Page 1

Maintenance & Troubleshooting

Oil-Less “ACE” Series Compressor

Description:

Apollo Dental Products’ Air Compressors are designed to provide years of trouble-free, reliable service. However, some components

do require periodic attention and service. Failure to adequetly service these components will not only cause failure of the compressor,

but will also result in unsatisfactory service. If you require additional information please contact ADP Technical Support between the

hours of 6:00 a.m. and 4:00 p.m. (Pacific Standard Time).

Maintenance:

A. Storage Tank

Check Water Build-Up In Storage Tank Monthly. To check, locate drain valve on bottom of storage tank and slowly

open. If moisture is present, allow all moisture to be expelled before closing the valve.

B. Air Intake Filter-Muffler

Replace Air Intake Filter-Muffler Annually. A dirty air intake filter-muffler decreases the efficiency of the

compressor and increases oil consumption. Replacement filter-muffler part #ACP90500.

C. Condensate Drain Canister

Empty Condensate Drain Canister Weekly.

D. Pump-Up Times

Check Pump-Up Times Monthly. Refer to table for proper time readings.

NOTE: Never lubricate this oil-less compressor. The Teflon-filled compressor rings are

self-lubricating and do not require oil. The motor and crankshaft bearings are

permanently lubricated.

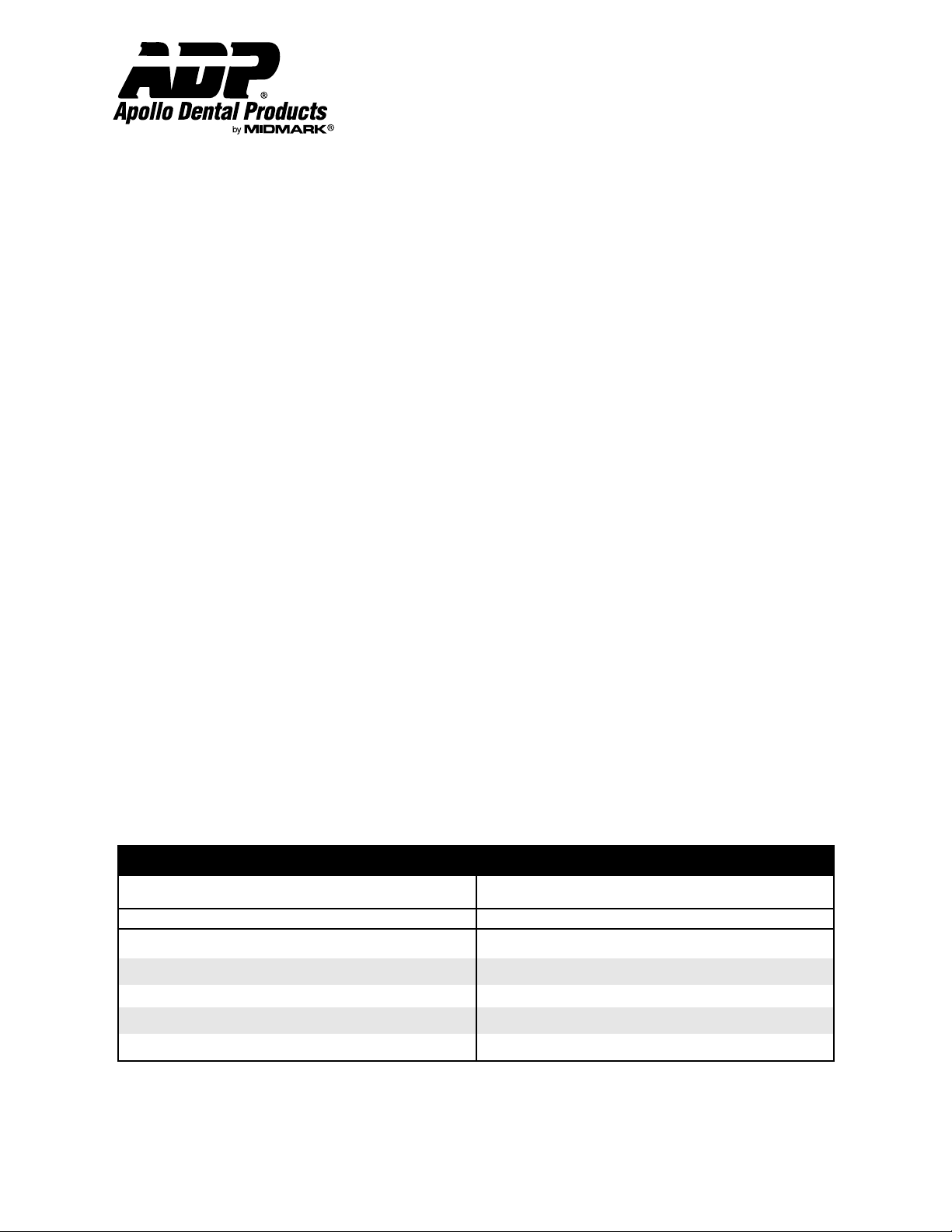

Compressor Pump-Up Chart

Standard Compressor Models Desiccant Compressor Models

Compressor Model Compressor Pump-Up Time 80-100 PSI Compressor Model Compressor Pump-Up Time 80-100 PSI

ACE11 30-40 Seconds ACE11D 50-57 Seconds

ACE12 30-40 Seconds ACE12D 50-57 Seconds

ACE21 15-25 Seconds ACE21D 20-30 Seconds

ACE22 15-25 Seconds ACE22D 20-30 Seconds

ACE2F 15-25 Seconds ACE2FD 20-30 Seconds

Apollo Dental Products, Inc. • 245 W. Dakota Ave. • Clovis, CA 93612 • Technical Support

559/292-1444 • 800/233-4151 • Fax 559/292-1555 • www.apollodental.com

Page 1

AMI60319 Rev. 12/00

Page 2

Maintenance & Troubleshooting

Oil-Less “ACE” Air Compressor

Technical Service - (800) 233-4151

PROBLEM: Compressor will not start.

Cause: No power at motor terminals.

Remedy: Check for voltage at wall outlet. If proper voltage is measured there and not at motor terminals, check for:

1. Broken or loose wire.

2. Pressure switch decfective or out of adjustment (contacts should be closed if tank pressure is below 80 PSI).

3. Defective On/Off switch (DPST). Replace.

Cause: Defective capacitor (Motor may hum but not start).

Remedy: 1. Short capacitor lead terminals and test capacitor using OHM meter, checking for resistence rise. If there is no

resistence, capacitor is defective and must be replaced.

2. Relay coil open. Check for continuity across relay coil terminals 2 and 5. If no continuity, relay should be replaced.

(Relay is located inside capacitor starting assembly box).

Cause: Thermal overload cut-off on high temperature.

Remedy: 1. Allow motor to cool. Compressor should then automaticaaly restart.

Cause: Frozen motor/compressor.

Remedy: 1. Turn off electrical power. Check to see if compressor fan will rotate by hand. If not, replace compressor head. Contact

ADP for Return Authorization on any part under warranty.

PROBLEM: Motor runs for only a few seconds or “chuggs”.

Cause: Low voltage.

Remedy: 1. Check line voltage, it should be at least 215 volt (230 volt units) when compressor is running, or 105 volts (115 volt

units). Install ADP transformer if necessary.

Cause: Blockage in air line.

Remedy: 1. Remove discharge line flex hose from head and test run. If unit runs correctly, check for obstruction in air line to

storage tank. It most likely would be at an orifice or other restriction.

PROBLEM: Compressor head runs but will not pressurize to 100 psi.

Cause: Quick exhaust valve or pressure switch unloader valve are not closing when compressor runs.

Remedy: 1. Quick exhaust valve or pressure switch unloader valve may be dirty or defective. Clean or replace.

Cause: Clogged air intake filter-muffler.

Remedy: 1. Check for excessive dirt/dust accumulation. Clean or replace.

Cause: Air leaks in system piping.

Remedy: 1. Check for leaks using soapy water solution. Repair any system piping air leaks.

Cause: Blockage in air line.

Remedy: 1. Inspect all air lines for restrictions.

Cause: Leak in compressor unit.

Remedy: 1. Close the storage tank shut-off valve. With compressor running, check discharge line flex hose, pressure safety valve

tank drain valve and all fitting for leaks, using soapy water.

Cause: Insufficient discharge.

Remedy: 1. Remove discharge line flex hose and check for pressure build-up by holding finger over discharge outlet fitting. If

low or no pressure build-up occurs head is defective. Contact ADP for Return Authorization information.

Page 2 AMI60319 Rev. 12/00

Page 3

Maintenance & Troubleshooting

Oil-Less “ACE” Air Compressor

Technical Service - (800) 233-4151

PROBLEM: Compressor cycles with no air being used.

Cause: Manual purge valve handle is in “ON” position (vertical).

Remedy: 1. Turn valve handle to normal “OFF” position (horizontal).

Cause: Leak in office air system.

Remedy: 1. Close the storage tank shut-off valve. Pump up storage tank to 100 PSI. If pressure is maintained at 100 PSI for

15-20 minutes, leak is in air system not in compressor.

Cause: Leak in compressor.

Remedy: 1. Storage tank check valve may be dirty or defective. Clean or replace.

2. Check for leaks at storage tank shut-off valve, pressure safety valve tank drain valve and all fittings attached to

storage tank, using soapy water solution.

PROBLEM: Moisure indicator is pink.

Cause: Unloading system not functioning properly.

Remedy: 1. Check to see that the quick exhaust valve closes when the compressor is pumping. Remove the exhaust muffler to

determine this.

2. Ensure that the quick exhaust valve and the pressure switch unloader valve opens as soon as the compressor stops.

The purge tank gauge pressure should drop from 100 PSI to zero.

3. If quick exhaust valve is suspected of malfunctioning, visually check for:

A: Leaking or dirty quick exhaust valve diaphragm.

B: Pressure switch unloader operation, adjust unloader tap screw if necessary.

Cause: Saturated Desiccant Drying chamber.

Remedy: 1. Operate drying system in the manual purge mode. If after 1 week the system is not dry, replace the silica gel

(desiccant).

Cause: Compressor running too frequently.

Remedy: 1. Compressor undersized for installation. Check with ADP Technical Support.

2. Leaks in air system. Locate and repair.

Cause: Condensation in air lines.

Remedy: 1. As the compressed air moves through the air lines to the operatory, it cools, causing condensation of any moisture

particles in the air. This can result in wet operatory air. To prevent this, it is necessary to install a Mini Spitter Filter

Kit (Part #ASA85315) in the dental unit. This will filter any condensation from the compressed air before it enters

handpieces.

Under normal operating conditions, a small amount of moisture may appear in the condensate bucket. This is not a malfunction. It is

evidence of what the Desiccant Drying System captured, and did permit to enter the operatory air supply.

Warranty Information: 1 Year

All ADP products are thoroughly inspected and tested in accordance with rigid specifications and standards. Our products are guaranteed against any

defective material and workmanship from the date of shipment; provided, that the installation, operation, and maintenance is done in accordance with

ADP procedures as outlined in our Installation and Maintenance Guides. Warranty cards must be returned to ADP within ten days of installation to

effect warranty. No other warranties or guarantees, expressed or implied are made.

ADP’s obligation under the warranty is to provide parts for the repair or, at its option, to provide the replacement product (excluding labor). All

special, incidental and/or consequential damages are excluded. We will not issue credit for product without first attempting to correct the problem in

the field. Written notice of breach of warranty must be given to ADP within the warranty period. The warranty does not cover damage resulting form

improper installation or maintenance, accident or misuse. The warranty does not cover damage resulting from the use of cleaning, disinfecting or

sterilizing chemicals and processes. The warranty does not cover vacuum failures due to hard water deposits. Failure to follow instructions provided

in ADP’s Installation and Maintenance Guides may void the warranty.

Page 3 AMI60319 Rev. 12/00

Loading...

Loading...