Page 1

RPLF4A Series

Reduced Pressure Principle Backflow Preventer

SUBMITTAL SHEET

DESCRIPTION

The Apollo® Model RPLF 4A Reduced Pressure Principle Backflow Preventers consist of two independently acting, TriForce™ center stem guided check

valves with a dierential pressure relief valve located between the check valves. The unit is designed to give maximum protection against backflow of

health or non-health hazard fluids by either back-pressure or back-siphonage. The durable domestic stainless steel units (2-1/2”-8”) and the FDA epoxy

coated ductile iron units (10” and 12”) are easily maintained in the line without any special tools. The TriForce™ check valves operate with a spring assist in

the flowing condition to provide excellent flow rates which are documented by an independent laboratory.

LEAD FREE

NSF/ANSI 61- 8 & 372

Job Name:

Job Location:

Engineer:

Contractor:

Tag :

PO#:

Rep:

Wholesale Dist.:

FEATU R ES

• Domestic Stainless Steel Body: 2-1/2” – 8”

• FDA Epoxy Coated Ductile Iron Body: 10” & 12”

• Easy Maintenance – No Special Tools Required

• Snap-In Check Retainers: 2-1/2” – 6”

• Bolted-In Checks: 8” – 12”

• Low Pressure loss as Documented by an

Independent Laboratory

• Center-Stem Guided TriForce™ Check Valves

• Approved for Horizontal Flow

• US Patents: 6,443,184; 7,025,085;

7,533,699; 8,240,333

• Made in the USA – ARRA Compliant

PERFORMANCE RATING

• Maximum Working Pressure: 175 psi

• Temperature Range: 33 ° F – 140 ° F

• Hydrostatic Test Pressure: 350 psi

APPROVALS

• Sizes 2-1/2” – 8”: AWWA C511

• Sizes 2-1/2” – 12”: ASSE 1013-2011,

CSA B64.4, FM, IAPMO, UL*, cUL*

• *UL and cUL installations Must Include

Indicating-Type Shut-O Valves

• NSF/ANSI 61 Water Quality (2-1/2” - 12”)

• NSF/ANSI 372 Lead Free (2-1/2” – 12”)

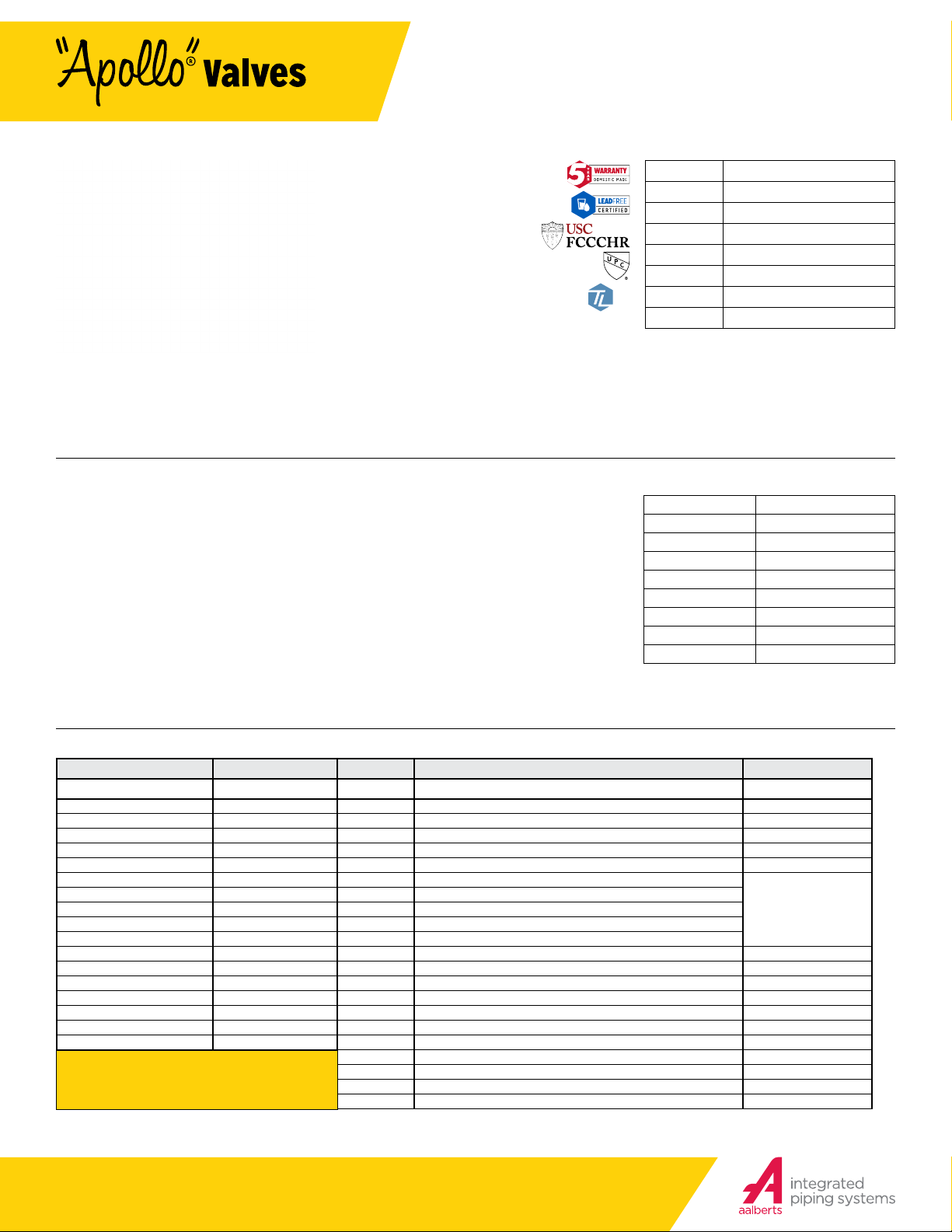

STANDARD MATERIALS LIST

BODY (2-1/2” - 8”)

BODY (10” & 12” )

COVERS (2-1/2” - 6”)

COVERS (8”)

COVERS ( 10” & 12”)

RELIEF VALVE

CHECK VALVES

SPRINGS

SEAT DISCS

304 Stainless Steel

FDA Epoxy Coated Ductile Iron

Glass Filled PP O/SS

304 Stainless Steel

FDA Epoxy Coated Ductile Iron

LF C89 836

Bronze/Glass-filled PPO/SS

Stainless Steel

Chloramine-Resistant Silicone

• Approved by the Foundation for CrossConnection Control and Hydraulic Research at

the University of Southern California (2-1/2” - 8”)

PART NUMBER MATRIX

4ALF 2 X X 0 X XX

Y-STRAINER SIZE SHUT-OFF VALVES OPTIONS

4ALF - LEAD FREE STANDARD 0 - STANDARD 9 - 2-1/2” 1 - LESS SHUT-OFF VALVES D - DOMESTIC ASSEMBLY

EXAMPLE: 4ALF 20A 07 = 4” size Lead Free

Reduced Pressure Assembly with OS&Y flanged

inlet x OS&Y grooved outlet shut-o valves.

† Butterfly valves not available in 12” size.

*LEAD FREE: The wetted surfaces of this product shall contain no more than 0.25% lead by weighted average. Complies with Federal Public Law 111-380 . ANSI 3rd party approved and listed.

1 - W/ Y-STRAINER 0 - 3" 2 - NRS FLANGE X NRS FLANGE R1 - RETROFIT*

(SHIPPED LOOSE) A - 4" 3 - OS&Y FLANGE X OS&Y FLANGE R2 - RETROFIT*

C - 6" 4 - OS&Y FLANGE X MONITORED (MON.) BUTTERFLY VALVE GROOVE

E - 8" 6 - OS&Y FLANGE X POST INDICATOR FLANGE

G - 10" 7 - OS&Y FLANGE X OS&Y GROOVE

H - 12” 8 - OS&Y GROOVE X OS&Y GROOVE

9 - MON. BUTTERFLY VALVE GROOVE X MON. BUTTERFLY VALVE GROOVE

10 - OS&Y FLANGE X POST INDICATOR GROOVE

11 - NRS GROOVE X NRS GROOVE

12 - NRS FLANGE X NRS GROOVE

13 - POST INDICATOR FLANGE X MON. BUTTERFLY VALVE GROOVE

14 - POST INDICATOR FLANGE X POST INDICATOR FLANGE

16 - MON BUTTERFLY VALVE GROOVE X POST INDICATOR FLANGE

17 - POST INDICATOR FLANGE X OS&Y GROOVE

18 - OS&Y GROOVE X POST INDICATOR GROOVE

19 - MON. BUTTERFLY VALVE GROOVE X POST INDICATOR GROOVE

20 - POST INDICATOR FLANGE X OS&Y FLANGE

21 - POST INDICATOR GROOVE X OS&Y GROOVE

22 - POST INDICATOR GROOVE X MON. BUTTERFLY VALVE GROOVE

23 - MON. BUTTERFLY VALVE GROOVE X OS&Y FLANGE

†

R3 - RETROFIT*

*CUSTOM LENGTH RETROFIT

ORDERS MUST BE ACCOM

†

PANIED WITH SIGNED FROM

#OFBFRETRO WITH EXACT

LENGTH REQUIRED.

†

†

†

-

(704) 841-6000

apollovalves.com

SS1273 © 02/19 Page 1 of 3

This specification is provided for reference only. Apollo reserves the right to change any portion of this specification without

notice and without incurring obligation to make such changes to Apollo products previously or subsequently sold.

Most current information available at apollovalves.com.

Page 2

SUBMITTAL SHEET

RPLF4A Series

Reduced Pressure Principle Backflow Preventer

LEAD FREE

Internal Component

Removal Space

Requirements

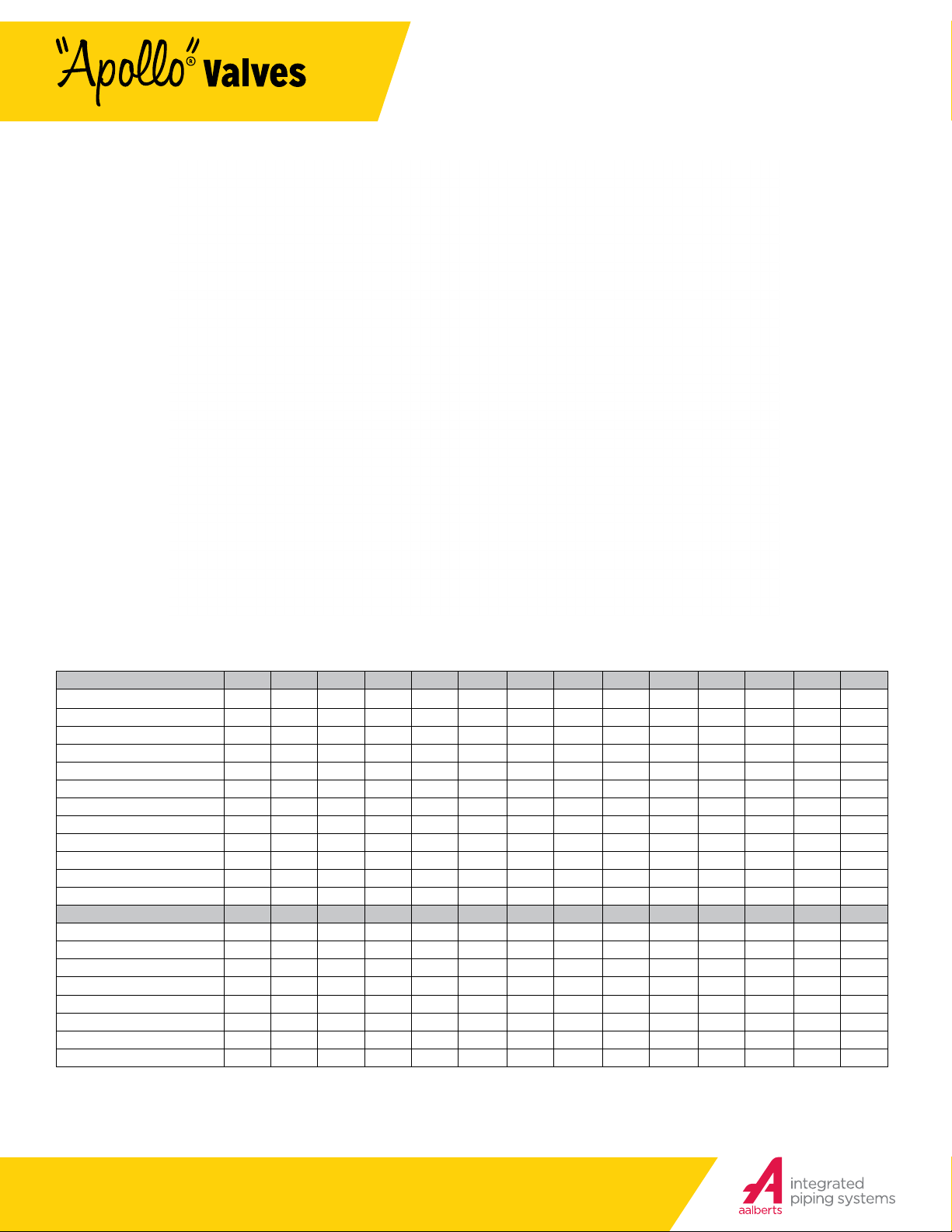

DIMENSIONS

Nominal dimensions are shown. Allowances must be made for manufacturers’ tolerances (± 1/8” (3 mm) per joint)

DIMENSIONS 2-1/2” 60 MM . 3” 75 MM. 4” 100 MM. 6” 150 MM . 8” 200 MM. 10” 250 MM. 12” 300 MM.

A (Butterfly Valves) 28 711 28.5 724 33.3 846 38.9 988 46.4 1179 56.3 1328 N/A N/A

A (Gate Valves) 31 787 32 813 38 965 45.9 1166 53.4 1356 62.3 1582 65.5 1664

B (less Shut-o Valves) 15.9 404 15.9 404 19.6 498 24.5 622 30 762 36 914 37 940

C (Butterfly Valves) 8 203 8.4 213 9.1 231 10.1 257 12 305 13.4 340 N/A N/A

C (NRS/PI Gate Valves) 11.8 300 13 330 14 356 17.8 452 21 533 24. 5 622 30 762

C (OS&Y Open) 18.8 478 20.3 515 22.1 562 29.4 747 36.8 934 45.2 1147 52.2 1326

D (Centerline to Bottom) 9.6 244 9.6 244 10.4 264 11.6 295 15.6 396 21 533 21 533

E (Width Max) 11.5 292 12 305 12.5 318 14.4 366 17.6 447 21 533 22 559

F (Check Removal Clearance) 4.8 122 4.8 122 6.5 165 7. 5 191 7. 5 191 10 254 10 254

G (With Strainer) 41.9 1064 43.6 1107 52 1321 64.5 1638 78.9 2004 88.4 2245 95.6 2428

H (Strainer Clearance) 8 203 8.8 224 9.5 241 12.6 320 16.4 417 19 483 22 559

Test Cocks (NPT) 1/2" 13 1/2" 13 1/2" 13 3/4 " 20 3/4 " 20 3/4" 20 3 /4" 20

WEIGHTS LB. KG LB. KG LB. KG LB. KG LB. KG LB . KG LB. KG

Net Wt. (Less Shuto's) 31 14 32 15 48 22 84 38 228 104 762 346 865 393

Ship Wt. (Less Shuto's) 61 28 62 28 78 35 144 65 328 149 952 433 1055 480

Net Wt. (W/ Butterfly Valves) 58 26 62 28 92 42 152 69 359 163 980 445 N/A N/A

Ship Wt. (W/ Butterfly Valves) 142 65 146 66 177 80 24 0 109 507 230 1170 532 N/A N /A

Net Wt. (W/ NRS Valves) 85 39 103 47 143 65 267 121 545 248 1269 577 1725 784

Ship Wt. (W/ NRS Valves) 169 77 187 85 228 104 355 161 693 315 1459 663 1915 870

Net Wt. (W/ OS&Y Valves) 103 47 119 54 1 74 79 327 149 620 282 1384 629 1840 836

Ship Wt. (W/ OS&Y Valves) 187 85 203 92 259 118 415 189 176 80 15 74 715 2030 923

Nominal dimensions are shown. Allowances must be made for manufacturers’ tolerances (1/8” per joint).

Internal body connections are grooved on 2 ½” – 10” sizes.

Internal body connections are flanged on 12” size.

Strainer option only available for flanged-end shut-o options.

(704) 841-6000

apollovalves.com

SS1273 © 02/19 Page 2 of 3

This specification is provided for reference only. Apollo reserves the right to change any portion of this specification without

notice and without incurring obligation to make such changes to Apollo products previously or subsequently sold.

Most current information available at apollovalves.com.

Page 3

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

0 100 200 300 400 500 600 700

Pressure Loss (psi)

Flowrate (gpm)

RPLF4A

2.5" 3" 4"

METER RATED FLOW

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

0 100 200 300 400 500 600 700

Pressure Loss (psi)

Flowrate (gpm)

RPLF4A

2.5" 3" 4"

METER RATED FLOW

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

0 200 400 600 800 1000 1200 1400 1600 1800 2000 2200 2400

Pressure Loss (psi)

Flowrate (gpm)

RPLF4A

6" 8"

METER RATED FLOW

RPLF4A Series

Reduced Pressure Principle Backflow Preventer

SUBMITTAL SHEET

FLOW CURVES

Pressure loss versus flow data as determined by independent approval agencies.

LEAD FREE

2.5" 3" 4"

Flowrate (gpm)

6" 8"

Flowrate (gpm)

10" 12"

Flowrate (gpm)

25

24

23

22

21

20

19

18

17

16

15

14

13

12

Pressure Loss (psi)

11

10

9

8

7

6

5

0 100 200 300 400 500 600 700

22

21

20

19

18

17

16

15

14

13

12

11

Pressure Loss (psi)

10

9

8

7

6

5

20

19

18

17

16

15

14

13

12

11

10

Pressure Loss (psi)

9

8

7

6

5

Meter Rated Flow

0 200 400 600 800 1000 1200 1400 1600 1800 2000 2200 2400

0 250 500 750 1000 1250 1500 1750 2000 2250 2500 2750 3000 3250 3500 3750 4000 4250 4500

RPLF4A

RPLF4A

RPLF4A

METER RATED FLOW

METER RATED FLOW

METER RATED FLOW

(704) 841-6000

apollovalves.com

SS1273 © 02/19 Page 3 of 3

This specification is provided for reference only. Apollo reserves the right to change any portion of this specification without

notice and without incurring obligation to make such changes to Apollo products previously or subsequently sold.

Most current information available at apollovalves.com.

Loading...

Loading...