Page 1

PRODUCTS

AUT OMATION

Operator’s Manual

GROUP, INC.

PG-2000

Automation Products Group, Inc.

APG...Providing tailored solutions for measurement applications

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www .apgsensors.com • E-mail: sales@apgsensors.com

Page 2

PG-2000 Rev. A5, 11/08

T able of Content s

Warranty ......................................................................................... 3

Instructions ..................................................................................... 4

Zero Trimming ............................................................................. 4

Battery Replacement (9 Volt Type)............................................... 4

Re-Calibration ............................................................................. 4

External Power............................................................................ 5

2

APG...Providing tailored solutions for measurement applications

T el: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

Automation Products Group, Inc.

Page 3

Rev. A5,11/08 PG-2000

• Warranty and Warranty Restrictions

APG warrants its products to be free from defects of material and workmanship

and will, without charge, replace or repair any equipment found defective upon

inspection at its factory, provided the equipment has been returned,

transportation prepaid, within 18 months from date of shipment from factory .

THE FOREGOING WARRANTY IS IN LIEU OF AND EXCLUDES ALL OTHER

W ARRANTIES NOT EXPRESSL Y SET FOR TH HEREIN, WHETHER

EXPRESSED OR IMPLIED BY OPERATION OF LAW OR OTHER WISE

INCLUDING BUT NOT LIMITED T O ANY IMPLIED WARRANTIES OF

MERCHANT ABILITY OR FITNESS FOR A PAR TICULAR PURPOSE.

No representation or warranty, express or implied, made by any sales

representative, distributor, or other agent or representative of APG which is not

specifically set forth herein shall be binding upon APG. APG shall not be liable

for any incidental or consequential damages, losses or expenses directly or

indirectly arising from the sale, handling, improper application or use of the

goods or from any other cause relating thereto and APG’s liability hereunder, in

any case, is expressly limited to the repair or replacement (at APG’s option) of

goods.

Warranty is specifically at the factory. Any on site service will be provided at

the sole expense of the Purchaser at standard field service rates.

All associated equipment must be protected by properly rated electronic/

electrical protection devices. APG shall not be liable for any damage due to

improper engineering or installation by the purchaser or third parties. Proper

installation, operation and maintenance of the product becomes the

responsibility of the user upon receipt of the product.

Returns and allowances must be authorized by APG in advance. APG will

assign a Return Material Authorization (RMA) number which must appear on

all related papers and the outside of the shipping carton. All returns are subject

to the final review by APG. Returns are subject to restocking charges as

determined by APG’s “Credit Return Policy”.

Automation Products Group, Inc.

APG...Providing tailored solutions for measurement applications

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www .apgsensors.com • sales@apgsensors.com

3

Page 4

PG-2000 Rev. A5, 11/08

• Instructions

All units are factory calibrated prior to shipment.

NOTE: Due to the temperature sensitivity of the strain gages within the

sensor, sudden temperature changes, such as holding an unmounted gauge by

the sensor, will cause the readings on the display to fluctuate. Please install

the gauge in your system before determining stability.

1. Zero Trimming:

If it becomes necessary to re-adjust the “Zero” on the display, this can be

accomplished by turning the trimpot marked “Z” just to the left of the On/Off

push button. On the PG-2000 there is either a zero adjustment knob or a black

nylon cover screw. If the gauge has a cover screw, it is necessary to remove the

cover screw to access the zero adjustment pot. An ideal zero is indicated by a

reading of 000 with an intermittently flashing “-” sign.

NOTE: A jewelers screwdriver or an eyeglass repair screwdriver (supplied)

is a suitable instrument. Do not make changes to the Span adjustment (the “S”

pot to the right of the push button) as part of the zero trimming. The Span

should only be changed as part of the re-calibration of a gauge with a known

pressure source.

2. Battery Replacement (9 V olt Type):

The battery can be replaced simply by removing the single screw at the top of

the battery door. Remove the old battery, unplug the cable connector and

replace with Eveready type 216 or equivalent. Replace the battery door and

secure with the self-tapping screw (do not overtighten).

NOTE: For best accuracy, re-calibration (see section below) should be

performed at the time batteries are replaced.

3. Re-Calibration:

This procedure requires a known pressure source of at least ±0.1% accuracy

in order to fully utilize the accuracy potential of the PG-2000. (If not available,

gauge can be returned to APG for re-calibration.)

Procedure:

A. Ensure the Gauge is at 0 psig (or vacuum if absolute), and adjust the zero

as per instructions in #1.

B. Apply full scale pressure to the pressure port and adjust the span (“S”)

pot until the display reads the correct pressure.

4

APG...Providing tailored solutions for measurement applications

T el: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

Automation Products Group, Inc.

Page 5

Rev. A5,11/08 PG-2000

C. Re-check the zero and re-adjust the zero (“Z”) pot if required.

D . Repeat steps B and C, until no further adjustment is required.

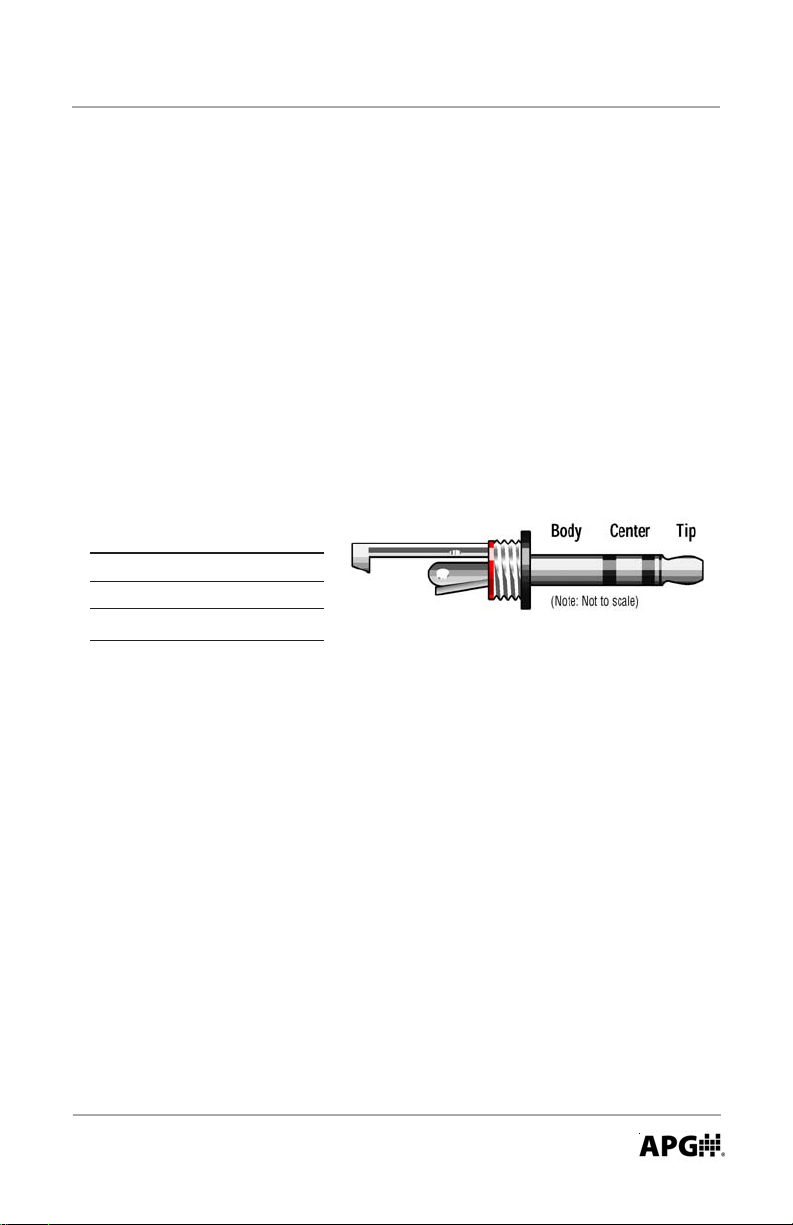

4. External Power:

When equipped with this option, the gauge no longer operates from batteries,

but instead is "externally" powered. The unit is powered via a miniature "Phone

Jack" on the back of the unit. The "Tip" connection is the "+Power", and the

"Center" is connected to the "-Power".

It is important that you never remove or insert the "Phone Jack" connector

into the gauge with the power turned on. This can damage the gauge and cause

it to fail. Only turn the power on after the "Phone Jack" has been inserted into

the external power connector.

External Power and Analog Output Plug

External Output Table

External Power

Tip + Power

Center – Power

Body No connection

Automation Products Group, Inc.

APG...Providing tailored solutions for measurement applications

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www .apgsensors.com • sales@apgsensors.com

5

Page 6

PG-2000 Rev. A4, 11/08

Notes

APG...Providing tailored solutions for measurement applications

Automation Products Group, Inc.

6

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www .apgsensors.com • sales@apgsensors.com

Page 7

Rev. A5, 11/08 PG-2000

Notes

Automation Products Group, Inc.

APG...Providing tailored solutions for measurement applications

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www .apgsensors.com • sales@apgsensors.com

7

Page 8

AUT OMATION

APG ...Providing tailored solutions

for measurement applications

Automation Products Group, Inc.

Tel: 1/888/525-7300

Fax: 1/435/753-7490

e-mail: sales@apgsensors.com

www.apgsensors.com

GROUP, INC.

1/435/753-7300

PRODUCTS

Automation Products Group, Inc.

1025 W. 1700 N.

Logan, UT 84321

To order additional copies of this manual, ask for APG part number PN9000040 Rev. A5, 11/08

Loading...

Loading...