Page 1

TOOLS

FITTINGS

FASTENERS

PEX Product Catalog

MANIFOLDS

TUBING

Page 2

TOOLS

PEX

Why Use PEX? What Is PEX?

Cross-linked polyethylene (PEX) is a high-temperature, flexible, polymer pipe. Cross-linking technology was first developed in

Europe and has since come into use around the world for a variety of applications. PEX has a 30-year history of successful use in

the European market with extensive testing for durability and material performance. It was first introduced in North America in 1984

where it has been primarily used for radiant floor heating, and more recently, for domestic water distribution systems. It is approved

for potable hot and cold water supply systems in all model plumbing and mechanical codes across the United States including

California and Canada.

Why Plumb With PEX?

• Easy to Install - PEX tube is joined with an easy to install test “crimp” system; no solvent welding with messy chemicals, no chance

of fire hazard possibilities due to soldering

• Cost Effective - When installed using Manifolds fewer ttings are needed to install PEX; meaning you save money in material and

time. PEX tubing also costs less than copper tubing.

• Availability of Pipe Sizes - PEX piping is available in a wide range of diameters.

• Energy Efciency - PEX piping minimizes heat transmission through the pipe wall.

• Quiet - When installed using Manifolds, PEX can be run in long lengths with smoother bends, meaning less water line noise. PEX

also does not amplify sound as readily as copper tube.

• Water Conservation - Well designed PEX plumbing systems can reduce the wait time for hot water to reach the xture.

• Environmentally Sound - PEX is an inert material and does not contain volatile organic compounds (VOCs).

• Installation Flexibility - PEX systems can be installed in either a conventional “branch and tee” system or a manifold system. PEX is

also great for adding xtures off of your existing copper or CPVC system.

• Corrosion Resistant - Because of PEX’s smooth inner walls, minerals do not build up as fast as with copper tubing. It is also more

resistant to the harmful effects of abrasive chemicals such as chlorine.

• Freeze Resistant - While freezing conditions often cause copper and CPVC tube to break or burst, causing thousands of dollars in

water damage, PEX tube will expand several times its original size without damage. However, it is recommended that you follow all

codes regarding water line freeze prevention.

Running PEX Tubing

FASTENERS FITTINGS

• Extreme Temperature and Sunlight - Keep PEX tube away from extreme temperatures - 12” away from recessed lighting and 6”

away from gas vents. Also keep away from attics, crawl spaces, outside walls, or insulate per plumbing codes. Also keep out of

direct sunlight.

• Allow for Mistakes - Leave extra tubing at the beginning and end of runs to simplify connection to manifolds and end points.

Immediate connection to the manifold or transition fittings and then making the run reduces the chance of cutting tube to short.

• Identify tubing runs - Clearly and permanently mark each run at each end to identify the xture it supplies (hot or cold water,

bathroom sink, kitchen sink, basement toilet, etc). Do not apply adhesive labels to PEX pipe.

• Thermal Expansion - Because PEX tube expands and contracts at about 1” per 100’ of pipe for every 10 degrees change in

temperature you must allow for expansion and contraction in long runs. This can be accomplished with an offset or expansion loop.

• PEX and Concrete - Tubing installed within or under concrete slabs should be continuous lengths of PEX tube. No ttings beneath

concrete.

• Support the Fitting - To prevent stress on the crimp joints, always support the tube before and after the tting

• Minimum Bend Radius - Do not bend tube too tightly. The minimum recommended bend radius is six times the tube size (i.e. ½”

tube = 3” bend radius). When making a 90 degree turn, use bend supports

• No Metal hangers - Metal hangers can damage PEX tube, we recommend only plastic hangers be installed. To prevent noise

transfer, only use hangers that keep the tube off of the nailing surface. Hangers should be used every 32” on horizontal runs every

4’ on vertical runs. Allow the tube to dip between hangers and never over tighten.

• Tube Through Studs - Grommets should be used when running tube through studs to prevent tube damage and reduce noise

transfer. Tube that is run within 2” of a stub nailing surface must be protected with a metal stud guard.

TUBING MANIFOLDS

2

Continued on page 3

Page 3

TABLE OF CONTENTS

PEX Tools....................................................4-5

PEX Crimp Tools..................................4

PEX Cinch Clamp Tools.......................4

PEX Miscellaneous Tools....................5

PEX Fittings...............................................6-13

Brass Couplings.................................6

Brass Elbows......................................6

Crimp Tees...........................................7

Crimp Test Plugs..................................7

Brass Adapters - MPT..........................8

Brass Adapters - FPT...........................8

Copper Stubout..................................9

Water Flex Connector.........................9

Valves..................................................9

Push Couplings.................................10

Push Elbows.....................................10

Push Tees..........................................11

Push Adapters..................................11

Push Valves.......................................11

Push Caps.........................................11

Poly Alloy Couplings.........................12

Poly Alloy Elbows.............................12

Poly Alloy Tees..................................13

Poly Alloy Plugs.................................13

PEX Fasteners.............................................14

Pinch Clamps...................................14

Crimp Rings......................................14

Pro Crimp Rings................................14

J-Hooks............................................14

Manifolds....................................................15

PEX Tubing.............................................16-17

Blue PEX Pipe Coils..........................16

Red PEX Pipe Coils...........................16

White PEX Pipe Coils........................16

White PEX Pipe Sticks......................17

PEX Oxygen Barrier Pipe..................17

Part Number Index.................................18-19

Warranty & Limitations of Liability...............19

TOOLS

FASTENERS FITTINGS

Oxygen Barrier PEX For Radiant Heating

Some applications require PEX with added oxygen barrier properties. Radiant oor heating (or hydronic heating systems) may include

some ferrous (iron-containing) components which will corrode over time if exposed to oxygen. Since standard PEX tubing allows some

oxygen to penetrate through the tube walls, “Oxygen Barrier PEX” tubing has been designed to prevent diffusion of oxygen into these

systems.

Oxygen barrier PEX has a layer of polymer laminated to the outside surface (or sandwiched internally between PEX layers). This extra

layer in your tubing will assure that no oxygen gets into your heating system. Radiant oor heating (or hydronic heating systems) may

include some ferrous (iron-containing) components which will corrode over time if exposed to oxygen. The oxygen barrier and rust

prevention allows you to use cast iron components in your system instead of all brass or bronze, which makes components like pumps

and flanges substantially less expensive and keeps them running smoothly for longer.

TUBING MANIFOLDS

3

Page 4

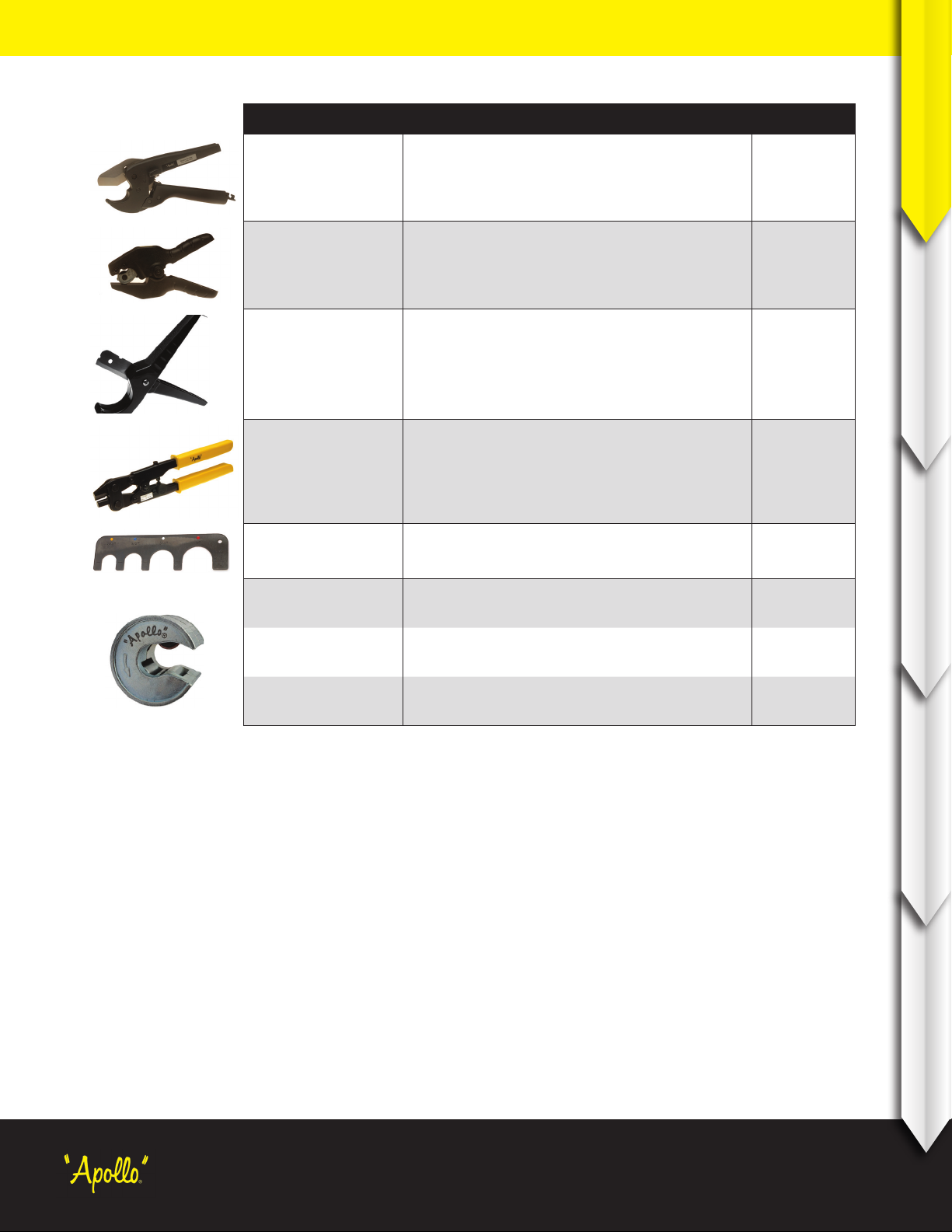

TOOLS

PEX TOOLS www.apolloflow.com

Part Number Description Pack Quantity

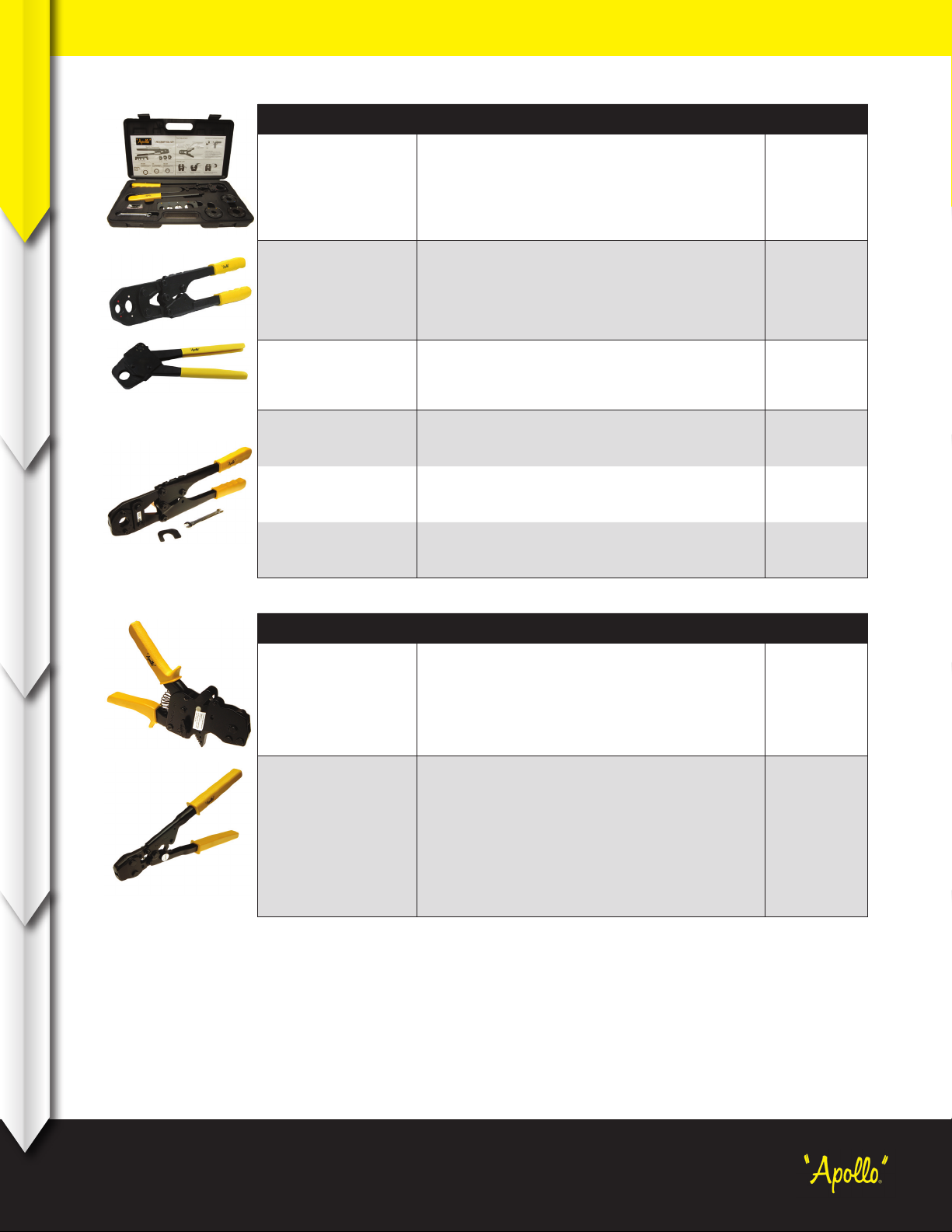

PEX CRIMP TOOLS

PEX Multi-Head Crimp Tool Kit

69PTKH0015K

69PTKH0014C PEX 1/2" & 3/4" Combo Crimp Tool 1

69PTKANG143 PEX 1/2" Angle Crimp Tool 1

69PTKH00143 PEX 1/2" Crimp Tool 1

Includes: Crimp Jaws 3/8", 1/2", 3/4", & 1",

GO / NO-GO Gauge, Adjustment Wrench

1

FASTENERS FITTINGS

MANIFOLDS

69PTKH00144 PEX 3/4" Crimp Tool 1

69PTKH00185 PEX 1" Crimp Tool 1

PEX PINCH CLAMP TOOLS

PEX One Hand Pinch Clamp Fastening

Tool

69PTBJ0010C

69PTKG1096

Fits Pinch Clamps - 3/8"-1", Ratcheting Action,

Full Auto-Release,

LED Light conrms full cinch

PEX Quick Pinch Clamp Tool

Fits Pinch Clamps - 3/8"-1"

1

5

TUBING

4

Page 5

www.apolloflow.com PEX TOOLS

Part Number Description Pack Quantity

PEX MISCELLANEOUS TOOLS

69PC02PZ

69PC03PZ

69PTKC001 PEX Tube Cutter 5

69PTKD0009

69PTKGONO Go/No-Go Gauge 20

PLTL82

Cuts up to 1-1/4” plastic and vinyl tubing

Works on PEX Rings and Clamps 1/2"-1"

Ratcheting Pipe Cutter

Clamp Pipe Cutter

Cuts up to 3/4” Copper and plastic pipe

PEX Ring Removal Tool

Cuts in seconds, making tting reusable

1/2” Quikcut Tubing Cutter

Cuts 1/2” Copper, PEX, and CPVC pipe

12

12

5

10

TOOLS

PLTL83

PLTL60 Quikcut Replacement Blades (2 Pack) 50

3/4” Quikcut Tubing Cutter

Cuts 3/4” Copper, PEX, and CPVC pipe

10

FASTENERS FITTINGS

TUBING MANIFOLDS

5

Page 6

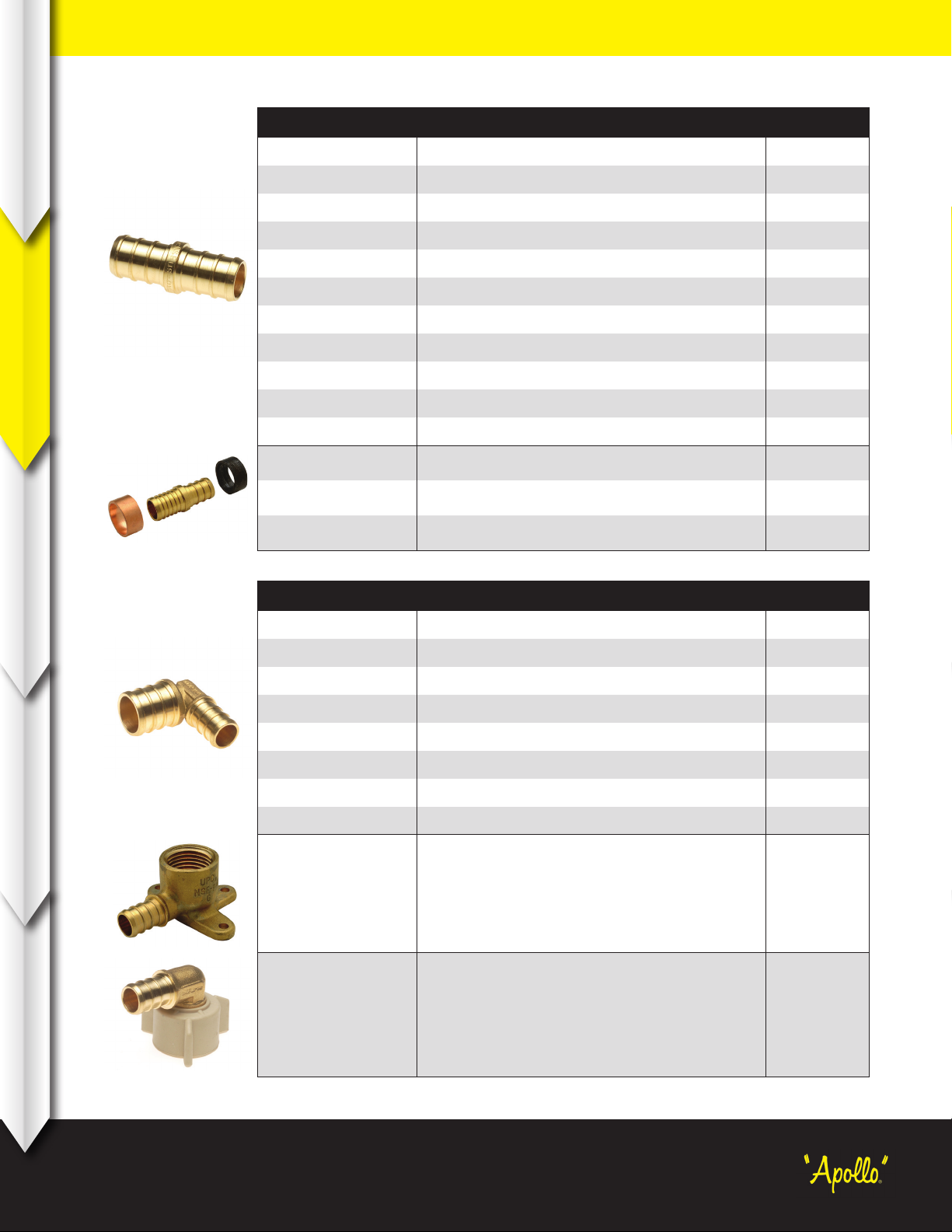

TOOLS

PEX FITTINGS www.apolloflow.com

Part Number Description Pack Quantity

BRASS COUPLINGS

APXC3838 3/8" PEX Coupling 5

APXC1212 1/2" PEX Coupling 40

APXC121210PK 1/2" PEX Coupling (10 Pack) 5

APXC1250PK 1/2” PEX Coupling (50 Pack) 5

APXC3434 3/4" PEX Coupling 25

APXC34345PK 3/4" PEX Coupling (5 Pack) 5

APXC3450PK 3/4” PEX Coupling (50 Pack) 5

APXC11 1" PEX Coupling 5

APXC1238 1/2" X 3/8" PEX Coupling 5

APXC1234 3/4" X 1/2" PEX Coupling 15

APXC341 1" X 3/4" PEX Coupling 5

APXBC1212 1/2" Coupling Poly B x PEX 20

FASTENERS FITTINGS

APXBC12125PK 1/2” Coupling Poly B x PEX (5 Pack) 10

APXBC3434 3/4" Coupling Poly B x PEX 15

BRASS ELBOWS

APXE12 1/2" Crimp Elbow 50

APXE121210PK 1/2" Crimp Elbow (10 Pack) 10

APXE1250PK 1/2” Crimp Elbow (50 Pack) 5

APXE1234 3/4" X 1/2" Crimp Elbow 5

APXE3434 3/4" Crimp Elbow 30

APXE34345PK 3/4" Crimp Elbow (5 Pack) 10

APXE3450PK 3/4” Crimp Elbow (50 Pack) 5

APXE11 1" Crimp Elbow 5

APXDEE12 1/2" X 1/2" FPT Drop Elbow 20

TUBING MANIFOLDS

6

APXFAE1212 1/2" X 1/2" FPT Elbow Swivel 10

Page 7

www.apolloflow.com PEX FITTINGS

Part Number Description Pack Quantity

CRIMP TEES

APXT38 3/8" Crimp Tee 5

APXT12 1/2" Crimp Tee 40

APXT1210PK 1/2" Crimp Tee (10 Pack) 5

APXT1250PK 1/2” Crimp Tee (50 Pack) 5

APXT34 3/4" Crimp Tee 15

APXT345PK 3/4" Crimp Tee (5 Pack) 5

APXT3450PK 3/4" Crimp Tee (50 Pack) 5

APXT11 1" Crimp Tee 5

APXT121234 1/2" X 1/2" X 3/4" Crimp Tee 5

APXT341212 3/4" X 1/2" X 1/2" Crimp Tee 5

APXT341234 3/4" X 1/2" X 3/4" Crimp Tee 5

APXT343412 3/4" X 3/4" X 1/2" Crimp Tee 20

TOOLS

APXT3434125PK 3/4" X 3/4" X 1/2" Crimp Tee (5 Pack) 5

APXT1112 1" x 1" x 1/2" Crimp Tee 5

APXT1134 1" x 1" x 3/4" Crimp Tee 5

CRIMP TEST PLUGS

APXP12 1/2" Test Plug Crimp 25

APXP1210PK 1/2" Test Plug Crimp (10 Pack) 5

APXP34 3/4" Test Plug Crimp 10

FASTENERS FITTINGS

TUBING MANIFOLDS

7

Page 8

PEX FITTINGS www.apolloflow.com

Part Number Description Pack Quantity

MALE BRASS ADAPTERS

APXMA1212 1/2" X 1/2" MPT Adapter 50

TOOLS

APXMA121210PK 1/2" X 1/2" MPT Adapter (10 Pack) 5

APXMA1250PK 1/2” X 1/2” MPT Adapter (50 Pack) 5

APXMA1234 1/2" MPT X 3/4" Barb Adapter 10

APXMA3412 3/4" MPT X 1/2" Barb Adapter 10

APXMA3434 3/4" X 3/4" MPT Adapter 25

APXMA34345PK 3/4" X 3/4" MPT Adapter (5 Pack) 5

APXMA3450PK 3/4” X 3/4” MPT Adapter (50 Pack) 5

APXMA341 3/4" X 1" MPT Adapter 5

APXMA11 1" X 1" MPT Adapter 5

APXMS1212 1/2" X 1/2" MS Adapter Solder 10

APXMS121210PK 1/2" X 1/2" MS Adapter Solder (10 Pack) 10

APXMS3434 3/4" X 3/4" MS Adapter Solder 5

APXMSA11 1" X 1" MS Adapter Solder 5

FEMALE BRASS ADAPTERS

APXFA1212 1/2" X 1/2" FPT Adapter 40

FASTENERS FITTINGS

APXFA12125PK 1/2" X 1/2" FPT Adapter (5 Pack) 5

APXFA3434 3/4" X 3/4" FPT Adapter 15

APXFA34B1F 3/4" X 1" FPT Adapter 5

APXFA11 1" X 1" FPT Adapter 5

APXFS1212 1/2" X 1/2" FS Adapter Solder 20

APXFS12125PK 1/2" X 1/2" FS Adapter Solder (5 Pack) 5

APXFS3434 3/4" X 3/4" FS Adapter Solder 10

APXFSA11 1" X 1" FS Adapter Solder 5

APXF3812S 3/8" X 1/2" FPT Swivel Adapter 5

APXFB1212S 1/2" X 1/2" FPT Swivel Adapter 10

APXFB1212SW5

APXFF3434S 3/4" X 3/4" FPT Brass Swivel Adapter 5

1/2" X 1/2" FPT

Swivel Adapter

(5 Pack)

5

TUBING MANIFOLDS

8

Page 9

www.apolloflow.com PEX FITTINGS

Part Number Description Pack Quantity

MISCELLANEOUS

APXSTUB8 1/2" X 8" Copper Stubout 12

APXCONN18 18" Water Flex Connector 5

VALVES

APXFF1212S 1/2" X 1/2" FPT Adapter Swivel 5

APXV1212 1/2" X 1/2" Ball Valve 12

TOOLS

APXV3434 3/4" X 3/4" Ball Valve 12

APXVS1238C 1/2" PEX X 3/8" C Straight Stop Valve 12

APXVA1238C 1/2" PEX X 3/8" C Angle Stop Valve 15

APXPV1238S 1/2" Push X 3/8" C Straight Stop Valve 12

APXPV1238A 1/2" Push X 3/8" C Angle Stop Valve 12

FASTENERS FITTINGS

TUBING MANIFOLDS

9

Page 10

PEX FITTINGS www.apolloflow.com

Part Number Description Pack Quantity

PUSH COUPLINGS

ALF1 3/8" Push Coupling 5

TOOLS

ALF2 1/2" Push X 3/8" Push Coupling 5

ALF3 1/2" Push Coupling 30

ALF4 3/4" Push X 1/2" Push Coupling 5

ALF5 3/4" Push Coupling 10

PUSH ELBOWS

ALF20 1/2" Push 90° Elbow 10

ALF21 3/4" Push X 1/2" Push 90° Elbow 5

ALF22 3/4" Push 90° Elbow 10

ALF24 1/2" Push X 1/2" MPT 90° Elbow 5

FASTENERS FITTINGS

ALF23 1/2" CTS X 1/2" FPT Swivel Elbow 5

ALF26 1/2" Push X 1/2" FPT Drop Ear Elbow 5

TUBING MANIFOLDS

10

Page 11

www.apolloflow.com PEX FITTINGS

Part Number Description Pack Quantity

PUSH TEES

ALF14 1/2" Push Tee 15

ALF15 3/4" Push Tee 5

ALF16 3/4" Push X 3/4" Push X 1/2" Push Tee 5

ALF17 3/4" Push X 1/2" Push X 1/2" Push Tee 5

PUSH ADAPTERS

ALF6 3/8" Push X 1/2" MIP Adapter 5

ALF7 1/2" Push X 1/2" MIP Adapter 15

ALF8 3/4" Push X 3/4" MIP Adapter 10

ALF9 1/2" Push X 1/2" FIP Adapter 10

TOOLS

ALF10 3/4" Push X 3/4" FIP Adapter 5

PUSH VALVES

ALF30 1/2" Push Straight Valve 10

ALF31 3/4" Push Straight Valve 5

PUSH CAPS

ALF27 1/2" Cap 5

FASTENERS FITTINGS

11

TUBING MANIFOLDS

Page 12

PEX FITTINGS www.apolloflow.com

Part Number Description Pack Quantity

POLY ALLOY COUPLINGS

PXPAC12 1/2" PEX PA Coupling (2 Pack) 25

TOOLS

FITTINGS

PXPAC34 3/4" PEX PA Couping (2 Pack) 25

PXPAC3412 3/4" x 1/2" PEX PA Coupling (2 Pack) 25

PXPAC341 1" x 3/4" PEX PA Coupling (2 Pack) 10

POLY ALLOY ELBOWS

PXPAE12 1/2" PEX PA Elbow (2 Pack) 25

PXPAE34 3/4" PEX PA Elbow (2 Pack) 25

PXPAE1234 3/4" x 1/2" PEX PA Elbow (2 Pack) 10

FASTENERS

TUBING MANIFOLDS

12

Page 13

www.apolloflow.com

PEX FITTINGS

Part Number Description Pack Quantity

POLY ALLOY TEES

PXPAT12 1/2" PEX PA Tee (2 Pack) 25

PXPAT121234 1/2" x 1/2" x 3/4" PEX PA Tee (2 Pack) 10

PXPAT34 3/4" PEX PA Tee (2 Pack) 25

PXPAT341212 3/4" x 1/2" x 1/2" PEX PA Tee (2 Pack) 10

PXPA343412 3/4" x 3/4" x 1/2" PEX PA Tee (2 Pack) 25

PXPAT341234 3/4" x 1/2" x 3/4" PEX PA Tee (2 Pack) 10

POLY ALLOY TEST PLUGS

PXPAP12 1/2" PEX PA Plug (2 Pack) 25

PXPAP34 3/4" PEX PA Plug (2 Pack) 25

TOOLS

FASTENERS FITTINGS

13

TUBING MANIFOLDS

Page 14

TOOLS

PEX FASTENERS www.apolloflow.com

Part Number Description Pack Quantity

PINCH CLAMPS

PXPC3810PK 3/8" Pinch Clamp (10 Pack) 10

PXPC1210PK 1/2" Pinch Clamp (10 Pack) 20

PXPC1225PK 1/2" Pinch Clamp (25 Pack) 10

PXPC3410PK 3/4" Pinch Clamp (10 Pack) 15

PXPC3425PK 3/4" Pinch Clamp (25 Pack) 10

PXPC15PK 1" Pinch Clamp (5 Pack) 10

CRIMP RINGS

APXCR3810PK 3/8" Crimp Rings (10 Pack) 5

APXCR1210PK 1/2" Crimp Rings (10 Pack) 30

APXCR1250PK 1/2" Crimp Rings (50 Pack) 10

APXCR3410PK 3/4" Crimp Rings (10 Pack) 15

APXCR3425PK 3/4" Crimp Rings (25 Pack) 10

APXCR15PK 1" Crimp Rings (5 Pack) 5

FASTENERS FITTINGS

PRO CRIMP RINGS

APXCR12LT 1/2" Pro Crimp Rings (10 Pack) 5

APXCR34LT 3/4" Pro Crimp Rings (10 Pack) 5

J-HOOKS

APXJH1225PK 1/2" J-Hooks (25 Pack) 4

APXJH3425PK 3/4" J-Hooks (25 Pack) 4

PIPE BENDS

PXBEND12 1/2" Pipe Bend 15

PXBEND34 3/4" Pipe Bend 10

TUBING MANIFOLDS

14

Page 15

www.apolloflow.com PEX MANIFOLDS

Why Use Manifolds

• Save Time and Money - Manifolds allow you to make longer continuous runs of PEX pipe, meaning you buy

fewer fittings and spend less time installing.

• Fewer Possible Leaks - Longer continuous runs with fewer crimp connections means fewer chances of

leaks and avoiding the possibility of thousands of dollars in water damage.

• Controls Scalding - When plumbed so that each branch line feeds only one xture, the manifold greatly

reduces pressure fluctuations and temperature swings that cause scalding.

• Quiet Plumbing - Longer runs of pipe using fewer ttings means smoother bends and turns which reduces

line noise and “water hammer”.

The Manifold Systems are available in a wide range of outlet ports, and include the appropriate number of

valves for each outlet. Each manifold has a galvanized back plate for easy mounting to any structure. The

cover plate, for labeling purposes, is constructed of 1/4" ABS. All manifolds are bolted to the back plate,

rather than screwed.

Each manifold consists of two inlet ports that supply the dual chambers. Typically one inlet is used for cold

water supply, and the other inlet is used for hot water supply. However, both inlets may be used for either hot

or cold water. The inlets are not temperature specic. The water inlets connections are 3/4" PEX Barb, The

outlets are 1/2" MPT. 1/2" FPT Swivel x Barb valves are included.

Each manifold is individually boxed, and includes red and blue labels for indicating the destination fixtures.

TOOLS

Part Number Description Pack Quantity

MANIFOLDS

6907912CP 12 Port Manifold 1

6907984CP 16 Port Manifold 1

6907920CP 20 Port Manifold 1

6907924CP 24 Port Manifold 1

6907928CP 28 Port Manifold 1

6907932CP 32 Port Manifold 1

6907936CP 36 Port Manifold 1

FASTENERS FITTINGS

15

TUBING MANIFOLDS

Page 16

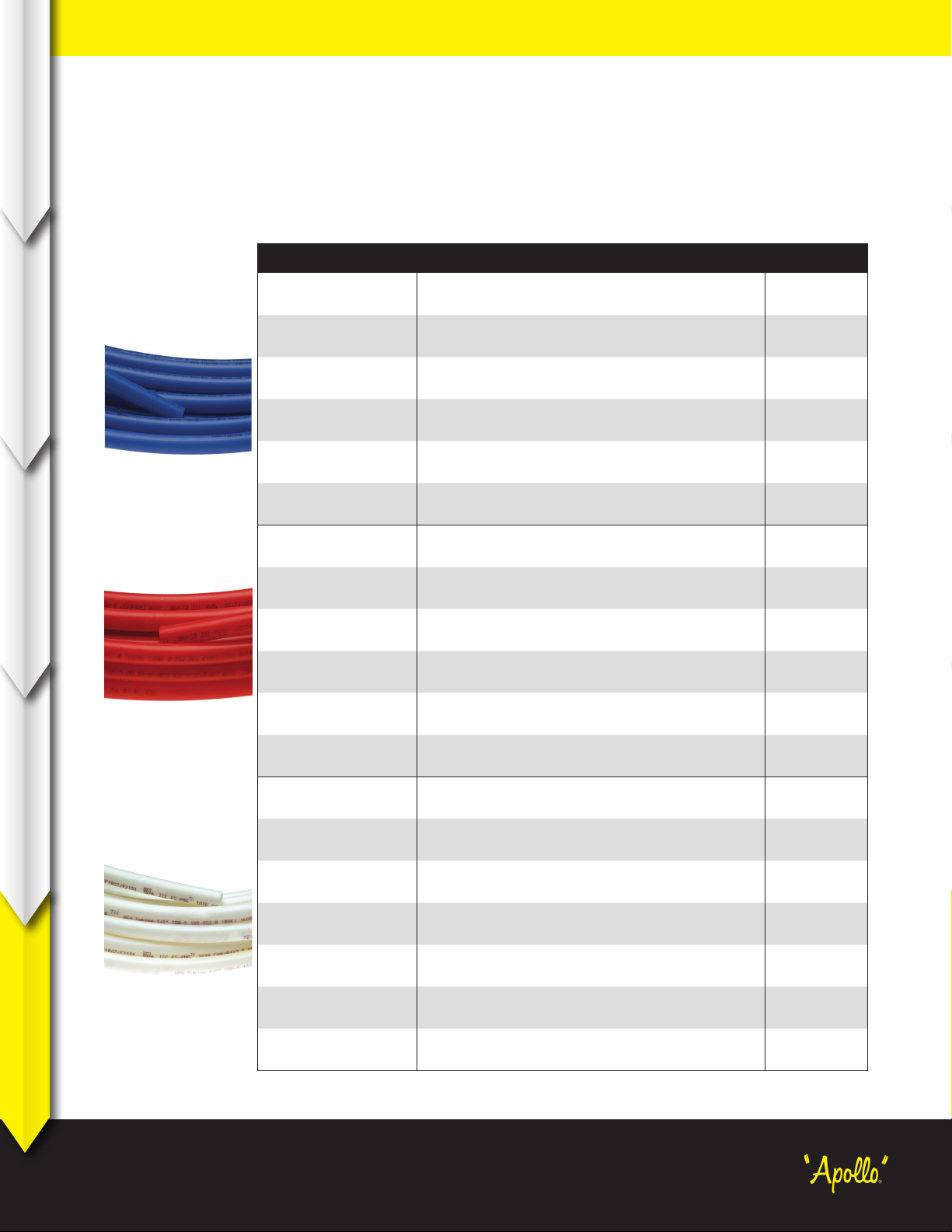

TOOLS

PEX TUBING www.apolloflow.com

PEX Tubing

PEX tubing is cross-linked, high-density polyethylene. It’s available in white, red, or blue colors for easy

identication of hot and cold water lines. Apollo PEX tubing is type PEX-B (PE-Xb, PEXb). PEX tubing is for

use in hot and cold potable water distribution systems as well as hydronic radiant heating systems. PEX

tubing can also be used in “continuously recirculating” plumbing systems up to 140° F while maintaining

chlorine resistance.

Part Number Description Pack Quantity

PEX COILS - For potable water only

APPB10012 PEX Pipe 1/2" x 100' Blue 3

APPB10034 PEX Pipe 3/4" x 100' Blue 2

APPB30012 PEX Pipe 1/2" x 300' Blue 1

APPB30034 PEX Pipe 3/4" x 300' Blue 1

APPB50012 PEX Pipe 1/2" x 500' Blue 1

FASTENERS FITTINGS

APPB50034 PEX Pipe 3/4" x 500' Blue 1

APPR10012 PEX Pipe 1/2" x 100' Red 3

APPR10034 PEX Pipe 3/4" x 100' Red 2

APPR30012 PEX Pipe 1/2" x 300' Red 1

APPR30034 PEX Pipe 3/4" x 300' Red 1

APPR50012 PEX Pipe 1/2" x 500' Red 1

APPR50034 PEX Pipe 3/4" x 500' Red 1

APPW10012 PEX Pipe 1/2" x 100' White 3

APPW10034 PEX Pipe 3/4" x 100' White 2

APPW1001 PEX Pipe 1" x 100' White 1

APPW30012 PEX Pipe 1/2" x 300' White 1

TUBING MANIFOLDS

16

APPW30034 PEX Pipe 3/4" x 300' White 1

APPW50012 PEX Pipe 1/2" x 500' White 1

APPW50034 PEX Pipe 3/4" x 500' White 1

Page 17

www.apolloflow.com PEX TUBING

Part Number Description Pack Quantity

PEX STICKS - For potable water only

APPW514 PEX Pipe 1/4" x 5' White 10

APPW538 PEX Pipe 3/8" x 5' White 10

APPW512 PEX Pipe 1/2" x 5' White 30

APPW534 PEX Pipe 3/4" x 5' White 20

APPW51 PEX Pipe 1" x 5' White 5

APPW1012 PEX Pipe 1/2" x 10' White 20

APPW1034 PEX Pipe 3/4" x 10' White 20

PEX Oxygen Barrier Tubing

Oxygen Barrier PEX tubing has been designed to prevent diffusion of oxygen into hydronic radiant heating

systems. A layer of polymer is laminated to the outside surface which is highly resistant to the passage

of oxygen. Oxygen Barrier PEX tubing is good for hydronic radiant heating, cooling, and snow melting

systems using water or water/glycol mix. The tubing may be installed in concrete, gypsum based lightweight

concrete, sand, asphalt, in or under wood ooring, or behind wallboard or plaster. Oxygen Barrier PEX tubing

may also be used as transfer lines for baseboard heating systems with a maximum operating temperature of

200° F @ 80 psi. Apollo PEX tubing is type PEX-B (PE-Xb, PEXb).

TOOLS

FASTENERS FITTINGS

Part Number Description Pack Quantity

PEX OXYGEN BARRIER -

APPOB2512 1/2" x 25' Oxygen Barrier PEX Pipe 1

APPOB30012 1/2" x 300' Oxygen Barrier PEX Pipe 1

APPOB10034 3/4" x 100' Oxygen Barrier PEX Pipe 1

APPOB30034 3/4xX 300' Oxygen Barrier PEX Pipe 1

For use with Radiant Heating

TUBING MANIFOLDS

17

Page 18

PART NUMBER INDEX

6907912CP...........................15

6907920CP...........................15

6907924CP...........................15

6907928CP...........................15

6907932CP...........................15

TOOLS

FASTENERS FITTINGS

6907936CP...........................15

6907984CP...........................15

69PC02PZ...............................5

69PC03PZ...............................5

69PTBJ0010C.........................4

69PTKANG143........................4

69PTKC001.............................5

69PTKD0009..........................5

69PTKG1096..........................4

69PTKGONO............................5

69PTKH00143........................4

69PTKH00144........................4

69PTKH0014C........................4

69PTKH0015K........................4

69PTKH00185........................4

ALF1.......................................10

ALF10.....................................11

ALF14.....................................11

ALF15....................................11

ALF16.....................................11

ALF17.....................................11

ALF2......................................10

ALF20....................................10

ALF21.....................................10

ALF22....................................10

ALF23....................................10

ALF24....................................10

ALF26....................................10

ALF27....................................11

ALF3......................................10

ALF30...................................11

ALF31....................................11

ALF4......................................10

ALF5......................................10

ALF6......................................11

ALF7......................................11

ALF8......................................11

ALF9......................................11

APPB10012.....................16

APPB10034.....................16

APPB30012.....................16

TUBING MANIFOLDS

APPB30034.....................16

APPB50012.....................16

APPB50034.....................16

APPOB10034........................17

APPOB2512.....................17

APPOB30012.....................17

APPOB30034.....................17

APPR10012.....................16

APPR10034.....................16

APPR30012.....................16

APPR30034.....................16

APPR50012.....................16

APPR50034.....................16

APPW1001.....................16

APPW10012.....................16

APPW10034.....................16

APPW1012.....................17

APPW1034.....................17

APPW30012.....................16

APPW30034.....................16

APPW50012.....................16

APPW50034.....................16

APPW51.....................17

APPW512.....................17

APPW514.....................17

APPW534.....................17

APPW538.....................17

APXBC1212...........................6

APXBC12125PK......................6

APXBC3434...........................6

APXC11...........................6

APXC1212...........................6

APXC121210PK......................6

APXC1234...........................6

APXC1238...........................6

APXC1250PK........................6

APXC341...........................6

APXC3434...........................6

APXC34345PK........................6

APXC3450PK........................6

APXC3838...........................6

APXCONN18.....................9

APXCR1210PK......................14

APXCR1250PK......................14

APXCR12LT.........................14

APXCR15PK.........................14

APXCR3410PK......................14

APXCR3425PK......................14

APXCR34LT.........................14

APXCR3810PK......................14

APXDEE12...........................6

APXE11...........................6

APXE12...........................6

APXE121210PK......................6

APXE1234...........................6

APXE1250PK........................6

APXE3434...........................6

APXE34345PK.......................6

APXE3450PK.......................6

APXF3812S.....................8

APXFA11.....................8

APXFA1212.....................8

APXFA12125PK.....................8

APXFA3434.....................8

APXFA34B1F.........................8

APXFAE1212...........................6

APXFB1212S.....................8

APXFB1212SW5.....................8

APXFF1212S.....................9

APXFF3434S.....................9

APXFS1212.....................8

APXFS12125PK.....................8

APXFS3434.....................8

APXFSA11.....................8

APXJH1225PK....................14

APXJH3425PK....................14

APXMA11...........................8

APXMA1212...........................8

APXMA121210PK...................8

APXMA1234...........................8

APXMA1250PK.......................8

APXMA341...........................8

APXMA3412...........................8

APXMA3434...........................8

APXMA34345PK.....................8

APXMA3450PK.......................8

APXMS1212...........................8

APXMS121210PK...................8

APXMS3434...........................8

APXMSA11...........................8

APXP12...........................7

APXP1210PK...........................7

18

Page 19

PART NUMBER INDEX

APXP34....................................7

APXPV1238A......................9

APXPV1238S.....................9

APXSTUB8.....................9

APXT11..............................7

APXT1112...........................7

APXT1134...........................7

APXT12.................................7

APXT1210PK...........................7

APXT121234...........................7

APXT1250PK.........................7

APXT34..................................7

APXT341212...........................7

APXT341234...........................7

APXT343412...........................7

APXT3434125PK....................7

APXT345PK...........................7

APXT3450PK...........................7

APXT38...........................7

APXV1212.....................9

APXV3434.....................9

APXVA1238C.....................9

APXVS1238C.....................9

PLTL60.......................5

PLTL82........................5

PLTL83........................5

PXBEND12...........................14

PXBEND34...........................14

PXPA343412.....................13

PXPAC12.....................12

PXPAC34.....................12

PXPAC341.....................12

PXPAC3412.....................12

PXPAE12.....................12

Warranty & Limitations of Liability

PXPAE1234.....................12

PXPAE34.....................12

PXPAP12........................13

PXPAP34.........................13

PXPAT12.....................13

PXPAT121234.....................13

PXPAT34.....................13

PXPAT341212.....................13

PXPAT341234.....................13

PXPC1210PK.........................14

PXPC1225PK........................14

PXPC15PK.........................14

PXPC3410PK.........................14

PXPC3425PK........................14

PXPC3810PK.........................14

TOOLS

Conbraco Industries, Inc. warrants, to its initial purchaser only, that its products which are delivered to this initial purchaser will be of

the kind described in the order or price list and will be free of defects in workmanship or material for a period of FIVE years from the

date of delivery to you, our initial purchaser. This warranty applies to Apollo brand product with “Made in the USA” markings only.

Should any failure to conform to this warranty appear within FIVE years after the date of the initial delivery to our initial purchaser,

Conbraco will, upon written notification thereof and substantiation that the goods have been stored, installed, maintained and

operated in accordance with Conbraco’s recommendations and standard industry practice, correct such defects by suitable repair or

replacement at Conbraco’s own expense.

APOLLO INTERNATIONAL PRODUCTS: Conbraco Industries, Inc. warrants its international products, to its initial purchaser only, that its

international products which are delivered to this initial purchaser will be of the kind described in the order or price list and will be

free of defects in workmanship or material for a period of TWO years from the date of delivery to you, our initial purchaser.

THIS WARRANTY IS EXCLUSIVE AND IS IN LIEU OF ANY IMPLIED WARRANTY OF MERCHANTABILITY, FITNESS FOR A PARTICULAR

PURPOSE OR OTHER WARRANTY OF QUALITY, WHETHER EXPRESSED OR IMPLIED, EXCEPT THE WARRANTY OF TITLE AND AGAINST

PATENT INFRINGEMENT. Correction of non-conformities, in the manner and for the period of time provided above, shall constitute

fulfillment of all liabilities of Conbraco to our initial purchaser, with respect to the goods, whether based on contract, negligence, strict

tort or otherwise. It is the intention of Conbraco Industries, Inc. that no warranty of any kind, whether expressed or implied shall pass

through our initial purchaser to any other person or corporation.

LIMITATION OF LIABILITY: CONBRACO INDUSTRIES, INC. SHALL NOT UNDER ANY CIRCUMSTANCES BE LIABLE FOR SPECIAL OR

CONSEQUENTIAL DAMAGES SUCH AS, BUT NOT LIMITED TO, DAMAGES TO OR LOSS OF OTHER PROPERTY OR EQUIPMENT, LOSS OF

PROFITS OR REVENUE, COST OF CAPITAL, COST OF PURCHASED OR REPLACEMENT GOODS, OR CLAIMS OF CUSTOMERS OF OUR

INITIAL PURCHASER. THE REMEDIES OF OUR INITIAL PURCHASER, AND ALL OTHERS, SET FORTH HEREIN, ARE EXCLUSIVE, AND THE

LIABILITY OF CONBRACO WITH RESPECT TO SAME SHALL NOT, EXCEPT AS EXPRESSLY PROVIDED HEREIN, EXCEED THE PRICE OF THE

GOODS UPON WHICH SUCH LIABILITY IS BASED.

FASTENERS FITTINGS

*It is the end user’s responsibility to conrm that items intended for use satisfy local codes and standards.

TUBING MANIFOLDS

19

Page 20

Matthews, NC 28105

1-888-229-2874

Catalog_Apollo PEX 12/12/14

www.apolloflow.com

Loading...

Loading...