Page 1

Gate Operators, Inc.

Residential & Medium Duty Commercial Slide Gate Operator

Model 7100

INSTALLATION MANUAL

04-01-97

Page 2

CONTENTS

Safety Precautions ......................................................................................... 2

Applications .................................................................................................... 3

Pre-Installation Checklist ............................................................................... 4

Parts Identification .......................................................................................... 5

Pad Installation ................................................................................................ 6

Operator Installation ....................................................................................... 7

Chain Bracket Installation .............................................................................. 8

Chain & Chain Bolt Installation ...................................................................... 9

Chain Magnets Installation ............................................................................. 10

Quick Release Operation ................................................................................ 11

Control Board Connections ............................................................................ 12

Control Board Adjustments ............................................................................ 13

Receiver Options ............................................................................................. 14

Warranty ........................................................................................................... 15

Page 3

IMPORTANT SAFETY PRECAUTIONS

IMPORTANT - READ CAREFULLY BEFORE BEGINNING INSTALLATION

WARNING—To reduce the risk of injury or death:

Read this installation manual completely prior to installation.

•

Installation should be performed by a professional installer.

•

Required welding should be performed by a qualified welder.

•

Should electricity be required, use a certified electrician only.

•

Any device that requires 120 Volts AC should be U.L. approved.

•

Review with the owner all safety concerns including:

•

Do not operate the gate unless area around gate is in full view.

⇒

Do not allow children or adults to “ride” on gate during operation.

⇒

Do not allow children to play in the gate area.

⇒

Periodically test the obstruction sensitivity to assure safe and

⇒

proper operation. **

gate and the hinge or stop post.

Keep the remote control away from children.

⇒

The “CAUTION AUTOMATIC GATE” sign should be clearly visible

⇒

from both sides of the gate.

Always insure that the gate has closed securely before leaving

⇒

area.

Arrange with local fire and law enforcement for emergency access.

⇒

Always keep people and objects away from the gate. No person

⇒

should cross the path of the moving gate.

Recommend safety devices such as loop detectors, edge switches, and

•

beam detectors when applicable.

Install control devices such as keypads far enough away (5 feet or further)

•

from any moving parts of the operator and gate to prevent possible injury.

Always disconnect the battery or power source when making adjustments

•

or repairs to any part of the gate or operator.

All rollers should be covered to prevent injury.

•

Test the gate operator monthly. The gate must reverse on contact with a rigid

object or stop when an object activates the non contact sensors. After adjusting the force or limit of travel, retest the gate operator. Failure to adjust and

retest the gate operator properly can increase the risk of injury or death.

Do not test sensitivity by standing between the

2

Page 4

APPLICATIONS

The

Apollo

to 27 feet in total length (accomodates a 25 foot drive) and 400 pounds. A

professional fence or gate dealer is recommended to assure proper installation.

Apollo Gate Operators

outstanding reputation in the fence and gate industry. These dealers will be able to

recommend the proper equipment for particular applications.

Operators

is recommended. There are several advantages with 12 Volt DC systems:

• Battery powered operators provide up to 200 operations in the event of

power outages.

• The battery may be recharged with a trickle charger or by solar energy

(eliminating the need for costly trenching to remote entrances).

If a trickle charger is used and a standard electrical outlet is not readily available, a

licensed electrician will be required for proper electrical hook up.

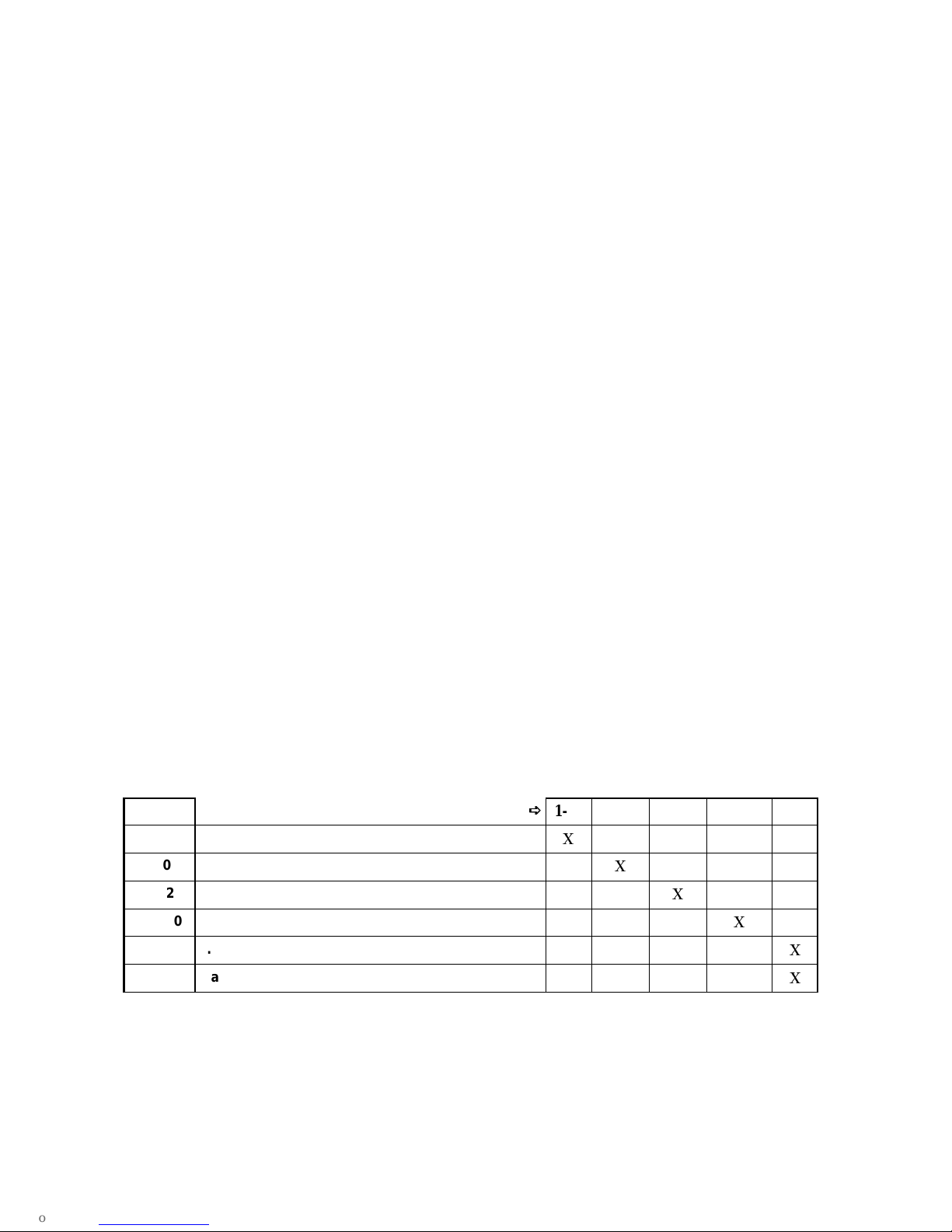

The following table should be used as a guide for capacity of operation of operators

only, additional options may reduce the the daily usage.

capability of solar panels will vary with different geographical lo cations.

Model 7100 Slide Gate Operator is designed to handle a slide gate up

are available only through qualified dealers with an

Apollo Gate

are 12 Volt DC (

Direct Current

) powered. A 12 Volt marine type battery

Please note that the charge

Model #

201 5 watt solar panel w/battery

210 10 watts of solar panel w/battery

MSX20 20 watts of solar panel w/battery & regulator SRX6

MSX40 40 watts of solar panel w/battery & regulator SRX6

404 1.5 amp automatic charger w/battery

405 6 amp automatic charger w/battery (dual gates)

Daily Usage

1-15 16-30 31-60 61-120 121+

X

X

X

X

X

X

3

Page 5

PRE-INSTALLATION CHECKLIST

The following checklist should be used before beginning installation:

Verify that the proper operator has been selected for this application.

♦

Verify proper installation and operation of the gate.

♦

1. Are all rollers covered with a protective housing?

2. Are the rollers servicable?

3. Does the gate roll free and level?

4. Will the gate require a locking device?

5. Are the main posts sturdy enough to handle the gate & operator?

Determine the general location of the operator, chian brackets, and solar

♦

panel (if used).

1. Is there a suitable location for the operator?

2.Can the solar panel (if used) be mounted in an unobstructed area facing

south?

3. Will additional solar panel cable be required?

4. Is electricity available (if required)?

Consider safety and access options. Recommend if needed.

♦

1. Will there be chidren or animals in the area?

2. Are safety loops, edge switches, or photo beam detectors required?

3. How can the gate be opened in emergencies?

4. How will visitors enter and exit?

5. Will vehicles (and trailers) have sufficient room off roadway to operate any

control devices such as keypads?

4

Page 6

# L Bracket

Chain Brackets (2 )

PARTS IDENTIFICATION

7100

Operator

5/16 Washers, Lock

Nuts, & Nuts (8 each)

Chain Bolts with hardware (2 each)

#Bolt50

#40 Link

Master Chain Links (2 each)

#201 #208

5 Watt Solar Panel & Bracket (optional)

#1933G

Magnetic Chain Limits

with hardware (2 each)

Tie Wraps (4 each)

#5/16 X 2

5/16 U Bolts (4 each)

#40 X 30

#40 Roller Chain (30 feet)

1.5 Amp Automatic Battery Charger (optional)

#404

CAUTION Signs (2 each)

#273G

5

Page 7

The required depth of the

pad will vary from site to

site. Normally, the pad

should be at least 4” above

the surface and 18” below

(Figure A & B).

Driveway

PAD INSTALLATION

Direction of Opening

5”

12” 24”

Pad Location

Pad Location

24”

Fig. A

Fig. B

In harder soil or rock, pilings may be preferred (Figure C).

Fig. C

Conduit requirements should be considered in the planning stage. If electrical power is required, a separate conduit should be

installed for electrical only. A certified electrician should be consulted for the proper conduit material (Figure D & E).

Note:

Allow the

concrete to cure

as per the

directions on the

bag. The

5”

14”

3”

AREA FOR CONDUIT

ENTRY

mounting holes

for the operator

should be drilled

after the concrete

has cured.

Fig. D

Fig. E

6

Page 8

OPERATOR INSTALLATION

Four 1/2” anchor bolts (

recommended to mount the chassis. The

holes should be drilled with a 1/2”

concrete drill bit.

STEP 1.

surface of the gate.

STEP 2.

STEP 3.

structions.

STEP 4.

Set the operator on the pad as shown. Align the sprockets 3 to 5 inches from the inside

Mark the four mounting holes on the pad.

Remove the operator and drill the holes according to the anchor bolt manufacturers in-

Replace the operator and fasten to the pad.

not supplied

) are

Chain path

(Make sure

the chain

path clears

all posts and

obstacles).

3”- 5”

Mounting

Holes (4)

TOP VIEW

7

Page 9

CHAIN BRACKET INSTALLATION

STEP 1.

Do not tighten at this time.

Assemble chain bracket with 5/16” U-bolt & hardware to each end of the gate as shown.

STEP 2.

bracket slot with the top teeth

of the idler sprocket.

Align the left chain

STEP 4.

Idler Sprocket

Main Sprocket

STEP 3.

chain bracket slot with the

bottom teeth of the main

sprocket.

Tighten all hardware.

Align the right

8

Page 10

CHAIN & CHAIN BOLT INSTALLATION

STEP 1.

Fig A

Connect chain bolt to the chain bracket as per Figure A & B on both ends of the gate.

Fig B

STEP 2.

master chain link.

Attach the chain to the chain bolt using the

Chain Path

9

Note:

A chain breaking tool may

be required to reduce the chain to

the proper length.

TIP:

If welding

equipment is available,

tack weld the chain

bracket to the gate on

each end to prevent

slippage.

Page 11

CHAIN MAGNETS INSTALLATION

1.

Align each magnet with the

corresponding switch on the

operator.

2.

Connect the battery and adjust

the magnets for proper open &

close limits.

WARNING : Always disconnect

battery prior to relocating the

magnet.

TIP:

If the gate automatically

opens after the close timer

expires, reverse the red &

black motor wires and reverse

the orange & white limit wires.

Switch

Magnet

Operator

Chain Path

Switch

Magnet

Switch

Magnet

Top View - Right Side

Switch

Magnet

Front View

10

Page 12

QUICK RELEASE OPERATION

Engaged

Engaged

Pull & turn 1/2 inch to disengage

11

Page 13

CONTROL BOARD CONNECTIONS #633/634

8 Pin White Connector (two on 634)

7

5

3

1

8

6

4

2

7 Pin Black Connectors

1 Edge 1

2 Edge 2

3 Ground

4 Ground

5 Stop Input (N/C)

6 Close Input (N/O) 3 Button Control Only

7 Open Input (N/O)

8 Ground

9 Ground

10 Free Exit

entry)

11 Ground

12 Under Gate Loop

13 Ground

14 Safety Loop

1 Open Limit

2 Close Limit

3 Motor 4 Motor -

Input

Input

Positive during open cycle, Negative duri ng clos e cycle

Negative during open cycle, Positive during close cycle

5 Ground

6 Ground

7 Ground -

Battery Negative

8 Battery Positive

Input

Input

}

Input (recommended telephone

Input

Input

(+12 VDC)

3 Pin Black Connectors (3)

GND

Ground

INP

Input (Activates gate when momentarily connected to ground)

12V

+12 Volt Output (For powering options - 2 Amps Max.)

Emergency Bypass Connector

Used when the control board is not functioning. Unplug the

motor harness from the main connector and momentarily

insert into the Emergency Bypass Connector to open the

gate. In the event the motor is not disconnected quickly

enough, the blue 15 amp fuse will protect the circuit board

from damage and should be replaced when the original

problem is fixed.

12

Page 14

633/634 CONTROL BOARD ADJUSTMENTS

PROGRAM SWITCHES

Factory Description

Setting

#1 ON TIMER TO CLOSE -

#2 OFF CURRENT SENSITIVITY OPTION -

#3 ON TIMER TO CLOSE OPTION

OFF - timer to close works from any open gate position

#4 OFF DUAL CONTROL SLAVE OPTION

OFF - enables slave side of dual board

#5 OFF DUAL CONTROL MASTER OPTION

OFF - Enables master side of dual board

#6 OFF MAXIMUM RUN TIMER OPTION

OFF - stops gate if run timer times out before closing

#7 ON MAXIMUM RUN TIMER VALUE

OFF - 5 to 15 seconds

#8 ON TIMER TO CLOSE VALUE

OFF - 10 to 35 seconds (adjustable)

#9 OFF OPEN, STOP, CLOSE CONTROL ENABLE

ON - Close timer enabled OFF - Close timer disabled

ON - 4 second delay OFF - 2 second delay

ON - timer to close works only when open limit switch is activated

ON - disables slave side of dual board

ON - disables master side of dual board

ON - stops and reverses gate if run timer times out before closing

ON - 10 to 30 seconds

ON - 20 to 70 seconds (adjustable)

ON - allows for open, stop, close unit (optional) to operate gate

Automatically closes gate

Delays current sensing from start

CLOSE

TIMER

AUTO

REVERSE

SENSITIVITY

13

TIMER TO C L OSE ADJUSTME NT

Rotate clockwise to increase time before gate closes.

Rotate counter clockwise to decrease time before gate

closes.

AUTO REVERSE SENSITIVITY

Rotate clockwise to decrease sensitivity (more force).

Rotate counter clockwise to increase sensitivity (less

force).

WARNING:

should be adjusted to prevent injury in the event of

someone being entrapped in the gate. This feature

should be periodically tested to assure proper

operation. Refer to SAFETY PRECAUTIONS.

The AUTO REVERSE SENSITIVITY

Page 15

Gate Operators

RECEIVER OPTIONS

Do not confuse the receiver code switches with the red program switches on the gate control board.

Never set all code switches to the same position. Transmitters must match code switches for proper operation.

If power is taken directly from battery or connected as shown below, receiver should be configured for 12VDC.

Multi-Code

Allister

Lift-Master

black

white

1

2

3

4

gray

black

gray

red

red

GND INP 12V

GND INP 12V

GND INP 12V

GND

INP

12V

GND

INP

12V

GND

INP

12V

Genie

Heddolf

Linear

white

black

white/silver

white

black

common

14

red

yellow

red

n/o

white/gold

GND INP 12V

GND INP 12V

GND INP 12V

GND

INP

12V

GND

INP

12V

GND

INP

12V

Page 16

LIMITED ONE-YEAR WARRANTY

months from the date of purchase, providing recommended installation

procedures are followed. This warranty is in lieu of all other warranties

expressed or implied (some states do not allow limitations on how long an

implied warranty lasts, so this limitation may not apply to you) and shall be

considered void if damage was due to improper installation or use,

connection to improper power source, or if damage was caused by fire,

flood, or lightning. The manufacturer will not be responsible for any labor

charges incurred in the removal or replacement of defective parts.

In case of failure due to defective material or workmanship during the

warranty period, the defective part will be repaired or replaced at the

manufacturer’s option at no charge if returned freight prepaid. New or factory

rebuilt replacements may be used. Replacement parts are warranted for the

remaining portion of the original warranty period. The manufacturer will pay

standard ground freight on the return of repaired or replaced items in

warranty.

Apollo products are warranted against defects for a period of 12

15

Loading...

Loading...