Page 1

SCALE: DRN: CHKD: NO. REV.

NAME:

MAT'L:

EXP. NO.

CHANGE DE SCRIPTION

ECN NO.

BY DATEREV.

APP'D:DATE:

R

1

2

3

4

5

6

7

8

9

10

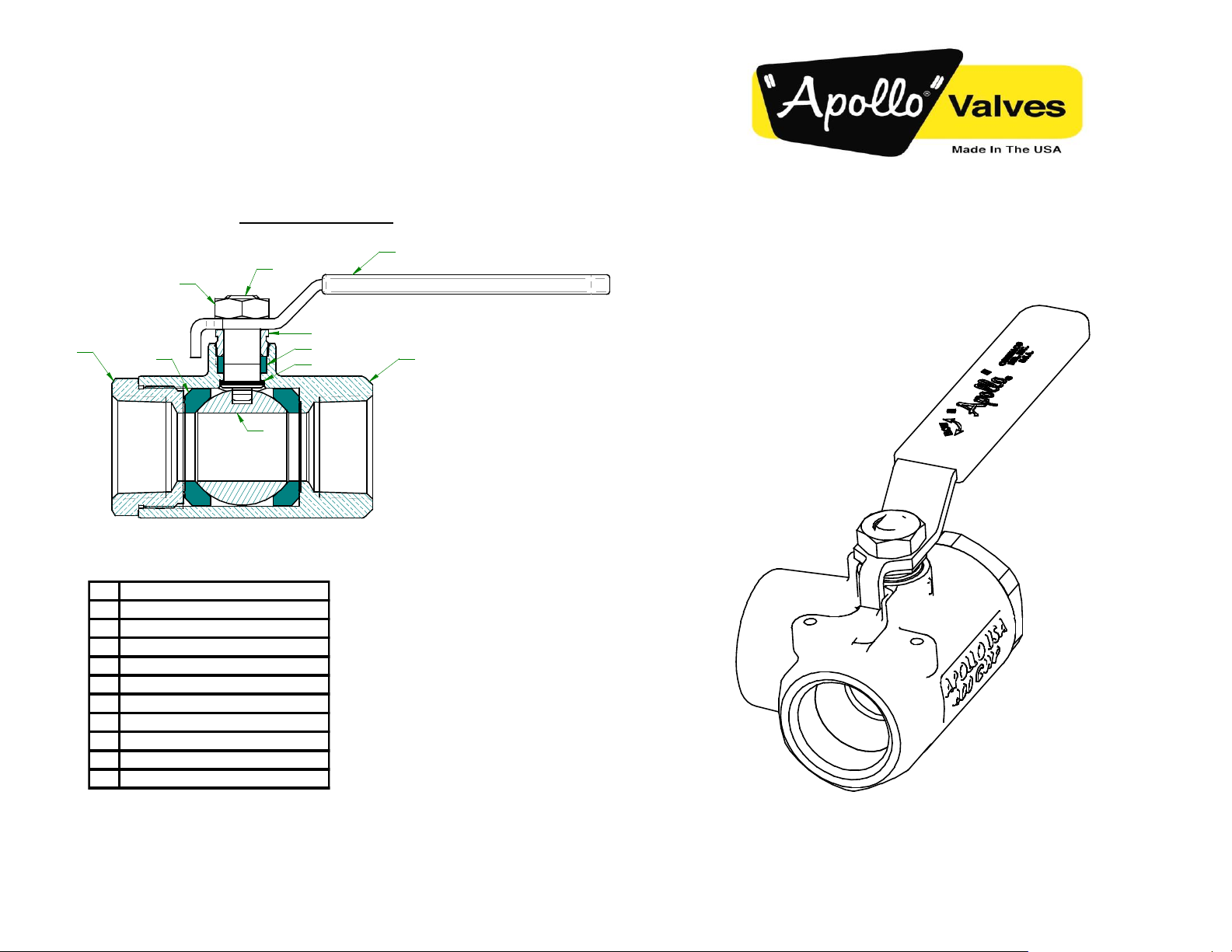

NO DESCRIPTION

1

STEM

2

STEM NUT

3

PACKING GLAND SCREW

4

PACKING

5

STEM BEARING

6

SEAT

7

BALL

8

RETAINER

9

BODY

10

HANDLE

11) With the ball in the closed position, thread the retainer into the body and

torque to manufacturing specification to secure the body joint. Contact factory

for torque values.

12) Cycle the valve to the open position and verify proper operation and alignment

of handle and/or mechanism.

Note: Always test valve and system before putting the system into service.

PARTS ILLUSTRATION

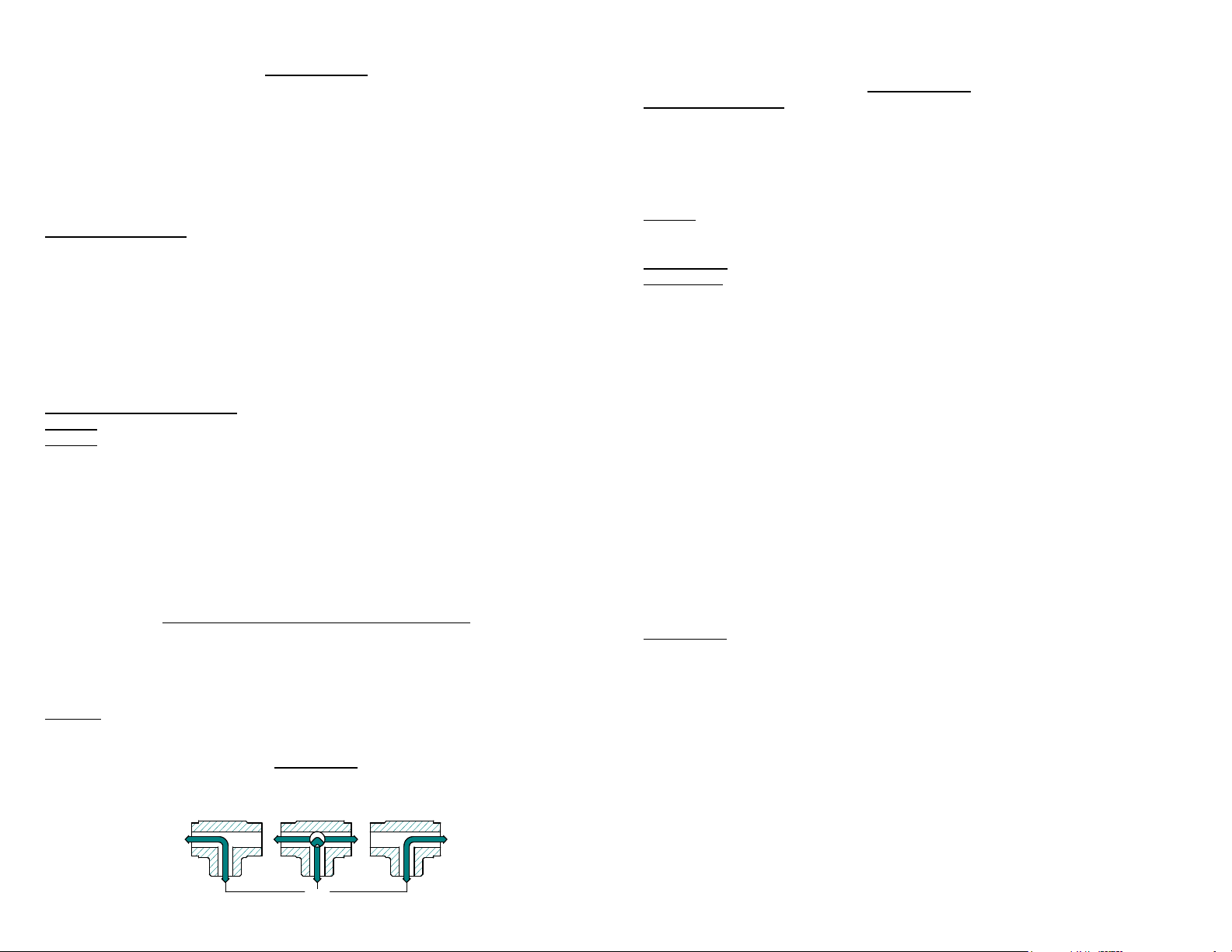

3 – WAY DIVERSION BALL VALVES

70600, 70900 and 76600 SERIES

INSTALLATION, OPERATION & MAINTENANCE GUIDE

Page 4 I414500. Rev C

Page 2

Page 1

INLET

LEVER POSITION

0° 45° 90°

INSTALLATION

Two piece threaded and solder end Apollo Ball valves are bi-directional. They may be

installed in vertical or horizontal pipe runs without regard to flow direction and without

regard to stem orientation.

Note: Valves must be installed in piping systems that comply with the applicable

portions of the ASME B31 standards. Special considerations must be taken with

respect to pipe line expansions and contractions and the media expansion and

contractions within the piping system.

Threaded End Valves

Mating pipe connections should be accurately threaded, clean and free of foreign

material or metal shavings. Two to four wraps of PTFE pipe tape (or pipe dope, but not

both) should be applied to the male threads. Two wrenches must be used when mating

up pipe joints to these valves. Apply one flat-faced wrench on the valve hex closest to

the pipe joint being tightened and use a pipe wrench on the pipe to prevent transmitting

torque through the valve body joint. Typical wrench make-up is 1-1/2 turns after

installing the pipe hand-tight. Do not overtighten the valve onto the pipe, as this can

damage or distort the valve. Do not reverse-rotate after tightening as this can damage

the body/retainer seal.

Solder End (Sweat In) Valves

Caution: Use only solders with melt points below 500°F.

Caution: Valves should only be soldered in the fully open or closed position.

During soldering, the mid-portion of the valve body should not exceed 300°F. This can

be monitored using Tempilstik® or an infra-red temperature sensor. Depending on the

fuel selected and the orientation of the installation it may be necessary to wrap the

valve body with wet rags or employ other heat absorbing techniques. Select a torch tip

size appropriate for the tube size being soldered. The flame must be directed away

from the valve body, concentrated on the solder cup. The cup should be heated evenly.

Allow heated joints to cool naturally. Quenching with water will cause unnecessary

stress on the joint.

Fuel Flame temp w/Oxygen

Propane 3596°F (1980°C)

Natural Gas 3560°F (1960°C)

MAPP Gas 3670°F (2021°C)

Acetylene 4622°F (2550°C)

Warning: Excessive heat input will damage the body seal resulting in leaks at the valve

body joint. In extreme cases, seats and stem packing may also be damaged.

OPERATION

The valve handle is marked showing proper “FLOW” direction in respect to lever

position at extreme end of lever travel.

Page 2

MAINTENANCE

Regular Maintenance

Normal stem packing wear can be compensated for by tightening the packing gland

screw. (Wrench part number H371400 is available to ease this operation.) Tighten the

packing gland screw clockwise in 1/8 turn increments until observed leakage stops. If

all of the adjustments to the packing gland screw have been made, remove the handle

nut, handle and packing gland screw and add one or two replacements bearings on top

of the old packing. Reinstall the handle and handle nut.

Caution: Do not disassemble valve while under pressure nor with entrapped hazardous

fluids therein.

Valve Repair

Disassembly

1) Operate the valve 0° to 90° to assure there are no trapped fluids or pressure in

the body cavity. Place the handle in the position such that is parallel to the

inlet port.

2) Remove the handle nut, handle and packing nut. Set aside for reuse.

3) Install pipe plugs in the body and retainer ports of NPT valves to prevent

collapsing those areas.

4) Remove the retainer from the body. It may be necessary to heat the body joint

above 450°F to breakdown the sealant used to secure the valve halves.

5) Remove the ball from the body cavity. Inspect the ball. If it is scarred, it is

recommended that the whole valve be replaced, but replacement balls are

available. Clean and set aside good balls for reuse.

6) Push the stem from the outside into the body cavity. Inspect the stem. If it is

scarred or has damaged threads, replacements are available. Clean and set

aside good stems for reuse.

7) Remove all seals and seats from the body and retainer then discard. Inspect

the body and retainer for damage. If damaged, scrap the valve as

replacements of these components are not offered.

Note: Union end valves cannot be easily repaired; therefore it is recommended

that the main valve section be replaced.

Re-Assembly

1) Install stem bearing on to stem.

2) Fit stem into body from the retainer end and position the stem with the handle

flats perpendicular to the flow axis.

3) Install stem packing over stem and fit into body recess.

4) Install packing gland screw into the threaded stem area.

5) Tighten the gland screw to manufacturing torque specifications: Contact

factory for torque values.

6) Install the handle and handle retaining hardware.

7) Apply suitable light lubricant to seat and fit into the seat pocket of the body.

8) Install the ball. Make sure that the handle is parallel to the inlet port.

9) Apply suitable light lubricant to seat and fit into the seat pocket of the retainer.

10) Apply an adequate amount of thread locking compound (Loctite 609, 648 or

680) to the retainer threads. Enough to cover no less than two complete

threads shall be applied to the leading threads opposite the retainer shoulder.

Note: Valves in oxygen service can only be sealed with oxygen compatible thread sealant.

In accordance with the U.S. Safe Drinking Water Act (SDWA), it is illegal to use this product in the United States for potable water services (water intended for human consumption).

Page 3

Amendment Register

Date

ECN

Revision

Page

Description

Initiator

Reviewed

07/16/18

M16975

C

1-2

Updated NPT thread instructions & SDWA warning

DRP

WGH

In accordance with the U.S. Safe Drinking Water Act (SDWA), it is illegal to use this product in the United States for potable water services (water intended for human consumption).

Loading...

Loading...