Apollo Conbraco DCLF4A, DC4A Installation Manual

INSTALLATION, OPERATION & MAINTENANCE MANUAL

BACKFLOW

BFMM DC4A SBF | EFFECTIVE AUGUST 1, 2016

Model DC4A / DCLF4A

1/2” - 2”

Double Check Valve (DC)

Backflow Preventer

INSTALLATION, OPERATION, & MAINTENANCE MANUAL

TABLE OF CONTENTS

Double Check Valve Backow Preventer 1/2” – 2”

Section Page

I Description and Operation ......................................................................3

II Installation .....................................................................................3

III Trouble Shooting Guide.........................................................................5

IV Maintenance Instructions .......................................................................5

V Testing Procedures............................................................................6-7

Parts List

Parts List (1/2”- 2”) .......................................................................... 8-10

Repair Kits

Repair Kits (1/2”- 2” ) ..........................................................................11

2

www.apollovalves.com Customer Service (704) 841-6000

BFMM DC4A SBF

DOUBLE CHECK VALVE BACKFLOW PREVENTER 1/2” 2”

I. DESCRIPTION AND OPERATION

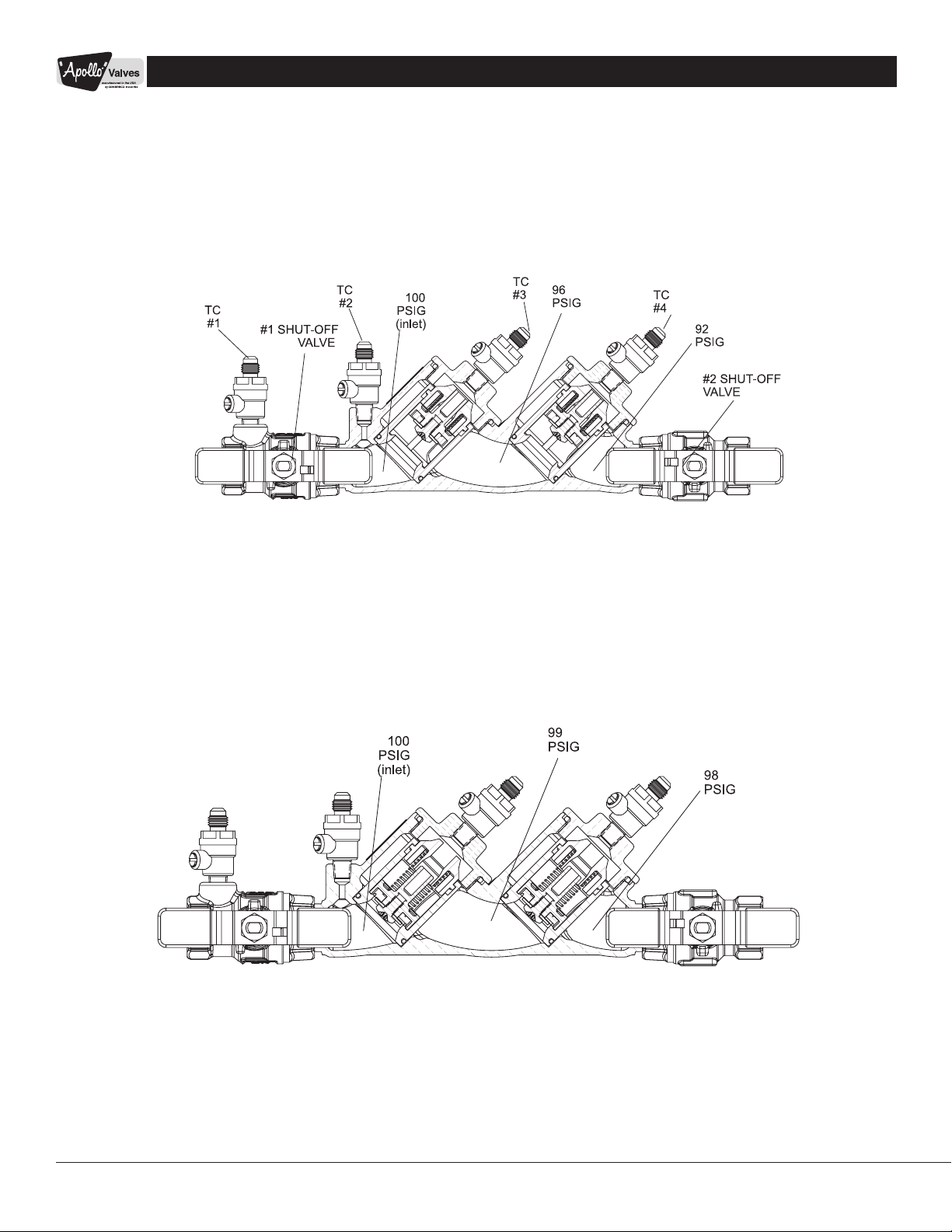

The Double Check Valve (DC) device consists of two independently-acting, spring-loaded check valves. Two resilient seated shuto valves and four test cocks complete the assembly. Each check is designed to maintain a minimum of 1 psi across the valve

during normal operation. If at any time the pressure downstream of the device increases above the supply pressure, both check

valves will close to prevent any backow from occurring. The owing and no ow conditions are illustrated in gures 1 and 2.

To initiate ow, supply pressure must be sucient to open both checks and overcome friction, normally a minimum of 3 to 5 psi

above the downstream pressure.

II. INSTALLATION

A. The DC must be installed in an accessible location to facilitate periodic eld testing and maintenance.

B. Flush all upstream piping thoroughly to remove foreign matter prior to installing the device.

C. The device should be installed either horizontally or vertical up for ease of maintenance and testing. A clearance between

the lower most portion of the device and ood grade or oor should be provided for ease of maintenance.

D. When shut-o valves are provided separately, they should be installed with a test cock on the upstream side of the inlet shut o valve.

E. After installing the assembly and with downstream or #2 shut-o valve closed, pressurize the device and bleed ALL air

through test cock #4. Then open #2 shut-o valve.

Customer Service (704) 841-6000 www.apollovalves.com

3

INSTALLATION, OPERATION, & MAINTENANCE MANUAL

Figure 1

FLOWING CONDITION

Figure 2

NO FLOW CONDITION

NOTE: Pressures shown are for illustrative

purposes only and are not necessarily

indicative of any actual valve.

4

www.apollovalves.com Customer Service (704) 841-6000

Loading...

Loading...