Page 1

THE APOLLO INTELLIGENT METER SERIES

MODEL IMY INSTRUCTION MANUAL

Page 2

INTRODUCTION

The Intelligent Meter for Thermistor Inputs (IMY) is another unit in our multipurpose series of industrial control products that are field-programmable to solve

multiple applications. This series of products is built around the concept that the

end user has the capability to program different personalities and functions into

the unit in order to adapt to different indication and control requirements.

The Intelligent Thermistor Meter which you have purchased has the same high

quality workmanship and advanced technological capabilities that have made

Red Lion Controls the leader in today’s industrial market.

Red Lion Controls has a complete line of industrial indication and control

equipment, and we look forward to being of service to you now and in the future.

CAUTION: Read complete instruc-

tions prior to installation

and operation of the unit.

CAUTION: Risk of electric shock.

Page 3

Table of Contents

SAFETY INFORMATION ······························································3

Safety Summary ···································································3

GENERAL DESCRIPTION ·····························································4

Theory Of Operation ·······························································4

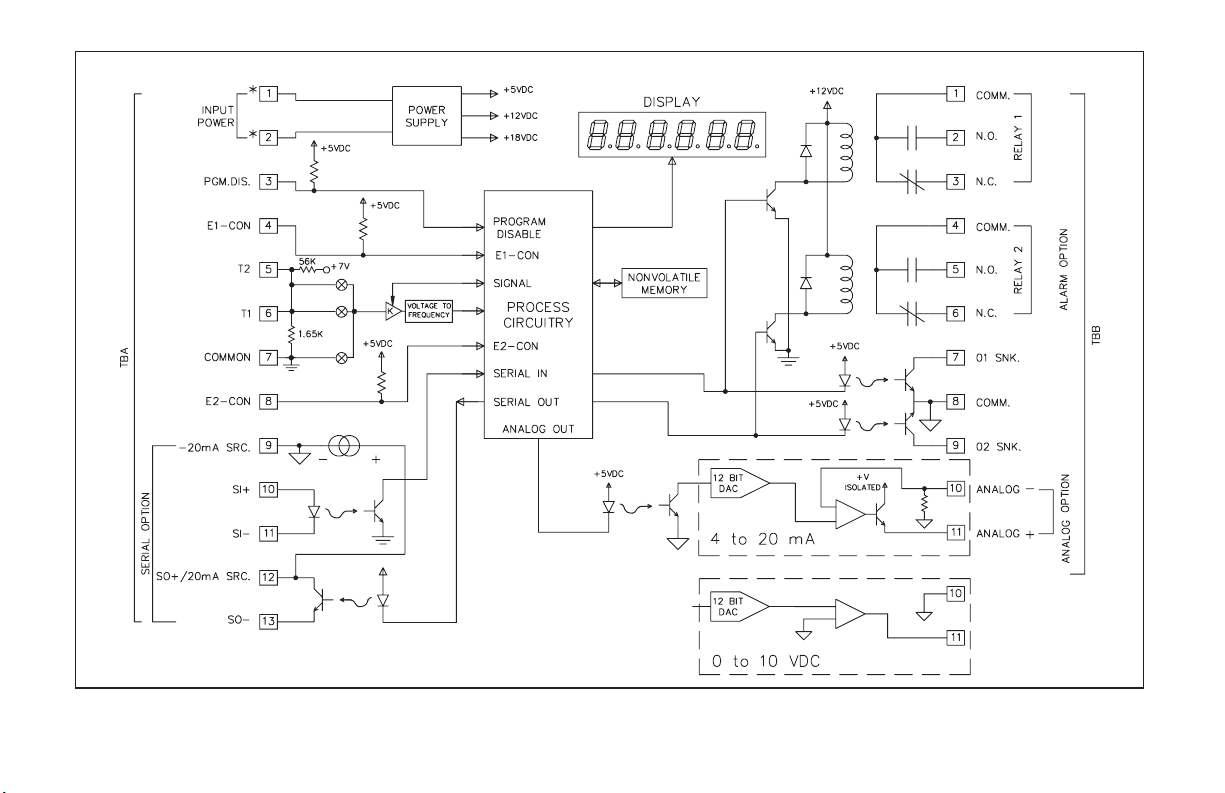

Block Diagram ····································································5

PROGRAMMING AND OPERATING THE IMY ············································6

Programming the IMY ······························································6

Module #1 - Program Thermistor Type, Temperature Scale (F or C)

and Decimal Point Position ···········································8

Module #2 - Program Temperature Display Offset and Slope ······························8

Module #3 - Program Functions Accessible W/ Front Panel Lockout ························9

Module #4 - Program Digital Filter and Remote Input ···································11

Module #5 - Program Integrator/Totalizer ·············································13

Module #6 - Program Alarm/Setpoint ·················································14

Module #7 - Program Serial Communications ··········································16

Module #8 - Program Re-Transmitted Analog Output ···································17

Module #9 - Service Operations ·····················································18

Operating The IMY ································································19

Quick Programming ·······························································19

Factory Configuration ·····························································20

Temperature Monitoring Example ···················································22

INTEGRATOR / TOTALIZER / PEAK / VALLEY / TEMPERATURE OFFSET (Optional) ·········23

Integrator/Totalizer ································································23

Peak/Valley ······································································23

Offset And Slope Display Temperature ···············································23

Integrator/Totalizer Example ························································24

Integrator/Totalizer Set-Up ·························································24

ALARMS (Optional) ·································································26

20 mA CURRENT LOOP SERIAL COMMUNICATIONS (Optional) ··························27

General Description ·······························································27

Communication Format ····························································27

Sending Commands to the IMY ·····················································28

-1-

Page 4

Command String Examples ·························································28

Receiving Data from the IMY ·······················································30

Current Loop Installation ···························································30

Serial Terminal Descriptions ························································30

Serial Communications Examples ···················································31

RE-TRANSMITTED ANALOG OUTPUT (Optional) ·······································33

Analog Output Calibration ··························································34

APPENDIX “A” - INSTALLATION & CONNECTIONS ·····································35

Installation Environment ···························································35

Panel Installation ······························································35

Select AC Power (115/230 VAC) ····················································35

EMC Installation Guidelines ························································36

Wiring Connections ·······························································37

Power Wiring ·································································37

Signal Wiring (Thermistor) ·······················································37

User Input Wiring ······························································37

Output Wiring ·································································37

APPENDIX “B” - SPECIFICATIONS AND DIMENSIONS ···································38

APPENDIX “C” - TROUBLESHOOTING GUIDE ··········································41

APPENDIX “D” - PROGRAMMABLE FUNCTIONS ·······································42

APPENDIX “E” - ORDERING INFORMATION ············································44

-2-

Page 5

SAFETY INFORMATION

SAFETY SUMMARY

All safety related regulations, local codes and instructions that appear in

the manual or onequipment must be observed to ensure personalsafetyand to

prevent damage to either the instrument or equipment connected to it. If

equipment is used in a manner not specified by the manufacturer, the

protection provided by the equipment may be impaired.

Do not use this unit todirectly command motors, valves, or other actuators

not equipped withsafeguards. To do so, can bepotentially harmful to persons

or equipment in the event of a fault to the unit.

DEFINITION OF TERMS

INSTALLATION CATEGORY (overvoltage category) I:

Signal level, special equipmentor parts of equipment, telecommunication,

electronic, etc. with smaller transient overvoltages than Installation

Category (overvoltage category) II.

INSTALLATION CATEGORY (overvoltage category) II:

Local level, appliances, portable equipment, etc. with smaller transient

overvoltages than Installation Category (overvoltage category) III.

-3-

Page 6

GENERAL DESCRIPTION

The Apollo Intelligent Thermistor Meter (IMY) accepts standard Thermistor

inputs and precisely linearizes them into temperature readings. Like an RTD, a

thermistor is a temperature sensitiveresistor, but thethermistor provides amuch

larger resistance change per degree. Since thermistors provide a large resistance

change, significant errors from long lead lengths or switches are eliminated.

Other advantages of using a thermistor are accuracy, repeatability, long term

stability, and sensor cost. A full 6-digit display accommodates a wide range of

temperature inputs and holds large totalization values. State-of-the-art digital

circuitry virtually eliminates errors due to drift. A full complement of option

packages is available to fulfill many process applications.

The IMY supports two popular thermistor series - the 400 Series 2,252

Ohm thermistor, and the 700 Series Thermolinearä thermistor. Selection

between the two types is done in Programming Module #1.

The indicator features areadoutchoice of either Fahrenheit or Celsiuswith

0.1 or 1 degree of resolution. English Style display prompts aid the operator

through set-up and operation. A front panel lock-out menu protects set-up

data and operation modes from unauthorized personnel. Programmable

digital filtering enhances the stability of the reading. Programmable remote

input “E1-CON” pin can be utilized to control a variety of functions, such as

totalizing, alarm control, peak/valley reading, display hold or offset

operations. All set-up data isstoredin the E

minimum of 10 years without power.

An optional integrator/totalizer can be used to totalize or integrate

temperatures up to a maximum display value of 999,999. It features

independent scaling and a low temperature cut-out to suit a wide variety of

temperature integration applications. A programmable remote input,

“E2-CON”, is included with the option andcan be utilized to control a variety

of functions, such as totalizing, alarm control, peak/valley readings, display

hold or offset operations, simultaneously with the “E1-CON”. Peak/valley

(max/min) reading memory functions are included with this option and they

are easily recalled and controlled by either the front panel or a remote input.

All readings are retained at power-down.

Optional dual relayswithparallel solid state outputs are fullyprogrammable

to operate in a wide variety of modes to suit many control or alarm applications.

Optional 20 mA loop, bi-directional serial communications provides

computer and printer interfacing to extend the capabilities of the indicator.

2

PROM, which will hold datafora

More than one unit can be connected in the loop with other RLC products

which have serial communications capabilities.

An optional 4to 20 mA or 0to 10 VDC re-transmitted analogoutput can be

scaled by the user to interface with a host of recorders, indicators and

controllers. The type of analog output is determined by the model ordered.

(See Ordering Information for available models.)

The indicator has several built-in diagnostic functions to alert operators of

most malfunctions. Extensive testing of noise interference mechanisms and

full burn-in makethe indicator extremely reliable in industrialenvironments.

The die-cast front bezel meets NEMA 4/IP65 requirements for washdown

applications. Plug-in style terminal blocks simplify installation wiring and

change-outs.

THEORY OF OPERATION

The IMY employs a microprocessor to perform the A/D conversion on the

input signal via a voltage-to-frequency converter. It digitally scales the

result, corrects for meter drift which may be present and then displays the

result in a6-digit display (4 digitsfor temperature, 6 digitsfor totalizer). The

inputs are filtered to enhance the stability of the display. A non-volatile

2

E

PROM provides permanent data retention for operating variables. The

display consists of drivers and 6-digit solid-state LEDs. The alarm option

employs opto-isolators to isolate the open collector devices from meter

common. Operating in parallel, the relays are type Form-C and are rated at

5-amps. The serial communication option features a built-in 20 mA current

source and completeopto-isolation. The analog optionfeatures a 12-bit DAC

and providesa4to20mAor0to10VDCoutput that is digitally scaled. The

analog output is isolated from meter common.

-4-

Page 7

BLOCK DIAGRAM

*Reference Installation and Connections section for power connection.

Note: Analog “-” and Alarm common are separate and isolated from the signal common. The commons should NOT be tied together.

-5-

Page 8

PROGRAMMING AND OPERATING THE IMY

PROGRAMMING THE IMY

Although the unit has been programmed at the factory, the set-ups will

generally have to be changed to suit the application. Basic set-up is complete

after selection of the temperature units, decimal point placement, and

selection of the digital filtering level.

Before actually tryingto program the indicator, itis advised to organize all

the data for the programming steps to avoid any possible confusion and to

read the programming procedure entirely before proceeding.

To set-up the indicator, connect primary power and signal wires as

outlined in the connections section (Appendix “A”). Remove the jumper

wire (if installed) fromTBA#3 (PGM. DIS.). This will allowtheoperator to

enter and modify all of the indicator’s parameters. Press the front panel

button labeled “P”, momentarily. Briefly, the display will show “Pro”

alternately flashing with “0”. This is the indicator’s programming mode.

The programming mode is divided into sections, numbered 0-9, each of

which can be individually accessed. The front panel “UP” and “DOWN”

arrow buttons canbe used to select one of these numbers and the “P” button

can be used to enter the selected programming module. In all of the

programming modules, “UP”and “DOWN” are usedto either select from a

list of choices or enter a value. The “P” button is used to save the new value

and progress to the next step within a module (Note: the new value takes

effect when “P” is pressed). Upon completion of a module, the indicator

returns to the “Pro” <>“0” stage. Pressing the “P” button at this time

causes the unit to display “End” after which the unit returns to the normal

display mode. The following table explains the basic function of each step.

Note: < > This indicates that the display will alternate between the English

prompt and the actual data.

-6-

Page 9

DISPLAY RESULT OF “P” BUTTON

DISPLAY

RESULT OF “P” BUTTON

“Pro” <>“0” - Causes the indicator to return to normal display mode.

Any changes to set-up data are permanently stored in the

2

E

PROM.

“Pro” <>“1” - Entry into this module allows the user to select the

Thermistor type, whether the display will read in degrees

Fahrenheit (F) or Celsius (C), and display decimal point

position.

“Pro” <>“2” - Entry into this module allows the user to select

non-standard display slope and display offset values.

This enables the meter to be “scaled” to a calibrated

temperature probe. (This scaling is NOT required for

most applications.)

“Pro” <>“3” - Module #3 allows the user to program what can be

accessed from the front panel when the PGM. DIS.

(Program Disable, TBA #3) pin is connected to common.

This feature protects critical set-up data from accidental

modification while allowing access to setpoints and other

functions. The front panel lock-out menu (quick

programming) includes setpoint modification,

integrator/totalizer resetting, and peak/valley resetting.

Note: Theterm “Quick Programming”is used to refer to the

ability to change the information that can be accessed from

the frontpanelwhen the “PGM. DIS.”terminalis connected

to “COMM.”.

“Pro” <> “4” - Module #4 programs the digital filtering level and the

function of the remote input “E1-CON” pin (TBA #4),and

if the totalizer option is installed, the remote input

“E2-CON” pin (TBA #8). The functions of the remote E1

and E2 pins are the same and include display hold,

peak/valley modes, totalizer reset, alarm reset, temperature

offset, reading synchronization or print request.

“Pro” <>“5” - This module sets the time base, scale factor and low

temperature disable function for the optional integrator/

totalizer.

“Pro” <>“6” - This module allows programming for the basic

configuration of the alarm option. The programming

includes HI/LO acting, tracking, alarm display, latched

or auto-reset, assignment to either the input or the

integrator/totalizer, and alarm and hysteresis values.

“Pro” <>“7” - Module #7 is the serial communication parameter

programming. Baud rate, unit address, print request

function and condensed prints are all programmable.

“Pro” <>“8” - This module allows digital scaling of the retransmitted

analog output. Display values that correspond to 4mA or

0 VDC and 20 mA or 10 VDC are keyed-in to scale the

output and it may be assigned to either the input or the

integrator / totalizer.

“Pro” <>“9” - This module is the service operation sequence and is not

normally accessed by the user. This step re-calibrates the

basic input and is used to compensate for long-term drift.

Execution of this module should be done by technicians

with the proper equipment in accordance with a

maintenance plan of yearly recalibrations. A code number

entry step isused to protect frominadvertent entries. Also,

there is a number of other access codes which provide test

and set-up changes as an aid in troubleshooting.

-7-

Page 10

MODULE #1 - PROGRAM THERMISTOR TYPE, TEMPERATURE SCALE (F OR C)

AND DECIMAL POINT POSITION

Select the desired Thermistor type by pressing the “UP” or “DOWN”

button.

“tYPE” < > “400” 400 = 400 Series, 2,252 ohm

Select the desired temperature scale by pressing the “UP” or “DOWN”

button.

Select the desired decimal point location by pressing the “UP” or

“DOWN” button.

“700” 700 = Thermolinearä Series

“SCALE” < > “F”

“C”

“ dECPNt” < > “0”

“0.0”

MODULE #2 - PROGRAM TEMPERATURE DISPLAY OFFSET AND SLOPE

If the totalizer option is installed, the offset and slope can be programmed

for various temperature probe differences. See the Offset and Slope Display

Temperature section for more details.

Select the desired temperature displayslope value bypressing the “UP”or

the “DOWN” button.

“SLOPE” < > “0.0001” to “10.0000” (ex. 1.0309)

Select the desiredtemperature display offset value bypressing the “UP” or

the “DOWN” button.

“OFFSEt” < > “-999” to “9999” (ex. -17.5)

-8-

Page 11

MODULE #3 - PROGRAM FUNCTIONS ACCESSIBLE W/ FRONT PANEL LOCKOUT

This programming module programs what is accessible through the front

panel when the PGM. DIS. pin is connected to common (COMM.).

Note: The term “QuickProgramming” is used to refer to the abilityto change the

information that can be accessed from the front panel when the “PGM. DIS.”

terminal is connected to “COMM.”.

DISPLAY ALARM VALUES

If the alarmoption is installed, this selectswhether the alarm values willor

will not be displayed.

“dSP AL” < > “yES” or “NO”

ENTER ALARM VALUES =

If “YES” was selected for display alarm values, this will select if alarm

values may be modified from the front panel. (If “NO” was selected for

display alarm values, then this step will default to “NO” and will not be

displayed for selection.)

“ENt AL” < > “yES” or “NO”

DISPLAY HYSTERESIS VALUES

If the alarm option is installed, this selects whether the hysteresis values

will or will not be displayed.

“dSPHYS” < > “yES” or “NO”

ENTER HYSTERESIS VALUES =

If “YES” was selected for display hysteresis values, this selects whether

hysteresis values may be modified from the front panel. (If “NO” was

selected for display hysteresis value, then this step will default to “NO” and

will not be displayed for selection.)

“ENtHYS” < > “yES” or “NO”

= Note: This sequence may be locked-out due to other programmed sequences.

* Note: This function operates independent of the state of the “PGM. DIS.” pin.

RESET LATCHED ALARMS

If the alarm option is installed and if either alarm is programmed to latch,

this will select if a latched alarm(s) can be reset from the front panel.

“rSt AL” < > “yES” or “NO”

DISPLAY PEAK/VALLEY MEMORY BUFFER

If the integrator/totalizer option is installed, this selects whether peak and

valley buffers will be displayed.

“dSPbUF” < > “yES” or “NO”

RESET PEAK/VALLEY MEMORY BUFFER =

If “YES” was selected for the previous step, this selects whether the peak

and valley buffers may be reset from the front panel. (If “NO” was selected,

then this step defaults to “NO” and will not be displayed for selection.)

“rStbUF” < > “yES” or “NO”

SELECT DISPLAY*

If the integrator/totalizer option is installed, this selects whether the

display can be switched from input display to total display and from total

display to input display.

Note: When “NO” is selected, whatever display (Input or total) is shown, willbe

the only display accessible.

“SELdSP” < > “yES” or “NO”

RESET TOTAL*

If the integrator/totalizer option is installed, this selects whether the total

can be reset from the front panel.

“rSttOt” < > “yES” or “NO”

-9-

Page 12

TEMPERATURE OFFSET VALUE =

If the Integrator/Totalizer/Peak/Valley/Temperature Offset option is

installed, this selects whether the programmed offset value will be displayed.

“dSPOFF” < > “yES” or “NO”

ENTER OFFSET VALUE =

If “YES” was selected for the previous step, this selects whether the offset

value can be entered from the panel. (If “NO” was selected, then this step

defaults to “NO” and will not be displayed for selection.)

“ENtOFF” < > “yES” or “NO”

Depending on functionsselected under Pro 3and Pro 6, alarms,hysteresis,

peak, valley and offset values can be monitored and/or changed with PGM.

DIS. istied to COMM. This provides a “QUICK PROGRAMMING” method

for “day to day” process changes. (See QUICK PROGRAMMING SECTION

for more details.)

= Note: This sequence may be locked-out due to other programmed sequences.

* Note: This function operates independent of the state of the “PGM. DIS.” pin.

-10-

Page 13

MODULE #4 - PROGRAM DIGITAL FILTER AND REMOTE INPUT

PROGRAM DIGITAL FILTERING

If the displayed process signal is difficult to read due to small process

variations or noise, increased levels of filtering will help to stabilize the

display. This programming step may be used in conjunction with display

rounding programming (Pro1&2)to help minimize this effect. Although the

digital filter features a “moving window” to help minimize response time,

higher degrees of filtering levels will have slightly longer response times.

“FILter” < > “0” - no digital filtering

PROGRAM FUNCTION OF E1-CON AND OPTIONAL E2-CON

The function of the remote input “E1-CON” (TBA #4) and, if the totalizer

option is installed, the remote input “E2-CON” (TBA #8) are the same.

Functions are activated, as described in the appropriate function, when

connected to signal common (TBA #7). Whether a function is edge or level

activated, it must be held low for a minimum of 20 msec in order for the

function to occur.The remote input pinscan be used simultaneously andwith

any combination of functions. When pins are tied together and activated,

E1-CON function is generally performed first.

“E1-CON”< > “0” - If the Totalizer/Peak/Valley/Display Offset option is

“1” - normal filtering

“2” - increased filtering

“3” - maximum filtering

installed, a negative going edge offsets the displayed

temperature to zero. (At the timethe E-Pin is activated,

the value of the actual temperature being displayed is

placed in the location of the display offset value. To

bring the unit into the normal temperature display

mode, reset the offset value to zero via the front panel.)

“1” - A negative going edge resets the contents of the

totalizer to zero. Totalization commences regardless

of the state of the remote input.

“2” - A negative going edge resets the contents of the

totalizer to zero and allows totalization as long as the

input is low. If the input goes high, totalization is

stopped and the contents are saved. This acts as a

totalization enable control from Time 1 to Time 2.

“3” - A low level allows totalization as long as the input is

low. If the input goes high, totalization is stopped and

the contents are saved. This acts as a totalization

enable control from Time 1 to Time 2.

“4” - A low levelholdsthe display (display hold). While this

input is low, the indicator continues to process the

input signal and drive the alarms, totalizer, etc., with

the actual signal. The contents of the totalizer are held

at the same time the input display is held.

Note: If display hold is activated, and input value is

requested via serial, the value on the display will be

sent instead of the actual input value at that time.

“5” -A negative going edgeresetsboth peak and valley buffers.

Note: If P/V is called up, a change will not appear on the

display until the next time the P/V is called up.

“6” - A negative going edge resets only the peak buffer and

the indicator enters a peak reading display mode as

long as the input is low. If the input goes high, peak

detection and indication are stopped and the last peak

reading is retained.

“7” - A negativegoing edge resets only the valleybufferand

the indicator enters a valley reading display mode as

long as the input is low. If the input goes high, valley

detection and indication arestopped and the last valley

reading is retained.

“8” - If the alarm option is installed, a negative going edge

resets the latched alarm(s).

-11-

Page 14

PROGRAM FUNCTION OF E1-CON AND OPTIONAL E2-CON

(Cont’d)

“9” - If the alarm option is installed, a low level resets a latched or

unlatched alarm into its inactivestate. This provides manual

override of alarms for system start-up and other unusual

events such as system testing.

“10” - A negative going edge toggles the display between “input”

and “total” (from input to total, or vice versa). No action is

taken on the positive going edge.

“11” - A negative going edge zeros(tares) the input signal and adds

the value that was in the input display to the totalizer value,

every time thisoperation is performed. The time-base, scale

factor and low cut-out in “Module #5” are in affect disabled,

when this function is selected.

“12” - Display hold with offset. Anegative going edge tares (zeros)

the input signal. Prior to the offset operation, the input

signal is saved and held (display hold) as long as the remote

input pin is low. On the positive edge, the input display will

show zero. If there is an increase tothe input signal while the

remote input is low, the display will reflect (show) the

increase at the positive edge.

“13”- Instrument reading synchronization. A lowlevel disables all

meter operations (alarms, total, analog out,etc.). A positive

edge resets the start of the A/D conversion, to allow

synchronization with external processes and controls.

While in this function, the other E-CON pin will be

operational.

“14”- Print request. Transmits data according to the print options

that have been selected in Program Module #7. If the low

time exceeds 800 msec, a second print-out may occur.

“E2-CON”<>Ifthetotalizer option is installed, E2-CON has the

same programmable functions as E1-CON.

-12-

Page 15

MODULE #5 - PROGRAM INTEGRATOR/TOTALIZER

Programming for the integrator/totalizer consists of four programming

steps: totalizer decimal point position, time base, scale factor and low

temperature disable. Note that the decimal point position of the

integrator/totalizer can be set independent ofthe decimal point position of the

input. The totalizer value will roll over and flash when the total exceeds,

999999 or -99999, indicating an overflow condition. Reverse signal input

will cause thetotalizer value to count inthe opposite direction and eventually

no longer be in an overflow condition.

PROGRAM DECIMAL POINT POSITION FOR THE

INTEGRATOR/TOTALIZER

The decimal point position for the totalizer are as follows:

“dECPNt” < > “0”

PROGRAM INTEGRATOR/TOTALIZER TIME BASE

The time base determines the rate at which readings increase. The

integrator/totalizer display is updated

base selected, but longer time bases decrease the magnitudeof each increase.

The three time bases are per second,perminuteandper hour. A constant input

temperature of 100°, for example, would integrate/totalize to 100° in one

second (with a TB of 1 sec.), 100° in oneminute(with a TB of 1 min.), and 100°

in one hour (with a TB of 1 hr.). (Note: Input changes can be made

synchronous to the display by programming E1 or optional E2-CON pin for

function 13, Instrument reading synchronization.) A multiplying scale factor

may be used to span the standard time ranges (or divide if scale factor < 1).

The following equation expresses the integration/totalization process.

D.T.

S.F. =

I.D. TIME I.D.D.P.

S.F. = Programmable Scale Factor

D.T. = Desired Totalizer value for a

fixed time duration

T.B. = Programmable Time Base

T.B.xD.T.D.P.

x

“0.0”

“0.00”

“0.000”

“0.0000”

1

times per second regardless of time

2

2

TB = If Program Select Number Chosen Is:

D.T.D.P. = Desired Totalizer Value Decimal Point

I.D.D.P. = Input Display Value Decimal Point

“tbASE” < > “0” - per second

PROGRAM THE INTEGRATOR/TOTALIZER SCALE FACTOR

As explained in the previous programming step, a multiplying scale factor

can be used to scale the update rate as required. This may be used to span the

standard ranges. A scale factor of “1.000” has no effect on the standard ranges.

“0” for sec. 1

“1” for min. 60

“2” for hr. 3600

I.D. = Input Display Value

TIME = Actual Time period in seconds

01

0.0 10

0.00 100

0.000 1000

0.0000 10000

01

0.0 10

“1” - per minute

“2” - per hour

“SCLFAC” < > “0.001” to “100.000”

Enter in Formula

Enter in Formula

Enter in Formula

PROGRAM THE LOW-END CUTOUT (low temperature level

disable)

In order to prevent false integration/totalization in situations where

integration/totalization is undesirable, a programmable setpoint can be used

to disable integration/totalization whentheinput temperature falls below this

low-end cutout level.

“Lo-cut” < > “-999” to “9999”

-13-

Page 16

MODULE #6 - PROGRAM ALARM/SETPOINT

If the alarm option is installed, this module is used to configure the

operation of the alarms to a variety of combinations. The programmable

options are HI/LO acting, auto/manual reset (latching), tracking, assignment

to input or integrator/totalizer, display alarms, alarm values and hysteresis

(deadband) values.

ALARM TRACKING

With alarm tracking, whenever alarm #2 is changed, alarm #1 will also

change so that the offset between alarm #2 and alarm #1 remains the same.

This is useful for hierarchical setpoints (pre-alarm and alarm) when one

change applies to both alarm values. When programming from the front

panel, tracking only occurs when PGM. DIS. is low (front panel lock-out

mode, alarm #1 will not appear). Tracking will always occur if alarm #2 is

modified via serial communications independent of PGM. DIS.

“trAc” < > “yES” or “NO”

DISPLAY ALARMS

If display alarms are desired, a message will flash on the display every 5-10

secs when an alarm activates. For alarm 1, the message will flash “AL1 ON”

and alarm 2 will flash “AL2ON”. This warns an operator of an alarm condition.

The message will stop when the unit is no longer in an alarm condition.

“dISP” < > “yES” or “NO”

AUTO OR MANUAL RESET FOR ALARM #1

The reset action of alarm #1 may be programmed to reset automatically

(unlatched) or be programmed to require a manual reset (latched), through

either a remote input (E1-CON or optional E2-CON) or through the front

panel. Latched alarms are usually used when an operator is required to take

some action for the alarm condition.

“LAtC-1” < > “yES” or “NO”

ALARM #1 ASSIGNMENT TO INPUT OR

INTEGRATOR/TOTALIZER

Alarm #1 may be programmed to activate on either the input or the

integrator/totalizer value. If the integrator/totalizer option is not installed,

this step defaults to the input.

“ASN-1” < > “INPUt” or “totAL”

PROGRAM VALUE FOR ALARM #1

The range of the alarm value is -999 to 9,999 for the input display and

-99999 to 999999 for the totalizer option display.

“AL-1” < > “-999” to “9999”

PROGRAM HYSTERESIS VALUE FOR ALARM #1

(Cannot be programmed if alarm latch is programmed)

The hysteresis (deadband) value for alarm #1 may be programmed from 1

to 9,999 for the input and 1 to 999999 for the totalizer option. The value is

either added to or subtracted from the alarm value depending on whether the

alarm is high or low acting. (See “alarm” section for operation.)

“HyS-1” < > “1” to “9999”

ALARM #1 HIGH OR LOW ACTING

The action of alarm#1maybe programmed to activate either when thedisplay

value goes above the alarm value (high acting) or goes below it (low acting).

“Act-1” < > “HI” or “LO”

AUTO OR MANUAL RESET FOR ALARM #2

The reset action of alarm #2 may be programmed to reset automatically

(unlatched) or be programmed to require a manual reset (latched), through

either a remote input (E1-CON or optional E2-CON) or through the front

panel. Latched alarms are usually used when an operator is required to take

some action for the alarm condition.

“LAtC-2” < > “yES” or “NO”

-14-

Page 17

ALARM #2 ASSIGNMENT TO INPUT OR INTEGRATOR/

TOTALIZER

Alarm #2 may be programmed to activate on either the input or the

integrator/totalizer value. If the integrator/totalizer option is not installed,

this step defaults to the input.

“ASN-2” < > “INPUt”or “totAL”

PROGRAM VALUE FOR ALARM #2

The range of the alarm value is -999 to 9,999 for the input display and

-99999 to 999999 for the totalizer option display.

“AL-2” < > “-999” to “9999”

PROGRAM HYSTERESIS VALUE FOR ALARM #2

(Cannot be programmed if alarm latch is programmed)

The hysteresis (deadband) value for alarm #2 may be programmed from 1

to 9,999 for the input and 1 to 999999 for the totalizer option. The value is

either added to or subtracted from the alarm value depending on whether the

alarm is high or low acting. (See “alarms” section for operation.)

“HyS-2” < > “1” to “9999”

ALARM #2 HIGH OR LOW ACTING

The action of alarm#2maybe programmed to activate either when thedisplay

value goes above the alarm value (high acting) or goes below it (low acting).

“Act-2” < > “HI” or “LO”

Note: Depending on options selected under Pro 3 and Pro 6, alarms, hysteresis,

peak, and valley values can be monitored and/or changed when PGM. DIS. is

tied to COMM.This provides a “QUICK PROGRAMMING” methodfor “day

to day” process changes. (See QUICK PROGRAMMING SECTION for more

details.)

-15-

Page 18

MODULE #7 - PROGRAM SERIAL COMMUNICATIONS

Several programmable parameters must be programmed before serial

communication can occur.

BAUD RATE

Select one of the baud rates from the list to match the baud rate of the

printer, computer, controller, etc.

“bAud” < > “300” - 300 baud

UNIT ADDRESS NUMBER

To allow multiple units to communicate on the 20 mA loop, different address

numbers must be assigned to each unit. If only one unit is on the loop, an

address of “0” may be given, eliminating the need for the address command.

“

PRINT REQUEST FUNCTION

A selection of print operations can be programmed. A print operation

occurs when a print request is activated via E1-CON (TBA #4) or optional

E2-CON (TBA #8),ora“P” command is sent from a terminal via the serial

communications option. If the option to which a particular print code applies

is not installed, then that parameter will not be printed.

If the totalizer is overflowed, an asterisk (*) will precede the digits that are

printed (ex. *000127 positive overflow, -*00127 negative overflow). If the

temperature exceeds the range of the unit, the print-out will show

“OLOLOL”. If the sensoropens, the print-out will show“ULULUL”.For the

negative direction or shorted, the print-out will show “SHOrt”.

“600” - 600 baud

“1200” - 1200 baud

“2400” - 2400 baud

“AddrES” < > “0” to “99”

“Print” < > “0” - input signal

FULL OR ABBREVIATED TRANSMISSION

When transmitting data, the IMY can be programmed to suppress the

address number, mnemonics and some spaces, if desired, by selecting “NO”.

A selection of “NO” results in faster transmission. This feature may be

helpful when interfacing with a computer. When interfacing to a printer, a

“yES” response is usually desirable.

An example of full and abbreviated transmission is shown below:

2 INP -125.7F < CR><LF> Full transmission

-125.7 < CR><LF> Abbreviated transmission

“1” - input signal, peak, valley and offset

“2” - input signal, alarm 1 and alarm 2

“3” - input signal, alarm 1, alarm 2, hysteresis 1,

hysteresis 2, peak, valley, and offset

“4” - totalizer

“5” - input signal and totalizer

“6” - input signal, totalizer, peak, valley, and offset

“7” - totalizer, alarm 1, and alarm 2

“8” - input signal, totalizer, alarm 1, and alarm 2

“9” - input signal, totalizer, alarm 1, alarm 2,

hysteresis 1, hysteresis 2, peak, valley, and

offset

“FULL” < > “yES” or “NO”

-16-

Page 19

MODULE #8 - PROGRAM RE-TRANSMITTED ANALOG OUTPUT

This programming module allows digital scaling of the 4 to 20 mA or 0 to

10 VDC analog output. The type of analog output is determined by the model

ordered. (See Ordering Information for available models.) The display value

at which 4 mA or 0 VDC and the displayvalue at which 20mA or 10 VDC are

transmitted are keyed-in. The indicator automatically calculates slope and

intercept values to complete the scaling. The analog output then follows the

calculated display value and as such will update every measurement cycle.

The output may also be programmed to proportionally re-transmit the

contents of the totalizer instead of the input. Reverse acting output can be

achieved by programming the “high” display value for the “AN-LO”

programming step and the “low” display value for the “AN-HI” step.

Note: DO NOT ADJUST THE ANALOG OUTPUT POTS ON THE BACK OF

THE UNIT. Fine offset and span adjustment pots are externally accessible to

compensate for small drifts in the output. These pots have been set at the

factory and do not normally require adjustment.

ANALOG OUTPUT SOURCE

Program whether the input or the totalizer will serve as the basis for the

analog output signal. If the integrator/totalizer option is not installed, then

this step defaults to “Input”.

“ASIN” < > “INPUt” or “totAL”

ANALOG OUTPUT LO DISPLAY VALUE

Program the display value at which the analog output transmits 4 mA or 0

VDC.

“AN-Lo” < > “-999” to “9999” for “INPUt”

ANALOG OUTPUT HI DISPLAY VALUE

Program the display value at which the analog output transmits 20 mA or

10 VDC.

“AN-HI” < > “-999” to “9999” for “INPUt”

“-99999” to “999999” for “totAL”

“-99999” to “999999” for “totAL”

-17-

Page 20

MODULE #9 - SERVICE OPERATIONS

The indicator has been fully calibrated at the factory. If the unit appears to

be indicating incorrectly or inaccurately, refer to the troubleshooting section

before attempting this procedure.

When re-calibration is required (generally every 2 years), this procedure

should only be performed by qualified technicians using appropriate

equipment. Resistance source accuracies of 0.01% or better are required.

The procedure consists of applying accurate signal levels to the indicator in

a series of two steps. Allow a 30 minute warm-up period before starting this

procedure.

Note: Once the access code has been entered, there is no exiting the program

module without completing the calibration procedure.

ENTER ACCESS CODE

“Code 48” must be keyed-in prior to the calibration sequence to guard

against inadvertent entries. Access code numbers other than those listed in

this section should not be entered at this step. If any areentered, undefined or

unpredictable operation could result.

If the code number for the previous step was not recognized, the indicator

returns to “Pro 0”, with no action taken.Otherwise, thecalibration procedure

is started.

ENTER ZERO REFERENCE

Apply 0 ohms to input by shorting Terminals 6 and 7 as

shown in the drawing to the right. Allow to stabilize for 20

seconds before pressing “P”.

APPLY PRECISION RESISTANCE

Connect a precision (0.01%) 5.11 KW resistor across

Terminals 6 and 7.

Allow to stabilize for 20 seconds before pressing “P”.

“CodE” < > “0” to “99”

“StEP 1” (Press “P”)

“StEP 2” (Press “P”)

Indicator calibration is complete. It is recommended that calibration be

checked by comparing the displayed temperature with a precision thermometer.

SERIAL HARDWARE (loop-back) DIAGNOSTICS

The internal serial communications hardware in the IMY can be tested to

verify proper operation. The procedure consists of connecting the Serial

Input (SI), Serial Output (SO), and

20 mA Source into a simple loop,

and then entering an access code.

Connect the IMY as shown at

right. Enter “Pro 9”, key-in “Code

39”, and thenpress “P”. If the serial

communication hardware is OK,

“PASS” will be displayed.

Conversely, if there is an internal

problem, “FAIL” will be displayed.

After the diagnostic test iscomplete,

press “P” to return to “Pro 0”.

“CodE” < > “39”

RESTORING ALL PROGRAMMING PARAMETERS BACK TO

FACTORY CONFIGURATION

All of the programming in Modules #1 through #8 can be restored back to

the factory configuration by entering a specific access code (refer to the

“Factory Configuration” section for the data that will be entered). The

procedure consists of entering “Pro 9”, keying-in “Code 66”, then pressing

“P”. The IMY responds by displaying “INItAL” for several seconds, and

then returns to “Pro 0”.

Note: When this procedure is performed, all of the scaling, presets, etc. that

were programmed into the IMY will be overwritten.

“CodE” < > “66”

-18-

Page 21

OPERATING THE IMY

After completing all set-up operations, the unit is ready to install and

operate. After power is applied, a display test consisting of illuminating all

segments for 2 seconds is performed. Afterward, the input or total will

appear, depending upon the display mode prior to the last power-down. To

switch the display to input, press “DOWN” (indicated by “arrows” on the

front panel) and to switch it to total, press “UP”. If the integrator/totalizer

option isnot installed, then display switching to total is inoperative. A minus

sign “-” will precede numbers that are negative.

QUICK PROGRAMMING

To limit access tothe set-up parameters, connect a key-switchor wire from

PGM. DIS. (TBA #3) to COMM. (TBA #7). With this pin connected to

common, only a predetermined amount of data can be viewed or altered, as

programmed by programming module #3. If “NO” was programmedfor allof

the available steps in module #3, then pressing “P” will cause the unit to

display “Loc”. However, if “YES” was programmed in one or more of the

steps, then “P” will invoke entry into a series of commonly modified

parameters while protecting thecrucialset-up information. This is referred to

as the “quick programming” mode. When “quick programming” mode is

entered, the alarms and hysteresis values can be modified inthe same manner

as in the regular programming mode. The new alarm and hysteresis values

will take effect when “P” is pressed.

The other operations in the “quick programming” mode require special

key sequences as shown:

To reset latched alarm, scroll through steps in “quick

programming” mode using the “P” button until “LAtCH1” or

“LAtCH2” appears inthe display. If they do not appear, they are

not latched.

To reset: While “LAtCH1” or “LAtCH2” is being

displayed, press and hold“DOWN”and press “P”.

Pressing “P” alone causes a step to the next item

with no action on the alarm.

To reset peak and valley buffers, scroll through steps in “quick

programming” mode using the “P” button until “PEA” or

“VAL” appears in the display.

To reset: While “PEA” or “VAL” is being

displayed, press and hold“DOWN”and press “P”.

Pressing “P” alone causes a step to the next item

with no action taken on the buffer.

The front panel buttons are not only used to input data during the

programming and “quick programming”mode,but control a number of other

functions (if enabled in Pro “3”) as well. In the normal meter mode, these

functions are available:

To switch to display of input: Press “DOWN” button.

To switch to display of totalizer: Press “UP” button.

To reset totalizer to zero: Press and hold “UP” and press “P”.

To enter programming or “quick programming”: Press “P”.

After each operation, a message will appear briefly to acknowledge the action.

-19-

Page 22

FACTORY CONFIGURATION

The following chartliststhe programming of the unit whenshipped from the

factory. (In Program Module #9, Code 66 will restore the unit to these values.)

“Pro 1”..... “tYPE” - “700”

“SCALE” - “F”

“dECPNt” - “0.0”

“Pro 2”..... “SLOPE” - “1.0000”

“OFFSEt” - “0.0 F”

“Pro 3”..... “dSP AL” - “yES”

“ENt AL” - “yES”

“dSPHYS” - “yES”

“ENtHYS” - “yES”

“rSt AL” - “yES”

“dSPbUF” - “yES”

“rStbUF” - “yES”

“SELdSP” - “yES”

“rSttOt” - “yES”

“dSPOFF” - “yES”

“ENtOFF” - “yES”

“Pro 6”..... “trAc” - “NO”

“dISP” - “NO”

“LAtC-1” - “NO”

“ASN-1” - “INPUt”

“AL-1” - “0.0 F”

“HYS-1” - “0.1 F”

“Act-1” - “HI”

“LAtC-2” - “NO”

“ASN -2” - “INPUt”

“AL-2” - “0.0 F”

“HYS-2” - “0.1 F”

“Act-2” - “HI”

“Pro 7”..... “bAud” - “1200”

“AddrES” - “0”

“Print” - “0”

“FULL” - “yES”

“Pro 8”..... “ASIN” - “INPUt”

“AN-Lo” - “0.0 F”

“AN-HI” - “100.0 F”

“Pro 4”..... “FILter” - “1”

“E1-CON” - “4” (Display Hold)

“E2-CON” - “4” (Display Hold)

“Pro 5”..... “dECPNt” - “0”

“tbASE” - “0”

“SCLFAC” - “1.000”

“Lo-cut” - “0.0 F”

-20-

Page 23

PROGRAMMING EXAMPLE

As an exampleofa programming sequence, the following values,gainedfrom

a temperature-time monitoring application, are programmed into the indicator.

DISPLAY: Display the actual temperature of a liquid solution in °F.

Activate alarm #1 output when temperature falls below 25°F, activate

display alarm. Peak and valley (max/min) readings for each cycle to be

recorded.

TOTALIZER: When total exceeds 30,000 degree-minutes then latch alarm

#2 which stops the heating process and sounds a process complete bell.

Reset alarm #2 by remote input. Disable totalization when temperature

falls below200°F. Reset the total from the front panel. Allow switching of

the display from/to temperature and total.

SERIAL: Provide hardcopy printout of total, input and peak/valley when

operator actuates print request. Baud rate 300.

ANALOG RE-TRANSMISSION: Record temperature profile. 4 mA at

50°F and 20 mA at 200°F.

“Pro 1”..... “tYPE” - Enter 400

“SCALE” - Enter F

“dECPNt” - Enter 0

“Pro 2”..... “SLOPE” - Enter 1.0000

“OFFSEt” - Enter 0

“Pro 3”..... “dSP AL” - Enter yes

“ENt AL” - Enter yes

“dSPHYS” - Enter no

“rSt AL” - Enter no

“dSPbUF” - Enter yes

“rStbUF” - Enter yes

“SELdSP” - Enter yes

“rSttOt” - Enter yes

“dSPOFF” - Enter no

“Pro 4”..... “FILter” - Enter 1 (Normal)

“E1-CON” - Enter 7 (reset alarm #2)

“E2-CON” - Enter 14 (print request)

“Pro 5”..... “tbASE” - Enter 1

“SCLFAC” - Enter 1.000

“Lo-cut” - Enter 200

“Pro 6”..... “trAc” - Enter no

“dISP” - Enter yes

“LAtC-1” - Enter no

“ASN-1” - Enter input

“AL-1” - Enter 25

“HYS-1” - Enter 1

“Act-1” - Enter LO

“LAtC-2” - Enter yes

“ASN -2” - Enter total

“AL-2” - Enter 30000

“HYS-2” - N/A

“Act-2” - Enter HI

“Pro 7”..... “bAud” - Enter 300

“AddrES” - Enter 0

“Print” - Enter 6

“FULL” - Enter yes

“Pro 8”..... “ASIN” - Enter input

“AN-Lo” - Enter 50

“AN-HI” - Enter 200

-21-

Page 24

TEMPERATURE MONITORING EXAMPLE

An IMY is installed as a monitoring device and back-up

controller for a freezer storage facility. Normally, the

freezer temperature is maintained at about -29°C ±2°. The

absolute maximum allowable temperature of the freezer is

0°C. In the event of a system failure, alarm output#1 of the

IMY is programmed to start a secondary cooling system

should the temperature reach 0°C. The additional alarm of

the IMY is used to signal personnel with a warning bell

when the temperature rises above -17°C (indicating a

possible failure of the main cooling system). This alarm is

programmed to latch in order to assure that personnel

inform maintenance of a possible problem. Key switches

are installed to lock out the front panel from unauthorized

personnel and to provide a means of resetting the latched

alarm. The Integrator/totalizer option is specified to store

peak and valley temperatures overnight, weekly, etc.

Programming module #5 (Pro 5) is used to set up the

integrator. The re-transmitted analog output isspecified to

drive a chart recorder with 4-20 mA for a hard copy of

temperature profiles for later evaluation.

-22-

Page 25

INTEGRATOR / TOTALIZER / PEAK / VALLEY / TEMPERATURE OFFSET (Optional)

INTEGRATOR/TOTALIZER

The integrator/totalizer option simply adds input readings together using a

programmable time base and scaling coefficient. The decimal point position

of the integrator/totalizer canbe programmed independent of the scaledinput

signal. The integrator/totalizer may be reset through a remote input, by the

front panel or through the serial communications option. Alarms may be

programmed to trigger from integrator/totalizer values; for example to total

“degree minutes” for batching operations. The programmable time bases are

“per second”, “perminute”and“perhour”,meaningthe integrator/totalizer

will accumulate at a fixed rate of

input level over the selected time period. For example, if the input is a

constant 100° and the “per minute” time base is selected, the

integrator/totalizer will accumulate at the rate of 100° per minute. The

totalizer is updated at this rate every 400 msec. As a result, the input is

accumulated in “batches” of 6.6 counts every 400 msec. Therefore, the

totalizer start and stop sequencing, as wellas alarm values set for triggering at

specific totalizer values, are only accurate to the 400 msec totalizer update

rate. The preceding example requires a scale factor of 1.000 to yield exact

time bases, but any scale factor can be used to span between the ranges. (See

section on integrator/totalizer programming for detailed information.) A

programmable low temperature level disable feature completes the

integrator/totalizer features (this will stop totalization when the input drops

below this programmed value, “low cut”). At loss of power to the indicator,

the contents of the integrator/totalizer is saved. This will allow

integrating/totalizing of interrupted processes. The total can accumulate to

999,999. If the low-end cut-out value is programmed negative (ex. -100,

reference Program Module #5), and the inputdisplay value is between zero and

the low-end cut-out value, the totalizer value will decrement. If the input

display value goesabove zero the total will increment.If the display value goes

below (more negative than), the low-end cut-out value, totalization will stop.

1

times per second and be equal to a fixed

2

2

PEAK/VALLEY

The other features of the integrator/totalizer option are peak and valley

detection. The indicator will record the lowest reading (valley) and the

highest reading (peak), automatically, for later recall. This information is

valuable in monitoring the limits of the process over any length of time since

these values are stored at power-down to span over shifts, days, etc. An

external input can be programmed to reset or engage the unit into a

peak/valley reading indicator. Additionally, the peak and valley can be

viewed and reset from the front panel, if so programmed, and viewed and reset

from the serial communication option.

Note: The peak/valley measurement is not instantaneous, and is based on a

nominal 2 sec. response time.

OFFSET AND SLOPE DISPLAY TEMPERATURE

If a difference exists between the displayed temperature and a reference

temperature point, the display may be offset for this effect. Similarly, a

correcting “slope” may be programmed, with the offset, to allow for two

point temperature correction.

For most applications,theslope and offset values are notchanged. But if it is

required to scale the display tomatch a calibrated probe,the following formula

and example show the calculation of appropriate slope and offset values.

Desired Display = (slope x actual temp. display) + offset

difference of two desired temperature points

slope =

offset = one desired temperature point - (slope x one

Example:

The meter is displaying 52 degrees and 146 degrees (actual temperature)

when the calibrated temperature reference shows that 50 degrees and 150

degrees respectively should be displayed (desired temperature).

First determine the new slope value using the sets of temperature points.

Next, determine the new offset valueby using either one of the temperature

pairs.

offset = 150 - (146 x 1.0638)

offset = 5.3

difference of two actual temperature points

corresponding actual temperature point)

slope =

150-50

146 - 52 94

=

100

= 1.0638

-23-

Page 26

OFFSET AND SLOPE DISPLAY TEMPERATURE (Cont’d)

SET-UP:

This feature allows the operator to manipulate the displayed temperature

reading. The operator may utilize this feature for example, when switching

thermistor probes, to compensate for differences in thermistor probe

accuracy from one manufacturer to another or to offset the input reading to

match a “Reference” temperature.

The displayed temperature can be offset either positive or negative to the

actual measured temperature. Programming a positive number for the offset

value increases the display value. Programming a negative number for the

offset value decreases the display value. For example, if the displayed

temperature is 10° less than the measured temperature, programming a +10

for the offset value will increase the displayed value by 10 throughout the

entire range. If the displayed temperature is 10° higher than the measured

temperature, programming a -10 for the offsetvalue will decrease thedisplay

value by 10 throughout the entire range.

“Pro 2” ..... “SLOPE” - 1.0638

“OFFSEt” - -5.3

INTEGRATOR/TOTALIZER EXAMPLE

The indicator is employed to indicate average daily (8 hour) temperatureof

a “Hot Room” used for storing various ingredients at a large food processing

plant. Ingredients which must be kept at temperatures above 100.0°F are

stored in this room. The desired constant temperature is 110.0°F. However,

frequent opening and closing of the door causes temperature variations. The

following programming steps are performed:

BASIC SET-UP

“Pro 1”.....“tYPE” - 400

“SCALE” - F

“dECPNt” - 0.0

INTEGRATOR/TOTALIZER SET-UP

With an average temperature input which gives a display of 110.0° at the

end of an 8 hour time period (one shift), the following formula applies:

T.B.

D.T.

S.F. =

S.F. = Programmable Scale Factor

D.T. = Desired Totalizer value for a

T.B. = Programmable Time Base

T.B. = If Program Select Number Chosen Is:

TIME = Actual Time period in seconds

D.T.D.P. = Desired Totalizer Value Decimal Point

I.D.D.P. = Input Display Value Decimal Point

R This value is normally 1, but can be used as a course scale factor of 60 or

3600.

x (

I.D. TIME I.D.D.P.

fixed time duration

“0” for sec. 1

“1” for min. 60

“2” for hr. 3600

I.D. = Input Display Value

01

0.0 10

0.00 100

0.000 1000

0.0000 10000

01

0.0 10

R

x

D.T.D.P.

Enter in Formula

Enter in Formula

Enter in Formula

)

-24-

Page 27

S.F . =

110

110 28800 10

3600RR

x (

(8 Hours x 3600)

S.F. = 1x.125

S.F. = .125

R

)

x

10

“Pro 5”.....“dECPNt” - 0.0

R This value is normally 1, but can be used as a course scale factor of 60 or

3600.

RR Since the time period is in Hrs., the selected T.B. is 3600 (Program select

value = 2) which equals per hour (3600 sec.).

The integrator/totalizer will accumulate up to 99999.9. At the endof the shift,

the average temperature over the previous 8 hours can be read directly. The

integrator/totalizer canthen be reset for thenext 8 hour shift.Anytime during the

shift, the average temperature can be calculated by the following formula:

For example, 6 hours and 37 minutes into the shift the integrator/ totalizer

reads “90.9”. To find the average temperature up to this point:

Av =

The average temperature over the last 6 hours and 37 minutes was 109.9°F.

RRR Time is in hours. The number of minutes must be divided by 60 and then

added to the hours.

“tbASE ” - 2

“SCLFAC” - .125

“Lo-cut ” - 0.0

Av =

I.V. = Integrator/Totalizer Value

S.F. = Programmable Scale Factor

T.T. = Total Time (From the beginning of the shift)

90.9

.125 x 6.6166 .827

I.V.

S.F. x T.T.RRR

90.9

=

Av = 109.9

-25-

Page 28

ALARMS (Optional)

The alarm option consists of an additional printed circuit board with nine

terminals. Six of these terminals are the two Form-Crelays andthe other three

are the two open collector transistors, which act in parallel with the relays.

The two alarms are completely independent with programmable values,

hysteresis (deadband), high or low acting, auto or manual reset, triggering

from input or total, and tracking one another, if desired. If the alarms are

programmed to latch (manual reset), then they will have to be reset either by

the front panel or remote input. The alarms can be made to trigger from the

integrator/totalizer instead of the input, to activate external alarms, control

valves, etc. Additionally,thealarms may be programmed toactivate an alarm

display to alert operators of the condition.

Alarm #1 can be made to track Alarm #2 byenabling alarmtracking.This is

useful in alarmset-ups where a pre-warning control activates before a second

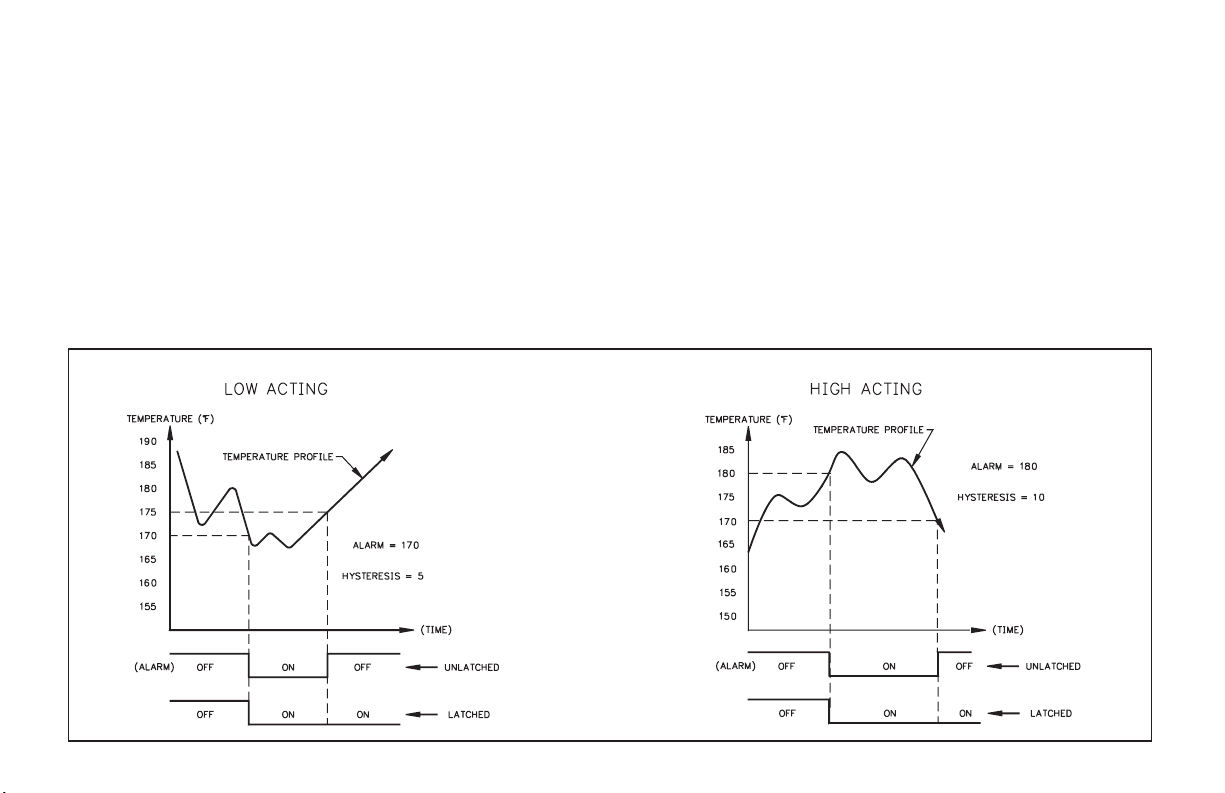

ALARM TIMING DIAGRAMS

alarm shuts off the process. When tracking is programmed, changing the

shut-off trip value (Alarm #2) automatically changes Alarm #1 so that the

offset between Alarm #2 and Alarm #1 remains the same. Alarm and

hysteresis values can be modified through the optional serial

communications to provide automatic control. The following diagrams

depict how the alarms work with both “HI” and “LO” acting set-ups.

Programming of the alarms can be accomplished in the normal

programming mode “Pro6”or the unit can beprogrammed so that the values

can only be changed in the “quick programming” mode.

If the display should indicate an “OLOLOL”, “ULULUL”,or“SHort” the

alarms will de-energize, whether they are latched or unlatched.

Note: Alarm Comm. (TBB #8) must be kept isolated from analog “-”.

-26-

Page 29

20 mA CURRENT LOOP SERIAL COMMUNICATIONS (Optional)

GENERAL DESCRIPTION

The serial communication option is a half-duplex, two-way, 20 mA loop

that can connect to avariety of printers,computers, terminals and controllers

to suit many data-polling or automatic operation applications. The indicator

responds to a hostofcommands, including change alarm value, resettotalizer

and transmit input value. Two loops are required for all hook-ups; a transmit

(out-going data) loop and a receive (in-coming data)loop. Sincethe indicator

monitors the receive loop for a busy signal (current interrupted) while

transmitting, the receive loop must be connected even if the indicator is

transmitting only, such as to a printer. A built-in 20 mA sourcecan be used in

the transmit loop (only) by connecting the current return wire to -20 mA

SRC., instead of SO+. To bypass the built-in current source, make transmit

loop connections to SO+ and SO-.Additionally, multiple units and other Red

Lion Controls instruments can be serially addressed, up to a maximum of 99

units. (The actual number in a single loop is limited by the serial hardware

specifications.) To eliminate problems with ground loops, the serial circuitry

is isolated from both signal common and output common. Optional 20 mA to

RS232C and 20 mA to RS422 converter modules expand the unit’s flexibility.

Note: When operating the unit with a printer, the receive loop of the indicator

must have current flowing into it before transmission can take place.

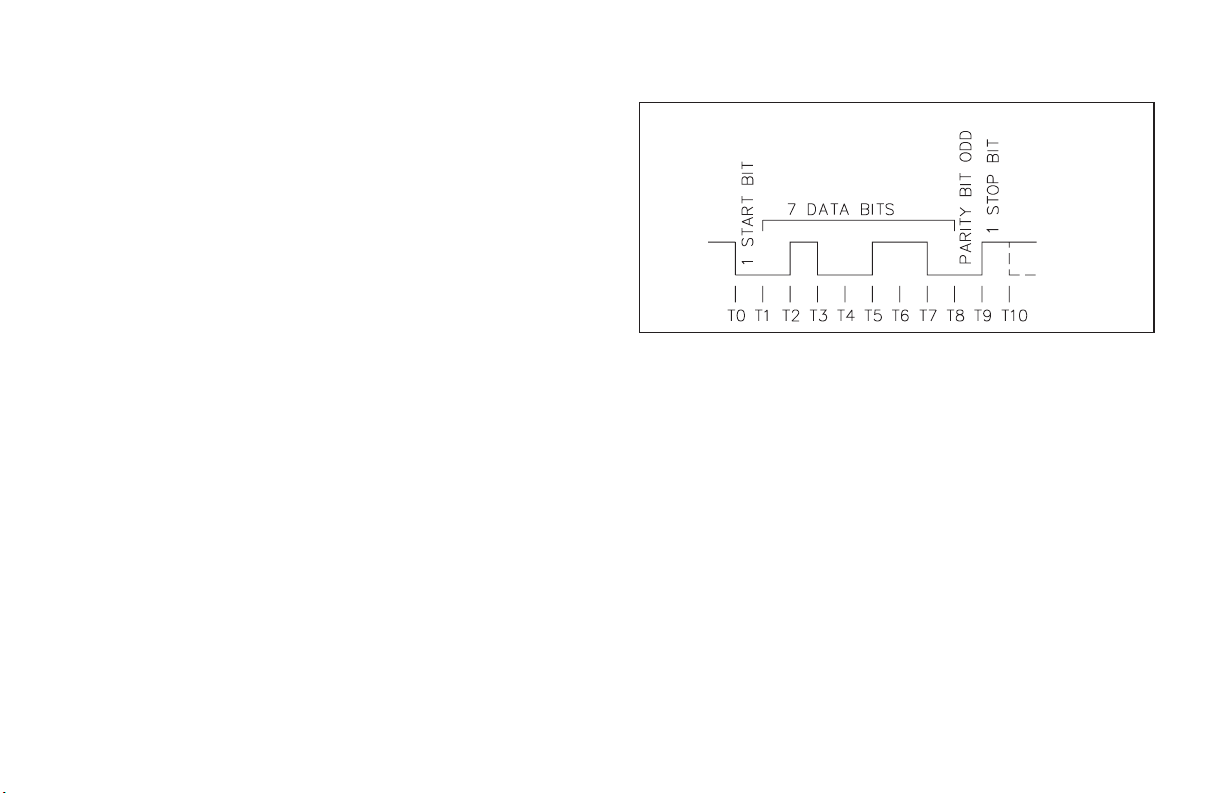

COMMUNICATION FORMAT

Data is sent by switching current on and off in the loop and is received by

monitoring the switching action and interpreting the codes that are

transmitted. In order for data to be correctly interpreted, there must be

identical formats and baud rates among the communicating equipment. The

only format available with thisindicator is 1start bit, 7 data bits, 1 odd parity

bit and 1 stop bit. The baud rates are programmable and the choices are: 300,

600, 1200 and 2400.

DATA FORMAT-10 BIT FRAME [300, 600, 1200, 2400 Baud]

Before serial communication can take place, the indicator must be

programmed to thesame baud rate as theconnected equipment. In addition, the

loop address number, print options and full or abbreviated transmission must

be programmed.If only oneindicator is tobe used, thena loop addressnumber

of “0” mayby used, to eliminate therequirement for the address specifierwhen

sending a command. If more than one indicator is on the loop, assignment of

unique addresses, other than zero, for each indicator is recommended. Valid

addresses of 0 to 99 may be assigned, but the built-in current source, if used, is

capable of drivingup to 7 units. Additionaldrivecapability may be afforded by

an external current source with a higher compliance voltage. Refer to

programming section “Pro 7” to program the serial option.

-27-

Page 30

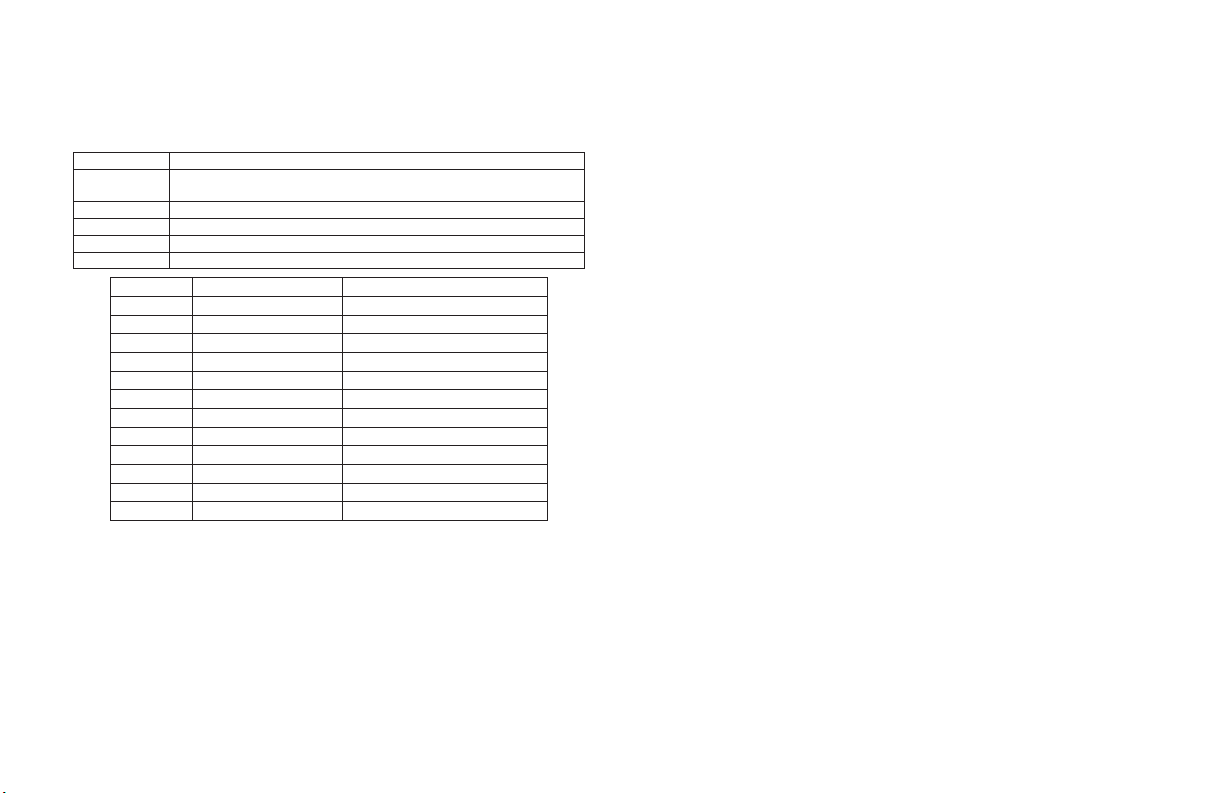

SENDING COMMANDS TO THE IMY

When sending commands to the unit a command string must be

constructed. The command string may consist of command codes, value

identifiers, and numerical data. Below is a table outlining the codes the

indicator will recognize.

COMMAND FUNCTIONS

T transmits the requested information specified by the

identifier (A-I, K, and L)

V change a value specified by the identifier (C-F, K, and L)

N address a particular indicator in a multiple unit loop (0-99)

R reset a value specified by the identifier (B-D, G, H, I, and J)

P print per programmable print options (A-I)

VALUE IDENTIFIERS SERIAL MNEMONICS

A temperature INP

B integrator/totalizer TOT

C alarm #1 AL1

D alarm #2 AL2

E hysteresis #1 HS1

F hysteresis #2 HS2

G peak reading PEK

H valley reading VAL

I zero offset OFS

J offset input

K analog low ANL

L analog high ANH

Note: RJ - offset the input (re-zeros). When the input is offset (via front panel or

“RJ”) the amount is stored in the offset reading (I). Ex. When an offset is

performed, the display reads “5.0”, the offset value will be “-00005.0” (and

the display will show 0.0).

A command string is constructed by using the above commands and

identifiers along with any data values that are required. The indicator will

accept “+” or “-” in front of the data value. Numbers without “+” are

understood to be positive. Leading zeros can be eliminated and both lower

and upper case characters are accepted. The address command is used to

allow a command to be directed to a specific unit on the loop. If the indicator

is assigned an address of “0”, transmission of the address command is not

required. This is done where only one indicator is in the loop.

The command string is constructed in a specific logical sequence. The

indicator will reject command strings that do not conform. Only one

operation can be performed per command string. Below is a description of

how to construct a command string.

1. If the indicator hasanaddress other than zero, the first two charactersofthe

string must consist of the address command (N) followed by the unit

address number (0-99). If the indicator has an address of 0, the address

command is optional.

2. The next two characters in the string are the actual command the indicator

must perform and the identifier on which it operates. Command P-print,

Value I-zero offset and J-offset input, have implied operators and need no

additional characters.

3. If the change value command is being used (V), the next characters in the

string after the value identifier, are the numerical data. When sending

numerical data, such aschangean alarm value, the correct numberofdigits

to the right, must be included. As an example, to change an alarm value

from 150.2 to 50.0. Sending 50 would cause the indicator to see 5.0 and

change the alarm value accordingly.

4. Allcommands must be terminated by an asterisk(*). The indicator will not

respond to any other code. Carriage return and line feed are not valid

terminators and should be suppressed with the character “;”, if using a

BASIC print statement (ex. Print “N9TA*”;).

COMMAND STRING EXAMPLES

Indicator with address 3, transmit temperature reading.

N3TA*

Indicator with address 0, change alarm #1 to 150.

VC150*

Indicator with address 1, reset totalizer.

N1RB*

Indicator with address 99, print the print options.

N99P*

Indicator with address 0, zero the offset value.

RI*

-28-

Page 31

If illegal commandsor characters are sent to theIM, an asterisk (*) mustbe

sent to clear the input buffer. The IM will not respond to an illegal or

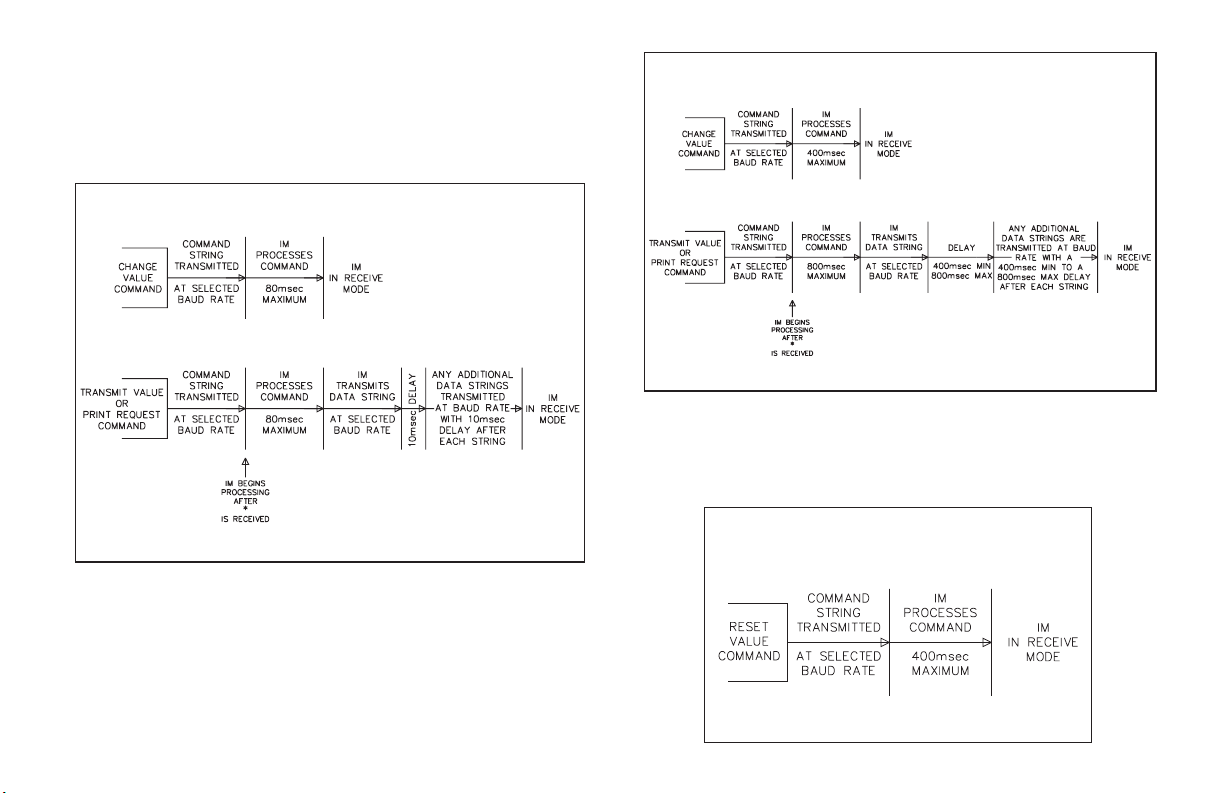

incomplete transmission. The diagrams show the difference in the timing

considerations for either Abbreviated or Full Character Transmission, or if a

Reset Command is issued.

Timing Diagrams

(Full Transmission Selected)

(Abbreviated Transmission Selected)

Timing Diagrams

Note: If FullTransmission is selected and thefront panel is being accessedat

the time of transmission, the IM may take as long as 2 seconds to respond.

Reset Command

Independent of Type

of Transmission Selected

-29-

Page 32

RECEIVING DATA FROM THE IMY

Data istransmitted from the indicator whenever a “T” or “P” command is

received via serial communications or a remote input, E1-CON or optional

E2-CON pin is programmed for print request, is activated. If the abbreviated

transmission was programmed, just data will be transmitted with no built-in

delay. (If full transmission is programmed, then there is a 400 msec min to

800 msec max delay built-in to the string.)

A data string transmission is shown below.

The first two characters transmitted are the unit address number, unless it is

zero, in which case it is left blank. Then two blank spaces are sent. The next

three characters are the abbreviation for the value(mnemonics), which is then

followed by a blank. The actual data is transmitted next. The field is right

justified with leading zeros. Negative numbers are indicated by a minus sign

fixed next to the identifier. A carriage return and a line feed are transmitted

next. For various reasons, “extra” characters are added onto the end of the

above character string. (These characterscould be and are used for control or

signaling purposes.) These characters are:

< CR> sent after single line transmissions from IM unit.

< SP>< CR>< LF> sent after “last line of a block” transmission from IM.

For a “T” command or after each “line of a block” transmission, no

additional characters are sent. If the abbreviated transmission is selected, the

address, mnemonics, and any blank spaces (first eight characters) are not

transmitted (the data strings are left justified in this case).

If the transmitted data is overrunning the peripheral’s buffer, the receive

channel to the indicator may be used for handshaking purposes. As a

consequence of this, even if theindicator is to transmit only (ex. to a printer),

current must be flowing in the receive channel to allow transmission.

Examples of transmissions are as follows:

2 INP -125.7F < CR> < LF > full transmission

-125.7 < CR> < LF > abbreviated transmission

CURRENT LOOP INSTALLATION

WIRING CONNECTIONS

When wiring the 20 mA current loop, remove the bottom terminal block

(TBA), located on the rear of the unit. Refer to the numbers listed with the

terminal descriptions below or those located on the label. It is recommended

that shielded (screened) cable be used for serial communications. This unit

meets the EMC specifications using Alpha #2404 cable or equivalent. There

are higher grades of shielded cable, such as four conductor twisted pair, that

offer an even higher degree of noise immunity. Install each wire in its proper

location on the terminal block. When all connections are made, replace the

terminal block into its proper location.

SERIAL TERMINAL DESCRIPTIONS

8. PRINT REQ. - The PrintRequestterminalis pulled low to activate the unit

to transmit data according to the print function selected in ProgramModule

#7 (Reference Programming Module #7 for more details). In order for a

print request function to occur, E1-CON (TBA #4) or E2-CON (TBA #8)

must be programmed for print request. Note: In order to guarantee a

print-out, the programmed E-CON pin must be held low for at least 20

msec. If this time exceeds 800 msec, a second print-out may occur.

9. -20 mA SRC. - 20 mA current source return path for the transmit loop.

Current flows into this pin.

10. SI+ (Serial In+) -

11. SI- (Serial In-) -

The unit receives commands on the SI terminals. They are connected in

series with the transmit or output terminals of the device to be connected.

12. SO+/+20 mA SRC.(SerialOut+) - 20 mA current sourceforthe transmit

loop (internally connected).

13. SO- (Serial Out-) -

The unit transmits the requested data on the SO terminals. They are

connected in series to the receive input of the device to be connected.

Note: The Serial Input terminals must be held in the mark condition (current

flowing) in order for the unit to respond to a Print Request terminal activation.

-30-

Page 33

SERIAL COMMUNICATIONS EXAMPLES

CONNECTING TO AN RLC PRINTER

The drawing shows the indicator with the 20 mA Serial Communication

Option set-up with an RLC Model DMPC printer. An external current source

is required to implement the printer’s busy signal to the indicator’s receive

loop, which prevents overruns. The “Print switch” is a momentary contact,

push button type connected between the E2-CON (TBA #8) and the signal

common (TBA #7). The print function and E2-CON must be pro- grammed

and the baud rate must match those of the printer. If a printer is used which

does not have a ‘busy’ line, current must still be flowing

receive loop before transmission can occur.

into the indicator’s

-31-

Page 34

PROCESS CONTROLLING SYSTEM

Six Model IMYswith Serial Communication Option

are used to monitor and control the temperature of 6

ovens at a largebakery. The IMYs are located at each of

the ovens in the production area of the building. The

communications lines are run to an industrial computer

located in the production offices.

The drawing below shows the Current Loop set-up.

Each IMY is given an address and programmed

accordingly (Program Module#7). A baud rate of 1200

is selected.

An application program is written, which sends and

retrieves data from the IMYs.

Note: On all IM indicators, the SO+ and the +20 mA SRC

are connected internally. Therefore it is not necessary

to have this terminal tied to any other terminal on the

unit if that unit is serving as the loop supply source.

-32-

Page 35

RE-TRANSMITTED ANALOG OUTPUT (Optional)

The re-transmitted analog output option transmits a digitally

programmable 4 to 20 mA or 0 to 10 VDC signal to drive chart recorders,

remote indicators and controllers. The option is contained on the upper PCB

and has two outputs, “ANALOG-” (TBB #10) and “ANALOG+” (TBB #11)

and is self-powered (active) with a compliance of 10 VDC. The analog “-”

output is isolated from the inputcommon, eliminating problems from ground

loops. Programming of the option is performed in “Pro 8” of the normal

programming mode.Display values are simply keyed in to providea4mAor

0 VDC output, “AN-Lo”, and a 20 mA or 10 VDC output, “AN-HI”. The

analog output then follows the assigned value and as such will update every

measurement cycle. Nonstandard current or voltage ranges can be supported

ANALOG OUTPUT DIAGRAMS

by calculating the slope and intercept of the display/output and calculating

the required display values at 4 mAor 0 VDC and20 mA or 10VDC. Reverse

action can be achieved by programming a “high” display value for “AN-Lo”

and a “low” display value for “AN-HI”.

If the display should indicate an “OLOLOL”, “ULULUL”,or“SHort” the

analog output will go to 20 mA or 10 VDCfor an“OLOLOL”or “SHort”, and

4mAor0VDCfora“ULULUL”.

Note: Analog “-” must be kept isolated from Alarm Comm. (TBB #8).

-33-

Page 36

ANALOG OUTPUT CALIBRATION

Although the analog output has been calibrated at the factory, zero and

span adjustments are provided to compensate for small offsets and drifts. If

excessive drift is noticed, the following calibration procedure may be

performed.

Scale the analog output by entering an arbitrarily larger display value for

“AN-HI” then for “AN-LO”, in “PRO 8”.

Note: Set the analog output source assignment for input.

4 to 20 mA Calibration

Exit the programming mode and apply a (temperature)/(resistance) to the

input of the indicator so that the display reading is below that of the value

entered for “AN-LO”. Adjust the zero potentiometer (right side) so that

exactly 4.00 mA flows, as verified by an accurate ammeter. Next, apply a

(temperature)/ (resistance) to the indicator so that the display reading is

above that of the value entered for “AN-HI”. (See Appendix “B” for max.