Page 1

APG

Thank You

using a non-POE

Thanks for purchasing a RST-5003 control module from us! We appreciate your business and

your trust. Please take a moment to familiarize yourself with the product and this manual before

installation. If you have any questions, at any time, don’t hesitate to call us at 888-525-7300.

RST-5003 Control Module

Installation Guide

NOTE: Scan the QR code to the below to visit www.apgsensors.com/support.

APG Support Website

Table of Contents

1.Description

2. How To Read Your Label

3. Warranty

4. Installation Procedure

Description

1

The RST-5003 Web Enabled Control Module oers a wide degree of integrated and exible remote

and local control and monitoring for your system. The RST-5003 can control up to ten APG Modbus

sensors--any combination of level, pressure, magnetostrictive and ultrasonic--along with one

4-20 mA sensor, and two input or out relay terminals. All readings are available for control and

monitoring via TCP/IP for local or remote network access. The RST-5003 also had exible power

options: it can use either POE or an independent 12-28 VDC power source.

5. Dimensions

6. Power Supply Wiring

Diagrams

7. Modbus System Wiring

Diagrams

8. Embedded Webpage

9. General Care

10. Repair Information

11. Removal Instructions

Web Enabled Series

R

Automation Products Group, Inc.

1025 W 1700 N Logan, UT 84321

www.apgsensors.com | phone: 888-525-7300 | email: sales@apgsensors.com

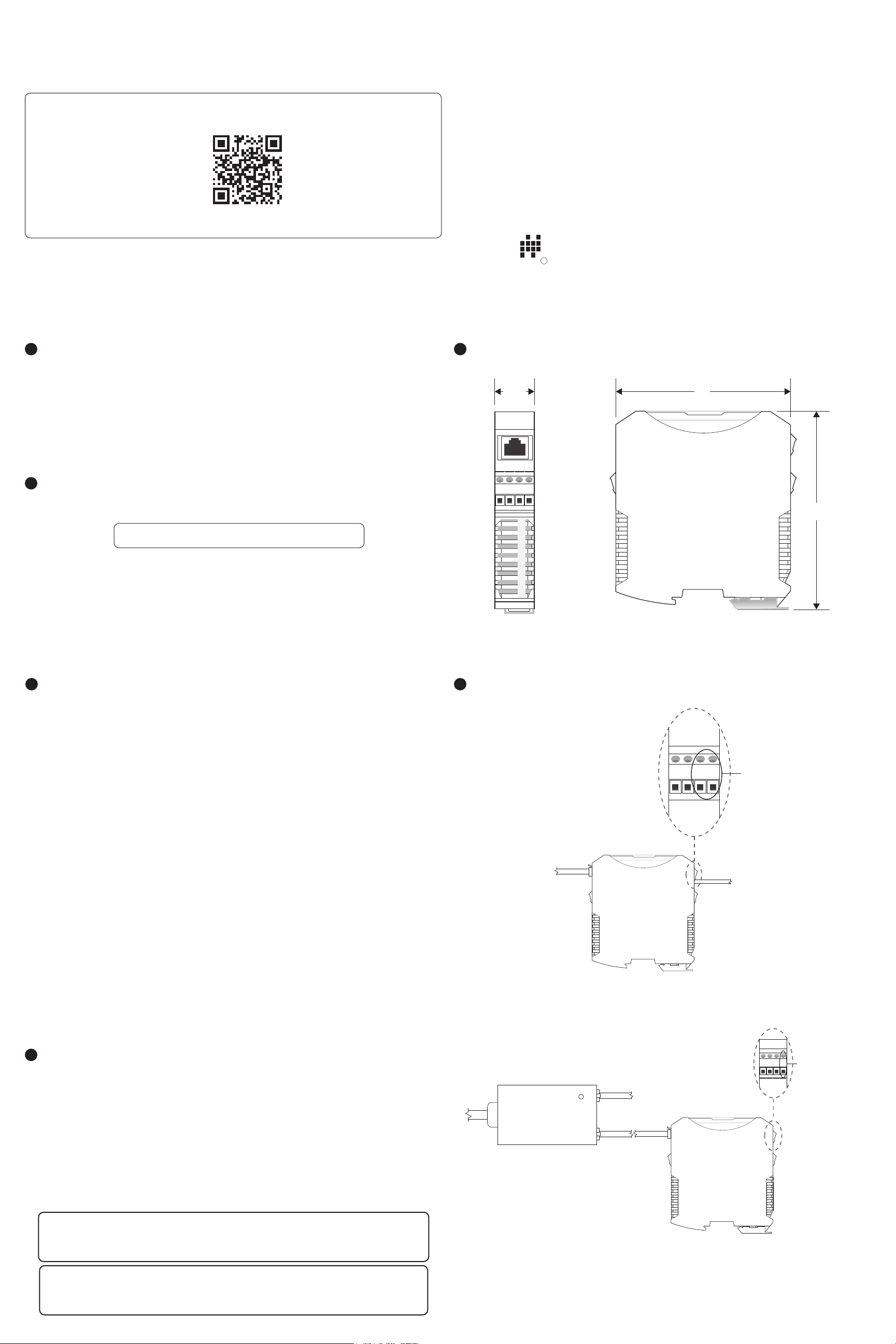

Dimensions

5

7/8”

4”

Part # 122950-0012

Doc #9004245 Rev A

How To Read Your Label

2

Each label comes with a full model number, a part number, and a serial number. The model

number for the RST-5003 will look something like this:

SAMPLE: RST-5013

The model number correlates with all the congurable options and tells you exactly what you have.

Compare the model number to the options on the datasheet to identify your exact conguration.

You can also call us with the model, part, or the serial number and we can help you.

Warranty

3

APG warrants its products to be free from defects of material and workmanship and will, without

charge, replace or repair any equipment found defective upon inspection at its factory, provided

the equipment has been returned, transportation prepaid, within 24 months from date of shipment

from factory.

THE FOREGOING WARRANTY IS IN LIEU OF AND EXCLUDES ALL OTHER WARRANTIES NOT

EXPRESSLY SET FORTH HEREIN, WHETHER EXPRESSED OR IMPLIED BY OPERATION OF LAW OR

OTHERWISE INCLUDING BUT NOT LIMITED TO ANY IMPLIED WARRANTIES OF MERCHANTABILITY

OR FITNESS FOR A PARTICULAR PURPOSE.

2

G

4

N

B

A

V

D

Power Supply Wiring Diagrams

6

4 1/2”

G

G

4

2

0

2

N

N

4

D

D

V

Input for supply

voltage when

power source

No representation or warranty, express or implied, made by any sales representative, distributor,

or other agent or representative of APG which is not specically set forth herein shall be binding

upon APG. APG shall not be liable for any incidental or consequential damages, losses or expenses

directly or indirectly arising from the sale, handling, improper application or use of the goods or

from any other cause relating thereto and APG’s liability hereunder, in any case, is expressly limited

to the repair or replacement (at APG’s option) of goods.

Warranty is specically at the factory. Any on site service will be provided at the sole expense of the

Purchaser at standard eld service rates.

All associated equipment must be protected by properly rated electronic/electrical protection

devices. APG shall not be liable for any damage due to improper engineering or installation by the

Purchaser or third parties. Proper installation, operation and maintenance of the product becomes

the responsibility of the user upon receipt of the product.

Returns and allowances must be authorized by APG in advance. APG will assign a Return Material

Authorization (RMA) number which must appear on all related papers and the outside of the

shipping carton. All returns are subject to the nal review by APG. Returns are subject to restocking

charges as determined by APG’s “Credit Return Policy”.

Installation Procedure

4

Installing your RST-5003 is easy if you follow a few simple steps:

• Connect any 4-20 mA sensor, relays, or switched inputs rst.

• Connect RST to Ethernet/network

• Connect independant 12-28 VDC supply if not using POE.

• Connect and set up one Modbus sensor at a time.

Please keep the following limitations in mind:

To AC

power

To Network

Connection

External 12-28VDC Power Supply Wiring

POE

Power

Injector

POWER

LAN + DC LAN

RST-5003

To Network Connection

To 12-28 VDC

Power Source

RST-5003

Provides 24 VDC

G

2

N

4

D

V

to supply a 4-20 mA

device when the RST

is powered via POE.

G

4

N

2

D

0

• Up to 10 Modbus sensors can be connected to the RST-5003 in any combination.

• Only one 4-20 mA sensor can be connected to the RST-5003.

IMPORTANT: Each Modbus sensor must be added to the network individually and

assigned a unique Sensor Number before the next sensor can be added.

NOTE: If you can control power to each Modbus sensor individually, you can connect

them all simultaneously, and power them on individually.

NOTE: A POE-enabled

Ethernet switch eliminates

the need for a POE Power

Injector.

POE (Power Over Ethernet) Wiring

Page 2

Modbus System Wiring Diagrams

7

Server Hosting

Website and

Logged Data

Network / Internet Connection

Connection

to

Internet

Modbus

Input

RST-5003

4-20 mA Input

(2) Solid State Relays

Computer

on

Internet

Computer

on

Local

Network

Equivalent 270 Ω

terminating resistor

internal to RST-5003

(Ethernet Port)

2

G

4

N

B

A

V

D

Use shielded cable

Sensor Line Drops

B

A

V+

GND

Sensor 1

Modbus Daisy Chain Wiring

Note: Terminating resistor size recommended

based on input resistance of RST-5003. Length

of cable and overall impedence of network may

necessitate a different size resistor.

Trunk Line

270 Ω

terminating

resistor at

last sensor

B

A

V+

GND

Sensor 2

B

Sensor 3

A

V+

GND

4-20 mA Type Level Sensor

MNU Ultrasonic Sensors MP Magnetostrictive Float Level Sensors

Modbus System & Network Diagram

Accessing the RST-5003’s Embedded Webpage

8

Each Modbus sensor attached to your RST-5003 must be congured via the RST-5003’s embedded

webpage before the next sensor can be added. The easiest way to access access the embedded

webpage is to type rst_xxx into a web browser on a computer connected to the same local network

as the RST-5003. xxx represents the numeric portion of the RST-5003’s serial number. See Figures

8.1 and 8.2.

NOTE: Refer to each sensor’s user manual for sensor specic wiring instructions. User

Manuals for all APG sensors and equipment are available at www.apgsensors.com.

Figure 8.1

General Care

9

Your RST-5003 is very low maintenance and will need little care as long as it was installed correctly.

However, in general, you should:

• Avoid applications for which the control module was not designed, such as extreme

temperatures, contact with incompatible corrosive chemicals and fumes, or other damaging

environments.

Repair Information

10

If your RST-5003 control module needs repair, contact us via email, phone, or on-line chat on our

website. We will issue you an RMA number with instructions.

• Phone: 888-525-7300

• Email: sales@apgsensors.com

• Online chat at www.apgsensors.com

Removal Instructions

11

• Disconnect power source to control module.

• Disconnect sensors and network cable to control module.

• Remove the control module and store it in a dry place, at a temperature between -40° F and

180° F.

Figure 8.2

IMPORTANT: See your RST-5003 User Manual for complete Modbus programming

instructions and tropubleshooting tips..

Loading...

Loading...