Page 1

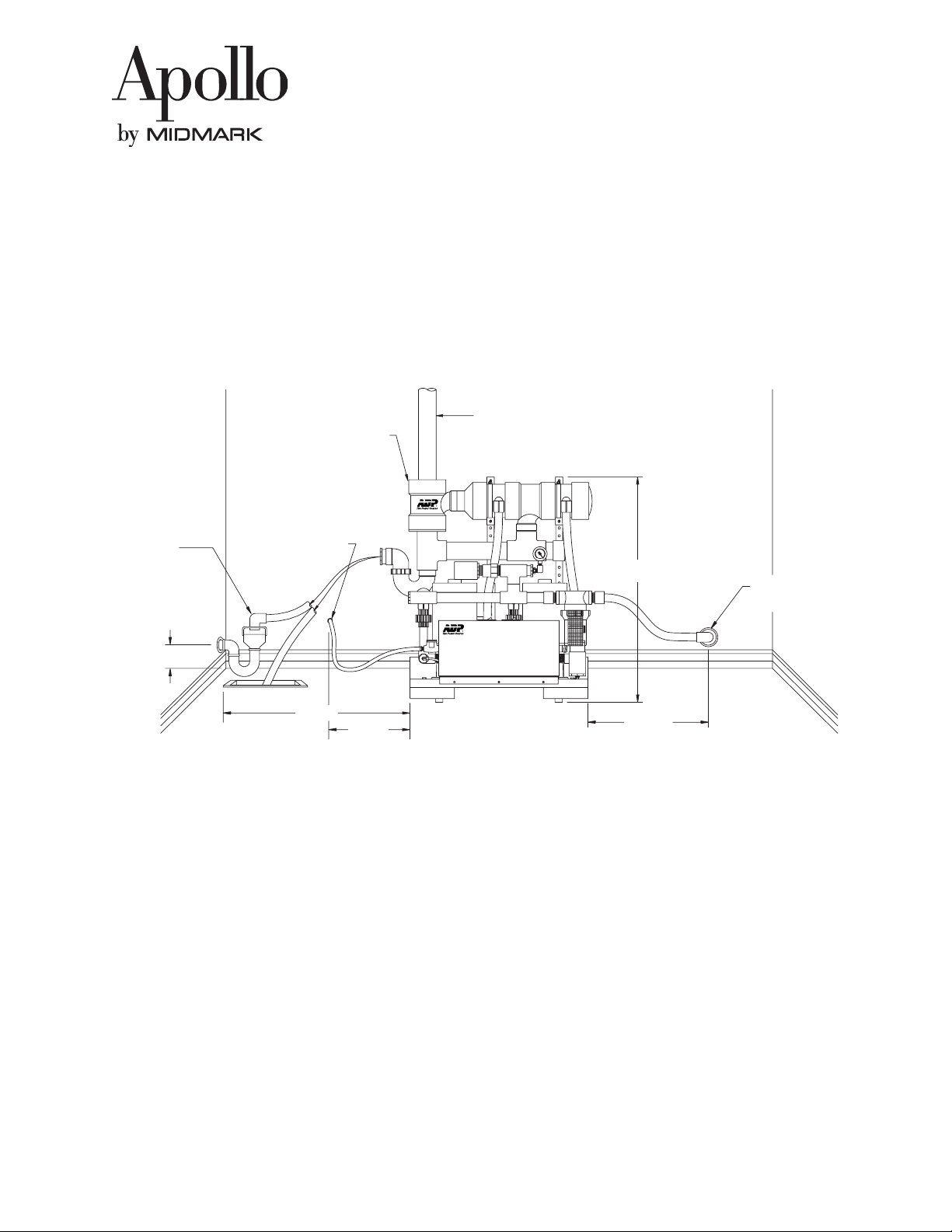

2" PVC Vent Pipe

(Provided By Plumber)

2" PVC Vent Connection

(Vent To Outdoors)

Installation & Operation

Twin Vacuum System

1/4" x 8' High Pressure Water Inlet Hose with

Water Control Valves Located On Platform

(1/2" or 1/4" MPT Fittings Provided)

See Note On Local Codes

1 1/2" P-Trap With 1" Air Gap

(Provided By Plumber)

(Refer To Local Plumbing Codes)

Low Voltage Wires For

24V Remote Operation

(Red and Blue Switching)

White = Light

"ON/OFF" 1/2 Amp Circuit Breaker

Switches (Provided)

Lifting Handle Receiver

NOTE: Some Local Codes Require A Reduced Pressure (RP) Backflow Preventor

On The Incoming Water Line. (Not Provided)

Optional Wall Mounting

(Extra Hose Provided)

Air / Water Separator

(Provided With Separator Models)

Disconnect Box

(Provided By Electrician)

(1 Circuit Per Pump)

6' Conduit (Provided)

1" x 4' Flex PVC Inlet Tubing

(Do Not Cement)

(1 1/4" x 4' Flex PVC On Twin

2 Or 3 HP Models) (Provided)

1" PVC Slip Coupling

and MPT Adapter (Provided)

Description:

Apollo Vacuum Systems have been tested and approved by various regulatory test agencies. The following list contains Apollo File

Numbers that may be helpful if questions arise regarding installation inspections.

Underwriter’s Laboratories (UL) (cUL) ..................... File Number: MH13627

U.S. Food and Drug Administration (FDA)................. File Number: 2937927

City of Los Angeles Mechanical Test Labs................. File Number M880066

This dental vacuum system should only be installed by qualified personnel. Should any questions arise during the installation, call

Apollo Technical Support between the hours of 7:00 a.m. to 4:00 p.m. (Pacific Standard Time).

Unpacking The System:

Place the Vacuum System in a clean, dry, well ventilated area, on a solid, level surface. Consider sound level and insulate as needed.

Be sure that adequate ventilation is available as the Vacuum System is air-cooled. Ambient temperature in the equipment room should

be within the temperature range of 40 degrees Fahrenheit (4o C) minimum to 100 degrees Fahrenheit (38o C) maximum.

Do Not Allow The Vacuum To Freeze.

1. Remove the cardboard from the shipping platform.

2. Inspect pump for freight damage and confirm that the Pump Installation Kit is in the box.

3. Remove the pump from the shipping platform.

Apollo by Midmark • 60 Vista Drive • Versailles, Ohio 45380 • Technical Support

1-800-MIDMARK • Fax 877-249-1793 • www.midmark.com

Page 1

AMI60333 Rev. 4/03

Page 2

Installation & Operation

Twin Vacuum System

Vacuum Pump Specifications:

Model Max Width Depth Height Shipping Total Volt Amperage Hz Wire Breaker

Users *** Weight HP (Per Pump) GA* Size**

AVG10TNFX / AVU10TNFX 6 66 cm 44 cm 76 cm 64 kg 2 220 8.1 50 14 2@20

AVG10TNX / AVU10TNX 6 26 in 18 in 30 in 140 lb 2 115/208-230 16.2/8.1 60 10/14 2@30/2@20

AVB10TN* 5 26 in 18 in 20 in 140 lb 2 115/208-230 16.2/8.1 60 10/14 2@30/2@20

AVB10TNFX 5 66 cm 44 cm 76 cm 66 kg 2 220 8.1 50 14 2@20

AVB10TNX 5 26 in 18 in 30 in 145 lb 2 115/208-230 16.2/8.1 60 10/14 2@30/2@20

AVG15TNFX / AVU15TNFX 7 66 cm 44 cm 76 cm 70 kg 3 220 11 50 14 2@20

AVG15TNX / AVU15TNX 7 26 in 18 in 30 in 115 lb 3 208-230 11 60 14 2@20

AVB15TN* 6 26 in 18 in 20 in 155 lb 3 208-230 11 60 14 2@20

AVB15TNFX 6 66 cm 44 cm 76 cm 73 kg 3 220 11 50 14 2@20

AVB15TNX 6 26 in 18 in 30 in 160 lb 3 208-230 11 60 14 2@20

AVB20TNX 8 26 in 18 in 32 in 165 lb 4 208-230 12.4 60 14 2@20

AVG20TNFX / AVU20TNFX 10 66 cm 44 cm 81 cm 75 kg 4 220 12.4 50 14 2@20

AVG20TNX / AVU20TNX 10 26 in 18 in 32 in 165 lb 4 208-230 12.4 60 14 2@20

AVG30TNFX / AVU30TNFX 12 66 cm 44 cm 81 cm 80 kg 6 220 14 50 14 2@30

AVG30TNX / AUG30TNX 12 26 in 18 in 32 in 175 lb 6 208-230 14 60 14 2@30

For Recycler option, add “R” to last prefix only. Example: AVB10TNR.

*Non separator models, VB10TN and VB15TN, are not recommended for single pump operation.

** Each pump requires a separate electrical circuit.

*** Height with Exhaust Separator

Dual Voltage Models

Blu

Red

Wht

Blu

Red

Wht

1/2 Amp

ON / OFF

Circuit Breaker Switch

Blu

Blu

Wht

Red

Yel

Yel

Blk

Motor Leads

Blu

Brn

Blu

Blu

Blu

Red

Vio

Blu

Yel

Blk

Red

Yel

Vio

3567

2

GRD

115 Volt Supply To Terminals

1 and 4

Install Jumpers From Terminals:

3 to 4

5 to 6

7 to 8

1/2 Amp

ON / OFF

Circuit Breaker Switch

Motor Leads

Blu

Blu

Brn

Blu

Blk

Vio

Wht

Blk

Yel

Yel

Blu

Wht

Brn

Yel

8

230 Volt Supply To Terminals

1 and 2

Install Jumpers From Terminals:

2 to 3

6 to 7

Third Jumper Not Required

Blu

Red

See Low Voltage Control

Wht

Blu

Wht

Blu

Red

115 or 230V Primary

Red

Transformer

24VAC Secondary

Blu

Blu

Yel

Wht

Wht

Org

Wht

Blk

Vio

Blu

Blk

Blu

Wht

Org

Wht

56 78

34

GRD

(FACTORY SETTING)

Blk

Wht

Solenoid Coil

GRD

Remote Lighted

Switch

Solenoid Coil

GRD

Blu

Red

Wht

LOW VOLTAGE CONTROL

See Low Voltage Control

Wht

Blk

Blk

Wht

Wht

Wht

Blu

Blk

Org

Wht

Blk

Blu

Vio

Yel

24VAC Secondary

Blk

Transformer

Wht

115 or 230V Primary

Org

IMPORTANT: All Vacuum Systems are to be installed according to local plumbing and electrical codes.

Never operate the equipment without complete and proper grounding.

Page 2

Page 3

Single Voltage Models

Installation & Operation

Twin Vacuum System

Technical Service - (800) 233-4151

Remote Lighted

Switch

Solenoid Coil

GRD

Blu

Red

Wht

LOW VOLTAGE CONTROL

See Low Voltage Control

Wht

Blk

Blk

Wht

Wht

Org

Blu

24VAC Secondary

Org

Wht

Transformer

230V Primary

Blu

Red

Wht

GRD

230 Volt Supply To Terminals

Blu

Red

Wht

Brn

1/2 Amp

ON / OFF

Circuit Breaker Switch

Blu

Wht

Blu

Blu

Brn

Wht

Wht

Blu

Blk

Wht

1/2 Amp

ON / OFF

Circuit Breaker Switch

Wht

Blu

Blu

Red

Wht

Yel

Motor Leads

Blu

Red

Brn

Blu

Blu

Red

Motor Leads

Blu

Blu

Red

See Low Voltage Control

Wht

Blu

Wht

Blu

Red

Wht

230V Primary

Yel

Transformer

24VAC Secondary

Yel

Blk

Wht

Blu

Org

Wht

Wht

Red

Blk

Wht

Wht

Wht Org

Solenoid Coil

GRD

A. Electrical Hook-Up Requirements:

Low Voltage Line (24V)

18-3 Thermostat wire from each remote control switch to each vacuum; if low voltage remote control switching is

desired. Red and Blue wires are for switching, the White wire is for a lighted switch, paired with Red.

Line Voltage (60 Hz)

Two, single-phase, 115 or 208-230 volt, 60 Hz, supply circuit with approved ground connection required. The 1HP units

are dual voltage 115/208-230 volt. The 1 1/2, 2 and 3HP units are 230 volts only. All units are factory wired for

208-230 volt operation: 208-230 volt operation is recommended for maximum efficiency.

Line Voltage (50 Hz)

Two, single phase, 220 volt, 50 Hz., supply circuit with approved ground connection is required. All units are factory

wired for 220 volt operation: 220 volt operation is recommended for maximum efficiency.

B. Plumbing Hook-Up Requirements: (See Illustration on Page 1)

Water Line

1/2 inch (13mm) cold water supply line with shut off valve terminating in 1/2 inch (13mm) FPT. The line must be

flushed out with 5 gallons of water prior to connection to vacuum.

IMPORTANT: Water is essential for the operation and longevity of the pump. The supply must not be restricted or

interrupted during operation. Water with high mineral content may cause mineral build-up and create water starvation, leading to seal failure. A water softener and filter are recommended for this situation. (*To prevent gradual

buildup, use StayClean™ Mineral Deposit Remover)

Waste Line

Water drains to sewer terminating in:

Option A - Floor sink.

Option B - P-trap adapted to 3/4 inch (19mm) PVC slip connection, A 1 inch (25mm) air gap may be required by local code.

Page 3

Page 4

Air Vent

2 inch PVC air vent to outdoors. Do not cap vent, serious back pressure may result in pump failure.

Vacuum Line (Do Not Cement)

1 inch (25mm) PVC female slip connection. 2 and 3 HP models require a 1 1/4 inch (38mm) PVC slip connection.

Guidelines for the proper design of a vacuum piping system are given in the following sections.

IMPORTANT: Continuosly running sinks or cuspidors must NEVER be connected to the vacuum piping

system as pump failure may result.

C. Vacuum Piping System Guidelines:

The design of the vacuum piping can have a large effect on the efficiency and reliability of the dental vacuum system.

Experience has shown that the most effective vacuum piping designs are based on the air velocity that will occur in the

lines. The velocity must be high enough to entrain all liquids and sediment in the air flow so that they do not accumulate in

the lines. At the same time; the velocity must not be so high as to cause unacceptable vacuum losses. The Vacuum Line

Sizing chart is based on maintaining an optimum air flow velocity according to the criteria described above. Use of single

size pipe will result in poor performance.

Installation & Operation

Twin Vacuum System

Technical Service - (800) 233-4151

D. Vacuum Line Sizing Chart:

Number Of Operatories Pipe Diameter In

Supplied Through Line Inches (MM)

1 3/4” (19)

2 1” (25)

3 1” (25)

4 1 1/4” (32)

5 1 1/4” (32)

6 1 1/2” (38)

7 1 1/2” (38)

8 1 1/2” (38)

9 2” (50)

10 2” (50)

11 2” (50)

12 2” (50)

NOTE:

Use the number of operatories being

supplied, not the number of outlets within the

operatories to determine line size at any given

point. Branch lines to individual operatories

off of the main suction line should be 3/4 inch

diameter.

To Vacuum Pump

Floor

Piping

Level

From Vacuum System

Line Termination At Vacuum Pump

(Low Restriction Trap)

To Vacuum Pump

Y Tee

(Flow Diagram)

1/2" (13MM) Pipe

Main Vacuum Line

Overhead System

Line Termination

(Floor Level Junction Box)

1/2" (13MM) Line To Floor

Level Junction Box

A Trap Is Required Here

To Prevent Backflow

1 1/2" Pipe

38MM

1 1/4" Pipe

32MM

1 1/4" Pipe

32MM

1" Pipe

25MM

Vacuum

System

1" Pipe

25MM

1" Pipe

25MM

Sample Vacuum Piping

Installation For 7

Operatory System

3/4" (19MM) Branch Line

To Junction Box

(7 Places)

3/4" Pipe

19MM

1/2" (13MM) Pipe From This

Bushing To Junction Box

Main Vacuum Line

Overhead System

Line Termination

(In Wall Junction Box)

45˚ Els

1/2" (13MM) Line To

Junction Box On Wall

A Trap Is Required Here To

Help Prevent Backflow

3/4" Pipe

19MM

The vacuum lines should be supported to prevent sag and should be sloped 1/4 inch (6 mm) for every 10 feet (3m) towards the

vacuum pump.

Page 4

Page 5

Installation & Operation

Twin Vacuum System

Technical Service - (800) 233-4151

It is of primary importance to minimize 90 degree turns in the system. These will not only cause vacuum losses, but will also provide

areas where sediment can accumulate. A combination of two 45 degree elbows are preferable to a 90 degree elbow. Restrictions in the

line will also cause vacuum loses. Y-tee fittings should be used whenever possible.

Overhead systems require the use of the next largest size vacuum pump. Overhead systems also require a 1/2 inch

(13mm) line rather than 3/4 inch (19mm) from the operatories to the main line, and special provisions to ensure that liquids do not

travel back into the operatories.

A sample vacuum piping diagram is shown. Consult Apollo Technical Support for further information regarding vacuum line sizing.

Typical Installation

2" PVC Vent To Outside Of Building

Air / Water Separator

(Provided With

Separator Models)

(Provided By Plumber)

*Do Not Cap

1 1/2" P-Trap

With 1" Air Gap

(Provided By Plumber)

6"

Fresh Water Line

Or

Floor Sink

2' Max.

5' Max

32" Max.

3' Max.

E. Installing Vacuum System With Exhaust Separator:

1. Place the vacuum unit on a solid level floor within 2 feet (0.6m) of waste line P-trap or floor sink.

2. The exhaust separator comes premounted to base. Should it need to be remotely wall mounted, simply glue in provided

hose using 3/4” couplings (provided). Next, remove holding pins and wall mount the separator utilizing the holes in the

extension tubing as mounting holes. Remember, the separator should be located at least 2 inches (5cm) above a waste

connection and within 3 feet (1m) of the vacuum exhaust.

3. Connect operatory vacuum line to intake strainer using the provided suction hose. Do not cement the suction line.

4. Attach provided 3/4 inch (19mm) drain hose to P-trap or floor sink from bottom drain fitting of exhaust separator and

CEMENT with PVC glue.

5. Install 2 inch (5cm) PVC vent line off the top of the exhaust separator and vent to the outdoors. *Failure to do so will result

in moist air in the room.

Operatory Piping

Termination

6. Connect the provided water hose to a 1/4 or 1/2 inch (13mm) water supply line with the provided hose fittings.

NOTE: It is recommended to purge at least 5 gallons of water through water line before attaching to

vacuum. (Sediment in water lines of new buildings is common.)

7. Connect high voltage electrical supply lines as indicated in the electrical diagram.

8. For low voltage remote control, connect low voltage wires of corresponding color from the Apollo Master Control Panel

vacuum switches.

Page 5

Page 6

Installation & Operation

Twin Vacuum System

Technical Service - (800) 233-4151

F. Initial Start-Up:

1. Check that the water supply valves are “OPEN”.

2. Start the pumps.

3. Check exhaust tubing to ensure that water is flowing through the pumps.

IMPORTANT: Do not run pump without full pressure water supply, or serious pump seal damage could result.

4. Check waste drain line to ensure that water is draining properly and that there are no water leaks.

5. Check vacuum gauges to ensure that each pump is functioning properly. Vacuum relief is factory preset for 10 inches

Hg (34 KPa) Vacuum.

6. Store this installation manual for future reference.

G. Vacuum Level Adjustment:

The Vacuum level is adjustable in the range of 8 to 13 inches Hg (27 to 44 KPa).

1. Remove the filter and valve from the PVC elbow.

2. Using a 1/4” nutdriver and a phillips screwdriver adjust the center mounted screw within the valve. Each full clockwise

turn increases the vacuum level by approximately 2” Hg.

Must Be Removed

To Adjust

1" Tee

Relief / Regulator Valve

Filter / Muffler

Maintenance:

Maintenance Procedure Daily Weekly Monthly Semi-Annually Annually

Cleanse Vacuum Piping System

Clean Vacuum Pump Intake Filter

Clean In-Operatory Strainers

Check Vacuum Level

Clean And Dust Off Vacuum Pumps

Replace Recycler Return Lines

Clean Or Replace Relief/Regulator Filter

Clean Water Inlet Strainer

•

•

•

•

•

•

•

•

Page 6

Page 7

Installation & Operation

Twin Vacuum System

Technical Service - (800) 233-4151

Trouble-Shooting Guide

PROBLEM: Motor will not start when turned “ON”.

Cause: No power to pump motor.

Remedy: 1. Check for proper voltage at pump terminal block input terminals(±10% of rated voltage). If proper voltage is not

present, check circuit breaker and supply circuit.

2. If low voltage switching is being used, bypass low voltage circuit by connecting the red and blue wires from the

top of the electrical box.

3. Reset circuit breaker switches located on top of electrical box. To reset, momentarily turn “OFF” then back “ON”.

4. Check the voltage between the blue and white low voltage wires. If it is not between 20 and 28 VAC the ON/OFF

switch or the transformer may be defective, or there is a faulty connection within the box.

5. If the voltage of step 3 is within limits and the relay contacts were not closing, replace relay.

PROBLEM: Pump runs but creates insufficient “suction”.

Cause: Vacuum intake filter clogged.

Remedy: 1. Clean filter, or replace with ADP Dispos-A-Bowl™.

Cause: Faulty vacuum system:

Remedy: 1. Remove the vacuum inlet line from the pump. If there is good suction at the pump, but little to none in the system,

the system is clogged or contains leaks. Locate the problem and repair.

Cause: Low relief/regulator valve setting

Remedy: 1. Adjust as illustrated in vacuum adjustment section. * Note: When adjusting be sure to block off inlet for maximum

vacuum adjustment.

Cause: Inadequate water supply.

Remedy: 1. Make sure water supply valve to pump is fully “OPEN”.

2. Unscrew hex cap from water inlet strainer and check for clogged filter screen. Clean as required.

3. Check for proper voltage at water solenoid coil (115 VAC ±10%). If proper voltage exists replace water solenoid.

(208 VAC ±10% on all Twin 2 or 3 HP models.)

4. Check water regulator to see if it is plugged.

Cause: Inadequately sized pump.

Remedy: 1. Check usage chart for maximum number of simultaneous users. Upgrade if necessary.

PROBLEM: Pump runs but creates excessive vacuum.

Cause: Clogged vacuum relief filter.

Remedy: 1. Unscrew filter/muffler from valve. Clean or replace filter media and reassemble.

Cause: High relief/regulator valve setting.

Remedy: 1. Adjust as indicated in vacuum level adjustment section. *Not recommended higher than 13” HG.

PROBLEM: Pump will not run continuously.

Cause: Overheating. Thermal protection shutdown.

Remedy: 1. Check for adequate ventilation. The motor is air cooled and a ventilation fan may be required.

Cause: Circuit breaker tripping.

Remedy: 1. Check for incorrectly sized or defective circuit breaker.

Cause: Faulty relay.

Remedy: 1. Check for proper gauge size. Replace relay if contacts fail to remain closed.

Page 7

Page 8

Installation & Operation

Twin Vacuum System

Technical Service - 1-800-MIDMARK

Description Part Number Description Part Number

Cover - Electrical Box .................................... ECB-80581

Bushing - 1” MPT x 3/4” FPT ........................ PCV-50992

Dispos-A-Bowl 3/4” ....................................... AVA60001

Dispos-A-Bowl 1”........................................... AVA60011

Dispos-A-Bowl 1 1/4” .................................... AVA60021

1/4” MPT x 1/4” Poly-flow ............................ PCB-50450

Elbow - 3/4” MPT x 3/4” SLP ........................ PVC-50207

Elbow - Street 1” NPT PVC ............................ PVC-51021

Filter - Relief Valve 1” FPT............................. SVA-95819

Gauge - Vacuum ............................................ PGA-70415

Jumper - 2 Terminal 115/230 VAC ................ ECC-10225

Motor - 1 HP (60 Hz.) .................................... HFM-30905

Motor - 1 HP (50 Hz.) .................................... HFM-30915

Motor - 1 1/2” HP (60 Hz.) ............................HFM-30910

Motor - 1 1/2” HP (50 Hz.) ............................HFM-30920

Motor - 2 HP (50/60 Hz.)...............................HFM-30911

Motor - 3 HP (50/60 Hz.)...............................HFM-30912

Nipple - 3/4” MPT Close (Brass) ...................PCB-50475

Nipple - 3/4” x 2” (Brass) .............................. PCB-50470

Nipple - 3/4” Close (PVC) ............................. PVC-50520

Nipple - 1” Close (PVC) ................................ PVC-51022

Relay - 24 VAC .............................................. ETR-10460

Feet - Studded Rubber ...................................MRP-70963

Feet - Rubber Washers .................................. MRP-70964

Seals - Shaft Seal Assembly, 1 & 1.5 HP....... SVA-95845

Seals - Shaft Seal Assembly, 2 & 3 HP.......... SVA-95847

PVC Tee 1”x 1”x 3/4” Slip ............................. PVC-50721

Strainer - 1” FPT Vacuum Inlet ...................... PVC-50706

Strainer - 1 1/4” FPT Vacuum Inlet ................PVC-50708

Strainer - 1/4” FPT Water .............................. PCB-50960

StayClean 64 oz. Bottle ...................................ASC00002

StayClean (64) 1 oz. Tubes .............................ASC00001

StayClean Non-Foaming Cleaner (4) 64 oz.....ASC00005

Switch - 1/2 Amp Circuit Breaker .................. ECS-10422

Transformer - 115/220 Volt 24 VAC............... ETR-10500

Tubing - 3/4” PVC (19mm) ............................ PCT-80460

Tubing - 1 1/4” PVC (32mm)......................... PCT-80461

Tubing - 1/4” Poly-flow 135 psi (6mm) ......... PCT-80610

Union - 3/4” Slip (PVC)................................. PVC-50200

Valve - 1/4” FPT Anti-Siphon ........................ PVV-50595

Valve - Check Valve Assembly (Intake) .......... SVA-95700

Valve - Relief / Regulator 1” MPT .................. PVV-85981

O-Ring - Pump Housing, 1 & 1.5 HP ............ MRP-70955

O-Ring - Pump Housing, 2 & 3 HP ............... MRP-70957

*To order parts, contact your authorized ADP Dealer.

Valve - Solenoid 1/4” FPT 115 VAC .............. PVV-10470

Valve - Solenoid 1/4” FPT 230 VAC .............. PVV-10472

Warranty Information:

• Classic Bronze™ = 2 Year

• Gold Series™ = 2 Year

• UltraVac® = 3 Year

All Apollo products are thoroughly inspected and tested in accordance with rigid specifications and standards. Our products are guaranteed against

defective material and workmanship from the date of shipment; provided, that the installation, operation, and maintenance is done in accordance with

Apollo’s procedures as outlined in the provided manuals. Warranty cards must be returned to Apollo within ten days of the installation to

effect warranty. No other warranties, or guarantees, expressed or implied are made.

Apollo’s obligation under the warranty is to provide parts for the repair or, at Apollo’s option, provide the replacement product, excluding labor and

shipping charges. All special, incidental and/or consequential damages are excluded. Apollo will not issue credit for product without first attempting

to correct the problem in the field. Written notice of breach of warranty must be provided to Apollo within the warranty period. The warranty does not

cover damage resulting from the use of cleaning, disinfecting or sterilizing chemicals and processes. On vacuum products, the warranty does not

cover failures due to hard water deposits. Failure to following installation and operation procedures will void the warranty.

Page 8 AMI60333 Rev. 10/03

Loading...

Loading...