For Residential and Commercial Applications

ES-LFN55B

Job Name

Job Location

Engineer

Approval

–––––––––––––––––––––––––––––––––––––––––––

–––––––––––––––––––––––––––––––––––––––––

–––––––––––––––––––––––––––––––––––––––––––––

–––––––––––––––––––––––––––––––––––––––––––––

LEAD FREE

*

Contractor

Approval

Contractor’s P.O. No.

Representative

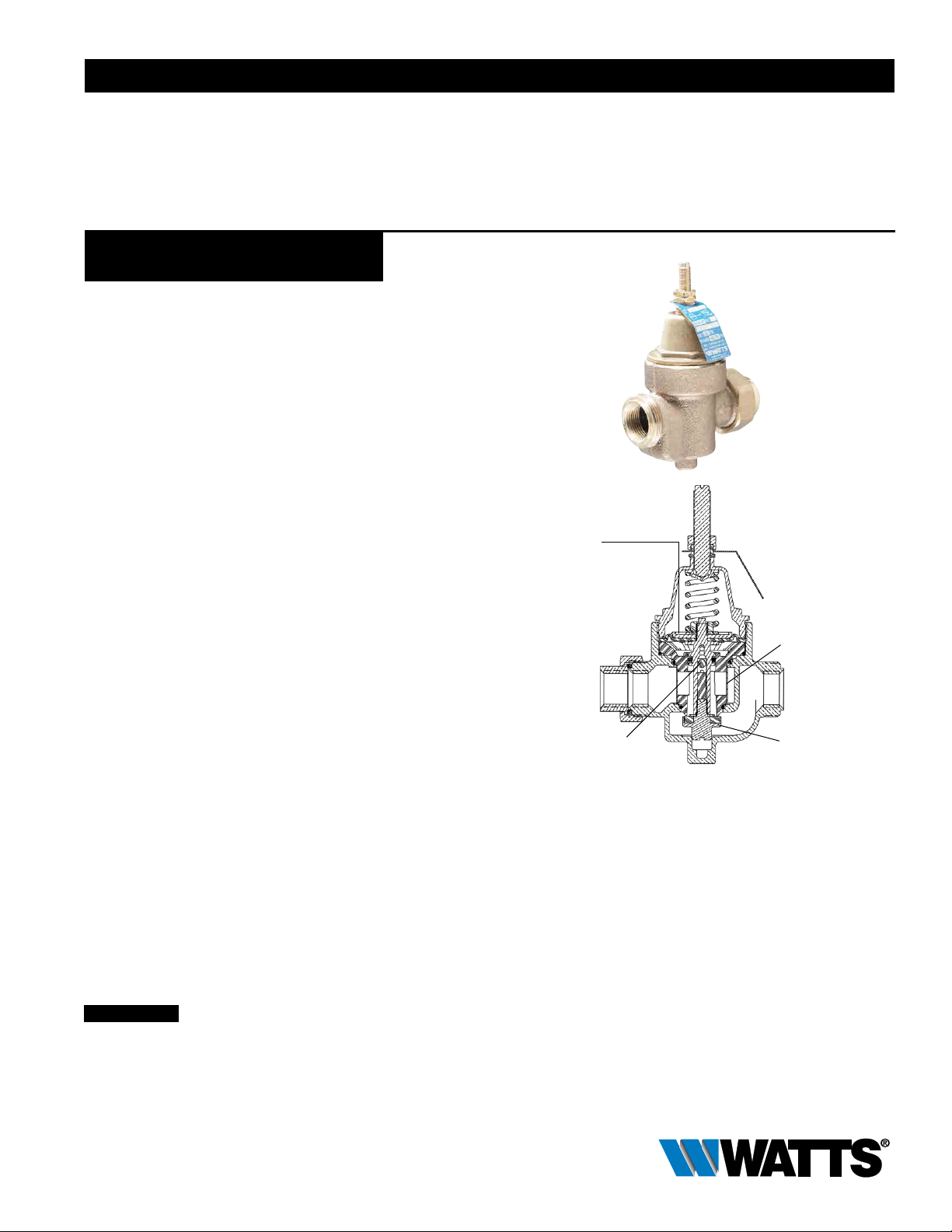

Series LFN55B-M1

Water Pressure Reducing Valves**

Sizes: 1⁄2" – 1"

Series LFN55B-M1 Water Pressure Reducing Valves are

designed to reduce incoming water pressure to a sensible level

to protect plumbing system components and reduce water

consumption. The LFN55B features Lead Free* construction to

comply with Lead Free* installation requirements. This series is

suitable for water supply pressures up to 400psi (27.6 bar) and

may be adjusted from 25 to 75psi (172 – 517 kPa). The standard

setting is 50psi (345 kPa). All parts are quickly and easily serviceable without removing the valve from the line. The standard

bypass feature permits the flow of water back through the valve

into the main when pressures, due to thermal expansion on the

outlet side of the valve, exceed the pressure in the main supply.

––––––––––––––––––––––––––––––––––––––––––––

–––––––––––––––––––––––––––––––––––––––––––––

––––––––––––––––––––––––––––––––––

––––––––––––––––––––––––––––––––––––––––

LFN55BU-M1

Reinforced

Diaphragm

Features

• Integral stainless steel strainer

• Thermoplastic seat

• Lead Free* brass body construction

• Serviceable in line

• Bypass feature controls thermal expansion pressure***

• Sealed spring cage on all models for accessible outdoor or pit

installations

Specifications

Standard Specifications: A Water Pressure Reducing Valve with

integral strainer shall be installed in the water service pipe near

its entrance to the building where supply main pressure exceeds

60psi (413 kPa) to reduce it to 50psi (345 kPa) or lower. The

water pressure reducing valve shall be constructed using Lead

Free* materials. Lead Free* regulators shall comply with state

codes and standards, where applicable, requiring reduced lead

content. The valve shall feature a Lead Free* brass body suitable

for water supply pressures up to 400psi (27.6 bar). Provision

shall be made to permit the bypass flow of water back through

the valve into the main when pressures, due to thermal expansion on the outlet side of the valve, exceed the pressure in the

main supply. Water Pressure Reducing Valve with builtin bypass

check valves will be acceptable. Approved valve shall be listed to

ASSE 1003 and IAPMO and certified to CSA B356. Valve shall

be a Watts Series LFN55B-M1.

NOTICE

The information contained herein is not intended to replace the full

product installation and safety information available or the experience of a trained product installer. You are required to thoroughly

read all installation instructions and product safety information

before beginning the installation of this product.

Integral Stainless

Steel Strainer

Thermal

Expansion Bypass

Thermoplastic

Seat

Materials

Body: Lead Free* brass

Seat: Thermoplastic

Cage: Bronze

Integral Strainer: Stainless steel

Diaphragm: Reinforced EPDM

Valve Disc: Elastomer

* The wetted surface of this product contacted by consumable

water contains less than 0.25% of lead by weight.

** A water saving test program concluded that reducing the

supply pressure from 80-50psi (551-345 kPa) resulted in a

water savings of 30%.

*** The bypass feature will not prevent the pressure relief valve

from opening on the hot water supply system with pressure

above 150psi (10.3 bar).

Watts product specifications in U.S. customary units and metric are approximate and are provided for reference only. For precise measurements,

please contact Watts Technical Service. Watts reserves the right to change or modify product design, construction, specifications, or materials without prior notice and without incurring any obligation to make such changes and modifications on Watts products previously or subsequently sold.

Pressure — Temperature

Temperature Range: 33°F – 180°F (0.5°C – 82°C)

Maximum Working Pressure: 400psi (27.6 bar)

Adjustable Reduced Pressure Range:

25 – 75psi (172 – 517 kPa)

Standard Reduced Pressure Setting: 50psi (345 kPa)

Capacity

kPa psi

0 0

34.5 5

Standards

Meets requirements of ASSE Standard 1003; (ANSI A112.26.2)

and CSA Standard B356. Certified by NSF to ANSI/NSF

Standard 61-G. Listed by IAPMO.

Options

Add Suffix

-“ “ NPT threaded female inlet x NPT female outlet

-U NPT threaded union inlet x NPT female outlet

-U-S Solder union inlet x NPT female outlet

-w/press**** Press inlet x press outlet (non union)

-DU Double Union - NPT threaded union female inlet

and outlet

-DU-S Double Union - Solder union inlet and outlet

-DU-PEX Double Union - PEX union inlet and outlet

-DU-CPVC Double Union - CPVC union inlet and outlet

-G Gauge tapping,

1

⁄8" (3mm)

-LP Low pressure range 10-35psi (69 - 241 kPa)

**** Viega ProPress

®

connections are optional factory installed

fittings on each end of the approved/certified assembly.

Dimensions – Weights

68.9 10

103.4 15

Pressure Drop

137.8 20

172.3 25

0 10 20 30 40 gpm

0 37.3 75.7 113.6 151.4 lpm

Flow

FNPT

ENPT

FSWEAT

ESWEAT

FPEX

C

FEMALE NPT THREAD

BOTH ENDS OF BODY

EPEX

FCPVC

D

ECPVC

A

A + E

ABOVE VALVE SHOWN WITH SINGLE NPT UNION CONNECTION ON INLET

VALVES MAY BE ORDERED WITH 0,1,OR 2 UNION CONNECTIONS USING ANY

COMBINATION OF NPT, SOLDER, PEX OR CPVC CONNECTIONS REQUIRED

“F” DIMENSIONS ARE APPROXIMATE ENGAGEMENT LENGTHS.

SIZE DIMENSIONS WEIGHT

A C D ENPT ESWEAT EPEX ECPVC EQC FNPT FSWEAT FPEX FCPVC FQC G

in. in. mm in. mm in. mm in. mm in. mm in. mm in. mm in. mm in. mm in. mm in. mm in. mm in. mm in. mm lbs. kgs.

1

⁄2 37⁄16 88 49⁄16 116 111⁄16 435⁄8 165⁄8 1513⁄16 219⁄16 15 17⁄16 361⁄2 131⁄2 135⁄8 161⁄2 13 11⁄2 38 21⁄4 57 2 .91

3

⁄4 37⁄16 88 49⁄16 116 111⁄16 435⁄8 167⁄8 2115⁄16 2413⁄16 21 19⁄16 409⁄16 143⁄4 195⁄8 163⁄4 18 111⁄16 42 21⁄4 57 2 .91

1

1 4

⁄8 105 49⁄16 116 111⁄16 433⁄4 20 1 26 11⁄8 29 11⁄16 26 111⁄16 4311⁄16 1715⁄16 2313⁄16 2115⁄16 23 13⁄4 45 21⁄4 57 3 1.36

A + E + E

G

FQC

EQC

Consult factory for dimensions with press connections.

USA: T: (978) 689-6066 • F: (978) 975-8350 • Watts.com

Canada: T: (905) 332-4090 • F: (905) 332-7068 • Watts.ca

Latin America: T: (52) 81-1001-8600 • F: (52) 81-8000-7091 • Watts.com

ES-LFN55B 1640 © 2016 Watts

Loading...

Loading...