Page 1

INSTALLATION, OPERATION & MAINTENANCE MANUAL

BACKFLOW

BFMM DC4A SBF | EFFECTIVE AUGUST 1, 2016

Model DC4A / DCLF4A

1/2” - 2”

Double Check Valve (DC)

Backflow Preventer

Page 2

INSTALLATION, OPERATION, & MAINTENANCE MANUAL

TABLE OF CONTENTS

Double Check Valve Backow Preventer 1/2” – 2”

Section Page

I Description and Operation ......................................................................3

II Installation .....................................................................................3

III Trouble Shooting Guide.........................................................................5

IV Maintenance Instructions .......................................................................5

V Testing Procedures............................................................................6-7

Parts List

Parts List (1/2”- 2”) .......................................................................... 8-10

Repair Kits

Repair Kits (1/2”- 2” ) ..........................................................................11

2

www.apollovalves.com Customer Service (704) 841-6000

Page 3

BFMM DC4A SBF

DOUBLE CHECK VALVE BACKFLOW PREVENTER 1/2” 2”

I. DESCRIPTION AND OPERATION

The Double Check Valve (DC) device consists of two independently-acting, spring-loaded check valves. Two resilient seated shuto valves and four test cocks complete the assembly. Each check is designed to maintain a minimum of 1 psi across the valve

during normal operation. If at any time the pressure downstream of the device increases above the supply pressure, both check

valves will close to prevent any backow from occurring. The owing and no ow conditions are illustrated in gures 1 and 2.

To initiate ow, supply pressure must be sucient to open both checks and overcome friction, normally a minimum of 3 to 5 psi

above the downstream pressure.

II. INSTALLATION

A. The DC must be installed in an accessible location to facilitate periodic eld testing and maintenance.

B. Flush all upstream piping thoroughly to remove foreign matter prior to installing the device.

C. The device should be installed either horizontally or vertical up for ease of maintenance and testing. A clearance between

the lower most portion of the device and ood grade or oor should be provided for ease of maintenance.

D. When shut-o valves are provided separately, they should be installed with a test cock on the upstream side of the inlet shut o valve.

E. After installing the assembly and with downstream or #2 shut-o valve closed, pressurize the device and bleed ALL air

through test cock #4. Then open #2 shut-o valve.

Customer Service (704) 841-6000 www.apollovalves.com

3

Page 4

INSTALLATION, OPERATION, & MAINTENANCE MANUAL

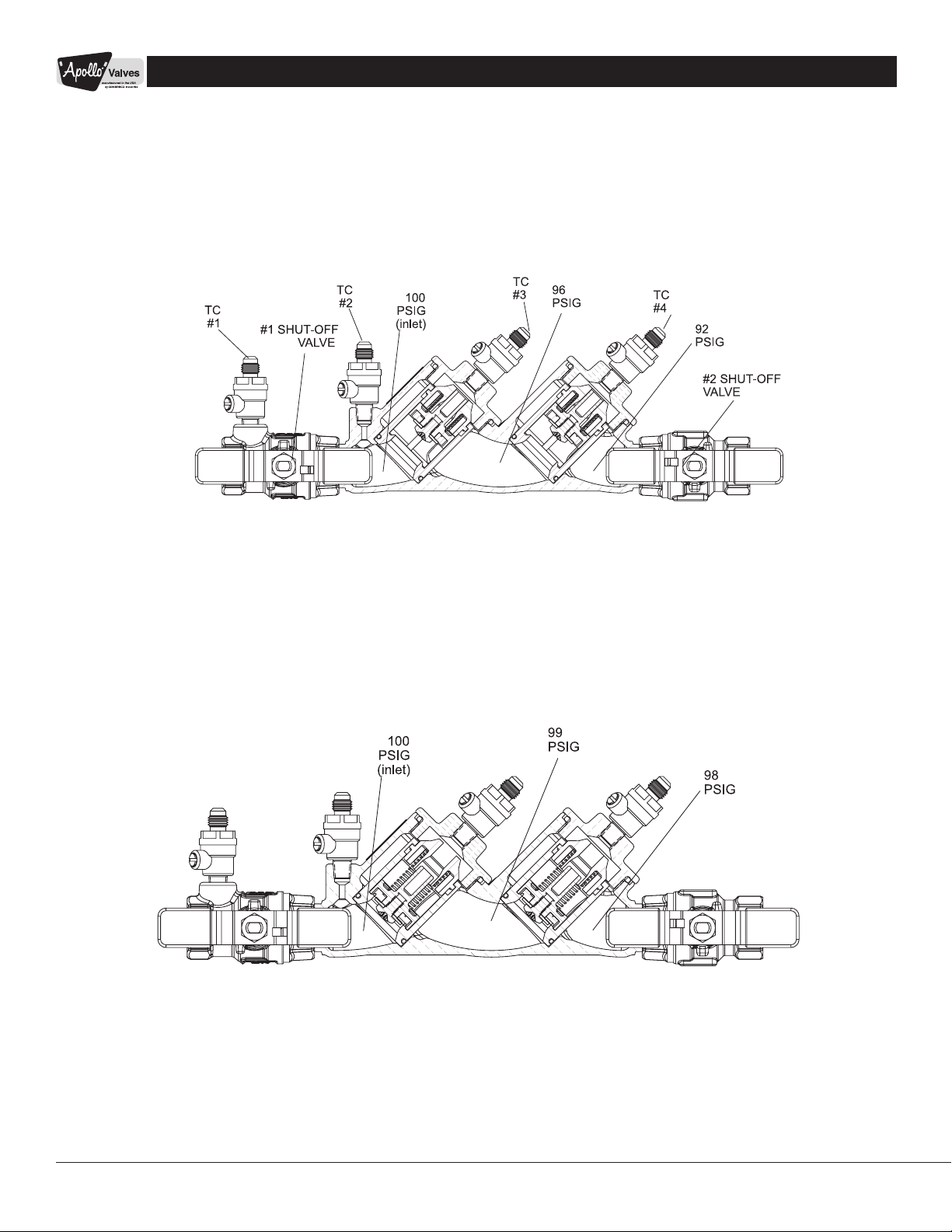

Figure 1

FLOWING CONDITION

Figure 2

NO FLOW CONDITION

NOTE: Pressures shown are for illustrative

purposes only and are not necessarily

indicative of any actual valve.

4

www.apollovalves.com Customer Service (704) 841-6000

Page 5

BFMM DC4A SBF

III. TROUBLE SHOOTING

SYMPTOM CAUSE CORRECTIVE ACTION

1. Check valve fails to hold

1 psid.

IV. MAINTENANCE INSTRUCTIONS 1/2” – 2”

A. Disassembly - Check Valves

1. Close #2 shut-o valve, then close #1 shut-o valve.

2. Bleed pressure from the assembly by opening #2, #3, and #4 test cocks.

3. Unscrew cap using hex head provided.

4. Push down and turn the spring retainer 90 degrees to remove. Remove the spring. Remove the poppet from the check seat.

5. Normally, the check seat need not be removed. If removal is required, rock it back and forth while pulling outward.

a. Shut-o valve not closed

completely.

b. Check valve fouled with

debris.

c. Check poppet stem not

moving freely in guide.

a. Close #2 shut-o valve or

inspect for possible

through leakage.

b. Inspect and clean seat

disc and seat.

c. Inspect for debris or

deposit on poppet stem

or guide.

B. Disassembly - Check Valve Poppet

CAUTION: Do not use pliers or other tools, which may damage or scratch the plastic stem.

1. Holding the poppet assembly in one hand, remove screw and retaining washer.

2. Remove the seat disc.

3. All parts should be carefully inspected for any damage or excessive wear and thoroughly rinsed in clean water prior to

reassembly. Replace worn parts as necessary.

C. Assembly - Check Valve Poppet

1. Install new disc in poppet and secure with washer and screw.

D. Assembly - Check Valve

1. If the check seat was removed, install the new o-ring and lubricate with a thin coat of Apollo supplied lubricant, DOW 111

or equal. Line up the seat with the bore and push it rmly into place.

2. Place and center the poppet assembly in the check seat.

3. Install the spring onto the poppet.

4. Install the spring retainer onto the spring by pushing down into the grooves of the check seat and turning 90 degrees.

Ensure spring retainer pops up about .1” and locks into the lugs. CAUTION: Ensure the spring retainer orientation matches

that in the parts list drawing or the device’s ow will be signicantly restricted.

5. Apply a thin coat of Apollo supplied lubricant, DOW 111 or equal on cap o-ring.

6. Install cap.

Customer Service (704) 841-6000 www.apollovalves.com

5

Page 6

INSTALLATION, OPERATION, & MAINTENANCE MANUAL

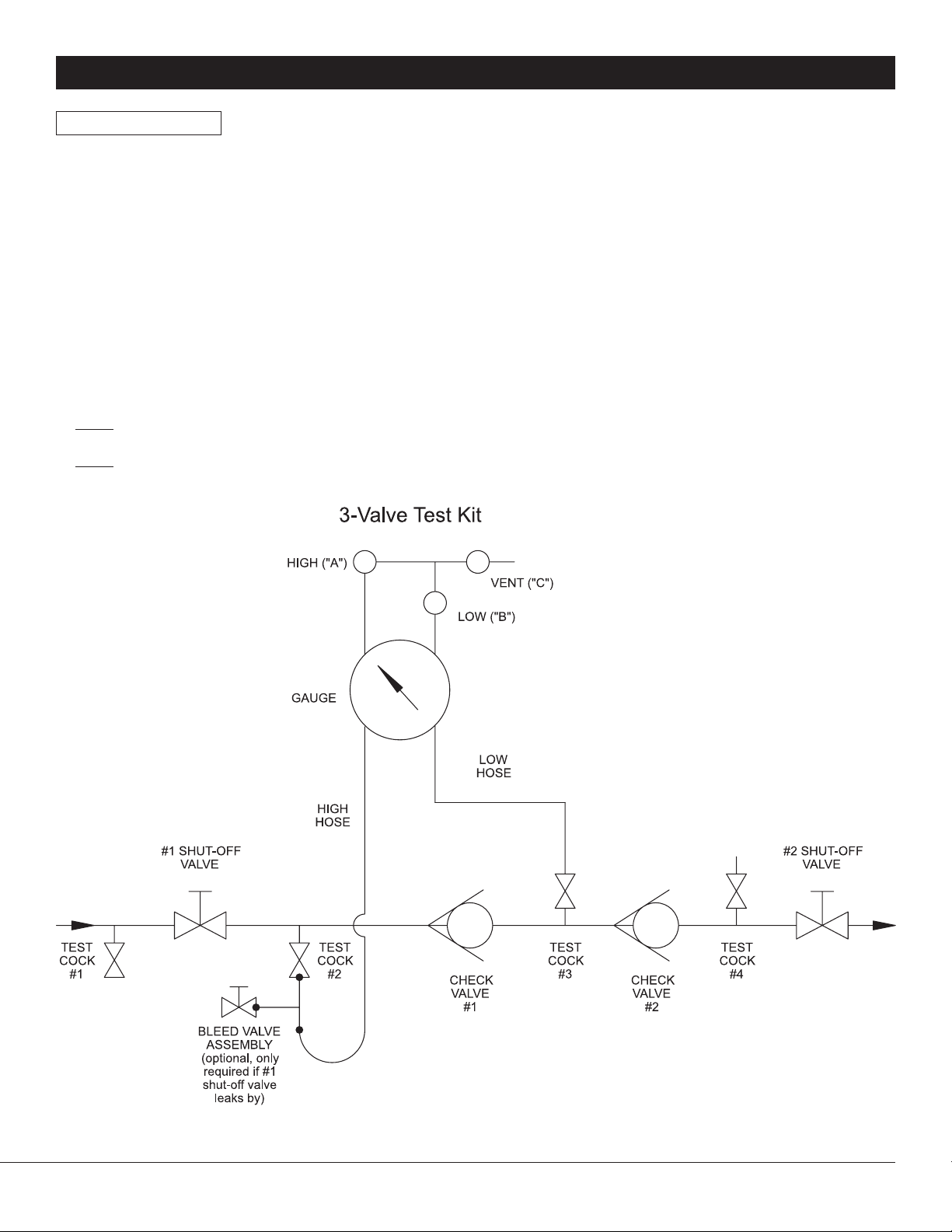

V. TESTING PROCEDURES

This test is performed with the Dierential Pressure Gauge Test Kit. The Dierential Pressure Gauge simply measures the pressure

drop across the check valve. This pressure drop is normally the same as the strength of the check valve spring. In using the

Dierential Pressure Gauge to test the Double Check assembly, a minimum of 1.0 psid is required for each check valve in order

for that check valve to pass the test. Such a small reading is often dicult to read on most test kits. This is one of the drawbacks

of this test. However, since the rst shut-o valve is left in the open position for this test, it is possible to use this test when the

rst shut-o valve is leaking badly.

NOTE: This is a three-valve test kit procedure and may or may not be approved in all jurisdictions. Consult your local water

purveyor for acceptable test procedures.

Test Setup

1. Notify customer that the water service will be o. Identify the make, model, and serial number on the backow device.

Inspect that this is an approved assembly - two check valves, two shut-o valves and four test cocks. Observe the area to

make sure there are no leaks.

2. Flush test cocks (1, 2, 3 & 4), then close all test cocks.

3. Install appropriate adapters (if necessary).

4. Close shut-o valve #2.

TEST NO. 1

PURPOSE: To test check valve #1

1. Close all valves on test kit.

2. Connect the high side hose to test cock #2 and the low side hose to test cock #3. Open test cock #2 and test cock #3.

3. Open vent valve “C” and high “A” on the test kit to bleed air from the high side of the kit. Close high “A” valve and then

open low “B” valve to bleed the low side. Close low “B” valve.

4. Record the gauge reading. It must be a minimum of 1.0 psid in order to pass. Close test cock #2 and test cock #3.

TEST NO. 2

PURPOSE: To test check valve #2

1. Move the high side hose to test cock #3 and the low side hose to test cock #4. Open test cock #3 and test cock #4.

2. Open vent “C” valve. Then open high “A” and bleed air from the high side of the kit. Close high “A” valve, and then open low

“B” valve and bleed the low side of the kit. Close low “B” valve.

3. Record the gauge reading. It must be a minimum of 1.0 psid in order to pass. Close test cock #3 and test cock #4. Remove

hoses and test kit. Slowly open shut-o valve #2 in order to restore water ow to the facility, placing the DC back into service.

6

www.apollovalves.com Customer Service (704) 841-6000

Page 7

BFMM DC4A SBF

TEST NO. 3

PURPOSE: To test leaking #2 shut-o valve

As previously mentioned, the above test is not accurate when the second shut-o valve is leaking. The following test will expose

a leaking shut-o valve.

1. Both shut-o valves should be open. Make sure all valves on test kit are closed. Connect the high “A” hose to test cock #2

and the low “B” hose to test cock #3. Open test cock #2 and test cock #3.

2. Open the high “A” valve and vent “C” valve to bleed air from high side of gauge. Open low “B” valve to bleed air from low side

of gauge. Close valves “A”, “B” and “C” on test kit.

3. Connect the vent hose to test cock #4. Open test cock #4.

4. Close shut-o valve #2. The dierential gauge needle should read at least 1.0 psid in order to pass.

5. Open the high “A” valve and vent “C” valve. This will put back pressure on check valve #2.

6. Close test cock #2.

NOTE: If gauge is steady, then shut-o valve #2 is holding tight. However, if gauge drops to zero psid, then shut-o valve #2 is leaking.

NOTE: If the gauge rises then the #2 shut-o valve is still leaking, but is under backpressure from the facility.

Customer Service (704) 841-6000 www.apollovalves.com

Figure 3

7

Page 8

INSTALLATION, OPERATION, & MAINTENANCE MANUAL

PARTS LIST 1/2” 2”

Figure 4

8

www.apollovalves.com Customer Service (704) 841-6000

Page 9

BFMM DC4A SBF

DC4A and DCLF4A Parts List

Item # Description

1 Body All 1 Consult Factory

2 Label Plate All 1 Consult Factory

3 Label Plate Tacks All 2 I-2614-00

4

4a

5

6 Cap O-Ring All 2 D-4881-00 D-4812-00 D-4884-00 D-4885-00 D-4888-00

7 Check Module O-Ring All 2 D-4880-00 D-4744-00 D-4882-00 D-4884-00 D-4885-00

8 Check S-Assy (see below) All 2 W-9075-05 W-9003-05 W-9074-05 W-9159-05 W-9204-05

Test Cock M x F (81 metal) Std

Test Cock M x F (Lead Free) LF 78LF-290-01 (Optional) 78LF-291-01 (Standard)

Test Cock SAE (81 metal) Std 78-292-01 (Standard) 78-293-01 (Optional)

Test Cock SAE (Lead Free) LF 78LF-292-01 (Standard) 78LF-293-01 (Optional)

Cap (81 metal) Std

Cap (Lead Free) LF F-3847-05 F-3823-05 F-3849-05 F-3851-05 F-3855-05

Std. or

LF

Qt y.

4

2

1/2” 3/4” 1” 1-1/4” 1-1/2” 2”

78-290-01 (Optional) 78-291-01 (Standard)

F-3846-05 F-3822-05 F-3848-05 F-3850-05 F-3854-05

Individual parts are only available for bulk sales. Please refer to the appropriate repair kits on pages 11.

Check Module Sub-Assembly Parts LIst

Item # Description

9 Check Seat All 1 L-7815-00 L-7727-00 L-7813-00 L-7979-00 L-7983-00

10 Screw All 1 B-3279-00 B-1750-00

11 Disc Retaining Washer All 1 E-2372-00 E-2841-00 E-2933-00 E-2860-00 E-2876-00

12 Seat Disc All 1 D-4771-00 D-4743-00 D-4770-00 D-4853-00 D-4873-00

13 Poppet All 1 K-4491-00 K-4471-00 K-4483-00 K-4511-00 K-4512-00

14 Spring All 1 A-2505-00 A-2503-00 A-2510-00 A-2511-00 A-2512-00

15 Spring Retainer All 1 L-7814-00 L-7726-00 L-7812-00 L-7980-00 L-7984-00

Std. or

LF

Qt y.

1/2” 3/4” 1” 1-1/4” 1-1/2” 2”

Individual parts are only available for bulk sales. Please refer to the appropriate repair kits on pages 11.

Part Number

Part Number

Customer Service (704) 841-6000 www.apollovalves.com

9

Page 10

INSTALLATION, OPERATION, & MAINTENANCE MANUAL

Item # Description

T2 Inlet NPT Ball Valve w/ “T”

Handle (Standard)

T4 Inlet Union Ball Valve w/ “T”

Handle (Option)

T2 Inlet NPT Ball Valve w/

Lever Handle (Standard)

T4 Inlet Union Ball Valve with

16

17

Lever Handle (Option)

T2 Inlet NPT Ball Valve with

Locking “T” Handle (Option)

T4 Inlet Union Ball Valve with

Locking “T” Handle (Option)

T2 Inlet NPT Ball Valve with

Locking Lever Handle (Option)

T4 Inlet Ball Union Valve with

Locking Lever Handle (Option)

T2 Outlet NPT Ball Valve with “T”

Handle (Standard)

T4 Outlet Union Ball Valve with

“T” Handle (Option)

T2 Outlet NPT Ball Valve with

Lever Handle (Standard)

T4 Outlet Union Ball Valve with

Lever Handle (Option)

T2 Outlet NPT Ball Valve with

Locking “T” Handle (Option)

T4 Outlet Union Ball Valve with

Locking “T” Handle (Option)

T2 Outlet NPT Ball Valve with

Locking Lever Handle (Option)

T4 Outlet Union Ball Valve with

Locking Lever Handle (Option)

Inlet and Outlet Shut-O Valves

Std. or

LF

81 Mtl

LF 77BLF-103-85 77BLF-104-83 77BLF-105-83

81 Mtl 77B-303-85 77B-304-83 77B-305-83

LF 77BLF-303-85 77BLF-304-83 77BLF-305-83

81 Mtl

LF 77BLF-106-84 77BLF-107-84 77BLF-108-84

81 Mtl

LF 77BLF-306-84 77BLF-307-84 77BLF-308-84

81 Mtl

LF 77BLF-104-91 77BLF-105-91

81 Mtl 77B-304-91 77B-305-91

LF 77BLF-304-91 77BLF-305-91

81 Mtl

LF 77BLF-106-86 77BLF-107-86 77BLF-108-86

81 Mtl

LF 77BLF-306-86 77BLF-307-86 77BLF-308-86

81 Mtl

LF 77CLF-103-85 77CLF-104-83 77CLF-105-83

81 Mtl 77C-303-85 77C-304-83 77C-305-83

LF 77CLF-303-85 77CLF-304-83 77C-305-83

81 Mtl

LF 77CLF-106-84 77CLF-107-84 77CLF-108-84

81 Mtl

LF 77CLF-306-84 77CLF-307-84 77CLF-308-84

81 Mtl

LF 77CLF-104-91 77CLF-105-91

81 Mtl 77C-304-91 77C-305-91

LF 77CLF-304-91 77CLF-305-91

81 Mtl

LF 77CLF-106-86 77CLF-107-86 77CLF-108-86

81 Mtl

LF 77CLF-306-86 77CLF-307-86 77CLF-308-86

Qt y.

1/2” 3/4” 1” 1-1/4” 1-1/2” 2”

77B-103-85 77B-104-83 77B-105-83

Not Available

Not Available

1

Not Available

77C-103-A4 77C-104-83 77C-105-83

1

Not Available

77B-104-91 77B-105-91

Not Available

Not Available

Not Available

Not Available

77C-104-91 77C-105-91

Not Available

Not Available

Part Number

Not Available

Not Available

77B-106-84 77B-107-84 77B-108-84

77B-306-84 77B-307-84 77B-308-84

Not Available

Not Available

77B-106-86 77B-107-86 77B-108-86

77B-306-86 77B-307-86 77B-308-86

Not Available

Not Available

77C-106-84 77C-107-84 77C-108-84

77C-306-84 77C-307-84 77C-308-84

Not Available

Not Available

77C-106-86 77C-107-86 77C-108-86

77C-306-86 77C-307-86 77C-308-86

Replacement Handles for Ball Valve Shut-O Valves (T2 & T4 options)

“T” Handle

Lever Handle Not Available W-9366-00

Locking “T” Not Available W-2394-00 Not Available

Locking Lever Not Available W-9686-00

All

W-9732-00 W-9864-00 W-9734-00

Stainless steel handles are standard on all Apollo® backow devices.

10

www.apollovalves.com Customer Service (704) 841-6000

Page 11

BFMM DC4A SBF

REPAIR KITS DC4A & DCLF4A 1/2” 2”

Check Module Rubber Kit (One kit repairs one check)

(Universal, for standard & lead free valves)

Repair Kit Model Number RK4A12CMR RK4A34CMR RK4A1CMR RK4A112CMR RK4A2CMR

Item # Ordering Number 4A-003-01 4A-004-01 4A-005-01 4A-007-01 4A-008-01

not Shown O-Ring Lubricant I-9016-00

11 Check Module Seat Disc 1 D-4771-00 D-4743-00 D-4770-00 D-4853-00 D-4873-00

7 Check Module O-Ring 1 D-4880-00 D-4744-00 D-4882-00 D-4884-00 D-4885-00

6 Cap O-Ring 1 D-4881-00 D-4812-00 D-4884-00 D-4885-00 D-4888-00

DC Checks Complete Kit (One kit repairs one check)

(Universal, for standard & lead free valves)

Repair Kit Model Number RK4A12CMC RK4A34CMC RK4A1CMC RK4A112CMC RK4A2CMC

Item # Ordering Number 4A-003-02 4A-004-02 4A-005-02 4A-007-02 4A-008-02

not Shown O-Ring Lubricant I-9016-00

8 Check Module S-Assy 1 W-9075-05 W-9003-05 W-9074-05 W-9159-05 W-9204-05

7 Check Module O-Ring 1 D-4880-00 D-4744-00 D-4882-00 D-4884-00 D-4885-00

6 Cap O-Ring (for DC/RP) 1 D-4881-00 D-4812-00 D-4884-00 D-4885-00 D-4888-00

extra part(s) Bonnet O-Ring (for PVB) 1 D-4812-00 D-4883-00 D-4887-00 D-4858-00

DC Complete Internals Kit (One kit repairs ONE DC valve)

(Universal, for standard & lead free valves)

Repair Kit Model Number RK4A12TDC RK4A34TDC RK4A1TDC RK4A112TDC RK4A2TDC

Item # Ordering Number 4A-003-08 4A-004-08 4A-005-08 4A-007-08 4A-008-08

not Shown O-Ring Lubricant I-9016-00

8 Check Module S-Assy 2 W-9075-05 W-9003-05 W-9074-05 W-9159-05 W-9204-05

7 Check Module O-Ring 2 D-4880-00 D-4744-00 D-4882-00 D-4884-00 D-4885-00

6 Cap O-Ring 2 D-4881-00 D-4812-00 D-4884-00 D-4885-00 D-4888-00

QTY

QTY

QTY

1/2” 3/4” 1” 1-1/4” – 1-1/2” 2”

1/2” 3/4” 1” 1-1/4” – 1-1/2” 2”

1/2” 3/4” 1” 1-1/4” – 1-1/2” 2”

Size

Size

Size

Customer Service (704) 841-6000 www.apollovalves.com

11

Page 12

Regional Management List now available online at http://conbra.co/rmlist

704.841.6000

CUSTOMER SERVICE

www.apollovalves.com www.elkhartproducts.com

BFMMDC4ASBF 07/16 1,500 iTek

800.395.7313

CUSTOMER SERVICE

800.776.2756

CUSTOMER SERVICE

www.lascottings.com

Loading...

Loading...