Page 1

AUTOMATION

Operator’s Manual

P R O D U C T S

GROUP, INC.

MPX

Series

Magnetostrictive Level Sensors

Doc 9003761

Rev. B 4/13

Automation Products Group, Inc.

APG...Providing tailored solutions for measurement applications

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • E-mail: sales@apgsensors.com

Page 2

MPX Series Magnetostrictive Level Sensors Rev. B, 4/13

Table of Contents

Warranty ........................................................................................ 3

How does it work?

Installaon

Wiring

...................................................................................... 5

.......................................................................................... 6-8

.......................................................................... 4

HazardousLocaonWiring ......................................................... 8

Communicaons/Soware

........................................................ 9-15

ConguringtheSoware...................................................... 10-11

MulpleSensorCommunicaons ......................................... 12-13

UsingtheProgrammingWindow ......................................... 14-15

Modbus Register Lists ........................................................... 16-17

SensorProgramming ............................................................... 18-34

ApplicaonParameters ........................................................ 14-29

SignalProcessingandControl(advancedonly) .................... 30-31

4-20mASengs ....................................................................... 32

Web Alarms .......................................................................... 33-34

SavingandRecallingSensorSengs ......................................... 35

InspeconandMaintenance ........................................................ 36

Specicaons

Dimensions

................................................................................ 37

.............................................................................. 38-39

CercateofCompliance ........................................................ 40-43

Automation Products Group, Inc.

2

APG...Providing tailored solutions for measurement applications

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

Page 3

Rev. B, 4/13 MPX Series Magnetostrictive Level Sensors

•Warranty and Warranty Restricons

APG warrants its products to be free from defects of material and

workmanship and will, without charge, replace or repair any equipment

found defecve upon inspecon at its factory, provided the equipment

has been returned, transportaon prepaid, within 24 months from date

of shipment from factory.

THE FOREGOING WARRANTY IS IN LIEU OF AND EXCLUDES ALL OTHER

WARRANTIES NOT EXPRESSLY SET FORTH HEREIN, WHETHER EXPRESSED

OR IMPLIED BY OPERATION OF LAW OR OTHERWISE INCLUDING BUT

NOT LIMITED TO ANY IMPLIED WARRANTIES OF MERCHANTABILITY OR

FITNESS FOR A PARTICULAR PURPOSE.

No representaon or warranty, express or implied, made by any sales

representave, distributor, or other agent or representave of APG

which is not specically set forth herein shall be binding upon APG.

APG shall not be liable for any incidental or consequenal damages,

losses or expenses directly or indirectly arising from the sale, handling,

improper applicaon or use of the goods or from any other cause

relang thereto and APG’s liability hereunder, in any case, is expressly

limited to the repair or replacement (at APG’s opon) of goods.

Warranty repairs are made specically at the factory. Any on site service

will be provided at the sole expense of the Purchaser at standard eld

service rates.

All associated equipment must be protected by properly rated

electronic/electrical protecon devices. APG shall not be liable for any

damage due to improper engineering or installaon by the purchaser

or third pares. Proper installaon, operaon and maintenance of the

product becomes the responsibility of the user upon receipt of the

product.

Returns and allowances must be authorized by APG in advance. APG

will assign a Return Material Authorizaon (RMA) number which must

appear on all related papers and the outside of the shipping carton. All

returns are subject to the nal review by APG. Returns are subject to

restocking charges as determined by APG’s “Credit Return Policy”.

Automation Products Group, Inc.

APG...Providing tailored solutions for measurement applications

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

3

Page 4

MPX Series Magnetostrictive Level Sensors Rev. B, 4/13

• How does it work?

The MP series level sensors are based on magnetostricve technology.

Inside the stainless steel stem is a wire waveguide made of a metal that has

magnetostricve properes. Magnetostricve means that the atoms in

the metal realign in the presence of a magnec eld causing the metal to

temporarily deform or elongate very slightly. Inside the oat(s) are permanent

magnets. When a quick pulse of current is sent through the wire waveguide,

the magnec eld generated by the current pulse interacts with the magnec

eld of the oat(s) to realign the atoms in the waveguide. This results in a

rapid torsion that sends vibraons through the waveguide at near the speed

of sound. The sensor picks up the vibraon pulse, and through precisely

measuring the me elapsed between the current pulse and the torsion

vibraon, determines with precision the locaon of the oat. The MP has the

capability to simultaneously monitor two oats on a single stem, giving it the

ability to measure an oil/water interface level in addion to the total tank level.

Automation Products Group, Inc.

4

APG...Providing tailored solutions for measurement applications

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

Page 5

Rev. B, 4/13 MPX Series Magnetostrictive Level Sensors

• Installaon

The MPX should be installed in an area, indoors or outdoors, which meets the

following condions:

• The ambient temperature does not exceed -40oC to 85oC (-40oF to

+185oF)

• Relave humidity up to 100%

• Polluon Degree 2

• Measurement Category II

• Altude 2000 meters or less.

• Locate the Probe away from strong magnec elds, such as those produced by motors, transformers, solenoid valves, etc.

• The medium is free from metallic substances and other foreign maer.

• No corrosive gases such as NH3, SO2, Cl2, etc.

• No excessive vibraon

• Ample space for maintenance and inspecon.

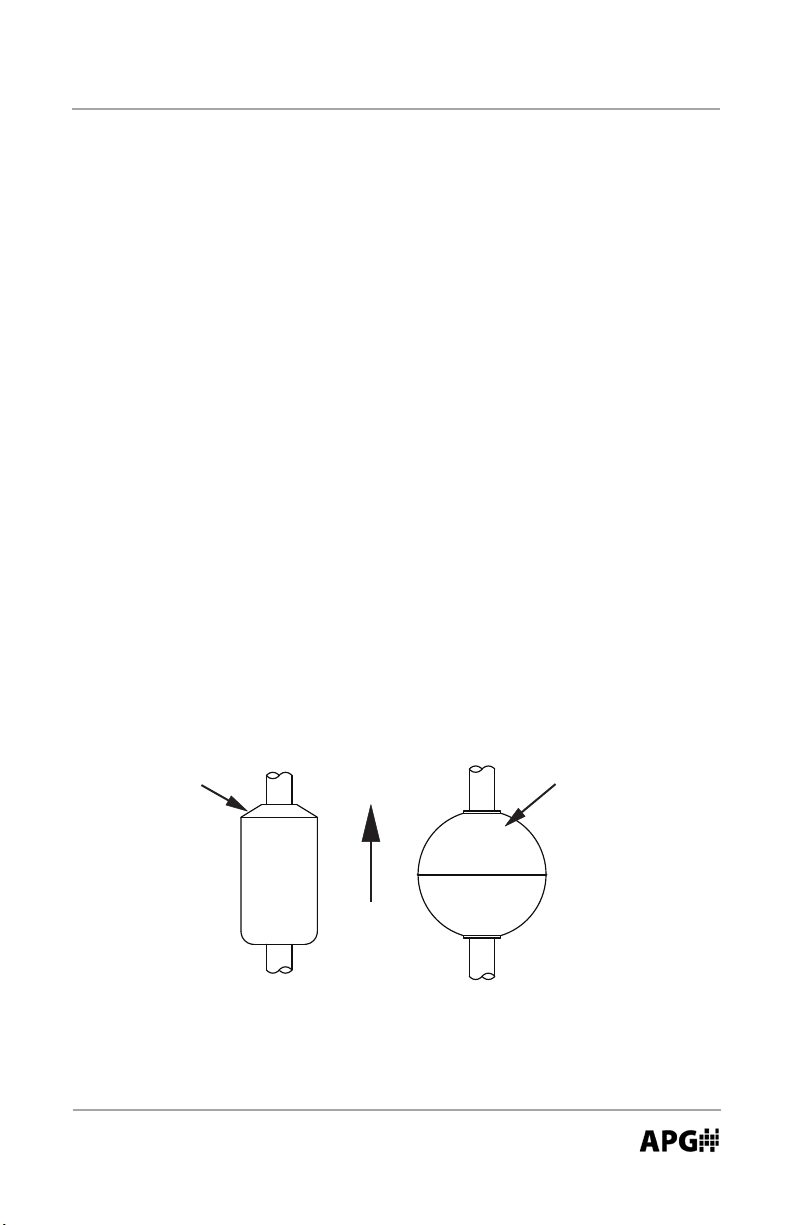

NOTE: Assure proper orientaon when installing the oat(s) on the stem

(refer to drawing below). Installing the oat(s) upsidedown can result in

unstable readings.

Taper Markings

XXXX

NC

UP

Automation Products Group, Inc.

APG...Providing tailored solutions for measurement applications

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

5

Page 6

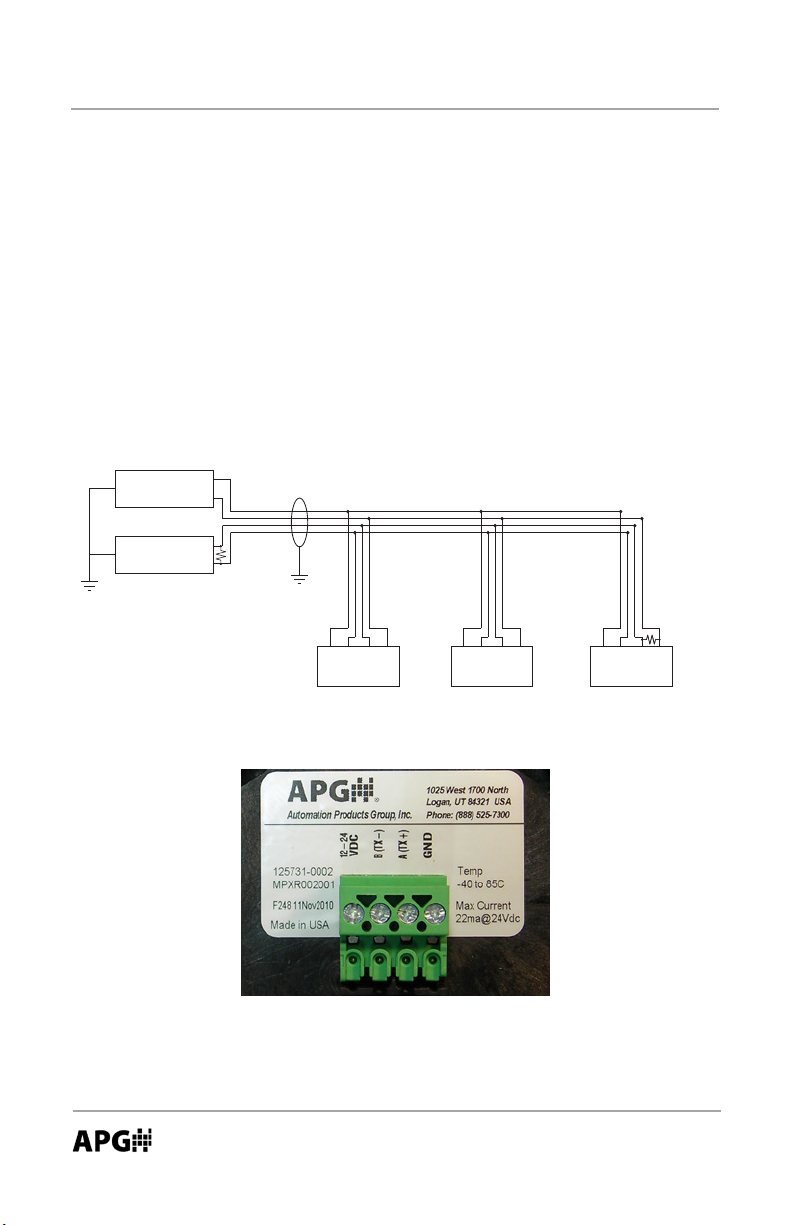

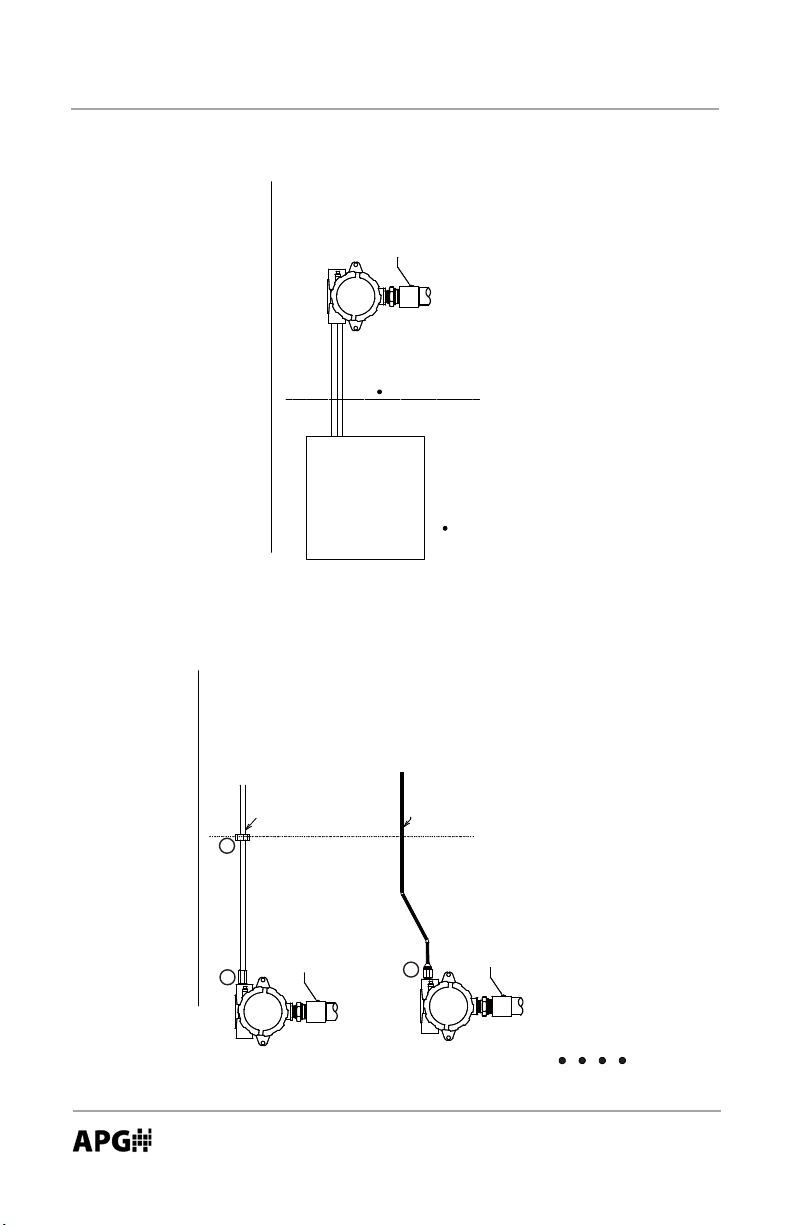

Modbus Daisy-Chain Wiring

MPX Series Magnetostrictive Level Sensors Rev. B, 4/13

• Sensor Wiring

All MPX models will operate on 10-24 Vdc. Always use a high quality power

source that will deliver clean, stable voltage.

Modbus RS-485 Wiring (MPX-E1 and MPX-R1 models)

Always use shielded cable. APG recommends using twisted-pair cable for all

Modbus network wiring.

+12-24 Vdc

Power

Supply

Master

Device

GND

RS-485 A

RS-485 B

120 Ω

terminating

resistor

Use Shielded Cable

B

V+

Sensor 1

120 Ω

terminating

resistor at last

A

GND

V+

Sensor 2

B

A

GND

B

V+

Sensor 3

sensor

A

GND

MPX-E1 and MPX-R1 wiring terminal

Automation Products Group, Inc.

6

APG...Providing tailored solutions for measurement applications

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

Page 7

Rev. B, 4/13 MPX Series Magnetostrictive Level Sensors

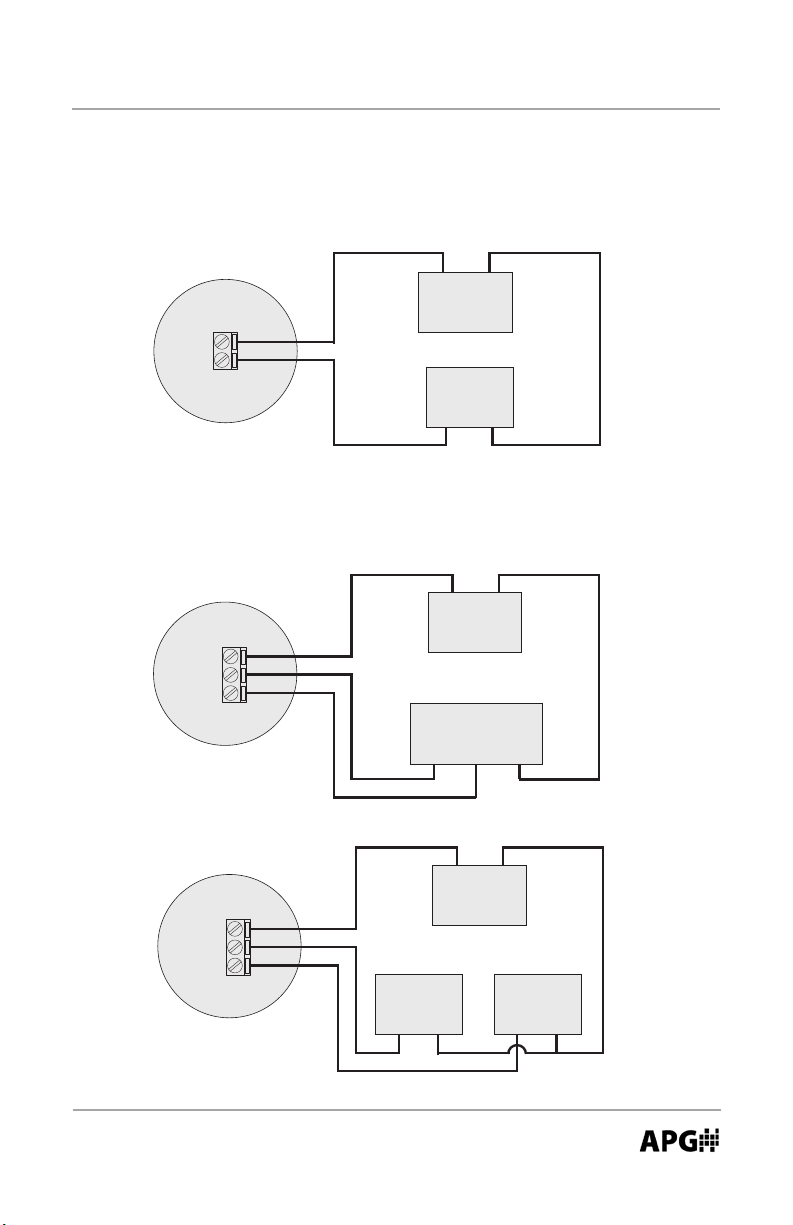

4-20 mA Loop Wiring (MPX-E2, MPX-R2 and MPX-E3, MPX-R3 models)

4-20 mA Loop Wiring

(MPX-E2 and MPX-R2 Series)

+

−

Sensor

12-24 Vdc

Out

Dual 4-20 mA Loop Wiring

(MPX-E3 and MPX-R3 Series)

Sensor

12-24 Vdc

Out 1

Out 2

Power Source

(12-24 Vdc)

Receiver

Input Com

−

+

Power Source

(12-24 Vdc)

Receiver

Input 1 Input 2 Com

OR

−

+

Sensor

12-24 Vdc

Out 1

Out 2

Automation Products Group, Inc.

APG...Providing tailored solutions for measurement applications

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

Receiver 1

Input Com

Power Source

(12-24 Vdc)

Receiver 2

Input Com

7

Page 8

MPX Series Magnetostrictive Level Sensors Rev. B, 4/13

Hazardous Locaon Wiring

C

0

Earth Ground

Connection

Hazardous Area

Non-Hazardous Area

Non-Incendive Wiring for Installation in

Class I Division 2 Groups C and D, Max. Tep. 85

C

0

Non-Hazardous Area

CSA/UL Listed Conduit

Certied Associated

Vmax = 28VDC,

Imax = 200ma,

Non-Incendive

Field Wiring Apparatus

Ci = 0nF, Li = 0

CSA/UL Listed Hazardous Location Cable

Vmax ≥ Voc,

Ca ≥ Ccable + Ci

La ≥ Lcable + Li

B

Hazardous Area

Earth Ground

A

Connection

A

Earth Ground

Connection

Install in accordance with Section 18 of the CEC or Article 500 of the NEC.

CSA listed or NRTL/UL listed conduit seal at location A & B.

Do NOT disconnect while circuit is live unless area is known to be non-hazardous

Installation in: Class I Division 1 & 2 Groups C and D, Max. Temp. 85

Ex d IIB : Ex nA IIB

Class I, Zone 1; AEx d IIB : Class I, Zone 2; AEx nA IIB

Tapering or replacement with non-factory components may adversely aect the safe use of the system.

Automation Products Group, Inc.

APG...Providing tailored solutions for measurement applications

8

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

Page 9

RST-4100

Rev. B, 4/13 MPX Series Magnetostrictive Level Sensors

• Sensor Communicaons

Modbus

(RS-485)

The MPX-E1 and MPX-R1 series ulizes standard Modbus RTU protocol (RS-

485). The sensor can only operate as a slave device. For more informaon

about Modbus RTU, please visit www.modbus.org.

The sensor will transmit at: 9600 baud, 8 bits, 1 Stop Bit, No parity (allow a

minimum delay of 300 ms between transacons).

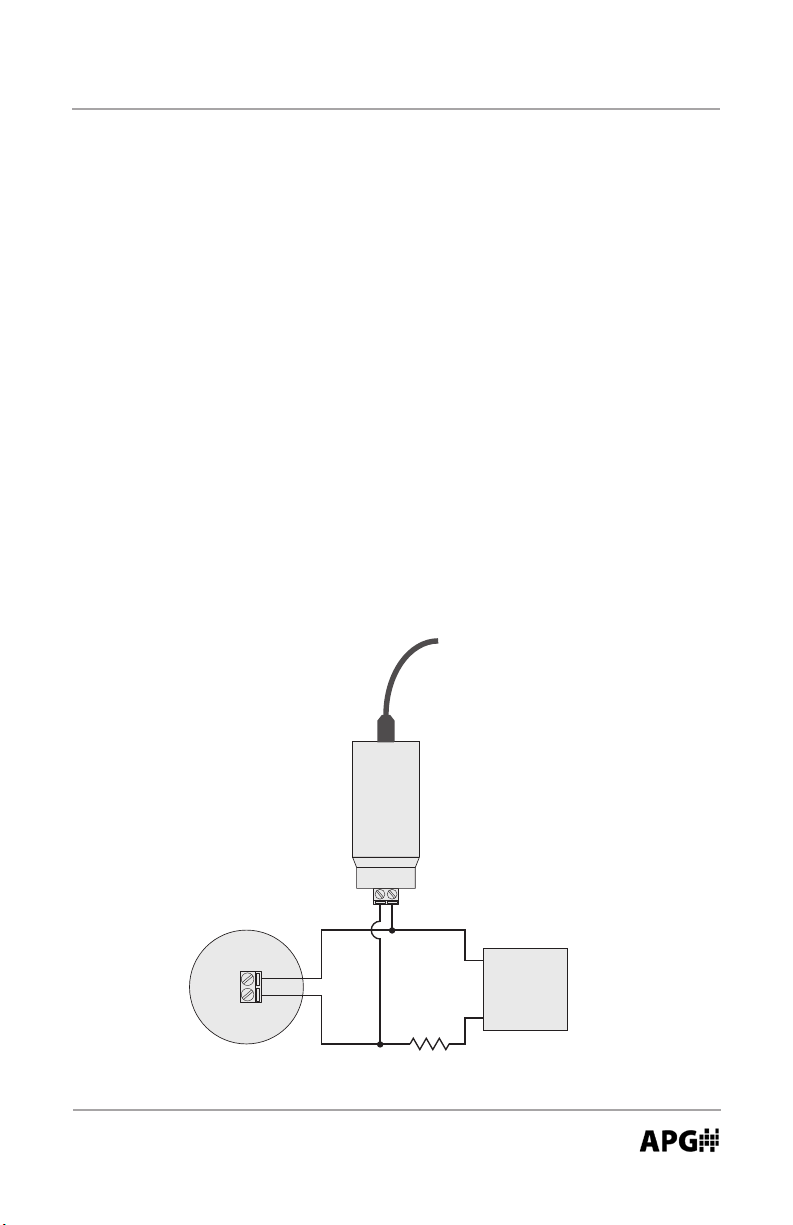

4-20 mA (requires RST-4100 module)

MPX-E2, MPX-R2, MPX-E3, and MPX-R3 sensor versions require the RST-4100

module and the APG Modbus soware for programming.

A load resistance is required at the DC Common (GND) end of the current

loop in order to establish communicaons. The RST-4100 is wired in parallel

between the power source and the sensor, with the load resistance between

the “Out” leg connecon and the power source ground (as shown below).

To USB

Programming Module

(MPX-E2, MPX-R2, MPX-E3, and MPX-R3)

Wiring

RST-4100

Out 24V

Note: a minimum of

14 Vdc is required to

Sensor

12-24 Vdc

Out

Load Resistor

(100 Ω to 700 Ω)

Automation Products Group, Inc.

APG...Providing tailored solutions for measurement applications

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

establish communications

+

Power Source

(14- 24 Vdc)

−

9

Page 10

MPX Series Magnetostrictive Level Sensors Rev. B, 4/13

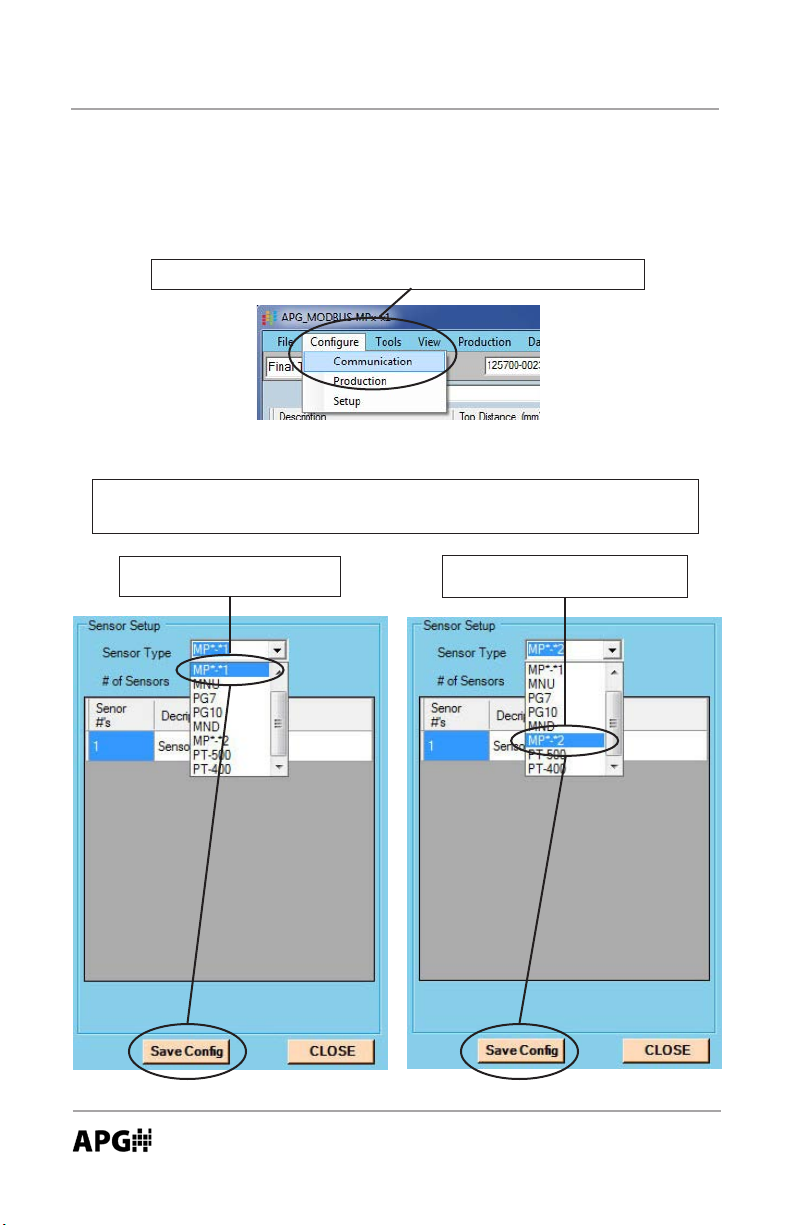

Conguring Soware Communicaons

All MPX versions use the same APG Modbus soware for sensor programming.

Use the following steps to congure the soware communicaons.

Step 1: select “Communicaon” from the “Congure” menu.

Step 2: select the appropriate Sensor Type, as shown below, then click the

“Save Cong” buon at the boom of the screen.

Modbus: select “MP*-*1”

(MPX-E1 and MPX-R1)

10

APG...Providing tailored solutions for measurement applications

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

4-20 mA: select “MP*-*2”

(MPX-E2, MPX-R2, MPX-E3, MPX-R3)

Automation Products Group, Inc.

Page 11

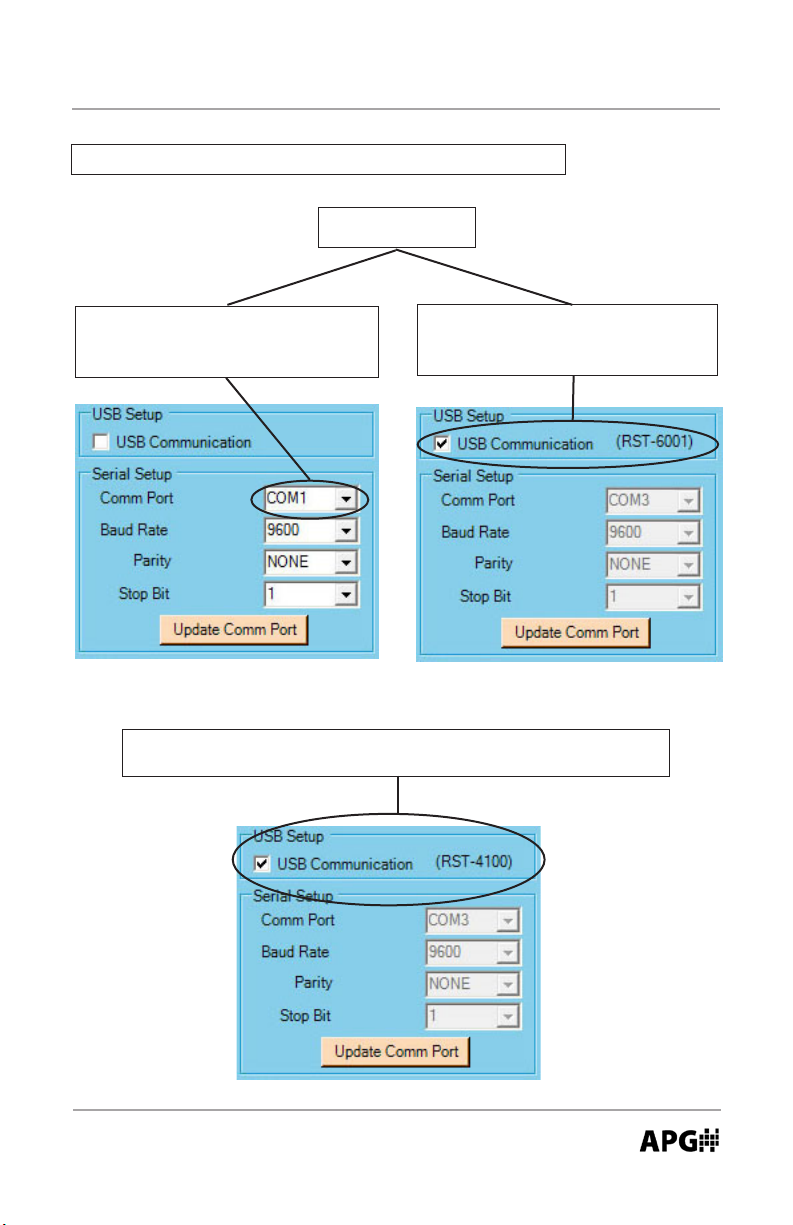

Rev. B, 4/13 MPX Series Magnetostrictive Level Sensors

Step 3: select the mode of communicaon as shown below.

Modbus (RS-485):

(MPX-E1 and MPX-R1)

OR

Select the appropriate Comm Port

when using direct serial communica-

ons.

Check the “USB Communicaons

(RST-6001)” box when using the RST-

6001 communicaons module.

4-20 mA: check the box labeled “USB Communicaon (RST-4100)”

(MPX-E2, MPX-R2, MPX-E3, MPX-R3)

Automation Products Group, Inc.

APG...Providing tailored solutions for measurement applications

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

11

Page 12

MPX Series Magnetostrictive Level Sensors Rev. B, 4/13

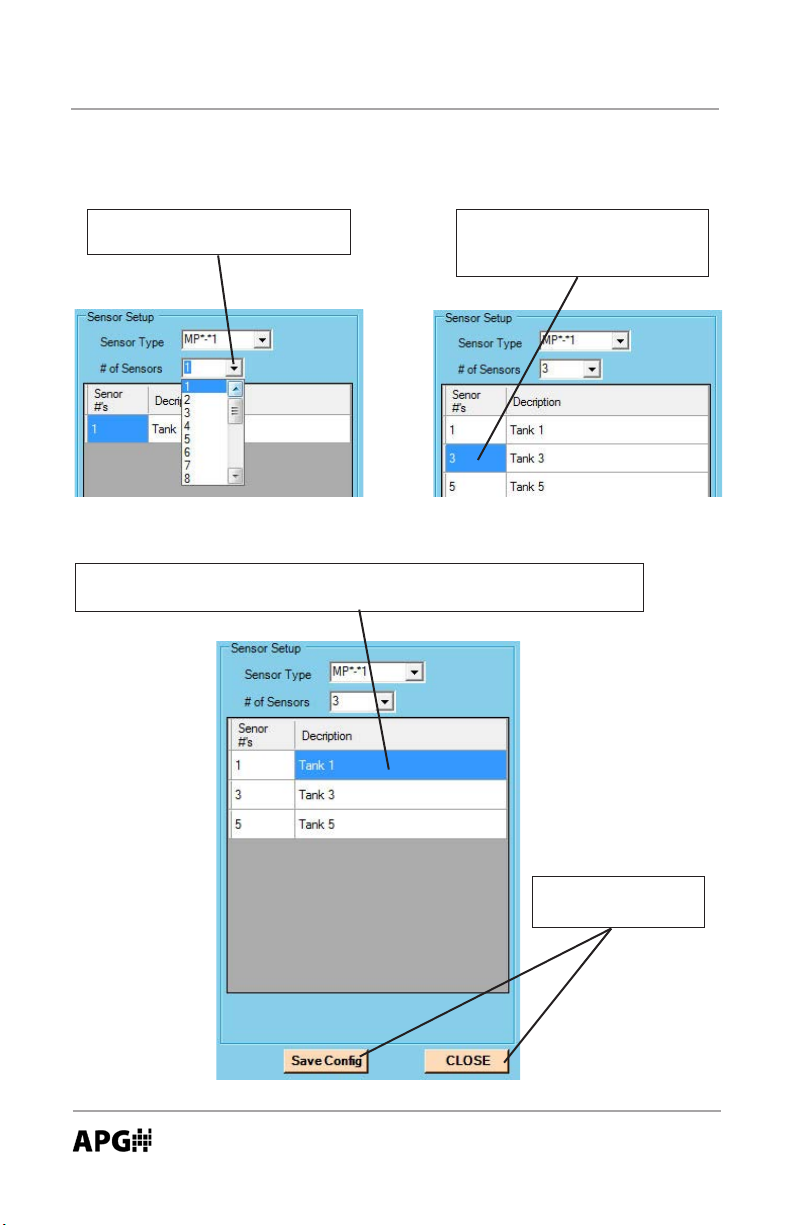

Conguring Soware Communicaons for Mulple Sensors

Step 1: select the total number

of sensors you wish to read.

Step 2: change the “Sensor #”

boxes to match the address’ of

the target sensors.

Step 3: Change the Descripon labels as desired. The Descripon is

used to dierenate between sensors in other areas of the soware.

12

Step 4: Click “Save

Cong” then “Close”.

(connued)

Automation Products Group, Inc.

APG...Providing tailored solutions for measurement applications

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

Page 13

Rev. B, 4/13 MPX Series Magnetostrictive Level Sensors

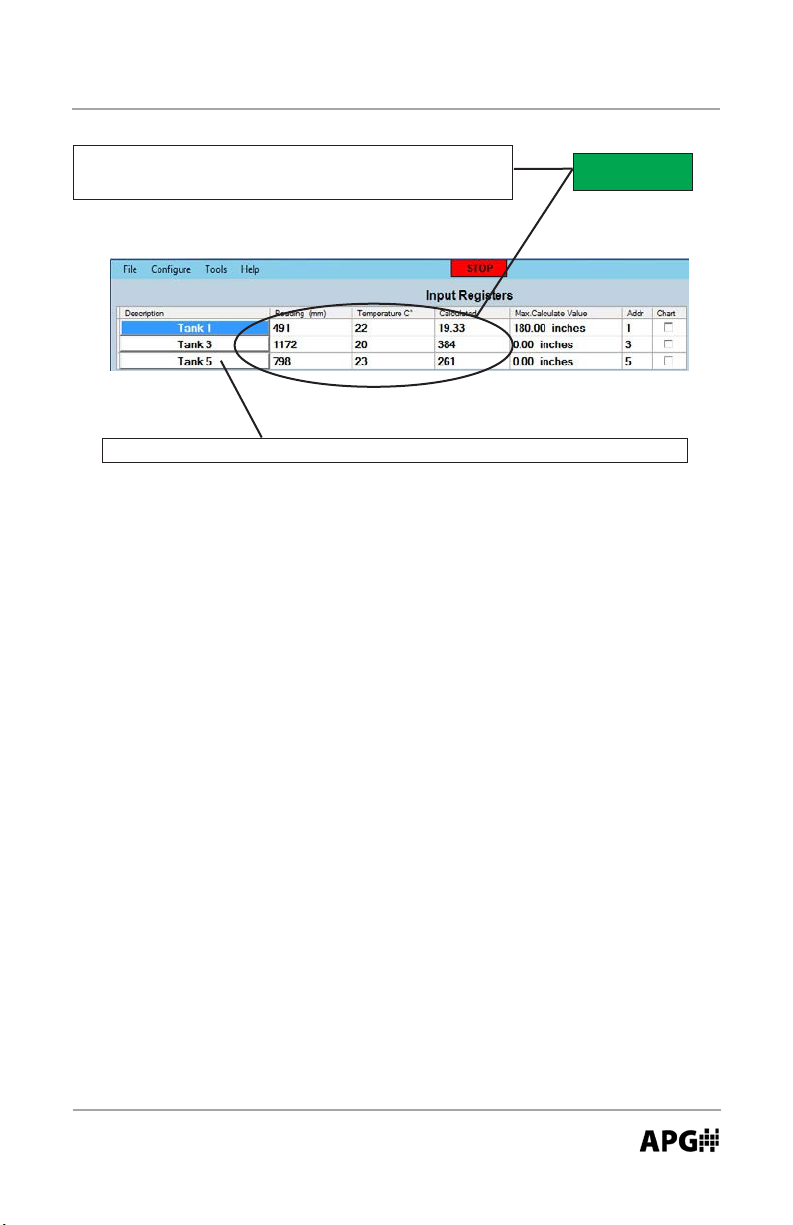

Step 5: Click on “Start”. The sensor readings should

populate as the soware cycles through each sensor.

START

Step 6: Click on a sensor descripon to access that sensor’s parameters.

Automation Products Group, Inc.

APG...Providing tailored solutions for measurement applications

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

13

Page 14

MPX Series Magnetostrictive Level Sensors Rev. B, 4/13

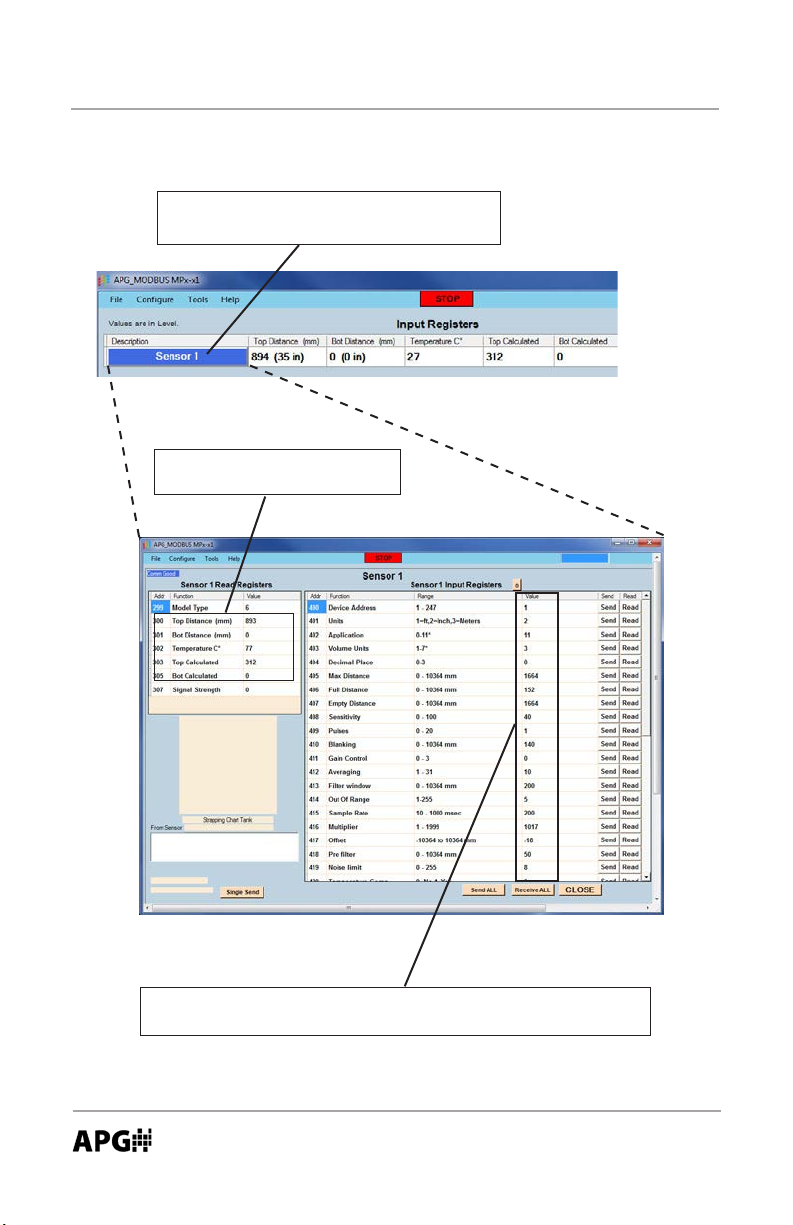

Using the Soware Programming Window

Click on the desired sensor descripon to

open that sensor’s programming window.

Sensor readings are displayed

in the Input Registers table.

14

The register values should automacally populate. If not, click

“Receive All” to retrieve the register values from the sensor.

(connued on next page)

Automation Products Group, Inc.

APG...Providing tailored solutions for measurement applications

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

Page 15

Rev. B, 4/13 MPX Series Magnetostrictive Level Sensors

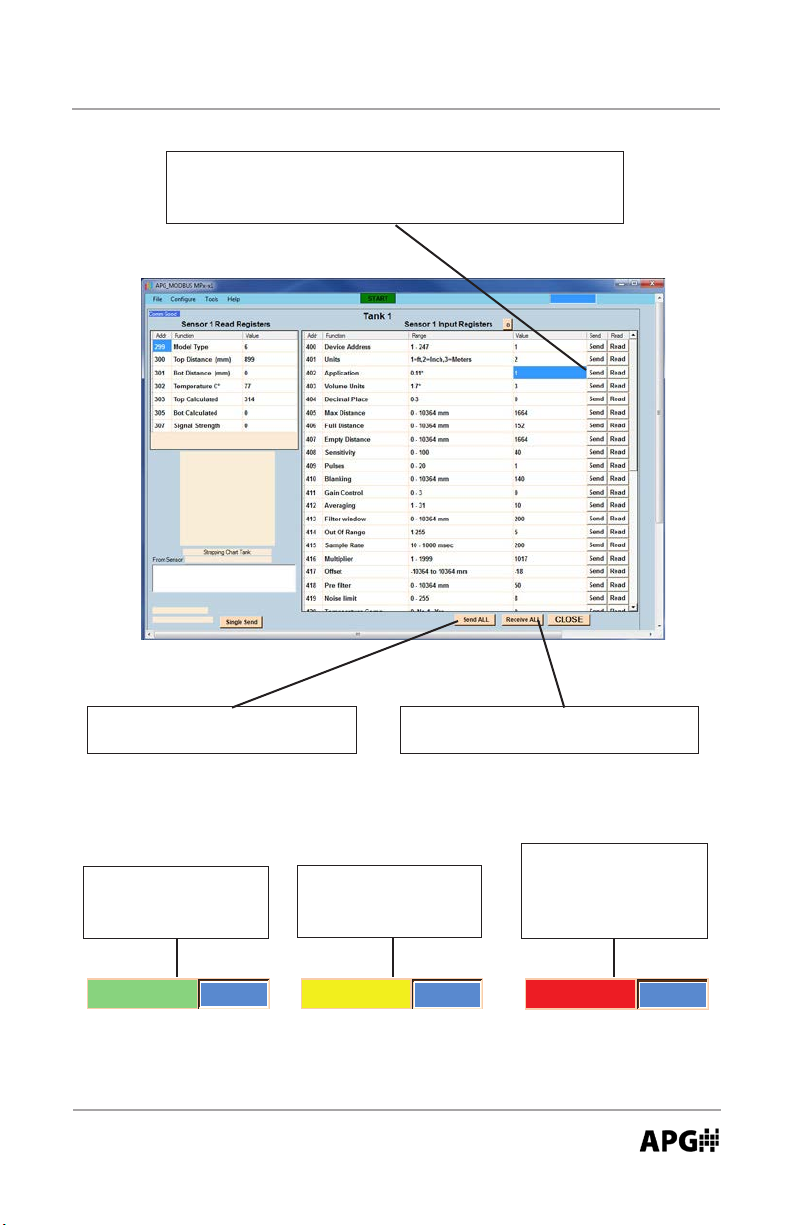

To change an individual parameter, click on the value

you wish to change, enter the desired value, then click

the adjacent “Send” buon to implement the change.

To send all the register values as

currently listed, click “Send All”

To retrieve the register values saved

in a sensor, click “Receive All”

A red window indi-

A green window

indicates successful

communicaon.

1500

APG...Providing tailored solutions for measurement applications

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

Send

Automation Products Group, Inc.

A yellow window

indicates a communi-

caon failure.

1500

Send

cates a value outside

the allowable limits

for the parameter.

150000

Send

15

Page 16

MPX Series Magnetostrictive Level Sensors Rev. B, 4/13

Modbus Register Lists

Input Registers (0x04):

Register Returned Data

30300 Raw Top Float Reading (in mm, unsigned)

30301 Raw Boom Float Reading (in mm, unsigned)

30302 Temperature Reading (in 0C, signed)

30303-30304 Calculated Top Float Reading (in selected Units)

30305-30306 Calculated Boom Float Reading (in selected Units)

NOTE: the Calculated Readings will be returned without a decimal place. In

order to aain the true result, the Decimal Place seng must be taken into

account. Refer to the Decimal Place seng on page 19 for more informaon.

Holding Registers (0x03):

Register Funcon Value Range

40400 Device Address 1 to 255

40401 Units 1 to 3

40402 Applicaon Type 0-10

40403 Volume Units 0 to 6

40404 Decimal Place 0 to 10364 mm

40405 Max Distance 0 to 10364 mm

40406 Full Distance 0 to 10364 mm

40407 Empty Distance 0 to 10364 mm

40408 Sensivity 0 to 100

40409 Pulses 0 to 20

40410 Blanking 0 to 10364 mm

40411 Reserved n/a

40412 Averaging 0 to 100

40413 Filter Window 0 to 10364 mm

40414 Out of Range Samples 0 to 255

16

Automation Products Group, Inc.

APG...Providing tailored solutions for measurement applications

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

Page 17

Rev. B, 4/13 MPX Series Magnetostrictive Level Sensors

(connued)

Register Funcon Value Range

40415 Sample Rate 50 to 1000 msec.

40416 Mulplier 1 to 1999

40417 Oset +/- 10364 mm

40418-40420 Reserved n/a

40421 RTD Oset (0C) -100 to 100

40422 Float Window 0 to 1000 mm

40423 Top Float Oset -10364 to 10364

40424 Boom Float Oset -10364 to 10364

40425 Gain Oset 0 to 255

40426 4 mA Set Point 0 to 10364 mm

40427 20 mA Set Point 0 to 10364 mm

40428 4 mA Calibraon 0 to 1000

40429 20 mA Calibraon 0 to 1000

40430 Web Alarm 1 Distance

40431 Web Alarm 1 Window

40432 Web Alarm 1 Type

40433 Web Alarm 2 Distance

40434 Web Alarm 2 Window

40435 Web Alarm 2 Type

40436-40437 Parameter 1 Data 0 to 100,000 mm

40438-40439 Parameter 2 Data 0 to 100,000 mm

40440-40441 Parameter 3 Data 0 to 100,000 mm

40442-40443 Parameter 4 Data 0 to 100,000 mm

40444-40445 Parameter 5 Data 0 to 100,000 mm

Automation Products Group, Inc.

APG...Providing tailored solutions for measurement applications

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

17

Page 18

MPX Series Magnetostrictive Level Sensors Rev. B, 4/13

Applicaon Parameters

Device Address (1 to 255) (40400)

Each device within the Modbus network must be assigned a unique address.

Each MPX sensor should be connected to the network individually and assigned

an address. Each sensor is set to address 1 by default.

Units (1 = Feet, 2 = Inches, 3 = Meters) (40401)

Determines the units of measure for the calculated reading (Input registers

30303-30304 and 30305-30306) when in Applicaon Types 0, 1, 7, or 11 (Distance, Depth of level, Pounds, Curve Fit).

Applicaon Type (1 to 11) (40402)

Determines the type of calculated reading performed by the sensor (refer to

pages 10-18). The calculated readings can be queried from Input registers

30303-30304 (top oat) and 30305-30306 (boom oat).

Applicaon Type 0: Distance

Sets the zero reference at the top of the stem and measures downward to

the oat posion.

Register Funcon Value Range

40401 Units 1 to 3

40402 Applicaon Type 0

40404 Decimal Place 0 to 3

Applicaon Type 1: Depth of level

Sets the zero reference to the boom of the stem and measures upward to

the oat posion.

Register Funcon Value Range

40401 Units 1 to 3

40402 Applicaon Type 1

40404 Decimal Place 0 to 3

40406 Full Distance Typically = Blanking Distance

40407 Empty Distance 0 to 10364 mm

Automation Products Group, Inc.

18

APG...Providing tailored solutions for measurement applications

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

Page 19

Rev. B, 4/13 MPX Series Magnetostrictive Level Sensors

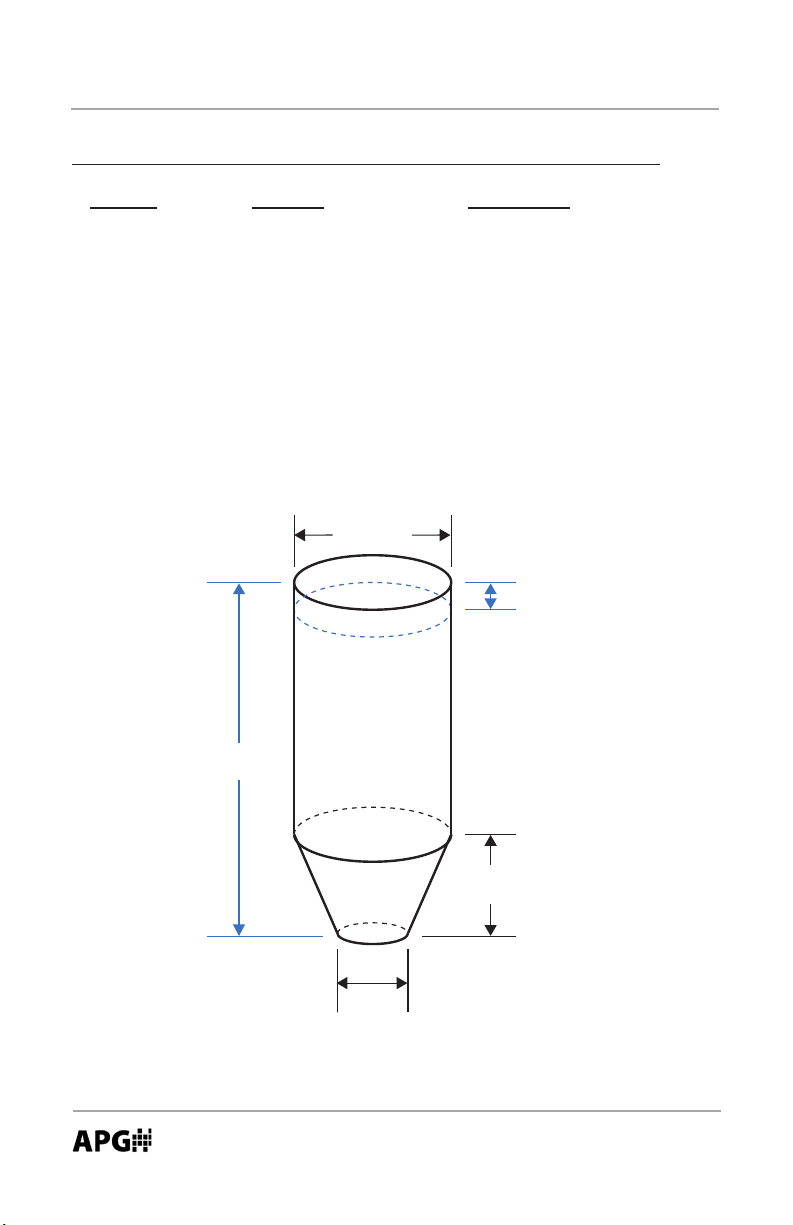

Applicaon Type 2: Volume of cylindrical tank with/without hemispherical boom

Register Funcon Value Range

40402 Applicaon Type 2

40403 Volume Units 1 to 7

40404 Decimal Place 0 to 3

40406 Full Distance Typically = Blanking

40407 Empty Distance 0 to 10364 mm

40436-40437 Tank Diameter 0 to 100,000 mm

40438-40439 Boom Radius 0 to 100,000 mm

Diameter

Full

Distance

Empty

Distance

or

Boom

Radius

Automation Products Group, Inc.

APG...Providing tailored solutions for measurement applications

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

19

Page 20

MPX Series Magnetostrictive Level Sensors Rev. B, 4/13

Applicaon Type 3: Volume of cylindrical tank with conical boom

Register Funcon Value Range

40402 Applicaon Type 3

40403 Volume Units 1 to 7

40404 Decimal Place 0 to 3

40406 Full Distance Typically = Blanking

40407 Empty Distance 0 to 10364 mm

40436-40437 Tank Diameter 0 to 100,000 mm

40438-40439 Cone Diameter 0 to 100,000 mm

40440-40441 Cone Length 0 to 100,000 mm

Diameter

Full

Distance

20

Empty

Distance

Cone

Length

Cone

Diameter

Automation Products Group, Inc.

APG...Providing tailored solutions for measurement applications

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

Page 21

Rev. B, 4/13 MPX Series Magnetostrictive Level Sensors

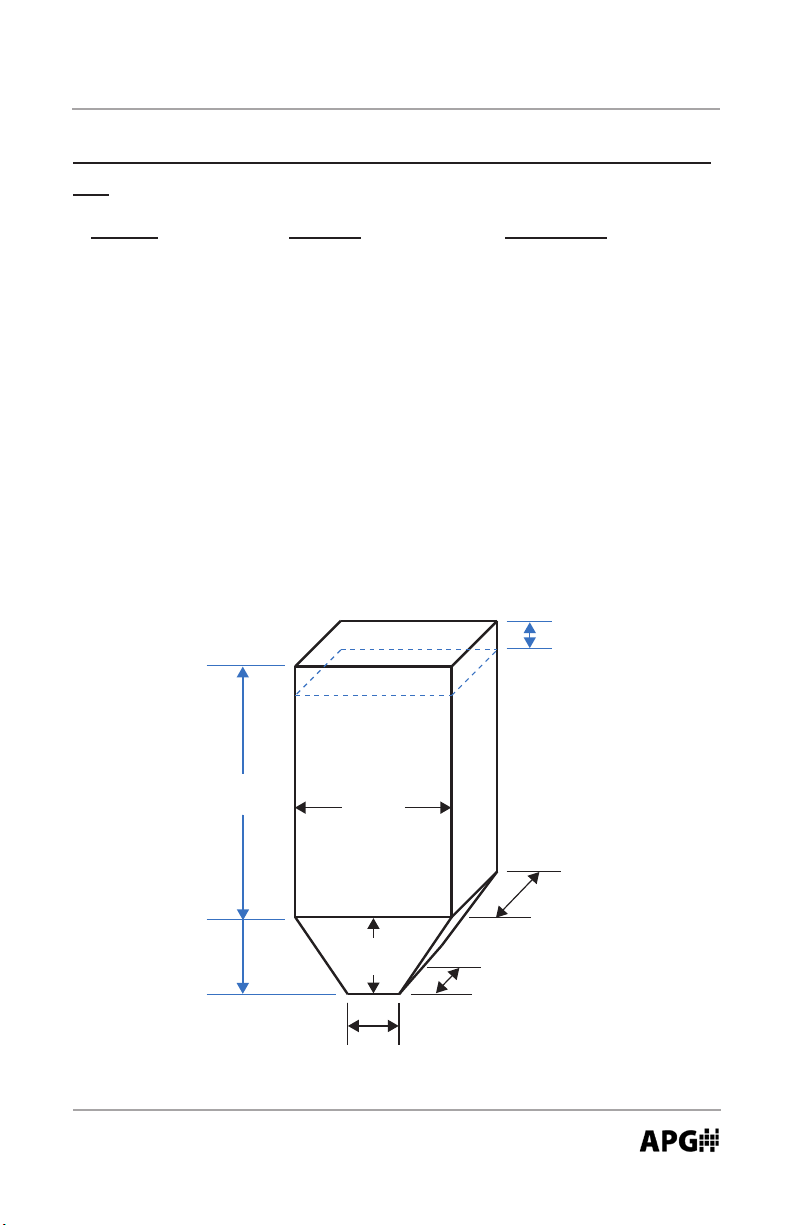

Applicaon Type 4: Volume of rectangular tank with/without chute bot-

tom

Register Funcon Value Range

40402 Applicaon Type 4

40403 Volume Units 1 to 7

40404 Decimal Place 0 to 3

40406 Full Distance Typically = Blanking

40407 Empty Distance 0 to 10364 mm

40436-40437 Tank X 0 to 100,000 mm

40438-40439 Tank Y 0 to 100,000 mm

40440-40441 Chute X 0 to 100,000 mm

40442-40443 Chute Y 0 to 100,000 mm

40444-40445 Chute Length 0 to 100,000 mm

Full

Distance

Empty

Distance

Tank X

Tank Y

or

Chute

Length

Chute Y

Chute X

Automation Products Group, Inc.

APG...Providing tailored solutions for measurement applications

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

21

Page 22

Distance

MPX Series Magnetostrictive Level Sensors Rev. B, 4/13

Applicaon Type 5: Volume of horizontal cylindrical tank with or without

hemispherical ends

Register Funcon Value Range

40402 Applicaon Type 5

40403 Volume Units 1 to 7

40404 Decimal Place 0 to 3

40406 Full Distance Typically = Blanking

40407 Empty Distance 0 to 10364 mm

40436-40437 Tank Length 0 to 100,000 mm

40438-40439 Tank Diameter 0 to 100,000 mm

40440-40441 End Radius 0 to 100,000 mm

Full

Distance

22

Diameter

End

Radius

Length

Automation Products Group, Inc.

APG...Providing tailored solutions for measurement applications

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

Empty

Page 23

Rev. B, 4/13 MPX Series Magnetostrictive Level Sensors

Applicaon Type 6: Volume of spherical tank

Register Funcon Value Range

40402 Applicaon Type 6

40403 Volume Units 1 to 7

40404 Decimal Place 0 to 3

40406 Full Distance Typically = Blanking

40407 Empty Distance 0 to 10364 mm

40436-40437 Tank Diameter 0 to 100,000 mm

Full

Distance

Empty

Distance

Automation Products Group, Inc.

APG...Providing tailored solutions for measurement applications

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

Diameter

23

Page 24

MPX Series Magnetostrictive Level Sensors Rev. B, 4/13

Applicaon Type 7: Pounds

Allows the user to apply a conversion mulplier to the calculated level reading.

NOTE: the decimal point for the mulplier (40436-40437) is always assumed

to be in the thousands posion, therefore a seng of 206250 = 206.250

actual mulplier.

Example: suppose the product in a tank weighs 206.25 pounds for every inch

of level. With the Units set to inches (Units = 2), enter a mulplier of 206250

into Holding registers 40436-40437.

Register Funcon Value Range

40401 Units 1 to 3

40402 Applicaon Type 7

40404 Decimal Place 0 to 3

40406 Full Distance Typically = Blanking Distance

40407 Empty Distance 0 to 10364 mm

40436-40437 Mulplier 0 to 1000000 (1000 = 1.000)

Automation Products Group, Inc.

24

APG...Providing tailored solutions for measurement applications

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

Page 25

Rev. B, 4/13 MPX Series Magnetostrictive Level Sensors

Applicaon Type 9: Volume of vercal oval tank

Register Funcon Value Range

40402 Applicaon Type 9

40403 Volume Units 1 to 7

40404 Decimal Place 0 to 3

40406 Full Distance Typically = Blanking

40407 Empty Distance 0 to 10364 mm

40436-40437 Tank Length 0 to 100,000 mm

40438-40439 Tank Depth 0 to 100,000 mm

40440-40441 Tank Width 0 to 100,000 mm

Full

Distance

Empty

Distance

Width

Depth

Length

Automation Products Group, Inc.

APG...Providing tailored solutions for measurement applications

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

25

Page 26

MPX Series Magnetostrictive Level Sensors Rev. B, 4/13

Applicaon Type 10: Volume of horizontal oval tank

Register Funcon Value Range

40402 Applicaon Type 10

40403 Volume Units 1 to 7

40404 Decimal Place 0 to 3

40406 Full Distance Typically = Blanking

40407 Empty Distance 0 to 10364 mm

40436-40437 Tank Length 0 to 100,000 mm

40438-40439 Tank Depth 0 to 100,000 mm

40440-40441 Tank Width 0 to 100,000 mm

Full

Distance

26

Empty

Distance

Depth

Length

Width

Automation Products Group, Inc.

APG...Providing tailored solutions for measurement applications

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

Page 27

Rev. B, 4/13 MPX Series Magnetostrictive Level Sensors

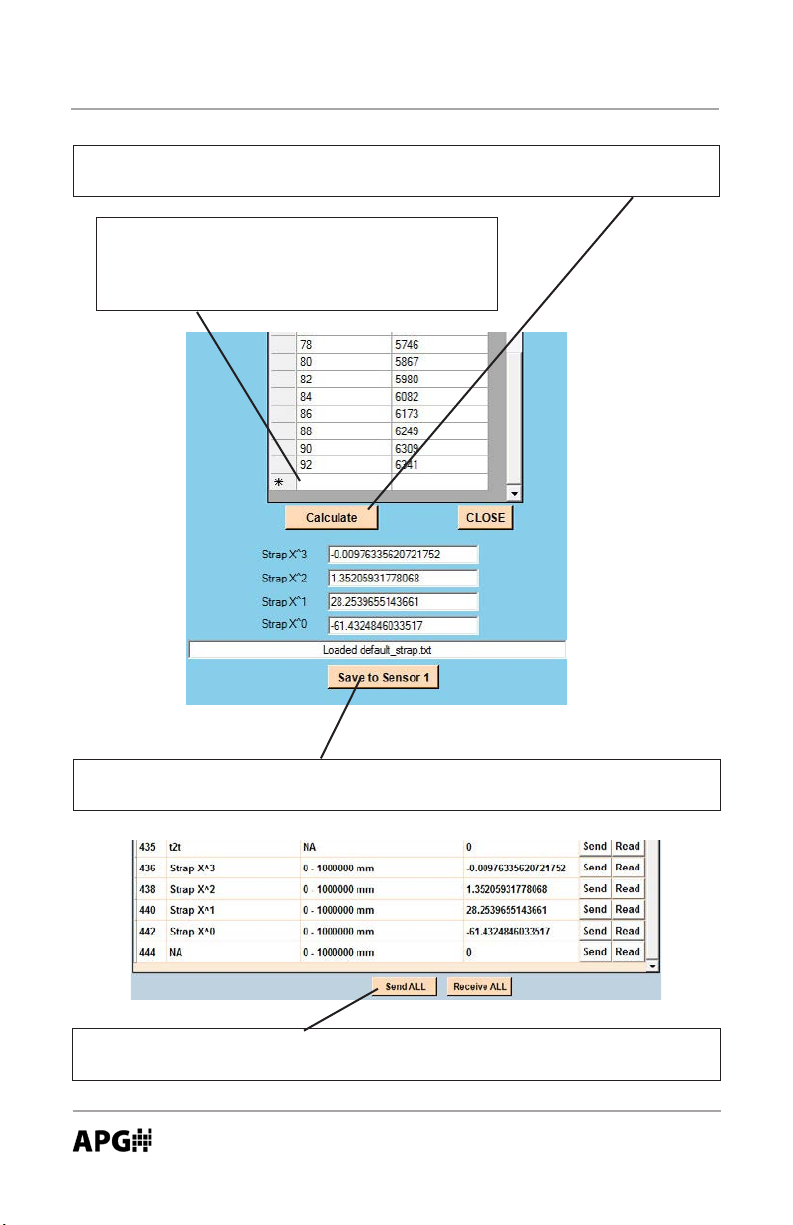

Applicaon Type 11: Curve Fit

Allows the sensor to mimic a tank strapping chart by using a 3rd degree polynomial equaon to produce a “curve t” approximaon.

Register Funcon Value Range

40401 Units 1 to 3

40402 Applicaon Type 11

40404 Decimal Place 0 to 3

40406 Full Distance Typically = Blanking

40407 Empty Distance 0 to 10364 mm

40436-40437 Parameter 1 0 to 100,000 mm

40438-40439 Parameter 2 0 to 100,000 mm

40440-40441 Parameter 3 0 to 100,000 mm

40442-40443 Parameter 4 0 to 100,000 mm

Open the APG Modbus soware and select “Strapping Chart” from the “Tools”

menu.

Enter the desired data points

into the table.

OR

Use the “Load” buon to recall a previously saved table.

OR

Import data from an electronic

document by copying the data

and then using the “Paste”

buon to populate the table.

Automation Products Group, Inc.

APG...Providing tailored solutions for measurement applications

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

27

Page 28

MPX Series Magnetostrictive Level Sensors Rev. B, 4/13

Once the all data points have been entered, click the “Calculate” buon to

determine the values required for the “curve t” calculaon.

NOTE: before clicking “Calculate” ensure that

there is only one empty row following the last

line of data (as shown). Use the keyboard

“Delete”key to remove any addion empty rows.

Click the “Save to Sensor” buon to populate the appropriate Holding Resister

elds (see below) and close the Strapping Chart window.

Click the “Send All” buon at the boom of the Holding Register page to write

the curve t values to the sensor.

Automation Products Group, Inc.

28

APG...Providing tailored solutions for measurement applications

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

Page 29

Rev. B, 4/13 MPX Series Magnetostrictive Level Sensors

Volume Units (1 to 7) (40403)

Determine the units of measure for all volumetric Applicaon Types.

1 = Cubic Feet 4 = Cubic Meter 7 = Barrels

2 = Million Cubic Feet 5 = Liters

3 = Gallons 6 = Cubic Inches

Decimal Place (0 to 3) (40404)

Set the number of digits aer the decimal place to be included in the calculated

reading (Input registers 30303-30304 and 30305-30306)

Example: a measurement of 1126.658 will be returned as follows:

Decimal Place = 0 Volume = 1127

Decimal Place = 1 Volume = 11267

Decimal Place = 2 Volume = 112666

Decimal Place = 3 Volume = 1126658

*Maximum Distance (0 to 10364 mm) (40405)

Sets the distance, beginning from the zero reference, to where the sensor will

stop looking for a oat signal (usually the boom of the stem).

*Full Distance (0 to 10364 mm) (40406)

Sets the distance, beginning from the zero reference, to the point where the

tank is considered full (usually set to match the Blanking--see next page).

*Empty Distance (0 to 10364 mm) (40407)

Sets the distance, beginning from the zero reference, to the boom of the stem

OR the boom of the tank, whichever is considered the empty level.

Parameter Data (0 to 100,000 mm) (40436 to 40445)

The Parameter Data registers are used to enter tank dimensions or conversion

mulpliers for all the volumetric Applicaon Types (types 2-11). Refer to the

individual Applicaon Types for more informaon.

*refer to drawing on next page for more informaon

Automation Products Group, Inc.

APG...Providing tailored solutions for measurement applications

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

29

Page 30

MPX Series Magnetostrictive Level Sensors Rev. B, 4/13

Full Distance

Increase the factory set Empty Distance

by “X” in millimeters (as shown below).

Empty

Distance

Maximum

Distance

Example for X = 25 mm (1”)

Factory sengs:

Maximum distance = 1500 mm (to end of stem)

Empty Distance = 1500 mm (to end of stem)

Adjusted Sengs:

Max Distance = 1500 mm

Empty Distance = 1525 mm

X (in mm)

30

Automation Products Group, Inc.

APG...Providing tailored solutions for measurement applications

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

Page 31

Rev. B, 4/13 MPX Series Magnetostrictive Level Sensors

• Signal Processing and Control (advanced users only)

The parameters in this secon (pages 24-25) are advanced factory sengs and

should not normally need adjustment.

Sensivity (0 to 100%) (40408)

Controls the level of amplicaon applied to the oat signal. The sensivity setng is expressed as a percentage; 0 to 100%.

Pulses (0 to 20) (40409)

Controls the strength of the drive signal being sent down the magnetostricve

wire inside the stem. The greater the number of pulses, the stronger the drive

signal.

Blanking (0 to 10364 mm) (40410)

Sets the distance, beginning at the coil inside the upper stem, downward to the

point where the sensor will begin looking for the oat signal. If the oat enters

the blanking area it will not be detected. The blanking should never be set to

less than the top dead-band of the sensor.

Averaging (1 to 20) (40412)

Denes the number of oat readings that will be averaged together to become

the calculated reading. Each qualied oat reading (see Filter Window and

Out of Range Samples below) is placed into a rst-in, rst-out (FIFO) buer

and averaged with previous samples to generate a steady output. A higher

Averaging seng will result in smoother readings, but will also result in slower

response me to rapid level changes.

Filter Window (0 to 10364 mm) (40413)

Sets the width of the oat acceptance window. The oat acceptance window

is a zone, centered at the oat, within which any reading detected will be

considered legimate and gured into the averaging buer. Any reading

detected outside of the Window will be considered “out of range” and will

be ignored based on the seng in the Out of Range Samples parameter

(see below). The Filter Window extends both direcons from the oat. For

example, if the oat sits at 5 . and the Filter Window is set at 1 ., then any

reading detected between 4 . and 6 . will be accepted.

Automation Products Group, Inc.

APG...Providing tailored solutions for measurement applications

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

31

Page 32

MPX Series Magnetostrictive Level Sensors Rev. B, 4/13

Out of Range Samples (1 to 255) (40414)

Determines the number of consecuve level readings that fall outside of the

acceptance window before the “out of range” target is recognized as being

legimate and gured into the averaging buer. Out of Range readings

detected fewer mes than the Out of Range Samples seng will be rejected.

Sample Rate (50 to 1000 msec) (40415)

Sets the interval between oat readings. Opons allow rates from 50 to

1000 msec. A higher Sample Rate will result in a more rapid response to level

changes. Lowering the Sample Rate will help decrease the chance of detecng

errant readings. It is highly recommended that the Sample Rate be set only as

fast as is necessary for the applicaon. A sample rate of 500 to 1000 msec. is

usually appropriate for slow moving level sensing applicaons.

Mulplier (0 to 19999) (40416)

Sets the calibraon mulplier that will be applied to the sensor readings.

Oset (-10364 to 10364 mm) (40417)

Used to adjust the zero reference point of the sensor.

RTD Oset (-100 to 100 mm) (40421)

Used to calibrate the internal temperature sensor located at the boom of the

stem (MPX-E1 and MPX-R1 only).

Float Window (0 to 1000 mm; 0 = single oat) (40422)

Sets the distance from top oat to the point where the sensor will start looking

for a second oat. If the Float Window is set too small, the trailing end of

the top oat signal will be picked up as the boom oat level, causing errant

readings.

NOTE: the Float Window should always be set to 0 when using only 1 oat.

1st and 2nd Float Oset (-10364 to 10364 mm) (40423 to 40424)

Used to calibrate the top and boom oat readings.

Gain Oset (0 to 255) (40425)

Factory set--do not adjust. Default = 128.

Automation Products Group, Inc.

32

APG...Providing tailored solutions for measurement applications

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

Page 33

Rev. B, 4/13 MPX Series Magnetostrictive Level Sensors

• 4-20 mA Sengs

MPX-E2, MPX-R2 and MPX-E3, MPX-R3 models only.

*4 mA Set-point (0 to 10364) (40426)

Sets the measurement value associated with a 4 mA signal. The set-point is

based on raw measurement value of register 30300 (in millimeters), and not

the calculated value of register 30303.

*20 mA Set-point (0 to 10364) (40427)

Sets the measurement value associated with a 20 mA signal. The set-point is

based on raw measurement value of register 30300 (in millimeters), and not

the calculated value of register 30303.

*4 mA Calibraon (0 to 1000) (40428)

Factory set--do not adjust.

*20 mA Calibraon (0 to 1000) (40429)

Factory set--do not adjust.

20 mA

Set-Point

4 mA

Set-Point

OR

4 mA

Set-Point

20 mA

Set-Point

Automation Products Group, Inc.

APG...Providing tailored solutions for measurement applications

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

33

Page 34

MPX Series Magnetostrictive Level Sensors Rev. B, 4/13

•Web Alarming (40430 to 40435)

When the MP is interfaced with an LOE or RST-5002 web-enabled master

device, the MP can be congured to generate website alarms via levelandow.

com. Refer to the LOE or RST-5002 user manual for more informaon about

website alarms and using levelandow.com.

Trip Alarm 1 (40430) or Alarm 2 (40433) Distance

Sets the level (in mm), beginning the boom of the stem, to the rst (lowest)

actuaon point (refer to next page for more informaon).

Trip Alarm 1 Window (40431 or 40434)

Sets the level (in mm), beginning from the Trip Distance locaon, to the secondary actuaon point (refer to next page for more informaon).

Trip Alarm 1 Type (40432 or 40435)

Determines the operaonal logic performed by the Trip Alarm (refer to next

page for more informaon).

Conguring Trip Alarm Types for Website Alarming:

(refer to Trip Types on next page)

Placing a “1” in front of any of the Trip Types designates an acve trip point as

an alarm condion. For example; Trip Type 3 would be designated as 13, and

would iniate a website alarm whenever the trip is acve (on).

Placing a “2” in front of any of the Trip Types designates an inacve trip point as

an alarm condion. For Example; Trip Type 3 would be designated as 23, and

would iniate a website alarm whenever the trip is inacve (o).

Automation Products Group, Inc.

34

APG...Providing tailored solutions for measurement applications

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

Page 35

Trip Type Explanaons

Rev. B, 4/13 MPX Series Magnetostrictive Level Sensors

Trip Type 0

(near)

Trip Type 1

(exclusive)

Trip Type 2

(hysteresis near)

Trip Type 3

(far)

Trip Type 4

(inclusive)

Trip Type 5

(hysteresis far)

Type 6: n/a

Trip

Distance

ON OFF OFF

ON

ON

OFF

OFF

OFF

Trip

Window

OFF

ON

(Raising Level)

OFF

(Falling Level)

ON

ON

ON

(Falling Level)

OFF

(Raising Level)

ON

OFF

ON

OFF

ON

Type 7 (Loss of Echo): the relay will acvate if the sensor enters a loss of echo condion (no

targets detected).

Type 8 n/a

Type 9 (Rate of Change): allows the user to dene a maximum rate of change (distance over

me), which if exceeded will acvate an alarm. The Trip Distance parameter is used to dene the

me value, and the Trip Window parameter is used to dene the distance value.

Automation Products Group, Inc.

APG...Providing tailored solutions for measurement applications

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

35

Page 36

MPX Series Magnetostrictive Level Sensors Rev. B, 4/13

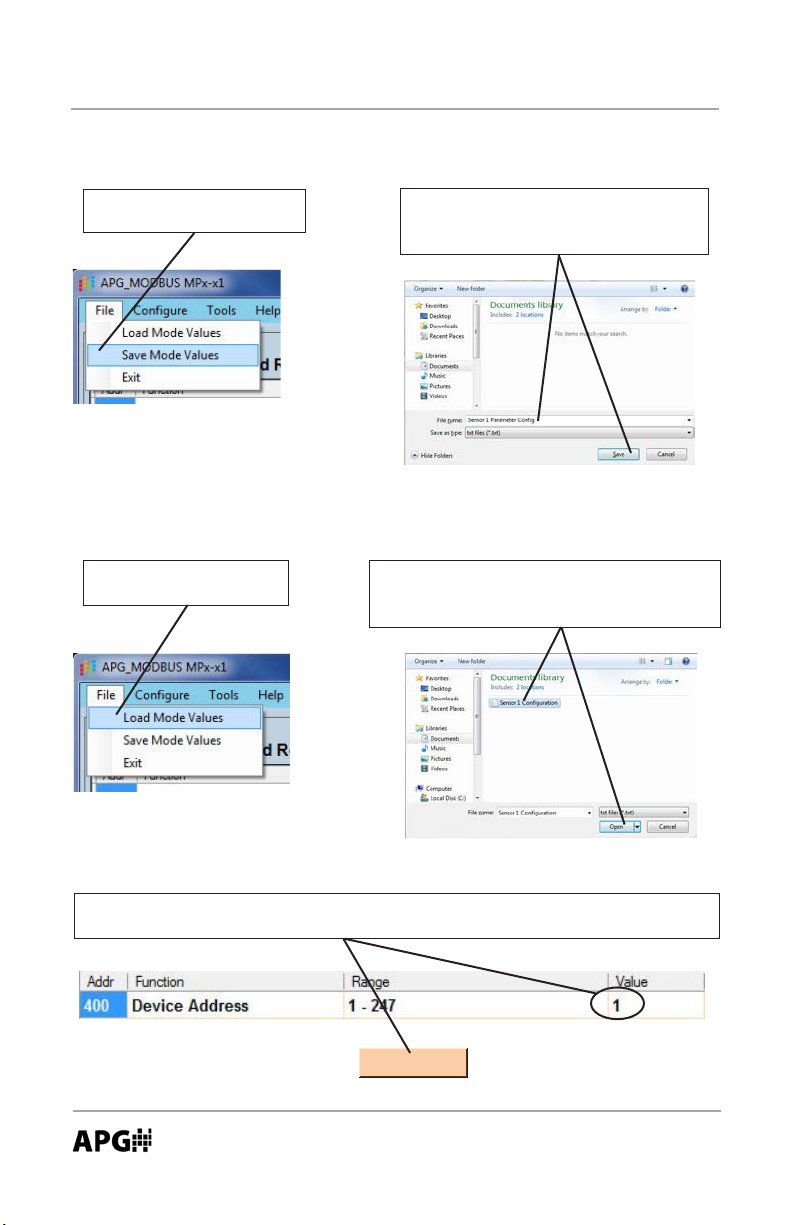

Saving Sensor Parameter Conguraons

Click on “File”, then select

“Save Mode Values”.

Choose a le name and the locaon

where you wish to save the le, then

click “Save”

Recalling Saved Sensor Conguraons

Click on “File”, then select “Load Mode Values”.

Choose a le you wish to upload, then

click “Open”. This will load the parameter

values into the soware.

Ensure the device address seng matches the target sensor’s address, then

click the “Send All” to write the parameters values to the sensor.

Send ALL

Automation Products Group, Inc.

36

APG...Providing tailored solutions for measurement applications

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

Page 37

Rev. B, 4/13 MPX Series Magnetostrictive Level Sensors

• Inspecon and Maintenance

Periodically inspect the MPX unit to ensure that the stem is free of any heavy

buildup that might impede the movement of the oat. If sediment or other

foreign maer becomes trapped between the stem and the oat, detecon

errors can occur.

Ensure that the housing cover is snuggly secured. If the cover becomes

damaged or is misplaced, order a replacement immediately.

Automation Products Group, Inc.

APG...Providing tailored solutions for measurement applications

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

37

Page 38

MPX Series Magnetostrictive Level Sensors Rev. B, 4/13

• Specicaons

Electrical Connecon: terminal block

Supply Voltage: 12 to 24 VDC

Current Draw

Modbus: 28 mA

4-20 mA: 22 mA (single), 44 mA (dual)

Output

MPX-x1: modbus (RS-485)

MPX-x2: 4-20 mA loop (2 wire)

MPX-x3: dual 4-20 mA loop (3 wire)

Resoluon

Modbus: 1 mm

4-20 mA: 14 bit

Accuracy: 0.05% of full scale reading

Top Dead-Band

MPX-E: 6 inches (150 mm)

MPX-R: 10 in (254 mm)

Temperature Sensor (modbus versions only): 1K RTD (+/- 1%)

Housing: cast aluminium, epoxy spray coated

Stem Material: 304 SS or 316L SS (MPX-R available in 316L SS only)

Environmental Protecon: NEMA 4X, IP65

Operang Temperature: -40 to 185 °F (-40 to 85°C)

Hazardous Locaon Approvals:

Class I Division 1 Groups C & D T4 (Ta 85°C)

Class I Division 2 Groups C & D T4 (Ta 85°C)

Class I, Zone 1; AEx d IIB T4

Class I, Zone 2; AEx nA IIB T4

Ex d IIB T4

Ex nA IIB T4

Specicaons are subject to change without noce.

For technical assistance, please contact APG at 435-753-7300.

Automation Products Group, Inc.

38

APG...Providing tailored solutions for measurement applications

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

Page 39

Rev. B, 4/13 MPX Series Magnetostrictive Level Sensors

• MPX-R Dimensions

5.72”

4.30”

3/4” NPT

5.00”

10”

Dead-Band

(from reference)

6”

Dead-Band

(from reference)

7.00”

5.00”

5.50”

U & V

3.03”

W & X

Float Opons

Ref.

Ref.

2.80”

5.50”

Ø 0.25”

S & T

Ref.

3.07”

Y & Z

Ref.

5.10”

Automation Products Group, Inc.

APG...Providing tailored solutions for measurement applications

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

3.08”

39

Page 40

MPX Series Magnetostrictive Level Sensors Rev. B, 4/13

• MPX-E Dimensions

5.72”

4.30”

3/4” NPT

5.00”

6”

Dead-Band

(from reference)

1.5”

Dead-Band

(from reference)

7.00”

2.00”

1.87”

A & B

2.06”

E

Float Opons

1.38”

Ref.

Ref.

2.20”

Ø 0.25”

C & D

Ref.

1.63”

F

Ref.

40

1.78”

1.47”

Automation Products Group, Inc.

APG...Providing tailored solutions for measurement applications

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

Page 41

Model Number Configuraon

Rev. B, 4/13 MPX Series Magnetostrictive Level Sensors

MPX –

– – –

C D

E FA B

A Stem Type

E 0.5 in. diameter

R 1 in. diameter

B Output

1 Modbus RTU

2 4-20 mA (loop powered, 2-wire)

3 Dual 4-20mA (loop powered, 3-wire)

C Float 1

MPX-E (0.5 in. stem)

A 316L SS Round (0.65 SG)

B 316L SS Round (0.92 SG)

C 316L SS Cylindrical (0.61 SG)

D 316L SS Cylindrical(0.92 SG)

E Buna-N Cylindrical (0.65 SG)

F 316L SS Oval (0.5 SG)

MPX-R (1 in. stem)

S 316L SS Round 3 in. (0.94 SG)

T 316L SS Round 3 in. (0.58 SG)

U 316L SS Oval (94 SG)

V 316L SS Oval (0.63 SG)

W 316L SS Round (0.92 SG)

X 316L SS Round (0.52 SG)

Y Blue Polyurethane (0.94 SG)

Z Red Polyurethane (0.65 SG)

H

G

D Float 2 (oponal)

Refer to float opons in secons C

N None

E Mounng Opons (include size)

F FF Flange, 150# ANSI (size: 2, 2.5, 3, 4, 5, 6 in.)

R RF Flange, 150# ANSI (size: 2, 2.5, 3, 4, 5, 6 in.)

S Tri-Clamp (size: 2, 2.5, 3, 4 in.)

P NPT Plug (size: 1.5, 2, 2.5, 3, 4 in.)

N None

O Other

F Mounng Type

W Welded (fixed)

S Slide (adjustable)

G Stem Material

A 304 SS

B 316L SS*

*MPX-R is available in 316L SS only

H Total Stem Length (in inches)

MPX-E: min. 12 in. - max. 153 in.

MPX-R: min. 24 in. - max. 300 in.

Example: MPX-E1-AN-P2.5WB-60

A B C D E F

Accessories

Programming Modules Part Number

RST-6001 (Modbus models; MPX-x1) 125734

RST-4100 (4-20 mA models; MPX-x2, MPX-x3) 125759

Automation Products Group, Inc.

APG...Providing tailored solutions for measurement applications

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

G

H

41

Page 42

MPX Series Magnetostrictive Level Sensors Rev. B, 4/13

Certificate of Compliance

Certificate:

Project:

Issued to: Automation Products Group Inc

2397437

2397437

1025 West 1700 North

Logan, UT 84321

USA

Attention: Karl Reid

The products listed below are eligible to bear the CSA

Mark shown with adjacent indicators 'C' and 'US' for

Canada and US or with adjacent indicator 'US' for

US only or without either indicator for Canada only.

Issued by:

Master Contract:

Date Issued:

Dennis Jerey

Dennis Jerey

237484

May 18, 2011

PRODUCTS

CLASS 2258 02

CLASS 2258 82

Class I, Division 1 & 2, Groups C, and D

Ex d IIB

Ex nA IIB

Class I, Zone 1; AEx d IIB

Class I, Zone 2; AEx nA IIB

Float Level Sensors, model MPX-ab-cd-efg-hhh, rated 12 - 24 Vdc, 80mA, or rated 12 to 24 Vdc, 4-20mA;

operating ambient Ta is 85°C; Temperature Code T4; Ingress protection IP65; Field wiring is non-incendive

when installed per drawing 9003468.

DQD 507 Rev. 2009-09-01 Page: 1

- PROCESS CONTROL EQUIPMENT - For Hazardous Locations

- PROCESS CONTROL EQUIPMENT - For Hazardous Locations Certied to US Standards

Automation Products Group, Inc.

APG...Providing tailored solutions for measurement applications

42

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

Page 43

Rev. B, 4/13 MPX Series Magnetostrictive Level Sensors

Certificate:

Project:

Notes:

• The model code breakdown is as follows: a= E or R; b= 1, 2 or 3; c= A, B, C, D, E, F, Z, or Y; d= N, B, D, or

Y; e= F, R, P, N, or O; f= W or S; g= A or B; and hhh= 12–153 for the 1/2" stem or 48–300 for the 1" stem.

• The equipment is intended to be installed as required by the applicable electrical code (CEC, NEC) and as

specied by the manufacturers Installation Instructions.

• The installation will be inspected by the authority with jurisdiction in the area where installed.

APPLICABLE REQUIREMENTS

CSA C22.2 No 0-10 General Requirements – Canadian Electrical Code, Part

CSA C22.2 No 30-M1986 (R 2007) Explosion-Proof Enclosures for Use in Class I

CSA C22.2 No 142-M1987 (R 2009) Process Control Equipment Industrial Products – Third

CSA C22.2 No 213-M1987 (R 2008) Non-incendive Electrical Equipment for Use in Class I,

CSA C22.2 No 60079-0-07 Electrical apparatus for explosive gas atmospheres –

CSA C22.2 No 60079-1-07 Electrical apparatus for explosive gas atmospheres –

CSA E60079-15-02 (R 2006) Electrical Apparatus for Explosive Gas Atmospheres –

UL 508 Industrial Control Equipment - Seventeenth Edition;

UL 1203 Explosion-Proof and Dust-Ignition-Proof Electrical

ANSI/ISA-12.12.01-2007 Nonincendive Electrical Equipment for Use in Class

MARKINGS

The following markings are provided on a UL Recognized (PGJI2) adhesive nameplate manufactured by

Datamax, type FantaStock-HCW, printed with a resin ribbon manufactured by Datamax, type Greatribbon

SDR or SDR-5, which is suitable for indoor/outdoor use on polyurethane paint coatings, at a maximum service

temperature of 135°C or higher. Alternatively a screw or rivet secured metal nameplate or other permanent

2397437

2397437

II – Tenth Edition

Hazardous Locations Industrial Products – Third

Edition

Edition

Division 2 Hazardous Locations Industrial Products –

First Edition

Part 0: General requirements – First Edition

Part 1: Flameproof enclosures "d" – First Edition

Part 15: Type of Protection "n" – Second Edition

Reprint with Revisions Through and Including April

15, 2010

Equipment for Use in Hazardous (Classied) Locations

- Fourth Edition; Reprint with Revisions through and

Including October 28, 2009

I and II, Division 2 and Class III, Divisions 1 and 2

Hazardous (Classied) Locations

Master Contract:

Date Issued:

237484

May 18, 2011

DQD 507 Rev. 2009-09-01 Page: 2

Automation Products Group, Inc.

APG...Providing tailored solutions for measurement applications

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

43

Page 44

MPX Series Magnetostrictive Level Sensors Rev. B, 4/13

Certificate:

Project:

manner can be used. The nameplate is axed to the top of the enclosure. Labels, if shown in the report, may

vary slightly in layout, provided that the required information continues to be shown.

The following markings appear on each product where applicable:

• Manufacturer’s name: "Automation Products Group", or CSA Master Contract Number “237484”, adjacent to

the CSA Mark in lieu of manufacturer’s name.

• Model number: As specied in the PRODUCTS section, above.

• Electrical ratings: As specied in the PRODUCTS section, above.

• Ambient temperature rating: As specied in the PRODUCTS section, above.

• Manufacturing date in MMYY format, or serial number, traceable to month of manufacture.

• Enclosure ratings: As specied in the PRODUCTS section, above.

• The CSA Mark with or without “C” and “US” indicators, as shown on the Certicate of Conformity.

• Hazardous Location designation: As specied in the PRODUCTS section, above (may be abbreviated).

• Temperature code: As specied in the PRODUCTS section, above.

• The name or mark of the certicate issuer and the certicate reference in the following form: the last two

gures of the year of the certicate followed by the serial number of the certicate in that year.

• The following words:

• “OPEN CIRCUIT BEFORE REMOVING COVER” or "KEEP COVER TIGHT WHILE CIRCUITS ARE

• “WARNING – EXPLOSION HAZARD - Substitution of components may impair suitability for Class I,

• “WARNING – EXPLOSION HAZARD – Do not connect while circuit is live unless area is known to be

• “Install per drawing 9003468 (as appropriate for nonincendive eld wiring only).”

An installation manual or data sheet shall be supplied with each unit, containing the following minimum

marking information:

General: Technical specications, instructions for use and details of where technical assistance may be obtained

if required.

Equipment Ratings: This includes equipment supply, description of I/O connections, duty cycle and operating

environmental conditions.

• Pollution degree 2;

• Measurement category II;

• Altitude 2000 m;

• Humidity 0 to 100%;

• Electrical supply DC,

• Indoor and outdoor use statement;

• Temperature - 40°C to 85°C;

Equipment Installation: This includes instructions for assembly and mounting, location requirements, details for

special services (cooling supply, etc.) as applicable.

2397437

2397437

ALIVE”.

Division 2.”

nonhazardous.”

Master Contract:

Date Issued:

237484

May 18, 2011

DQD 507 Rev. 2009-09-01 Page: 3

Automation Products Group, Inc.

APG...Providing tailored solutions for measurement applications

44

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

Page 45

Rev. B, 4/13 MPX Series Magnetostrictive Level Sensors

Certificate:

Project:

PERMANENTLY CONNECTED EQUIPMENT requires the special considerations to satisfy the CEC and the

Canadian deviations in the standard, including overcurrent and fault protection as required.

Equipment Operation: This includes explanations of operating controls and warning symbols used, and

instructions for interconnection, replacement of consumables (e.g. paper) and cleaning as required.

Equipment Maintenance: This includes instructions for preventative maintenance, inspection and cleaning,

replacement of parts, etc.

Note - Jurisdictions in Canada may require these markings to also be provided in French language. It is the

responsibility of the manufacturer to provide bilingual marking, where applicable, in accordance with the

requirements of the Provincial Regulatory Authorities. It is the responsibility of the manufacturer to determine

this requirement and have bilingual wording added to the "Markings".

2397437

2397437

Master Contract:

Date Issued:

237484

May 18, 2011

DQD 507 Rev. 2009-09-01 Page: 4

Automation Products Group, Inc.

APG...Providing tailored solutions for measurement applications

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

45

Page 46

MPX Magnetostrictive Level Sensors Rev. B, 4/13

Notes

46

Automation Products Group, Inc.

APG...Providing tailored solutions for measurement applications

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

Page 47

Rev. B, 4/13 MPX Magnetostrictive Level Sensors

Notes

Automation Products Group, Inc.

APG...Providing tailored solutions for measurement applications

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

47

Page 48

AUTOMATION

P R O D U C T S

GROUP, INC.

APG...Providing tailored solutions

for measurement applications

Automation Products Group, Inc.

Tel: 1/888/525-7300

1/435/753-7300

Fax: 1/435/753-7490

e-mail: sales@apgsensors.com

www.apgsensors.com

Automation Products Group, Inc.

1025 W. 1700 N.

Logan, UT 84321

Loading...

Loading...