Page 1

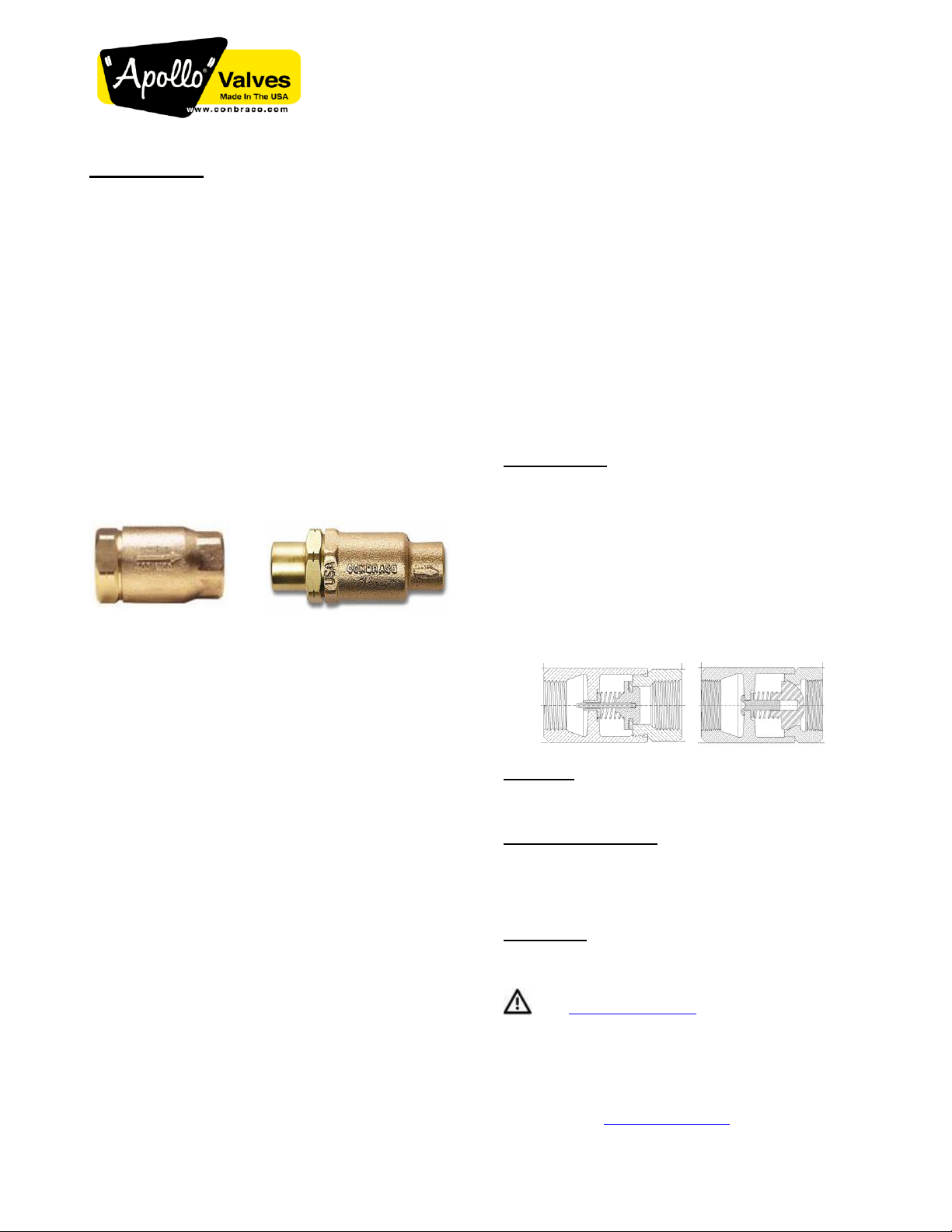

61 & 62 SERIES (Model: CVBE & CVS)

IN-LINE CHECK VALVE INSTALLATION,

OPERATION AND MAINTENANCE MANUAL

INSTALLATION

Overall Cautions

1. It is the installers and/or system designer’s

responsibility to ensure that these valves and

adjoining piping are installed and supported in

accordance with applicable ASME B31 standards.

2. These check valves are not recommended for use

with reciprocating pumps and similar applications

which may induce repetitious vibrations.

3. Low flow rates which do not fully open the valve may

result in undesirable noise and premature valve

failure.

4. Upstream flow disturbances which create turbulence

may also result in rapid wear. It is recommended

that a minimum of 10 pipe diameters of straight pipe

be provided between the check valve and any

upstream devices such as control valves or elbows

etc.

Threaded Valves

1. The 61 and 62 series Apollo check valves are

designed to be installed horizontally or vertically with

upward flow.

2. Make sure all pipe end connections are clean, burr

free and free of any debris.

3. Apply pipe sealant (pipe dope, Teflon® tape,

Loctite® compound, etc.) to the make end pipe prior

to installing the valve.

4. Make sure the valve is installed in the piping system

so that the intended flow direction corresponds with

the flow arrow on the side of the valve body.

5. When tightening the valve onto adjoining pipe, apply

the wrench to the valve at the hex closest to the joint

being completed. Do not over-tighten the pipe joint.

No more than 1 ½ turns should be necessary beyond

finger tight to create a leak free joint. Caution: Do

no apply installation torque through the valve as

it may damage the valve body or body joint seal.

6. Check the valve and joints for leaks prior to putting

the system into service.

Solder End Valves

1. The 61 and 62 series Apollo check valves are

designed to be installed horizontally or vertically with

upward flow.

Conbraco Industries, Inc. 701 Matthews Mint Hill Rd. Matthews NC 28106 USA; www.apollovalves.com ; 704-841-6000

This specification is provided for reference only. Conbraco reserves the right to change any portion of this specification without notice and without incurring obligation to

make such changes to Conbraco products previously or subsequently sold.

2. Make sure all pipe end connections are clean, burr

free and free of any debris.

3. Make sure the valve is installed in the piping system

so that the intended flow direction corresponds with

the flow arrow on the side of the valve body.

4. 61-600 Series solder end check valves are designed

to be soft soldered using solder with a melting point

less than 500F.

5. Apply heat with the flame directed away from the

center of the valve body and distribute evenly around

the joint. Do not concentrate heat on any one point

(i.e. the bottom of the joint). Make one joint at a time

and allow it to cool to the touch before starting the

second joint. Caution: Excessive heat can damage

the valve’s soft components.

6. Check the valve and joints for leaks prior to putting

the system into service.

MAINTENANCE

1. The 61 and 62 series Apollo check valves are

designed to be virtually maintenance free.

2. Should a problem develop, do not disassemble the

valve while the under pressure.

3. Repair kits are available from the factory should the

seat, check or spring need replacing.

4. When reassembling the valve, use Loctite

Compound 569 on the 61 Series and Loctite

Compound AA with Loctite Primer N on the 62

Series.

FREEZING

Provide means to protect the valve from freezing and

bursting when used on liquids.

FLUID COMPATIBILITY

Consider the corrosive, erosive and adhesive effects of

fluids on the valves and piping components. It is the

user’s responsibility to ensure that the valve is compatible

with the media in the system.

OPERATION

No manual operation is required, nor is it possible once

the check valve has been installed in the piping system.

CALIFORNIA PROP 65: WARNING: Cancer and Reproductive

--------Harm - www.P65Warnings.ca.gov.

FOR NON-LEAD FREE VALVES: It is illegal to use this product in the

United States for potable water services (water intended for human

consumption).

FOR LEAD FREE VALVES: This product complies with U.S. Safe

Drinking Water Act (SDWA). Suitable for potable water applications

intended for human consumption.

ES-1487 Rev. C Page 1 of 1

Loading...

Loading...