Page 1

APG

RST-5003 Control Module

User Manual

Web Enabled Series

R

Doc #9004240

Rev A1, 05/2016

Page 2

Table of Contents

Introduction ................................................................................................................ iii

Warranty and Warranty Restrictions .................................................................... iv

Chapter 1: Specications and Options.....................................................................1

Dimensions ........................................................................................................................................1

Specications ...................................................................................................................................2

Model Number Congurator .......................................................................................................... 3

System Wiring Diagrams ............................................................................................................3-5

Chapter 2: Installation and Removal Procedures and Notes ..............................6

Tools Needed .....................................................................................................................................6

Connection Notes ............................................................................................................................. 6

Electrical Installation .....................................................................................................................6

Software Setup ............................................................................................................................ 7-11

Removal Instructions ....................................................................................................................11

Chapter 3: Programming with Modbus TCP/IP ................................................... 12

Modbus Polling via Ethernet with Modbus TCP/IP ...........................................................12-13

RST-5003 Generic Modbus Register List ................................................................................... 13

Modbus Programming of Individual Sensors .......................................................................... 14

Chapter 4: RST-5003 Embedded Web Server ........................................................ 14

Accessing the RST-5003 Embedded Web Server .................................................................... 14

Navigating the RST-5003 Embedded Web Server ..............................................................14-15

4-20 mA Sensor Input Conguration Submenus .............................................................. 16-29

Modbus Sensor Conguration Registers ............................................................................ 30-32

RST-5003 Utility Menus ......................................................................................................... 33-36

Chapter 5: Maintenance ...........................................................................................37

General Care .................................................................................................................................... 37

Repair and Returns ........................................................................................................................37

ii

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

Page 3

Introduction

Thank you for purchasing an RST-5003 Web Enabled Control Module from APG. We appreciate your

business! Please take a few minutes to familiarize yourself with your RST-5003 and this manual.

The RST-5003 Web Enabled Control Module oers a wide degree of integrated, exible, remote and local

control and monitoring for your system. The RST-5003 can control up to 10 APG Modbus sensors--any

combination of level, pressure, magnetostrictive and ultrasonic--along with one 4-20 mA sensor, and two

input or output relay terminals. All readings are available for control and monitoring via TCP/IP for local

or remote network access. The RST-5003 also had exible power options: it can use either POE or an

independent 12-28 VDC power source.

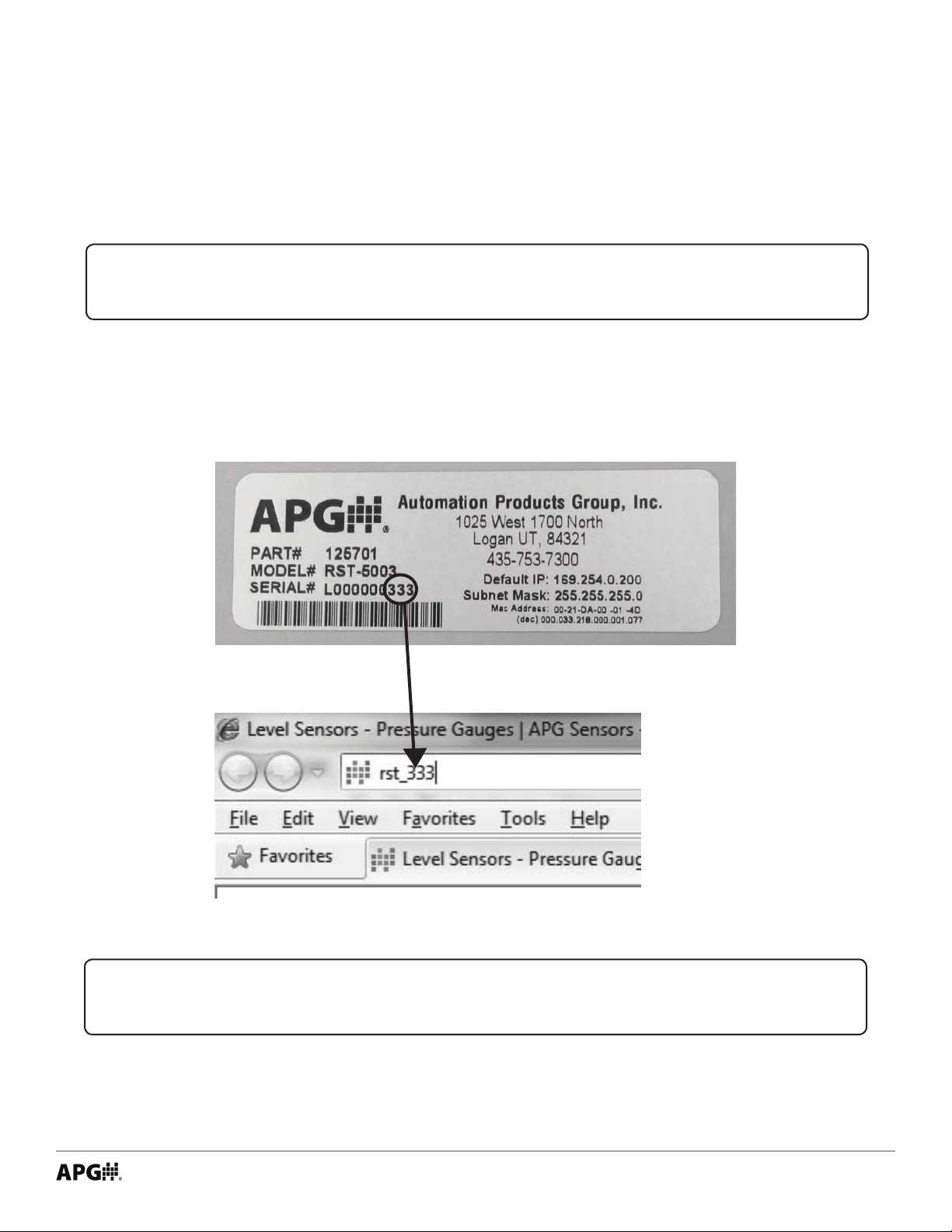

Reading your label

Every APG controller comes with a label that includes the controller’s model number, part number, and

serial number. The RST-5003 label also indicates the default IP address, subnet mask, and mac address.

Please ensure that the model number on your label matches your order.

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

iii

Page 4

Warranty and Warranty Restrictions

This product is covered by APG’s waranty to be free from defects in material and workmanship under

normal use and service of the product for 24 months. For a full explanation of our Warranty, please visit

https://www.apgsensors.com/about-us/terms-conditions. Contact Technical Support to recieve a Return

Material Authorization before shipping your product back.

Scan the QR code below to read the full explanation of our Warranty on your tablet or smartphone.

iv

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

Page 5

Chapter 1: Specications and Options

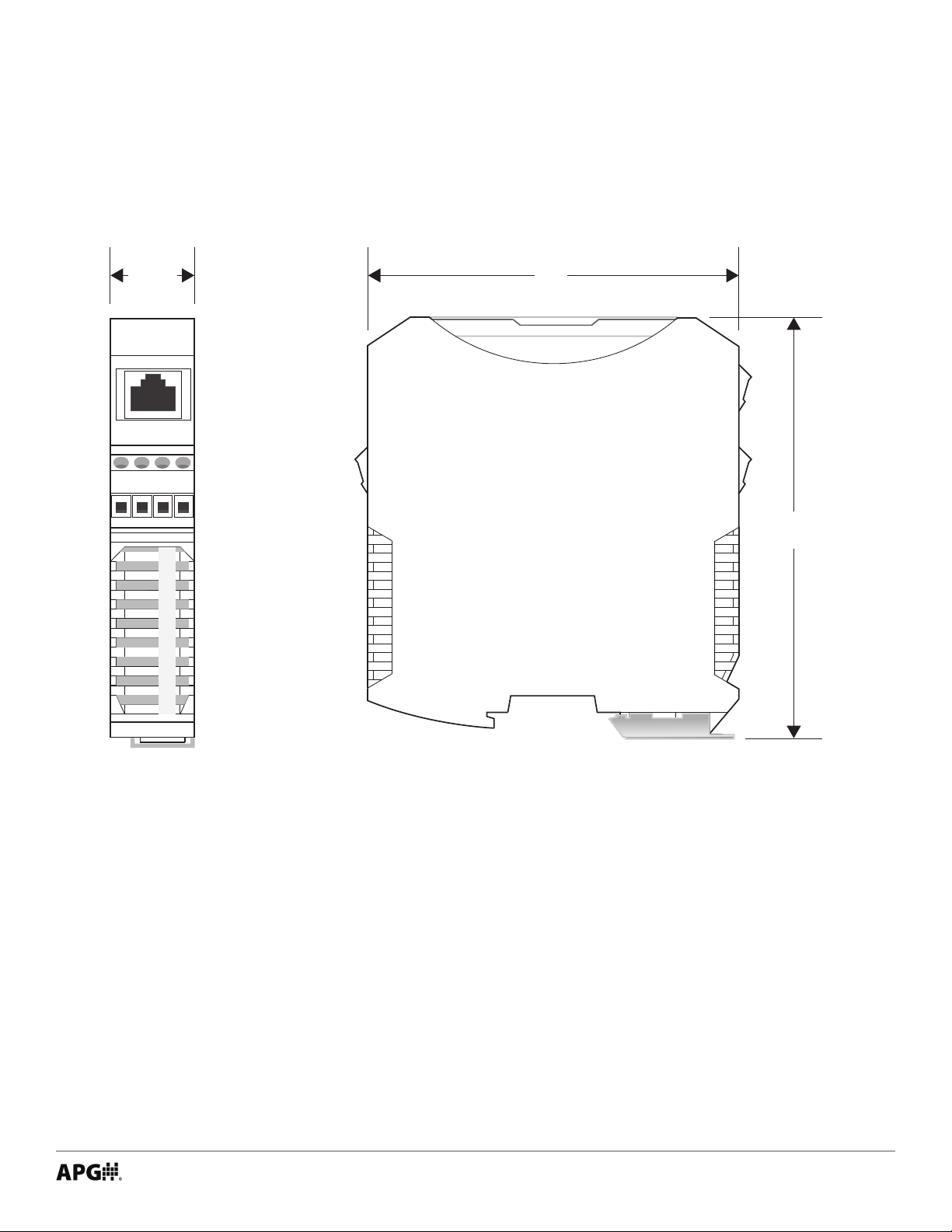

• Dimensions

7/8”

B

A

4”

2

G

4

N

V

D

4 1/2”

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

1

Page 6

• Specications

Communications

Digital Output Ethernet TCP/IP Modbus

Ethernet TCP/IP to internal web page

Ethernet TCP/IP to APG-provided website

0-2 Isolated Solid State Relays

Inputs RS-485 Modbus

4-20 mA

0-2 Discrete Switches

Electrical

Operational Supply Voltage (at sensor) 48 VDC via POE (requires injector or switch)

12-28 VDC

Current Draw 40 mA @ 48 VDC

Power Rating 2.0 W Max

Issolated SSRs 120V, 120 mA Max

Accuracy

Resolution 12 bit

Environmental

Operating Temperature -40 to 60°C (-40 to 140°F)

Materials of Construction

Housing Polyamide

Mounting

33 mm Din-Rail

Compatible APG Modbus Senors

Ultrasonic MNU

Magnetostrictive MPX-E1, MPX-R1

Pressure PT-400-L5, PT-400-L31, PT-500-L5, PT-500-L31

Controllers DCR-1006A, MND

2

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

Page 7

• Model Number Congurator

using a non-POE

Model Number: RST - _____

A

A. Model

□ 5003 2 relay outputs

□ 5013 1 relay output, 1 switch input

□ 5113 2 switch inputs

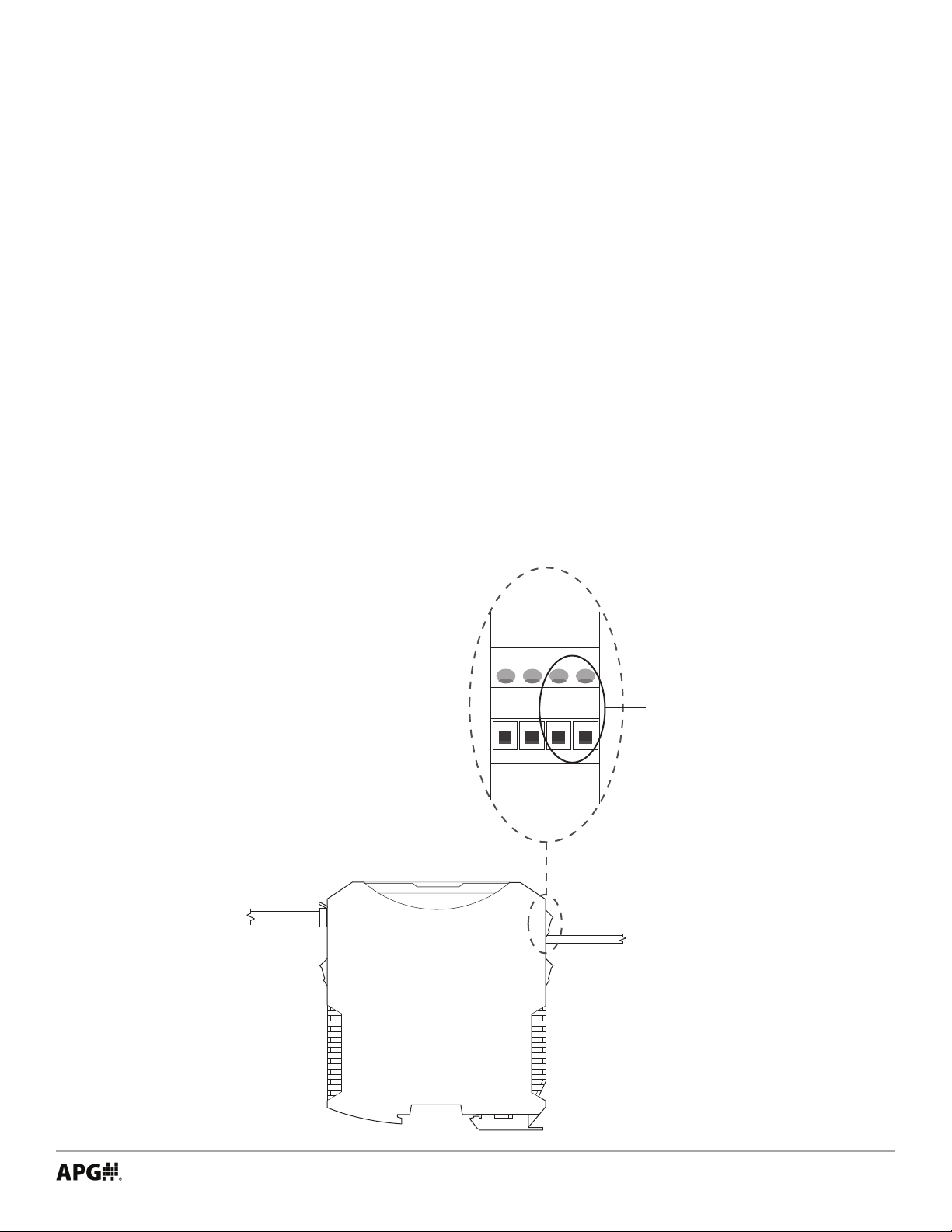

• System Wiring Diagrams

External 12-28 VDC Source Wiring

To Network

Connection

RST-5003

G

4

2

0

G

N

D

2

N

4

D

V

Input for supply

voltage when

power source

To 12-28 VDC

Power Source

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

3

Page 8

POE (Power over Ethernet) Wiring

Provides 24 VDC

G

G

4

N

N

2

D

D

0

to supply a 4-20 mA

2

4

device when the RST

V

is powered via POE.

To AC

power

POWER

POE

Power

Injector

LAN + DC LAN

NOTE: A POE-enabled

Ethernet switch eliminates

the need for a POE Power

Injector.

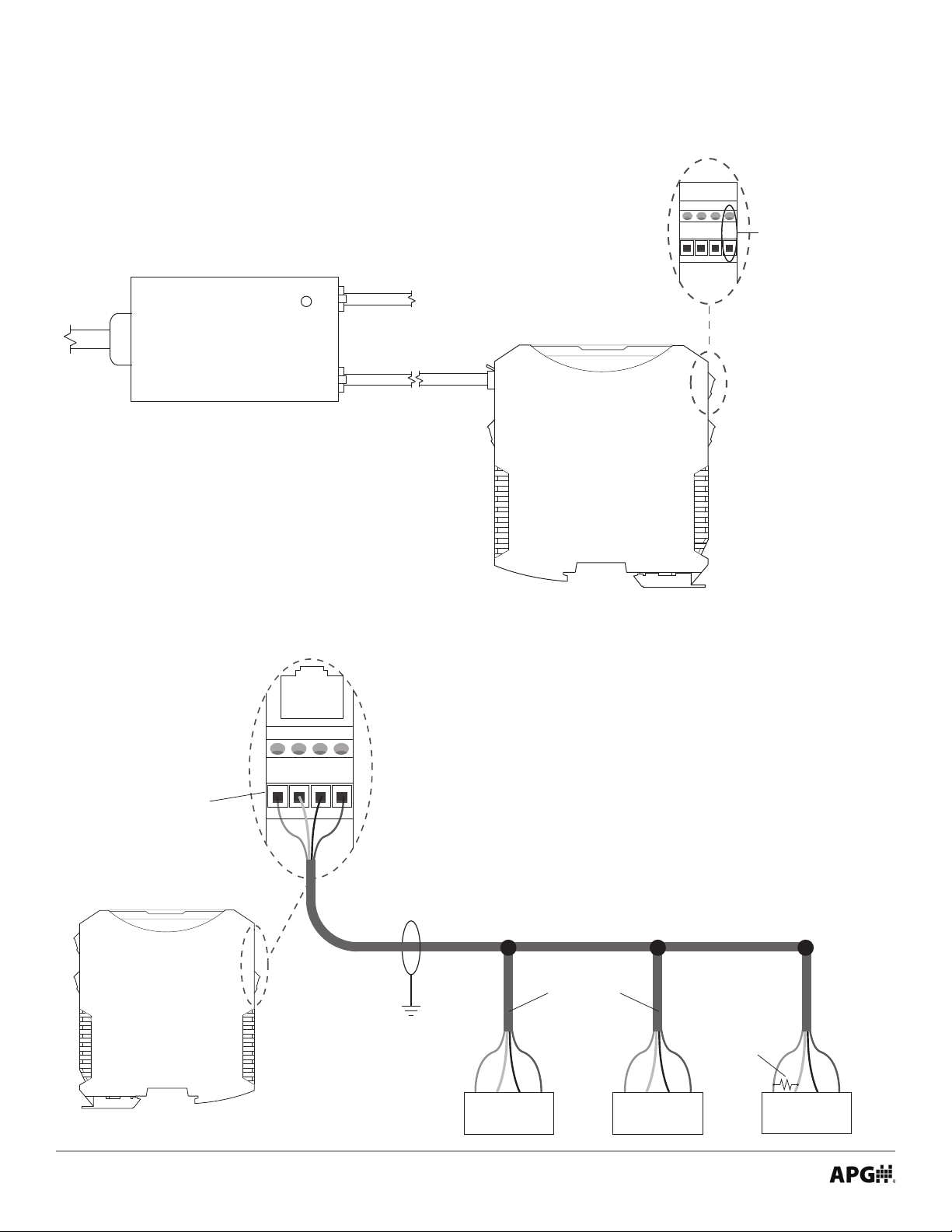

Modbus Sensor Daisy-chain Wiring

(Ethernet Port)

To Network Connection

RST-5003

2

G

4

N

B

Equivalent 270 Ω

terminating resistor

internal to RST-5003

4

A

V

D

Note: Terminating resistor size recommended

based on input resistance of RST-5003. Length

of cable and overall impedence of network may

necessitate a different size resistor.

Use shielded cable

Trunk Line

Sensor Line Drops

B

A

V+

GND

Sensor 1

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

B

A

Sensor 2

GND

270 Ω

terminating

resistor at

last sensor

V+

B

A

Sensor 3

GND

V+

Page 9

System Overview - RST-5003 with Modbus and 4-20 mA sensors and Internet Connection

Server Hosting

Website and

Logged Data

Network / Internet Connection

Connection

to

Internet

Computer

on

Internet

Computer

on

Local

Network

4-20 mA Input

RST-5003

Modbus

Input

(2) Solid State Relays

4-20 mA Type Level Sensor

MNU Ultrasonic Sensors MP Magnetostrictive Float Level Sensors

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

5

Page 10

Chapter 2: Installation and Removal Procedures and Notes

• Tools Needed

• You do not need any tools to install your RST-5003. Please consult each sensor’s user manual for any

sensor installation notes and instructions.

NOTE: For any APG sensor user manual, please visit http://apgsensors.com/support.

• Connection Notes

• Up to 10 Modbus sensors can be connected to the RST-5003 in any combination.

• Only one 4-20 mA sensor can be connected to the RST-5003.

IMPORTANT: Each Modbus sensor must be connected to the network individually and

assigned a unique Sensor Number before the next sensor can be added.

• Electrical Installation

• Connect any 4-20 mA sensor, relays, or switched inputs rst.

• Connect RST to Ethernet/network.

• Connect independant 12-28 VDC supply if not using POE.

• Connect and set up one Modbus sensor at a time.

IMPORTANT: Multiple Modbus sensors added to the network simultaneously are all

assigned the same Modbus address/sensor number: 1. Sensors MUST be added to the

network individually.

6

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

Page 11

• Software Setup

Initial setup of the RST-5003 and individual Modbus sensors is done via an embedded web server. The page

can be accessed by using either the serial number or local IP address of the RST-5003 and a web browser

(Internet Explorer, Chrome, Firefox, etc).

NOTE: Port 6700 must be open on your local network for the RST-5003 to connect.

Accessing RST-5003 Embedded Web Server

The easier way to access the embedded web server is to type rst_xxx into a web browser on a computer

connected to the same local network as the RST-5003. xxx represents the numeric portion of the RST-5003’s

serial number. See Figures 2.1 and 2.2.

Figure 2.1

Figure 2.2

NOTE: If your web browser performs a web search for “rst_xxx” istead of loading the

page, type “http://rst_xxx”.

Some networks will block this direct access to the RST-5003. If this is the case, you will need to use the IP address of your RST-5003 to access the embedded web server. The IP address can be obtained two ways: ask

your local network administrator, or logon to your APG-provided website, www.levelandow.com.

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

7

Page 12

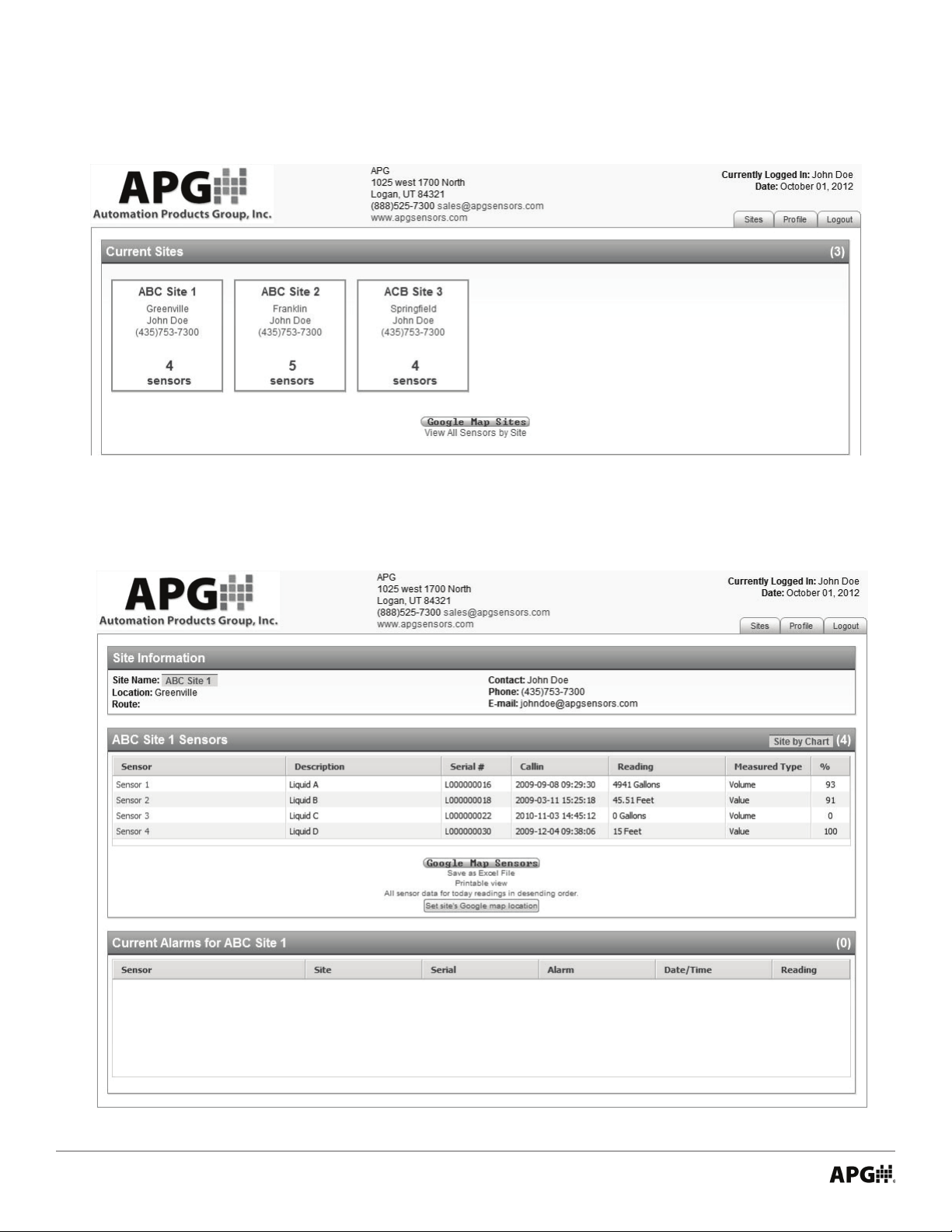

After logging on to your APG-provided website, a list of sites will be displayed on your screen (see Figure

2.3). Select the site where the new RST-5003 is installed.

Figure 2.3

From the list of sensors at this site, select the sensor with the serial number that corresponds to the new

RST-5003. (See Figure 2.4.)

Figure 2.4

8

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

Page 13

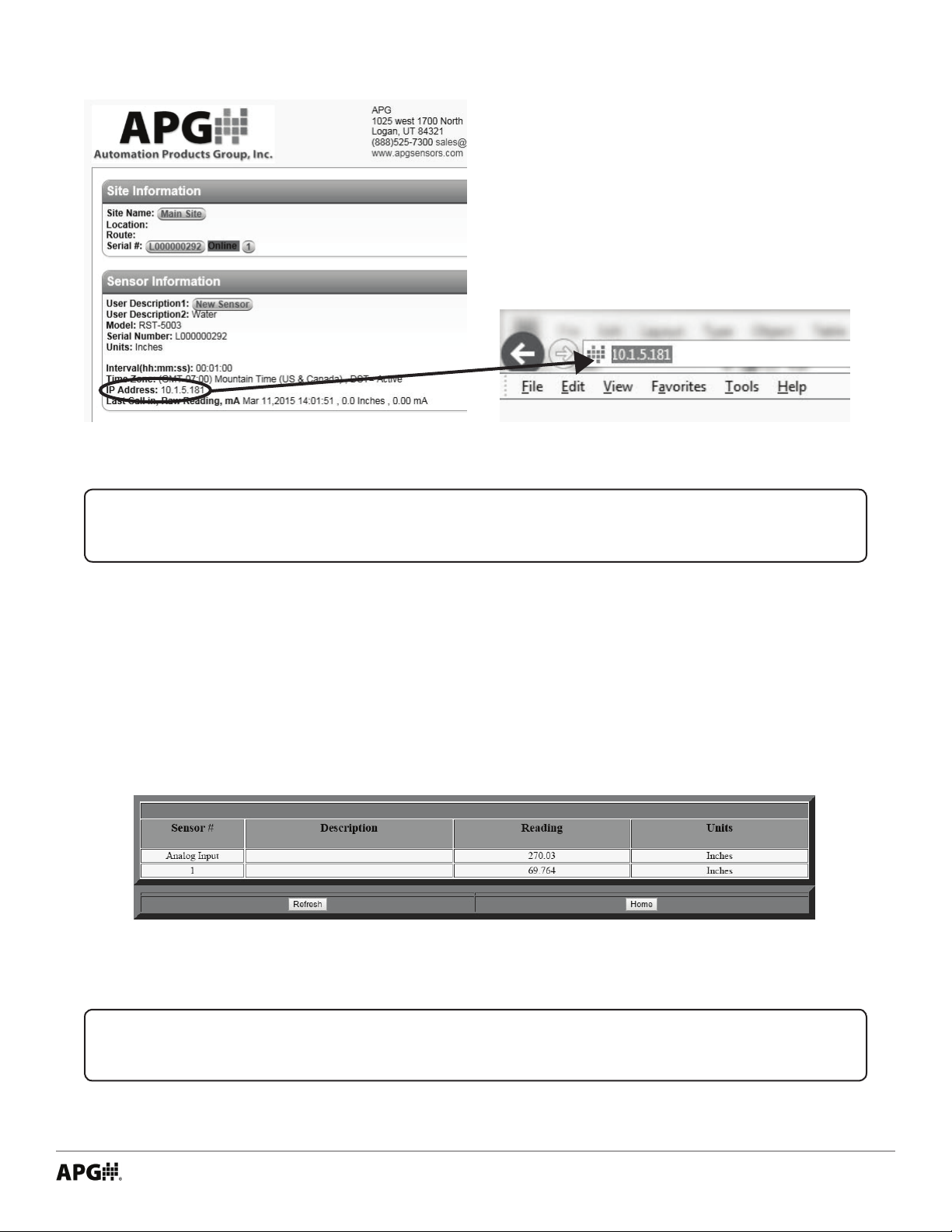

On the Sensor Information screen you will see

the IP Address of the newly installed RST-5003.

(See Figure 2.5.)

Type the RST’s IP address into your browser’s

address bar (See Figure 2.6).

Figure 2.5

Figure 2.6

NOTE: For further information on using your APG-provided remote website, please

visit www.apgsensors.com/support for a user manual, or contact us at 1-888-525-7300.

Logging on to the RST-5003 Embedded Web Server

The RST’s embedded webpage should now be open, showing the Main Display page (See Figure 2.7). This

page lists the sensors attached to the RST-5003 and displays each sensor’s current reading. A 4-20 mA sensor will have “Analog Input” as its Sensor Number. The congured sensor number for each Modbus sensor

will show as its Sensor Number. Every new Modbus sensor defaults to sensor number 1.

Figure 2.7

IMPORTANT: Multiple Modbus sensors added to the network simultaneously are all

assigned the same sensor number: 1. Sensors must be added to the network individually.

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

9

Page 14

Click on Home to bring up the Menu page (See Figure 2.8). The rst menu link clicked during each session

will prompt a User Name and Password login for the RST-5003 (See Figure 2.9). The default User Name is

admin, and the default Password is password.

Figure 2.8 Figure 2.9

NOTE: See the Security Setting Menu (Page 35) to change this user name and pass-

word.

Assigning Modbus Senor Numbers

Click on RS-485 Network Settings to bring up the RS485 Settings page. (See Figure 2.10.) See section RS-485

Network Settings for a full descrition of each parameter in this menu (Page 36).

10

Figure 2.10

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

Page 15

Change Numb of Sensors On Line to relfect the total number of Modbus sensors you will be connecting. Click

Change to send the new value to the RST-5003.

With Sensor Number to View set to 1 (for the latest sensor added to the Modbus network), set New Sensor

Number to the highest available number. Click Change to send the new value to the RST-5003.

Repeat this process for each Modbus sensor as it is added to the network.

NOTE: If you control the power to each Modbus sensor seperately, powering up a new

sensor after assigning a Modbus address to the previous sensor will allow you to assign

an address to the new sensor without leaving the RS845 Settings Menu.

IMPORTANT: None of parameters in the RS485 Settings menu automatically update.

Each one must be manually congured.

• Removal Instructions

• Disconnect power to the RST-5003 rst.

• Disconnect network connection.

• Disconnect any sensors, relays, and switched inputs.

• Remove the RST-5003 and store it in a dry place, at a temperature between -40° F and 180° F.

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

11

Page 16

Chapter 3: Programming with Modbus TCP/IP

• Modbus Polling via Ethernet with Modbus TCP/IP

Using the RST-5003’s IP address, and port number 502, readings can be polled from the RST-5003 for any

attached sensors via RS-485 Modbus commands. Up to 14 32-bit Input Registers, beginning with register

298, can be polled with a single command. Below is a sample Modbus command illustrating the necessary

syntax.

Example:

00 01 : Transaction Identier

00 00 : Protocol Identier

00 06 : Message Length (6 bytes to follow)

0B : The Reporting Unit Identier [i.e., Sensor Number] (0B hex = 11)

04 : The Function Code (04 = read Input Registers)

01 2E : The Data Address of the rst register requested. (12E hex + 1 = 303)

00 02 : The total number of registers requested. (read 2 registers, i.e. 303 to 304)

Byte order (hex values)

00 01 00 00 00 06 0B 04 01 2E 00 02

Notes:

• Reporting Unit indicates the sensor reading being polled from the RST-5003, in hex. 01 - 0A are for Modbus sensors 1 - 10 attached to the RST-5003. 0B reads the interpreted values from the 4-20 mA sensor

attached to the RST-5003. Unused registers (i.e., those not associated to an attached sensor) will return

zeros when polled.

• Function Code 04 reads the Input Registers. No other functionality (e.g., polling from or writing to

Holding Registers) is supported via Modbus TCP/IP with the RST-5003. Complete control functionality is

available through the embedded web server and through your APG-provided website (www.levelandow.com).

• Data Address of registers, decimal to “hex minus 1” conversion:

Decimal Address Hex minus 1 Decimal Address Hex minus 1

299 12A 306 131

300 12B 307 132

301 12C 308 133

302 12D 309 134

303 12E 310 135

304 12F 311 136

305 130 312 137

12

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

Page 17

• Total number of registers requested, up to 14, given in hex:

# of Registers Hex equivalent # of Registers Hex equivalent

01 01 08 08

02 02 09 09

03 03 10 0A

04 04 11 0B

05 05 12 0C

06 06 13 0D

07 07 14 0E

• RST-5003 Generic Modbus Register List

Input Registers (0x04)

Register Returned Data

30299 Sensor Type

30300 Distance/Level 1, Top (in mm, unsigned)

30301 Distance/Level 2, Bottom (in mm, unsigned)

30302 Sensor Temperature Reading (in 0C, signed)

30303-30304 Calculated 1 (raw)

30305-30306 Calculated 2 (raw)

30307 (upper bits) Version

30307 (lower bits) Signal Strength

30308 Battery Voltage

30309 (upper bits) Sensor Trip 1 Alarm

30309 (lower bits) Sensor Trip 1 Status

30310 (upper bits) Sensor Trip 2 Alarm

30310 (lower bits) Sensor Trip 2 Status

30311 (upper bits) Sensor Trip 3 Alarm

30311 (lower bits) Sensor Trip 3 Status

30312 (upper bits) Sensor Trip 4 Alarm

30312 (lower bits) Sensor Trip 4 Status

This is the list of generic Input Registers for polling the RST-5003 and any connected sensors. Actual registers used vary by sensor. Please see the user manual for each sensor for a full and accurate list of registers.

NOTE: For more information about Modbus RTU, please visit www.modbus.org.

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

13

Page 18

• Modbus Programming of Individual Sensors

The RST-5003 does NOT support full Modbus programming of attached sensors. Full control and conguration of individual sensors is supported through the RST-5003’s embedded web server and through the

APG-provided webpage, www.levelandow.com.

NOTE: For any APG sensor user manual, please visit http://apgsensors.com/support.

Chapter 4: RST-5003 Embedded Web Server

• Accessing the RST-5003 Embedded Web Server

See the Software Setup section of chapter 2 (pages 7 - 9) for instructions for accessing and signing into the

RST-5003 embedded web server.

• Navigating the RST-5003 Embedded Web Server

The RST-5003 embedded web server has two primary screens--the Main Display Page (Figure 4.1) and Menu

Page (Figure 4.2)--and a screen for each of 9 submenus. The submenus can be understood in three groups:

• 4-20 mA Sensor Input Conguration Submenus

Application Parameters

Analog Parameters

• Modbus Sensor Conguration Registers

RS-485 Modbus Input Reg

RS-485 Modbus Holding 1

RS-485 Modbus Holding 2

• RST-5003 Utility Menus

Network

Security

Labels

RS-485 Network Settings

The Menu Page also has a link back to the Main Display Page.

14

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

Page 19

Figure 4.1

Figure 4.2

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

15

Page 20

• 4-20 mA Sensor Input Conguration Submenus

Analog Application Settings

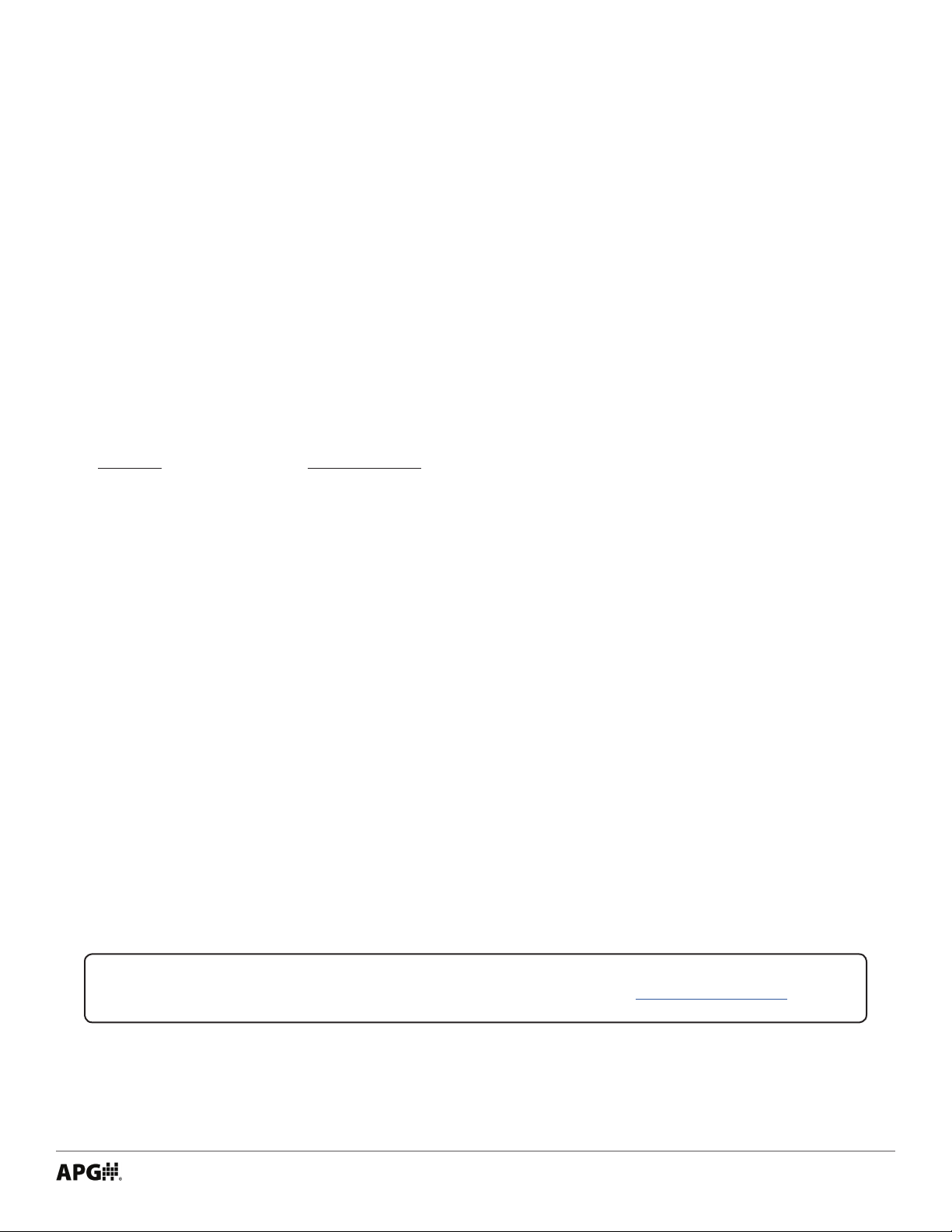

Figure 4.3

The Application Parameters menu congures the application-specic parameters applied to the calculated

reading from the 4-20 mA sensor.

PARAMETER RANGE

Units 1 - feet

2 - inches

3 - meters

Units is used to select the units of measurement for distance or level applications. The units will also

determine the resolution of Calculated Units, 4ma Value, 20ma Value, Window, Current Reading (See Figure

4.5), and all of the Application Parameters (See Figure 4.3). The resolution is: feet 0.01, inches 0.1, and

meters 0.001.

16

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

Page 21

Figure 4.4

PARAMETER RANGE

Decimal Place 0 - 0

1 - 0.1

2 - 0.01

3 - 0.001

Decimal Place sets the resolution of Calc. Dist,Level,Volume (See Figure 4.5). This resolution is also used Trip

Values and Trip Windows (See Figure 4.5), and the reading on Main Display Page (See Figure 4.1).

PARAMETER RANGE

Full Distance 0 - Sensor Maximum

Full Distance sets the distance from the sensor Reference Position (See Figure 4.5) to the full level of the vessel

being monitored. Not used when Application Type is set to 0 Value.

PARAMETER RANGE

Empty Distance 0 - Sensor Maximum

Empty Distance sets the distance from the sensor Reference Position (See Figure 4.5) to the empty level of the

vessel being monitored. Not used when Application Type is set to 0 Value.

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

17

Page 22

PARAMETER RANGE

Application Type 0 = Value (Distance)

1 = Level

2 = Volume of Standing Cylindrical Tank with or without Hemispherical Bottom

3 = Volume of Standing Cylindrical Tank with or without Conical Bottom

4 = Volume of Standing Rectangular Tank with or without Chute Bottom

5 = Volume of Horizontal Cylindrical Tank with or without Spherical Ends

6 = Volume of Spherical Tank

7 = Pounds (Linear Scaling)

8 = User Dened Units

9 = Volume of Vertical Oval Tank

10 = Volume of Horizontal Oval Tank

11 = Polynomial (strapping chart)

Application Type is used to choose the parameter conguration to convert the distance/value of Calculated

Units into Calc. Dist,Level,Volume. After selecting an Application Type and pressing “Change,” the Application

Parameters menu updates to reect the parameters of the chosen application (Compare Figure 4.3 and

Figure 4.4).

See Tank Parameters for an explaination of each Application Type and its associated parameters.

PARAMETER RANGE

Volume Units 1 = Feet3

2 = Million Feet3

3 = Gallons

4 = Meters3

5 = Liters

6 = Inches

3

7 = Barrels

Volume Units selects the units of measure for Calc. Dist,Level,Volume when a volumetric application is

selected. The settings is not used when the Application Type is set to 0, 1, 7, or 8.

Tank Parameters

Application Type Tank Parameter Function

0 - Value (Distance) Parameter 1 Not Used

Parameter 2 Not Used

Parameter 3 Not Used

Parameter 4 Not Used

Parameter 5 Not Used

Value (Distance) calculates Calc. Dist,Level,Volume using only the 4ma Value and 20ma Value settings. The result is a linear value or distance measurement.

18

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

Page 23

Application Type Tank Parameter Function

Radius

Distance

1 - Level Parameter 1 Not Used

Parameter 2 Not Used

Parameter 3 Not Used

Parameter 4 Not Used

Parameter 5 Not Used

Level calculates Calc. Dist,Level,Volume using only the 4ma Value and 20ma Value settings, just as Value (Distance) does. The dierence is that Level allows for the denition of Full Distance and Empty Distance, which

then creates a display for percentage of level on the remote website.

Application Type Tank Parameter Function

2 - Standing Cylindrical Parameter 1 Tank Diameter

Tank with Parameter 2 Bottom Radius

Hemispherical Parameter 3 Not Used

Bottom Parameter 4 Not Used

Parameter 5 Not Used

Application Type Tank Parameter Function

3 - Standing Cylindrical Parameter 1 Tank Diameter

Tank with Parameter 2 Bottom Radius

Conical Parameter 3 Cone Length (Height)

Bottom Parameter 4 Not Used

Parameter 5 Not Used

Empty

Distance

or

Diameter

Diameter

Full

Bottom

Full

Distance

Distance

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

Empty

Cone

Diameter

Cone

Length

19

Page 24

Application Type Tank Parameter Function

4 - Standing Rectangular Parameter 1 Tank X Dimension

Tank with Parameter 2 Tank Y Dimension

Chute Parameter 3 Chute X Dimension

Parameter 4 Chute Y Dimension

Parameter 5 Chute Length (Height)

Empty

Distance

Tank X

Full

Distance

Tank Y

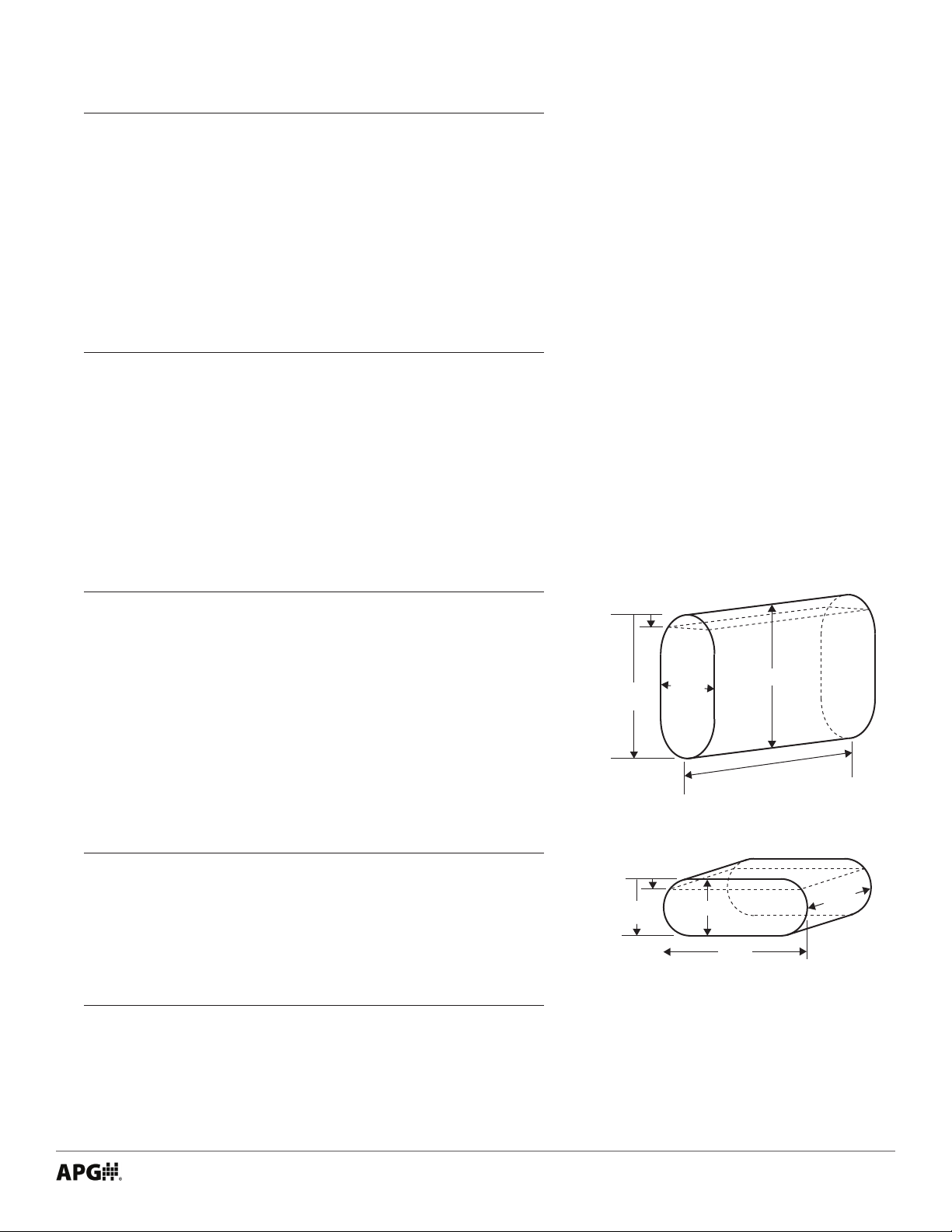

Application Type Tank Parameter Function

5 - Horizontal Cylindrical Parameter 1 Tank Length

Tank with Parameter 2 Tank Diameter

Spherical Ends Parameter 3 Radius of Ends

Parameter 4 Not Used

Parameter 5 Not Used

Diameter

End

Radius

Length

Full

Distance

Empty

Distance

or

Chute

Length

Chute X

Chute Y

Application Type Tank Parameter Function

6 - Spherical Tank Parameter 1 Tank Diameter

Parameter 2 Not Used

Parameter 3 Not Used

Parameter 4 Not Used

Parameter 5 Not Used

20

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

Empty

Distance

Diameter

Full

Distance

Page 25

Application Type Tank Parameter Function

Full

Full

7 - Pounds Parameter 1 Multiplier

(Linear Scaling) Parameter 2 Unit Denition (label)

Parameter 3 Not Used

Parameter 4 Not Used

Parameter 5 Not Used

Pounds allows for a multiplier (Parameter 1) to be applied to the Calculated Units, creating a linear scalar as

the output to Calc. Dist,Level,Volume. Such a multplier could convert the distance or level measurement of a

tank with simple geometry into a measurement of weight.

Application Type Tank Parameter Function

8 - User Dened Units Parameter 1 Not Used

Parameter 2 Unit Denition (label)

Parameter 3 Not Used

Parameter 4 Not Used

Parameter 5 Not Used

User Dened Units allows the user to set custom units for the output to Calc. Dist,Level,Volume. The label for

the custom units is stored in Parameter 2, and is applied to the the 4ma Value and 20ma Value settings, which

are used to calculate the output.

Application Type Tank Parameter Function

9 - Vertical Oval Parameter 1 Tank Length

Tank Parameter 2 Tank Depth

Parameter 3 Tank Width

Parameter 4 Not Used

Parameter 5 Not Used

Application Type Tank Parameter Function

10 - Horizontal Oval Parameter 1 Tank Length

Tank Parameter 2 Tank Depth

Parameter 3 Tank Width

Parameter 4 Not Used

Parameter 5 Not Used

Application Type Tank Parameter Function

11 - Curve Fit Polynomial Parameter 1 X^3 Coecient

(Strapping Chart) Parameter 2 X^2 Coecient

Parameter 3 X^1 Coecient

Parameter 4 X^0 Coecient

Parameter 5 Not Used

Distance

Empty

Distance

Distance

Empty

Distance

Width

Depth

Depth

Length

Length

Width

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

21

Page 26

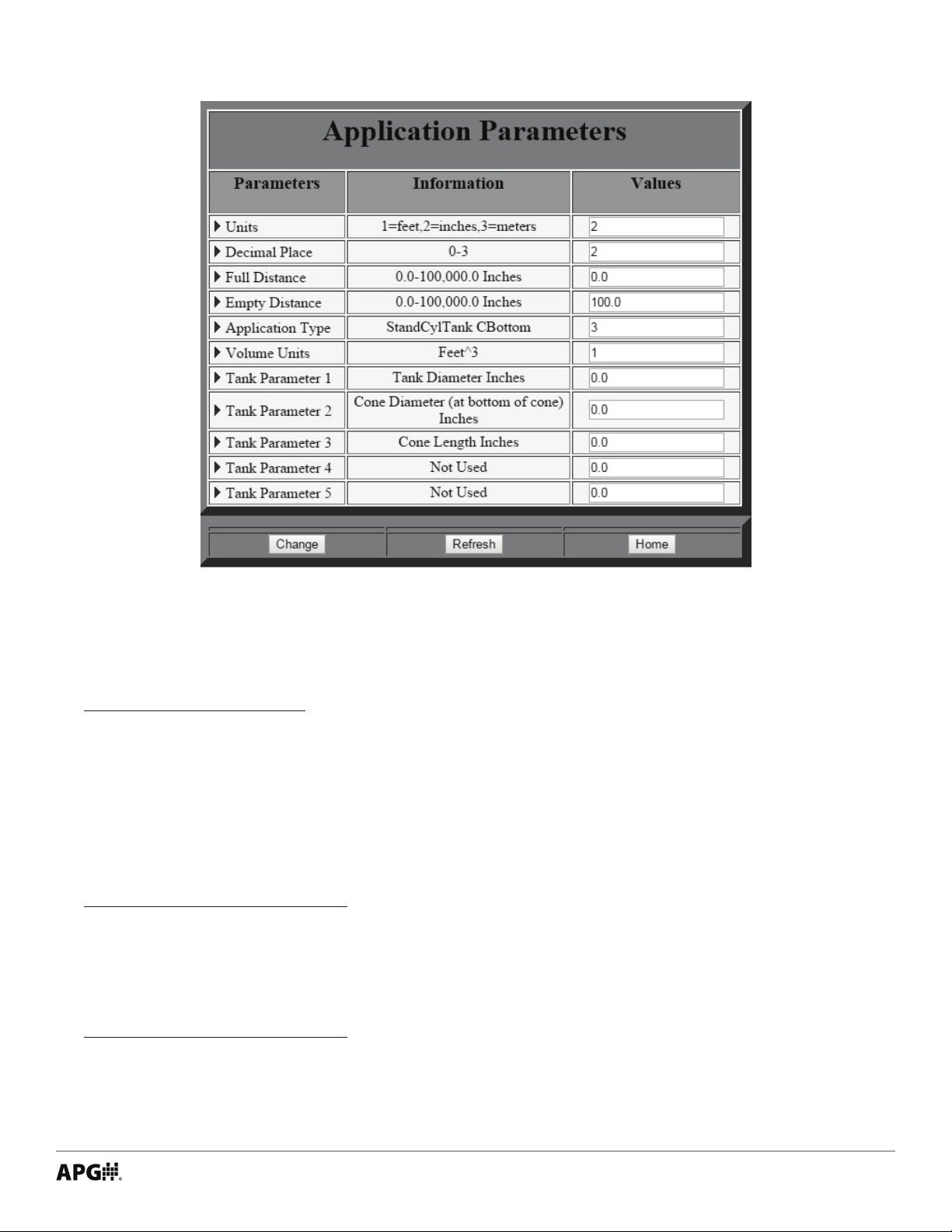

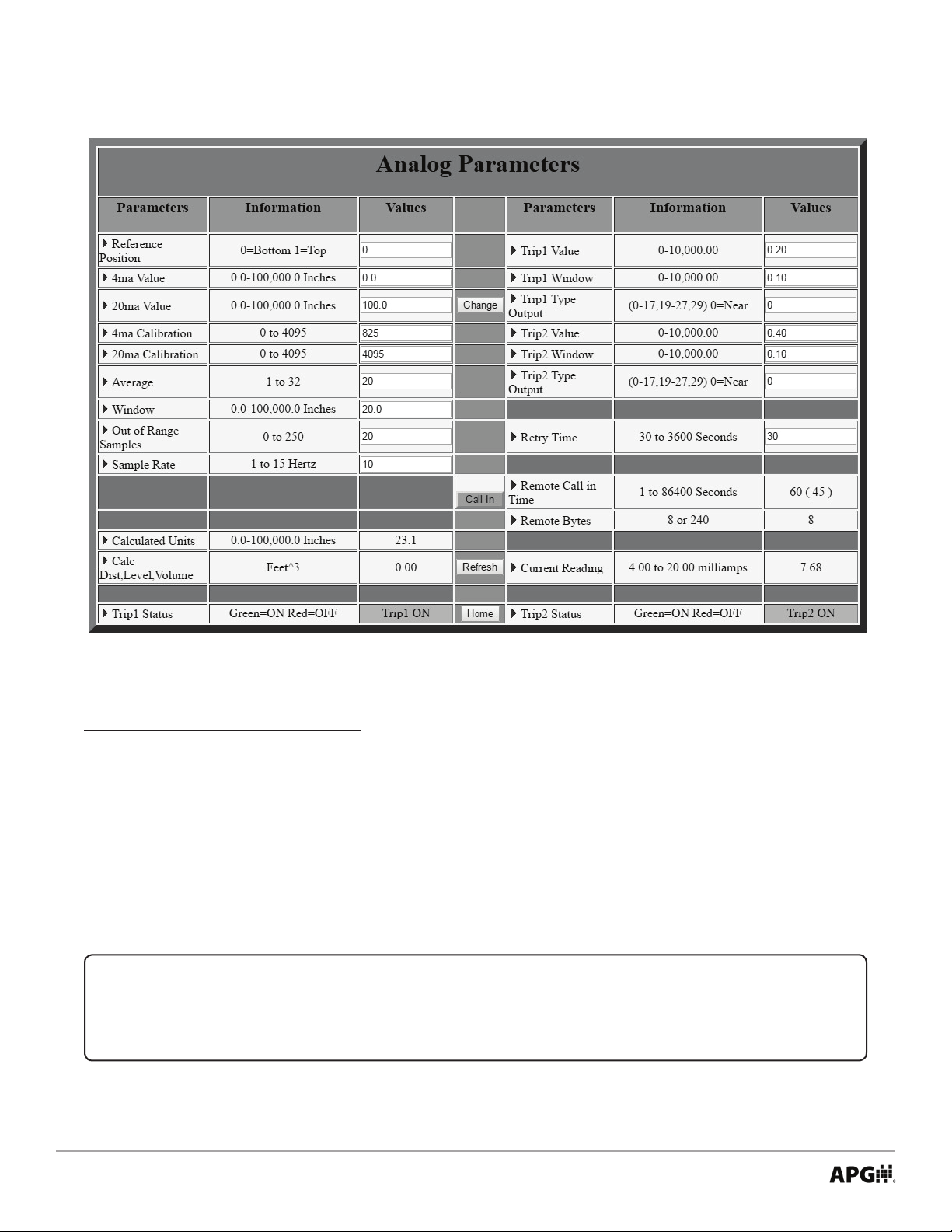

Analog Parameters

Figure 4.5

PARAMETER RANGE

Reference Position 1 = Top

0 = Bottom

0 = Not Used

Reference Position denes the zero-reference point of the sensor in relation to the vessel being monitored.

Ultrasonic sensors measure from the top down and submersible pressure transducers measure from

the bottom up. MPX magnetostrictive sensors and non-submersible pressure sensors do not use a top or

bottom reference point. Reference Position is not used when Application Type is set to 0 Value (See Figure 4.3).

IMPORTANT: Parameter values stored on the RST-5003 will not update until the

“Change” button is clicked.

22

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

Page 27

PARAMETER RANGE

4ma Value 0 - Sensor Max Distance

4ma Value assigns the RST-5003 distance output corresponding to the output of 4 mA from the sensor.

PARAMETER RANGE

20ma Value 0 - Sensor Max Distance

20ma Value assigns RST-5003 distance output corresponding to the output of 20 mA from the sensor.

NOTE: For ultrasonic sensors only:

For Distance conguration (i.e., to interpret a greater mA output as a target surface further from sensor), set the 4ma Value to be less than the 20ma Value.

For Fill conguration (i.e., to interpret a greater mA output as a target surface closer to

sensor), set the 4ma Value to be greater than the 20ma Value. See Figure 4.6.

4 ma

Reference

Position

4mA

Value

20mA

Value

20 ma

Max.

Distance

20 ma

Reference

Position

20mA

Value

4mA

Value

4 ma

Distance

Max.

Figure 4.6

PARAMETER RANGE

4ma Calibration 0 - 4095

Default: 825

4ma Calibration ne tunes the amount of recieved signal interpreted by the RST-5003 as the 4 mA signal.

PARAMETER RANGE

20ma Calibration 0 - 4095

Default: 4095

20ma Calibration ne tunes the amount of recieved signal interpreted by the RST-5003 as the 20 mA signal.

PARAMETER RANGE

Average 1-32

Average sets the number of qualied samples to average for the displayed reading. Qualied samples are

placed in a rst-in, rst-out buer, the contents of which are averaged for Calculated Units. The larger the

number of qualied samples being averaged, the smoother the output reading will be, and the slower the

reading will be to react to quick changes.

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

23

Page 28

PARAMETER RANGE

Example:

Window 0 - Sensor Maximum

Window determines the corresponding physical range for qualied samples, based on the current Calculated

Units. Samples beyond the +/- Window range of the current Calculated Units will not qualify unless the

average moves. Samples outside the extents of the Window are written to the Out of Range Samples buer.

(See Figure 4.7.)

PARAMETER RANGE

Out of Range Samples 0-250

Out of Range Samples sets the number of consecutive samples outside the Window necessary to

automatically adjust the current Calculated Units and move the Window.

PARAMETER RANGE

Sample Rate 1 - 15 Hz

Sample Rate is the number of samples of the sensor output taken by the RST-5003 every second.

Window = 6 Inches

Out of Range Samples = 10

All readings

Readings are rejected within

this area unless they persist

for 10 consecutive samples

Min. Reading Max. Reading

Current value of

Calculated Units

are accepted

within this area

6” 6”

Readings are rejected within

this area unless they persist

for 10 consecutive samples

Figure 4.7

Analog Calculated Displays

Figure 4.8

DISPLAY RANGE

Calculated Units Determined by Units

Calculated Units displays the “raw” reading--converted from the Current Reading (See Figure 4.15) from the

sensor, based on the 4ma Value and 20ma Value settings--using the decimal places determined by the Units

(See Figure 4.3). Calculated Units functions as the midpoint for Window.

DISPLAY RANGE

Calc. Dist,Level,Volume

Calc. Dist,Level,Volume displays the output calculated from Calculated Units using the Application Parameters

(See Figures 4.3 and 4.4). Calc. Dist,Level,Volume is the evaluation basis for Trip settings (see Figures 4.9 and

4.11) and shows as the Reading on the Main Display Page (See Figure 4.1).

24

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

Page 29

Analog-to-SS-Relay Trip Outputs and Settings

Figure 4.9

Figure 4.10

The RST-5003 and RST-5013 have output relays that

can be congured to turn on or o based on the Calc.

Dist,Level,Volume of the sensor.

Trip Type Outputs are congured with two independent

digits: the rst for Alarm Type (Blank, 1, or 2), and the

second for Trip Condition (0-5, 7, or 9).

PARAMETER RANGE

Trip Value 0 - Sensor Max Distance

Trip Value sets the value of the primary trip position,

which is closest to the Reference Position of the sensor.

PARAMETER RANGE

Trip Window 0 - Sensor Max Distance

Trip Window sets the value from the primary trip position

to the secondary trip position, which is farther from the

sensor’s Reference Position.

REFERENCE

POSITION

TRIP

CONDITION _0

NEAR

TRIP

CONDITION _1

EXCLUSIVE

TRIP

CONDITION _2

HYSTERESIS

NEAR

TRIP

CONDITION _3

FAR

TRIP

VALUE

ON

ON

ON

OFF

TRIP

WINDOW

OFF

OFF

ON

OFF

ON

ON

OFF

Alarm Type

Blank_ - No Alarm

Designates that no alarm is to be activated or deactivated

on the remote APG-provided website (i.e., www.

levelandow.com) for the indicated Trip Condition. To

initiate only the visual Trip Status indicator (See Figure

4.10) for Trip Condition 3, Trip Type would be set to 3.

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

TRIP

CONDITION _4

INCLUSIVE

TRIP

CONDITION _5

HYSTERESIS

FAR

OFF

OFF

Figure 4.11

ON

OFF

ON

OFF

ON

25

Page 30

Alarm Type

1_ - Active Alarm

Designates the active trip point as a web alarm condition.

To initiate web alarm whenever the Trip Condition 3 is

ON, Trip Type would be set to 13.

Alarm Type

2_ - Inactive Alarm

Designates an inactive trip point as a web alarm

condition. To initiate a web alarm whenever the Trip

Condition 3 is OFF, Trip Type would be set to 23.

Trip Condition

0 - Near

Near activates the Trip whenever the Calc.

Dist,Level,Volume is less than the Trip Value setting.

Trip Condition

1 - Exclusive

Exclusive activates the Trip whenever the Calc.

Dist,Level,Volume is less than the Trip Value setting OR

greater than the Trip Value + Trip Window settings.

Trip Condition

2 - Hysteresis Near

REFERENCE

POSITION

TRIP

CONDITION _0

NEAR

TRIP

CONDITION _1

EXCLUSIVE

TRIP

CONDITION _2

HYSTERESIS

NEAR

TRIP

CONDITION _3

FAR

TRIP

CONDITION _4

INCLUSIVE

TRIP

CONDITION _5

HYSTERESIS

FAR

TRIP

VALUE

ON

ON

ON

OFF

OFF

OFF

TRIP

WINDOW

OFF

OFF

ON

OFF

ON

ON

OFF

ON

ON

OFF

OFF

ON

Hysteresis Near activates the Trip whenever the Calc.

Figure 4.11

Dist,Level,Volume becomes less than than the Trip Value setting. The Trip remains activated until the Calc.

Dist,Level,Volume becomes greater than the Trip Value + Trip Window settings. The Trip remains o until the

Calc. Dist,Level,Volume becomes less than the Trip Value setting again.

Trip Condition

3 - Far

Far activates the Trip whenever the Calc. Dist,Level,Volume is greater than the Trip Value setting.

Trip Condition

4 - Inclusive

Inclusive activates the Trip whenever the Calc. Dist,Level,Volume is greater than the Trip Value setting AND less

than the Trip Value + Trip Window settings.

26

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

Page 31

Trip Condition

INTERVAL TIME

5 - Hysteresis Far

Hysteresis Far activates the Trip whenever the Calc. Dist,Level,Volume becomes greater than the Trip Value +

Trip Window settings. The Trip remains activated until the Calc. Dist,Level,Volume becomes less than the Trip

Value setting. The Trip remains o until the Calc. Dist,Level,Volume becomes greater than the Trip Value + Trip

Window settings again.

Trip Condition

6 - Disable Trip

16 - Disable Relay

26 - N/A

Disable de-activates the Trip or SS Relay output.

Trip Condition

7 - Loss of Echo

Loss of Echo activates the output when the maximum calculated reading (i.e., the greater of 4ma Value and

20ma Value, see Figure 4.6) is reached.

Trip Condition

8 - Timed Interval

Timed Interval activates the output for a set amount of seconds every set amount of minutes (See Figure

4.12). When Trip Type is set to 8, Trip Value and Trip Window are changed to “Interval Time (minutes)” and

“On Time (seconds)”.

(in minutes)

“ON” TIME

(in seconds)

Relay “OFF”(open)

Figure 4.12

Trip Condition

9 - Abrupt Change

Abrupt Change activates the output whenever a user-dened maximum rate of level change (change in

distance or level divided by elapsed time) is exceeded. Trip Value denes the distance and Trip Window

denes the time.

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

27

Page 32

Switched Input Alarms (RST-5013 and RST-5113 only)

Figure 4.13

The RST-5013 and RST-5113 have switched inputs (one and two, respectively) designed to continuously

monitor the status of a simple switch or contact closure. The RST can be congured to alarm on either an

open or closed input, and will immediately report to the remote APG-provided website, regardless of the

call-in interval, whenever an alarm condition is detected. The following are the three conguration options

for the switched input:

Input Alarm/Trip Type

18 - Closed Input Alarm

Closed Input Alarm activates the alarm when the input switch or contact closes.

Input Alarm/Trip Type

28 - Open Input Alarm

Open Input Alarm activates the alarm when the input switch or contact opens.

Input Alarm/Trip Type

30 - On Time Check Limit Alarm

On Time Check Limit Alarm will immediately report to the remote website whenever the input remains

continuously closed beyond the user specied time limit (in seconds, as set in the Trip Value parameter).

The RST will report to the website a second time once the alarm condition clears.

IMPORTANT: Inputs are NOT designed to monitor switches controlling a voltage or

electrical signal. The inputs are designed to detect continuity at the closure of un-powered contacts.

28

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

Page 33

External Website Communication Status

Figure 4.14

The RST-5003 embedded web server includes one parameter, one button, and two status reports for

communication with the remote APG-provided website (i.e., www.levelandow.com).

PARAMETER RANGE

Retry Time 30 - 180 Seconds

Retry Time sets the time delay (in seconds) between attempts by the RST-5003 to contact the external

website.

BUTTON

Call In

Call In forces the LOE to call in to the external website.

DISPLAY RANGE

Remote Call in Time 1 - 86400 Seconds

Remote Call in Time displays the duration of the last communication between the RST-5003 and the external

website.

DISPLAY RANGE

Remote Bytes 8 or 240 Bytes

Remote Bytes displays the number of bytes of data sent in the last communication between the RST-5003

and the external website. 8 bytes indicates a normal, successful transmission. 240 bytes indicates an error

occured in the transmission.

Analog Sensor Current Reading

Figure 4.15

DISPLAY RANGE

Current Reading 4.00 - 20.00 milliamps

Current Reading displays the current 4-20 mA reading from the analog sensor. The RST converts this reading

to a distance/value measurement based on the 4ma Value and 20ma Value settings (See Figures 4.3 and 4.5).

This converted “raw” reading (Calculated Units) is the basis for the Window function, rather than the 4-20 mA

reading from the sensor (See Figure 4.7).

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

29

Page 34

• Modbus Sensor Conguration Registers

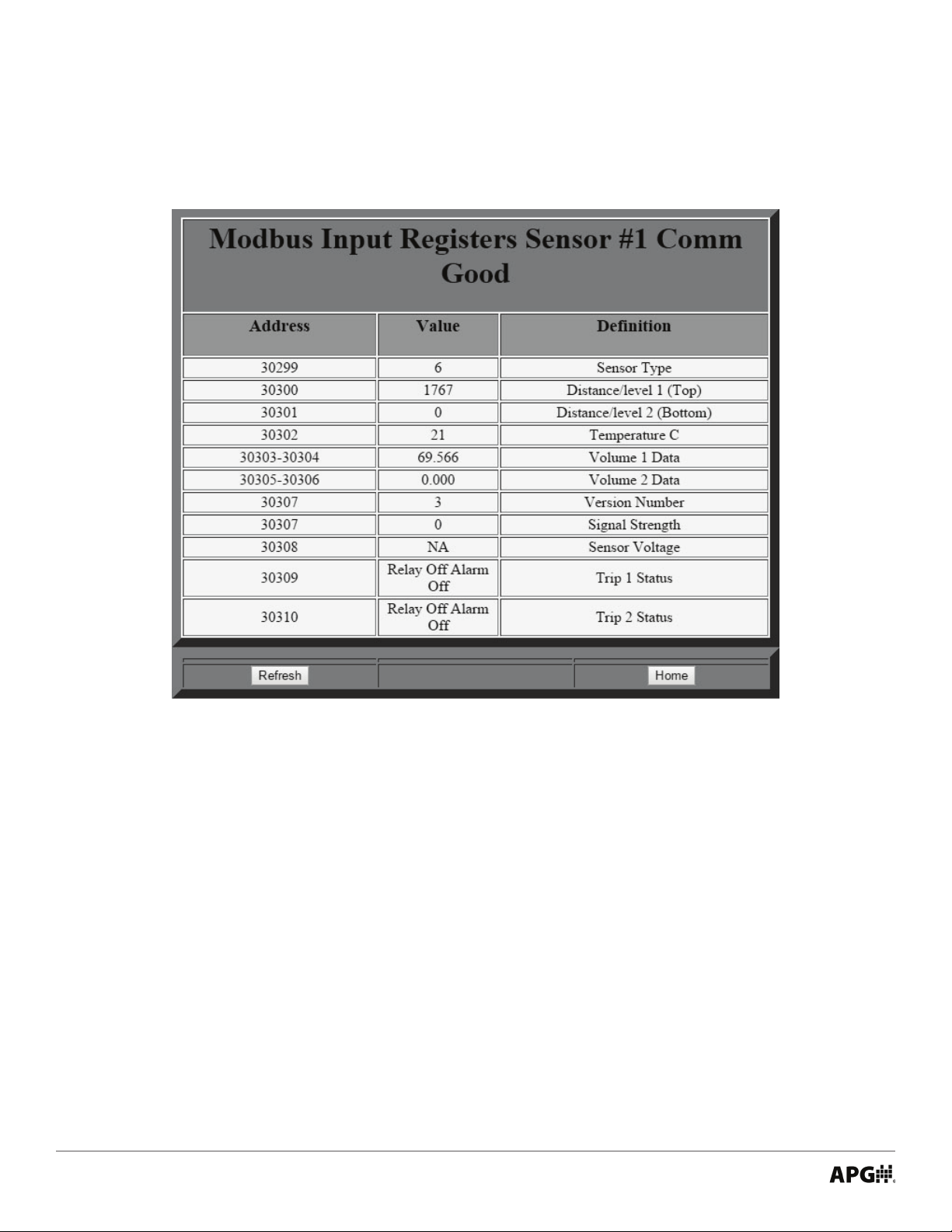

RS-485 Modbus Input Registers

Figure 4.16

This display-only menu shows the contents of the Input Registers for the selected Modbus sensor (See Figure 4.1). Registers used vary by sensor. Please see the user manual for each sensor for a full list of registers.

• Sensor Type Number and Sensor Model Number List:

Type Number Model Number Type Number Model Number

0 LOE-2126 9 PT-400/PT-500-L31 (Level)

1 LOE-6126 10 PT-400/PT-500-L5 (Pressure)

2 LOE-3136 11 DCR-1006A

3 LOE-7126 12 LPD

4 RST-5001 13 MND

5 MPX-E1/R1 (2 oats) 14 RST-5003/4

6 MPX-E1/R1 (1 oat) 15 AUS-7123

7 PG-7 16 MTM-1000

8 PG-10

Note: This list represents sensors that interface with various APG Modbus software packages. Not all inter-

face with the RST-5003.

30

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

Page 35

RS-485 Modbus Holding 1

Figure 4.17

This menu shows the contents of the rst set of Holding Registers for the selected Modbus sensor (See

Figure 4.1). The register names and value restrictions are automatically congured for the type of sensor

detected (See Figure 4.16). Because register name and use varies by sensor, including a full breakdown of

the registers in this manual would be counterproductive. Please see the user manual for each sensor for a

full list of registers.

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

31

Page 36

RS-485 Modbus Holding 2

Figure 4.18

This menu shows the contents of the second set of Holding Registers for the selected Modbus sensor (See

Figure 4.1). The register names and value restrictions are automatically congured for the type of sensor

detected (See Figure 4.16). Because register name and use varies by sensor, including a full breakdown of

the registers in this manual would be counterproductive. Please see the user manual for each sensor for a

full list of registers.

32

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

Page 37

• RST-5003 Utilty Menus

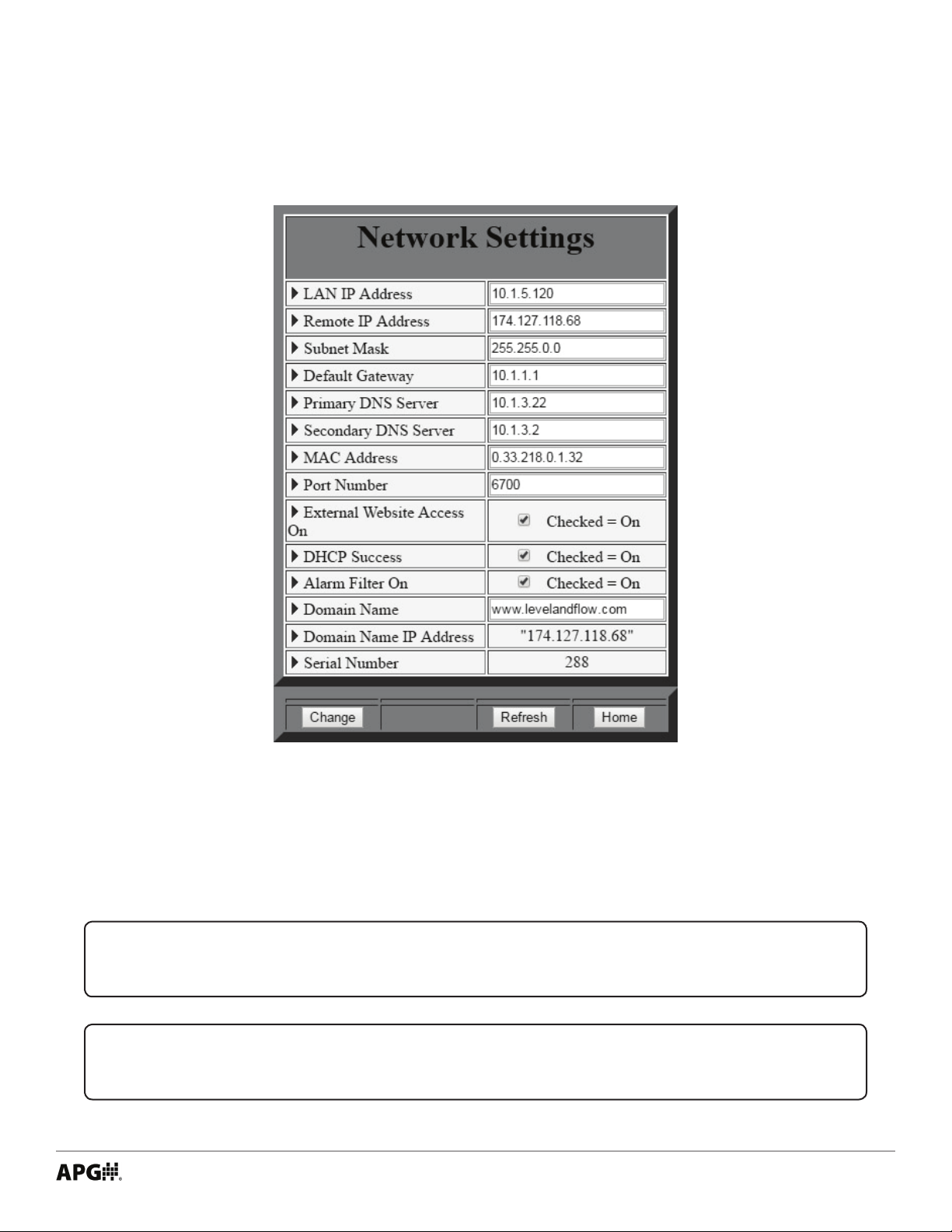

Network Settings

Figure 4.19

The Network Settings are provided for advanced users only and should not normally require changes. Each

RST ships with the DHCP enabled, which means it will automatically connect to the the APG-provided remote

website (usually www.levelandow.com) and congure its own Network Settings when plugged into a port

providing direct internet access.

NOTE: Port 6700 must be open on your local network for the RST-5003 to connect.

NOTE: Please contact APG for access to your remote access website.

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

33

Page 38

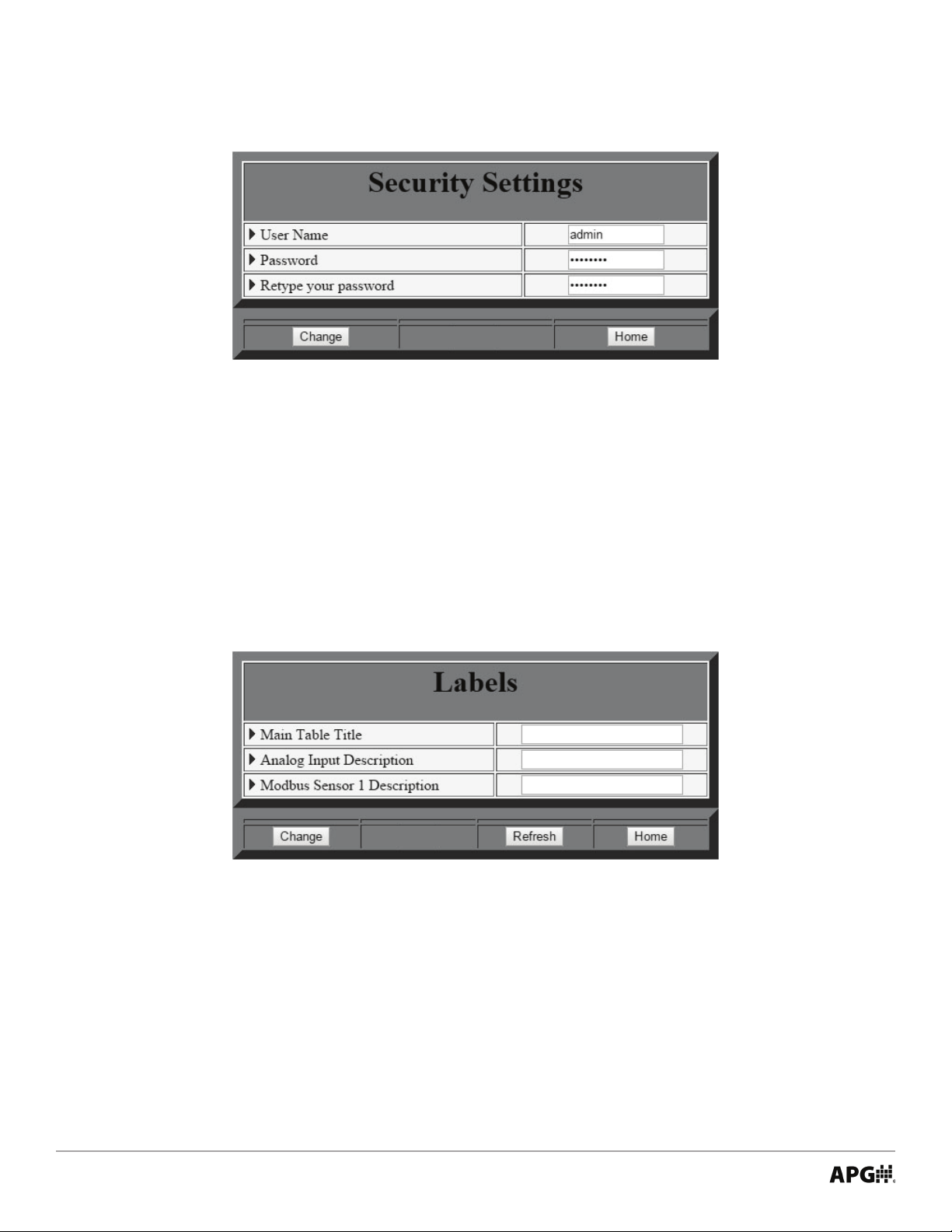

Security Settings

Figure 4.20

The Security Settings allow users to set their own user name and password for logging into the embedded

webpage.

Labels

Figure 4.21

The Labels menu allow users to create custom labels for the Main Menu and the sensors attached to the

RST-5003.

34

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

Page 39

Figure 4.22

When labels are created in the Labels menu, they will be reected on the Main Menu page (See Figure 4.22).

RS-485 Network Settings

Figure 4.23

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

35

Page 40

The RS-485 (Modbus) Settings menu controls the settings for the Modbus sensors (up to 10) attached to the

RST-5003.

PARAMETER RANGE

Baud Rate Checkbox 9600 Baud

Baud Rate Checkbox is used to indicate the baud rate of the of the sensors connected to the RST-5003. All

APG Modbus sensors communicate at 9600 Baud.

PARAMETER RANGE

Numb of Sensors On Line 0 - 10

Numb of Sensors On Line sets the number Modbus sensors connected to the RST-5003. This setting is not

automatically populated or updated. The user must change the setting manually. Numb of Sensors On Line

must always be equal or greater than the number of actual sensors attached to the RST-5003.

NOTE: For best results, set Numb of Sensors On Line to the highest number of num-

ber of sensor TO BE connected. No further adjustments will be needed as those sensors

are connected to the RST-5003.

PARAMETER RANGE

Sensor Number to View 1 - 10

Sensor Number to View selects number of the sensor for the RST-5003 to poll for populating the Main Menu

and for editing parameters in the Modbus Holding Register menus.

PARAMETER RANGE

New Sensor Number 0 = No Change

1 - 10

New Sensor Number changes the sensor number assigned to the sensor selected by Sensor Number to View.

IMPORTANT: When “Change” is pressed to assign a new sensor number, Sensor Num-

ber to View DOES NOT update.

PARAMETER RANGE

RS485 Sample Rate 1 - 20 Seconds

RS485 Sample Rate determines how often the RST-5003 polls the selected Modbus sensor.

36

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

Page 41

Chapter 5: Maintenance

• General Care

Your RST-5003 series controller is very low maintenance and will need little care as long as it was installed

correctly. However, you should avoid applications for which the controller was not designed, such as

extreme temperatures, contact with incompatible corrosive chemicals and fumes, or other damaging

environments.

• Repair and Returns

Should your RST-5003 series control module require service, please contact the factory via phone, email, or

online chat. We will issue you a Return Material Authorization (RMA) number with instructions.

• Phone: 888-525-7300

• Email: sales@apgsensors.com

• Online chat at www.apgsensors.com

Please have your RST-5003’s part number and serial number available. See Warranty and Warranty

Restrictions for more information.

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

37

Page 42

APG

R

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

Automation Products Group, Inc.

Loading...

Loading...