Page 1

APG

C US

Rev. 7.05

Automation Products Group, Inc.

®

OPL

Optical Liquid Level Sensors

OPL Optical Liquid Level Sensors

■

Operational Description

e OPL series utilizes the optical

principles of a prism to detect the

presence or absence of a liquid

as compared with air. e sensor

contains a small infrared LED and

a phototransistor light receiver.

Light from the LED is directed into

the prism at the tip of the sensor.

When the container is empty, light

from the LED is reflected within

the prism back to the receiver. As

the liquid rises to cover the sensor,

light is refracted out into the liquid

and is not returned to the receiver.

e change in state is detected and

results in an output signal.

e OPL is designed to meet

standards set by major food and

health agencies around the world. It

conforms to the Japan Ministry of

Health and Welfare and to the FDA

standards in the USA.

UL approved components are

used in construction of the sensor.

■

■

■

■

Automation Products Group, Inc.

1025 West 1700 North Tel. 1/888/525-7300

Logan, UT 84321 USA Fax 1/435/753-7490

Very small OEM type optical level

sensors

Standard rubber grommet fitting

for commercial applications

Estel sensor material suitable for

pure water and most oils

Polysulphone sensor material

option for acids and alkalines or

high temperatures

■

DC powered at 5 VDC, other

voltages are available on request

■

PNP transistor output

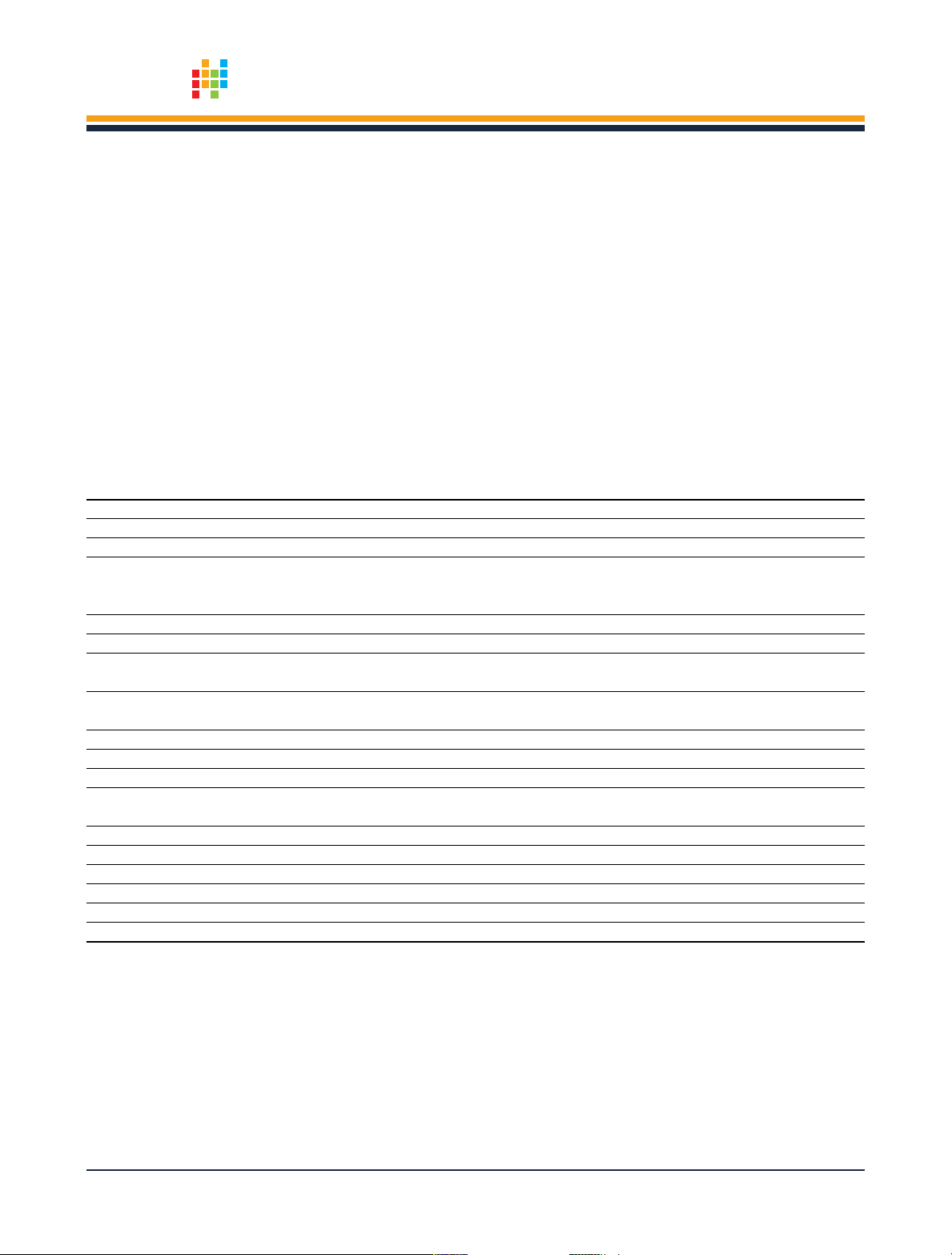

ReceiverTransmitter

Sensor in Air

1

ReceiverTransmitter

Sensor in Liquid

w w w . a p g s e n s o r s . c o m

s a l e s @ a p g s e n s o r s . c o m

Page 2

APG

Automation Products Group, Inc.

®

OPL Optical Liquid Level Sensors

■

Applications

e OPL series of sensors are

designed for low cost liquid level

monitoring and leak detection.

Typical industries served are:

semiconductor, clean water,

pharmaceutical, automotive OEM,

machine tool, home appliances such

as oil fitted heaters, and electrical

suspended solids to coat sensor and

block optical beam). Typical liquids

sensed are: petroleum and vegetable

oils (diesel, kerosene, gasoline,

hydraulic, lubricant, transmission

fluid), alcohols (ethyl, methyl),

ethylene glycol (antifreeze) and pure

water (DI or distilled water).

■

Options

Polysulphone sensor body will

allow for use in caustic liquids

such as acids and alkalines. Check

chemical compatibility tables at the

APG website or other sources for

specific compatibility.

equipment such as liquid insulated

transformers and capacitors.

e optical principle employed

is suitable for pure liquids (no

■

Specications

OPL-003 OPL-004 OPL-006

PERFORMANCE

Function: Switch on low level Switch on high level Switch on low level

Sensor Output: PNP open collector; PNP open collector; PNP open collector;

18 mA max. 18 mA max. 18 mA max.

500 mA PNP 500 mA PNP 500 mA PNP

Approvals: UL approved components UL approved components UL approved components

ELECTRICAL

Supply Voltage: 5 VDC (±0.5 VDC) 5 VDC (±0.5 VDC) 5 VDC (±0.5 VDC)

10-30 VDC on request 10-30 VDC on request 10-30 VDC on request

Wiring: #26 AWG, 3 cond. #26 AWG, 3 cond. #26 AWG, 3 cond.

Connectors available Connectors available Connectors available

PHYSICAL

Material: Estel sensor (standard) Estel sensor (standard) Polysulphone (standard)

Potting Compound: Epoxy Epoxy Silicone

Dimensions: 0.45 x 1.83 in. standard 0.45 x 1.48 in. standard 0.45 x 1.48 in. standard

(11.5 dia. x 46.5 mm) (11.5 dia. x 37.5 mm) (11.5 dia. x 37.5 mm)

Rating: NEMA 6P/IP67 NEMA 6P/IP67 NEMA 6P/IP67

Mounting: Rubber grommet (standard) Rubber grommet (standard) Rubber grommet (standard)

ENVIRONMENTAL

Operating Temperature: -4 to 140°F (-20 to 60°C) -4 to 140°F (-20 to 60°C) -4 to 302°F (-20 to 150°C)

Storage Temperature: -22 to 158°F (-30 to 70°C) -22 to 158°F (-30 to 70°C) -22 to 338°F (-30 to 170°C)

Maximum Pressure: 10 bar, 145 psi (1 Mpa) 10 bar, 145 psi (1 Mpa) 10 bar, 145 psi (1 Mpa)

Automation Products Group, Inc.

1025 West 1700 North Tel. 1/888/525-7300

Logan, UT 84321 USA Fax 1/435/753-7490

2

w w w . a p g s e n s o r s . c o m

s a l e s @ a p g s e n s o r s . c o m

Page 3

APG

Automation Products Group, Inc.

■

Corrosion Resistance Guide

®

OPL Optical Liquid Level Sensors

Estel Body Material of

Optic Level Sensor and ermistor

Level Sensor

is chart is intended as a general

guide and has been complied from

many sources believed to be reliable,

however, no guarantee is implied.

Because of the extensive scope

of this field, the tabulation is not

complete or conclusive. Corrosion

rates vary widely with concentration,

temperature and the presence of

abrasives. Impurities or other trace

elements common in industrial

liquids may inhibit or accelerate the

reaction of the material.

Key to Ratings:

A: No effect Usable

B: Minor effect Usable, but life my be

shorter than usual

C: Fair to poor Do not use

D: Not recommended Do not use

Chemical Rating

Acetic Acid 5% B

Acetic Acid 10% D

Acetone C

Alcohols Ethyl A

Methyl A

Aromatic Solvents C

ASTM Motor Fuel A A

B A

C C

ASTM Ref Oil #1 A

#2 A

#3 A

Beer A

Benzene C

Bleaching Liquors 5% A

10% C

Calcium Hydroxide B

Calcium Hypochlorite 5% A

10% C

Calcium Oxide B

Chlorine Water D

Chlorine D

Cider (Apple Juice) B

Ethanol A

Ethylene Glycol A

Fatty Acid B

Ferric Chloride C

Ferrous Sulfate B

Fruit Juice B

Gasoline A

Glucose (Corn Syrup) B

Glue, P.V.A. B

Glycerin A

Grease A

n-Hexane C

Hydrochloric Acid D

Hydrogen Peroxide D

Jet Fuel/ASTM-A D

Kerosene A

Lubricant Oil A

Specifications are subject to change without notice.

Immersion test conditions: 73°F (23°C) x 672 hours

The estel material is chemically similar to DuPont Hytrel® (Reg TME.I. DuPont de Nemours

& Co.)

Chemical Rating

Methanol A

Methyl Ethyl Ketone B

Methyl Isobutyl Ketone B

Milk A

Naphtha B

Nitric Acid D

Oils Aniline D

Castor A

Corn A

Diesel Fuel A

Fuel A

Mineral A

Silicone A

Transmission A

Vegetable A

Petroleum B

Propane (LPG) B

Propylene Glycol A

Salt Brine (NaCl Saturated) A

Sea Water A

Soap Solutions A

Sodium Carbonate B

Sodium Bicarbonate B

Sodium Chloride A

Sodium Hydroxide 10% A

20% B

50% D

Sodium Hypochlorite 20% A

100% D

Sulfuric Acid 10% A

25% B

50% D

Toluene C

Urea B

Vinegar C

Water Fresh A

Salt A

Whiskey B

Wine A

Xylene C

Automation Products Group, Inc.

1025 West 1700 North Tel. 1/888/525-7300

Logan, UT 84321 USA Fax 1/435/753-7490

3

w w w . a p g s e n s o r s . c o m

s a l e s @ a p g s e n s o r s . c o m

Page 4

APG

Automation Products Group, Inc.

0.118±0.004

3.0±0.1

Ø0.393+0/-0.008

10.0+0/-0.2

Drilled or

Punched Hole

Metal or

Plastic

Tank Wall

1.67±0.06

4.25±1.5

1.34+0.04/-0.08

34.0+1.0/-2.0

1.34+0.04/-0.08

34.0+1.0/-2.0

0.62

15.8

Ø0.45

11.5

Ø0.45

11.5

Ø0.45

11.5

Ø0.39

9.9

Ø0.39

9.9

Ø0.39

9.9

1.83

46.45

1.48

37.5

1.48

37.5

OPL-003 OPL-004 OPL-006

®

OPL Optical Liquid Level Sensors

■

Installation

Standard rubber grommet mounting.

■

Wiring

Blue

Yellow

Gray

10K

5.0VDC

OUT

■

Dimensions — in./mm

■

Ordering Information

OPL – –

Basic Function

003 Low level (switch ON when dry)

004 High level (switch ON when wet)

006 Low level (switch ON when dry); high temperature

007 High level (switch ON when wet); high temperature

Power

(null) 5 VDC standard voltage

S 12-30 VDC

Automation Products Group, Inc.

1025 West 1700 North Tel. 1/888/525-7300

Logan, UT 84321 USA Fax 1/435/753-7490

4

w w w . a p g s e n s o r s . c o m

s a l e s @ a p g s e n s o r s . c o m

Loading...

Loading...