Page 1

YCF-E Series

Class 125 Cast Iron Wye Strainer

SUBMITTAL SHEET

DESCRIPTION

The Apollo InternationalTM YCF Strainers are designed to protect piping systems and process equipment from unwanted foreign particles with minimum

pressure loss.

LEAD FREE

Job Name:

Job Location:

Engineer:

Contractor:

Tag :

PO#:

Rep:

Wholesale Dist.:

FEATU R ES

• Iron Strainer with Flat Face Flanges Conforms to

ASME/ANSI 16.1 Class 125

• One-Piece Cast Body Meets ASME Standard

PERFORMANCE RATING

• Working Pressure (non-shock):

CWP 200 PSIG @ 150°F

Not for steam service

• NSF/ANSI 372 - Lead Free

• All Models Epoxy Coating (FDA CFR21, Section 175.300)

• Equipped with Bolted Cover Employing Flat Gasket Seal

• Upper and Lower Machined Seats for Screen for SelfAligning Screen Design

• 304 SS Perforated Screens are Standard

(P045 STD 2”-3”, P125 STD 4”-12”)

• Tapped Blow-O Connection with Plug

• 100% Factory Pressure Tested

OPTIONS

• (M20) – 20 Mesh

• (M40) – 40 Mesh

• (M80) – 80 Mesh

• (M100) – 100 Mesh

• (P045) – .045” Perf (Standard 2”-3”)

• (P125) – 1/8” Perf (Standard 4”-12”)

NOTES:

All screens not available for all sizes.

For wire mesh screens, a P045 perf. liner is added to support the mesh screen.

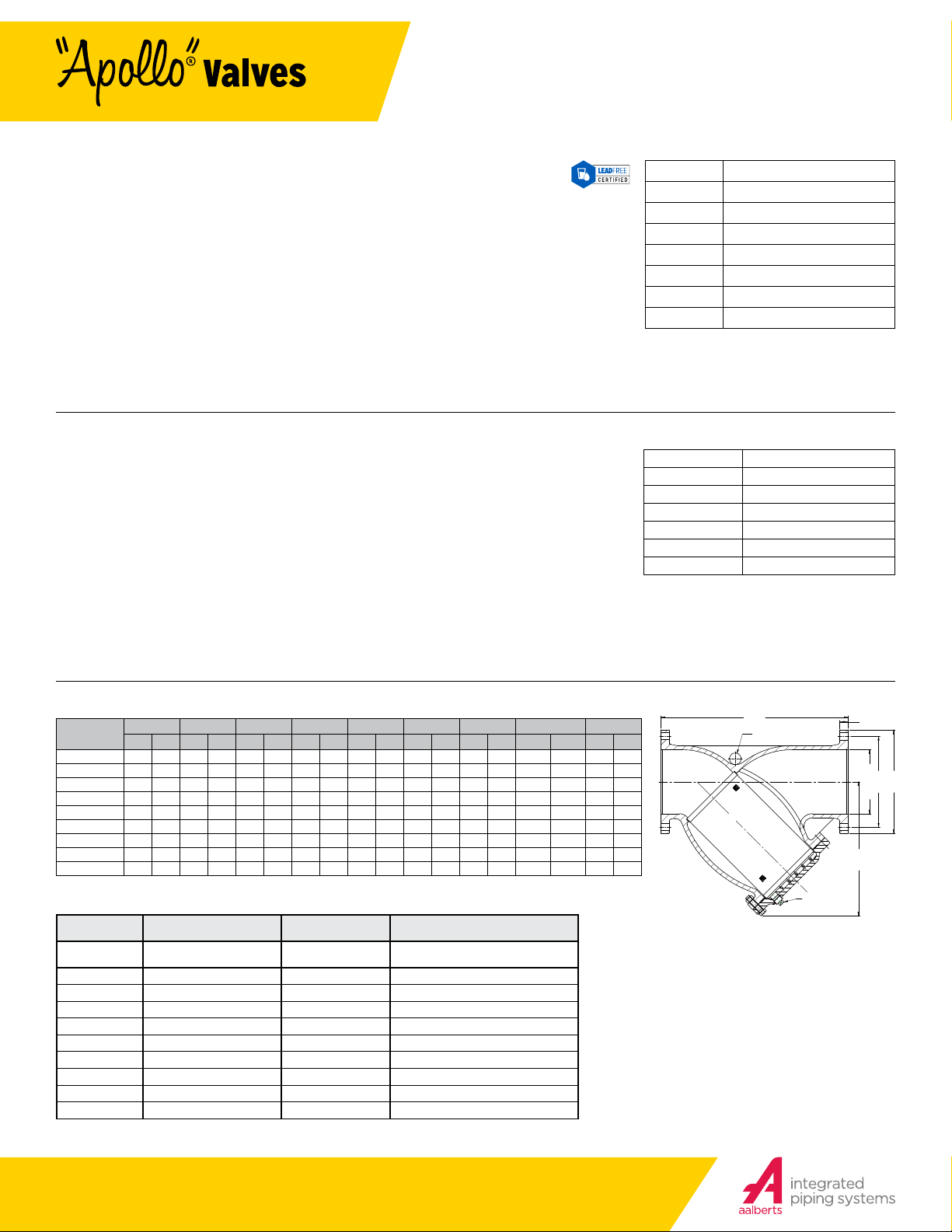

DIMENSIONS

PART

NUMBER

YCF02P045E 2” 50 8.86 255 0.63 16 5.98 152 4.75 121 0.75 19 6.30 160 1/2” 4 23 11

YCF25P045E 2-1/2” 65 10.75 273 0.69 18 7.01 178 5.50 140 0.75 19 7.6 4 194 1” 4 34 15

YCF03P0 45E 3” 80 11.50 292 0.75 19 7.48 190 6.00 153 0.75 19 8.86 225 1” 4 47 21

YCF04P125E 4” 100 13.86 352 0.94 24 8.98 228 7. 50 191 0.75 19 10.63 270 1-1/4 ” 8 72 33

YCF05P125E 5” 125 16.38 416 0.94 24 10.00 254 8.50 216 0.88 22 12.60 320 1-1/4 ” 8 111 50

YCF0 6P125E 6” 150 18.50 470 1.00 25 10.98 279 9.50 242 0.88 22 14.69 373 1-1/2” 8 150 68

YCF08P125E 8” 200 21.38 543 1.12 29 13.46 3 42 11.75 299 0.88 22 17.7 2 450 1-1/2” 8 235 107

YCF10P 125E 10” 250 25.98 660 1.18 30 15.98 406 14.25 362 1.00 25 20.67 525 2” 12 369 168

YCF12P125E 12” 300 30.00 762 1.25 32 19.02 483 17.00 432 1.00 25 23.94 608 2” 12 552 250

SIZE/DN A B C D E F DRAIN PLUG WEIGHT

IN MM IN MM IN MM IN MM IN MM IN MM IN MM IN MM LB. KG.

STANDARD MATERIALS LIST

BODY

CAP/COVER

PLUG

BO LT/ST U D/ NUT

SCREEN

GASKET

COATING

Cast Iron, AS TM A126-B

Cast Iron, AS TM A126-B

Carbon Steel, A STM A307

Carbon Steel, A STM A307

304 Stainless Steel

Graphite

Epoxy, FDA Approved

Au0.090

HOLE PRESENT ON 4"

THRU 12" ONLY

B +0.060 - 0.000

0.040

u

0.060

u

D

SIZE/DN

0.100

u

F

0.060

u

C

PART NUMBER MATRIX

DRAIN PLUG

YCF XXX XXX[X] X

CONNECTION SIZE SCREEN TYPE OPTION

YCF (FLAT FACE) F02 - FLANGED 2” M20 - 20 MESH E - EPOXY COATING, FDA APPROVED

F25 - FLANGED 2.5” M40 - 40 MESH LEAD FREE ONLY, NOT FOR STEAM

F03 - FLANGED 3” M80 - 80 MESH

F04 - FLANGED 4” M100 - 100 MESH

F05 - FLANGED 5” P045 - .045” PERF

F06 - FLANGED 6” P125 - .125” PERF

F08 - FLANGED 8”

F10 - FLANGED 10”

F12 - FLANGED 12”

*LEAD FREE: The wetted surfaces of this product shall contain no more than 0.25% lead by weighted average. Complies with Federal Public Law 111-380. ANSI 3rd party approved and listed.

(704) 841-6000

apollovalves.com

SS1001 © 07/18 Page 1 of 1

This specification is provided for reference only. Apollo reserves the right to change any portion of this specification

without notice and without incurring obligation to make such changes to Apollo products previously or subsequently

sold. Most current information available at apollovalves.com.

Loading...

Loading...