Page 1

Model MVE

34E Series Emergency Mixing Valve

DESCRIPTION

Apollo® Model “MVE” Emergency Mixing Valves are designed to ensure safe and reliable delivery

of tepid water to emergency eyewash / face wash xtures. The device includes a patented

temperature and ow control feature in the event of cold water, hot water and thermostatic

element failures.

Job Name:

Job Location:

Engineer:

Contractor:

Tag:

PO Number:

Representative:

Wholesale Distributor:

FEATURES

• Patented Hot and cold water supply

failure protection

(US Patent 6,926,205 B2)

• Tepid water temperature limit control

• Locking handle for tamper-proof

protection

• Integral inlet check valves and strainers

• Superior thermostatic element

technology

• Thermostatic element over-travel

protection

• 100% factory tested and pre-set

to 85°F (29.4°C)

• In-line accessibility and serviceability

• Corrosion, Dezincication and scale

resistant materials

• Made in the USA

APPROVALS

• ASSE 1071-2008 – Temperature

Actuated Mixing Valves for Plumbed

Emergency Equipment

• ANSI/ISEA Z358.1 2009– Emergency

Eyewash & Shower Equipment

PERFORMANCE RATING

• Maximum working pressure:

150 psig (1034 kPa)

• Hot water inlet temperature range:

120 – 180 °F (49 – 82 °C)

• Cold water inlet temperature range:

40 – 70 °F (4.4 – 21 °C)

• Tepid water temperature adjustment

range: 65 – 95 °F (18.3 – 35 °C)

• Mixed water temperature tolerance:

±5 °F (±2.8 °C)

• Max. Flow rate @ 30 psi (207 kPa)

dierential: 15 gpm (56.8 lpm)

• Cold water bypass @ 30 psi (207 kPa)

dierential: 13.5 gpm (51 lpm)

• Minimum Flow Rate:

1.5 gpm (5.6 lpm)

(Note: The cold water supply shall be at least 20 °F

(-6.7 °C) lower than the outlet water temperature

setting)

OPTIONS

• Size: 1/2” or 3/4”

• Inlets: FNPT or Solder

• Outlet: FNPT or Solder

• Outlet Temperature Gauge

• Hot and Cold Inlet Shut-o Ball Valves

• Lead Free Construction (ANSI 3rd Party

Listed) Model 34ELF - select models

• Rough Chrome Finish

STANDARD MATERIALS LIST

Part Name Material

Body ASTM B584 Bronze

Shuttle Noryl®

Thermostat Brass/Wax lled

O-ring Chloramine Resistant EPDM

Spring ASTM A313 Stainless Steel

Cap ABS Polymer

Module components Noryl®

Apollo Valves, Manufactured by Conbraco Industries, Inc.

701 Matthews Mint-Hill Road, Matthews, NC 28105 USA

This specication is provided for reference only. Conbraco Industries Inc. reserves the right to change any portion of this specication without notice and without incurring

obligation to make such changes to Conbraco products previously or subsequently sold. Please visit our website @ www.apollovalves.com for the most current information.

SS1223 © 07/14 Page 1 of 2

www.apollovalves.com | (704) 841-6000

Page 2

Model MVE

34E Series Emergency Mixing Valve

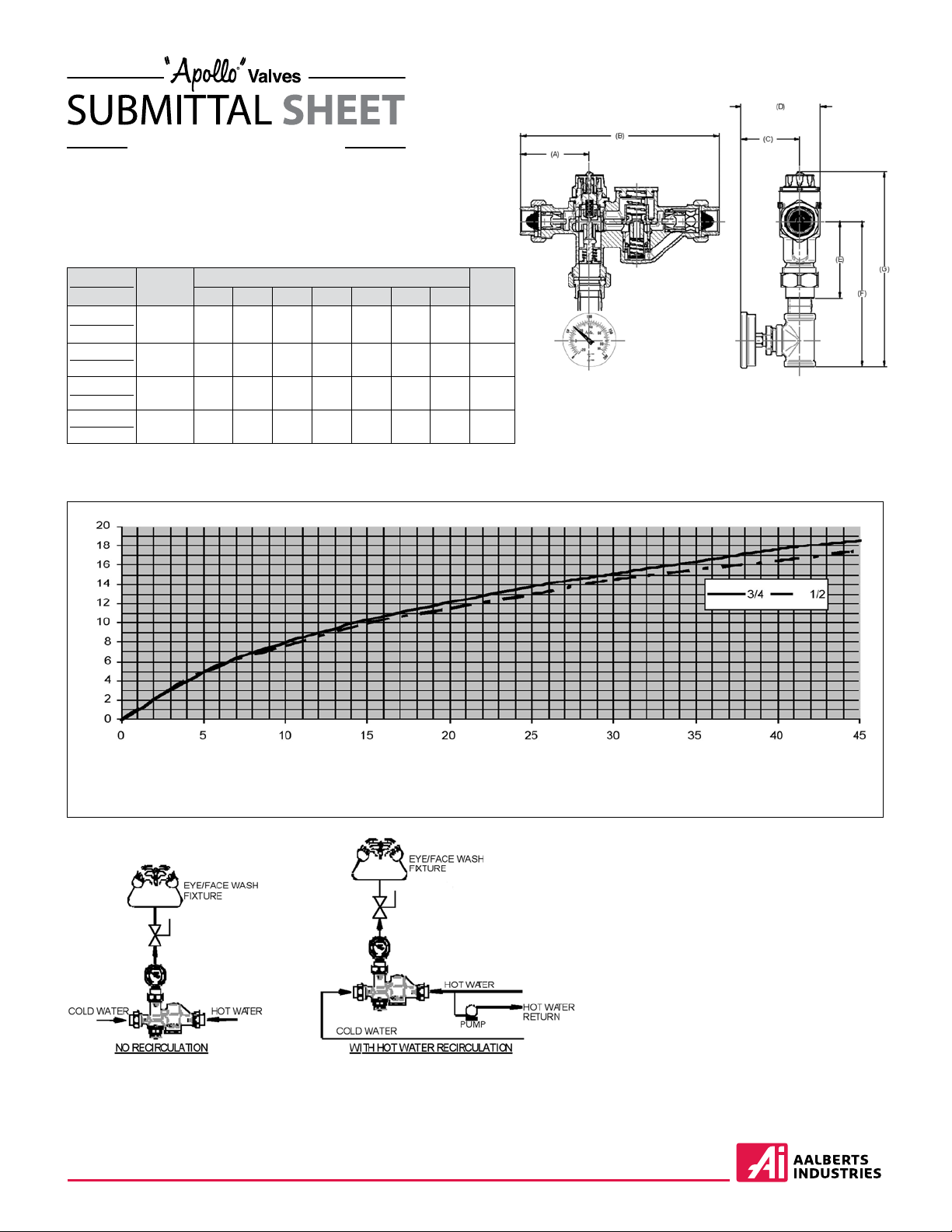

DIMENSIONS

Model No.

Part No.

MVE12G

34E113T

MVES12G

34E113S

MVE34G

34E114T

MVES34G

34E114S

FLOW CURVES

Size

Connection

A B C D E F G

1/2” FPT 3.09 8.90 2.66 3.60 3.45 5.77 7.83 3.94

1/2” SLDR. 3.22 9.15 2.66 3.60 3.45 5.77 7.83 3.73

3/4” FPT 3.09 8.90 2.67 3.60 3.45 6.32 8.39 5.13

3/4” SLDR. 3.10 8.90 2.67 3.60 3.45 6.32 8.39 5.07

Dimensions (in.)

Unit Wt.

(lbs.)

FLOW GPM

PRESSURE DROP PSIG

Flow curve is based on the following: Cold and hot water inlet pressures at 45 ±1.0 psig (310 ±6.9 kPa); cold water supply temperature at 60 ±5 °F (15.6 ±2.8 °C);

hot water supply temperature at 140 ±3 °F (60.0 ±1.7 °C), and mixed water temperature at 85 ±2 °F (29.4 ±1.1 °C). Flow rates may vary depending on actual

system operating conditions.

34E TYPICAL INSTALLATIONS:

Note: Piping and installation of the device must be in

accordance to federal, state, and local plumbing codes.

Note: If the valve is some distance from the hot

water source, recirculation is required to keep the

hot water supply temperature within the required

operational limits

Apollo Valves, Manufactured by Conbraco Industries, Inc.

701 Matthews Mint-Hill Road, Matthews, NC 28105 USA

www.apollovalves.com | (704) 841-6000

This specication is provided for reference only. Conbraco Industries Inc. reserves the right to change any portion of this specication without notice and without incurring

obligation to make such changes to Conbraco products previously or subsequently sold. Please visit our website @ www.apollovalves.com for the most current information.

SS1223 © 07/14 Page 2 of 2

Loading...

Loading...