Page 1

Installation Instructions

Series V Control Panel

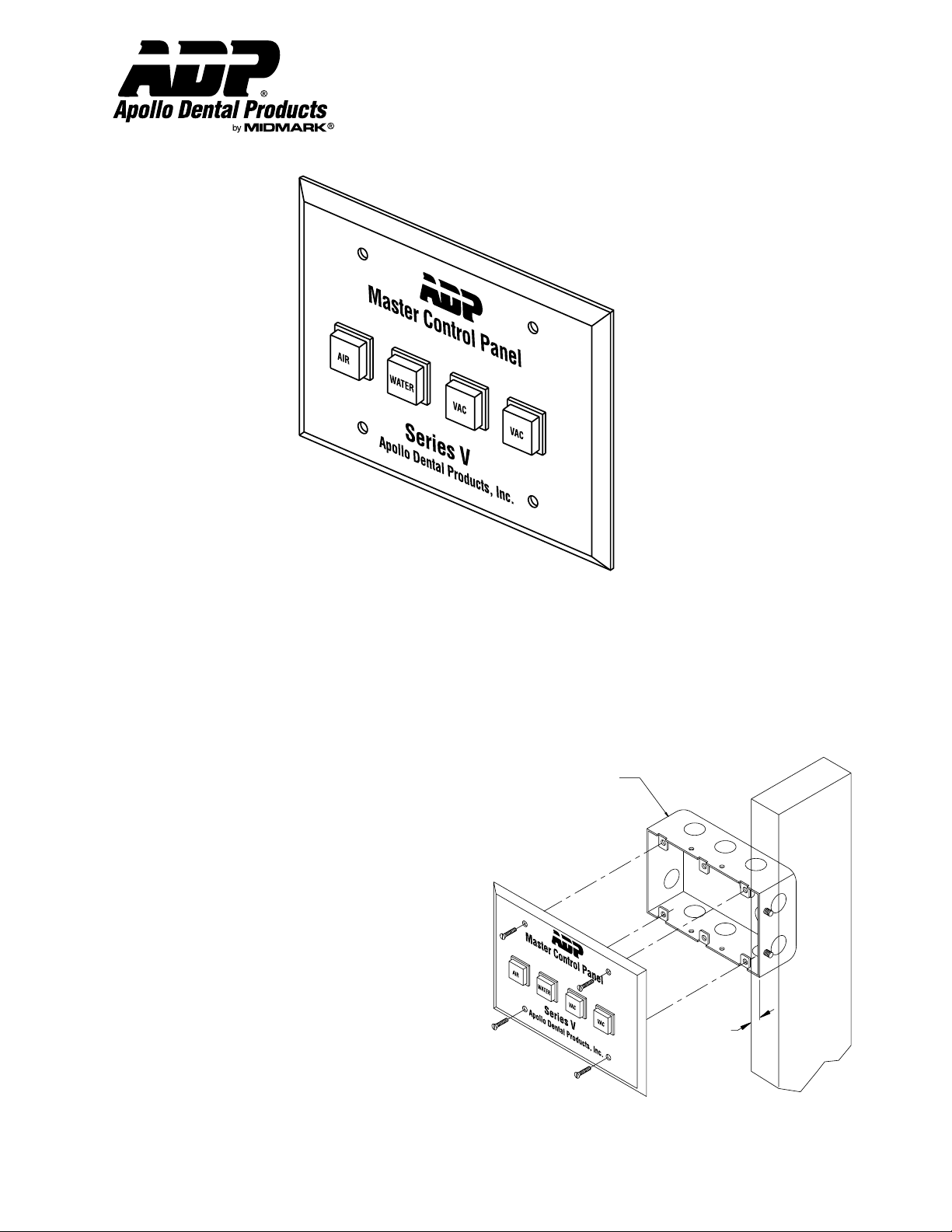

Description

The Apollo Dental Products Control Panel is designed to provide a convenient means of controlling dental equipment from inside the

office area. Features include lighted switches and an attractive brushed stainless steel mounting plate.

Master Control Panels include 50 feet of 18-3 bell wire with each switch, connecting fittings, and mounting fasteners.

Although the panel can be installed directly in drywall, many local codes require the use of a juction box. The juction box (not

provided) must be a standard three gang box measuring 2 1/2” deep by 4” high by 5 3/4” wide. With either mounting method, the

panel requires a standard three wire 24 VAC control circuit from each piece of equipment being controlled. ADP also manufactures a

complete line of remote contactor boxes for 24 VAC control.

Junction Box

(Not Provided)

Instructions For Junction Box Mounting

1. Prior to installation of sheet rock, mount the three gang

junction box to a stud as illustrated at right. The box should

be placed so that it’s front surface is set back 1/2” to 5/8”.

2. Run one 18-3 bell wire from each piece of equipment up to

the installed junction box.

3. Cut and install sheet rock.

4. Connectors are provided to complete the wiring of the control

panel by connecting wires to corresponding colored wires

from the Apollo low voltage contactor box(es).

1/2" To 5/8"

Set Back

5. Position the panel, then insert and tighten screws.

Apollo Dental Products, Inc. • 245 W. Dakota Ave. • Clovis, CA 93612 • Technical Support

559/292-1444 • 800/233-4151 • Fax 559/292-1555 • www.apollodental.com

Page 1

Box Mounted Control Panel Diagram

AMI60354 Rev. 4/00

Page 2

Installation & Operation

Series V Control Panel

Technical Service - (800) 233-4151

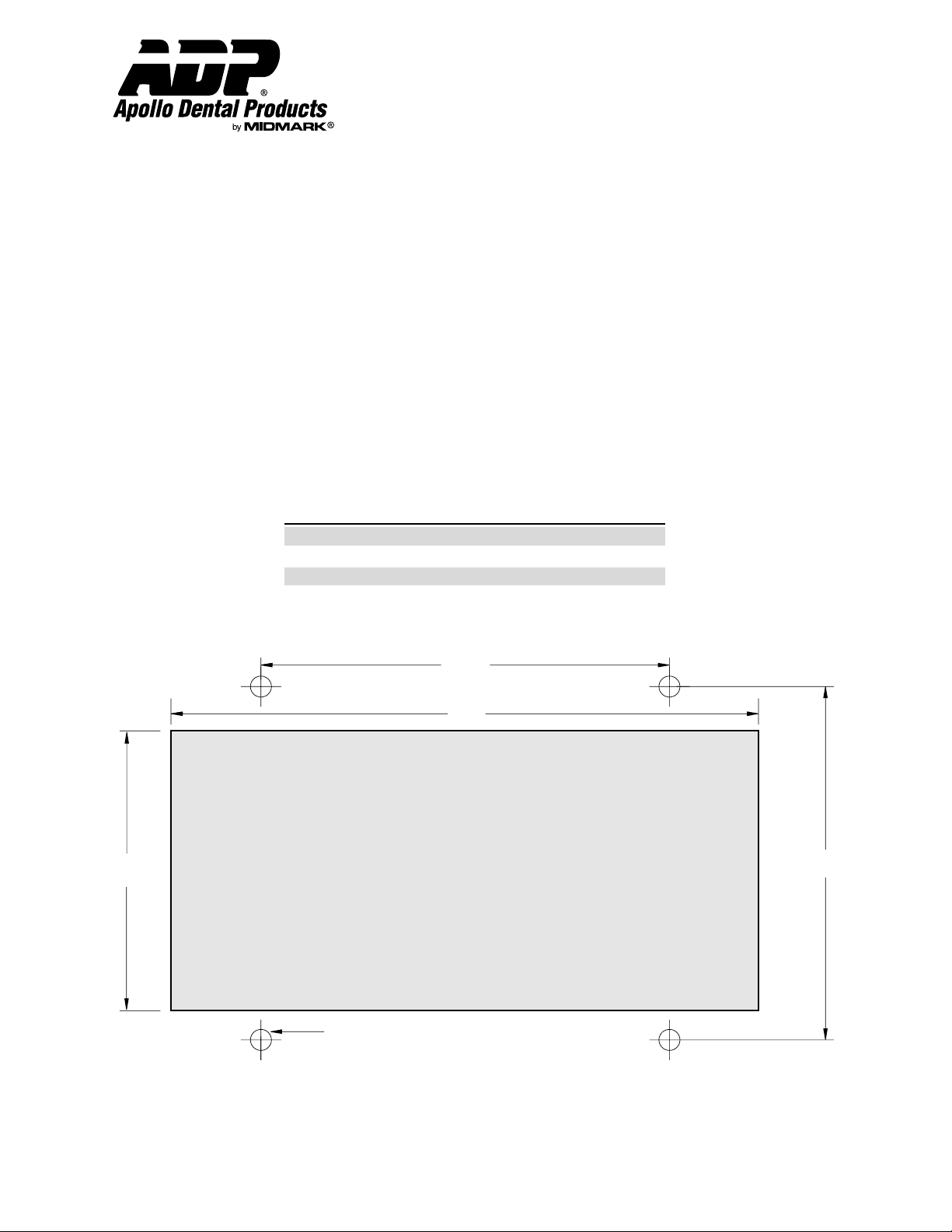

Instructions For Drywall Mounting

Warning: All Control Panels must be installed according to local codes.

1. Place the provided template on wall and mark the position of the four 3/16” diameter holes and the switch area.

2. Cut and remove the area from the drywall.

CAUTION: Do not cut hole larger than shown on the template.

3. Drill 3/16” holes.

4. Insert the provided anchors into the 3/16” holes.

5. Run one 18-3 bell wire from each piece of equipment to the area the panel is to be mounted.

6. Use the provided connectors to complete the wiring of the control panel. Attach each colored wire to the corresponding colored

wire from the Apollo contactor box(es).

7. Position the panel and insert screws. After the screw has contacted the mounting plate, use the chart below to find the additional

number of turns needed for proper expansion of the anchors.

Drywall Thickness Additional Turns After Contact

1/2” 5 - 7 Turns

3/4” 3 - 4 Turns

1” 1 - 2 Turns

21/32"

3

1/4

5

"

1/2

2

"

CUT OUT

5/32

3

"

THIS AREA

Drill Drywall Here (4 Places)

3/16" Diameter Hole

Drywall Mounting Template

Page 2 AMI60354 Rev. 4/00

Page 3

Installation & Operation

Series V Control Panel

Technical Service - (800) 233-4151

B = Blue

R = Red

W = White

Vac

R

W

Vac Water Air

R

W

B

B

Vac 1Vac 2

W

To WFB To Comp

R

B

R

W

B

Wiring Schematic (4 Switch)

Electrical Information

Note 1: As shown above, Control Panel equipped with a water control switch are wired such that water switch must be in the

“ON” position in order to start the vacuum pump(s). This feature is provided as a standard protective measure to ensure

that the vacuum pump(s) are not operated without water and thereby damaged.

Note 2: In panels without a water switch, the vacuum switch(es) are wired using the same configuration as shown on the air switch

above.

Trouble-Shooting Guide

Problem:

Problem:

Dental equipment does not start when switch is engaged.

Cause A: Broken or loose low voltage wire.

Corrective Action: 1. Check all wire connections.

Cause B: Defective switch.

Corrective Action: 1. Connect red and blue wires together at the contactor box, thus bypassing the switch.

2. Order new switch: SEA95227 “AIR”, SEA95228 “VAC”, SEA95229 “WATER”.

Dental equipment starts when switch is engaged but switch does not illuminate.

Cause A: Broken or loose wire.

Corrective Action: 1. Check all wire connections.

Cause B: Defective bulb.

Corrective Action: 1. Relamp switch by removing switch lens, then pulling bulb ejector lever located on inner

lower edge of switch. Press in new bulb (#SEA95225).

Warranty Information: 90 Days

All ADP accessories are thoroughly inspected and tested in accordance with rigid specifications and standards. Our accessories are guaranteed

against any defective material and workmanship from the date of shipment; provided that the installation, operation, and maintenance is done in

accordance with ADP procedures as outlined in our Installation and Maintenance Guides. Warranty cards must be returned to ADP within ten days of

installation to effect warranty. No other warranties or guarantees, expressed or implied are made.

ADP’s obligation under the warranty is to provide parts for the repair or, at its option, to provide the replacement product (excluding labor). All special,

incidental and/or consequential damages are excluded. We will not issue credit for accessories without first attempting to correct the problem in the

field. Written notice of breach of warranty must be given to ADP within the warranty period. The warranty does not cove damage resulting form

improper installation or maintenance, accident or misuse. The warranty does not cover damage resulting from the use of cleaning, disinfecting or

sterilizing chemicals and processes. Failure to follow instructions provided in ADP’s Installation and Maintenance Guides may void the warranty.

Page 3 AMI60354 Rev. 4/00

Loading...

Loading...