Page 1

APG

Thank You

Thanks for purchasing a PT-400 series pressure transmitter from us! We appreciate your business

and your trust. Please take a moment to familiarize yourself with the product and this manual

before installation. If you have any questions, at any time, don’t hesitate to call us at 888-525-7300.

NOTE: Scan the QR code to the right to see the full

user manual on your tablet or smartphone. Or visit

www.apgsensors.com/support to nd it on our website.

Table of Contents

PT-400 Series Pressure Transmitters

Installation Guide

For The PT-400

1.Description

2. How To Read Your Label

3. Warranty

4. Dimensions

Description

1

5. Mounting Instructions

6. Wiring Information

7. Zero Trimming

8. Re-calibration

9. General Care

10. Repair Information

11. Disassembly Instructions

12. Hazardous Location Wiring

The PT-400 series pressure transmitter oers reliability over a wide range of pressures and in

harsh industrial conditions and hazardous locations. It is certied intrinsically safe for hazardous

areas in the US, Canada, Europe and internationally by CSA, ATEX, and IECEx for Class 1, Zone 0

environments.

How To Read Your Label

2

Each label comes with a full model number, a part number, and a serial number. The model

number for the PT-400 will look something like this:

SAMPLE: PT-400-L1-100-PSI-G-E5-5-P5-N0-M1-S0

The model number correlates with all the congurable options and tells you exactly what you have.

Compare the model number to the options on the datasheet to identify your exact conguration.

You can also call us with the model, part, or the serial number and we can help you.

The label also includes the pinout, as does this installation guide.

You’ll also nd all hazardous certication information on the label.

R

Automation Products Group, Inc.

1025 W 1700 N Logan, UT 84321

www.apgsensors.com | phone: 888-525-7300 | email: sales@apgsensors.com

Mounting Instructions

5

Part # 122950-0001

Doc #9004026 Rev C

The PT-400 should be installed in an area--indoors or outdoors--which meets the following

conditions:

• Ambient temperature between -40°F and 185°F (-40°C to 85°C)

• Relative humidity up to 100%

• Altitude up to 2000 meters (6560 feet)

• IEC-664-1 Conductive Pollution Degree 1 or 2

• IEC 61010-1 Measurement Category II

• No chemical corrosive to stainless steel (such as NH3, SO2, Cl2, etc.)

• Ample space for maintenance and inspection

• Class II power supply

Mounting your pressure transducer is easy if you follow a few simple steps:

• Never over-tighten the sensor. This can compress the diaphragm, changing how it reacts

to pressure. In all cases, tighten the sensor as little as possible to create an adequate seal.

On straight threads, tighten only until you feel the o-ring compress - making sure you don’t

damage or extrude the o-ring.

• Always use thread tape or sealant compound on tapered threads. Straight threads use an

o-ring. If using thread tape, wrap the tape in the opposite direction of the threads so it does

not unravel as you screw it into place. Unraveling can cause uneven distribution and seal

failure.

• Always start screwing in your sensor by hand to avoid cross-threading. Thread failure can be a

problem if you damage threads by over-tightening them or by crossing threads.

Warranty

3

This product is covered by APG’s waranty to be free from defects in material and workmanship

under normal use and service of the product for 24 months. For a full explanation of our Warranty,

please visit https://www.apgsensors.com/about-us/terms-conditions. Contact Technical Support to

recieve a Return Material Authorization before shipping your product back.

Scan the QR code below to read the full explanation of our Warranty on your tablet or smartphone.

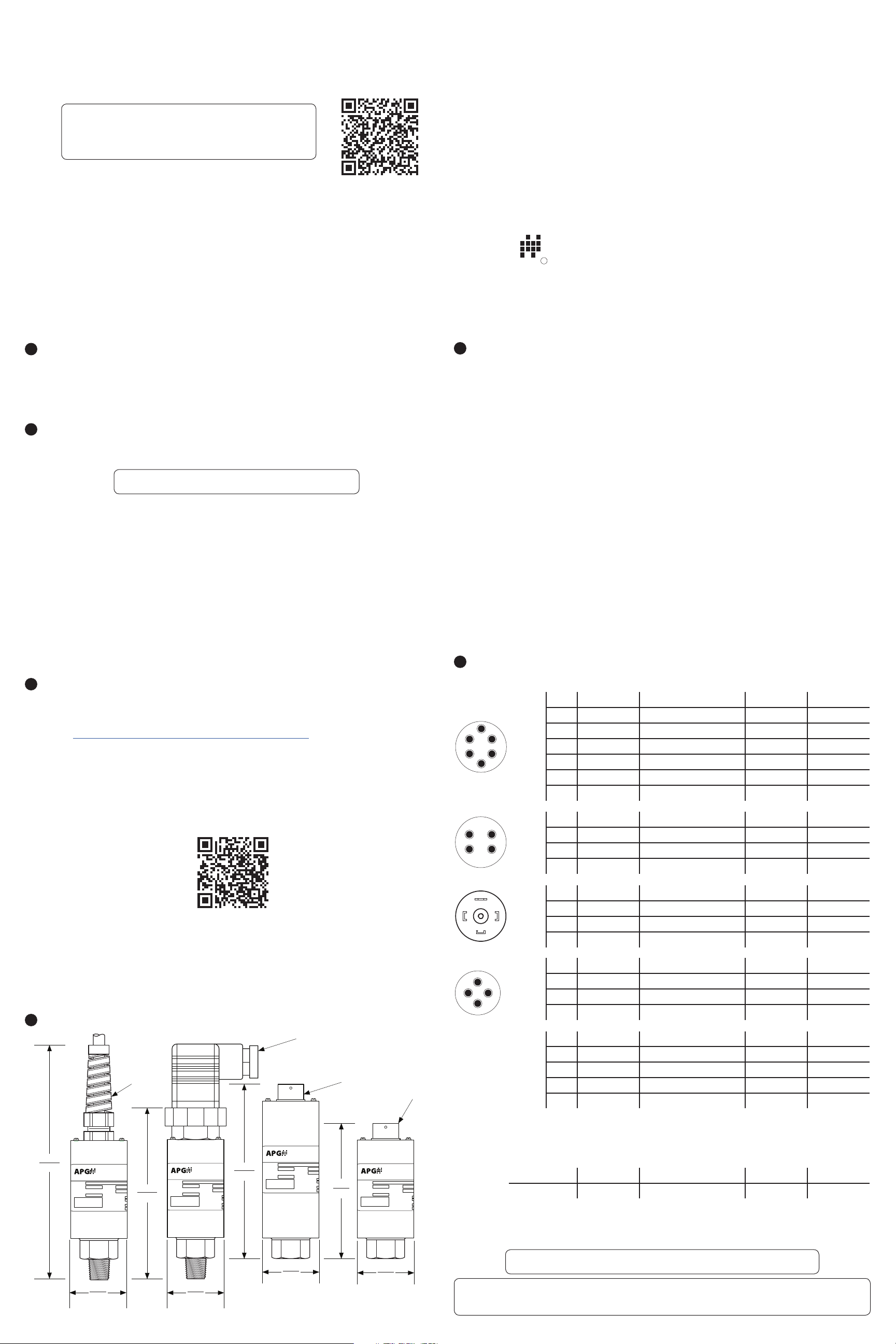

Dimensions

4

Pigtail

DIN Connector

with L Bracket*

4 or 6 pin

Bayonet

Connector on

Extended Can

4 or 6 pin

Bayonet

Connector

Wiring Information

6

PT-400 Series Pin Out Table

A

F

E

A

B

1 2

+

3

B

D

6 Pin

C

Bayonet

D

C

4 Pin

Bayonet

4

DIN

4 Pin

3

4

1

2

4 Pin

M12

Cable

4-20 mA 0-5 / 0.5-4.5 / 1-5 VDC 0-10 VDC RS-485

A + Excitation + Excitation + Excitation + Excitation

B - Excitation + Output + Output - Excitation

C N/C - Output - Output N/C

D N/C - Excitation - Excitation B (Tx-)

E N/C N/C N/C A (Tx+)

F N/C N/C N/C Case GND

A + Excitation + Excitation + Excitation N/A

B - Excitation + Output + Output N/A

C N/C - Output - Output N/A

D N/C - Excitation - Excitation N/A

1 + Excitation + Excitation + Excitation + Excitation

2 - Excitation + Output + Output A (Tx+)

3 N/C - Output - Output B (Tx-)

4 Case GND - Excitation - Excitation - Excitation

1 + Excitation + Excitation + Excitation + Excitation

2 - Excitation + Output + Output A (Tx+)

3 N/C - Output - Output - Excitation

4 N/C - Excitation - Excitation B (Tx-)

Red + Excitation + Excitation + Excitation + Excitation

Grn N/C + Output + Output B (Tx-)

Wht N/C - Output - Output A (Tx+)

Blk - Excitation - Excitation - Excitation - Excitation

Shld Gnd Gnd Gnd

5.80

147.32

Automation Products Group, Inc.

Model #:

Part #:

Serial #:

Made in USA

1.50

38.10

Output:

Range:

Wiring:

Pin A:

Pin B:

Pin E:

Pin F: N/C

1025 West 1700 N

Logan, Utah USA

888.525.7300

+ Exc

- Exc

N/CPin C:

N/CPin D:

N/C

N/C indicates no connection

For alternate pinouts, please consult factory

1025 W 1700 N

Logan, Utah USA

Made in USA

1.50

38.10

Output:

Range:

Wiring

Pin A: +Ex

Pin B: -Ex

Pin C: N/C

Pin D: N/C

Pin E: N/C

Pin F: N/C

888.525.7300

1025 W 1700 N

Logan, Utah USA

Made in USA

1.50

38.10

Output:

Range:

Wiring

Pin A: +Ex

Pin B: -Ex

Pin C: N/C

Pin D: N/C

Pin E: N/C

Pin F: N/C

888.525.7300

Date:

Due:

Mfg:

3.50

88.90

Automation Products Group, Inc.

Model #:

Part #:

Serial #:

Date:

Due:

Mfg:

PT-400 Series Supply Power Table

4-20 mA 0-5 / 0.5-4.5 / 1-5 VDC 0-10 VDC RS-485

Power Supply 9-28 VDC 9-28 VDC 12.5-28 VDC 9-28 VDC

IMPORTANT: Refer to section 12 for Hazardous Location Wiring.

IMPORTANT: PT-400 Modbus sensors use reversed Tx+/Tx- pins. When connecting to your

system, ensure continuity of Tx- to Tx- and Tx+ to Tx+, rather than A to A and B to B.

Automation Products Group, Inc.

Model #:

Part #:

1025 W 1700 N

Logan, Utah USA

888.525.7300

=

Automation Products Group, Inc.

Model #:

Part #:

Made in USA

1.50

38.10

Output:

Range:

Wiring

Pin A: +Ex

Pin B: -Ex

Pin C: N/C

Pin D: N/C

Pin E: N/C

Pin F: N/C

4.45

Serial #:

113.03

Date:

Due:

Mfg:

4.50

=

114.30

Serial #:

Date:

Due:

Mfg:

* Total length of PT-400 with DIN Connector and L Bracket

is equal to total length of PT-400 with Pigtail.

Page 2

Zero Trimming

7

General Care

9

• Remove the protective screw.

• Ensure that the transducer is at 0 psig or 0 psia (vacuum if absolute). For compound ranges,

i.e. -15 psi to 30 psi, the 4 mA, 0 V, 0.5 V, or 1V set point is also at vacuum.

• Using a jeweler’s screwdriver or a suitable instrument, adjust the “Z” pot until you have a 4

mA, 0 V, 0.5 V, or 1 V output.

NOTE: You

may also return

the transducer

to the factory

for repair and/

or adjustment.

IMPORTANT: Do not

make changes to the Span

adjustment (the “S” pot to the

right, see Figure 7.1) as part of

the zero trimming. The Span

should only be changed as part

of the recalibration of a gauge

with a known pressure source.

Re-Calibration

8

Zero & Span

Adjustment

Figure 7.1

Your pressure transmitter is very low maintenance and will need little care. As long as it was

installed correctly, it will need very little care and maintenance. However, in general, you should:

• Keep the sensor and the area around it generally clean.

• Avoid applications for which the sensor was not designed, such as extreme temperatures,

contact with incompatible corrosive chemicals, or other damaging environments.

• Inspect the threads whenever you remove the sensor from duty or change its location.

• Avoid touching the diaphragm. Contact with the diaphragm, especially with a tool, could

permanently shift the output and ruin accuracy.

• Cleaning the diaphragm or the diaphragm bore should be done with extreme care. If using a

tool is required, make sure it does not touch the diaphragm.

Repair Information

10

If your pressure transmitter needs repair, contact us via email, phone, or online chat on our

website. We will issue you an RMA number with instructions.

• Phone: 888-525-7300

• Email: sales@apgsensors.com

• Online chat at www.apgsensors.com

Removal Instructions

11

This procedure requires a known pressure source of at least ±0.1% accuracy in order to fully utilize

the accuracy potential of the transducer. (If not available, you can return it to the factory for re-

calibration.)

• Ensure that the transducer is at 0 psig or 0 psia (vacuum if absolute), and adjust zero as per

instructions for zero trimming.

• Apply full scale pressure to the pressure port and adjust the Span (“S”) pot (on the right of

Figure 7.1) until the full scale signal is reached.

• Re-check zero and re-adjust the zero (“Z”) pot if required

• Repeat previous two steps until no further adjustment is required.

NOTE: You may also return the transducer to the factory for repair and/or adjustment.

Removing your pressure transducer from service must be done with care. It’s easy to create an

unsafe situation, or damage your sensor, if you are not careful to follow these guidelines:

• Make sure the pressure is completely removed from the line or vessel where your sensor is

installed. Follow any and all procedures for safely isolating any media contained inside the line

or vessel.

• Remove the sensor with an appropriately sized wrench (per your process connection).

• Clean the sensor’s threads of any sealant compound or tape. Inspect the threads and the

diaphragm for any damage.

• Store your sensor in a dry place between -40° F and 180° F.

DANGER: Removing the pressure transmitter while there is still pressure in the line or

vessel could result in injury or death.

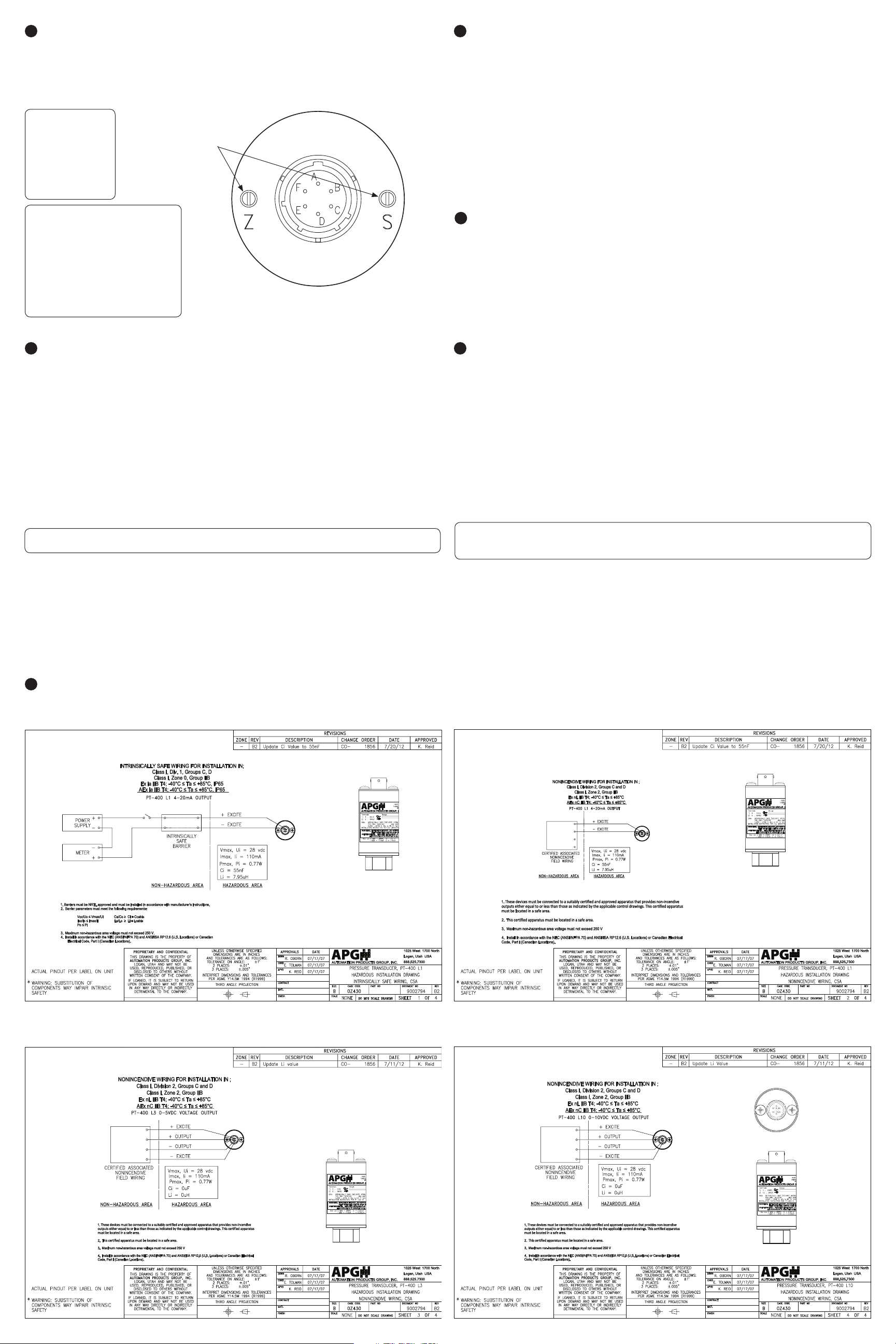

Hazardous Location Wiring

12

Intrinsically Safe Wiring (4-20mA Output) Non-Incendive Wiring (4-20mA Output)

Non-Incendive Wiring (0-5 VDC Output) [includes 0.5-4.5 VDC and 1-5 VDC] Non-Incendive Wiring (0-10 VDC Output)

Loading...

Loading...