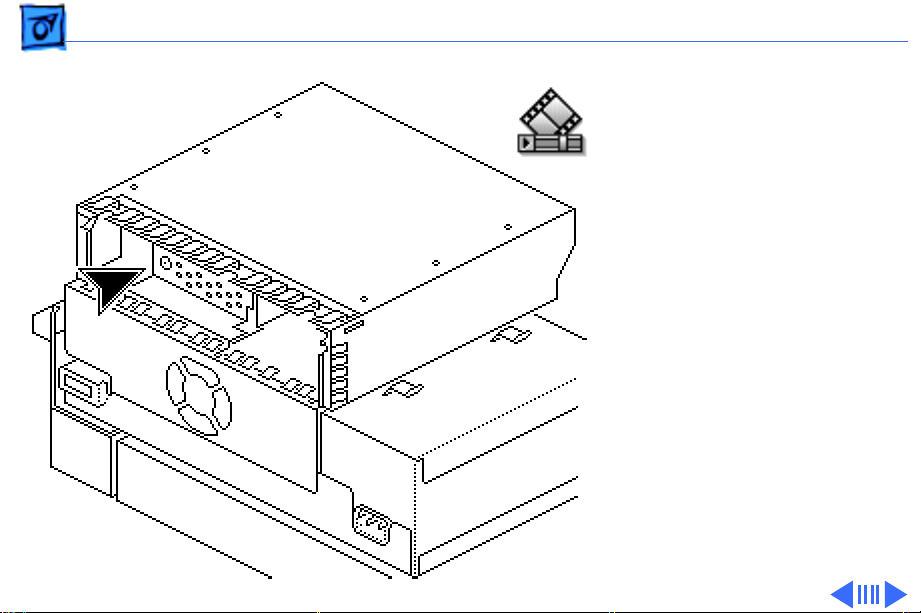

SC, NT, NTR

Service Test Page

Page 19

Basics Service Test Page - 17

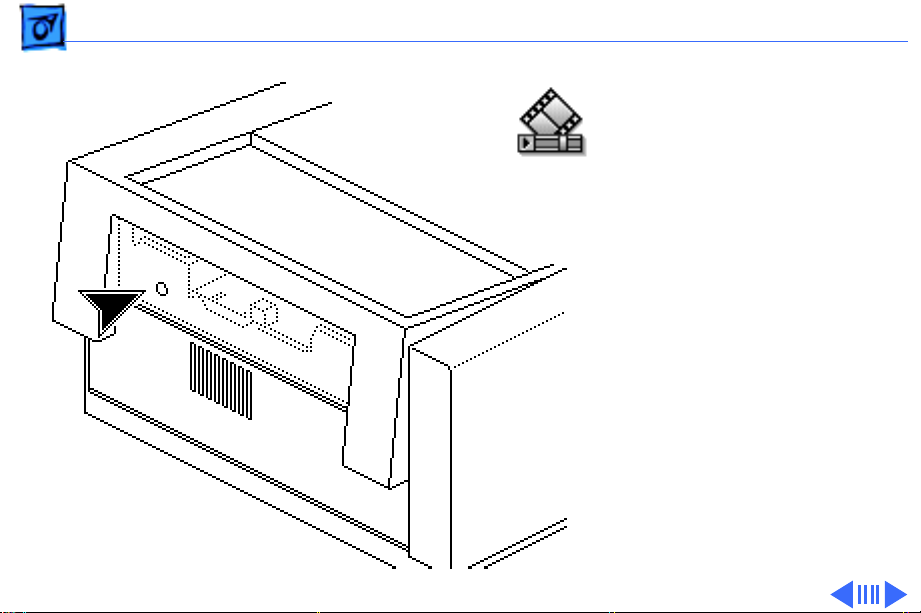

LS

First remove the I/O board

bracket. You can then access

the test button through the

1/4-inch diameter opening

in the end plate.

LS

Service Test Page

Page 20

Basics Service Test Page - 18

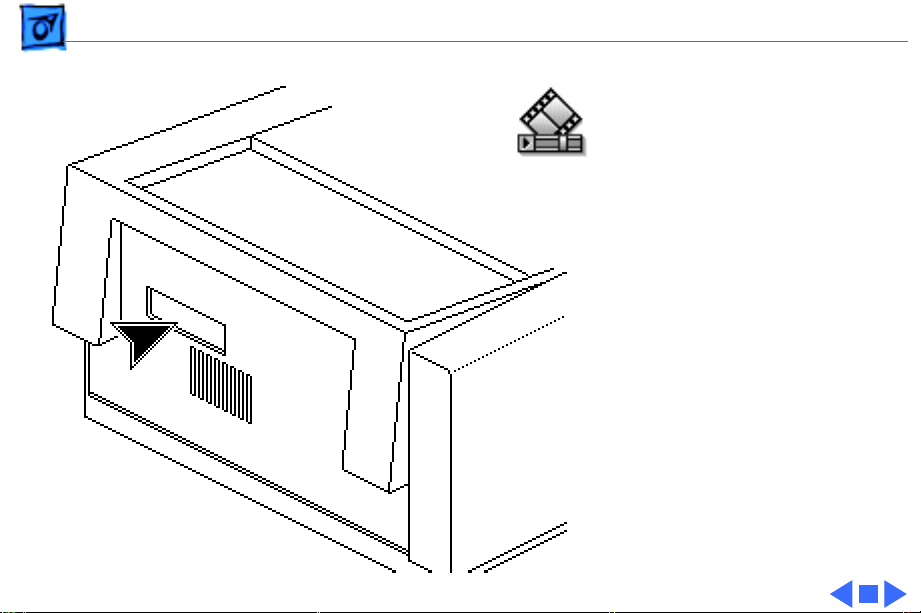

LS/L

First remove the test button

cover on the rear panel of

the printer. You can then

access the test button

through the opening in the

rear panel.

LS/L

Service Test Page

Page 21

K

Service Source

Specifications

PLW SC/NT/NTR/LS

Page 22

Specifications General - 1

General

Engine

Printing Method

Optical System

Resolution

Imaging Languages Supported

Canon P110 engine

Electrophotography using single-component dry toner

Semiconductor laser and a rotating dual-faced scanning mirror

300 dpi

SC: QuickDraw

NT: PostScript, HP LaserJet Plus, and a subset of Diablo 630

NTR: PostScript, HP LaserJet Plus, and a subset of Diablo 630

LS: QuickDraw

LS/L: QuickDraw

Page 23

Specifications Intro Dates - 2

Intro Dates

SC and NT

LS

LS/L and NTR

July 1990

March 1991

March 1992

Page 24

Specifications Logic Board - 3

Logic Board

CPU

DRAM

SC: Motorola 68000 microprocessor (7.275 MHz)

NT: Motorola 68000 microprocessor (12 MHz)

NTR: N/A

LS: N/A

LS/L: N/A

SC: 1 MB

NT: 2 MB, expandable to 8 MB

NTR: 3 MB, expandable to 4 MB

LS: 512K, expandable to 1 MB

LS/L: 512K, expandable to 1 MB

Page 25

Specifications Logic Board - 4

ROM

I/O

SC: 32K

NT: 1.25 MB

NTR: 3 MB

LS: N/A

LS/L: N/A

SC: SCSI

NT: LocalTalk, RS-232, RS-422

NTR: LocalTalk, RS-232, RS-422, Centronics parallel

LS: RS-422

LS/L: RS-422

Page 26

Specifications Performance - 5

Performance

Printing Speed

Print Delivery

Life Expectancy

4 pages per minute maximum; actual performance depends on the

application

Face-down or face-up (manually selectable)

150,000 pages with no monthly page limit

Page 27

Specifications Paper - 6

Paper

Paper W eights

Cassette Sizes

Capacity In

Capacity Out

Cassette feed: 20 lb., single-sheet, photocopy bond

Manual feed: 20-28 lb., letterhead and colored stock, medium-

weight transparency material, envelopes, and labels

US letter standard; legal, A4, B5, and envelope cassettes optional

Cassette: 250 sheets

Manual: 50/70 sheet capacities

Envelope cassette: 15 envelopes, minimum size 86 x 178 mm

(3.5 x 7 in.), maximum size 188 x 267 mm (7.4 x 10 in.)

Face-down tray: 50 sheets

Face-up tray: 20 sheets

Page 28

Specifications Built-In Fonts - 7

Built-In Fonts

SC, LS, and LS/L

NT

NTR

N/A

Times, Helvetica, Helvetica Narrow, Courier, Symbol, Palatino,

ITC Avant Garde, Gothic, ITC Bookman, New Century

Schoolbook, ITC Zapf Chancery, and ITC Zapf Dingbats

Times, Helvetica, Helvetica Narrow, Courier, Symbol, Palatino,

ITC Avant Garde, Gothic, ITC Bookman, New Century

Schoolbook, ITC Zapf Chancery, ITC Zapf Dingbats, and IBM PC

Graphics Extended Character Set (ECS)

Page 29

Specifications Environmental - 8

Environmental

Temperature

Humidity

Noise Level

50-90.5° F (10-32.5° C)

20-80% relative humidity

Printing: Under 53 dB(A)

Standby: Under 43 dB(A)

Page 30

Specifications Electrical - 9

Electrical

Line V oltage

Power Consumption

US/Japan: 100/115 V, 50/60 Hz

Europe/Australia: 220/240 V, 50 Hz

600 W maximum (100/115 V)

550 W maximum (220/240 V)

Page 31

Specifications Physical - 10

Physical

Dimensions

Weight

Height: 8 in. (20.3 cm), 9.8 in. (24.8 cm) with cassette feeder

Width: 15 in. (38 cm)

SC, NT, and NTR: 32 lb. (15 kg)

LS and LS/L: 31 lb. (14.5 kg)

Page 32

K

Service Source

Troubleshooting

PLW SC/NT/NTR/LS

Page 33

Troubleshooting Status Panel LEDs - 1

Status Panel LEDs

On the next page is an illustration that shows the possible LED

patterns that can occur with the Personal LaserWriter.

Note:

Refer to "Print Engine Check" in Flowcharts for full

troubleshooting paths.

Page 34

Troubleshooting Status Panel LEDs - 2

Front Access Door Open

No Toner Cartridge

or Face-Up Cover Open

System Theory” in Basics.)

LS and LS/L display only

these configurations

(see “LS Error Messages”)

(see PS11/PS502 in “Sensing

Ready Paper

Out

Paper

Jam

I/O Board

Alternating

FLASH

Fuser or

Laser/Scanner

Simultaneous

FLASH

Page 35

Troubleshooting Capacitor Discharge - 3

Capacitor Discharge

When there is a failure of the fusing system, the DC controller

board shuts off current to the fuser roller heater and charges

capacitor C212 to prevent overheating (C209 on the LS/L serial

controller board).

DC Controller Board

(SC, NT, NTR, LS)

C212

C209

Serial Controller

(LS/L)

Page 36

Troubleshooting Capacitor Discharge - 4

Before you can use the printer again, you must switch the power

off and wait 3 minutes for the capacitor to discharge. If you do not

want to wait, you can manually discharge the capacitor as

described below.

Remove the top cover, locate the capacitor described on the

previous page, and carefully jumper the two wires at the base of

the capacitor as shown on the next page.

Note:

Remove the I/O board and/or shield if you are servicing an

SC, NT, or NTR. Remove the PCB shield if you are servicing an LS/

L.

Caution:

components around the capacitor. There are many different tools

that can be used to discharge the capacitor: a flat blade

screwdriver, paper clip, or aluminum foil doubled over. The tool

illustrated is a length of lead solder. It has the advantage of being

ductile and is less apt to damage the controller board.

Take care not to damage the board tracings or the

Page 37

Troubleshooting Capacitor Discharge - 5

Capacitor C212

(C209 on LS/L)

Page 38

Troubleshooting LS Error Messages - 6

LS Error Messages

The SC, NT, and NTR display errors through status panel readouts

(see “Status LEDs”). The LS and LS/L display errors through

alert dialogs on the host computer.

For other hardware-related messages, go to “Print Engine

Check.” For non-hardware error messages, follow the prompt

given, or call the Apple Technical Assistance Center.

Note:

If you are having communication problems with an LS,

make sure that you have used the installer to load the printer

driver.

Page 39

Troubleshooting Roller Diameters - 7

Roller Diameters

Repetitive printing defects can often be isolated by measuring the

tracking left by rollers. On the next page is a diagram that shows

all the rollers in the Personal LaserWriter that come into contact

with paper. The dimension given is the distance between tracks.

Page 40

Troubleshooting Roller Diameters - 8

Toner Cartridge Rollers

1.5" (38 mm): primary charging roller

2.0" (51 mm): developer roller

3.7" (94 mm): photosensitive drum

Fuser Assembly

2.15" (54 mm): lower fuser roller

2.9" (74 mm): upper fuser roller

Other Rollers

1.9" (49 mm): paper feed roller

2.05" (52 mm): transfer roller

Page 41

Troubleshooting Drum Check - 9

Drum Check

Interrupting a print cycle and inspecting the photosensitive drum

can help isolate the cause of print quality problems. If the image

on the surface of the drum exhibits the same problem as the

printed page, the fault is before the drum, probably somewhere in

the scanning system.

If the image on the drum is okay, the fault is after the drum,

probably in the fuser assembly, transfer roller, or high-voltage

power supply.

Note:

Refer to “Roller Diameters” in this chapter for further

quick-check troubleshooting tips.

Page 42

Troubleshooting Flowcharts - 10

Flowcharts

The flowcharts for this manual are contained in an interactive file

called “PLW SC/NT/NTR/LS Flowcharts.” This file has been

derived from the original version of Service Source but is a

standalone self-launching application. To launch this file, click

the button below..

Page 43

220/240V

Models

CB101

BK BKCB101

TB101 TB102

L

IL101

N

RT101

TB102

C101

C102

Power Supply

C101

C102

L101

Door

Switch

Unit

L101

R101

J11

VZ101

ACH

ACLFU1

FSRDRV

Power

Switch

SW11

256

3

TB103

YB105

TB106

TB104

C104 Q101

TB107

J102

1

2

J152

TB109-2

2

1

TB109-1

+5V

TB108

Door

Switch

L102

2

J101

SQ101C103

Fuser

PCB

Assembly

TB501

TB502

1

1A 3A

1B 3B

SW101

R102

R103

SSR101

426

1

R104

Front Access Door

Fuser Assembly

TP1

J501

1

RT501

TP2

3

Roller

Clutch

Solenoid

RT502

TH1

SL501Pick-Up

Fixing

DC PCB

H1

1

1

TB503

RT505 RT102

D502

RT503 RT504

3

2

J5802

3

2

TB504

D501

J503

132

PS501

C

GND

Multi-Purpose

Tray

Paper

Sensor

A

J504

Cartridge Sensor

Delivery Paper Sensor

PS11

PS12

CGA

CGA

J13

123

123

12312

TB702 J12

TB703

R701

3

R702

PS502

C

-1-3-2

Exhaust Fan

123

J701

Driver

VR701

GND

Fan

A

Delivery

Unit

Door

Open

Sensor

FM11

EP-L Cartridge

Primary Charging

Roller

Drum

Developing

Cylinder

Transfer

Charging

Roller

RT103

RT104

FT101

1

4

P. Primary

TB601

SG

T. Transfer

J602

HVT

+24V

GND

HVACVR+8V

123456789

J601

RT105

J602

2

D. Development

HVDC

HVT1

HVD

HVT2

10

HVT3

Cassette Paper Feeder

GND

SW903

A

R902

R901

SW902

SW901

Cassette

Feed

Roller

Clutch

Solenoid

SL902

5

4

Q902 Q901

Cassette

Paper

Sensor

PS901

C

132

132

J902 J905

R904

Cassette Size

Sensing

Switches

R903

123456789

Cassette

Pick-Up

Roller

Clutch

Solenoid

SL901

7

6

Cassette

Paper

Feeder

PCB

Main Motor

+5V

+5V

BRBRBL

GND

GND

BL

J212

4

3

2

1

GND

+24V

GND

+24V

GND

+12V

GND

BLBLRRBLORBLBRY

123456789

GND

GND

GND

GND

+24V

+24V

+12V

SG

PPRDY

TOP

A1A2A3A4A5A6A7A8A9

J301

J302

GND

GND

+5V

+5V

LED Power

LED 1

LED 2

123

123

4

4

LED 3

J303

Display Panel

+5V

FSRDRV

+5V

FSRDRV

STS

CBSY

N.C.

VDOI

CCLK

/CCLK

/PRFD

/VDO

J304

A1A2A3A4A5A6A7A8A9

PS13

Pick-up Unit

Paper Sensor

C

GND

A

123

J208 J14

123

GND

PFA

PFSNS

PRFD

RESET

BOO

RDY

SBSY

PCLK

B1B2B3B4B5B6B7B8B9

A10

Interconnect PCB

Reserved

/CBSY

/STS

/TOP

/PPRDY

LED Power

PRNT

LED 1

A10

CPRDY

CMD

Reserved

A11

GND

A12

N.C.

N.C.

TSTPNT

B10

GND

GND

GND

GND

A13

A14

A15

A16

I/O Board

123456789

J209

POA

GND

PFDRV

/CMD

FSRTH

/CPRDY

POUT

/PRNT

GND

/PCLK

DOSNSE

/SBSY

/RDY

+24V

Reserved

Reserved

B1B2B3B4B5B6B7B8B9

123456789

TB701J213

10

123456789

+8V

DOA

GND

+12V

DC Controller

/BD

LED 2

LED 3

+5V

B11

B12

B10

+5V

B13

+5V

+5V

B14

POSNS

DOSNSE

+5V

B15

FMDRV

+5V

B16

CNTD

VR

GND

Density

Adj.

PCB

1234567

1234567

J401 J202

J204

+5V

GND

Laser

Driver

123456789

J206

Optical Fiber

GND

+24V

APCIN

LSRPWR

VDOUT

GND

+8V

M1

SCNCLK

SCNTAC

J205 J901

SCNON

+12V

1

1

123456789

+5V

+5V

+24V

OPSIZ2

OPMD

OPSIZ1

OPSIZ0

OPPOUT

+5V

+12V

123456789

J207

10

VR

+8V

HVD

HVTI

HVT2

HVDC

HVT3

GND

65432

65432

J301 J203

HVAC

+24V

OPCD

GND

GND

RDYNH

12345

J210

COA

LPC

TSS

TSC

+8V

6

OAOBOA

OB

COB

APCIN

TSTPE

TSTPNT

10

11

12

Scanner

Motor Unit

Personal LaserWriter SC/NT

Wiring Diagram

Page 44

220/240V

Models

CB101

BK BKCB101

TB101 TB102

L

IL101

N

RT101

TB102

C101

C101

L101

C102

Power Supply

Unit

L101

C102

Door

Switch

R101

Power

Switch

J11

VZ101

ACH

ACLFU1

FSRDRV

SW11

256

3

TB103

YB105

TB106

TB104

C104 Q101

TB107

J102

1

2

J152

TB109-2

2

1

TB109-1

+5V

TB108

Door

Switch

L102

J101

SQ101C103

Fuser

PCB

Assembly

TB501

TB502

2

1A 3A

1B 3B

SW101

R102

SSR101

426

R104

1

R103

1

Pick-Up

Roller

Clutch

Solenoid

Front Access Door

Fuser Assembly

TP1

J501

1

RT501

TP2

3

RT502

SL501

TH1

Fixing

DC PCB

H1

1

1

TB503

RT505 RT102

D502

RT503 RT504

3

2

3

2

TB504

J5802

D501

J503

132

PS501

C

GND

MultiPurpose

Tray

Paper

Sensor

A

J504

Cartridge Sensor

Delivery Paper Sensor

PS11

PS12

CGA

CGA

J13

123

123

12312

TB702 J12

TB703

R701

3

R702

PS502

C

GND

A

-1-3-2

Exhaust Fan

123

J701

Fan

Driver

VR701

Delivery

Unit

Door

Open

Sensor

FM11

EP-L Cartridge

Primary Charging

Roller

Drum

Developing

Cylinder

Transfer

Charging

Roller

RT103

RT104

FT101

1

4

J602

TB601

SG

P. Primary

T. Transfer

HVT

+24V

GND

HVACVR+8V

123456789

J601

RT105

J602

2

D. Development

HVDC

HVT1

HVD

HVT2

10

HVT3

Cassette Paper Feeder

GND

SW903

A

R902

R901

SW902

SW901

Cassette

Feed

Roller

Clutch

Solenoid

SL902

5

4

Q902 Q901

Cassette

Paper

Sensor

PS901

C

132

132

J902 J905

R904

Cassette Size

Sensing

Switches

R903

123456789

Cassette

Pick-Up

Roller

Clutch

Solenoid

SL901

7

6

Cassette

Paper

Feeder

PCB

Main Motor

Display

Panel

J208 J14

PS13

C

123

123

PFSNS

GND

GND

Pick-up Unit

Paper Sensor

A

PFA

123456789

J209

GND

+24V

POUT

FSRTH

PFDRV

GND

POA

10

GND

DOSNSE

123456789

TB701J213

123456789

+8V

DOA

+12V

+5V

POSNS

DOSNSE

Density

Adj.

M1

PCB

J204

VR

GND

CNTD

FMDRV

123456789

J206

Optical Fiber

VR

GND

+24V

HVAC

+8V

HVDC

HVTI

HVD

10

HVT2

J205 J901

HVT3

123456789

+5V

+24V

OPSIZ2

OPSIZ1

OPSIZ0

OPMD

OPPOUT

OPCD

GND

12345

J210

COA

6

OAOBOA

OB

COB

GND

+24V

GND

+24V

GND

BLBLRRBLORBLBRY

123456789

J212

GND

GND

GND

+24V

+24V

+12V

+12V

GND

GND

+5V

+5V

FSRDRV

FSRDRV

DC Controller

SG

PPRDY

TOP

STS

CBSY

N.C.

VDO

CCLK

PRFD

N.C.BDRDY

SBSY

PCLK

PRNT

CPRDY

CMD

+5V

N.C.

N.C.

A1A2A3A4A5A6A7A8A9

1

1

2

2

3

3

4

4

LED Power

LED 1

LED 2

LED 3

J301

J803

B1B2B3B4B5B6B7B8B9

A10

I/O Board

B10

+5V

GND

APCIN

LSRPWR

1234567

1234567

J401 J202

Laser

Driver

VDOUT

GND

+8V

GND

SCNCLK

SCNTAC

SCNON

65432

65432

J301 J203

Scanner

Motor Unit

+12V

+5V

1

1

+5V

+24V

GND

RDYNH

LPC

+12V

123456789

J207

TSS

TSC

+8V

APCIN

10

TSTPE

11

TSTPNT

12

Personal LaserWriter LS

Wiring Diagram

Page 45

K

Service Source

T ak e Apart

PLW SC/NT/NTR/LS

Page 46

Take Apart Top Cover - 1

Top Cover

Top Cover

This topic applies to all

models of the printer.

No preliminary steps are

required before you begin

this procedure.

Page 47

Take Apart Top Cover - 2

1 Open the front access

door.

2

Note:

There is a pin on

the inside of the rear

panel that seats in a

notch in the chassis. You

must shimmy the cover

about an inch toward the

rear of the printer to

unseat this pin before

you can lift off the cover.

Remove the two screws

and lift off the top cover.

Page 48

Take Apart Front Cover - 3

Front Cover

This topic applies to all

models of the printer.

No preliminary steps are

required before you begin

this procedure.

1 Open the front access

door.

Front Cover

Page 49

Take Apart Front Cover - 4

2 Remove the two screws

that secure the front

Holding

Tab

cover to the front access

door. Lift up the facedown delivery assembly

and using needlenose

pliers release the

holding tab.

3 Lift off the front cover.

Face-Down

Delivery

Assembly

Front Cover

Page 50

Take Apart Front Cover - 5

Screw

Mount

Grooves

Right Holding Notch

Front Door

Replacement Note:

Lower

the multipurpose tray and

remove the face-up delivery

tray. Insert the right

holding tab first, then

swing the cover to the left,

making sure that the two

screw mounts align with the

grooves in the side of the

door. Press firmly until the

front cover snaps into place.

Page 51

Take Apart LED Cover - 6

LED Cover

This topic applies to all

models of the printer.

LED Cover

Before you begin, remove

the front cover.

Page 52

Take Apart LED Cover - 7

1 Remove the two screws

that secure the LED

cover to the front access

door.

LED Cover

Page 53

Take Apart LED Cover - 8

2 Lift off the LED cover

and disconnect the LED

cable from the LED

holder.

LED Cable

Connector

Page 54

Take Apart Cassette Feeder Tray - 9

Cassette Feeder Tray

This topic applies to all

models of the printer.

No preliminary steps are

required before you begin

this procedure.

Note:

The cassette feeder

tray and its associated parts

are optional on the LS, LS/L,

and NTR models.

Cassette Feeder Tray

Page 55

Take Apart Cassette Feeder Tray - 10

1 Turn the printer upside

down so that it is resting

on its top.

2 Remove the four

mounting screws and

lift off the cassette

Cassette

Feeder

Tray

feeder tray.

Page 56

Take Apart Pedestal Covers - 11

Pedestal Covers

Cassette

Stop

Cover

Left

Bottom

Cover

Right

Bottom

Cover

This topic applies to all

models of the printer.

Before you begin, remove

the cassette feeder tray.

Note:

The cassette feeder

tray and its associated parts

are optional on the LS, LS/L,

and NTR models.

Page 57

Take Apart Pedestal Covers - 12

1 Unhook the spring from

the cassette feeder tray,

Cassette Stop Cover

and remove the cassette

stop cover.

Spring

Page 58

Take Apart Pedestal Covers - 13

2

Caution:

Be careful not

to damage the cassette

Cassette

Microswitches

microswitches when

removing or replacing

the right bottom cover.

If you need to take apart

the right bottom cover,

remove the three

screws that secure it to

the cassette feeder tray.

3 Lift off the right bottom

cover.

Right Bottom Cover

Page 59

Take Apart Pedestal Covers - 14

4 If you need to take apart

the left bottom cover,

remove the two screws

that secure it to the

Left Bottom Cover

cassette feeder tray.

5 Lift off the left bottom

cover.

Page 60

Take Apart Cassette Feeder Roller Shaft - 15

Cassette Feeder Roller Shaft

This topic applies to all

models of the printer.

Before you begin, remove

the following:

• Cassette feeder tray

• Pedestal covers

Note:

The cassette feeder

tray and its associated parts

are optional on the LS, LS/L,

and NTR models.

Cassette Feeder Roller Shaft

Page 61

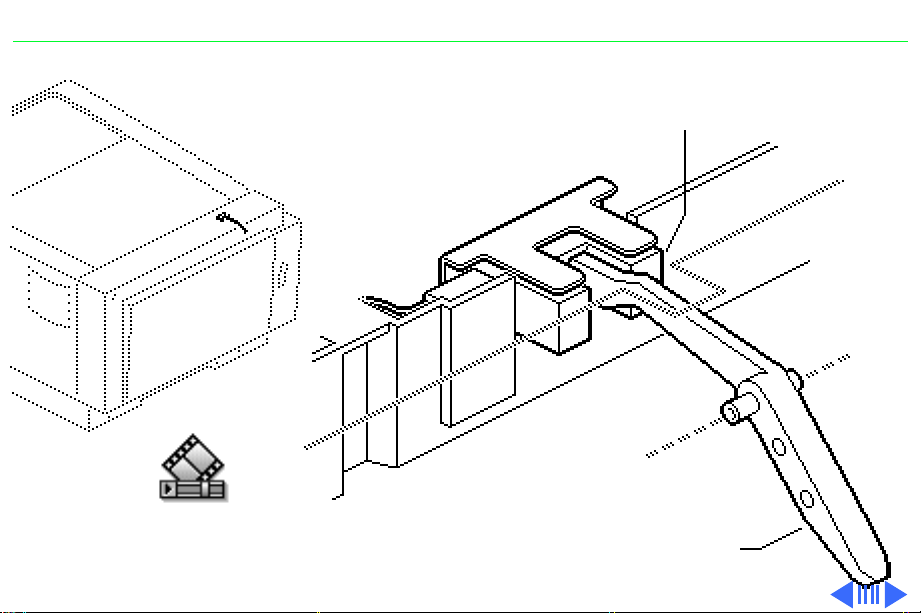

Take Apart Cassette Feeder Roller Shaft - 16

1 Using a small

screwdriver or gripring pliers, remove the

E-rings at each end of

Feeder

Roller

Shaft

the feeder roller shaft

(opposite end not

shown).

E-Ring

2 Slide off the two white

gears.

White

Gears

Page 62

Take Apart Cassette Feeder Roller Shaft - 17

3 Remove the holding pin.

4 Unhook the three plastic

feeder roller clamps

Feeder

Roller

Shaft

(rightmost clamp is

shown).

Roller

Clamp

Holding Pin

Page 63

Take Apart Cassette Feeder Roller Shaft - 18

5 Slide the bushings off

each end of the feeder

roller shaft (opposite

end not shown) and

Feeder

Roller

Shaft

Bushing

remove the shaft from

the cassette feeder tray.

Page 64

Take Apart Cassette Pickup Roller Shaft - 19

Cassette Pickup Roller Shaft

This topic applies to all

models of the printer.

Before you begin, remove

the following:

• Cassette feeder tray

• Pedestal covers

Note:

The cassette feeder

tray and its associated parts

are optional on the LS, LS/L,

Cassette Pickup

Roller Shaft

and NTR models.

Page 65

Take Apart Cassette Pickup Roller Shaft - 20

Pickup Roller

Shaft

Pickup Clutch Assembly

Setscrew E-Ring

1 Using a small

screwdriver or gripring pliers, remove the

E-rings at each end of

the pickup roller shaft

(opposite end not

shown).

2

Note:

Do not lose the

small metal holding pin

mentioned in the

following step. You will

need the pin when

replacing the pickup

roller.

Using a 1.5 mm Allen

wrench, loosen the

setscrew and remove the

Page 66

Take Apart Cassette Pickup Roller Shaft - 21

clutch assembly. The

holding pin from the

roller shaft will fall into

your hand.

Page 67

Take Apart Cassette Pickup Roller Shaft - 22

Pickup Roller

Shaft

Bushing

3 Slide the bushings off

each end of the pickup

roller shaft (opposite

end not shown) and

remove the shaft from

the cassette feeder tray.

Page 68

Take Apart Cassette Pickup Roller Shaft - 23

Pickup Roller

Pickup Clutch Assembly

0.2 mm

Replacement Note:

When

replacing the pickup roller

shaft, give special care to

the following:

• Rotate the roller shaft

so that the crescentshaped pickup rollers

protrude through the

sheet metal.

• Be careful not to let

the holding pin slide

out of the shaft when

sliding the pickup

roller clutch onto the

roller shaft.

• Place a 0.2-mm

thickness gauge

between the cassette

Page 69

Take Apart Cassette Pickup Roller Shaft - 24

pickup roller clutch

and the E-ring.

• Adjust the setscrew so

that the distance

between the pickup

roller clutch and the

E-ring is 0.2 mm.

Then tighten the

setscrew into position.

Page 70

Take Apart Cassette Feeder Board - 25

Cassette Feeder Board

Cassette Feeder

Board

This topic applies to all

models of the printer.

Before you begin, remove

the following:

• Cassette feeder tray

• Cassette stop cover

• Right bottom cover

Note:

The cassette feeder

tray and its associated parts

are optional on the LS, LS/L,

and NTR models.

Page 71

Take Apart Cassette Feeder Board - 26

1 Remove the four black

screws that secure the

cassette feeder board to

Cassette Feeder Board

the feeder tray.

2 Disconnect connector

J902.

3 Remove the cassette

feeder board from the

cassette feeder tray.

J902

Cassette Feeder Tray

Page 72

Take Apart I/O Board (SC, NT, NTR) - 27

I/O Board (SC, NT, NTR)

I/O Board (SC,

NT, NTR)

This topic applies to the only

SC, NT, and NTR models.

Before you begin, remove

the top cover.

Note:

If the I/O board is

removed from the printer,

the LEDs no longer function.

Page 73

Take Apart I/O Board (SC, NT, NTR) - 28

1 Loosen the two screws

I/O Board

that secure the I/O board

to the shield.

I/O Shield

2 Handling the I/O board

only by the metal

bracket, carefully slide

the I/O board out of the

I/O shield.

Note:

Before returning an

I/O board to Apple, remove

the metal connector

bracket. Keep this bracket

and install it on the

replacement I/O board. If

you are replacing an NTR

board that has Rev. 4.0

ROMs, you need to remove

Page 74

Take Apart I/O Board (SC, NT, NTR) - 29

the ROMs and install them on

the replacement board.

Refer to “NTR ROM

Upgrade” in Upgrades for

complete information.

Replacement Note:

Reinstall the I/O board

component-side down.

Page 75

Take Apart I/O Shield (SC, NT, NTR) - 30

I/O Shield (SC, NT, NTR)

I/O Shield

(SC, NT, NTR)

This topic applies only to the

SC, NT, and NTR models.

Before you begin, remove

the following:

• Top cover

• I/O board

Page 76

Take Apart I/O Shield (SC, NT, NTR) - 31

1 Remove the five

mounting screws and

lift the I/O shield from

the chassis.

I/O Shield

Page 77

Take Apart End Plate (SC, NT, NTR) - 32

End Plate (SC, NT, NTR)

This topic applies only to the

SC, NT, and NTR models.

Before you begin, remove

the following:

End Plate

(SC, NT, NTR)

• Top cover

• I/O board

• I/O shield

Page 78

Take Apart End Plate (SC, NT, NTR) - 33

1 Remove the four

mounting screws and

lift the end plate out of

the chassis.

End Plate

Page 79

Take Apart I/O Shield (LS) - 34

I/O Shield (LS)

This topic applies only to the

LS model.

I/O Shield (LS)

Before you begin, remove

the top cover.

Page 80

Take Apart I/O Shield (LS) - 35

1 Remove the seven screws

that secure the I/O

shield and lift the I/O

shield from the printer.

I/O Shield

Page 81

Take Apart I/O Board (LS) - 36

I/O Board (LS)

This topic applies only to the

I/O Board (LS)

LS model.

Before you begin, remove

the following:

• Top cover

• I/O shield (LS)

Page 82

Take Apart I/O Board (LS) - 37

1 Disconnect the cable

I/O Board

J803

from connector J803 on

the I/O board.

2 Remove the three screws

that secure the I/O board

in place.

3 Holding the board only

by the edges, disengage it

from the I/O bracket.

Gently lift straight up,

and disconnect the I/O

board from the

controller board.

Page 83

Take Apart End Plate (LS) - 38

End Plate (LS)

End Plate (LS)

This topic applies only to the

LS model.

Before you begin, remove

the following:

• Top cover

• I/O shield (LS)

• I/O board (LS)

Page 84

Take Apart End Plate (LS) - 39

1 Remove the five

mounting screws and

lift the end plate out of

the chassis.

Page 85

Take Apart PCB Shield - 40

PCB Shield

This topic applies only to the

LS/L model.

PCB Shield

Before you begin, remove

the top cover.

Page 86

Take Apart PCB Shield - 41

1 Remove the two screws

Duct Plate

that secure the duct plate

to the printer chassis.

Lift out the duct plate.

Page 87

Take Apart PCB Shield - 42

PCB Shield

2 Remove the six screws

that secure the PCB

shield to the printer

chassis. Lift out the PCB

shield.

Page 88

Take Apart Serial Controller - 43

Serial Controller

Serial Controller

This topic applies only to the

LS/L model.

Before you begin, remove

the following:

• Top cover

• PCB shield

Page 89

Take Apart Serial Controller - 44

±

Warning:

Never

disconnect optical fiber

cable J204 when the

printer is powered on. Its

invisible laser beam can

damage your eyes.

1 Disconnect the following

cables from the serial

controller board:

• Laser assembly board

cable from J202

J204

J202

J206

J203

J205

J209

J208

J210

J212

J213

J215

• Scanner motor board

Serial Controller Board

cable from J203

• Optical fiber cable

from J204

• Cassette feeder board

cable from J205

Page 90

Take Apart Serial Controller - 45

• High-voltage power

supply cable from

J206

• Paper pickup sensor

cable from J208

• Fuser assembly cable

from J209

J204

J206

J203

J205

J209

J208

J210

• Main motor cable

J202

J212

J213

from J210

• DC power supply

cable from J212

J215

• Fan-and-sensor

board cable from

Serial Controller Board

J213

• Status light cable

from J215

Page 91

Take Apart Serial Controller - 46

2 Remove the four

mounting screws and

lift the board from its

mounting plate.

Page 92

Take Apart Serial Controller Mounting Plate - 47

Serial Controller Mounting Plate

This topic applies only to the

LS/L model.

Before you begin, remove

the following:

Serial Controller

Mounting Plate

• Top cover

• PCB shield

±Warning: Never

disconnect optical fiber

cable J204 when the

printer is on. Its invisible

laser beam can damage your

eyes.

Page 93

Take Apart Serial Controller Mounting Plate - 48

1 Disconnect the following

cables from the serial

controller board:

• Laser assembly board

cable from J202

J205

J206

J204

J203

J202

J209

J208

J210

J215

J212

J213

• Scanner motor board

cable from J203

• Optical fiber cable

from J204

• Cassette feeder board

cable from J205

• High-voltage power

supply cable from

J206

Serial Controller Board

• Paper pickup sensor

cable from J208

• Fuser assembly cable

from J209

Page 94

Take Apart Serial Controller Mounting Plate - 49

• Main motor cable

from J210

• DC power supply

cable from J212

• Fan-and-sensor

J205

J206

J204

J203

J202

J209

J208

J210

J212

J213

board cable from

J213

• Status light cable

from J215

2 Remove the cables from

the cable retainer near

J212.

J215

Serial Controller Board

Page 95

Take Apart Serial Controller Mounting Plate - 50

3 Remove the six screws

that secure the serial

controller mounting

plate to the chassis. Lift

the mounting plate out

of the printer.

Replacement Note: The

two metal tabs along the

rear mate into the

chassis on the LS/L

model.

Page 96

Take Apart Fan - 51

Fan

This topic applies to all

models of the printer.

Before you begin, remove

the top cover.

Fan

Page 97

Take Apart Fan - 52

1 Remove the two fan

J701

mounting screws.

2 Using small diagonal

cutters, carefullly cut

the tie-wrap that

secures the fan cable.

3 Disconnect fan

connector J701 from the

density-adjusting board.

Page 98

Take Apart Fan - 53

4 Unlatch the holding tab

and lift out the fan

bracket and the fan.

Replacement Note:

• Install the fan with

the label facing out.

• Place the gold-colored

grounding plate over

the fan bracket.

Holding

Tab

Page 99

Take Apart Sensor Mounting Plate - 54

Sensor Mounting Plate

Sensor Mounting Plate

This topic applies to all

models of the printer.

Before you begin, remove

the top cover.

Page 100

Take Apart Sensor Mounting Plate - 55

1 Remove the two black

mounting screws and

washers and slightly lift

the sensor mounting

plate.

Sensor

Mounting

Plate

2 Disconnect connectors

J11 and J12 and lift out

the sensor mounting

plate.

Replacement Note:

Connect connectors J11

and J12 before seating

the sensor mounting

plate.

Connector

J12

Connector

J11

Loading...

Loading...