Page 1

APOLLO 120 /150 III

12.1”/15.0”/15.1” TFT Intel®

Celeron/Pentium® III

Plastic-housing Panel PC with

Versatile

Stand design

User’s Manual (Version 2305)

Page 2

Copyright Notice

This document is copyrighted 2003 by the Manufacturer.

The information provided in this document has been

carefully checked and is accurate at the time of publication.

However, the Manufacturer assumes no responsibility for

any infringements of patents or other rights of third parties

that may result from its use.

No part of this publication may be reproduced, stored in a

retrieval system, or transmitted in any form of or via any

means without the prior written permission of the

Manufacturer. Further, this publication and features

described herein are subject to change without notice.

Trademarks

All brand and product names used for identification in this

document are trademarks or registered trademarks of their

respective companies.

© Copyright 2003, May Version 2305

All rights reserved.

Printed in Taiwan

Page 3

Unpacking

After unpacking the APOLLO 120/150 III carton, check

and see if the following items are included and in good

condition.

u APOLLO III main system x 1

u Accessories

- Power cord (90o) x 1

- External FDD cable (optional) x 1

- External 5V/12V DC power cable (optional) x 1

- Utilities & drivers & user manual CD diskette x 1

(for touchscreen drivers, please download the

updated drivers from the following website

http://www.3m.com or

http://www.elotouch.com or

http://www.eturbotouch.com

- Base knob with rubber cushion x 1

- Panel mounting kit (optional) x 1 set

Make sure that all of the items listed above are present. If

any of the above items is missing, contact your dealer

immediately.

Warranty

All products manufactured by the Manufacturer. are

warranted against defective materials and workmanship for

one year starting from the date of delivery to the original

purchaser. However, warranty or service will not be

extended if 1). the product is repaired, modified or altered

unless such repair, modification or alteration is authorized

by the Manufacturer; or 2). the product serial number or

warranty label is defaced or missing; or 3). the product is

not properly used.

Page 4

Important Safety Precautions

Before getting started, read these instructions and save

them for later reference.

1. Turn off the computer before cleaning. Clean with a

damp or dry cloth only. Do not spray any liquid cleaner

on screen directly.

2. The power outlet socket used to plug in the computer

power cord must be located near the system and easily

accessible. Do not use outlets on the same circuit of

the systems that regularly switched on and off.

3. Make sure the voltage of the power source is correct

before connecting the computer to the power outlet.

4. If the computer is sharing an extension cord with other

devices, make sure the total ampere rating of the

devices plugged into the extension cord does not

exceed the cord’ s ampere rating.

5. Do not expose the power cord, extension cord and

power outlet to moisture.

6. Install the computer on a reliable surface to prevent

damage caused by dropping.

7. This computer is not equipped with an operating

system. An operating system must be loaded first

before installing any software into the computer.

8. Disconnect the power cord from the computer before

any installation. Make sure both the computer and the

external devices are turned off. The sudden surge of

power may ruin any sensitive components. Also make

sure the computer is properly grounded.

9. During installation of any internal components, be sure

to ground yourself to keep from any static charge.

Most electronic components are sensitive to the static

electric charge. Use a grounding wrist strap and place

all electronic components in any static-shielded

devices.

Page 5

10. The openings on the computer enclosure are for the

cabin ventilation to prevent the computer from

overheating. DO NOT COVER THE OPENINGS.

11. The brightness of the flat panel display will decrease

with use. However, hours of use will vary depending on

the application environment.

12. If the computer is equipped with a touch panel, avoid

using sharp objects to operate the touch panel.

Scratches on the touch panel may cause

mal-calibration or non-function to the panel.

13. The LCD panel display is not subject to shock or

vibration. When assembling the computer, make sure

it is securely installed.

Page 6

Table of Contents

1. INTRODUCTION............................................. 1-1

1.1. GENERAL INFORMATION ..................................1-2

1.2. WHAT COVERS IN THIS MANUAL.........................1-3

1.3. SPECIFICATIONS...........................................1-5

1.4. DIMENSIONS .............................................1-10

1.4.1. APOLLO 120 ........................................1-10

1.4.2. APOLLO 150 ........................................1-11

2. USING THE SYSTEM.....................................2-13

2.1. IDENTIFYING THE SYSTEM..............................2-14

2.1.1. Front View...........................................2-14

2.1.2. Side Views...........................................2-15

2.1.3. I/O Outlets..........................................2-16

2.2. SYSTEM SETUP FOR THE FIRST-TIME USE ............2-17

2.2.1. Installation Procedures..........................2-17

2.2.2. Running the BIOS Setup .......................2-18

2.2.3. Operating System and Driver Installation 2-19

3. VERSATILE STANDING & MOUNT OPTIONS . 3-21

3.1. VERSATILE STAND .......................................3-22

3.1.1. Standing Upright..................................3-22

3.1.2. 45 to 900 Free Standing ........................3-22

3.1.3. Fixed Standing.....................................3-23

3.1.4. Cable Management...............................3-24

3.2. WALL MOUNTING AND MOBILE APPLICATIONS.......3-25

3.3. PANEL MOUNTING .......................................3-27

3.4. KIOSK INTEGRATION ..................................3-28

Page 7

4. I/O CONNECTION........................................ 4-29

4.1. PARALLEL PORT ..........................................4-30

4.2. COM PORTS X 4 ........................................4-31

4.3. 100/10 BASE-T ETHERNET (RJ-45)................4-33

4.4. VGA INTERFACE.........................................4-33

4.5. 2

ND

DISPLAY GRAPHIC SUPPORT MODE...............4-34

4.5.1. When System Memory Clock = 66MHz....4-34

4.5.1.1. Single Display Mode........................4-35

4.5.1.2. Mirror Display Output Mode..............4-36

4.5.1.3. Multiple Display Output Mode ...........4-37

4.5.2. When System Memory Clock = 100MHz ..4-38

4.5.2.1. Single Display Mode........................4-38

4.5.2.2. Mirror Display Output Mode..............4-39

4.5.2.3. Multiple Display Output Mode ...........4-40

4.5.3. When System Memory Clock = 133MHz ..4-41

4.5.3.1. Single Display Mode........................4-42

4.5.3.2. Mirror Display Output Mode..............4-43

4.5.3.3. Multiple Display Output Mode ...........4-44

4.6. PS/2 KEYBOARD INTERFACE...........................4-45

4.7. PS/2 MOUSE INTERFACE...............................4-45

4.8. EXTERNAL FDD (DB-15) .............................4-46

4.9. +5V/12V DC-OUT ....................................4-47

4.10. VR BRIGHTNESS CONTROL ............................4-47

4.11. DIO (DIGITAL INPUT & OUTPUT) ....................4-48

4.12. AUDIO INTERFACE (LINE-IN, MIC-IN, SPK-OUT) .4-50

4.13. USB PORTS..............................................4-50

4.14. IR KEYBOARD SENSOR (OPTIONAL) ..................4-50

4.15. AC/DC INLET/POWER SWITCH .......................4-50

Page 8

5. HARDWARE INSTALLATION AND UPGRADE. 5-51

5.1. RECOGNIZING THE SYSTEM MAJOR PARTS ...........5-53

5.2. INSTALLING THE CPU...................................5-55

5.3. INSTALLING THE SDRAM MEMORY MODULE ........5-56

5.4. MOTHERBOARD ASSEMBLY .............................5-57

5.5. TOUCH CONTROLLER ASSEMBLY .......................5-58

5.6. HDD MODULE ASSEMBLY ..............................5-59

5.7. TOUCHSCREEN OR FRONT BEZEL ASSEMBLY .........5-60

5.8. LCD MODULE ASSEMBLY...............................5-62

5.9. CD-ROM/DVD-ROM/FDD MODULE ASSEMBLY ..5-67

5.9.1. Internal CD-ROM/FDD Assembly ............5-67

5.9.2. External FDD Connection.......................5-69

5.10. POWER MODULE ASSEMBLY ............................5-70

5.11. EXPANSION OUTLETS & RISER CARD ASSEMBLY....5-72

5.12. BACK PANEL ASSEMBLY.................................5-73

5.13. STAND MODULE ASSEMBLY.............................5-74

6. SYSTEM MOTHERBOARD & I/O BOARD........ 6-77

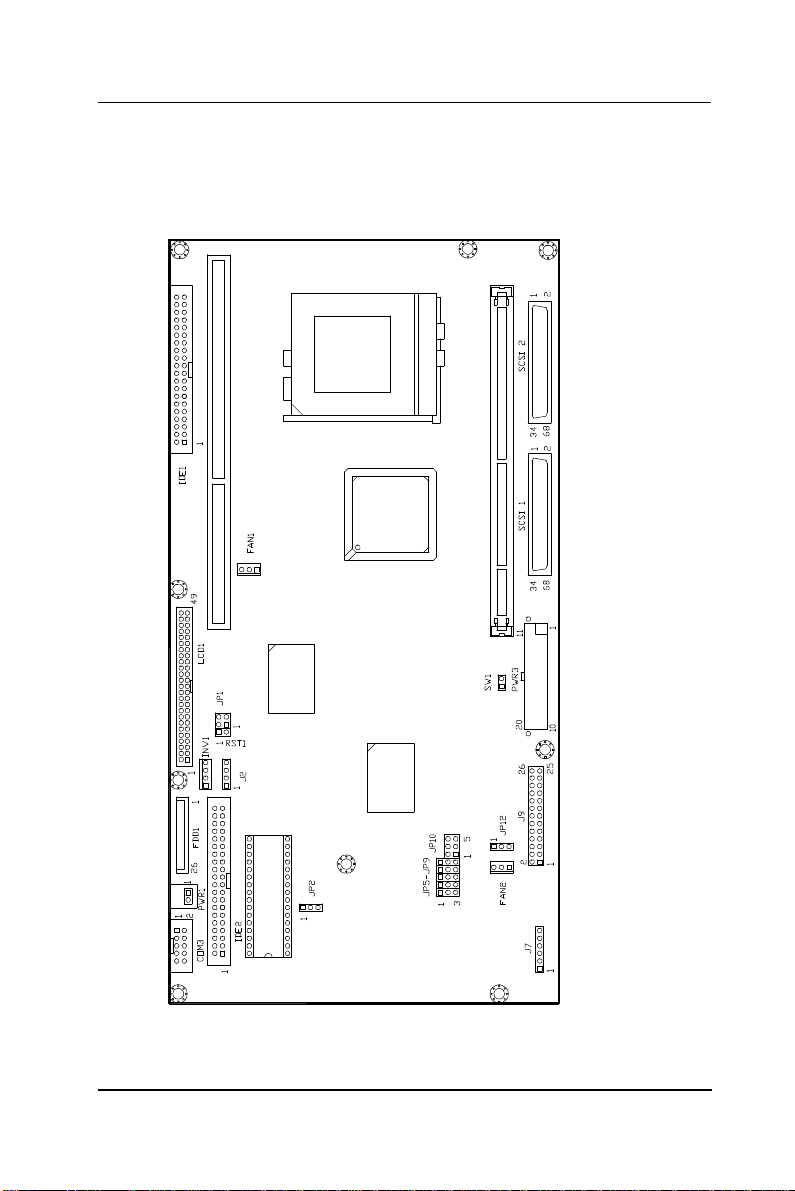

6.1. APOLLO III MOTHERBOARD..........................6-78

6.1.1. General Information .............................6-78

6.1.2. Specifications.......................................6-79

6.1.3. Locating Jumpers & Connectors..............6-81

6.1.4. Jumpers & Jumper Setting.....................6-82

6.1.4.1. DOC 2000 Address Setting (JP1).......6-83

6.1.4.2. Clear CMOS (JP2) ...........................6-83

6.1.4.3. COM 2 232/422/485 Setting ............6-83

Page 9

6.1.5. Connectors & Pin Assignment.................6-84

6.1.5.1. PWR3: ATX Power connector ............6-85

6.1.5.2. J2: CD Audio IN.............................6-86

6.1.5.3. J7: HDD LED & ACPI LED & SMI........6-86

6.1.5.4. J8: IR / CIR Connector ....................6-86

6.1.5.5. J9: Power LED & KB ........................6-87

6.1.5.6. SW1: ATX Power ON/OFF & Reset .....6-87

6.1.5.7. COM3............................................6-87

6.1.5.8. LCD1: LCD Connector......................6-88

6.1.5.9. INV1: LCD Inverter Connector.........6-89

6.1.5.10. FDD1: FDD connector.....................6-89

6.1.5.11. IDE1/IDE2: Primary/Secondary HDD.6-90

6.1.5.12. SCSI 1: PRT/Serial Port/DIO Port......6-91

6.1.5.13. SCSI 2: KB/MS/VGA/LAN USB/FDD...6-92

6.1.5.14. CN4: PCI/ISA Expansion Slot............6-93

6.2. APOLLO III I/O BOARD ..............................6-96

6.2.1. Locating Jumpers & Connectors..............6-96

6.2.2. Jumpers & Jumper Setting.....................6-97

6.2.2.1. JP1: Keyboard Power Select ............6-97

6.2.2.2. COM port Power Selection................6-97

6.2.3. Connectors & Pin Assignment.................6-98

6.2.3.1. KB1: PS/2 Keyboard Connector ........6-99

6.2.3.2. KBMS: PS/2 Mouse .........................6-99

6.2.3.3. COM1, COM2, COM4: DB-9 .............6-99

6.2.3.4. CN1: DC Power Output.................6-100

6.2.3.5. LPT1: D-SUB-25 Parallel Port.......... 6-100

6.2.3.6. CRT1: VGA (D-SUB 15 Pin) ............6-100

6.2.3.7. FDD1: External FDD Connector.....6-101

6.2.3.8. J11: USB 1 , USB2 Connector.......6-101

6.2.3.9. DIO1: RJ-11 Connector ................. 6-101

6.2.3.10. LAN1: RJ-45 Ethernet Connector .... 6-101

6.2.3.11. MIC1........................................... 6-102

6.2.3.12. LINE 1......................................... 6-102

6.2.3.13. SPK 1.......................................... 6-102

6.2.3.14. SCSI 1: PRT /Serial Port/DIO Port...6-103

6.2.3.15. SCSI 2: KB/MS/VGA/LAN USB/FDD. 6-104

Page 10

7. AWARD BIOS SETUP.................................. 7-105

7.1. AWARD BIOS..........................................7-106

7.2. CONTROL KEY DEFINITION........................... 7-107

7.3. GETTING HELP .........................................7-108

7.3.1. Main Menu......................................... 7-108

7.4. AWARD BIOS SETUP ............................... 7-108

7.4.1. AWARD BIOS Setup Main Menu............7-108

7.4.2. Standard CMOS Features.....................7-110

7.4.3. Advanced BIOS Features..................... 7-113

7.4.4. Advanced Chipset Features..................7-117

7.4.5. Integrated Peripherals ........................ 7-123

7.4.6. Power Management Setup...................7-127

7.4.7. PnP/PCI Configuration.........................7-131

7.4.8. PC Health Status ................................ 7-133

7.4.9. Frequency Voltage Control................... 7-134

7.4.10. Load Fail-Safe Defaults .......................7-136

7.4.11. Load Optimized Defaults......................7-137

7.4.12. User Password ...................................7-138

7.4.13. Save and Exit Setup ...........................7-139

7.4.14. Exit Without Saving............................7-140

8. SOFTWARE & DRIVERS INSTALLATION ..... 8-141

8.1. ETHERNET DRIVERS................................... 8-142

8.2. PC 610 AGP XGA................................... 8-143

8.3. AUDIO SETUP .......................................... 8-144

8.4. TOUCHSCREEN DRIVERS .............................. 8-145

8.5. DRIVER INSTALLATION................................ 8-146

APPENDIX .....................................................8-147

A: LCD SPECIFICATION.........................................8-147

B: DISKONCHIP INSTALLATION.............................. 8-150

C: WAKE-ON-LAN ..............................................8-152

D: FIRST MB MEMORY MAP.................................... 8-155

E: POWER SUPPLY................................................8-156

Page 11

User Manual version 2305

1. INTRODUCTION

This chapter provides background

information and detail specification on

the APOLLO 120/150 III. Sections in this

chapter include:

u General Information

u What covers in this Manual

u Specification

u Dimension

APOLLO 120/150 III

1-1

Page 12

User Manual version 2305

1.1. General Information

The information revolution which started from the mid ’90

inaugurated a new competitive era where consumercomputing technology was exploited to business operation

quicker than ever before. Many enterprises from our life

related industries such as POS, POI, KIOSK, Banking,

Medical to the high-tech Telecom, Aerospace,

Semiconductor … etc. all are eager or forced to automate

their industries with PCs in order to thrive in this new age. For

their industrial automation, there is one thing in common, i.e.

space is always a premium and system stability is always a

must in their environmental applications.

The APOLLO 120/150 is a 12.1"/15.0” or 15.1" TFT Intel

Celeron/Pentium III/Pentium IV plastic-housing multimedia

panel PC system. With a 150W or 200W ATX power supply as

its engine, the APOLLO is a genuine P4 panel PC designed for

high performance multimedia application. Featuring with

versatile stand design for different environmental

applications, the APOLLO itself can be used as a

ready-to-play system by connecting to necessary peripherals.

By integrating the APOLLO system to the special designed

HERCULUS KIOSK, the complete system is widely used for

KIOSK integration. It also provides 2 sets of VESA holes for

market-available swing arms for mobile application. Also with

the availability of both AC and DC systems, the APOLLO is the

best turnkey solution platform for any system integration.

In terms of panel size, the APOLLO has 12.1” and 15.0” or

15.1” systems. In terms of system engine, the APOLLO also

have two versions, one APOLLO III, Celeron/Pentium III

system and the other APOLLO IV, Pentium IV system. To

upgrade the system, simply replace the motherboard.

Fully configurable and with its sleek outlook, the APOLLO is

an ideal platform for any space-constricted application.

1-2

APOLLO 120/150 III

Page 13

User Manual version 2305

1.2. What Covers in this Manual

This handbook contains most information you need to set up

and use the APOLLO III system. You do not need to read

everything in this handbook to use the system.

For a quick start, see the following chapter summaries;

Chapter 1 (the current chapter) provides background

information and detail specification on the

APOLLO 120/150 III.

Chapter 2 identifies the APOLLO III system exterior

components and provides instructions to help

you to use the system as soon as possible.

Chapter 3 details the panel PC’s various standing and

mounting options by graphical illustrations.

Chapter 4 provides the procedures to connect external

devices to the I/O interface

Chapter 5 helps you to recognize the APOLLO system

internal components. It also provides the

installation procedures including LCD,

touchscreen, power supply module, CPU, system

memory, FDD, HDD and CD-ROM drive.

Chapter 6 provides detail information of the jumper settings

and connector signals of the system control

board.

Chapter 7 explains the AWARD BIOS setup.

Chapter 8 introduces the Ethernet, XGA and audio drivers.

Chapter 9 details the procedures to install the touchscreen

software drivers under DOS and Windows

operation

APOLLO 120/150 III

1-3

Page 14

User Manual version 2305

Appendix A details the 12.1”/15.0” or 15.1” LCD

specifications.

Appendix B introduces the DiskOnChip installation.

Appendix C introduces the Wake-On-LAN feature.

Appendix D explains the first MB memory map.

Appendix E provides the specifications for the built-in power

supply.

1-4

APOLLO 120/150 III

Page 15

User Manual version 2305

1.3. Specifications

APOLLO: 12.1”/15.0” or 15.1” TFT Intel® Celeron/Pentium®

III Plastic-housing Panel PC with Versatile Stand

design

SYSTEM

Flat Panel

u APOLLO 120: 12.1” color TFT, 800*600

Viewing angle 100

Luminance (cd/m2) 150 or above

Simultaneous mode yes

u APOLLO 150: 15.0”/15.1” color TFT, 1024*768

Viewing angle 120

Luminance (cd/m2) 250/200 or above,

optional high-luminance

model

Simultaneous mode yes

CPU (Socket 370)

u Intel Pentium III FCPGA 1GHz/133MHz

u Intel Pentium III FCPGA 650-933/133MHz

u Intel Pentium III FCPGA 500E-850E/100MHz

u Intel Celeron FCPGA 800MHz-1.10GHz/100MHz

u Intel Celeron FCPGA 533AMHz-766MHz/66MHz

u Intel Celeron PPGA 300A-533MHz/66MHz

System Chipset

u SiS 630ST

System BIOS

u Award PnP Flash BIOS

System Memory

u 1*168pin DIMM socket supporting SDRAM up to 512MB

L2 Cache

u CPU built-in

APOLLO 120/150 III

1-5

Page 16

User Manual version 2305

Standard I/O

u Serial ports*4: COM 1, 2 & 4 with +5V/12 power output

on pin #9, COM 3 internal type reserved for touchscreen,

COM2 RS-232/485 jumper selectable

u Parallel Port*1: supports SPP/EPP/ECP

u External FDD Interface*1

u +5V/+12V DC-out*1

u PS/2 Keyboard Interface*1

u PS/2 Mouse Interface*1

u DIO: Input*2, output*2

u USB Interface*2

u VGA Interface*1

u Brightness VR*1

u Speaker-out, MIC-in, Line in

Ethernet

u 100/10 Base-T Ethernet with RJ-45 phone jack

u Supports WAKE-ON-LAN

Watchdog Timer

Display

u Integrated 2D/3D graphics engine, 4X AGP

u Share system memory architecture able to utilize the

display memory size up to 64MB

u Supporting LCD/VGA dual display mode (under

Windows 98 and Windows ME and Windows XP)

1-6

APOLLO 120/150 III

Page 17

User Manual version 2305

Audio Function

u Full duplex and independent sample rate converter for

audio recording & playback

u Supports Microsoft DirectSound

u 3D positional audio effects

u Hi-performance, mixed-signal, stereo

u MIC-In, Speaker-Out, Line-In

u Pin header for CD-audio in

Hardware Monitor

u Monitoring processor & system

u Monitoring 5VSB, VBAT, 1.5V, 3.3V, +5V, +12V, -12V, and

processor voltages

u Monitoring processor, chassis fan speeds

u Controlling processor and chassis fan speed and failure

alarm

u Automatic fan on/off control

u Read back capability that displays temperature, voltage

and fan speed

u Supporting Intel processor thermal diode output (real

processor temperature)

Expansion Slot

u PCI*2 or PCI*1 + ISA*1

u Expansion card size (L*W)

PCI card: max. 190*120 mm

ISA card max. 190*120 mm if no internal FDD is

installed; 170*120 mm if internal FDD is installed

Front Bezel

u LED indicators for HDD, LAN, POWER

u IrDA receiver (optional)

APOLLO 120/150 III

1-7

Page 18

User Manual version 2305

PERIPHERAL & STORATE DEVICES

Touchscreen (optional, sharing COM3)

u 12.1”/15.1” analog resistive type with RS-232 controller

u 12.1”/15.1” capacitive type with RS-232 controller

u 12.1”/15.1” surface acoustic wave type (SAW)

Power Supply

u ATX 150W, input range: 100~240V/5A @60Hz,

200~240V/2.5A @50Hz

u DC 150W, 20~28VDC, 40~56VDC or DC 200W, 36~72VDC

(optional)

Speakers

u Water-proof speakers*2

CD-ROM or CD-RW or DVD-ROM or COMBO

u Slim type*1 (optional) or

u External type via USB

Floppy Disk Drive

u Slim type*1 (optional) or

u Via external FDD or

u External type via USB

Hard Disk Drive

u 3.5" HDD*1 (optional) or 2.5” HDD x 2 (optional)

1-8

APOLLO 120/150 III

Page 19

User Manual version 2305

MECHANICAL & ENVIRONMENTAL

Construction

u Inside: heavy-duty steel

u Outside: fire-proof resilient ABS/PC plastic

Color (standard)

u Beige

u Black

Dimension (chassis only, unit: mm)

u APOLLO 120: 368*321*116.5 (L*W*D);

334.7*284.21 (for panel mount)

u APOLLO 150: 406*360*129 (L*W*D);

384*284.2 (for panel mount)

Mounting

u Panel mount with mounting kits

u Wall mount with swing arm: standard VESA mounting

holes (75*75 mm)

Versatile Stand

u 45~90o free standing

u Avocado-shape holes for fixed standing

u Cable Management design

§ Specifications are subject to change without notice.

APOLLO 120/150 III

1-9

Page 20

User Manual version 2305

10

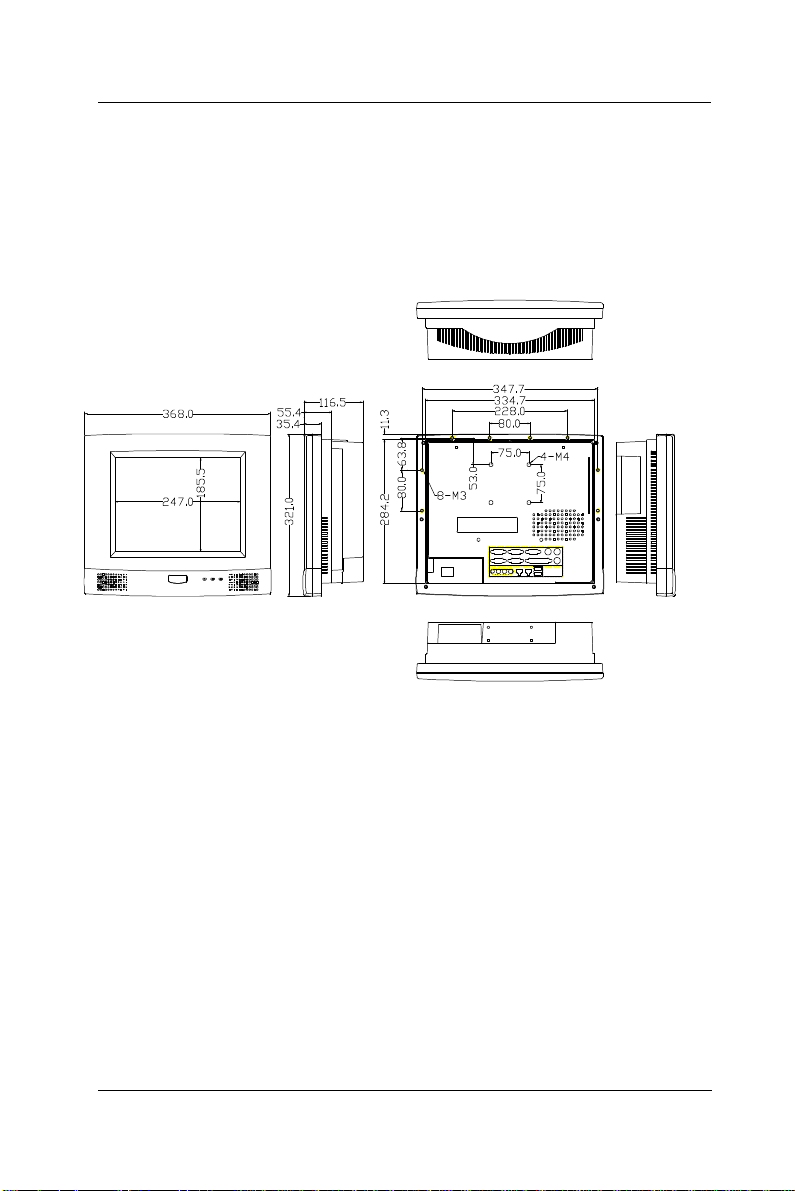

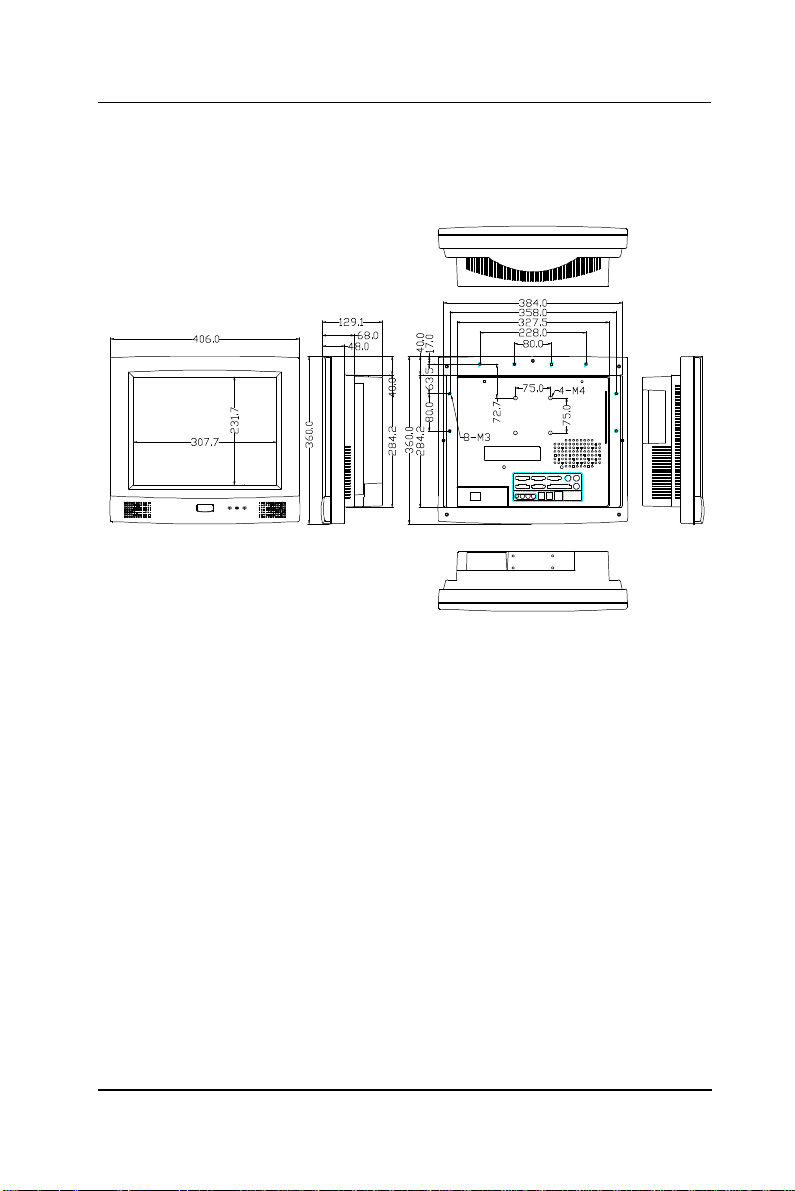

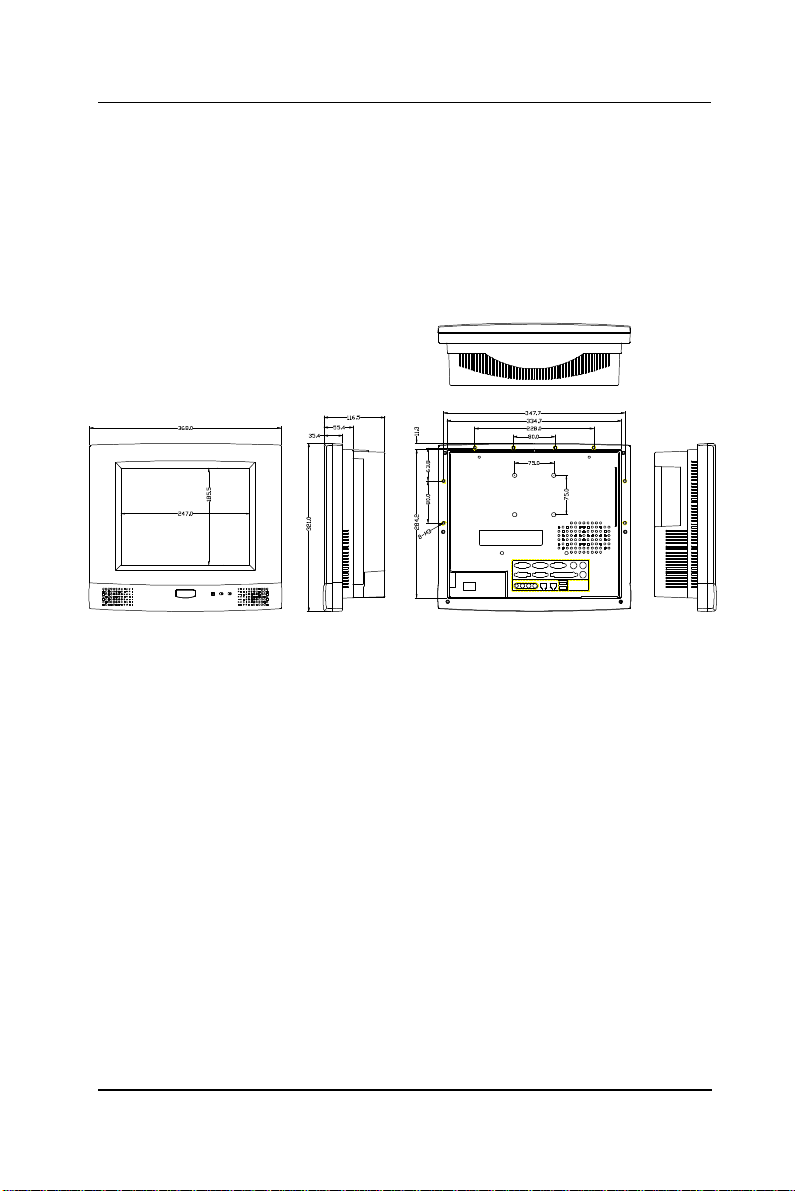

1.4. Dimensions

1.4.1. APOLLO 120

The APOLLO 120’s chassis size is shown below. This does not

include the dimension of the stand. This does not include the

dimension of the stand.

1-

Figure 1-1: APOLLO 120 DIMENSION

APOLLO 120/150 III

Page 21

User Manual version 2305

1.4.2. APOLLO 150

The APOLLO 150’s chassis size is shown below. This does not

include the dimension of the stand.

Figure 1-2: APOLLO 150 DIMENSION

APOLLO 120/150 III

1-11

Page 22

User Manual version 2305

2-12

APOLLO 120/150 III

Page 23

User Manual version 2305

2. USING THE SYSTEM

u Identifying the APOLLO system

u System setup for the first-time use

APOLLO 120/150 III

2-13

Page 24

User Manual version 2305

12.1”/ 15.1” LCD

PCI/ISA expansion outlet

able management

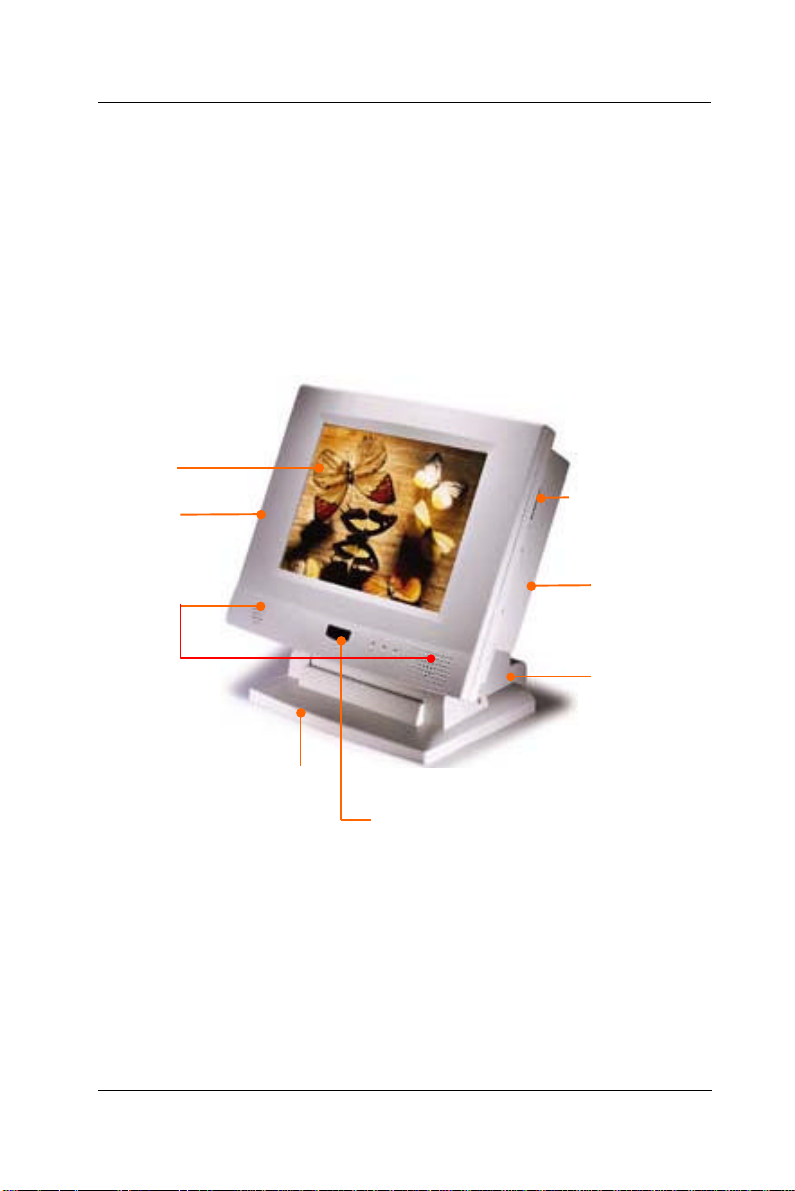

2.1. Identifying the System

Before getting started, take a moment to familiarize yourself

with the system and the I/O arrangement of the APOLLO

120/150.

2.1.1. Front View

When the APOLLO 120/150 is put upright on the desktop with

the provided pedestal, its front view appears as below.

The illustrations of the APOLLO 120/150 may differ slightly

because the APOLLO system series has two different LCD size:

12.1” & 15.1”.

& touchscreen

Side door for two

Speaker

Versatile stand for

desktop standing

Wireless KB sensor or

Motion sensor or IrDA

FDD drive &

CD-ROM drive

Fire-proof

resilient plastic

C

covers

2-14

APOLLO 120/150 III

Page 25

User Manual version 2305

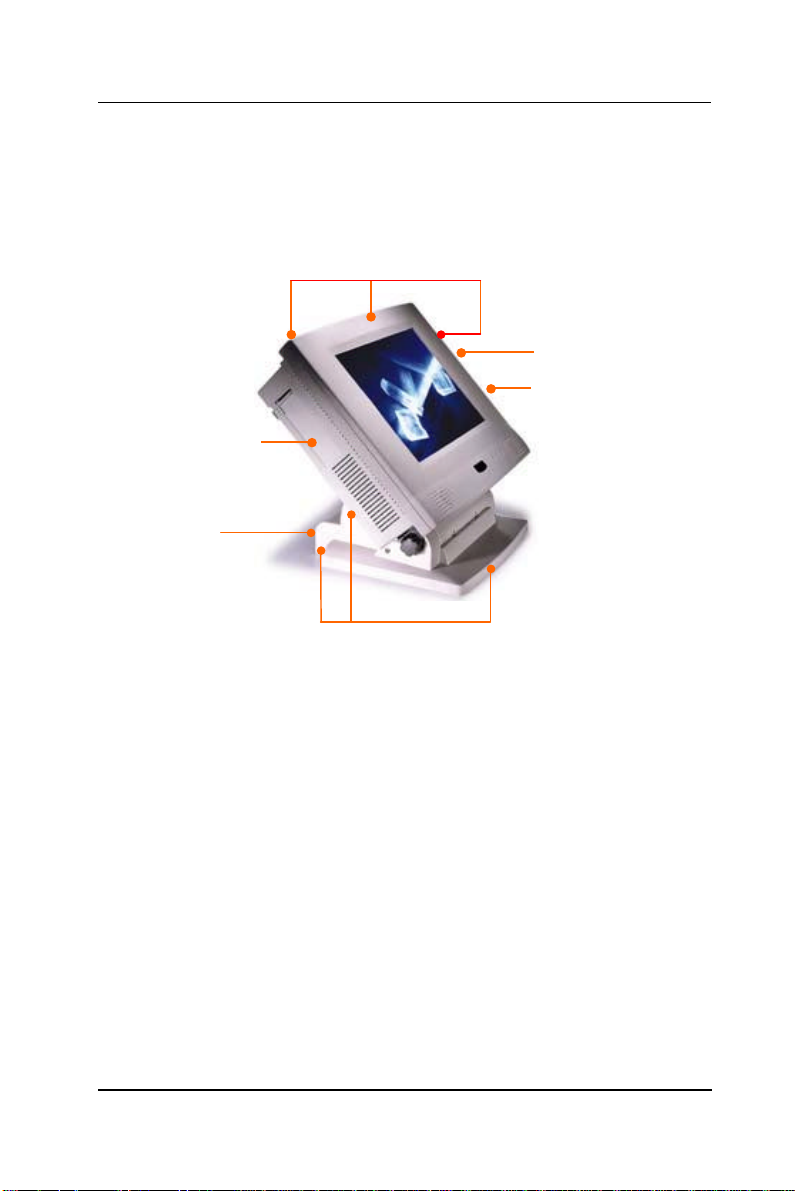

2.1.2. Side Views

The left side of the panel PC appears as below:

Side door for two PCI/ISA

expansion outlet

Cable management

cutout

Screw holes for peripheral

device attachment

Base covers +pedestal = versatile stand

Floppy disk drive

CD-ROM

APOLLO 120/150 III

2-15

Page 26

User Manual version 2305

P

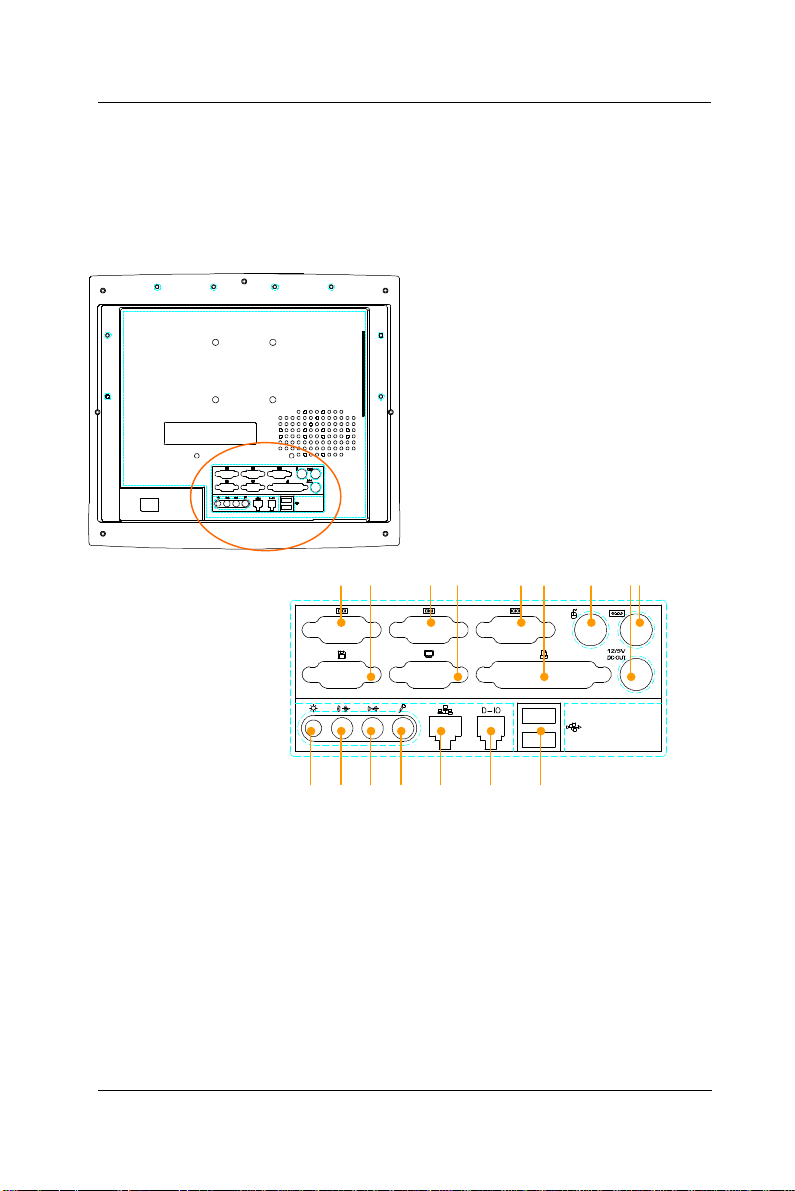

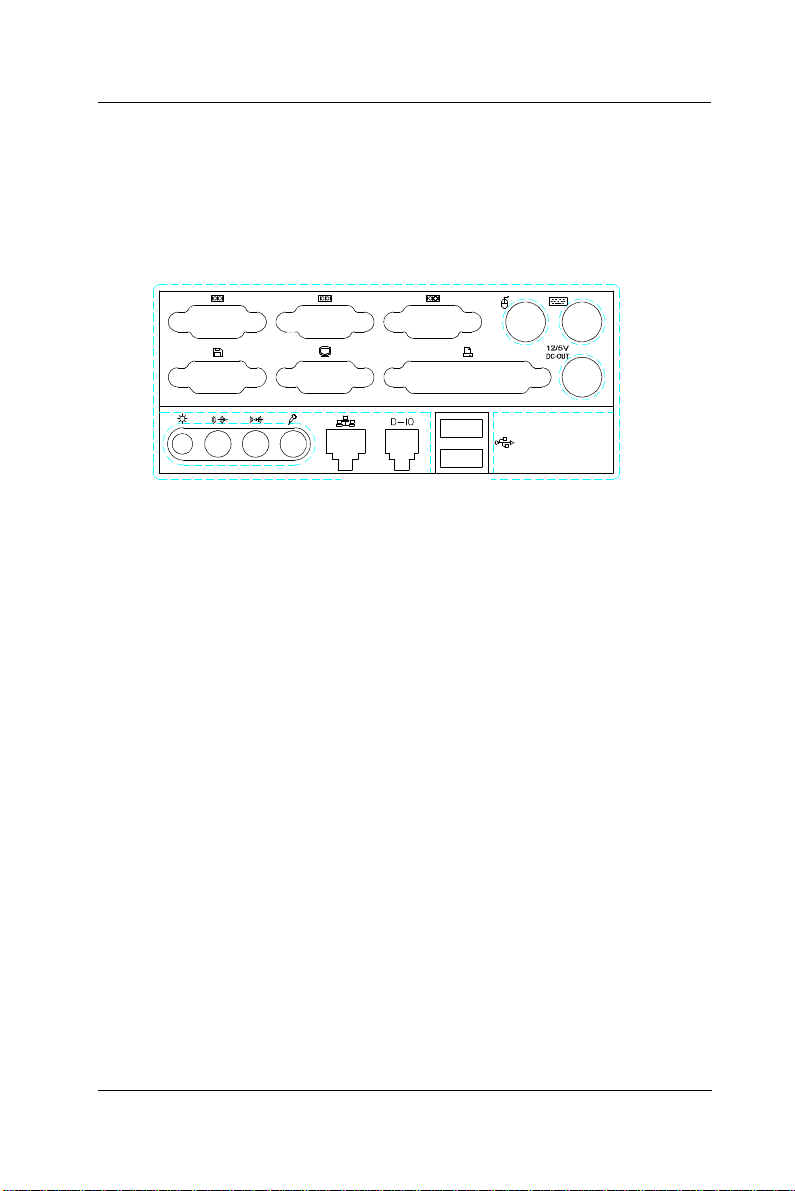

2.1.3. I/O Outlets

When you turn around the APOLLO system, you will find the

power switch and all the I/O ports are located at the rear

cover of the panel PC.

A. COM 4 B. EXTERNAL FDD C. COM 2

D. VGA PORT E. COM 1 F. PRINTER PORT

G. PS/2 MOUSE H. +5/12V DC-OUT I. PS/2 KEYBOARD

J. VR BRIGHTNESS K. SPEAKER-OUT L. LINE-IN

M. MIC-IN N. ETHERNET (RJ-45) O. 2-CHANNEL DIO

P. USB*2

4 2 1

A B C D E F G H I

4 2 1

J K L M N O

2-16

APOLLO 120/150 III

Page 27

User Manual version 2305

2.2. System Setup for the First-time Use

To set up the APOLLO 120/150 for the first-time use, you

should have the following items ready. The items are either

in the accessory box or available in any computer stores.

u 110V or 220V power cord

u PS/2 or AT keyboard or wireless keyboard

u PS/2 or serial mouse

2.2.1. Installation Procedures

The APOLLO system can be powered either by an AC

electrical outlet (100~240V/5A @60Hz, 200~240V/2.5A @50Hz)

or by DC power source (20~28VDC or 40~56VDC or 36~72VDC).

If the system is to be powered up by AC power, be sure to use

the right power cord (110V or 220V) for connection.

1. Connect the female end of the power cord to the AC inlet

located at the rear bottom side of the panel PC.

2. Connect the 3-pin male end of the power cord to an

electrical outlet.

3. Connect a PS/2 keyboard or an AT keyboard to keyboard

port. If you are using an AT keyboard, you need an

adapter (AT to PS/2 KB) for this connection.

4. Connect the PS/2 mouse to the PS/2 mouse port. If you

are using a serial mouse, it can be connected to the COM

port.

5. Turn on the main switch on the power supply if there is

one.

6. Power on the panel PC by switching the power switch

located at the rear bottom side.

APOLLO 120/150 III

2-17

Page 28

User Manual version 2305

2.2.2. Running the BIOS Setup

If you are a commercial user, the APOLLO 120/150 III should

have been properly set up and configured by your dealer. You

may still find it necessary to change the system configuration

information. In this case, you need to run the system’s BIOS

setup program.

Under the following conditions, the CMOS settings are to be

changed.

1. The system is starting for the first time.

2. The hardware devices attached to the APOLLO III system

have been changed.

3. The CMOS memory has lost power and the configuration

information has been erased.

The BIOS setup program is stored in ROM, which can be

accessed by pressing <DEL> key on the keyboard

immediately when the system is powered on.

In order to retain the specified setup information when the

system power is turned off, the system setup information is

stored in a battery-backed CMOS RAM. The battery is to

ensure the settings will not be erased when the computer is

turned off or reset. When the computer is powered on again,

the system will read the settings stored in the CMOS RAM and

compare them to the equipment check conducted during the

power on self-test (POST). If any error or mismatch occurs,

an error message will be shown on the screen and the

computer will be prompted to run the setup program.

To change the BIOS setup, please refer to Chapter 7 for more

information.

2-18

APOLLO 120/150 III

Page 29

User Manual version 2305

2.2.3. Operating System and Driver Installation

The APOLLO III system is not equipped with an operating

system when delivered from the original manufacturer. If

you are a commercial user, the system is likely to have been

pre-installed proper operating system and software drivers

by your dealer or system integrator.

If the system is not pre-installed with any system OS and

drivers or you intend to install your preferred ones, there are

several ways to load OS and software into the system.

1. Via the external FDD or internal FDD

2. Via the CD-ROM

3. Via Ethernet: You can boot up the system via Ethernet

bootrom (optional) and download system OS or software

from the network.

Recent releases of operating systems always include setup

programs that load automatically and guide you through the

installation. You can also refer to your OS user manual for

instructions on formatting or partitioning the hard disk drive

before any software installation.

The APOLLO III system provides the following utility drivers

stored in the CD-ROM diskette or utilities diskettes;

² Ethernet utilities

² VGA utilities

² Audio drivers

² Touchscreen drivers

APOLLO 120/150 III

2-19

Page 30

User Manual version 2305

3-20

APOLLO 120/150 III

Page 31

User Manual version 2305

3. VERSATILE STANDING & MOUNTING OPTIONS

The APOLLO 120/150 is designed for universal

standing and mounting to fit into various

environmental applications. This chapter

highlights the steps of different mounting

options with graphical illustrations. Sections

include

u Versatile Stand

u Wall Mounting

u Panel Mounting

APOLLO 120/150 III

3-21

Page 32

User Manual version 2305

3.1. Versatile Stand

The APOLLO comes with a versatile and functional stand, able

to fit into different environmental application.

3.1.1. Standing Upright

Compact in its size, all-in-one in its design along with its

industrial-grade reliability, the APOLLO system standing

upright is the best replacement for a desktop computer.

When the APOLLO is to stand upright, the two base back

covers can either be assembled or not to be assembled to the

pedestal.

However, if the APOLLO system is to stand upright while the

touchscreen is also frequently used, then it is suggested that

the two base back covers and another knob are assembled

with the pedestal to prevent possible wobbling when the

touchscreen is being used.

3.1.2. 45 to 900 Free Standing

The sleek and sturdy pedestal assembled with the two cable

management covers enables the APOLLO system to endure

the long-time operation in any public sectors. By swiveling

the knob on the left side of the base cover and pulling the

base up and down, the angle can be adjusted from 45 to 900.

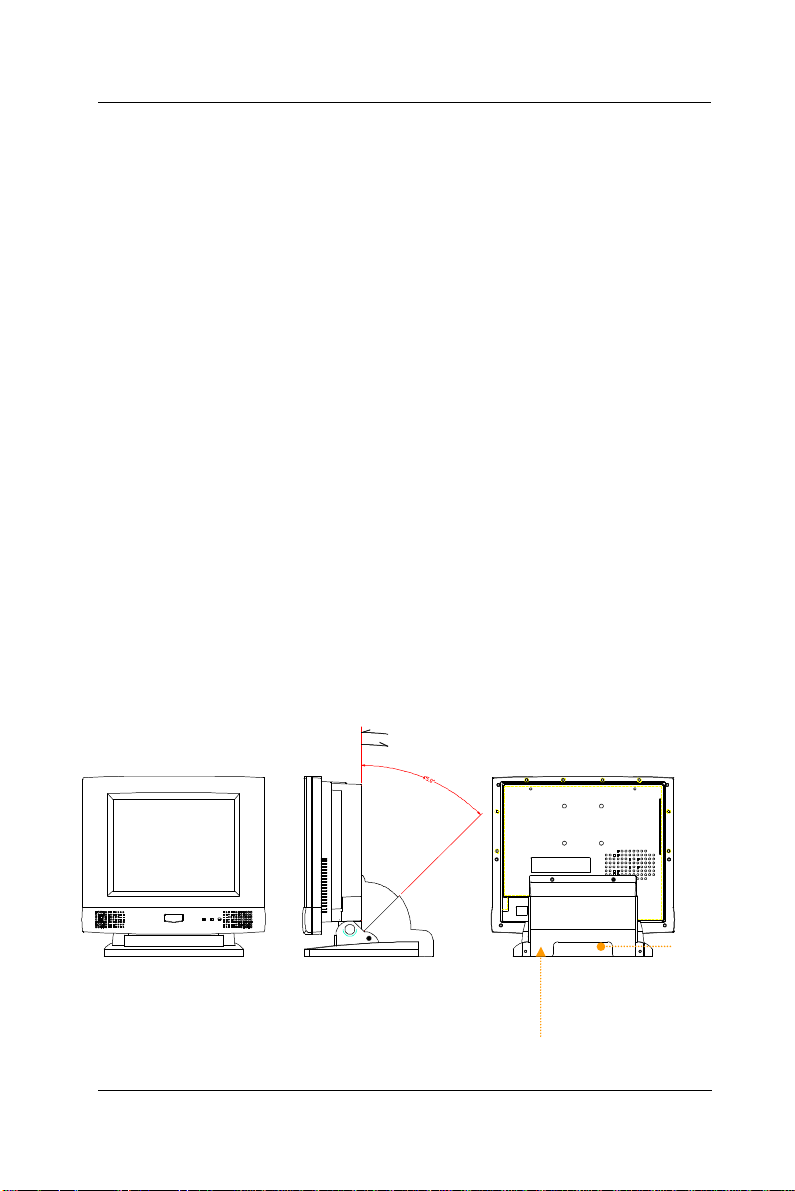

FIGURE 3-1: APOLLO’S VERSATILE STANDING OPTIONS

Cable management cover

3-22

APOLLO 120/150 III

Cable

management

cutout

Page 33

User Manual version 2305

23

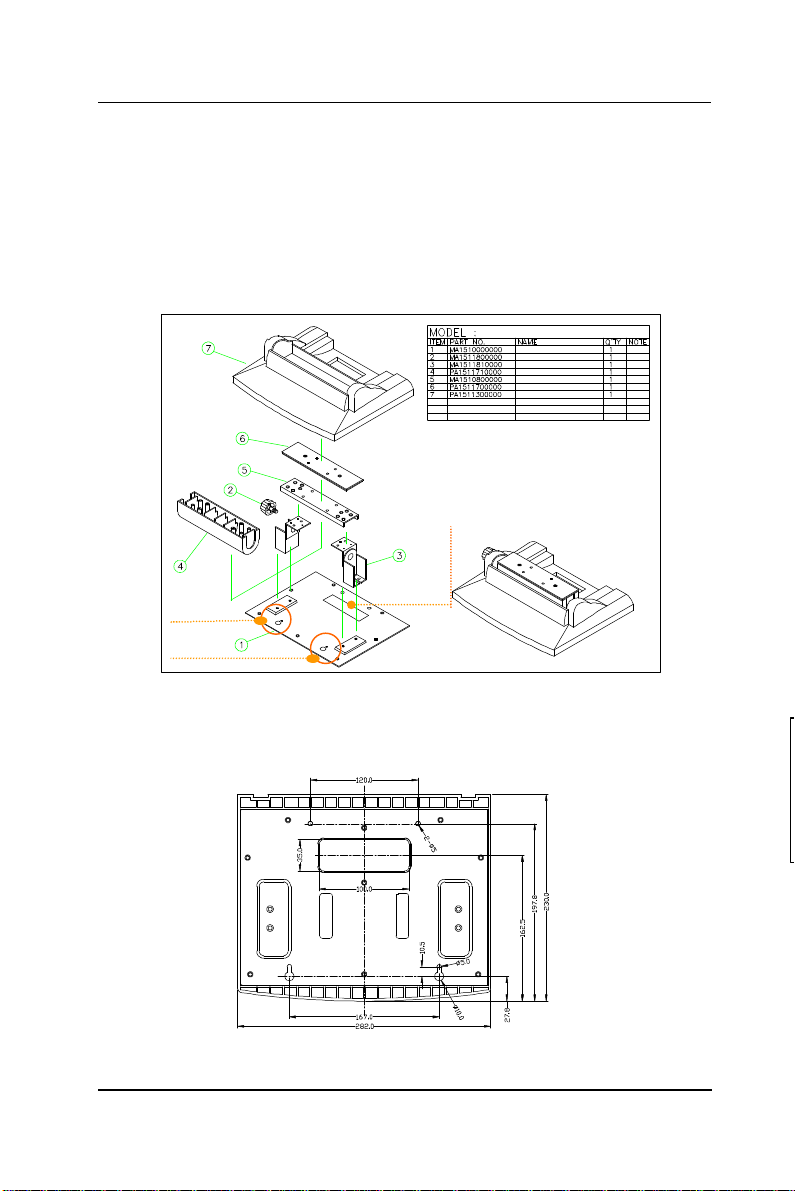

3.1.3. Fixed Standing

At the bottom side of the big pedestal, there are two

avocado-shape holes which are used to fix the APOLLO to the

table with screws. When the APOLLO is fixed to the table, the

angle from the main system to the table can be adjusted from

45 to 900 by swiveling the knob on the left side of the base

cover and pulling the base up and down.

Cable management cutout

Avocadoshape holes

FIGURE 3-2: APOLLO PEDESTAL KIT

The following figure illustrates the distance between the

avocado holes.

APOLLO °ò®y¼Ò²Õ

©³®yÅKªO

HINGE (¥ª) with LOCK

HINGE (¥k)

APOLLO 120/150 Âà¶b-×¹¢¤U»\

Âà¶b¤ä¬[

APOLLO 120/150 Âà¶b-×¹¢¤W»\

APOLLO 120/150 ¶ì½¦©³®y

FIGURE 3-3: APOLLO PEDESTAL BASE AVOCADO HOLES

APOLLO 120/150 III

3-

Page 34

User Manual version 2305

24

3.1.4. Cable Management

The APOLLO’s pedestal is not only a versatile stand but a

functional stand able to manage the system cabling.

1. The rectangle-shape opening (Fig. 3-2) at the bottom

side of the big pedestal can act as a cable management

cutout. All the cables connecting to the I/O ports can

come out from this opening, then down to the table.

2. The two base back covers (Fig. 3-1) can act as a set of

cable management covers. All the cables connecting to

the I/O ports come down in the covers, then out from this

opening at the rear side of the base.

3-

APOLLO 120/150 III

Page 35

25

User Manual version 2305

3.2. Wall Mounting and Mobile Applications

The APOLLO system provides 1 set of VESA mounting holes,

75*75mm on the rear side of the chassis. System integrators

can design their special wall mount brackets per the two sets

of VESA holes or obtain market-available swing arms for wall

mounting, table mounting or mobile applications.

FIGURE 3-4: APOLLO 120 VESA HOLES

APOLLO 120/150 III

3-

Page 36

User Manual version 2305

26

FIGURE 3-5: APOLLO 150 VESA HOLES

FIGURE 3-6 FIGURE 3-7

3-

APOLLO 120/150 III

Page 37

User Manual version 2305

27

3.3. Panel Mounting

The APOLLO system provides a set of optional mounting

brackets for system panel mounting. The following figures

illustrate the way to use the brackets for panel mounting.

FIGURE 3-8

APOLLO 120/150 III

FIGURE 3-9

3-

Page 38

User Manual version 2305

28

3.4. KIOSK Integration

The APOLLO system can also be integrated to a KIOSK

cabinet to make a ready-to-play KIOSK terminal. The

following is an example of APOLLO KIOSK. It is a flexible and

robust device that can be mounted virtually anywhere and in

any forms including tabletop, pedestal, pole and wall

mounting.

HERCULES T

HERCULES M

HERCULES K

3-

HERCULES P

HERCULES PK

APOLLO 120/150 III

Page 39

User Manual version 2305

4. I/O CONNECTION

This chapter describes the APOLLO

system I/O ports and how to use the I/O

interface to connect to external devices.

APOLLO 120/150 III

4-29

Page 40

User Manual version 2305

The I/O interfaces located at the rear side of the chassis are

used to connect external peripheral devices, such as a mouse,

a keyboard, a monitor, serial devices or parallel printer…etc.

Before any connection, make sure that the computer and the

peripheral devices are turned off.

4 2 1

FIGURE 4-1

4.1. Parallel Port

The APOLLO 120/150 can support the latest EPP and ECP

parallel port protocols. It can be used to connect to a wide

array of printers, ZIP drive, parallel scanner and any other

parallel devices. The printer interface on the APOLLO

120/150 III is a 25-pin female D-SUB connector. To connect

any parallel device, follow the steps below:

1. Turn off the system and the parallel devices.

2. Plug in the male connector of the parallel device to the

25-pin female D-SUB connector and fasten the retaining

screws.

3. Turn on the system and the attached parallel devices.

4. Refer to the parallel device’s manual for instruction to

configure the operation environment to recognize the new

attached devices.

5. You may need to run the CMOS setup to change the

hardware device setup.

4-30

APOLLO 120/150 III

Page 41

User Manual version 2305

4.2. COM Ports x 4

The APOLLO 120/150 features with four onboard COM ports.

COM 1, 2 & 4 are D-SUB serial ports located at the rear side

of the chassis, ready to connect to a wide range of serial

devices. COM 3 is internal serial port reserved for

touchscreen for internal connection. COM1, COM3 and COM4

are RS-232 and COM2 is RS-232/422/485, selected via

jumper setting. For COM 2 RS-232/422/485 selection,

please refer to SEC. 6.1.2.

COM 1, 2 & 4 are equipped with +5V/+12V power capabilities

on pin 9, providing easy accommodation to a broad range of

serial devices.

The COM port 5V/12 power is selected via jumper setting on

the IO board. The IO is the signal board attached to the rear

panel with 2 SCSI cables linking to the system motherboard

to connect the onboard signal out to the external I/O ports.

Please refer to SEC. 6.2.2 for 5V/12 power selection.

APOLLO 120/150 III

4-31

Page 42

User Manual version 2305

If a touchscreen module is installed, for factory default

setting, its controller will occupy COM3.

COM1, 2 & COM4 are all D-SUB 9-pin connectors. To connect

to any serial device; follow the procedures below;

1. Turn off the APOLLO system and the serial devices.

2. Attach the interface cable of the serial device to the 9-pin

D-SUB serial connector. Be sure to fasten the retaining

screws.

3. Turn on the computer and the attached serial devices.

4. Refer to the serial device’s manual for instruction to

configure the operation environment to recognize the new

attached devices.

5. If the serial device needs specified IRQ or address, you

may need to run the CMOS setup to change the hardware

device setup.

If the COM2 is to be set to RS-422/485 for long distance

transmission, the related onboard jumpers have to be set

correctly first. Refer to section 6.1.4.3 for the

RS-232/422/485 jumper settings.

4-32

APOLLO 120/150 III

Page 43

User Manual version 2305

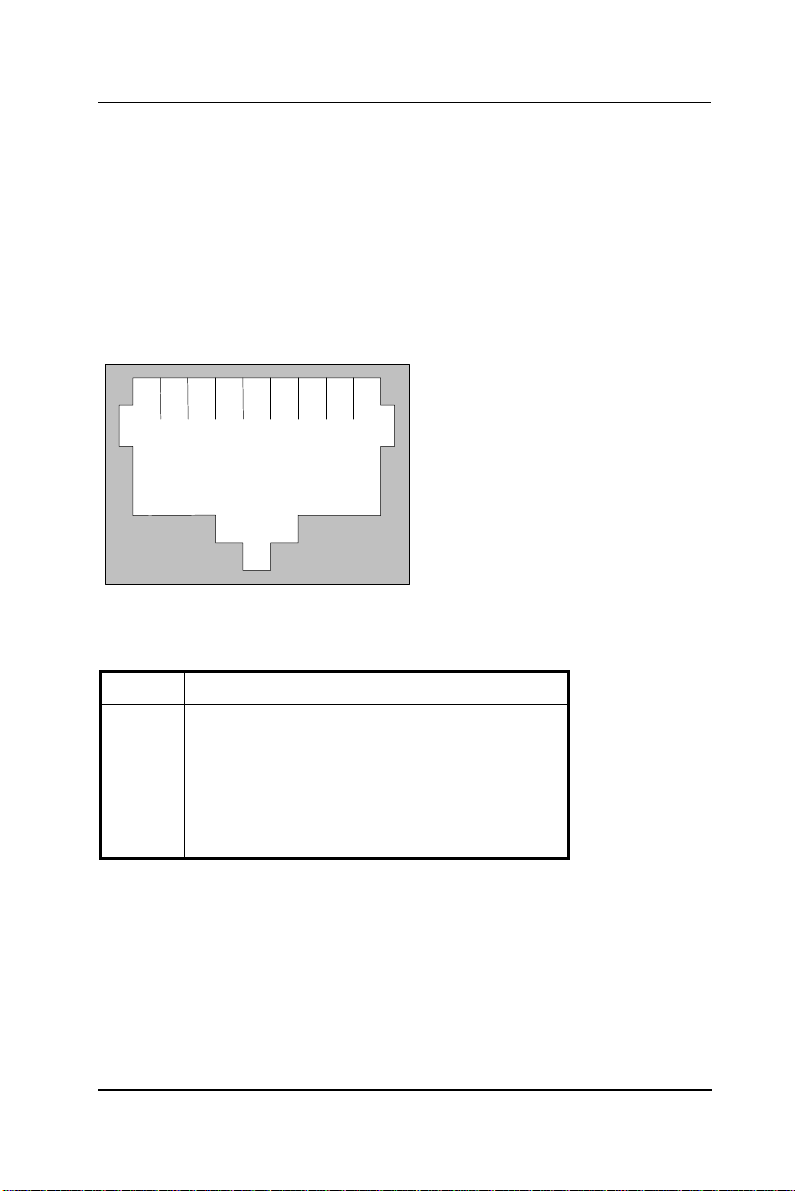

4.3. 100/10 Base-T Ethernet (RJ-45)

The APOLLO 120/150 provides a 100/10 Base-T NE2000

compatible Ethernet (RJ-45) interface. For network

connection, follow the instructions below.

1. Turn of the APOLLO system and the Ethernet hubs.

2. Plug in one end of cable of a 100/10 Base-T hub to the

system’s RJ-45 phone jack. The pin assignment of the

RJ-45 is listed as follow;

1

RJ-45 Connector Pin Assignment

Pin Description

1

2

3

6

others

2 3 4 5 6 7

RJ-45

Tx+ (data transmission positive)

Tx- (data transmission negative)

Rx+ (data reception positive)

Rx- (data reception negative)

No use

8

4.4. VGA Interface

The APOLLO 120/150 has a 15-pin analog RGB connector

located at the rear side of the chassis. It can support its own

LCD display and an expansion CRT or analog monitor at the

same time. The connection to an analog monitor is an easy

plug-in of the VGA D-SUB 15-pin connector to the RGB

interface.

APOLLO 120/150 III

4-33

Page 44

User Manual version 2305

34

4.5. 2nd Display Graphic Support Mode

The APOLLO can support SINGLE DISPLAY MODE and DUAL DISPLAY

MODE. For dual display mode, it can support MIRROR MODE

(same screen) or MULTIPLE-MONITOR MODE (different screens).

PLEASE NOTE THAT THE MULTIPLE-MONITOR MODE ONLY WORKS WHEN

THE OPERATING SYSTEM IS WINDOWS 98 OR WINDOWS ME OR

WINDOWS XP.

The APOLLO itself is onboard with an AGP LCD/VGA

controller. When dual display mode is activated, it can

support a LCD panel (digital TTL) and a CRT or an analog

monitor at either mirror mode or multiple-monitor mode.

The following sections describe all the graphic support modes

based on system memory clock frequency (66MHz, 100MHx

and 133MHz). All these tables apply only to video memory

size is equal or larger than 8MB.

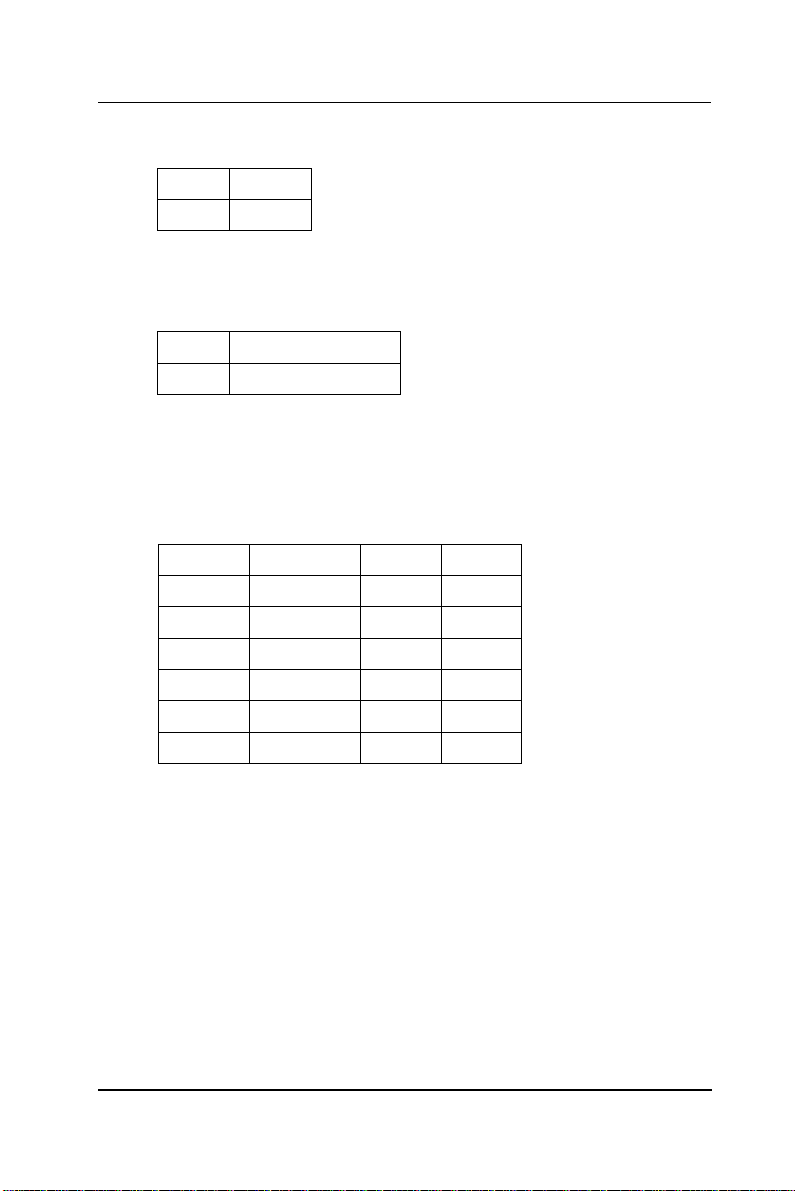

4.5.1. When System Memory Clock = 66MHz

The following tables contain all graphic support modes under

the following condition and are classified under three output

modes (single mode, mirror mode and multiple-monitor

mode).

System memory clock = 66MHz

Memory bus width = 64 bit

Video memory size = 8MB or above

4-

APOLLO 120/150 III

Page 45

35

User Manual version 2305

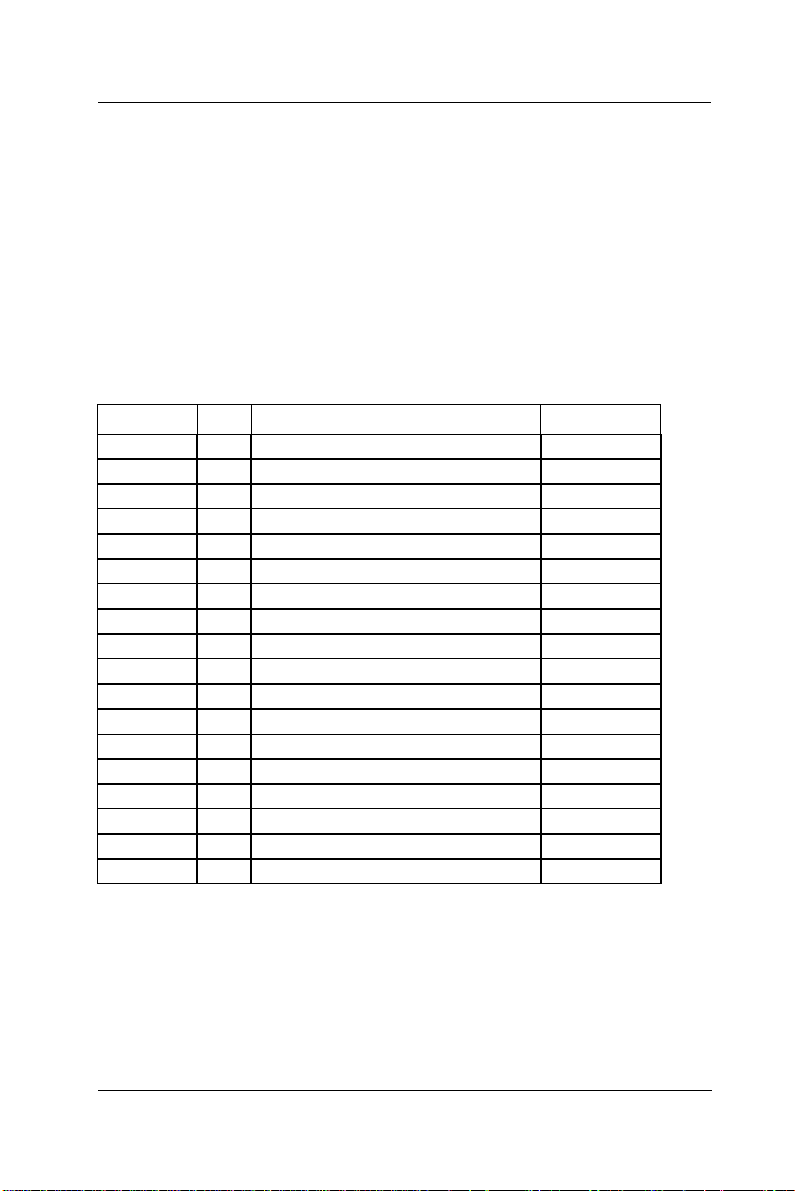

4.5.1.1. Single Display Mode

Resolution Bpp

640*480 8 60, 72, 75, 85, 100, 120, 160, 200 60, 70, 75

16 60, 72, 75, 85, 100, 120, 160, 200 60, 70, 75

32 60, 72, 75, 85, 100, 120, 160 60, 70, 75

800*600 8 56, 60, 72, 75, 85, 100, 120, 160 60, 70, 75

16 56, 60, 72, 75, 85, 100, 120, 160 60, 70, 75

32 56, 60, 72, 75, 85, 100, 120 60, 70, 75

1024*768 8 43, 60, 70, 75, 85, 100, 120 60, 70, 75

16 43, 60, 70, 75, 85, 100, 120 60, 70, 75

32 43, 60, 70, 75

1280*1024 8 43, 60, 75, 85 60

16 43, 60, 75, 85

32 43

1600*1200 8 60, 65, 70, 75, 85

16 60

32

1920*1440 8 60

16

32

CRT1 LCD

APOLLO 120/150 III

4-

Page 46

User Manual version 2305

36

56, 60, 72, 75, 85, 100,

56, 60, 72, 75, 85, 100,

43, 60, 70, 75, 85, 100,

4.5.1.2. Mirror Display Output Mode

When LCD is selected as secondary display at mirror mode:

Resolution Bpp CRT1 at mirror mode LCD at mirror mode

640*480 8 60, 72, 75, 85, 100,

16 60, 72, 75, 85, 100,

32 60, 72, 75, 85, 100 60

800*600 8

16

32

1024*768 8

16

32

60, 70, 75

120, 160, 200

60, 70, 75

120, 160, 200

60, 70, 75

120, 160

60, 70, 75

120

60, 70, 75

120

4-

APOLLO 120/150 III

Page 47

37

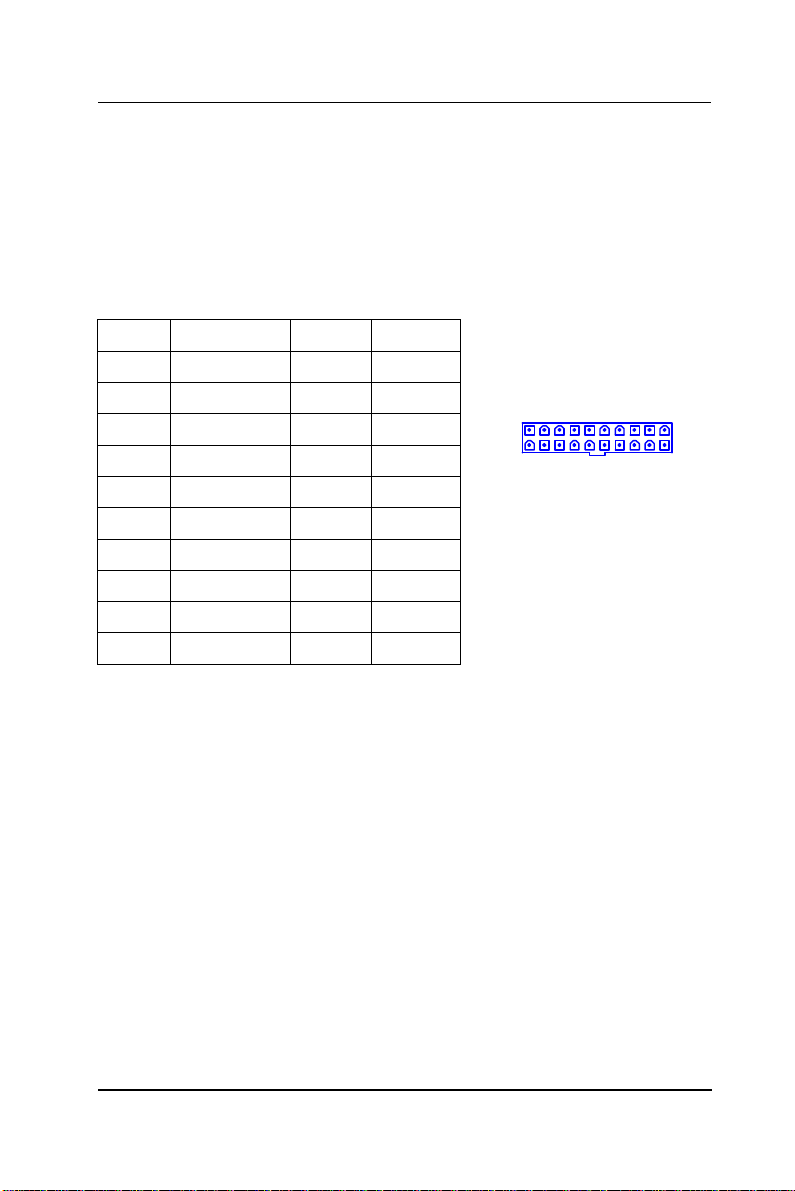

4.5.1.3. Multiple Display Output Mode

56, 60, 72, 75, 85, 100,

56, 60, 72, 75, 85, 100,

43, 60, 70, 75, 85, 100,

When LCD is selected as secondary display at

multiple-monitor mode:

Resolution Bpp CRT1 at MM mode LCD at MM mode

640*480 8 60, 72, 75, 85, 100,

16 60, 72, 75, 85, 100,

32 60, 72, 75, 85, 100 60

800*600 8

16

32 56, 60

1024*768 8

16 43, 60, 70, 75

32 43

1280*1024 8 43, 60, 75, 85

16 43

32

1600*1200 8 60, 65

16

32

User Manual version 2305

60, 70, 75

120, 160, 200

60, 70, 75

120, 160, 200

60, 70, 75

120, 160

60, 70, 75

120

60, 70, 75

120

APOLLO 120/150 III

4-

Page 48

User Manual version 2305

38

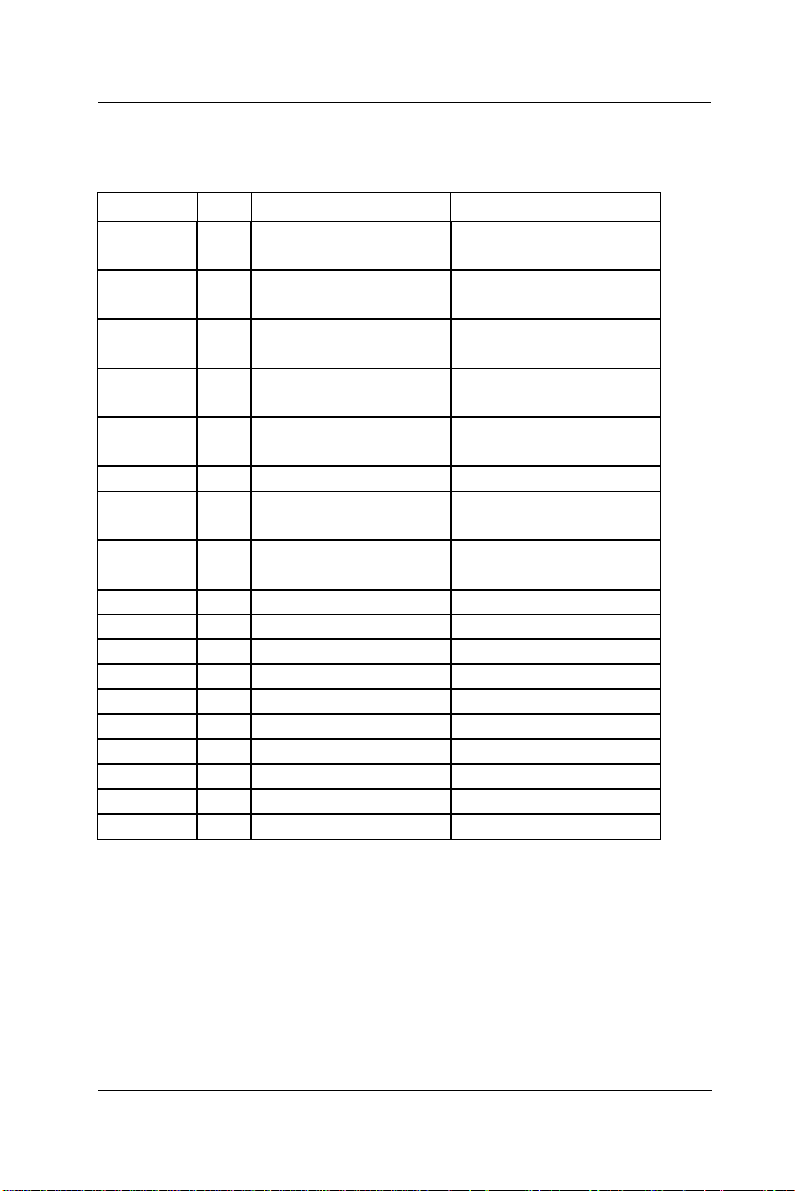

4.5.2. When System Memory Clock = 100MHz

The following tables contain all graphic support modes under

the following condition and are classified under three output

modes (single mode, mirror mode and multiple-monitor

mode).

System memory clock = 100MHz

Memory bus width = 64 bit

Video memory size = 8MB or above

4.5.2.1. Single Display Mode

Resolution Bpp

640*480 8 60, 72, 75, 85, 100, 120, 160, 200 60, 70, 75

16 60, 72, 75, 85, 100, 120, 160, 200 60, 70, 75

32 60, 72, 75, 85, 100, 120, 160, 200 60, 70, 75

800*600 8 56, 60, 72, 75, 85, 100, 120, 160 60, 70, 75

16 56, 60, 72, 75, 85, 100, 120, 160 60, 70, 75

32 56, 60, 72, 75, 85, 100, 120, 160 60, 70, 75

1024*768 8 43, 60, 70, 75, 85, 100, 120 60, 70, 75

16 43, 60, 70, 75, 85, 100, 120 60, 70, 75

32 43, 60, 70, 75, 85, 100 60, 70, 75

1280*1024 8 43, 60, 75, 85 60

16 43, 60, 75, 85 60

32 43, 60

1600*1200 8 60, 65, 70, 75, 85

16 60, 65, 70, 75, 85

32

1920*1440 8 60

16 60

32

CRT1 LCD

4-

APOLLO 120/150 III

Page 49

39

4.5.2.2. Mirror Display Output Mode

56, 60, 72, 75, 85, 100,

56, 60, 72, 75, 85, 100,

43, 60, 70, 75, 85, 100,

43, 60, 70, 75, 85, 100,

When LCD is selected as secondary display at mirror mode:

Resolution Bpp CRT1 at mirror mode LCD at mirror mode

640*480 8 60, 72, 75, 85, 100,

16 60, 72, 75, 85, 100,

32 60, 72, 75, 85, 100,

800*600 8

16

32 56, 60, 72, 75, 85 60

1024*768 8

16

32

User Manual version 2305

60, 70, 75

120, 160, 200

60, 70, 75

120, 160, 200

60, 70, 75

120, 160

60, 70, 75

120, 160

60, 70, 75

120, 160

60, 70, 75

120

60, 70, 75

120

APOLLO 120/150 III

4-

Page 50

User Manual version 2305

40

56, 60, 72, 75, 85, 100,

56, 60, 72, 75, 85, 100,

43, 60, 70, 75, 85, 100,

43, 60, 70, 75, 85, 100,

4.5.2.3. Multiple Display Output Mode

When LCD is selected as secondary display at

multiple-monitor mode:

Resolution Bpp CRT1 at MM mode LCD at MM mode

640*480 8 60, 72, 75, 85, 100,

16 60, 72, 75, 85, 100,

32 60, 72, 75, 85, 100,

800*600 8

16

32 56, 60, 72, 75, 85 60

1024*768 8

16

32 43, 60

1280*1024 8 43, 60, 75, 85

16 43, 60, 75

32

1600*1200 8 60, 65, 70, 75, 85

16

32

1920*1440 8 60

16

32

60, 70, 75

120, 160, 200

60, 70, 75

120, 160, 200

60,70, 75

120, 160

60, 70, 75

120, 160

60, 70, 75

120, 160

60, 70, 75

120

60, 70, 75

120

4-

APOLLO 120/150 III

Page 51

User Manual version 2305

41

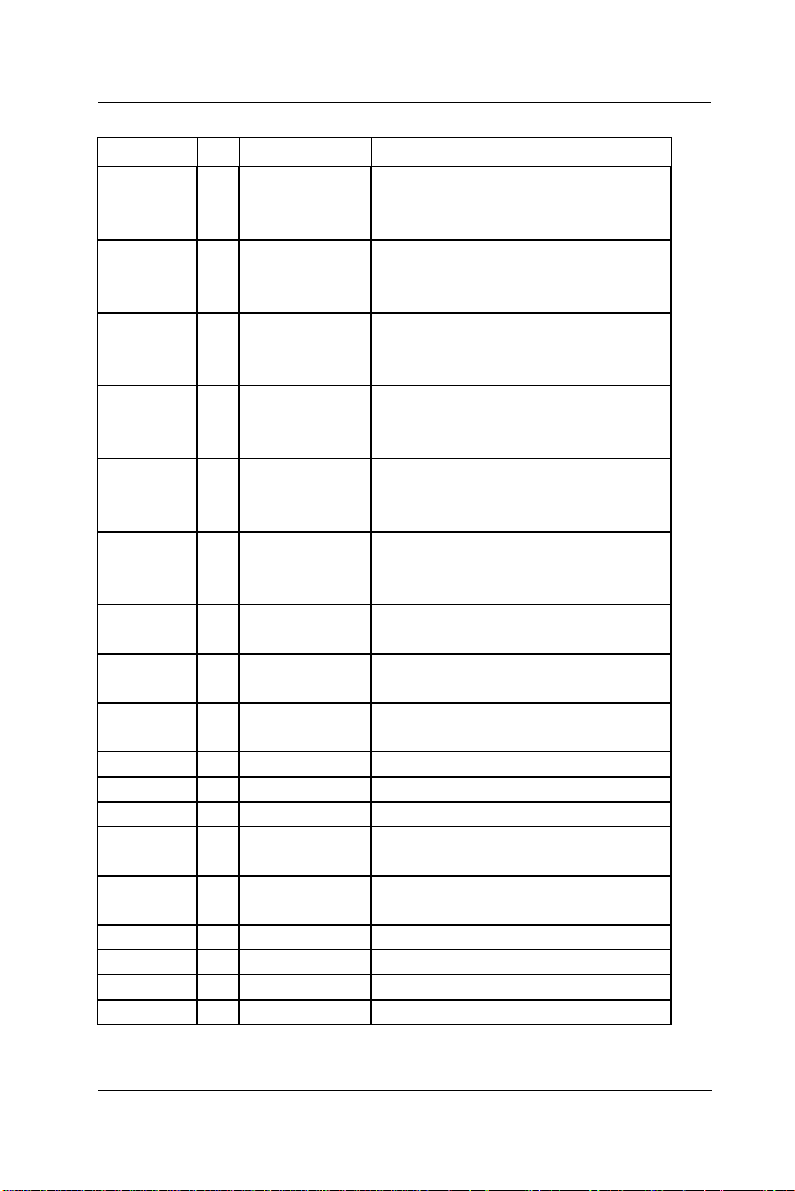

4.5.3. When System Memory Clock = 133MHz

The following tables contain all graphic support modes under

the following condition and are classified under three output

modes (single mode, mirror mode and multiple-monitor

mode).

System memory clock = 133MHz

Memory bus width = 64 bit

Video memory size = 8MB or above

APOLLO 120/150 III

4-

Page 52

42

User Manual version 2305

4.5.3.1. Single Display Mode

Resolution Bpp

640*480 8 60, 72, 75, 85,

16 60, 72, 75, 85,

32 60, 72, 75, 85,

800*600 8 56, 60, 72, 75,

16 56, 60, 72, 75,

32 56, 60, 72, 75,

1024*768 8 43, 60, 70, 75,

16 43, 60, 70, 75,

32 43, 60, 70, 75,

1280*1024 8 43, 60, 75, 85 60

16 43, 60, 75, 85 60

32 43, 60, 75, 85 60

1600*1200 8 60, 65, 70, 75,

16 60, 65, 70, 75,

32 60

1920*1440 8 60

16 60

32

CRT1 LCD

60, 70, 75

100, 120, 160,

200

60, 70, 75

100, 120, 160,

200

60, 70, 75

100, 120, 160,

200

60, 70, 75

85, 100, 120,

160

60, 70, 75

85, 100, 120,

160

60, 70, 75

85, 100, 120,

160

60, 70, 75

85, 100, 120

60, 70, 75

85, 100, 120

60, 70, 75

85, 100, 120

85

85

4-

APOLLO 120/150 III

Page 53

43

4.5.3.2. Mirror Display Output Mode

56, 60, 72, 75, 85, 100,

56, 60, 72, 75, 85, 100,

56, 60, 72, 75, 85, 100,

43, 60, 70, 75, 85, 100,

43, 60, 70, 75, 85, 100,

When LCD is selected as secondary display at mirror mode:

Resolution Bpp CRT1 at mirror mode LCD at mirror mode

640*480 8 60, 72, 75, 85, 100,

16 60, 72, 75, 85, 100,

32 60, 72, 75, 85, 100,

800*600 8

16

32

1024*768 8

16

32

User Manual version 2305

60, 70, 75

120, 160, 200

60, 70, 75

120, 160, 200

60, 70, 75

120, 160, 200

60, 70, 75

120, 160

60, 70, 75

120, 160

60, 70, 75

120

60, 70, 75

120

60, 70, 75

120

APOLLO 120/150 III

4-

Page 54

User Manual version 2305

44

56, 60, 72, 75, 85, 100,

56, 60, 72, 75, 85, 100,

56, 60, 72, 75, 85, 100,

43, 60, 70, 75, 85, 100,

43, 60, 70, 75, 85, 100,

4.5.3.3. Multiple Display Output Mode

When LCD is selected as secondary display at

multiple-monitor mode:

Resolution Bpp CRT1 at MM mode LCD at MM mode

640*480 8 60, 72, 75, 85, 100,

16 60, 72, 75, 85, 100,

32 60, 72, 75, 85, 100,

800*600 8

16

32

1024*768 8

16

32 43, 60, 70, 75

1280*1024 8 43, 60, 75, 85

16 43, 60, 75, 85

32 43

1600*1200 8 60, 65, 70, 75, 85

16 60, 65

32

1920*1440 8 60

16

32

60, 70, 75

120, 160, 200

60, 70, 75

120, 160, 200

60,70, 75

120, 160, 200

60, 70, 75

120, 160

60, 70, 75

120, 160

60, 70, 75

120

60, 70, 75

120

60, 70, 75

120

4-

APOLLO 120/150 III

Page 55

User Manual version 2305

45

4.6. PS/2 Keyboard Interface

The APOLLO provides a standard PS/2 keyboard connector

located at the rear panel. If the user would like to use AT

keyboard, then an adapter to connect the PS/2 KB to AT KB is

needed.

4.7. PS/2 Mouse Interface

The APOLLO system has one PS/2 mouse connector located

at the rear side. A simple plug-in will make the connection.

APOLLO 120/150 III

4-

Page 56

User Manual version 2305

46

1

2

3

4

5

6

7

8

9

1

0

out connector when an external floppy

4.8. External FDD (DB-15)

The APOLLO 120/150 provides two ways to connect to a

floppy disk drive to fit into specific environmental

applications:

1. Internal FDD

2. External FDD

If the FDD is frequently used, it is suggested to use an

internal floppy disk drive. If the drive is used only for system

installation or maintenance, then, an external device can

fulfill this need and is more economical. Please note that if an

internal floppy disk drive already exists, no external floppy

drive can be used.

The APOLLO external FDD interface is a 15-pin D-sub

connector located at the rear side of the chassis. An external

FDD cable is provided to connect a standard 3.5” FDD to the

system. Its pin position and pin assignment are listed as

follows.

Pin # Signal Pin #

1 DELSEL

2 -INDEX

3 -MTR1

4 -DVR1

5 -DIR 13 -DSKCHG

6 -WP 14 +5V

7 -TRKO

8 -WG

The APOLLO system is equipped with a

+5V/12V DC-out connector to provide 5V

power to drive the external floppy disk

drive. Use the provided FDD power cable

to connect the floppy drive to the 5V

DCdrive is attached to the system.

4-

9 -WD

10 -STEP

11 -RD

12 -HDSEL

15 +12V

Signal

11

12

13

14

15

APOLLO 120/150 III

Page 57

User Manual version 2305

47

4.9. +5V/12V DC-Out

The APOLLO system provides a +5V/12V DC-out connector.

It is used to provide necessary power source for some

external devices. For example, if the APOLLO III system is to

be housed in a KIOSK cabinet which requests extra cooling

fan for heat dispensing, then the fan power cable can be

attached to 5V/12V DC-out to obtain power from the

computer directly. If an external floppy disk drive is attached

to the system, it will need +5V power source from the system.

A power cable for the external floppy disk drive is already

provided for this connection. For other devices, you might

need to make your own power cable for the connection.

4.10. VR Brightness Control

The APOLLO system provides a VR control to adjust the

brightness of the LCD. The VR control is with a “+” shape

cutout on it. You will need a “+” shape screwdriver to adjust

it for display brightness control.

APOLLO 120/150 III

4-

Page 58

User Manual version 2305

48

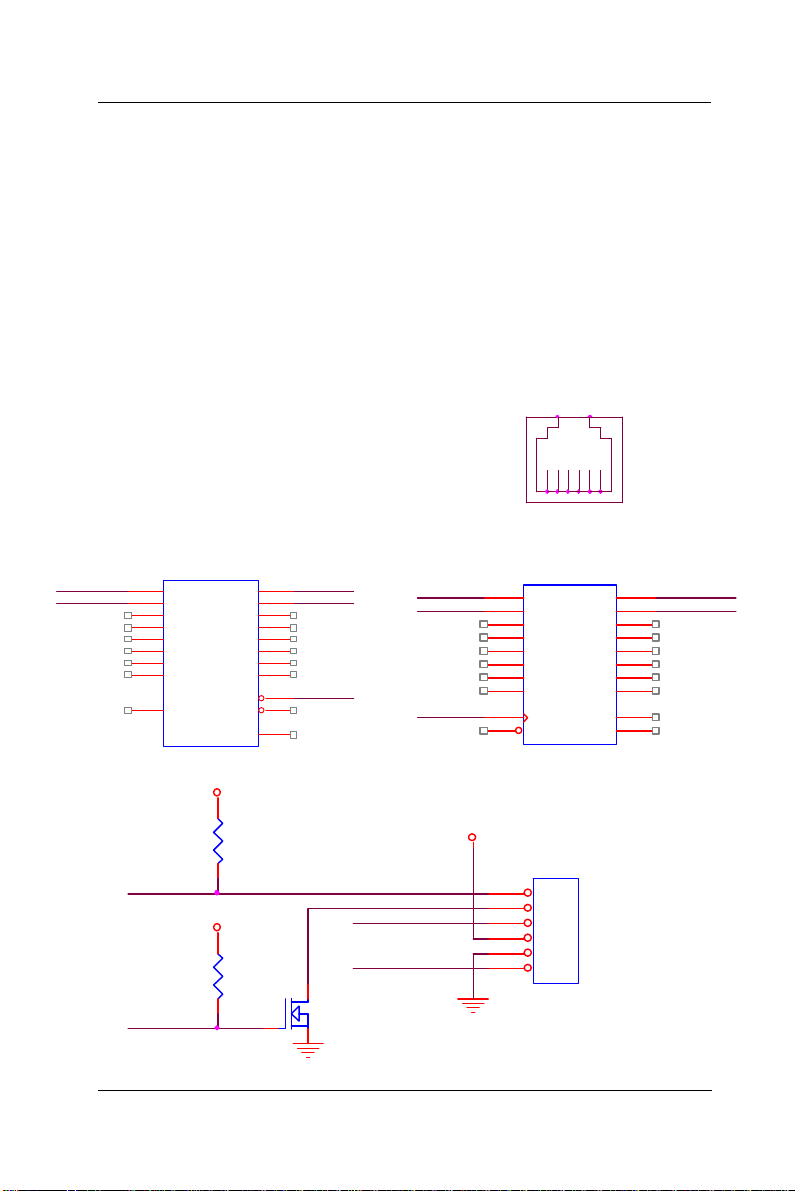

4.11. DIO (Digital Input & Output)

The APOLLO III provides 2-channel digital input and output

that can be used for the system’s simple automation control

needs. The digital I/O can be configured to control the

opening of a cash drawer or to sense the warning signal of an

uninterrupted power system (UPS) or to do the store security

control.

The DIO port address and pin definition is listed below;

I/O Port address: 208H

Read: SD0, SD1

Write: SD4, SD5

IO 208H(READ)

IO 206H(READ)

74LS244

VCC5

1A11Y1

1A21Y2

1A31Y3

1A41Y4

2A12Y1

2A22Y2

2A32Y3

2A42Y4

GND

218

416

614

812

119

137

155

173

-IOR206H

1

1G

1920

2GVDD

10

SD0 IN_0

SD1 IN_1

OUT_0

4.7K

VCC5

OUT_1

4.7K

IN_0

IN_1

MOSFET N

SD4

SD5

-IOW206H

VCC12

DIO1

RJ11

1 2 3 4 5 6

IO 208H(WRITE)

IO 206H(WRITE)

13

14

17

18

11

3

4

7

8

1

D1

D2

D3

D4

D5

D6

D7

D8

CLK

CLR

74LS273

1

2

3

4

5

6

VCC

GND

Q1

Q2

Q3

Q4

Q5

Q6

Q7

Q8

DIO1

RJ11

2

5

6

9

12

15

16

19

20

10

OUT_0

OUT_1

4-

APOLLO 120/150 III

Page 59

User Manual version 2305

49

The Digital I/O is of TTL interface. It is controlled via

software programming.

Digital I/O Programming

Input/output address: 208H

In_Data 0~3=SD0~SD1

Out_Data 0~3 SD4~SD7

EXAMPLE:

10 REM Digital I/O example program

20 X = INP (&H208) REM INPUT Digital I/O port

for 4 bit

30 X = OUT (&H208) REM OUTPUT Digital I/O port

for 4 bit

60 END

100 Return

Port 208H Definition

APOLLO 120/150 III

4-

Page 60

User Manual version 2305

50

4.12. Audio Interface (Line-in, MIC-in, SPK-out)

The audio interface contains three jacks, microphone-in,

line-in and speaker-out.

The microphone-in jack is used to record sound or voice by

connecting to an external microphone. The line-in jack is

used to input audio from an external audio device such as a

CD player, tape recorder or a radio. The speaker-out jack is

to output the audio to external devices such as speakers or

earphones. The audio device can be directly attached to the

jacks. Please note that the audio driver has to be installed

first before using any audio device.

4.13. USB Ports

The APOLLO 120/150 III also provides two USB ports to

connect to external USB devices. A simple plug-in of the USB

device interface cable to the USB port will make the

connection. Before using the USB devices, remember to

install the device driver first.

4.14. IR Keyboard Sensor (optional)

The APOLLO III features with an optional IR keyboard sensor.

The IR KB sensor containing wireless KB firmware is located

at the front bezel. To use the wireless keyboard, please note

that the APOLLO III IrKB sensor on the front bezel and the

wireless keyboard sensor have to face each other at the same

horizontal level and the distance of the IR transceiver and

receiver should not exceed 1 meter.

4.15. AC/DC Inlet/Power Switch

For APOLLO 120/150 III AC system, it can operate in the

input range from 100 ~ 240 volts, 50 ~ 60 Hz. For DC system,

the input range can be from 18V to 72V with different power

supply.

4-

APOLLO 120/150 III

Page 61

User Manual version 2305

51

5. HARDWARE INSTALLATION AND UPGRADE

This chapter overviews the installation of the

APOLLO III’s internal components and devices.

This chapter is for service engineers not for the

end user. Sections include:

u The exploded diagram

u Motherboard assembly

u Touchscreen controller

u LCD module assembly

u Front Bezel assembly

u HDD module assembly

u CD-ROM/FDD assembly

u Power module assembly

u Expansion slots

u Stand assembly

APOLLO 120/150 III

5-

Page 62

User Manual version 2305

52

The APOLLO 120/150 III consists of a Celeron/ Pentium® III

multimedia motherboard with an adequate CPU and relevant

SDRAM on it. The system control board and other internal

devices such as expansion card, HDD and power supply are

already housed in a plastic rear cover. The system’s

performance depends on the installed CPU and the capacity

of the system memory and hard disk drive. In some

circumstances, you might intend to upgrade or maintain the

system. By removing the rear cover and the metal covers,

the internal components such as CPU, SDRAM, HDD, internal

FDD, CD-ROM and power supply can be easily accessed for

maintenance and upgrade.

The APOLLO is composed of 10 major modules. The

installation procedure is also listed as below.

1. Motherboard module

2. Touchscreen controller module

3. HDD module

4. LCD module

5. Front bezel module

6. CD-ROM/FDD module

7. Power supply module

8. Expansion slot module

9. Back panel module

10. Stand module

To disassemble the system module for maintenance, the

procedure is from step 10 to 1.

5-

APOLLO 120/150 III

Page 63

User Manual version 2305

53

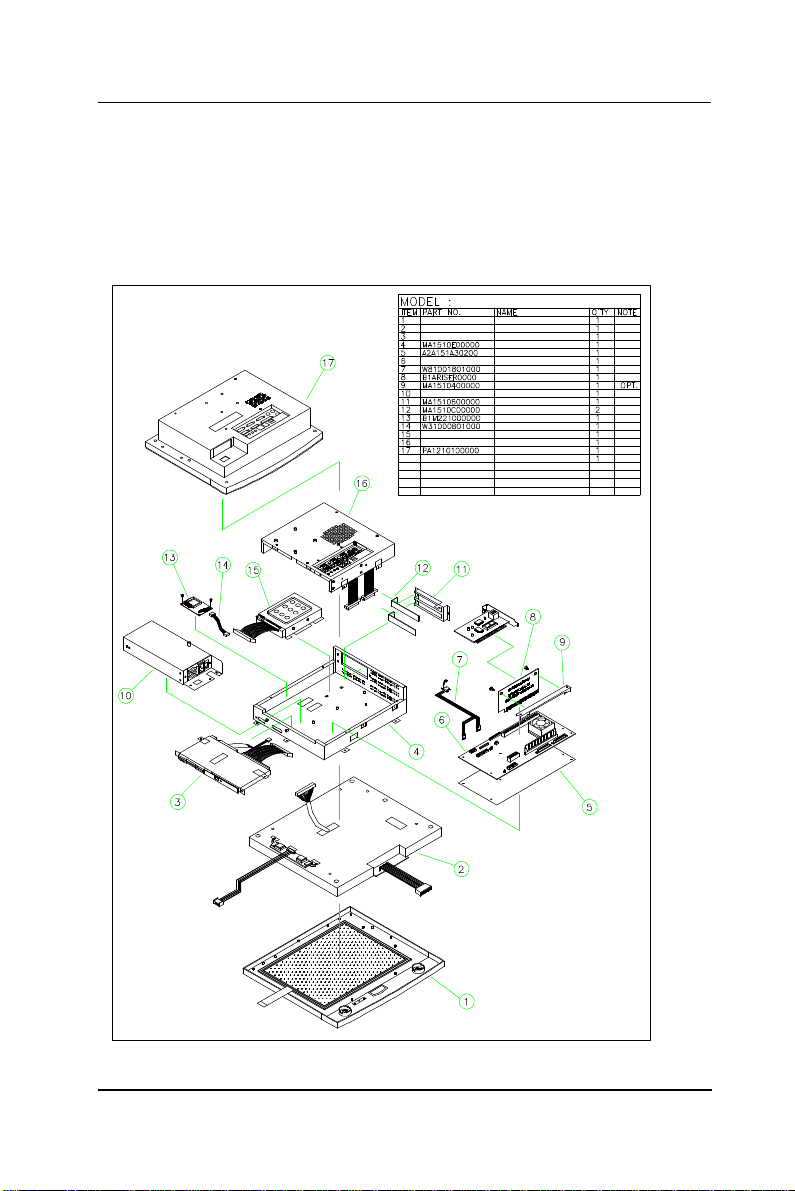

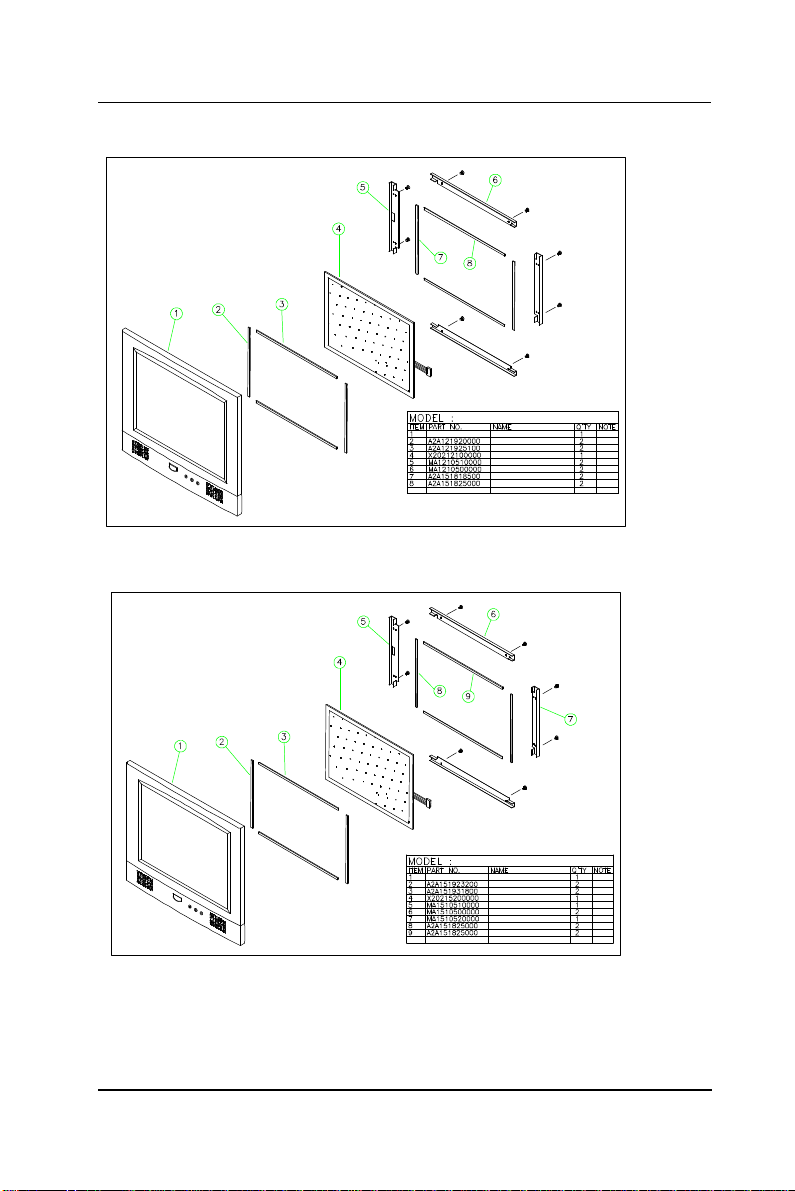

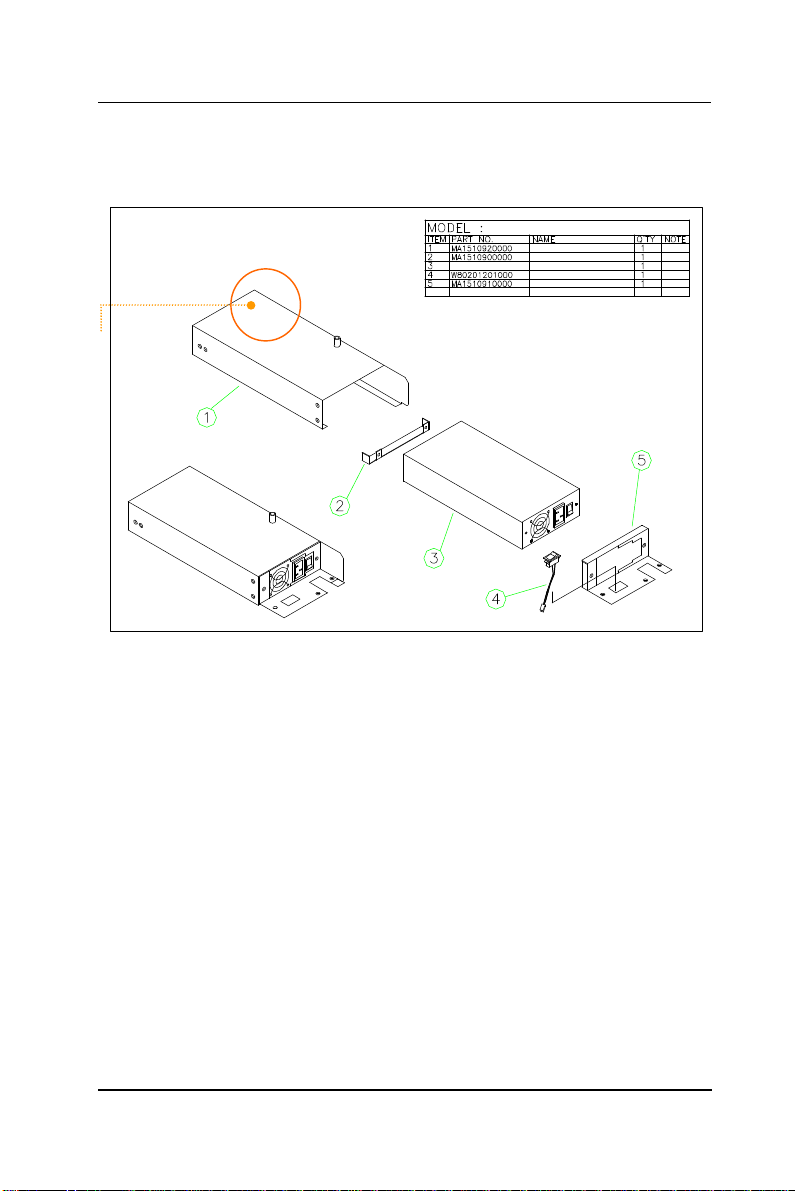

XPLODED DIAGRAM

5.1. Recognizing the System Major Parts

In terms of LCD size, the APOLLO has two models, one 12.1”

and the other 15.1”. The assembly of the two models is

basically the same except the LCD assembly. The following

diagram highlights the system major parts that make up the

APOLLO 120 main system.

FIGURE 5-1: APOLLO 120 E

APOLLO 120 ¥DÅé²Õ«~

APOLLO 120 -±ªO²Õ«~

APOLLO 120 LCD²Õ«~

CDROM-FDD²Õ«~

½cÅé

¥D¾÷ªOµ´½t¤ù302*148*0.35

PC620 ¼Ò²Õ A1.0

POWER CABLE ¤j4P-¤p4P*2-2P 180mm

MODULE APOLLO RISER A1.0

RISER CARD¸É±j±ì

POWER ²Õ«~

«áµ¡

µL¤ÕÅK¤ù

MODULE M2210 A1.0

TOUCH COM3 CABLE 80mm

HDD ²Õ«~

ÅK¥ó«á»\²Õ«~

APOLLO 120¶ì½¦«á»\

APOLLO 120/150 III

5-

Page 64

User Manual version 2305

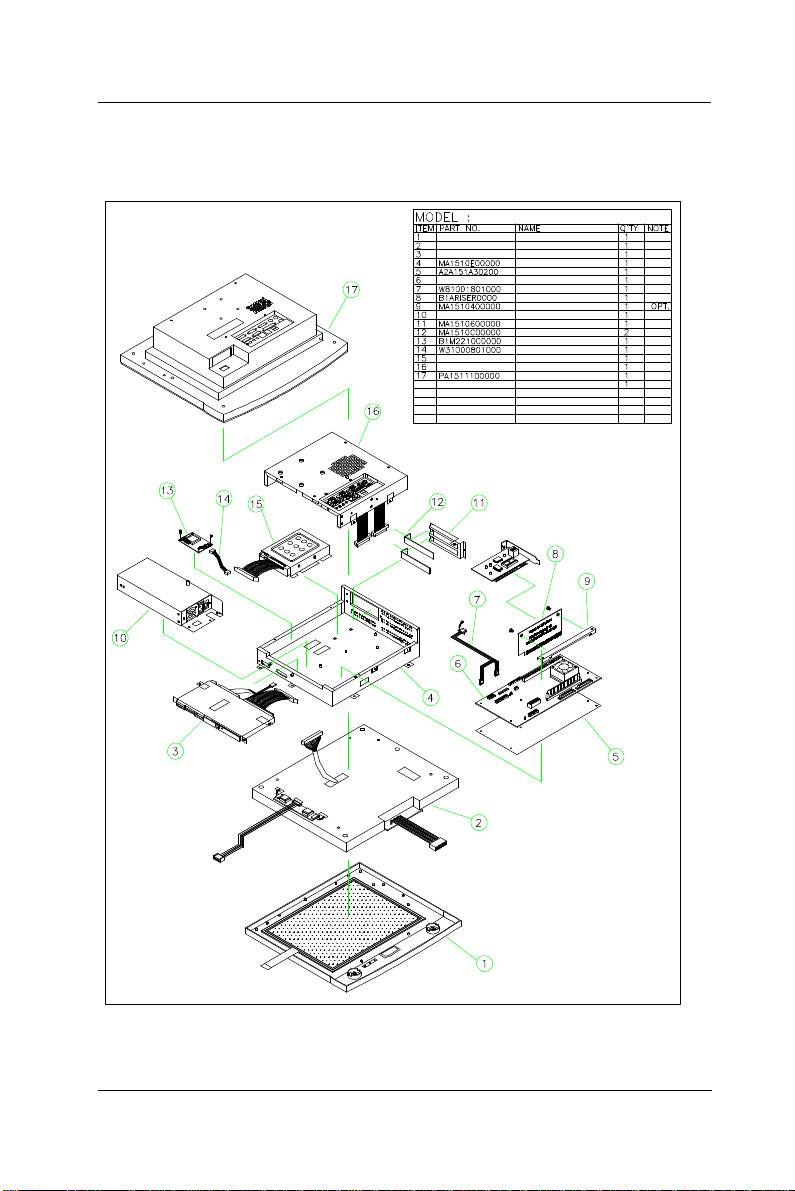

54

The following diagram shows the system major parts that

make up the APOLLO 150 main system.

APOLLO 150 ¥DÅé²Õ«~

APOLLO 150 -±ªO²Õ«~

APOLLO 150 LCD²Õ«~

CDROM-FDD²Õ«~

½cÅé

¥D¾÷ªOµ´½t¤ù302*148*0.35

PC620 ¼Ò²Õ A1.0

POWER CABLE ¤j4P-¤p4P*2-2P 180mm

MODULE APOLLO RISER A1.0

RISER CARD¸É±j±ì

POWER ²Õ«~

«áµ¡

µL¤ÕÅK¤ù

MODULE M2210 A1.0

TOUCH COM3 CABLE 80mm

HDD ²Õ«~

ÅK¥ó«á»\²Õ«~

APOLLO 150¶ì½¦«á»\

5-

FIGURE 5-2: APOLLO 150 EXPLODED DIAGRAM

APOLLO 120/150 III

Page 65

User Manual version 2305

55

5.2. Installing the CPU

The APOLLO III can adapt Socket 370 Intel Celeron or

Pentium III CPU. Upgrading the CPU can increase the system

performance. When Pentium III 1GB 133MHz is used with

the system, it is suggested to attach another system cooling

fan at the right side of the system compartment to prevent

the system from overheating.

The APOLLO’s motherboard provides one 370-pin ZIF socket

(Socket 370). The CPU must come with a CPU fan with a heat

sink on to avoid overheating.

To install a CPU or upgrade a new CPU, follow the instructions

below.

1. If there is an existing CPU on the socket, remove the CPU

cooling fan first. Then remove the CPU by pulling the

lever out a little and raising it, then lifting out the existing

CPU from the socket.

2. To insert the CPU into the socket, the notch on the corner

of the CPU (the corner with golden dot) should point

toward the end of the socket lever. If the insertion of the

CPU to the socket is not easy, check whether the CPU pins

correspond with the holes on the socket.

3. After insert the CPU into the socket, pull the lever down to

make sure the CPU is in place.

4. The CPU cooling fan comes with a 3-pin power cable.

Connect the power cable to the 3-pin power connector,

FAN1 on the motherboard.

5. There are two white clips on the CPU socket. Make sure

the cooling CPU fan clips click into place.

3-pin CPU fan power connector

CPU socket

APOLLO 120/150 III

FIGURE 5-3

5-

Page 66

User Manual version 2305

56

5.3. Installing the SDRAM Memory Module

The APOLLO 120/150 III system control board provides 1 x

168-pin DIMM socket, able to support SDRAM memory from

32MB up to 512MB. To install the memory module, follow the

instructions below.

1. Find the 168 pin DIMM socket on the motherboard

2. There are two white eject levers at each end of the DIMM

socket. Push them outward until they separate from the

two vertical posts.

3. Holding the memory module with the notch on the upper

right corner, then insert the memory module into the

DIMM socket at 90° angle.

4. Push the two eject levers toward the vertical posts until

they click into place. The memory module is now

upright.

The system is able to auto detect the new memory size and

there is no need to change the system configuration after

installation.

Make sure that the memory module you are using can handle

the specified SDRAM MHz. Inadequate memory module will

make the computer unable to boot up.

5-

APOLLO 120/150 III

Page 67

User Manual version 2305

57

5.4. Motherboard Assembly

The motherboard is the first component to be assembled to

the system compartment. Follow the steps below to

assemble the motherboard to the system chassis. Make sure

the CPU with cooling fan and SDRAM are already properly

installed to the motherboard before the motherboard is

attached to the system chassis. (Refer to Sec. 5-2 and 5-3 for

CPU and SDRAM installation).

1. The lower side of the chassis has a rectangle opening at

the bottom of the chassis. Make the lower side of the

chassis to be near you.

2. From your point of view, the motherboard module is to be

installed to the lower side of the system compartment.

3. Tape the motherboard insulator (5) (Fig. 5-1 & 5-2 (5)) to

the motherboard (6) first. The insulator is to separate the

electronic components on the reverse side of the

motherboard from the metal compartment to prevent

short circuitry caused during system operation.

4. Fix the motherboard (6) to the chassis with 7 PMS

anti-fallen 3*6 screws.

5. The IR/LED 2*13-pin cable (Fig. 5-7 (7) & Fig. 5-8 (5)) has

to go through the rectangle opening located at the bottom

side of the chassis, then connected to motherboard’s J9,

the HDD LED & ACPI LED & SMI connector.

APOLLO 120/150 III

5-

Page 68

User Manual version 2305

8

5.5. Touch Controller Assembly

If a touchscreen is integrated with the system, the

touchscreen controller is to be installed right after the

installation of the motherboard.

For easy maintenance in the future, the controller is to be

installed to a bracket rather than to the system compartment

directly. From your point of view, there is a rectangle opening

at the left upper side of the chassis. Insert the touch

controller bracket to the opening and retain it to the chassis

with 2 FMS 3*5 screws.

For easy assembly, the related cables are to be connected

first.

1. For Elo touch, the touchscreen cable (Fig. 5-1. (14)) is a

2*5-pin to 2*5-pin flat cable. One end is connected to the

touchscreen controller first.

2. There is a 2-pin (black & red) cable to provide the power

source for the touchscreen. Connect one end to the

controller.

3. Connect the other end of the 2*5-pin to 2*5-pin flat cable

to the onboard COM 3 box header connector and connect

the other end of the 2-pin power cable to the

motherboard’s PWR1.

4. Fix the touchscreen controller (13) to the bracket with 2

PMS 3*6 screws.

5. Fold both cables properly.

6. Make sure the two screws at the outward upper side of the

chassis are also properly fixed.

5-5

APOLLO 120/150 III

Page 69

User Manual version 2305

59

5.6. HDD Module Assembly

The APOLLO provides enough space to build in a 3.5” hard

disk drive in the system compartment. The following steps

show the way to install an internal hard disk drive.

1. Make the chassis lower side near you. Now, from your

point of view, the 3.5" HDD module is to be installed to the

right upper side of the system compartment.

2. Refer to Figure 5-4. Fix the hard disk drive (1) to the HDD

bracket (3) with one FTS 3*5 screw.

3. Connect the one end of the 40-pin IDE cable (2) to hard

disk drive.

4. There are two clips at the bottom of the compartment used

to hold the HDD module to the system compartment.

Insert the HDD module to the compartment and clip it into

place. Fix the HDD module to the chassis with one 3*5

FMS screw outside of the right upper side of the chassis.

5. Make sure the other end of the 40-pin IDE cable is

connected to the motherboard IDE 1 connector.

HDD ²Õ«~

HDD

HDD CABLE 220mm

HDD ¬[

FIGURE 5-4: HDD INSTALLATION

APOLLO 120/150 III

5-

Page 70

User Manual version 2305

60

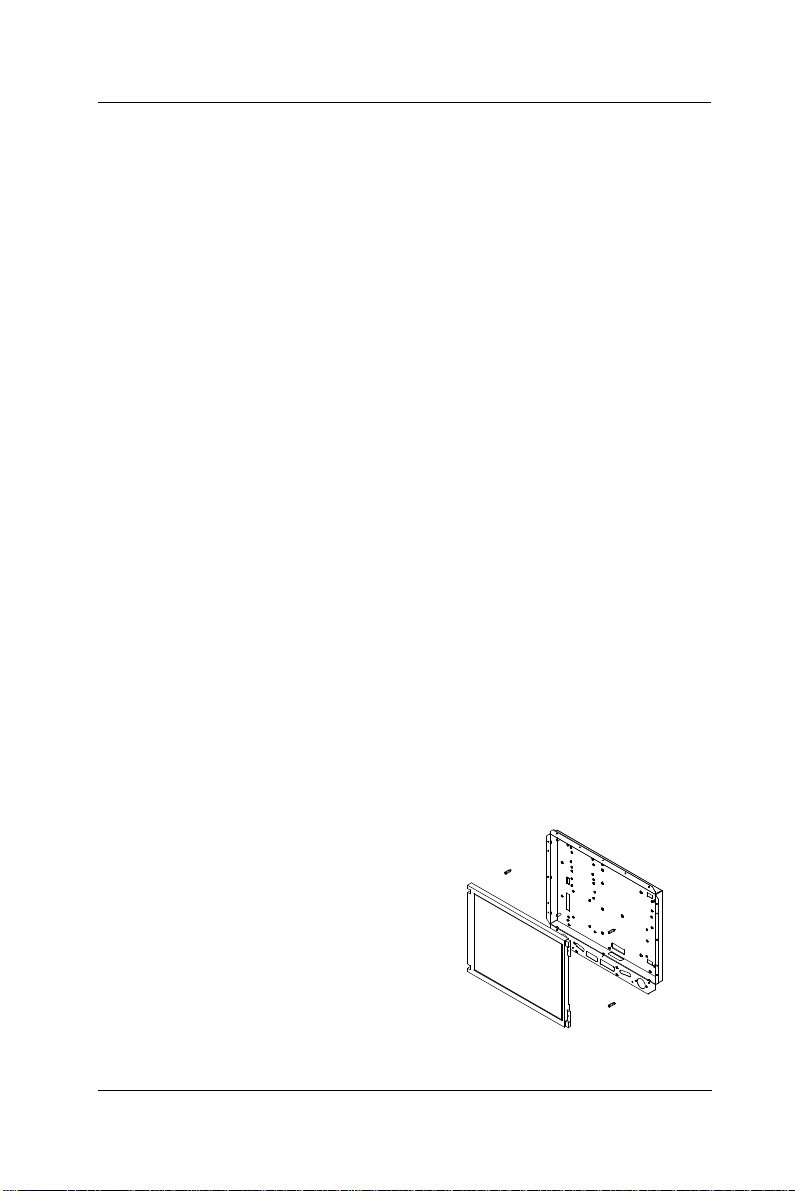

5.7. Touchscreen or Front Bezel Assembly

The APOLLO is able to accommodate Elo analog resistive

touch or Intelli (SAW) touch or MicroTocu capacitive

touchscreen. PLEASE NOTE THAT WHEN DIFFERENT TOUCH MODULE IS

INSTALLED, DIFFERENT TOUCHSCREEN METAL BRACKETS ARE NEEDED.

YOU CAN NOT REPLACE ONE TYPE OF TOUCH PANEL WITH THE OTHER

WITHOUT CHANGING THE TOUCHSCREEN METAL BRACKETS USED TO HOLD

THE TOUCH PANEL TO THE FRONT BEZEL.

The following steps illustrate the ways to assemble the

toucshcreen to the front bezel.

1. There are 4 rubber slips with one-side taped with glue.

Glue the 4 slips to the gutters located at the reverse side

of the plastic front bezel. The 4 rubber slips act as

cushions to absorb the pressure when the touchscreen is

fixed to the front bezel with screws.

2. There are 4 metal brackets used to fix the touchscreen to

the front bezel. The metal brackets have to be taped with

soft tapes as shown on Figure 5-6 (7) & (8).

3. Then, fix the touchscreen to the front bezel with the 4

metal brackets with screws. The soft tapes are used to

absorb the pressure when the metal brackets fix the

touchscreen to the front bezel.

If no toushcreen is installed, there are two options. One is to

put a resilient glass instead. The advantage of putting a

resilient glass is to protect the LCD panel.

The other option is to fix 4

bronze sticks (5 mm) to the

LCD bracket to push the LCD

panel forward to make up the

gap between the LCD and the

front bezel. But when using

this way, two screw holes on

the front bezel need to be cut

to prevent LCD mechanism

interference to the front bezel.

FIGURE 5-5: APOLLO W/O TOUCH

5-

APOLLO 120/150 III

Page 71

User Manual version 2305

61

APOLLO 120 -±ªO²Õ«~

12" -±ªO²Õ¥ó

12" ¾ó½¦À£±ø(¥ª¥k)

12" ¾ó½¦À£±ø(¤W¤U)

12.1"ELO TOUCH ¹qªý¦¡

ELO 12.1"À£±ø(¥ª¥k)

ELO 12.1"À£±ø(¤W¤U)

ªw´ÖÀ£±ø 185*5*1 mm ¥ª¥kPE

ªw´ÖÀ£±ø 250*5*1 mm ¤W¤UPE

FIGURE 5-6: APOLLO 120 FRONT BEZEL ASSEMBLY

FIGURE 5-7: APOLLO 120 FRONT BEZEL ASSEMBLY

APOLLO 150 -±ªO²Õ«~

15" -±ªO²Õ¥ó

15" ¾ó½¦À£±ø232*5*2(¥ª¥k)

15" ¾ó½¦À£±ø318*5*2(¤W¤U)

15.0"ELO TOUCH ¹qªý¦¡

ELO 15.0"À£±ø(¥ª)

ELO 15.0"À£±ø(¤W¤U)

ELO 15.0"À£±ø(¥k)

ªw´ÖÀ£±ø 185*5*1 mm ¥ª¥kPE

ªw´ÖÀ£±ø 250*5*1 mm ¤W¤UPE

APOLLO 120/150 III

5-

Page 72

User Manual version 2305

62

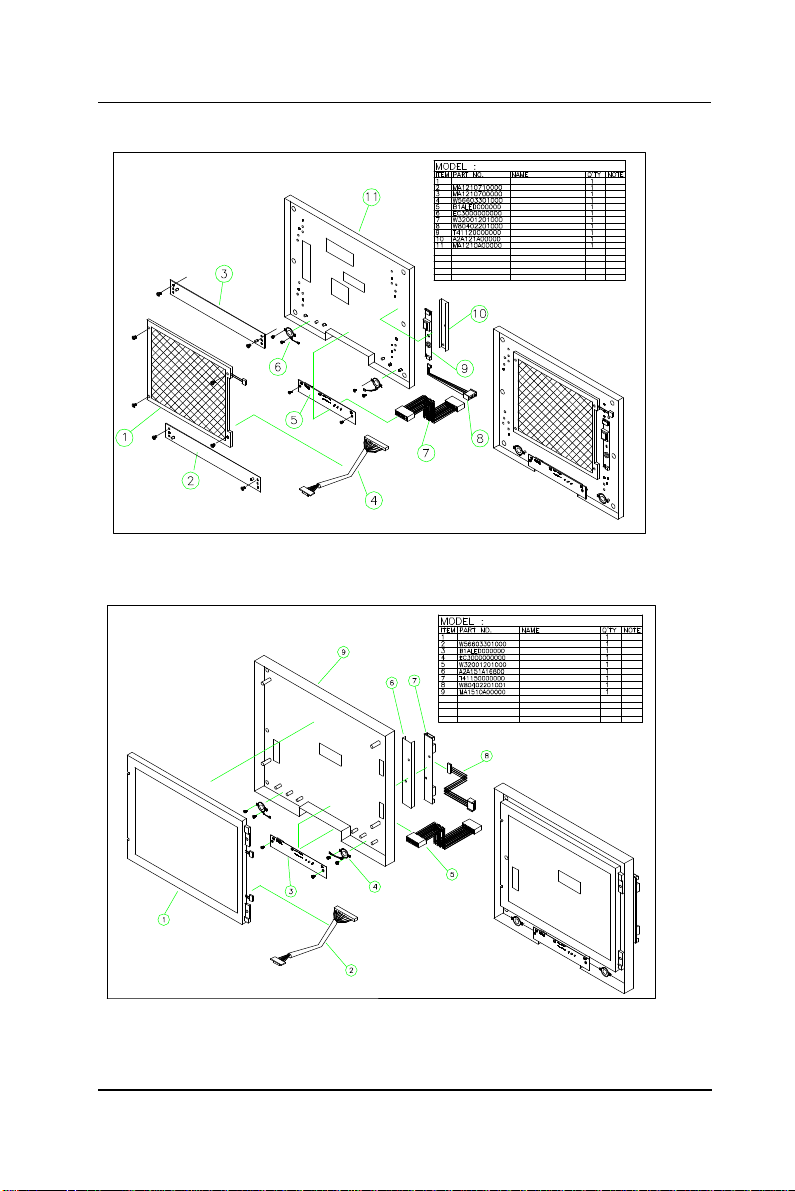

5.8. LCD Module Assembly

Figure 5-8 and 5-9 illustrate the way to assemble the

APOLLO’s LCD module.

The LCD does not fix to the main system directly. Rather, it is

to be fixed to a LCD holder, then to the main system. The

assembly of APOLLO 120 LCD module slightly differs from

that of APOLLO 150.

APOLLO 120

1. Refer to Figure 5-8. There are two LCD brackets (2) & (3)

used to fix to the LCD panel (1) to the LCD holder (11)

from the up & down sides.

2. Fix the LCD panel to the LCD holder with four PMS 3*8

screws.

3. The standard LCD used in APOLLO 120 is SANYO

MXS121022010 or its equivalent. It is a TTL interface

LCD. The LCD cable (4) is a DF9-41S to 2*25-pin cable

with around 35 cm in its length. Insert the 41-pin end

into the opening at the rear side of the LCD holder and

have it firmly plugged to the 41-pin connector at the rear

side of the LCD panel.

4. Attach the insulator (10) to the invertor (9).

5. The invertor cable (8) is a 4-pin to 4-pin cable with wafer

connectors at both sides. Connect the one end to

invertor first. The other end is for later connection to the

INV1 on the motherboard.

6. Connect the pink-white high voltage wires from the LCD

to the invertor.

7. The invertor module is to be fixed at the right middle

side of the LCD holder with the up side down.

8. For APOLLO 120, the IR/LED board (2) is to be fixed to

the lower side of the LCD holder.

9. The two speakers are to be fixed to the right and left

sides of the IR/LED board. The speaker wires are to be

connected to the 2-pin header on the IR/LED board.

5-

APOLLO 120/150 III

Page 73

User Manual version 2305

63

APOLLO 150

1. Refer to Figure 5-9. The standard LCD used in APOLLO

150 is either 15.1” TTL LG 151X2 or 15” LVDS Chi Mei

M150X3-L01 or their equivalent. The assembly of TTL

LCD differs from that of the LVDS LCD.

2. Fix the LCD panel (1) to the LCD holder (9) with four

PMS 3*8 screws.

3. For the TTL LCD, LM151X2 or its equivalent, the LCD

cable (2) is a DF9-41S to 2*25-pin cable with around 35

cm in its length. Insert the 41-pin end into the opening

at the rear side of the LCD holder and have it firmly

plugged to the 41-pin connector at the rear side of the

LCD panel. The other end is for later connection to the

LCD1 on the motherboard.

4. For the LVDS LCD, M150X3-L01 or its equivalent, as the

motherboard’s display is a TTL controller, to connect the

onboard LCD controller to the LVDS LCD, an LVDS

transceiver board is needed.

5. The APOLLO 150’s LVDS transceiver board is to be fixed

at the system chassis between the touch controller and

HDD.

6. The LCD cable for the LVDS LCD is a DF14-20 to

DF14-20 cable with around 35 cm in its length. Connect

one end to the connector located at the rear side of the

LCD panel with the other end going through the opening

at the rear side of the LCD holder for later connection to

the LVDS1 on the LVDS board.

7. There is a 2*25-pin to 2*25-pin LVDS cable. Plug one

end to the LCD1 on the LVDS board with the other end

connected to the 2*25-pin header connector, LCD1 on

the motherboard.

8. Attach the insulator (6) to the invertor (7).

9. The invertor cable (8) for APOLLO 150 is a 7-pin to 4-pin

cable with wafer connectors at both sides. Connect the

7-pin end to the invertor first. The other end is for later

connection to the INV1 on the motherboard.

APOLLO 120/150 III

5-

Page 74

User Manual version 2305

64

10. Connect the pink-white high voltage wires from the LCD

to the invertor.

11. The invertor module is to be fixed at the reverse side of

the LCD holder after the LCD module is to be installed to

the system.

12. For APOLLO 150, fix 6 bronze sticks (15 mm) to the

lower sides of the LCD holder. Fix the IR/LED board to

the LCD holder with two 3*6 screws.

13. The two speakers (Fig. 5-8 (6)) are to be fixed to the

right and left sides of the IR/LED board. The speaker

wires are to be connected to the 2-pin header on the

IR/LED board.

5-

APOLLO 120/150 III

Page 75

User Manual version 2305

65

12" LCD ²Õ«~

12.1"LCD PANEL

12"LCD©T©w¬[¤U

12"LCD ©T©w¬[¤W

LCD CABLE DFP41-50P 330mm

MODULE APOLLO LED A1.0

SPEAKER

LED CABLE 120mm

12"INVERTER MOLEX P-HRS4P 220mm

INVERTER 12.1"TORISAN

12"INVERTERµ´½t¤ù120*26.7*0.35

12"«eÅKªO

FIGURE 5-8: APOLLO 120 LCD MODULE ASSEMBLY

15" LCD ²Õ«~

15.0" LCD PANEL

LCD CABLE DFP41-50P 330mm

MODULE APOLLO LED A1.0

SPEAKER

LED CABLE 120mm

15"µ´½t¤ù168*39*0.35

INVERTER 15"

15" INVERTER MOLEX 4P-JAE7P 220mm

15"«eÅKªO

FIGURE 5-9: APOLLO 150 LCD MODULE ASSEMBLY

APOLLO 120/150 III

5-

Page 76

User Manual version 2305

66

After finishing the LCD module installation, the module is to

be assembled to the front bezel module, then to the chassis

with the motherboard and touch controller already on.

1. Use special air blower to blow any dust between the LCD

and touchscreen before the two modules are assembled

together. Retain the LCD module and the front bezel

module together with 8 FMS 3*6 screws.

2. Install the whole front bezel module with LCD already on

to the system chassis with the motherboard, touchscreen

controller and HDD module already on.

3. The LCD cable is already at the rear side of the LCD holder

through the cutout. Make sure the other end is to go

through the rectangle opening at the rear side of the

system chassis and have it connected to LCD connector,

LCD1 on the motherboard.

SPECIAL ATTENTION NEEDS TO BE PAID WHEN PLUGGING THE LVDS OR

LCD CABLE TO THE LCD HEADER CONNECTOR ON THE MOTHERBOARD.

MAKE SURE PIN 1 OF THE ONBOARD LCD CONNECTOR MATCH PIN 1 OF

THE CABLE. ANY WRONG PLUGGING OR SHIFTED PLUGGING WILL

DAMAGE THE LCD PANEL OR LEAD TO MAL-FUNCTION.

4. The touchscreen 5-pin flat cable should go through the

rectangle opening at the left side of the LCD holder, then

get into the chassis from the oval-shape cutout at the left

side of the chassis. Connect this cable to the touchcreen

controller. Connect the other end of the touch power cable

to the onboard PWR 1.

5. For APOLLO 150, the invertor now is to be fixed to the left

outward side of the chassis and have the invertor cable go

into the chassis through the cutout. Connect the other

end of the invertor cable to the motherboard’s INV1.

6. Connect the other end of the IR/LED cable to the IR/LED

board.

5-

APOLLO 120/150 III

Page 77

User Manual version 2305

67

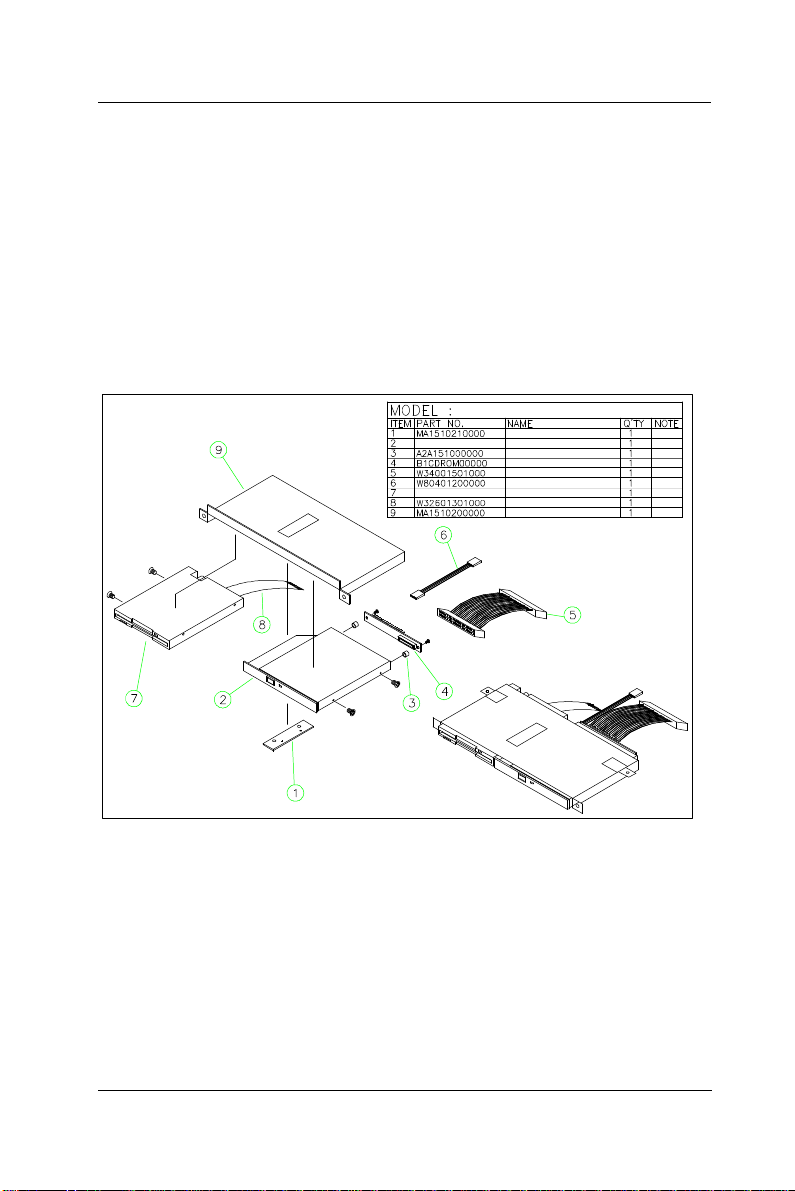

5.9. CD-ROM/DVD-ROM/FDD Module Assembly

The APOLLO provides enough space to accommodate a

CD-ROM or CD-RW or DVD-ROM and a floppy disk drive. The

CD-ROM or DVD-ROM drive used in the APOLLO 120/150 is

not the common 5.25” drive seen in computer stores. Rather,

it is a slim type drive widely used in notebook computers.

The APOLLO 120/150 can connect to an external floppy disk

drive or an internal slim type floppy disk drive, depending on

the system requirement.

Please note that either an external floppy disk drive or

internal floppy disk drive can be used.

5.9.1. Internal CD-ROM/FDD Assembly

The following steps show the ways to install an internal

CD-ROM or DVD-ROM and floppy disk drive.

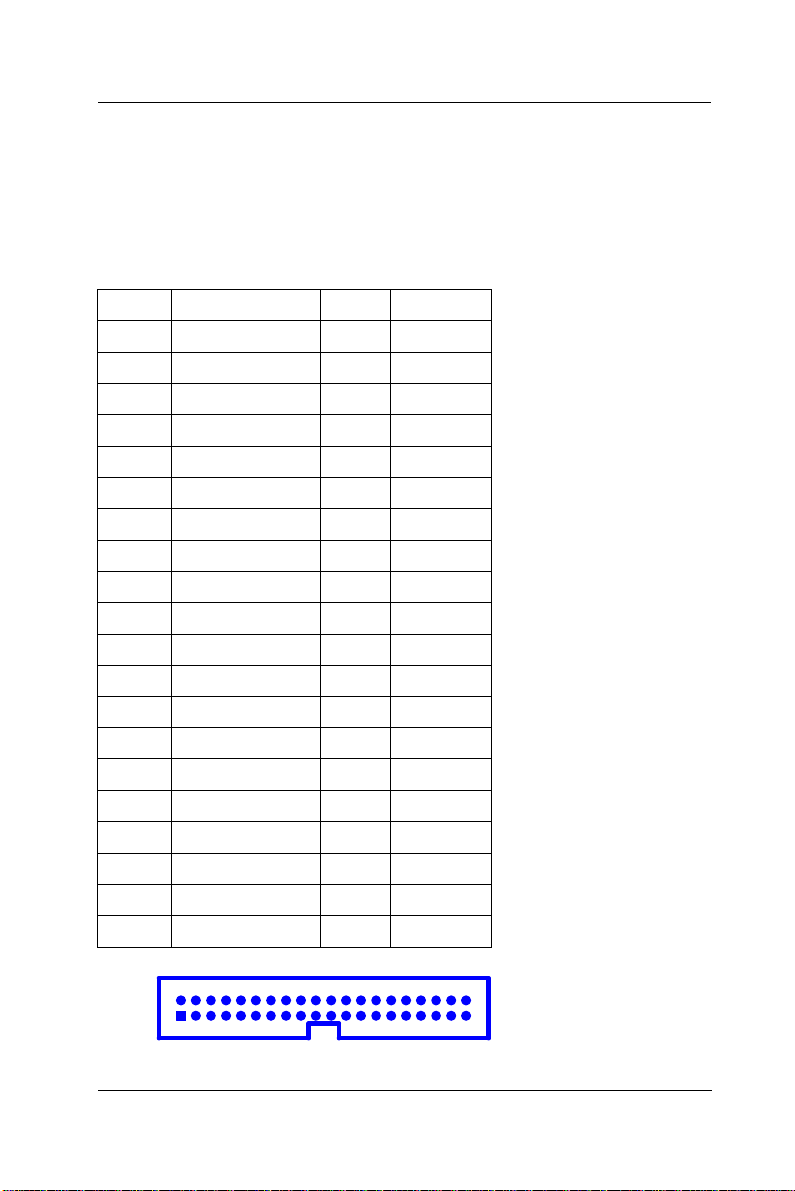

1. Make the chassis’ lower side near you. Now, from your