Page 1

XP95 ENGINEERING PRODUCT GUIDE

Ionisation Smoke Detector

Optical Smoke Detector

Heat Detector

Multisensor Detector

Manual Call Point

Isolating Base

Sounders & Beacons

Page 2

The XP95 range of intelligent fire detectors is

advanced in design, improved in performance and

has unique features that benefit the installer and

the end user. The range includes ionisation and

optical smoke detectors, heat detectors as well as

a multisensor. All have an unobtrusive profile, a

zero insertion force base, user friendly addressing

and extended data and alarm features. A manual

call point, an isolating base, sounders, beacons

and other compatible products are also available.

These detectors have been carefully researched

and developed by the Apollo design team and the

range has undergone rigorous testing to ensure

that it meets not only European and other

standards but also the demands of today’s high

technology environments.

This Product Guide aims to provide engineers with

full information on XP95, in order to be able to

design optimum solutions to fire protection

problems.

Key features

Analogue Value Report

•

Digital data transmission

•

Input Bits Reporting

•

Interrupt Warning

•

Apollo Fire Detectors Limited, part of the Halma

plc group of companies, operates from one site at

Havant, near Portsmouth, England. All departments

– Research and Development, Sales and Marketing,

Manufacturing and Finance – are located there.

Apollo applies the most modern production

techniques and has invested in sophisticated

manufacturing equipment to ensure consistent

high quality of product and fast response to

customer requirements. Through planned

expansion Apollo has reached a leading position

in the market for professional fire detectors and

exports over half of its production to countries

around the world.

Automatic Type Identification

•

Address Confirmation

•

XP95 Device Flag

•

Information in this guide is given in good faith, but Apollo Fire

Detectors Limited cannot be held responsible for any omissions

or errors . The company res erves the right to change

specifications of products at any time without prior notice.

Page 3

XP95 TABLE OF CONTENTS

Application of XP95 Detectors 4

Addressing and Communications 4

Features of the XP95 Range 5

Ionisation Smoke Detector

Operating principles 6

Electrical description 7

Environmental characteristics 7

Safety note 7

Technical data 7

Optical Smoke Detector

Operating principles 9

Electrical description 9

Environmental characteristics 9

Technical data 10

Heat Detector

Operating principles 11

Electrical description 11

Environmental characteristics 11

Technical data 12

Multisensor Detector

Operating principles 13

Technical data 14

Manual Call Point

Operating principles 15

Technical data 16

XP95 Mounting Base 17

XP95 20D Isolating Base

Operating principles 18

Electrical description 18

Technical data 18

XP95 Isolator 19

XP95 Loop-Powered Beam Detector 19

Intelligent Reflective Beam Detector 19

MiniDisc Remote Indicator 19

Loop-powered Sounders, Beacon & Sounder Beacons 19

XP95 Flame Detector 20

page

3

Approvals and Regulatory Compliance 21

EMC 21

Maintenance of Detectors 22

Page 4

APPLICATION OF XP95 DETECTORS

ADDRESSING AND COMMUNICATIONS

page

4

The choice of detector from the XP95 range follows the

well established principles of system design. That is, the

optimum detector type will depend on the type of fire risk

and fire load, and the type of environment in which the

detector is sited.

For general use, smoke detectors are recommended since

these give the highest level of protection. Smoke detectors

from the XP95 range may be ionisation, optical or

multisensor types. It is generally accepted that ionisation

types have a high sensitivity to flaming fires whereas

optical detectors have high sensitivity to smouldering fires.

As a result of this, ionisation types are widely used for

property protection, and optical types for life protection.

These general principles still apply to XP95 detectors

although the availability of a multisensor in the range

offers more choice to the system designer.

The multisensor is basically an optical smoke detector and

will therefore respond well to the smoke from smouldering

fires. The detector also senses air temperature. This

temperature sensitivity allows the multisensor to give a

response to fast burning (flaming) fires, which is similar to

that of an ionisation detector. The multisensor can

therefore be used as an alternative to an ionisation detector

Where the environment is smoky or dirty under normal

conditions, a heat detector may be more appropriate. It

must be recognised, however, that any heat detector will

respond only when the fire is well established and

generating a high heat output.

Unless otherwise specified, devices described in this guide

are suitable for indoor use only.

Each XP95 device responds to interrogation and command

from central control equipment. It communicates to the

panel information on status, command bits, type, location,

and other information that allows an alarm to be raised

even when the device is not itself being interrogated.

Message error checking is also provided. The devices are

compatible with Series 90, Discovery®and XPlorer systems

and control equipment to aid maintenance, extension and

upgrade of existing systems.

A unique, patented XPERT card provides simple, user

friendly and accurate identification of detector location

whereby a coded card, inserted in the base, is read by

any detector once it is plugged in. All the electronic

components are in the detector but the location information

is held in the base. The address card simplifies and speeds

up installation and commissioning. Addressing errors

during maintenance and service are eliminated.

The XP95 manual call point continues to use DIL switch

addressing, but its interrupt feature also provides automatic

reporting of its location in the interrupt mode.

The XP95 detectors provide an alarm facility that automatically

puts an alarm flag on the data stream and reports its address

when the pre-set EN54 thresholds are exceeded. The

devices provide great flexibility in system design with the

control equipment determining the characteristics of the

system. A large and growing range of compatible control

equipment is available from many sources - details are

included in Apollo publication PP1010, which is available

on request.

Page 5

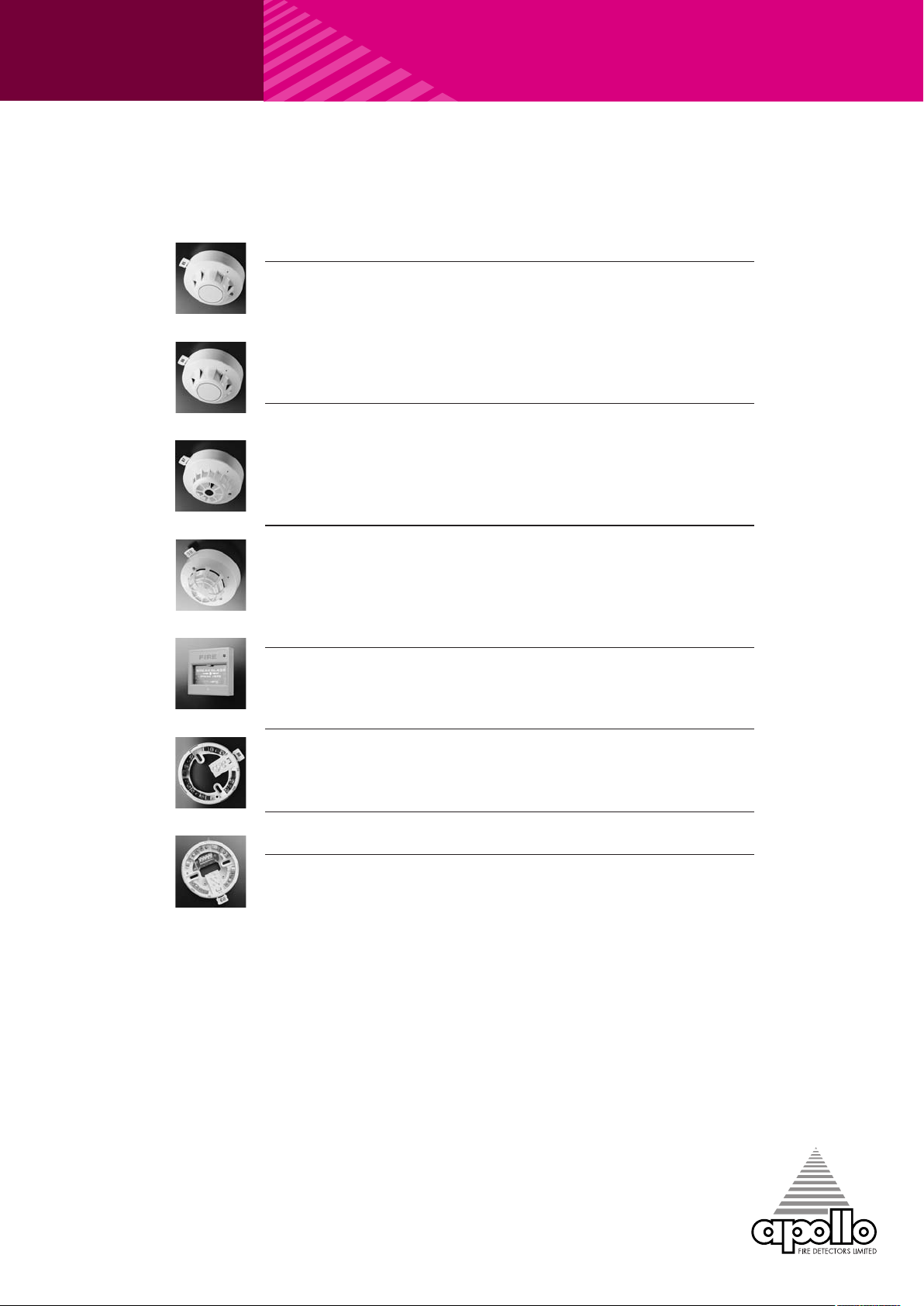

Ionisation Optical Multisensor Heat

Overheating/thermal combustion Poor Very Good Very Good Very Poor

Smouldering/glowing combustion Moderate/Good Good Good Very Poor

Flaming combustion Very Good Good Good Poor

Flaming with high heat output Very Good Good Very Good Moderate/Good

Flaming - clean burning Poor Very Poor Moderate/Good Moderate/Good

Table1 Response characteristics of smoke and heat detectors.

PROTOCOL FEATURES

Control Unit Interrogation and Command:

3 bits of command instruction and the 7- bit address are

issued by the control equipment following an initiating pulse.

Interrupt Warning:

Notification that an XP95 manual call point or XP95 Mini

Switch Monitor (interrupt) has been operated.

Analogue Value Report:

Status continually reported.

Input Bits Reporting:

Field devices advise control equipment of actions they have

taken. For smoke and temperature detectors, these confirm

compliance with the output command bits. Bit information

depends on device type.

Automatic Type Identification:

The device being interrogated replies with a 5 bit type

code, allowing up to 32 device types.

Address Confirmation:

The 7- bit address (up to 126 devices per loop) of the

detector responding is confirmed back to the control unit.

XP95 Device Flag:

Tells the control equipment that more information is available.

Alarm Flag:

For accelerated alarm reporting.

Parity Error Check:

For received message accuracy.

Interrupt or Alarm Address:

Provides fast location of a device in alarm state.

ENGINEERING FEATURES

High Level Integration:

ASICs technology for lower component count.

Zero Insertion Force Base:

For easier installation and maintenance.

Ease of Maintenance:

Snap lock chambers for easy cleaning.

Surface Mounted Components:

For long life and high reliability

Latest Data Reported:

As well as free running data update, device will update

data when the preceding device is being interrogated.

XPERT Card Addressing:

For fast reliable installation and service.

Unobtrusive Design:

For elegant designs in modern buildings.

page

5

Page 6

XP95 IONISATION SMOKE DETECTOR

Fig.1 Sectional view - XP95 Ionisation Smoke Detector

page

6

XP95 Ionisation Smoke Detector Part Number 55000-500

outer smoke chamber (Fig 1).

OPERATING

PRINCIPLES

The XP95 ionisation smoke

detector has a moulded

self-extinguishing white

polycarbonate case with

wind resistant smoke inlets.

Stainless steel wiper contacts

connect the detector to the

terminals in the mounting

base. Inside the detector case

is a printed circuit board that

has the ionisation chamber

mounted on one side and

the address capture, signal

processingandcommunications

electronics on the other.

The ionisation chamber

system is an inner reference

chamber contained inside an

The outer smoke chamber

has smoke inlet apertures

that are fitted with an insect

resistant mesh.

The radioactive source

holder and the outer smoke

chamber are the positive

and negative electrodes

respectively. An Americium

241 radioactive source

mounted within the inner

reference chamber irradiates

the air in both chambers to

produce positive and

negative ions. On applying a

voltage across these

electrodes an electric field is

formed as shown in Fig 2.

The ions are attracted to the

electrode of the opposite

sign, some ions collide and

recombine, but the net result

is that a small electric current

flows between the electrodes.

At the junction between the

reference and smoke chambers

is the sensing electrode that is

used to convert variations in

the chamber currents into a

voltage.

When smoke particles enter

the ionisation chamber, ions

become attached to them

with the result that the current

flowing through the ionisation

chamber decreases. This

effect is greater in the smoke

chamber than in the reference

chamber and the imbalance

causes the sensing electrode

to go more positive.

The voltage on the sensing

electrode is monitored by

the sensor electronics and

is processed to produce a

signal that is translated by

the A/D converter in the

communications ASIC ready

for transmission when the

device is interrogated.

Fig.2 Diagramshowing lines of equipotential fortheXP95 Ionisation Smoke Monitor

Page 7

ELECTRICAL

DESCRIPTION

he detector is designed to

T

be connected to a two wire

loop circuit carrying both

data and a 17V to 28V dc

supply. The detector is

connected to the incoming

and outgoing supply via

terminals L1 and L2 in the

mounting base. A remote

LED indicator requiring not

more than 4mA at 5V may

be connected between +R

and -R terminals. An earth

connection terminal is also

provided, although this is

not required for the

functioning of the detector.

When the device is energised

the ASICs regulate the flow

of power and control the data

processing. The ionisation

chambers are energised and

the ultra low leakage sensor

ASIC provides a conditioned

analogue signal to the

analogue to digital (A/D)

converter within the

communications and

processing ASIC. When

smoke enters the ionisation

chambers through the integral

gauze, the voltage at the

sensing electrode increases to

produce an analogue signal.

An A/D conversion of the

signal from the ionisation

chambers is carried out once

per second or when either

the detector or preceding

address is being interrogated.

Whenever the device is

interrogated this data is sent

to the control equipment.

EN54 threshold alarm levels

are calibrated within the

processing ASIC. If the

device is not addressed

within 1 second of its last

polling and the analogue

value is greater than 55 the

alarm flag is initiated and

the device address is added

to the data stream every 32

olling cycles from its last

p

polling for the duration of

the alarm level condition,

except when the alarming

device is being interrogated.

This can provide a location

identified alarm from any

device on the loop in

approximately two seconds.

The detector is calibrated to

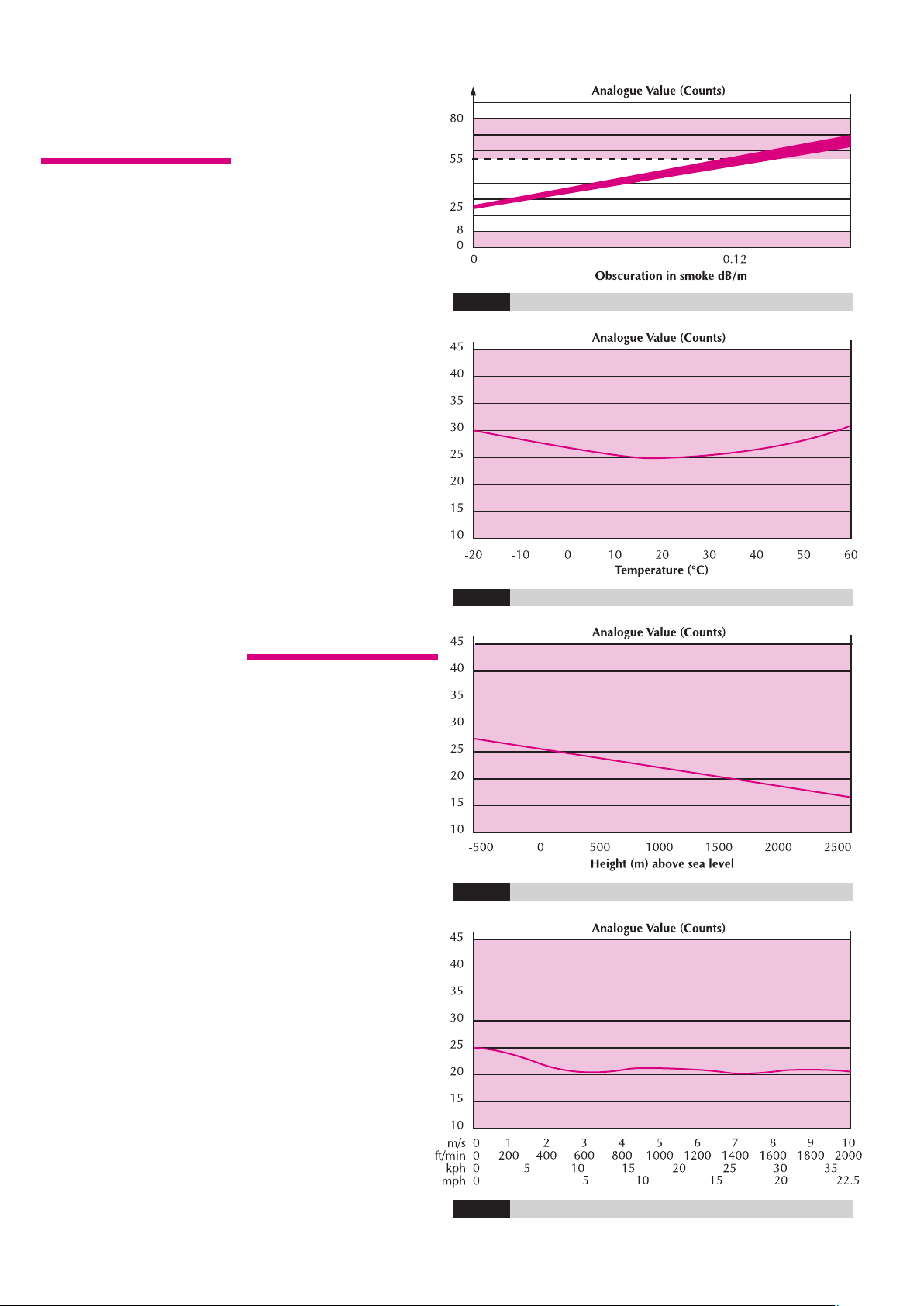

give an analogue value of

25±7 counts in clean air. This

value increases with smoke

density. A count of 55

corresponds to the EN54 alarm

sensitivity level. See Fig 3.

Counts of 8 or less indicate

fault conditions. Count levels

between 45 counts and 55

counts can be used to provide

an early warning of fire.

ENVIRONMENTAL

CHARACTERISTICS

XP95 ionisation smoke

detectors are designed to

operate in a wide variety of

environments (See Figs 4 to

6). There are only small

effects from temperature,

humidity, atmospheric

pressure and wind. Detectors

are well protected against

electromagnetic interference

over a wide frequency range.

The XP95 ionisation detector,

like all ionisation detectors,

has some sensitivity to air

movement (wind). The

extent to which the analogue

value will change depends

on the wind speed and on

the orientation of the

detector relative to the wind

direction. Relatively small

changes in wind direction

can cause significant changes

in analogue value.

Fig.3 Typical response characteristics - XP95 Ionisation Detector

Fig.4 Typical temperature response - XP95 Ionisation Detector

page

7

Fig.5 Typical pressure response - XP95 Ionisation Detector

Fig.6 Typical wind speed response - XP95 Ionisation Smoke Detector

Page 8

TECHNICAL DATA

XP95 Ionisation

Detector Part No 55000-500/

520/560

ase Part No 45681-210

B

Specifications are typical

and given at 23°C and 50%

relative humidity unless

otherwise stated.

Detector Type:

Point type smoke detector for

fire detection and fire alarm

systems for buildings

Detection Principle:

Ionisation Chamber

Chamber Configuration:

Twin compensating

chambers using one single

sided ionising radiation

source

Radioactive Isotope:

Americium 241

Activity:

33.3kBq, 0.9µCi

Sampling Frequency:

Continuous

Sensitivity:

Nominal threshold y value of

0.7 to EN54–7:2000

Supply Wiring:

Two wire supply, polarity

nsensitive

i

Terminal Functions:

L1&L2 supply in and out

+R remote indicator

-R remote indicator

Supply Voltage:

17 to 28 Volts dc

Modulation Voltage at

Detector:

5 to 9 Volts peak to peak

Quiescent Current:

280µA average, 500µA peak

Power-up Surge Current:

1mA

Duration of Power-up Surge

Current:

0.3 seconds

Maximum Power-up Time:

4 seconds for communications

(measured from application of

power and protocol)

connections (polarity

insensitive)

positive connection

(internal 2.2kΩ

resistance to supply

ve)

+

negative connection

(internal 2.2kΩ

resistance to supply

- ve)

10 seconds to exceed 10

counts 15 seconds for stable

clean air value

Clean Air Analogue Value:

25±7 counts

larm Level 55 Counts:

A

EN54 y value of 0.7

Alarm Indicator:

Red light emitting diode (LED)

Alarm LED Current:

2mA

Remote LED Current:

4mA at 5V (measured across

remote load)

Type Code:

(210 43) 011 00

Storage Temperature:

-30°C to +80°C

Operating Temperature:

-20°C to +70°C

Guaranteed Temperature

Range:

(No condensation or icing)

-20°C to +60°C

Humidity:

(No condensation or icing)

0% to 95% relative humidity

Wind Speed:

10m/s maximum

Atmospheric Pressure:

Automatic compensation by

dual chambers to maintain

sensitivity up to a height of

2000m above sea level

Vibration, Impact & Shock:

To EN54–7:2000

Electro-magnetic

Compatibility:

See page 21 for full details

IP Rating:

23D

pprovals & Regulatory

A

Compliance:

See page 21 for full details

Dimensions:(diameter x height)

etector: 100mm x 42mm

D

Detector in Base:

100mm x 50mm

Weights:

Detector: 105g

Detector in Base: 161g

Materials:

Detector Housing: White

polycarbonate V-0 rated to

UL 94

Terminals: Nickel plated

stainless steel

0832

page

8

technical data

For wind speeds up to 1m/s

(200ft/min) the change in

analogue value will not

exceed 5 counts.

Continuous operation in

wind speeds greater than

2m/s (400ft/min) is not

recommended. However,

wind speeds up to 10m/s

(2000ft/min) can be tolerated

for short periods and will

not under any conditions

increase the probability of

false alarms.

SAFETY NOTE

In the United Kingdom,

ionisation smoke detectors are

subject to the requirements of

the Radioactive Substances

Act 1993 and to the Ionising

Radiations Regulations 1999

made under the provisions

of the Health and Safety at

Work Act 1974.

The detectors, independently

tested by the National

Radiological Protection

Board (NRPB), conform to all

the requirements specified

in the ‘Recommendations for

ionisation smoke detectors in

implementation of radiation

standards’ published by the

Nuclear Energy Agency of the

Organisation for Economic

Co-operation and

Development (OECD) 1977.

There is no limit to the number

of ionisation smoke detectors

which may be installed in

any fire protection system

within the UK. See

Certificate of Approval No.

TA1 of 1999 issues by the

HSE for further details.

Storage regulations depend

on local standards and the

legislation, but, in the UK, the

number of ionisation smoke

detectors in any building or

premises shall be less than

500. See Certificate of

Approval No. TA3 of 1999

issued by the HSE for further

details.

At the end of their

recommended working life

of ten years, ionisation

smoke detectors should be

returned to Apollo for safe

disposal or disposed of in an

otherwise locally approved

and environmentally safe

manner. Please see "A Guide

to the Care, Maintenance

and Servicing of Apollo

Products", PP2055.

Guidance on storage can be

given by Apollo Fire

Detectors and full details

can be requested from:

Radioactive Substances

Regulation Function

Environment Agency

Rio House, Waterside Drive

Aztec West, Almondsbury,

Bristol, BS32 4UD

Outside the UK, please contact

the relevant national agency.

Page 9

XP95 OPTICAL SMOKE DETECTOR

XP95 Optical Smoke Detector Part Number 55000-600

In clear air the photo-diode

receives no light directly

OPERATING

PRINCIPLES

The XP95 optical detector

uses the same outer case as

the ionisation smoke detector

and is distinguished by the

indicator LED which is clear

in standby and red in alarm.

Within the case is a printed

circuit board which on one

side has the light proof

labyrinth chamber with

integral gauze surrounding

the optical measuring system

and on the other the address

capture, signal processing and

communications electronics.

An infrared light emitting

diode within its collimator is

arranged at an obtuse angle

to the photo-diode. The

photo-diode has an integral

daylight-blocking filter.

The IR LED emits a burst of

collimated light every second.

from the IR LED because of

the angular arrangement

and the dual mask. When

smoke enters the chamber

it scatters photons from the

emitter IR LED onto the

photo-diode in an amount

related to the smoke

characteristics and density.

The photo-diode signal is

processed by the optical

ASIC and passed to the A/D

converter on the

communications ASIC ready

for transmission when the

device is interrogated.

ELECTRICAL

DESCRIPTION

The detector is designed to

be connected to a two wire

loop circuit carrying both

data and a 17V to 28V dc

supply. The detector is

connected to the incoming

and outgoing supply via

erminals L1 and L2 in the

t

mounting base. A remote

LED indicator requiring not

more than 4mA at 5V may

be connected between the

+R and -R terminals. An

earth connection terminal is

also provided.

When the device is energised

the ASICs regulate the flow

of power and control the

data processing. The optical

ASIC is controlled by the

communications ASIC and

pulses the IR LED. The signal

from the photo-diode is

processed by the optical

ASIC and transferred to

the A/D converter in the

communications ASIC

where it is then stored.

When smoke enters the

chamber the photo-diode

signal increases. The

information to the A/D

converter is updated once

per second or when either

the monitor or the preceding

address is interrogated.

Whenever the device is

interrogated this data is sent

to the control equipment.

EN54 threshold alarm levels

are calibrated within the

processing ASIC. If the

Fig.7 Top section - XP95 Optical Smoke Detector

evice is not addressed

d

within 1 second of its last

polling and the analogue

value is greater than the

EN54 alarm level the alarm

lag is initiated and the

f

device address is added to

the data stream every 32

polling cycles from its last

polling for the duration of

the alarm level condition,

except when the alarming

device is being interrogated.

This can provide a location

identified alarm from any

device on the loop in

approximately 2 seconds.

The detector is calibrated to

give an analogue value of

25±7 counts in clean air.

This value increases with

smoke density. A count of 55

corresponds to the EN54 alarm

sensitivity level. See Fig.9.

ENVIRONMENTAL

CHARACTERISTICS

The XP95 optical smoke

detector is unaffected by

wind or atmospheric

pressure and operates over

the temperature range -20°C

to +60°C. See Fig. 10.

page

9

Page 10

TECHNICAL DATA

XP95 Optical Smoke Detector

Detector Part No 55000-600/

620/660

ase Part No 45681-210

B

Specifications are typical

and given at 23°C and 50%

relative humidity unless

otherwise stated.

Detector Type:

Point type smoke detector for

fire detection and fire alarm

systems for buildings

Detection Principles:

Photo-electric detection of

light scattered in a forward

direction by smoke particles

Chamber Configuration:

Horizontal optical bench

housing an infrared emitter

and sensor arranged radially

to detect scattered light

Sensor:

Silicon PIN photo-diode

Emitter:

GaAs Infra-red light emitting

diode

Sampling Frequency:

1 second

Sensitivity:

Nominal response threshold

value of 0.12 dB/m when

measured in accordance with

N54-7:2000

E

Supply Wiring:

Two wire supply, polarity

insensitive

Terminal Functions:

L1&L2 supply in and out

+

-R remote indicator

Supply Voltage:

17 to 28 Volts dc

Quiescent Current:

340µA average, 600µA peak

Power-up Surge Current:

1mA

Duration of Power-up Surge

Current:

0.3 seconds

connections (polarity

insensitive)

R remote indicator

positive connection

(internal 2.2kΩ

resistance to supply

+ve)

negative connection

(internal 2.2kΩ

resistance to supply

- ve)

Maximum Power-up Time:

4 seconds for communications

(measured from application of

power and protocol)

10seconds to exceed10 counts

35 seconds for stable clean

air value

Alarm Level Analogue Value:

55

Clean Air Analogue Value:

25±7 counts

larm Indicator:

A

Clear light emitting diode

(LED) emitting red light

Alarm LED Current:

mA

4

Remote LED Current:

4mA at 5V (measured across

remote load)

Type Code:

(210 43) 101 00

Storage Temperature:

-30°C to +80°C

Operating Temperature:

-20°C to +60°C

Guaranteed Temperature

Range:

(No condensation or icing)

-20°C to +60°C

Humidity:

(No condensation or icing)

0% to 95% relative humidity

ind Speed:

W

Unaffected by wind

Atmospheric Pressure:

Unaffected

lectro-magnetic

E

Compatibility:

See page 21 for full details

IP Rating:

3D

2

Approvals & Regulatory

Compliance:

See page 21 for full details

Vibration, Impact & Shock:

To EN54-7:2000

Dimensions:(diameter x height)

Detector: 100mm x 42mm

Detector in Base:

100mm x 50mm

Weights:

Detector: 105g

Detector in Base: 157g

Materials:

Detector Housing: White

polycarbonate V-0 rated to

UL 94

Terminals: Nickel plated

stainless steel

page

10

technical data

0832

Fig.9 Typical Response Characteristic - XP95 Optical Smoke Detector

Fig.8 Schematic diagram - XP95 Optical Smoke Detector

Fig.10 Typical Temperature Response - XP95 Optical Smoke Detector

Page 11

XP95 HEAT DETECTOR

XP95 Heat Detector Part Number 55000-400

external air temperature.

OPERATING

PRINCIPLES

The XP95 heat detectors

have a common profile with

ionisation and optical smoke

detectors but have a low air

flow resistance case made of

self-extinguishing white

polycarbonate. The devices

monitor heat by using a

single thermistor network

which provides a voltage

output proportional to the

Fig.11 Schematic diagram - XP95 Heat detector

The standard heat detectors,

55000-400 and 55000-420,

respond to increasing air

temperature in such a way

that they are classified as an

A2S device. See figure 13.

Both devices will give 55

counts at 55°C.

A high temperature CS heat

detector, 55000-401, which

can be installed in a typical

ambient temperature of

55°C is available. See

figure 14. This device will

give 55 counts at 90°C.

Fig.12 XP95 Heat Detector

ELECTRICAL

DESCRIPTION

The detectors are designed

to be connected to a two

wire loop circuit carrying

both data and a 17V to 28V

dc supply. The detectors are

connected to the incoming

and outgoing supply via

terminals L1 and L2 in the

mounting base. A remote

LED indicator requiring not

more than 4mA at 5V may

be connected between +R

and -R terminals. An earth

connection terminal is also

provided.

When a device is energised

the ASIC regulates the flow

of power and controls the

data processing. The

thermistor provides an output

over normal operating ranges

that is proportional to the

external air temperature.

This voltage output is

processed in the A/D

converter and stored by the

communications ASIC. It is

transmitted to control

equipment when the device

is interrogated. When a

count of 55 is exceeded the

alarm flag is initiated and

the device address is added

to the data stream every 32

polling cycles from its last

polling for the duration of

the alarm level condition,

except when an alarming

device is being interrogated.

This can provide a location

identified alarm from any

device on the loop in

approximately two seconds.

The detector is calibrated to

give an analogue value of

25±5 counts at 25°C.

ENVIRONMENTAL

CHARACTERISTICS

XP95 Standard Heat

Detectors operate over the

range -20°C to +70°C, the

High Temperature Heat

Detectors operate over the

range –20°C to +120°C.

The detectors are unaffected

by atmospheric pressure.

page

11

Page 12

page

12

TECHNICAL DATA

XP95 Heat Detector

(Standard)

Detector Part No

5000-400/420

5

Base Part No 45681-210

Specifications are typical

and given at 23°C and 50%

elative humidity unless

r

otherwise stated.

Detector Type:

Point type heat detector for

fire detection and fire alarm

systems for buildings

Detector Principle:

Linear approximation over

temperature range 25°C to

90°C

Sensor:

Single NTC Thermistor

Sampling Frequency:

Continuous

Sensitivity:

25°C to 90°C: 1°C/count.

-20°C returns 8 counts

Supply Wiring:

Two wire supply, polarity

insensitive

Terminal Functions:

L1&L2 supply in and out

+R remote indicator

connections (polarity

insensitive)

positive connection

(internal 2.2kΩ

resistance to supply

+ve)

-R remote indicator

Supply Voltage:

17 to 28 Volts dc

Modulation Voltage at

Detector:

5 to 9 Volts peak to peak

Quiescent Current:

250µA average, 500µA peak

P

1mA

Duration of Power-up Surge

Current:

0.3 seconds

Maximum Power-up Time:

4 seconds

Analogue Value at 25°C

25± 5 counts

Alarm Level 55 Counts:

55°C when measured under

static conditions

Alarm Indicator:

Red light emitting diode (LED)

Alarm LED Current:

2mA

Remote LED Current:

4mA at 5V (measured across

remote load)

Type Code:

(210 43) 110 00

negative connection

(internal 2.2kΩ

resistance to supply

- ve)

ower-up Surge Current:

Storage Temperature:

-30°C to +80°C

Operating Temperature:

-20°C to +70°C

Guaranteed Temperature

Range:

(No condensation or icing)

-20°C to +70°C

Humidity:

(No condensation)

0% to 95% relative humidity

Wind Speed:

Unaffected in fixed

temperature use

Atmospheric Pressure:

Unaffected

Vibration, Impact & Shock:

To EN54-5:2000

Electro-magnetic

Compatibility:

See page 21 for full details

IP Rating:

53

Approvals & Regulatory

Compliance:

See page 21 for full details

Dimensions:(diameter x height)

Detector: 100mm x 42mm

Detector in Base:

100mm x 50mm

Weights:

Detector: 105g

Detector in Base: 157g

Materials:

Detector Housing: White

polycarbonate V-0 rated to

UL 94

Terminals: Nickel plated

stainless steel

XP95 High Temperature

Heat Detector

Detector Part No:

5000-401

5

Specifications are the same

as those for the standard

detector, apart from the

following points:

Detector Principles:

Linear approximation

designed to give 25 counts

at 25°C and 55 counts at

90°C

Sensitivity:

25°C to 90°C: 2.17°C/count

-20°C returns 20 counts.

0832

technical data

Fig.13 Typical response charateristic -XP95 Standard heatdetector

Fig.14 Typical response charateristic -XP95 Hightemperature heatdetector

Page 13

XP95 MULTISENSOR DETECTOR

XP95 Multisensor Detector Part Number 55000-885

the smoke level and the air

OPERATING

PRINCIPLES

The XP95 multisensor detector

contains an optical smoke

sensor and a thermistor

temperature sensor whose

outputs are combined to

give the final analogue value.

The multisensor construction

is similar to that of the optical

detector but uses a different

lid and optical mouldings to

accommodate the thermistor

temperature sensor. The

sectional view (Fig.15) shows

the arrangement of the optical

chamber and thermistor.

The signals from the optical

smoke sensing element and

the temperature sensor are

independent, and represent

temperature respectively in

the vicinity of the detector.

The detector’s microcontroller

processes the two signals.

The temperature signal

processing extracts only

rate of rise information for

combination with the optical

signal. The detector will not

respond to a slow temperature

increase - even if the

temperature reaches a high

level. A large sudden change

in temperature can, however,

cause an alarm without the

presence of smoke, if

sustained for 20 seconds.

The processing algorithms in

the multisensor incorporate

drift compensation. The

control panel must not have

a drift compensation

algorithm enabled.

The sensitivity of the detector

is considered the optimum

for most general applications

since it offers good response

to both smouldering and

flaming fires.

Note: in situ testing of

the multisensor should be

carried out as for smoke

detectors.

page

13

Fig.15 Sectional view - XP95 Multisensor Detector

Page 14

page

14

TECHNICAL DATA

XP95 Multisensor Detector

Detector Part No 55000-885

Base Part No 45681-210

Specifications are typical

and given at 23°C and 50%

relative humidity unless

therwise stated.

o

Detector Type:

Point type smoke detector for

fire detection and fire alarm

systems for buildings

Detector principle:

Smoke: Photoelectric

scattered by smoke

particles

Heat: Temperature-sensitive

Type code:

Bits (2 1 0 4 3)

Supply wiring:

Two-wire supply, polarity insensitive

Terminal functions:

L1&L2 supply in and out

detection of light

resistance

1 0 1 1 1

connections (polarity

insensitive)

R remote indicator

+

-R remote indicator

Operating voltage:

17-28V DC

Communications protocol:

Apollo Series 90/XP95 5-9V

peak to peak

Quiescent current:

500µA average 750µA peak

Power-up surge current:

1mA

Maximum power-up time:

10s

Alarm LED current:

3.5mA

Remote LED current:

4mA at 5V (measured across

remote load)

Clean air analogue value:

23 +4/-0

Alarm level analogue value:

55

positive connection

(internal 2.2kΩ

resistance to positive

remote indicator

negative connection)

negative connection

(internal 2.2kΩ

esistance to negative)

r

Alarm indicator:

2 colourless Light Emitting

Diodes (LEDs); illuminated

red in alarm

Optional remote LED

Electro-magnetic compatibility:

See page 21 for full details

Temperature range:

Max. continuous operating:

+60°C

Min. continuous operating:

0°C

Min. operating (no

condensation/icing): -20°C

Storage -30°C to +80°C

Humidity:

(No condensation)

0 to 95% relative humidity

Effect of temperature on

optical detector:

Less than 15% change in

sensitivity over rated range.

Slow changes in ambient

conditions will automatically

be compensated and will

not affect sensitivity

Effect of atmospheric

pressure on optical sensor:

None

Effect of wind on optical

sensor:

None

IP rating:

23D

Approvals & Regulatory

Compliance:

See page 21 for full details

ibration, Impact and

V

Shock:

To prEN54-7

Dimensions:

00mm diameter

1

50mm height

58mm (height in base)

Weight:

etector: 105g

D

Detector in base: 160g

Materials:

Housing: White

polycarbonate V-0 rated

to UL94

Terminals: Nickel plated

stainless steel

Smoke element only:

Chamber configuration:

Horizontal optical bench

housing infra-red emitter

and sensor, arranged

radially to detect forward

scattered light

Sensor:

Silicon PIN photo-diode

Emitter:

GaAlAs infra-red light

emitting diode

Sampling frequency:

1 per second

technical data

WARNING: if the control panel incorporates a drift compensation algorithm,

this should be disabled when polling the XP95 Multisensor detector.

Page 15

XP95 MANUAL CALL POINT

XP95 Manual Call Point (MCP)

OPERATING

PRINCIPLES

The new Apollo XP95 EN5411:2001 compliant Manual

Call Point (MCP) is based on

the KAC conventional MCP

range. It is electronically

and mechanically backward

compatible with previous

Apollo call points based on

KAC’s World Series product.

The address of each call

point is set at the

commissioning stage by

Colour Deformable Backbox Pattress Isolated Non-

Fig.16 Typical response characteristic - XP95 Manual Call Point

means of a seven-segment

DIL switch.

A single bi-coloured alarm

LED is provided on the call

point. This LED is controlled,

independently of the call

point, by the control panel.

The red LED is lit when the

call point has been activated.

An amber/yellow LED

indicates a fault.

Call points can be remotely

tested from the panel by

transmission of a single bit

in the communications

protocol. Call points

respond by providing a

Element for surface Box isolated

Wiring

value of 64 which

corresponds to the alarm

value. The panel should

recognise this response as a

test signal and should not

raise a general alarm.

XP95 Manual Call Points are

available with or without an

isolator. Each version is

available with a resettable

element and a backbox for

surface mounting as standard.

If a glass or flush mounting

tray is required, these are

available on request.

Versions with a pattress box

are also available with and

without an isolator. For all

part numbers please refer to

Table 2.

To provide additional

protection against accidental

operation, a transparent

hinged cover with a locking

tag, part number 26729-152

is available, which can be

fitted to the manual call

point. Please note that the

call point dos not conform

to EN54-11:2001 when this

lid is fitted and secured with

the locking tag.

Important Note – the use

of lubricants, cleaning

solvents or petroleum

based products should be

avoided.

page

15

55100-905 Red •• •

55100-907 Red •••

55100-908 Red •• •

55100-909 Red •••

Table2

Page 16

page

16

TECHNICAL DATA

XP95 Manual Call Point

Specifications are typical

and given at 23°C and 50%

relative humidity unless

otherwise stated.

Call Point Type:

eformable element

D

Weight:

151g

Call Point Principle:

Operation of a switch

Alarm Indicator:

Red Light Emitting Diode (LED)

Fault Indicator:

Amber/yellow light emitting

diode (LED)

Type Code:

(2 1 0 4 3)

1 1 1 1 1

Supply Wiring:

Two-wire supply, polarity

sensitive

Loop connections L1/L2:

Terminal block

Operating Voltage:

17V-28V dc

Communication Protocol:

5V-9V peak to peak

uiescent Current:

Q

100µA

Power-up Surge Current:

1mA

aximum Power-up Time:

M

1 second

Alarm Current, LED

illuminated:

mA

4

Normal Analogue Value:

16

Alarm State Value:

64

Electro-magnetic

Compatibility:

See page 21 for full details

Temperature Range:

Max. continuous operating:

Min. continuous operating:

Min. operating: -20°C

(no condensation/icing)

Storage: -30°C to +80°C

+60°C

0°C

Humidity:

(No condensation)

to 95% relative humidity

0

Compliance Standard:

EN54-11:2001

EN54-17:2005 (isolated

ersion)

v

IP Rating:

24

Dimensions:

9mm x 93mm x 26.5mm

8

(manual call point)

87mm x 87mm x32mm

(back box)

Materials:

Housing: Red self-coloured

Polycarbonate/ABS

Hinged cover and locking

tag are also available, part

number: 26729-152

XP95 glasses are also

available, part number:

26729-154 (pack of 5)

technical data

Page 17

XP95 MOUNTING BASE

Fig.17 Schematic wiring diagram - XP95 mounting base

XP95 Mounting Base Part Number 45681-210

The remaining single terminal

XP95 Mounting Bases and

XPERT cards.

The XP95 smoke and heat

detectors all fit the XP95

mounting base. The base is

a zero insertion force base

with dual finger receptacles

of stainless steel into which

the detector terminals slide.

Cable connections of up to

2.5mm diameter are made

via captive cable clamps.

There are four double

terminals and one single one.

L1 line IN and OUT,

double terminal

L2 line IN and OUT,

double terminal

+R remote LED positive

supply, double terminal

-R remote LED negative

supply, double terminal

is isolated and can be used

to provide continuity of an

earth or shield.

Universal address cards,

known as XPERT cards are

supplied with all bases.

Consult the coding guide to

determine which pips are to

be removed. Pre-printed and

pre-punched address cards

that save time and increase

accuracy during

commissioning are

available in sets, part

number: 38531-771

The base has a ‘one way

only’ fit and detectors can

be locked into the base by a

grub screw with the aid of a

1.5mm hexagonal driver,

part number: 29600-095.

For more information on

Apollo’s range of bases,

please refer to the Range of

Bases & Mounting Accessories

brochure, PP1089.

Fig.18 Schematic wiring diagram of XP95 detector circuit with a

common remote LED

page

17

Page 18

XP95 20D ISOLATING BASE

page

18

XP95 20D Isolating Base Part Number 45681-284

OPERATING

PRINCIPLES

The XP95 20D isolating base

senses and isolates short

circuit faults on XP95 loops

and spurs. The base is loop

powered, polarity sensitive

and accepts the XPERT card

to set the associated device

address.

In short circuit conditions

the integral yellow LED is

illuminated. The detector

associated with the base

remains active under short

circuit conditions. Power

and signals to the affected

section are restored

automatically when the

fault is cleared.

ELECTRICAL

DESCRIPTION

Under normal operating

conditions, a low impedance

is present between the –IN

and –OUT terminals of the

base, so that power and

signals pass to the next

base in the line.

If a short circuit or abnormally

low impedance occurs, the

fall in voltage is sensed and

the base isolates the negative

supply in the direction of

the fault.

In applications where it is not

necessary to use an isolating

base for each detector, up to

twenty devices (detectors

and XP95 interfaces) may be

installed between isolating

bases, provided that their

TECHNICAL DATA

XP95 20D Isolating Base

Device Part No:

45681-284

Maximum Loop Operating

Voltage:

28V DC plus 9V protocol

pulses

Minimum Normal Loop

Operating Voltage:

17V DC

Power-up Time:

>10mS

Isolation time, 2Ω load at

28V:

20µs

Isolation Voltage:

14V

Isolation Indicator:

Yellow LED, lit continually

in isolation condition

Current Consumption:

at 18V 23µA

at 28V 43µA

at 18V and adjacent

sector isolated 4mA

total switch-on surge current

doesnotexceed 20mA.

Circuits may include spurs,

which should be connected

between the spare –OUT

terminal and the base L2

terminal. Spurs connected

in this way appear directly

across the loop on the

output side of the isolating

base. Short-circuit faults

on the spur therefore short

circuit the loop and vice

versa. The effect of such

short circuits must be taken

into account in the system

design and may require the

use of extra isolating bases.

For further information on

the use of XP95 isolators,

please refer to PP2090 Short

Circuit Isolation in XP95

and Discovery Fire Systems.

Maximum Line Current:

Non-isolatingcontinuous 1.0A

Transition into isolation 3.0A

On Resistance:

<0.2Ω

Device Reset Resistance:

300Ω

EMC:

ee page 21 for full details

S

Operating Temperature:

-20°C to +60°C

Storage Temperature:

-30°C to +80°C

Relative Humidity (no

condensation/icing):

0% to 95%

Dimensions:

100mm (diameter) x 24mm

(height)

100mm (diameter) x 60mm

(height) base with detector

fitted

Weight:

100g

Page 19

XP95 ISOLATOR

MINIDISC REMOTE INDICATOR

LOOP-POWERED SOUNDERS.FLAME DETECTOR

.

LOOP-POWERED BEAM DETECTOR

P95 ISOLATOR

X

Part Number: 55000-720

Base Part Number: 45681-211

‘Stand-alone’ isolators,

which have their own bases,

may be used instead of

isolating bases. The

isolators are wired to a loop

between detectors or other

devices.

XP95 LOOP-POWERED

BEAM DETECTOR

Part Number: 55000-265

The XP95 optical beam

detector has been designed

to protect large open spaces

such as museums, churches,

warehouses and factories. It

consists of three main parts:

the transmitter, which projects

a beam of infra-red light,

the receiver, which registers

the light and produces an

electrical signal, and the

interface, which processes

the signal and generates

alarm or fault signals.

The transmitter and receiver

are designed to be fitted on

opposite walls approximately

30cm to 60 cm below the

level of the ceiling. They

can protect an area up to

100m long and 15m wide,

a total of 1500m

The interface contains the

electronic circuitry needed

to control the beam detector

and communicate with the

control panel via the XP95

loop.

The beam detector is looppowered and needs no

separate 24V supply. This

not only eliminates the need

for additional equipment, it

also saves both cost and

time in installation.

2

.

NTELLIGENT REFLECTIVE

I

BEAM DETECTOR

Part Numbers:

55000-268 (5-50m)

5000-273 (50-100m)

5

The intelligent reflective

beam detector is a compact

detector for detecting smoke

in large open areas such as

atria, warehouses, theatres

and churches. It also has a

built-in 20D negative bidirectional short circuit

isolator.

The transmitter and receiver

form a single unit mounted

to a wall of the building. A

reflector which returns the

IR beam from the transmitter

to the receiver is mounted

on the opposite wall. In the

event of smoke partially

obscuring the light an

imbalance between the

transmitted and received

light will occur. On

interrogation by the control

panel the detector will then

transmit an alarm value.

The intelligent reflective

beam detector is an addition

to the Apollo range and not

a replacement for the XP95

loop-powered beam

detector.

The intelligent reflective

beam detector is supplied in

two versions: one for use at

distances of 5–50m from

detector to reflector and the

other for distances of 50–

100m.

The detector is non-latching

and resets 30 seconds after

an alarm event ceases and

in 3 seconds after the

removal of a fault.

A termination backbox, part

no 29600-241, is available.

This allows easy first fixing of

he cabling and terminations

t

to the intelligent reflective

beam detector. The

termination backbox can

be surface or flush mounted.

MINIDISC REMOTE

INDICATOR

Part Number: 53832-070

A light-weight, compact

indicator for use in fire

protection systems. The

indicator may be used in all

installations incorporating

Series 60, XP95, Discovery

and Intrinsically Safe

detectors. It is only 20mm

high and 80mm in diameter.

It comprises two parts – the

base, which is installed onto

a wall or soffit and the lid,

which is fitted to the base

with a bayonet lock.

LOOP-POWERED

SOUNDERS, BEACON &

SOUNDER BEACONS

There are two types of looppowered sounder available,

allowing fire engineers to

specify not only the sound

output but also the

functionality of individual

sounders.

The 85dB(A) Low-Profile

loop sounder is intended for

use in confined spaces such

as hotel rooms and corridors.

It is designed to have a base

and detector mounted upon

it, but can also be used as a

stand-alone sounder. The

100dB(A) loop sounder is

intended as an open-space

sounder, where a higher

output is required.

larms may be signalled

A

visually by means of a

flashing beacon. Combined

sounder beacon units are

available where both

udible and visual signalling

a

is required.

The following types of

device are available:

Ancillary Base Sounder

Part Number: 55000-276

A local-area sounder with

an integral base for a

detector head. The sounder

is switched by the detector

remote output and needs no

address of its own. Sound

output 85dB(A) at 1 metre.

Integrated Base Sounder

Part Numbers:

45681-278 (sounder)

45681-291 (slow whoop)

45681-277 (with isolator)

45681-290 (slow whoop

with isolator)

45681-292 (white cap)

45681-293 (red cap)

A sounder with two volume

ranges 55–75dB(A) and

75–91dB(A) which

incorporates a detector

base. It is supplied with a

built-in isolator and ‘alert’

and ‘evacuate’ tones. A

version with a Dutchstandard slow whoop is

also available.

page

19

Page 20

page

20

ntegrated Base Sounder

I

(DIN Tone)

Part Number: 45651-300

A sounder with an integral

detector base configured

to the requirements of

German standard

DIN33404, Part 3.

Loop-powered 100dB(A)

Sounder

Part Numbers:

55000-276 (slow whoop,

red)

55000-277 (slow whoop,

white)

55000-274 (weatherproof,

red)

55000-275 (weatherproof,

white)

55000-278 (red)

55000-279 (white)

Designed for use in

open areas this sounder is

available in red or white.

The weatherproof version is

also available in red and

white. The indoor version

may be ordered with a

Dutch-standard slow whop

tone.

oop-powered Beacon

L

Part Numbers:

55000-877 (red lens)

55000-878 (clear lens, red

lash)

f

55000-879 (amber)

The beacon has been

developed to alert those

with hearing difficulties and

to be used in areas with a

high background noise

level. The beacon is fitted

to any XP95 or Discovery

base.

Beacon Enclosure

Part Number: 29600-318

This is an enclosure with a

clear lid and which has an

IP rating of 67, allowing a

beacon to be fitted for use

outdoors.

Sounder Beacon Base

Part Numbers:

45681-330 (with isolator)

45681-331

45681-332 (slow whoop

with isolator)

45681-292 (white cap)

45681-293 (red cap)

ulti-tone Open-area

M

Sounder Beacons

Part Numbers:

55000-293 (with isolator,

ed)

r

55000-298 (weatherproof,

with isolator, red)

Audio-visual fire alarm

devices for large open areas.

Sound output is nominally

100dB(A). The product

features selectable tones,

thus minimising the

number of regional variants

required. Available in red

or white, indoor use or

weatherproof, with or

without isolator.

XP95 FLAME DETECTOR

Part Number: 55000-280

Operating Principles

An infrared sensor designed

to detect specific types of

flame, making it immune

to solar radiation and other

nuisance sources of infrared.

The detector is rated at

IP65, uses XP95 protocol

and is loop powered –

eliminating the need for a

separate power supply.

This device combines a

local-area sounder and a

flashing beacon. It has an

integral isolator and base for

a detector head. Detection

is thus co-located with both

audible and visual alarms

and short circuit isolation.

Page 21

XP95 APPROVALS & REGULATORY COMPLIANCE

EMC

APPROVALS AND REGULATORY

COMPLIANCE

he XP95 range of detectors and manual call points is

T

approved by a large number of third party certification

bodies around the world. These include detector approvals

to EN54:2000 with LPCB, VdS, DIBT, BOSEC and FG and

to UL 268 and 521 with UL. For further information and

updates on approvals held by Apollo for the XP95 range,

contact the company directly or see our website,

www.apollo-fire.co.uk

XP95 detectors comply with the requirements of a number

of European New Approach Directives, such as the EMC

Directive 89/336/EEC and the Construction Products

Directive 89/106/EEC. Copies of EC certificates of

conformity issued by LPCB as a Notified Body under the

Construction Products Directive are available from our

website www.apollo-fire.co.uk or directly from Apollo.

In addition, copies of Declarations of Conformity issued

by Apollo for all applicable New Approach Directives are

available upon request.

All XP95 products will comply with the marking

requirements of the WEEE Directive, 2002/96/EC. For

further information on disposing of applicable electrical

and electronic waste, contact Apollo directly.

EMC

All XP95 detectors and manual call points comply with the

equirements of the following EMC standards:

r

Generic Emission Standard EN 61000-6-3

Emission standard for residential, commercial and light

industrial environments.

Generic Emission Standard EN 61000-6-4

Emission standard for industrial environments.

EN 50130-4 : Alarm Systems

Electromagnetic compatibility - product family standard :

Immunity requirements for components of fire, intruder and

social alarm systems

EN 6100-4-2

Electrostatic discharge

EN 6100-4-3

Radiated immunity

EN 6100-4-4

Fast transient bursts

EN 6100-4-5

Surge immunity

EN 6100-4-6

Conducted immunity

In addition, all of the XP95 detectors have been assessed to

the additional VdS EMC requirements, which are shown

below and have been demonstrated full compliance.

Additional VdS requirements:

30V/m with 80% Am sine and 100% pulse modulation

depth over the frequency ranges 415 to 467MHz and 890

to 960MHz.

page

21

Page 22

MAINTENANCE OF DETECTORS

Apollo Fire Detectors has published a guide to the

care, maintenance and servicing of Apollo products,

P2055, which is available on request. This guide

P

outlines the maintenance routines recommended for

optimum detector performance and the services

available from Apollo’s factory-based Service

Department.

page

22

Page 23

page

23

Page 24

PP1039/2006/Issue 8a

For more information on any of the products mentioned in this engineering guide, please refer to

the following literature which is available on request.

Publication Name Publication Number

ompatible Panel Manufacturers PIN Sheet PP1010

C

Range of Bases & Mounting Accessories Brochure PP1089

XP95 20D Isolating Base PIN Sheet PP2039

A Guide to the Care, Maintenance and Servicing of Apollo Products PP2055

XP95 Range of Interfaces Brochure PP2025

XP95 Switch Monitor PIN Sheet PP2015 (std enclosure)

PP2048 (DIN-rail enclosure)

PP2084 (with isolator)

Mini Switch Monitor PIN Sheet PP2021

ini Switch Monitor with Interrupt PIN Sheet PP2020

M

Switch Monitor Plus PIN Sheet PP2014 (std enclosure)

PP2047 (DIN-rail enclosure)

PP2083 (with isolator)

Zone Monitor PIN Sheet PP2016 (std enclosure)

PP2049 (DIN-rail enclosure)

PP2101 (with isolator)

Sounder Control Unit PIN Sheet PP2019 (std enclosure)

PP2050 (DIN-rail enclosure)

PP2094 (with isolator)

Input/Output Unit PIN Sheet PP2017 (std enclosure)

PP2045 (DIN-rail enclosure)

PP2092 (with isolator)

Output Unit PIN Sheet PP2018 (std enclosure)

PP2046 (DIN-rail enclosure)

PP2093 (with isolator)

XP95 Mains Switching Input/Output Unit PIN Sheet PP2107

Dual Isolator PIN Sheet PP2051 (DIN-rail enclosure)

XP95 Three Channel Input/Output Unit PIN Sheet PP2121

MiniDisc Remote Indicator PIN Sheet PP2074

XP95 Loop-Powered Beam Detector Sales Leaflet PP2078

XP95 Flame Detector Sales Leaflet PP2111

XP95 Flame Detector PIN Sheet PP2110

Short Circuit Isolation in XP95 and Discovery Fire Systems PP2090

Intelligent Reflective Beam Detector PP2155

Ancillary Base Sounder PP2148

Integrated Base Sounder PP2209

Integrated Base Sounder (DIN Tone) PP2227

Loop-powered 100dB Sounder PP2082

Loop-powered Beacon PP2156

Beacon Enclosure PP2204

Sounder Beacon Base PP2235

Multi-tone Open-area Sounder Beacon PP2256

© Apollo Fire Detectors Ltd 1999 - 2006

Assessedto ISO 9001: 2000

Certificate number 010

36 Brookside Road, Havant, Hampshire PO9 1JR, UK. Tel: +44 (0)23 9249 2412. Fax: +44 (0)23 9249 2754.

Email: sales@apollo-fire.co.uk Website: www.apollo-fire.co.uk

Apollo GmbH, Am Anger 31, 33332 Gütersloh, Germany. Tel: +49 5241 33060. Fax: +49 5241 330629

Loading...

Loading...