Page 1

Therma-Seal

™

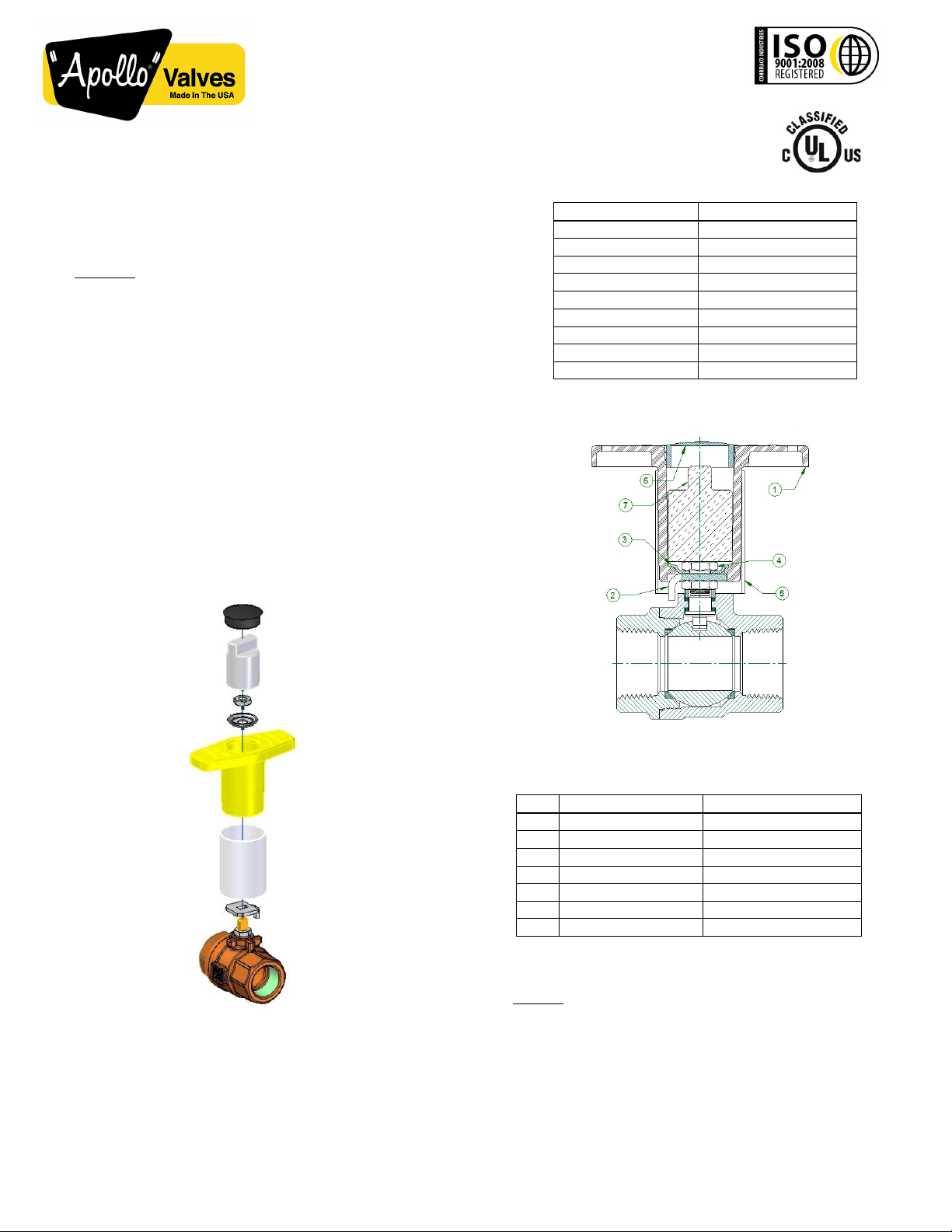

Insulating Tee-Handle

Assembly Instructions

Conbraco Industries, Inc. 701 Matthews Mint Hill Rd. Matthews NC 28106 USA; www.apollovalves.com ; 704-841-6000

This specification is provided for reference only. Conbraco reserves the right to change any portion of this specification without

notice and without incurring obligation to make such changes to Conbraco products previously or subsequently sold.

I931300 Rev. C

ECN M14888

Installation of the Apollo® Thermal-Seal™ thermal insulating

tee-handle is simple and can be accomplished without any

specialized tools.

Warning: Do not attempt to work on any valve under

pressure. De-pressurize the piping system before any work

begins. Use appropriate protective gear as required to protect

against possible burns or uncontrolled release of fluids.

Step 1: Remove any existing handle or other operating

mechanism and set aside.

Step 2: Install the stop plate, item 2, as shown in figures 1 and

2.

Step 3: Place the plastic sleeve, item 5, over the molded teehandle, item 1. See figure 2.

Step 4: Place the molded handle and sleeve over the stop

plate as shown. Make certain the stop plate and tee-handle

are properly aligned.

Step 5: Position the cup washer, item 3, and handle nut, item

4, as shown. Tighten the handle nut to the torque shown in

table 1. An appropriately sized deep well socket and torque

wrench will be required to complete this step.

Step 6: Complete the assembly by pressing the plastic cap,

Item 6, into the molded tee-handle.

Figure 1: Exploded View

Table 1: Handle Nut Assembly Torque

Figure 2: Sectional View

Table 2: Standard Materials List

Caution: Handle should not be used in applications where its

temperature will exceed 275°F. Secure the clear plastic sleeve off the

valve body and direct the flame away from the core of the valve when

installing solder end valves.

Kit Number

Handle Nut Torque

78218301

35-40 in. lbs.

78218401

50-55 in. lbs.

78218501

100-110 in. lbs.

78219001

50-55 in. lbs.

78219101

70-75 in. lbs.

78219201

95-105 in. lbs.

78231001

144-216 in. lbs.

78233001

55-65 in. lbs.

78233101

55-65 in. lbs.

Item

Name

Material

1

Molded Tee-Handle

Glass reinforced nylon

2

Stop Plate

Zinc plated steel

3

Cup Washer

Zinc plated steel

4

Handle Nut

Zinc plated steel

5

Plastic Sleeve

Clear CAB plastic

6

Plastic Cap

Heat stabilized nylon

7

Insulation Plug

Polystyrene Foam

Loading...

Loading...