Page 1

PRODUCTS

AUT OMATION

Operator’s Manual

GROUP, INC.

VBL Series

General Purpose

Vibrating Level Sensor

Rev. A2, 9/09

Automation Products Group, Inc.

APG...Providing tailored solutions for measurement applications

T el: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • E-mail: sales@apgsensors.com

Page 2

VBL Series Rev. A2, 9/09

T able of Content s

Warranty ......................................................................................... 3

Introduction .................................................................................... 4

Specifications.................................................................................. 5

Dimensions...................................................................................... 7

Nomenclature.................................................................................. 8

Electronics ...................................................................................... 9

Principle of Operation .................................................................. 10

Installation .................................................................................... 11

Adjustment Procedure .................................................................. 14

Sensitivity...................................................................................... 16

Wiring............................................................................................ 17

Start Up ........................................................................................ 17

Maintenance ................................................................................. 18

Troubleshooting ............................................................................ 20

Automation Products Group, Inc.

APG...Providing tailored solutions for measurement applications

2

T el: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

Page 3

Rev. A2, 9/09 VBL Series

• Warranty and Warranty Restrictions

APG warrants its products to be free from defects of material and workmanship

and will, without charge, replace or repair any equipment found defective upon

inspection at its factory, provided the equipment has been returned,

transportation prepaid, within 24 months from date of shipment from factory .

THE FOREGOING WARRANTY IS IN LIEU OF AND EXCLUDES ALL OTHER

W ARRANTIES NOT EXPRESSLY SET FOR TH HEREIN, WHETHER

EXPRESSED OR IMPLIED BY OPERATION OF LAW OR OTHER WISE

INCLUDING BUT NOT LIMITED TO ANY IMPLIED WARRANTIES OF

MERCHANT ABILITY OR FITNESS FOR A P AR TICULAR PURPOSE.

No representation or warranty , express or implied, made by any sales

representative, distributor, or other agent or representative of APG which is not

specifically set forth herein shall be binding upon APG. APG shall not be liable

for any incidental or consequential damages, losses or expenses directly or

indirectly arising from the sale, handling, improper application or use of the

goods or from any other cause relating thereto and APG’s liability hereunder, in

any case, is expressly limited to the repair or replacement (at APG’ s option) of

goods.

Warranty is specifically at the factory. Any on site service will be provided at

the sole expense of the Purchaser at standard field service rates.

All associated equipment must be protected by properly rated electronic/

electrical protection devices. APG shall not be liable for any damage due to

improper engineering or installation by the purchaser or third parties. Proper

installation, operation and maintenance of the product becomes the

responsibility of the user upon receipt of the product.

Returns and allowances must be authorized by APG in advance. APG will

assign a Return Material Authorization (RMA) number which must appear on

all related papers and the outside of the shipping carton. All returns are subject

to the final review by AP G. Returns are subject to restocking charges as

determined by APG’ s “Credit Return Policy”.

Automation Products Group, Inc.

APG...Providing tailored solutions for measurement applications

T el: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

3

Page 4

VBL Series Rev. A2, 9/09

• Introduction

The vibrating level sensor, VBL-12, VBL-22, and VBL-32 are made specifically

for solid level measurement in containers. It is designed for minimum density of

bulk solid (loose) 12 lbs. per cubic feet (0.2 g/cm3). Not only fine powders,

ordinary powder, granular materials and pellets, but also for detecting sediments

in the liquids such as sludge, sand, etc. The model VBL is usable in a wide range

of specifications. Since the detecting point is at the tip of the vibration pipe, it is

immune to buildup of the medium on the inside wall of the vessel.

Automation Products Group, Inc.

APG...Providing tailored solutions for measurement applications

4

T el: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

Page 5

Rev. A2, 9/09 VBL Series

• Specifications

Operational Versions

VBL-12: Compact

VBL-22: For extended probes

VBL-32: For flexible extension

Performance

3

Bulk Density: Min 0.2 g/cm

sensitivity

Output Contact Rating: 1 SPDT , 240 V 3A AC, 30 V 3 A DC (resistive)

Vibration Frequency: Approximately 330 Hz

Sensitivity Adjustments

Very High for highly fluidized powders

High for fine powders (bulk density 0.2-0.5 g/cm

3

)

Standard for bulk density 0.5 g/cm3 or more (factory setting)

Low for sticky media

Loss of Power Mode: Provided (high or low) by switch

Detection Time Delay (optional field adjustable)

Covered: 1 sec.

Free: 5 sec.

Indication:

Green LED for Power status

Red LED for Relay status

Electrical

Supply V oltage: 90 to 132 VAC, 180 to 264 VAC or 24 VDC

Power Consumption: Approximately 5 VA

Physical

Material

Housing: Aluminum die cast (ADC)

Vibration Probe: 304SS (316SS optional)

Cable Entries: G 3/4, G 1/2 or NPT 1/2

Rating: IP65/NEMA 4

Automation Products Group, Inc.

APG...Providing tailored solutions for measurement applications

T el: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

5

Page 6

VBL Series Rev. A2, 9/09

Environmental

Operating T emperatur e:

Vibration Rod Housing

VBL-12, 22 -4 to 300°F -4 to 140°F

(-20 to 150°C) (-20 to 60°C)

VBL-31 -4 to 158°F -4 to 140°F

(-20 to 70°C) (-20 to 60°C)

Maximum Pressure: 290 psi (20 bar)

Automation Products Group, Inc.

APG...Providing tailored solutions for measurement applications

6

T el: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

Page 7

Rev. A2, 9/09 VBL Series

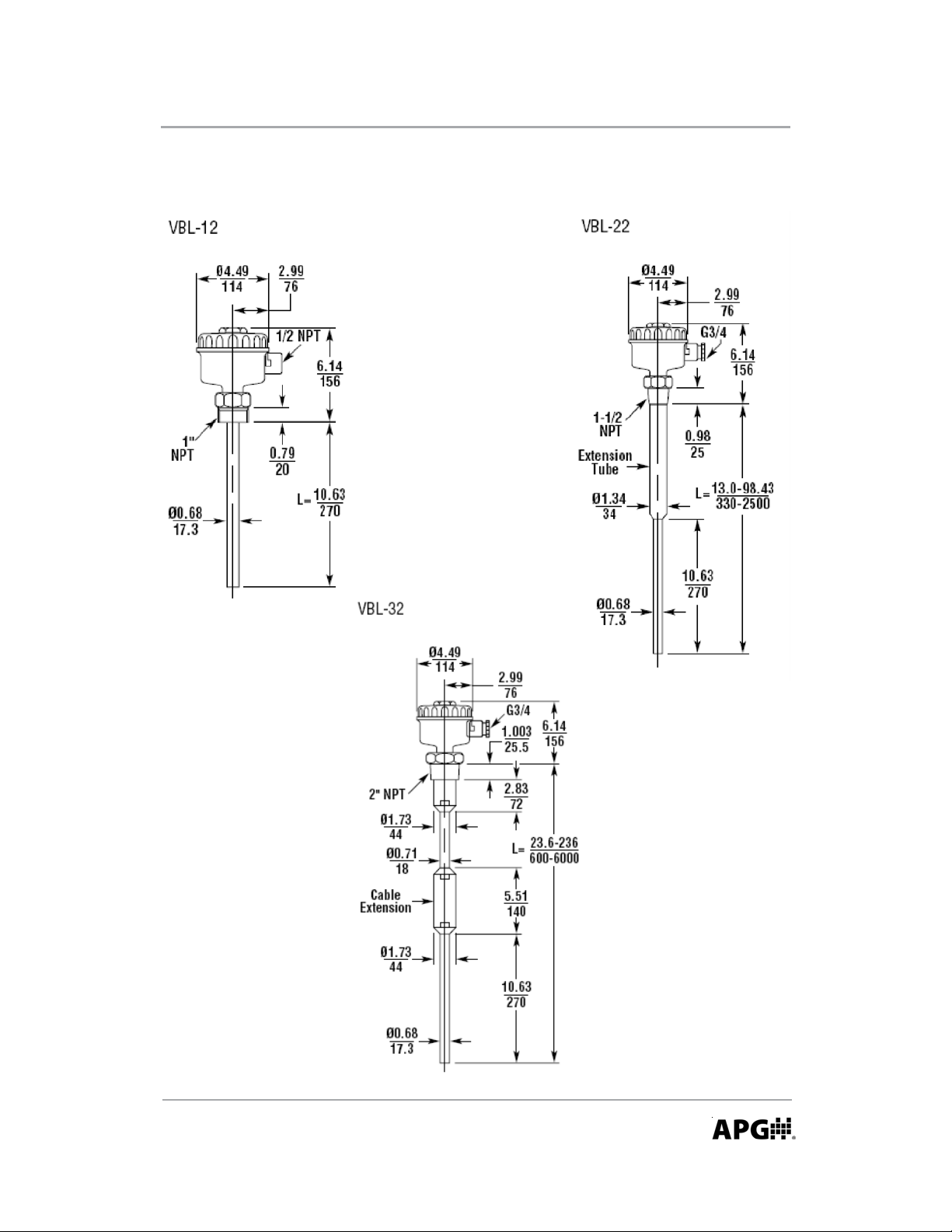

Dimensions — in./mm

Automation Products Group, Inc.

APG...Providing tailored solutions for measurement applications

T el: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

7

Page 8

VBL Series Rev. A2, 9/09

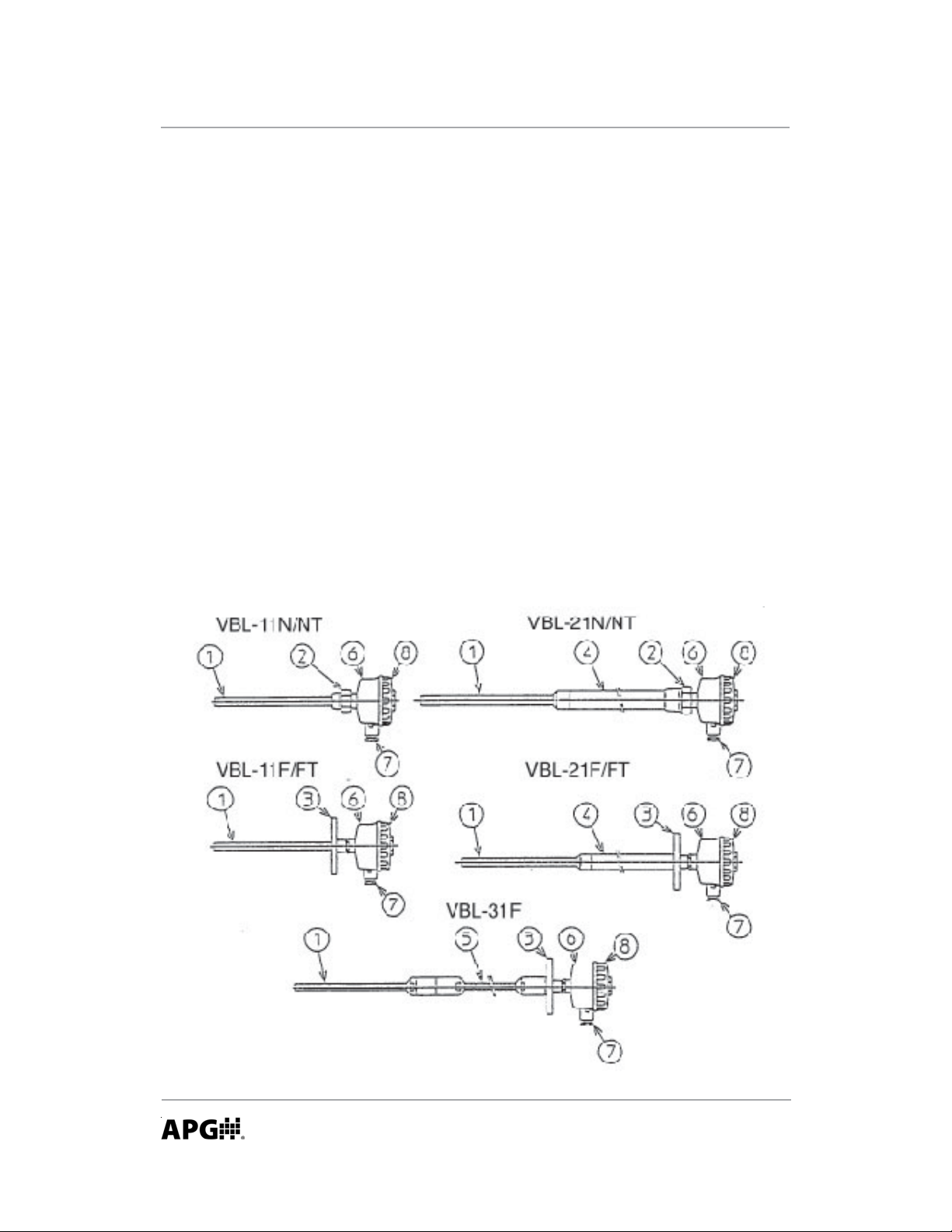

• Nomenclature

1. Vibration Pipe

Detecting part which touches

directly to the powders. It

vibrates when there’s no

powders, but vibration will

dampen or stop when it becomes

buried in the measured materials.

2. Plug for VBL-12N/NT and VBL22N/NT

Screw to install the sensor to the

tank.

3. Flange for VBL-12F/FT ,

VBL-22F/FT and VBL-32F

Flange to install the sensor to the

tank.

4. Extension pipe for VBL-22F/FT

and VBL-22N/NT

Sensor measuring length

extension part.

5. Flexible cable for VBL-32F

Sensor measuring length

extension part.

6. Housing

Electronic circuit is placed.

7. Cable Gland

Cable entry to enter the cable.

Sizes are JIS F 20a (G 3/4) and JIS

F 15c (G 1/2) (Optionally

available.)

8. Cover for the sensor.

Automation Products Group, Inc.

APG...Providing tailored solutions for measurement applications

8

T el: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

Page 9

Rev. A2, 9/09 VBL Series

• Electronics

9. Terminals

Output terminal for power

connection and sensor relay

contact signal.

10. Power Indicator

Green lamp lights when the

sensor power is on.

11. Alarm Indicator

Red lamp lights when the sensor

detects the measuring materials.

12. Sensitivity Setting Volume

To set the sensor detecting

sensitivities or to check the

operating condition.

13. Sensitivity Setting Switch

To set the sensor detecting

sensitivities or to check the

operating condition.

14. Meter Test Points

Meter test points for performance

check and fine adjustment of

sensitivity: [Red for positive (+)

point and Black for negative (-)

point.]

Automation Products Group, Inc.

APG...Providing tailored solutions for measurement applications

T el: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

9

Page 10

VBL Series Rev. A2, 9/09

• Principle of Operation

The vibration rod vibrates by installing piezo-electric element and

acceleration pickup mounted vibration board at the tip of the internal pipe. The

piezoelectric element provides vibration and the acceleration pickup detects

changes in the vibrational frequency. Covered with solids dampens vibration of

the vibration pipe. The electronic circuit detects the damping of these vibration

pipe. The electronic circuit detects the damping of these vibration and converts

into an relay output.

10

Automation Products Group, Inc.

APG...Providing tailored solutions for measurement applications

T el: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

Page 11

Rev. A2, 9/09 VBL Series

• Installation

Unpacking

This unit has been thoroughly inspected and carefully packed at the factory

to prevent damage shipment. When unpacking, open shipping cartons of unit

and inspect the units for shipping damage. If there is evidence of damage, notify

the carrier immediately . Also verify the contents for properly ordered units.

Environment

The VBL should be installed in an area which meets the following conditions:

• The ambient temperature range is within the following:

Housing Probe

VBL-12/22/32 -20 to +60°C -20 to +150°C

VBL-12-T/VBL22-T -20 to +50°C -20 to +150°C

Note: Install a sun shield over the housing if exposed to direct sunlight. Do

not install in an area where the ambient temperature drops rapidly (for

example, 40°C to 0°C). This may cause dew and damage the sensor .

• Locate away from splashing water. The housing protection is IP65.

• No corrosive gases (such as NH3, SO2, C12, etc.).

• Nonhazardous area.

• Ample space is provided for maintenance/inspection.

Location

• Locate the VBL at the position where the material level will actually make

contact with the probe. In case of high level control, pay attention to the

angle of repose. In case of low level control, prevent from being surrounded

by dead stock.

• The maximum length for the threaded boss/standoff pipe is 70 mm.

• The vibration rod should not be in contact with standoff pipe or tank wall.

• The VBL may be mounted in any position or orientation. However, it is

recommended that the cable entry be pointed downward where possible to

prevent intrusion from rain or splashing.

• In case of negative or positive pressure in the container, use suitable pipe

compound, gaskets or thread tape.

Automation Products Group, Inc.

APG...Providing tailored solutions for measurement applications

T el: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

11

Page 12

VBL Series Rev. A2, 9/09

Installation

• The maximum load at the tip of the vibration is 60 kgf. If it exceeds, the

vibration pipe will be bent. Install the guard at least 100 mm above the

vibrating pipe if necessary.

Automation Products Group, Inc.

APG...Providing tailored solutions for measurement applications

12

T el: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

Page 13

Rev. A2, 9/09 VBL Series

• The maximum length for the threaded boss/mounting nozzle is 70 mm. If

exceeds 70 mm, the sensor will detect the dead stock despite there aren’t

any measuring materials in case of horizontal mounting.

• The vibration pipe will not vibrate despite there aren’t any measuring

materials.

• When used as a high level control, calculate the angle of repose for

measuring materials and install the vibration rod where it surely covers.

• When using as a low level control, install the guard above the vibration rod

as bridge or overload is anticipated.

Automation Products Group, Inc.

APG...Providing tailored solutions for measurement applications

T el: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

13

Page 14

VBL Series Rev. A2, 9/09

• Adjustment Procedure

Fundamentally , the model VB L needs no adjustments. But adjust the

detecting sensitivity for:

• Fine powders

• Highly fluidized powders

• Sticky and buildup materials.

• Improper adjustment

Powder Detecting Sensitivity

The adjustment of the detecting

sensitivity depends on bulk density,

fluidity, buildups concentrate features and

so on. Accordingly, the data written below

will be nearly general. See the table below:

Polycarbonate pellet (PC pellet), salt,

powdered coffee’s detecting sensitivities

are written below for your reference.

Detecting Levels

Standard Super High

Powder Names Bulk Density Sensitivity Sensitivity

Salt 1.4 Less than 20 mm Less than 20 mm

PC Pellet 0. 7 Less than 40 mm Less than 10 mm

Powdered Coffee 0.26 Undetectable Less than 80 mm

Standard Sensitivity: The sensitivity when shipping

Super High Sensitivity: The most high detecting sensitivity.

14

Automation Products Group, Inc.

APG...Providing tailored solutions for measurement applications

T el: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

Page 15

Rev. A2, 9/09 VBL Series

Adjusting the detecting sensitivity

• Prepare the following equipment:

- 0 ~ 10 V AC range tester. (In case of voltmeter , input resistive more than

10ý.)

- Small-sized slotted blade screw driver .

• Clean up the vibration pipe. While adjusting, make sure the measuring

materials are not contacting the vibration rod. If it contacts, exact

adjustment will be impossible.

• Turn on the power supply if it is not on.

• Wait for 5 seconds.

• Set the sensitivity setting switch to AJ (middle point).

• Plug in the positive reed to positive (red) meter test point and negative reed

to negative (black) meter test point. Adjust the tester to voltage range

which can detect the direct current 0 ~ 10 V every 0.5 V.

- Super-high sensitivity for highly fluidized powders. Adjust the check

terminal voltage to 4.5 ~ 5.5 V by sensitivity setting volume. Set the

sensitivity switch to H (high sensitivity range).

- High sensitivity for fine powders. Adjust the check terminal voltage to

2 ~ 3 V by sensitivity setting to L (ordinary sensitivity range).

- Low sensitivity for sticky and build-up material. Adjust the check terminal

voltage to 4.5 ~ 5.5 V by sensitivity setting volume. Set the sensitivity

switch to L (ordinary sensitivity range).

Consult APG for repair or replacement in case of indicating the incorrect

voltage.

Automation Products Group, Inc.

APG...Providing tailored solutions for measurement applications

T el: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

15

Page 16

VBL Series Rev. A2, 9/09

• Sensitivity

The sensitivity can be adjusted by using the sensitivity switch and by

adjusting the voltage.

H with 4.5~5.5 VDC: for highly fluidized materials.

L with 2.0~3.0 VDC: for light materials.

L with 4.5~5.5 VDC: standard adjustment (bulk density 0.2/cm3 or more)

L with 6.0~7.0 VDC: for sticky materials.

Set the sensitivity switch to AJ.

Turn sensitivity volume until the desired voltage is read.

After adjustment, set the switch to H or L and make sure 8~10 VDC can be

read.

16

Automation Products Group, Inc.

APG...Providing tailored solutions for measurement applications

T el: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

Page 17

Rev. A2, 9/09 VBL Series

• Wiring

Wiring should be in accordance with all local codes. Control cable should be a

minimum of 0.75 mm2.

• Contact capacity

240 V 3 A AC (Resistive)

30 V 3 A DC (Resistive)

• Power supply

90 to 132 V AC 50/60 Hz

180 to 264 V AC 50/60 Hz

• Power consumption

5 V A

Caution: Make sure the

supply voltage matches the

markings on the circuit board

terminals. Applying the wrong

voltage or miswiring will

damage the sensor and may

cause injury.

• Start Up

1. Test Points

For fine adjustment of the

sensitivity.

2 . Sensitivity Switch

To set high or low

sensitivity.

3 . Sensitivity V olume

To adjust the sensitivity.

4 . Detection Status LED

5 . Power Status LED

Automation Products Group, Inc.

APG...Providing tailored solutions for measurement applications

T el: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

17

Page 18

VBL Series Rev. A2, 9/09

• Maintenance

In general, the sensitivity properly set VBL needs no maintenance. But in

order to use the sensor stable for a long time, maintenance and inspection are

needed in periodic intervals.

Inspection

Inspection is held to examine

• If the sensitivity is set to proper sensitivity.

• If it is affected by the build-up.

• If the sensor is operating correctly.

Proceed as follow:

• Make sure the measuring materials are not touching the vibrating pipe.

Replace the sensor out of the tank if necessary.

• Supply power to the sensor.

• Make sure which the sensor sensitivity is set. Super-high, high, standard

(shipping sensitivity) or low.

• Prepare the 0 ~ 10 VDC range voltmeter .

• Plug the voltmeter leads to the test points, positive to Red (+) and negative

to Black (-).

• See the table below. Ensure both A and B stated voltage can be read for

each set sensitivity.

Position for Sensitivity Setting

Switch and Voltage Reading

Set Sensitivity A B

Super-high H: 8 ~ 9 V AJ: 4.5 ~ 5.5 V

High L: 8 ~ 9 V AJ: 2.0 ~ 3.0 V

Standard L: 8 ~ 9 V AJ: 4.5 ~ 5.5 V

Lo w L: 8 ~ 9 V AJ: 6.0 ~ 7.0 V

• If the voltage reading is accomplished, the sensitivity adjustment is correct.

Nevertheless malfunction occurs. See Troubleshooting section.

• If the voltage reading is low, clean up the build-up on the vibration rod.

Then adjust the sensitivity volume in the state of sensitivity setting switch

is AJ until the correct voltage can be read. Otherwise, the sensor is

defective. Consult APG for repair/replacement.

Automation Products Group, Inc.

APG...Providing tailored solutions for measurement applications

18

T el: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

Page 19

Rev. A2, 9/09 VBL Series

• If the voltage reading is high, the sensitivity adjustment is not properly set.

Adjust the sensitivity volume in the state of sensitivity setting switch is AJ

until the correct voltage can be read. Otherwise, the sensor is defective.

Consult APG for repair/replacement.

Maintenance

In order to use model VBL for a long time, maintenance is needed in periodic

intervals. Periodic inspections are important to maintain good service.

Maintenance method is as follow:

• A large amount of build-up on the tip of the vibration rod will cause wrong

signal output. Clean build-up in periodic intervals in case of measuring

strong adherence materials.

• Make sure the raindrops (waterdrops) are not intruding inside the housing.

For outdoor use, the waterdrops will intrude easily if the housing cover or

the cable entry is loose. Intrude of the waterdrops will cause an erroneous

signals, make sure to tighten periodically . A crack of water-drop-proof Oring (special article) between housing and cover will deteriorate the waterdrop-proof. Replace it with new ones.

• Depending on the measuring materials, the sensor will cause corrosion or

rubbing. Make sure the corrosion and rubbing are not outbreaking or

progressing periodically ,

Automation Products Group, Inc.

APG...Providing tailored solutions for measurement applications

T el: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

19

Page 20

VBL Series Rev. A2, 9/09

• Troubleshooting

Problem

Not detecting powders when covered.

Possible Causes

• Powder build density is too small. Bulk density under 0.2 cannot be

detected.

• Power supply not connected.

• Material too fluid.

• Effected by heavy hopper vibration.

Remedies

• Set high sensitivity

• Connect power supply.

• Install sensor in a better location.

Problem

• It keeps detecting powders while the hopper is empty.

Possible Causes

• Heavy deposit on vibration rod.

• Material has dead stock.

Remedies

• Clean vibration rod.

• Install sensor in better location or isolate dead stock.

20

Automation Products Group, Inc.

APG...Providing tailored solutions for measurement applications

T el: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

Page 21

Rev. A2, 9/09 VBL Series

Notes

Automation Products Group, Inc.

APG...Providing tailored solutions for measurement applications

T el: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

21

Page 22

VBL Series Rev. A2, 9/09

Notes

22

Automation Products Group, Inc.

APG...Providing tailored solutions for measurement applications

T el: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

Page 23

Rev. A2, 9/09 VBL Series

Notes

Automation Products Group, Inc.

APG...Providing tailored solutions for measurement applications

T el: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

23

Page 24

PRODUCTS

AUT OMATION

APG ...Providing tailored solutions

for measurement applications

Automation Products Group, Inc.

Tel: 1/888/525-7300

1/435/753-7300

Fax: 1/435/753-7490

GROUP, INC.

e-mail: sales@apgsensors.com

www.apgsensors.com

Automation Products Group, Inc.

1025 W. 1700 N.

Logan, UT 84321

Loading...

Loading...