Page 1

I979100 REV. A

2 PIECE THREADED BRONZE BALL VALVES

WITH SPRING RETURN

INSTALLATION, OPERATION, & MAINTENANCE GUIDE

71-500 Series

INSTALLATION

Two piece threaded and solder end Apollo Ball valves are bi-directional. They may be

installed in vertical or horizontal pipe runs without regard to flow direction and without

regard to stem orientation.

Note: Valves must be installed in piping systems that comply with the applicable

portions of the ASME B31 standards. Special considerations must be taken with

respect to pipe line expansions and contractions and the media expansion and

contractions within the piping system.

Pipe connections to be threaded into these valves should be accurately threaded, clean

and free of foreign material or metal shavings. PTFE pipe tape is recommended for use

as the pipe joint sealant. Two wrenches must be used when making up pipe joints to

these valves. Apply one wrench on the valve end closest to the pipe joint being

tightened and the other wrench to the pipe to prevent transmitting torque through the

valve body joint. Typical pipe make-up is 1-1/2 turns after installing the pipe hand-tight.

MAINTENANCE

Regular Maintenance

Normal stem packing wear can be compensated for by tightening the packing gland

screw. (Wrench part number H371400 is available to ease this operation.) Tighten the

packing gland screw clockwise in 1/8 turn increments until observed leakage stops. If

all of the adjustments to the packing gland screw have been made, remove the handle

assembly as described in step 1-6 below. Remove packing gland screw and add one or

two replacements bearings on top of the old packing. Reinstall the handle and handle

nut.

Caution: Do not disassemble valve while under pressure nor with entrapped hazardous

fluids therein.

Valve Repair

Disassembly

1) Operate the valve fully opened to fully closed to assure there are no trapped

fluids or pressure in the body cavity. Leave the valve in the closed position.

2) Remove handle extension. Clean and set aside for reuse.

3) Remove the two hex jam nuts and the washer. Then remove the nyloc hex nut

and spring.

4) Remove anchor screw then remove spring rod from the spring return handle

adapter.

5) Remove stem nut and spring return handle adapter.

6) Install pipe plugs in the body and retainer ports of NPT valves to prevent

collapsing those areas.

7) Remove the retainer from the body. It may be necessary to heat the body joint

above 450°F to breakdown the sealant used to secure the valve halves.

8) Remove the ball from the body cavity and inspect. The ball must be smooth

and without pits, burrs or scratches.

9) Remove the packing gland then push the stem from the outside into the body

cavity and remove.

10) Remove all seals and seats from the body, stem and retainer then discard.

Re-Assembly

1) Install stem bearing on to stem.

2) Fit stem into body from the retainer end and position the stem with the handle

flats perpendicular to the flow axis.

3) Install stem packing over stem and fit into body recess.

4) Install packing gland screw into the threaded stem area.

5) Tighten the gland screw to manufacturing torque specifications: see Table 1

6) Apply suitable light lubricant to seat and fit into the seat pocket of the body.

7) Install the ball in the closed position interlocking with stem.

8) Apply suitable light lubricant to seat and fit into the seat pocket of the retainer.

9) Apply an adequate amount of thread sealant compound (Loctite 609, 648 or

680) to the retainer threads. Enough to cover no less than two complete

threads shall be applied to the leading threads opposite the retainer shoulder.

10) With the ball in the closed position, thread the retainer into the body and

torque to manufacturing specification to secure the body joint. See Table 1.

11) Apply thread locking compound to each socket head screw. Attach the anchor

base using the two socket head screw.

12) Apply two drops of thread lock compound to the stem nut and attach spring

return handle adapter to the stem.

13) Insert spring rod assembly thru the hole in the spring return handle adapter.

Verify rod tip orientation as noted * in drawing. Apply thread lock compound to

the anchor screw and attach the rod assembly to the anchor base.

14) Place spring over rod assembly and into the threaded hole of the spring return

handle adapter. Slide the washer into place and secure with the nyloc hew nut.

Tighten the nyloc nut to achieve dimension “A” shown in Table 2. Assemble

the other washer and two hex jam nuts at the end of the rod as shown in parts

illustration and apply thread lock compound.

15) Place handle extension over spring assembly and apply two drops of thread

sealant to the threads. Tighten the handle extension into the spring return

handle adapter.

16) Cycle the valve to the open position and verify proper operation and alignment

of handle and/or mechanism.

Warning: Be sure extremities are free of flow path to prevent bodily harm.

Warning: (Required by California) This product contains a chemical known to the state of

California to cause Cancer and Birth Defects or other Reproductive Harm.

Warning: For NON LEAD FREE products – It is illegal to use this product in the United

States for potable water services (water intended for human consumption)

Page 2

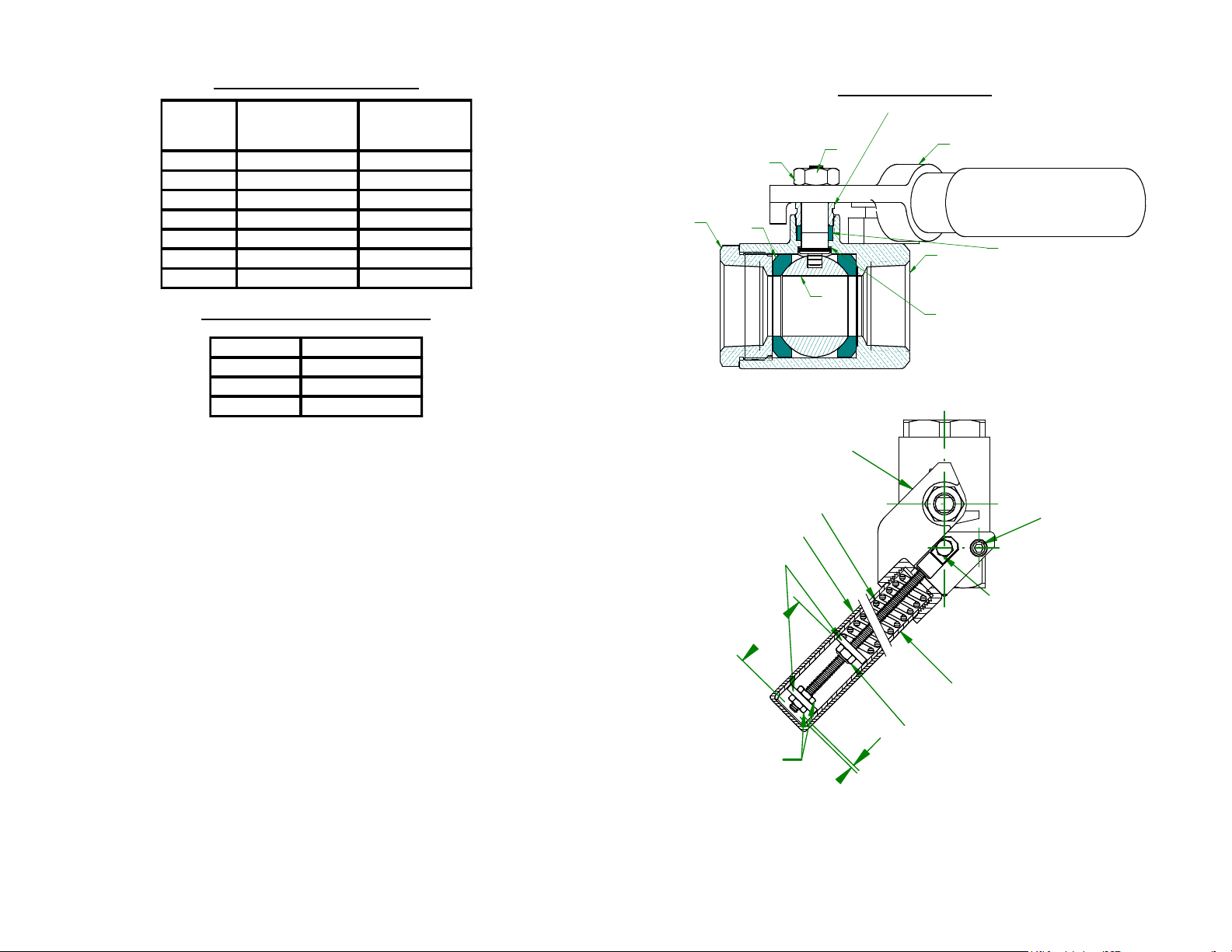

Valve Size

Gland Screw

Torque

(+ or – 10%)

Retainer Torque

(+ or – 10%)

(ft-lb)

1/4" - 3/8"

10-12 13

1/2"

10-12 16

3/4"

15 - 20 42

1"

15 - 20 63

1-1/4"

35 - 40 130

1-1/2"

35 - 40 199

2"

35 - 40 282

Valve Size A - Approx.

1/4", 3/8", 1/2"

1-5/8"

3/4", 1"

7/8"

1-1/4" - 2"

1-7/8"

STEM

HANDLE NUT

GLAND SCREW

STEM PACKING

STEM BEARING

SEAT

BALL

RETAINER

HANDLE

BODY

.12

MAX.

SPRING

GRIP

WASHERS (2)

NYLOC NUT

*

A

SOCKET HEAD

SCREW (2)

NOTE: POSITION OF ANCHOR

SCREW OFFSET AT SPRING

ROD TIP. MUST BE

ASSEMBLED AS SHOW N.

HANDLE EXTENSION

(WITH GRIP)

HEX NUTS

(2)

SPRING RETURN

HANDLE ADAPTER

Table 1: Torque Requirements

PARTS ILLUSTRATION

Table 2: “A” Height Requirements

Page 3

Amendment Register

Date

ECN

Revision

Page

Description

Initiator

Reviewed

8/28/2014

M14578

A

1-2

Released

TH

GDG

Loading...

Loading...