Page 1

Operator’s Manual

AUTOMATION

P R O D U C T S

GROUP, INC.

Automa! on Products Group, Inc.

APG...Providing tailored solu• ons for measurement applica• ons

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • E-mail: sales@apgsensors.com

MNU

series

Ultrasonic Sensors

Rev. B1 5/13

Page 2

MNU Series Ultrasonic Sensors Rev. B1, 5/13

2

Automa! on Products Group, Inc.

APG...Providing tailored solu• ons for measurement applica• ons

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

Table of Contents

Warranty ........................................................................................ 3

Understanding Ultrasonics .......................................................... 4-5

Installa• on ................................................................................... 6-8

Wiring ............................................................................................. 9

Sensor Communica• ons .......................................................... 10-17

Parameter Descrip• ons ........................................................... 16-32

Web Alarming .......................................................................... 33-34

Inspec• on and Maintenance ........................................................ 35

Specifi ca• ons ................................................................................ 36

Dimensions ................................................................................... 37

Page 3

Rev. B1, 5/13 MNU Series Ultrasonic Sensors

3

Automa! on Products Group, Inc.

APG...Providing tailored solu• ons for measurement applica• ons

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

APG warrants its products to be free from defects of material and workmanship

and will, without charge, replace or repair any equipment found defec! ve

upon inspec! on at its factory, provided the equipment has been returned,

transporta! on prepaid, within 24 months from date of shipment from factory.

THE FOREGOING WARRANTY IS IN LIEU OF AND EXCLUDES ALL OTHER

WARRANTIES NOT EXPRESSLY SET FORTH HEREIN, WHETHER EXPRESSED OR

IMPLIED BY OPERATION OF LAW OR OTHERWISE INCLUDING BUT NOT LIMITED

TO ANY IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A

PARTICULAR PURPOSE.

No representa! on or warranty, express or implied, made by any sales

representa! ve, distributor, or other agent or representa! ve of APG which is

not specifi cally set forth herein shall be binding upon APG. APG shall not be

liable for any incidental or consequen! al damages, losses or expenses directly

or indirectly arising from the sale, handling, improper applica! on or use of the

goods or from any other cause rela! ng thereto and APG’s liability hereunder, in

any case, is expressly limited to the repair or replacement (at APG’s op! on) of

goods.

Warranty is specifi cally at the factory. Any on site service will be provided at

the sole expense of the Purchaser at standard fi eld service rates.

All associated equipment must be protected by properly rated electronic/

electrical protec! on devices. APG shall not be liable for any damage due

to improper engineering or installa! on by the purchaser or third par! es.

Proper installa! on, opera! on and maintenance of the product becomes the

responsibility of the user upon receipt of the product.

Returns and allowances must be authorized by APG in advance. APG will

assign a Return Material Authoriza! on (RMA) number which must appear

on all related papers and the outside of the shipping carton. All returns are

subject to the fi nal review by APG. Returns are subject to restocking charges as

determined by APG’s “Credit Return Policy”.

• Warranty and Warranty Restric! ons

Page 4

MNU Series Ultrasonic Sensors Rev. B1, 5/13

4

Automa! on Products Group, Inc.

APG...Providing tailored solu• ons for measurement applica• ons

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

• Understanding Ultrasonics

Ultrasonic sensors use a transducer to transmit bursts of ultrasonic sound

waves. Each burst contains a series of pulsed sound waves that emit in the

shape of a cone, refl ect off the target, and are detected by the sensor. The # me

required for the sound waves to travel to and from the target is converted into

a distance measurement by the sensor. Ultrasonic sensing is aff ected by several

factors including the target surface, distance, size, and angle. The following

considera# ons will help ensure the best possible target condi# ons.

Surface

The ideal target surface is hard and smooth. This type of surface will refl ect a

greater amount of signal than a so$ or uneven surface. Sound wave absorbent

materials, such as granules and powders, will reduce the opera# ng range of the

sensor and decrease measurement accuracy.

Distance

Sound wave a% enua# on increases as the distance traveled increases.

Therefore, targets at longer ranges require be% er refl ec# ve characteris# cs than

targets that are closer to the sensor.

Size

A large object will have a greater surface area to refl ect the signal than a

smaller one. Therefore, a large target will be detected at a greater distance

than a small target. The surface area recognized as the target will generally be

the por# on closest to the sensor.

Page 5

Rev. B1, 5/13 MNU Series Ultrasonic Sensors

5

Automa! on Products Group, Inc.

APG...Providing tailored solu• ons for measurement applica• ons

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

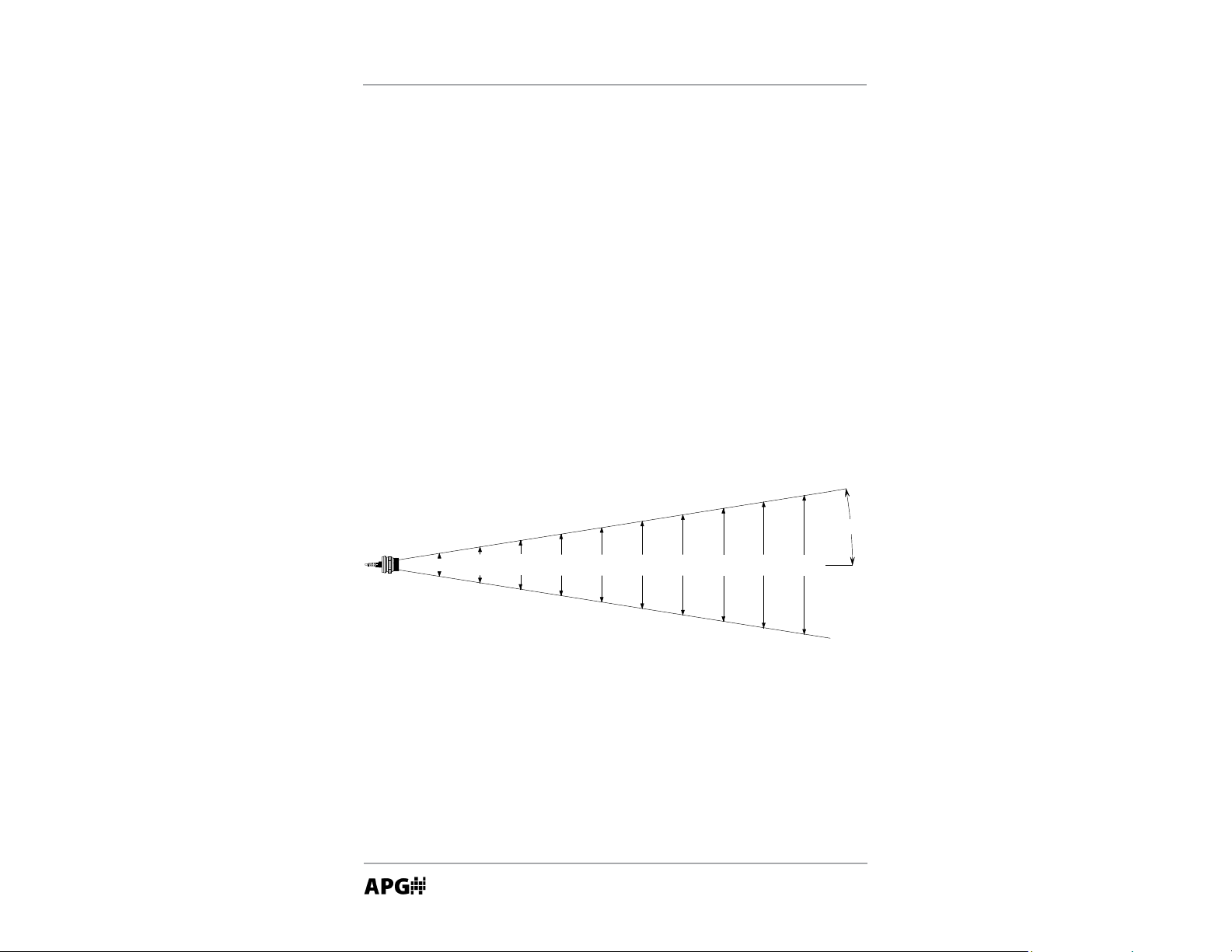

Angle

The inclina! on of the object’s surface in rela! on to the sensor face will aff ect

the strength of the refl ected sound waves. Surfaces perpendicular to the

sensor will refl ect more signal directly back to the sensor. If a surface is more

than a few degrees off perpendicular, enough of the signal will be refl ected

away from the sensor that the target will not be detected. Generally speaking,

a target angle greater than 5 degrees off perpendicular will not be detected.

The target angle becomes increasingly cri! cal as the distance to the target

increases.

Environmental Condi! ons

Temperature, humidity, vapors, dust, and pressure can aff ect the sensor’s

performance. APG ultrasonic sensors are designed to compensate for many of

these condi! ons. However, if the condi! ons are extreme, sensor performance

can be degraded enough to require the use of a longer-range sensor than

normal condi! ons would require. Ultrasonic sensors may not be suitable for

applica! ons with heavy chemical vapors (such as solvents or gasoline), heavy

dust or when signifi cant surface foam is present.

Page 6

MNU Series Ultrasonic Sensors Rev. B1, 5/13

6

Automa! on Products Group, Inc.

APG...Providing tailored solu• ons for measurement applica• ons

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

NOTE: S! lling pipes are an excellent solu! on for liquid level

applica! ons where an unobstructed path to the target is not feasible

(see s! lling pipe moun! ng on page 9 for details).

• When moun! ng outdoors, it’s best to shade the sensor from direct

sunlight. Direct sunlight can warm the sensor housing above the ambient

temperature causing false temperature readings and overcompensa! on by

the sensor.

• Installa! on

Proper sensor moun! ng is cri! cal for successful opera! on of an ultrasonic

sensor. Using the following guidelines can help ensure trouble free installa! on

and opera! on:

• Ensure that the sensor face is perpendicular to the target surface. If the

target is more than a few degrees off perpendicular, it may not be

detected. Targets at greater distances will require more precise sensor

alignment.

• Mount the sensor in a loca! on that provides an unobstructed column

of air from the sensor to the target. The required width of the air

column depends on several factors, including the angle and refl ec! ve

characteris! cs of any poten! al targets on the edge of the column, the

sensi! vity se$ ng of the sensor, the maximum distance to the target, and

the refl ec! ve characteris! cs of the target itself. Generally speaking a 3 to 4

foot diameter unobstructed column is suffi cient even at longer ranges.

11.4

in

.

1

9

i

n

.

2

2

.

8

in

.

2

6

.6

in

.

30.

4

i

n

.

3

4

.

2

in

.

3

8

i

n

.

3

.

8

in

.

7

.

6

i

n

.

9

°

1

5

.

2

i

n

.

2

ft.

4

f

t

.

3

f

t

.

5

f

t

.

6

f

t

.

7ft

.

8

f

t

.

9

f

t

.

1

0

f

t

.

1

f

t.

dLJƉŝĐĂůďĞĂŵƐƉƌĞĂĚŽĨĂƐĞŶƐŽƌŽƉĞƌĂƟŶŐĂƚŵĂdžŝŵƵŵƐĞŶƐŝƟǀŝƚLJ

Page 7

Rev. B1, 5/13 MNU Series Ultrasonic Sensors

7

Automa! on Products Group, Inc.

APG...Providing tailored solu• ons for measurement applica• ons

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

• Always mount above the highest an! cipated target level by at least the

published minimum blanking distance. If a target enters into the blanking

area, error in the detec! on will occur. It is always advisable to allow for

suffi cient headroom to ensure that the target does not enter the blanking

area.

• Generally it is advisable to mount the sensor away from any vessel fi ll

spouts. However, if heavy foam is expected, it is o$ en helpful to mount the

Sensor near a fi ll spout where the foam is being dispersed.

• Avoid moun! ng the sensor in the direct center of a tank with a signifi cantly

domed top. A domed top can act as parabolic dish, amplifying small

undesired signals that may be present inside the tank.

• Avoid moun! ng the sensor in close proximity to tank walls, especially on

tanks with corrugated walls or in applica! ons where product buildup on

the tank walls may occur.

>Žǁ^ĞŶƐŝƟǀŝƚLJĞƚĞĐƟŽŶƌĞĂ,ŝŐŚ^ĞŶƐŝƟǀŝƚLJĞƚĞĐƟŽŶƌĞĂ

Page 8

MNU Series Ultrasonic Sensors Rev. B1, 5/13

8

Automa! on Products Group, Inc.

APG...Providing tailored solu• ons for measurement applica• ons

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

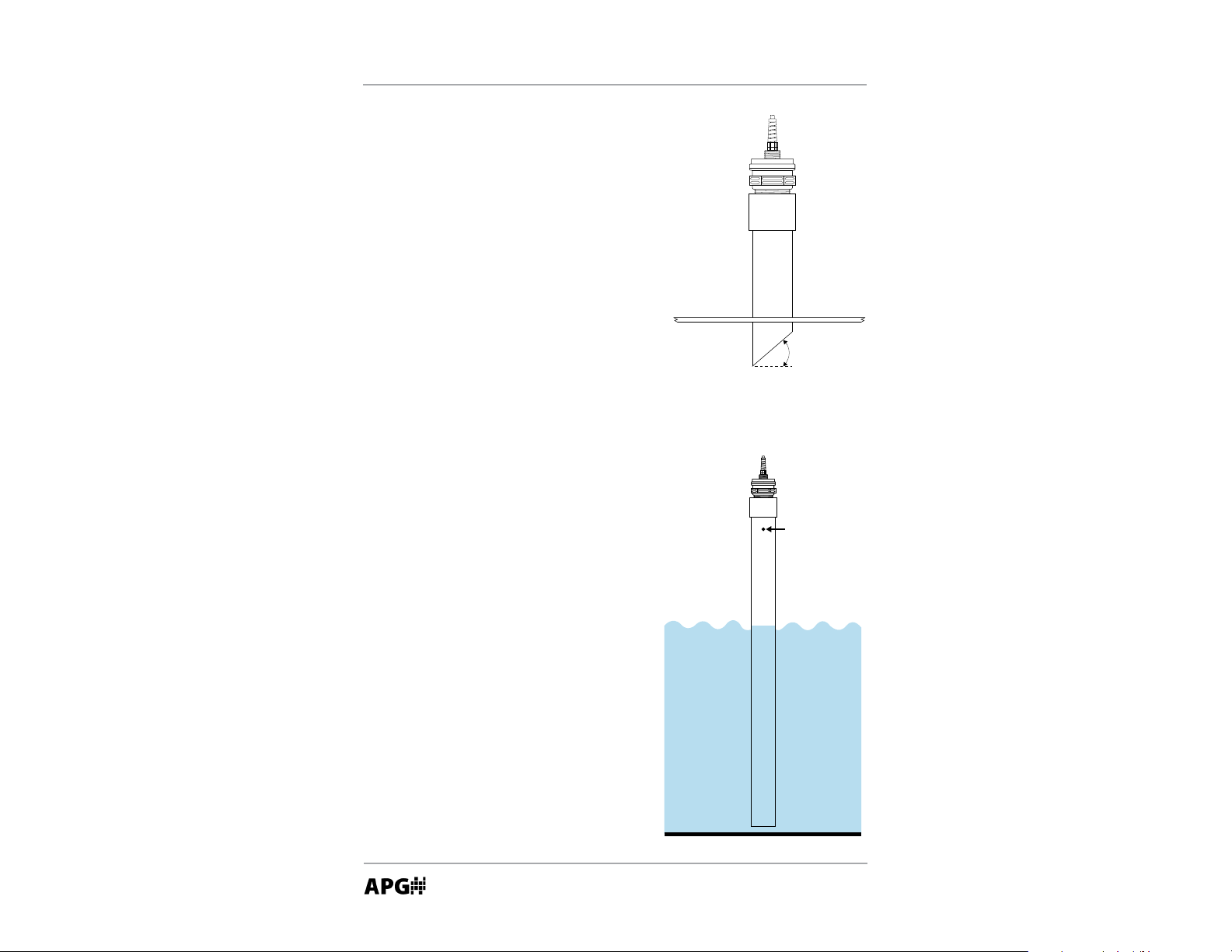

Stand Pipe Moun! ng

Stand pipes are used to provide headroom at

the top of a tank when the target is expected

to come closer to the sensor than the

minimum blanking distance. It’s very cri! cal

that the stand pipe be installed perpendicular

to the target. This is especially important

on longer range applica! ons. The pipe must

have smooth walls (no joints) and no burs or

obstruc! ons. If possible, cut the end of the

pipe at a 10°-45° angle (see drawing). Use

the largest diameter pipe and shortest length

possible. As a general rule, the diameter of

the pipe should be 1/2 the length. The pipe

ID must remain the same through it’s en! re

length.

S! lling Pipe Moun! ng

S! lling pipes provide access to diffi cult areas

and help eliminate problems with foam.

The pipe must have smooth walls (no burs

or joints). Because the sound waves will

concentrate and propagate down the inside

walls of the tube, any irregulari! es on the

tube walls may produce echo returns and

cause false readings. S! lling pipes are limited

to liquid targets that will not leave heavy

deposits on the tube walls. Because the

sound waves are confi ned inside the pipe,

it is usually necessary to greatly reduce the

sensors sensi! vity and pulses se$ ngs. A vent

hole must be provided at the top of the pipe.

Be sure to keep the vent hole inside of the

blanking area.

Cut at angle

when possible

Vent Hole

Page 9

Rev. B1, 5/13 MNU Series Ultrasonic Sensors

9

Automa! on Products Group, Inc.

APG...Providing tailored solu• ons for measurement applica• ons

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

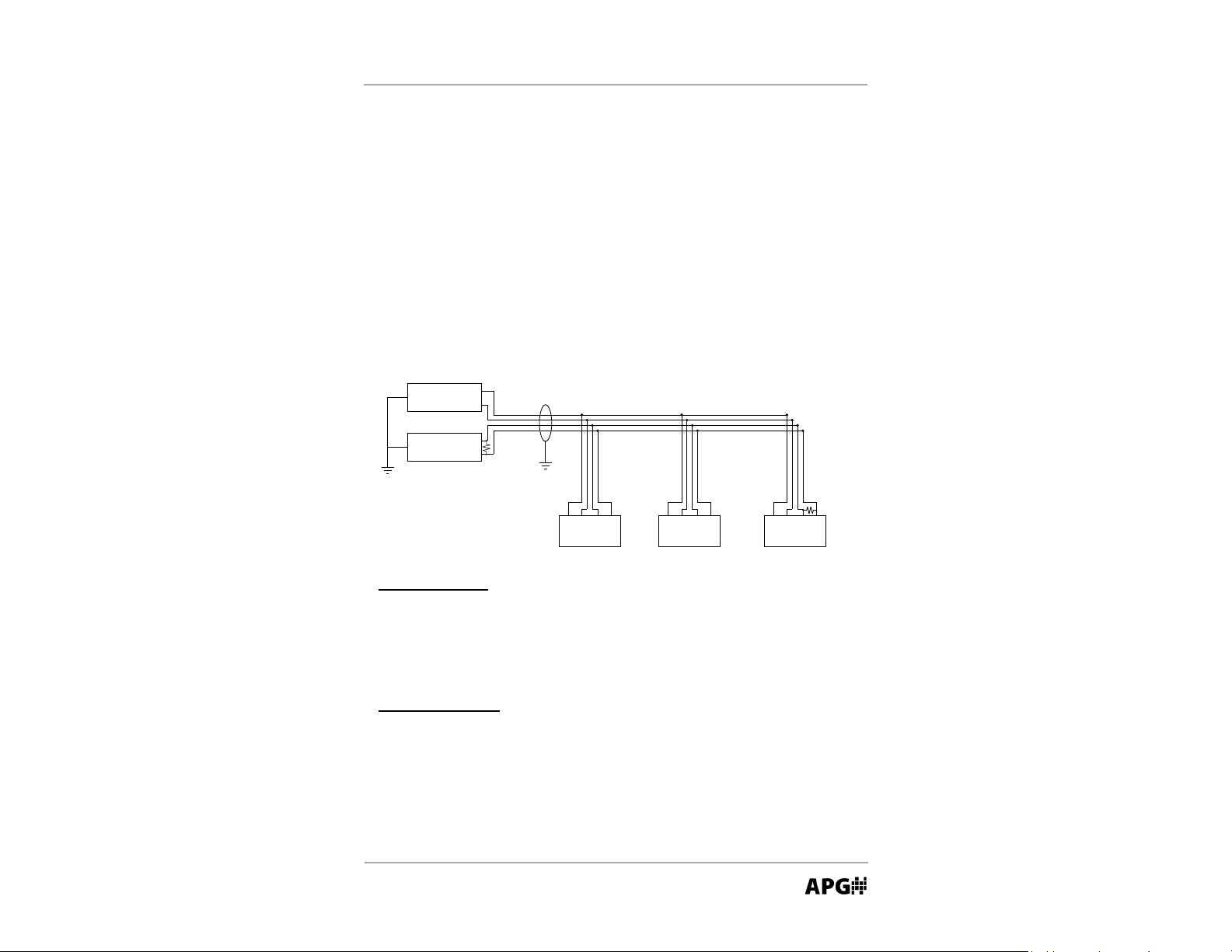

• Wiring

Always use shielded cable. It is recommended that twisted-pair cable be used

between sensors when connec! ng mul! ple sensors to the Modbus network.

NOTE:

Always use a high quality power supply that will deliver clean, stable

voltage.

The MNU series sensors are wired in a daisy-chain confi gura! on, as shown

below. Each sensor should be connected individually and assigned a unique

address before wiring the sensor into the Modbus network.

Power

Supply

Master

Device

RS-485 A

RS-485 B

Vdc

Vdc

+

-

Sensor 1

V+ V- A B

Sensor 2

V+ V- A B

Sensor 3

V+ V- A B

Use Shielded Cable

120 Ohm

Terminating

Resistor

120 Ohm

Terminating

Resistor

Modbus Daisy-Chain Wiring

Mirco Connector:

Pin 1 (Brown) +24 VDC

Pin 2 (White) RS-485 A

Pin 3 (Blue) DC Common

Pin 4 (Black) RS-485 B

4-Conductor Cable:

Red +24 VDC

Black DC Common

White RS-485 A

Green RS-485 B

Page 10

MNU Series Ultrasonic Sensors Rev. B1, 5/13

10

Automa! on Products Group, Inc.

APG...Providing tailored solu• ons for measurement applica• ons

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

• Sensor Communica! ons

The MNU sensor u! lizes standard Modbus RTU protocol (RS-485). The MNU

sensor can only operate as a slave device. For more informa! on about Modbus

RTU, please visit www.modbus.org.

The MNU sensor will transmit at (allow a minimum delay of 300 ms between

transac! ons):

9600 bps

8 data bits

No parity

1 stop bit

Input Registers (0x04):

Register Returned Data

30300 Raw Distance/Level Reading (in mm, unsigned)

30302 Temperature Reading (in

0

C, signed)

30303-30304 Calculated Reading (in selected units, without decimal place)

NOTE: the Calculated Reading will be returned as a whole number. In order

to a" ain the true result, the Decimal Place se# ng must be taken into account. Refer to Decimal Place se# ng on page 21 for more informa! on.

Holding Registers (0x03):

Register Func! on Value Range

40400 Device Address 1 to 255

40401 Units 1 to 3

40402 Applica! on Type 0-10

40403 Volume Units 0 to 6

40404 Decimal Place 0 to 3

40405 Max Distance 0 to 10364 mm

40406 Full Distance 0 to 10364 mm

40407 Empty Distance 0 to 10364 mm

Page 11

Rev. B1, 5/13 MNU Series Ultrasonic Sensors

11

Automa! on Products Group, Inc.

APG...Providing tailored solu• ons for measurement applica• ons

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

(con! nued)

Register Func! on Value Range

40408 Sensi! vity 0 to 100

40409 Pulses 0 to 20

40410 Blanking 0 to 10364 mm

40411 Gain Control 0 to 4

40412 Averaging 0 to 100

40413 Filter Window 0 to 10364 mm

40414 Out of Range Samples 0 to 255

40415 Sample Rate 50 to 1000 msec.

40416 Mul! plier 1 to 1999

40417 Off set +/- 10364 mm

40418-40419 reserved n/a

40420 Temperature Compensa! on 0 = off , 1 = on

40421-40435 reserved n/a

40436-40437 Parameter 1 Data 0 to 100,000 mm

40438-40439 Parameter 2 Data 0 to 100,000 mm

40440-40441 Parameter 3 Data 0 to 100,000 mm

40442-40443 Parameter 4 Data 0 to 100,000 mm

40444-40445 Parameter 5 Data 0 to 100,000 mm

Page 12

MNU Series Ultrasonic Sensors Rev. B1, 5/13

12

Automa! on Products Group, Inc.

APG...Providing tailored solu• ons for measurement applica• ons

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

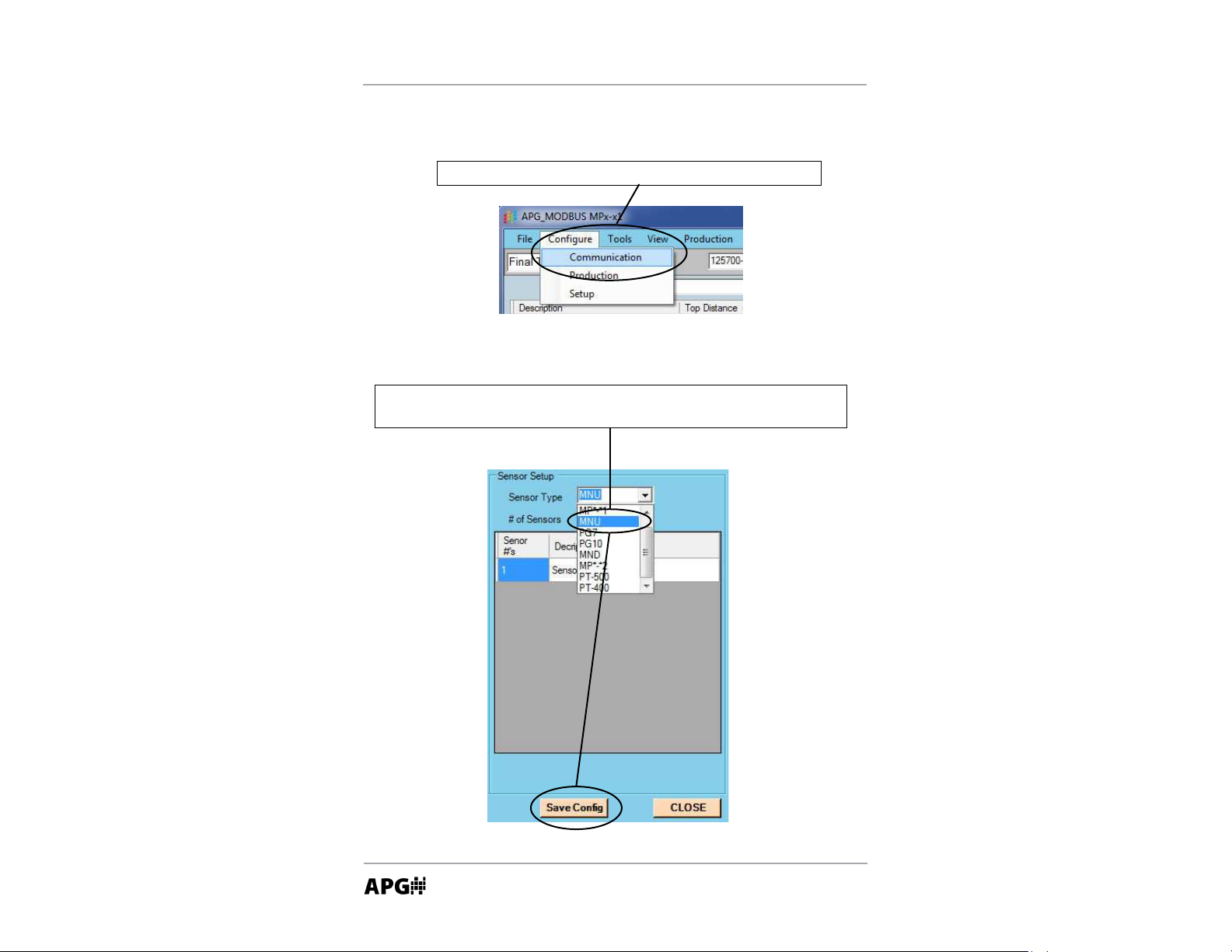

Confi guring So# ware Communica! ons

Step 2: select “MNU” from the Sensor Type menu, then click the “Save

Confi g” bu" on at the bo" om of the screen.

Step 1: select “Communica# on” from the “Confi gure” menu.

Page 13

Rev. B1, 5/13 MNU Series Ultrasonic Sensors

13

Automa! on Products Group, Inc.

APG...Providing tailored solu• ons for measurement applica• ons

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

Step 3: set the mode of communica! on by selec! ng the .

Select the appropriate Comm Port when using direct serial communica! ons.

Check the “USB Communica! ons (RST-6001)” box when using the RST-6001

communica! ons module.

OR

Page 14

MNU Series Ultrasonic Sensors Rev. B1, 5/13

14

Automa! on Products Group, Inc.

APG...Providing tailored solu• ons for measurement applica• ons

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

Step 2: change the “Sensor #”

boxes to match the address’ of

the target sensors.

Step 3: Change the Descrip! on labels as desired. The Descrip! on is

used to diff eren! ate between sensors in other areas of the so$ ware.

Step 4: Click “Save

Confi g” then “Close”.

Step 1: select the total number

of sensors you wish to read.

Confi guring So# ware Communica! ons for Mul! ple Sensors

(con! nued)

Page 15

Rev. B1, 5/13 MNU Series Ultrasonic Sensors

15

Automa! on Products Group, Inc.

APG...Providing tailored solu• ons for measurement applica• ons

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

START

Step 6: Click on a sensor descrip! on to access that sensor’s parameters.

Refer to “Using the So" ware Programming Window” on the next page

for informa! on on adjus! ng sensor parameters.

Step 5: Click on “Start”. The sensor readings should

populate as the so" ware cycles through each sensor.

Page 16

MNU Series Ultrasonic Sensors Rev. B1, 5/13

16

Automa! on Products Group, Inc.

APG...Providing tailored solu• ons for measurement applica• ons

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

Click on the desired sensor descrip! on to

open that sensor’s programming window.

The register values should automa! cally populate. If not, click

“Receive All” to retrieve the register values from the sensor.

Using the So" ware Programming Window

Sensor readings are displayed

in the Input Registers table.

(con! nued on next page)

Page 17

Rev. B1, 5/13 MNU Series Ultrasonic Sensors

17

Automa! on Products Group, Inc.

APG...Providing tailored solu• ons for measurement applica• ons

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

To send all the register values as

currently listed, click “Send All”

A green window

indicates successful

communica! on.

A yellow window

indicates a communi-

ca! on failure.

To change an individual parameter, click on the value

you wish to change, enter the desired value, then click

the adjacent “Send” bu" on to implement the change.

To retrieve the register values saved

in a sensor, click “Receive All”

1500

Send

1500

Send

150000

Send

A red window indi-

cates a value outside

the allowable limits

for the parameter.

Page 18

MNU Series Ultrasonic Sensors Rev. B1, 5/13

18

Automa! on Products Group, Inc.

APG...Providing tailored solu• ons for measurement applica• ons

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

• Parameter Descrip! ons

Device Address (1 to 255) (40400)

Each device within the Modbus network must be assigned a unique address.

Each MNU sensor should be connected to the network individually and assigned an address. By default the each sensor is set to address 1.

Units (1 to 3) (40401)

Determines the unit of measure for the Calculated Reading (input registers

30303-30304) when in Applica! on Types 1, 2 or 7 (see below).

Applica! on Type (0 to 11) (40402)

Determines how the sensor calculates the readings.

Applica! on Type 0: Distance to target

(measurement result in register 30300)

Register Func! on Value Range

40401 Units 1 to 3

40402 Applica! on Type 0

40404 Decimal Place 0 to 3

40405 Max Distance 0 to 10364 mm

Applica! on Type 1: Depth of level

(measurement result in register 30300)

Register Func! on Value Range

40401 Units 1 to 3

40402 Applica! on Type 1

40404 Decimal Place 0 to 3

40405 Max Distance ≥ Empty Distance

40406 Full Distance Typically = Blanking Distance

40407 Empty Distance 0 to 10364 mm

Distance

Level

Page 19

Rev. B1, 5/13 MNU Series Ultrasonic Sensors

19

Automa! on Products Group, Inc.

APG...Providing tailored solu• ons for measurement applica• ons

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

Applica! on Type 2: Volume of cylindrical tank with or without hemispherical bo" om (measurement result in register 30303-30304)

Register Func! on Value Range

40402 Applica! on Type 2

40403 Volume Units 1 to 7

40404 Decimal Place 0 to 3

40405 Max Distance # Empty Distance

40406 Full Distance Typically = Blanking Distance

40407 Empty Distance 0 to 10364 mm

40436-40437 Tank Diameter 0 to 100,000 mm

40438-40439 Bo" om Radius 0 to 100,000 mm

NOTE: for fl at bo" om tanks, set the Bo" om Radius to 0.

Diameter

Empty

Distance

ŽƩŽŵ

Radius

Full

Distance

or

Page 20

MNU Series Ultrasonic Sensors Rev. B1, 5/13

20

Automa! on Products Group, Inc.

APG...Providing tailored solu• ons for measurement applica• ons

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

Applica! on Type 3: Volume of cylindrical tank with conical bo" om

(measurement result in register 30303-30304)

Register Func! on Value Range

40402 Applica! on Type 3

40403 Volume Units 1 to 7

40404 Decimal Place 0 to 3

40405 Max Distance # Empty Distance

40406 Full Distance Typically = Blanking Distance

40407 Empty Distance 0 to 10364 mm

40436-40437 Tank Diameter 0 to 100,000 mm

40438-40439 Cone Diameter 0 to 100,000 mm

40440-40441 Cone Length 0 to 100,000 mm

Diameter

Full

Distance

Empty

Distance

Cone

Length

Cone

Diameter

Page 21

Rev. B1, 5/13 MNU Series Ultrasonic Sensors

21

Automa! on Products Group, Inc.

APG...Providing tailored solu• ons for measurement applica• ons

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

Applica! on Type 4: Volume of rectangular tank with or without chute

bo" om (measurement result in register 30303-30304)

Register Func! on Value Range

40402 Applica! on Type 4

40403 Volume Units 1 to 7

40404 Decimal Place 0 to 3

40405 Max Distance # Empty Distance

40406 Full Distance Typically = Blanking Distance

40407 Empty Distance 0 to 10364 mm

40436-40437 Tank X 0 to 100,000 mm

40438-40439 Tank Y 0 to 100,000 mm

40440-40441 Chute X 0 to 100,000 mm

40442-40443 Chute Y 0 to 100,000 mm

40444-40445 Chute Length 0 to 100,000 mm

Tank X

Chute

Length

Tank Y

Empty

Distance

Full

Distance

or

Chute Y

Chute X

Page 22

MNU Series Ultrasonic Sensors Rev. B1, 5/13

22

Automa! on Products Group, Inc.

APG...Providing tailored solu• ons for measurement applica• ons

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

Applica! on Type 5: Volume of horizontal cylindrical tank with or without

hemispherical ends (measurement result in register 30303-30304)

Register Func! on Value Range

40402 Applica! on Type 5

40403 Volume Units 1 to 7

40404 Decimal Point 0 to 3

40405 Max Distance ≥ Empty Distance

40406 Full Distance Typically = Blanking Distance

40407 Empty Distance 0 to 10364 mm

40436-40437 Tank Length 0 to 100,000 mm

40438-40439 Tank Diameter 0 to 100,000 mm

40440-40441 End Radius 0 to 100,000 mm

Diameter

Length

Empty

Distance

End

Radius

Full

Distance

Page 23

Rev. B1, 5/13 MNU Series Ultrasonic Sensors

23

Automa! on Products Group, Inc.

APG...Providing tailored solu• ons for measurement applica• ons

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

Applica! on Type 6: Volume of spherical tank

(measurement result in register 30303-30304)

Register Func! on Value Range

40402 Applica! on Type 6

40403 Volume Units 1 to 7

40404 Decimal Point 0 to 3

40405 Max Distance ≥ Empty Distance

40406 Full Distance Typically = Blanking Distance

40407 Empty Distance 0 to 10364 mm

40436-40437 Tank Diameter 0 to 100,000 mm

Empty

Distance

Diameter

Full

Distance

Page 24

MNU Series Ultrasonic Sensors Rev. B1, 5/13

24

Automa! on Products Group, Inc.

APG...Providing tailored solu• ons for measurement applica• ons

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

Applica! on Type 7: Pounds

Allows the user to apply a conversion mul! plier to the calculated level reading.

(measurement result in register 30303-30304)

NOTE: the decimal place for the Mul! plier is always assumed to be in the

thousands posi! on, therefore a se" ng of 206250 = 206.250 actual mul! plier.

Example: suppose the product in a tank weighs 206.25 pounds for every

inch of level. Assuming the Units are set to inches (Units = 2), the Mul! plier

would be 206250.

Register Func! on Value Range

40401 Units 1 to 3

40402 Applica! on Type 7

40404 Decimal Place 0 to 3

40405 Max Distance ≥ Empty Distance

40406 Full Distance Typically = Blanking Distance

40407 Empty Distance 0 to 10364 mm

40436-40437 Mul! plier 0 to 1000000 (1000 = 1.000)

Page 25

Rev. B1, 5/13 MNU Series Ultrasonic Sensors

25

Automa! on Products Group, Inc.

APG...Providing tailored solu• ons for measurement applica• ons

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

Applica! on Type 9: Volume of ver! cal oval tank

(measurement result in register 30303-30304)

Register Func! on Value Range

40402 Applica! on Type 9

40403 Volume Units 1 to 7

40404 Decimal Place 0 to 3

40405 Max Distance ≥ Empty Distance

40406 Full Distance Typically = Blanking Distance

40407 Empty Distance 0 to 10364 mm

40436-40437 Tank Length 0 to 100,000 mm

40438-40439 Tank Depth 0 to 100,000 mm

40440-40441 Tank Width 0 to 100,000 mm

Full

Distance

Empty

Distance

Depth

Length

Width

Page 26

MNU Series Ultrasonic Sensors Rev. B1, 5/13

26

Automa! on Products Group, Inc.

APG...Providing tailored solu• ons for measurement applica• ons

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

Applica! on Type 10: Volume of horizontal oval tank

(measurement result in register 30303-30304)

Register Func! on Value Range

40402 Applica! on Type 10

40403 Volume Units 1 to 7

40404 Decimal Place 0 to 3

40405 Max Distance ≥ Empty Distance

40406 Full Distance Typically = Blanking Distance

40407 Empty Distance 0 to 10364 mm

40436-40437 Tank Length 0 to 100,000 mm

40438-40439 Tank Depth 0 to 100,000 mm

40440-40441 Tank Width 0 to 100,000 mm

Length

Width

Depth

Empty

Distance

Full

Distance

Page 27

Rev. B1, 5/13 MNU Series Ultrasonic Sensors

27

Automa! on Products Group, Inc.

APG...Providing tailored solu• ons for measurement applica• ons

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

Applica! on Type 11: Curve Fit (Strapping Chart)

Allows the sensor to mimic a tank strapping chart by using a 3rd degree polynomial equa! on to produce a “curve fi t” approxima! on.

(measurement result in register 30303-30304)

Register Func! on Value Range

40401 Units 1 to 3

40402 Applica! on Type 11

40404 Decimal Place 0 to 3

40406 Full Distance Typically = Blanking

40407 Empty Distance 0 to 10364 mm

40436-40437 Parameter 1 0 to 100,000 mm

40438-40439 Parameter 2 0 to 100,000 mm

40440-40441 Parameter 3 0 to 100,000 mm

40442-40443 Parameter 4 0 to 100,000 mm

Open the APG Modbus so# ware and select “Strapping Chart” from the “Tools”

menu.

Enter the desired data points

into the table.

Use the “Load” bu$ on to recall a previously saved table.

Import data from an electronic

document by copying the data

and then using the “Paste”

bu$ on to populate the table.

OR

OR

Page 28

MNU Series Ultrasonic Sensors Rev. B1, 5/13

28

Automa! on Products Group, Inc.

APG...Providing tailored solu• ons for measurement applica• ons

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

Once the all data points have been entered, click the “Calculate” bu! on to

determine the values required for the “curve fi t” calcula# on.

Click the “Save to Sensor” bu! on to populate the appropriate Holding Resister

fi elds (see below) and close the Strapping Chart window.

Click the “Send All” bu! on at the bo! om of the Holding Register page to write

the curve fi t values to the sensor.

NOTE: before clicking “Calculate” ensure that

there is only one empty row following the last

line of data (as shown). Use the keyboard

“Delete”key to remove any addi# on empty rows.

Page 29

Rev. B1, 5/13 MNU Series Ultrasonic Sensors

29

Automa! on Products Group, Inc.

APG...Providing tailored solu• ons for measurement applica• ons

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

Volume Units (0 to 6) (40403)

Determine the unit of measure for the volumetric Applica! on Types.

1 = Cubic Feet

4 = Cubic Meters 7 = Barrels

2 = Million Cubic Feet 5 = Liters

3 = Gallons 6 = Cubic Inches

Decimal Place (0 to 3) (40404)

Used to set the number of decimal places included in the Calculated Reading.

The Calculated Reading will always be returned as a whole number.

Example: a Calculated Reading of 1126.658 (gallons, " 3, etc.) will be returned

as follows:

Decimal Place = 0 Volume = 1127 (rounded to nearest whole number)

Decimal Place = 1 Volume = 11267 (divide by 10 to get true result)

Decimal Place = 2 Volume = 112666 (divide by 100 to get true result)

Decimal Place = 3 Volume = 1126658 (divide by 1000 to get true result)

Maximum Distance (0 to 10364 mm) (40405)

Sets the distance (beginning from the sensor face) to the point where the sensor will stop looking for target signals. Targets detected beyond the Maximum

Distance value will be ignored by the sensor.

Full Distance (0 to 10364 mm) (40406)

Sets the distance (beginning from the sensor face) to the point where the tank

is considered full.

Empty Distance (0 to 10364 mm) (40407)

Sets the distance (beginning from the sensor face) to the point where tank is

considered empty. This will typically be the same as the tank depth unless the

sensor is mounted on a stand pipe.

Page 30

MNU Series Ultrasonic Sensors Rev. B1, 5/13

30

Automa! on Products Group, Inc.

APG...Providing tailored solu• ons for measurement applica• ons

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

Sensi! vity (0 to 100%) (40408)

Controls the level of amplifi ca" on applied the returning target echoes (signals).

The sensi" vity se# ng is expressed as a percentage; 0 to 100%. When operating in Autosense mode, the Sensi" vity se# ng acts as an upper limit constraint

(refer to Gain Control below for more informa" on on Autosense).

Pulses (0 to 20) (40409)

Controls the number of sound wave pulses being sent in each ultrasonic

burst. The greater the number of pulses, the stronger the transmi$ ed signal.

When opera" ng in Autosense mode, the Pulses se# ng acts as an upper limit

constraint (refer to Gain Control below for more informa" on on Autosense).

Blanking (0 to 10364 mm) (40410)

Sets the distance, beginning at the sensor face, to the point where the sensor

will begin looking for target signals. All targets closer than the blanking distance

will be ignored. The blanking should never be set to less than the minimum

range specifi ca" on of the sensor. If the target enters the blanking area, errant

readings will occur.

Gain Control (0 = Manual Mode; 1 = Autosense Mode) (40411)

Determines how the sensor applies gain (amplifi ca" on) to returning target

echoes. In Manual mode the Sensi" vity and Pules se# ngs are applied as

a sta" c values. In Autosense Mode, the sensor self-adjusts the Pulses and

Sensi" vity levels (within the bounds of their respec" ve se# ngs) in order to

op" mize the signal level.

Averaging (1 to 20) (40412)

Defi nes the number of readings that will be averaged together to become

the Calculated Value. Each qualifi ed reading (see Filter Window and Out of

Range Samples on next page) is placed into a fi rst-in, fi rst-out (FIFO) buff er

and averaged with previous readings. A higher Averaging se# ng will result in

smoother readings, but will also slow the response to rapid target changes.

Page 31

Rev. B1, 5/13 MNU Series Ultrasonic Sensors

31

Automa! on Products Group, Inc.

APG...Providing tailored solu• ons for measurement applica• ons

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

Filter Window (0 to 10364 mm) (40413)

Sets the width of the target acceptance window. The target acceptance

window is a zone, centered around the current target reading, within which

any target detected will be considered legi! mate and fi gured into the averaging

buff er. Any target detected outside of the Window will be considered “out of

range” and will be ignored based on the se$ ng in the Out of Range Samples

parameter (see below). The Filter Window extends in both direc! ons from the

current target reading. For example, if the sensor is detec! ng a target at 5 % .

and the Filter Window is set at 1 % ., then any target detected between 4 % . and

6 % . will be accepted.

Out of Range Samples (1 to 255) (40414)

Determines the number of consecu! ve target readings that fall outside of the

acceptance window before the “out of range” target is recognized as being

legi! mate and fi gured into the averaging buff er. For example, suppose the

Out Of Range Samples is set to 10. If a target is suddenly detected outside

of the acceptance window, it will be ignored un! l it has been detected for 10

consecu! ve samples, at which point it will be qualifi ed as a legi! mate target. If

the “out of range” target was detected for only 9 consecu! ve samples before

moving out of the sensing area, it would never be acknowledged as a target and

the reading would stay with the last qualifi ed target sample.

Sample Rate (50 to 1000 msec) (40415)

Sets the interval between target readings. Op! ons allow rates from 50 to

1000 msec. A higher Sample Rate will result in a more rapid response to target

movements. Lowering the Sample Rate will help increase sensor lifespan and

decrease the chance of detec! ng errant echoes. It is highly recommended that

the Sample Rate be set only as fast as is necessary for the applica! on. A sample

rate of 500 to 1000 msec. is usually appropriate for slow moving level sensing

applica! ons.

Page 32

MNU Series Ultrasonic Sensors Rev. B1, 5/13

32

Automa! on Products Group, Inc.

APG...Providing tailored solu• ons for measurement applica• ons

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

Mul! plier (0 to 1999) (40416)

Sets the conversion Mul! plier that will be applied to the sensor readings. The

default is 1000 (see note below) and typically does not need to be adjusted.

However, since the speed of sound is not constant through all environments,

the mul! plier parameter allows the user to adjust for varia! ons in atmosphere

when maximum accuracy is required.

NOTE: the decimal place for the Mul! plier is always assumed to be in the

thousands posi! on, therefore a se" ng of 1025 = 1.025 actual mul! plier.

Off set (-10364 to 10364 mm) (40417)

Used to adjust the zero reference point of the sensor. When the Off set is set to

0, the zero reference of the sensor is at the face of the transducer. Se" ng the

Off set to a nega! ve number will move the zero reference backward (behind the

sensor face), while a posi! ve se" ng will move the reference forward (in front

of the sensor face).

Temperature Compensa! on (0 = Off , 1 = On) (40420)

Used to enable or disable the internal temperature compensa! on of the sensor.

Enabling the internal temperature compensa! on can reduce the eff ects of

temperature changes by 50% or more, depending on the temperature gradient

through the sensing range.

Parameter Data (0 to 100,000 mm) (40436 to 40445)

The Parameter Data registers are used to enter tank dimension or conversion

mul! pliers for all the volumetric Applica! on Types (types 2-10).

Page 33

Rev. B1, 5/13 MNU Series Ultrasonic Sensors

33

Automa! on Products Group, Inc.

APG...Providing tailored solu• ons for measurement applica• ons

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

•Web Alarming (40430 to 40435)

When the MNU is interfaced with an LOE or RST-5002 web-enabled master

device, it can be confi gured to generate website alarms via levelandfl ow.com

(refer to the LOE or RST-5002 user manual for more informa# on about website

alarms and using levelandfl ow.com).

Trip Alarm 1 (40430) or Alarm 2 (40433) Distance

Sets the level (in mm), beginning the bo$ om of the stem, to the fi rst (lowest)

actua# on point (refer to next page for more informa# on).

Trip Alarm 1 Window (40431 or 40434)

Sets the level (in mm), beginning from the Trip Distance loca# on, to the secondary actua# on point (refer to next page for more informa# on).

Trip Alarm 1 Type (40432 or 40435)

Determines the opera# onal logic performed by the Trip Alarm (refer to chart on

next page for more informa# on).

Confi guring Trip Alarm Types for Website Alarming:

(refer to Trip Types chart on next page)

Placing a “1” in front of any of the Trip Types designates an ac# ve trip point as

an alarm condi# on. For example; Trip Type 3 would be designated as 13, and

would ini# ate a website alarm whenever the trip is ac# ve (on).

Placing a “2” in front of any of the Trip Types designates an inac# ve trip point as

an alarm condi# on. For Example; Trip Type 3 would be designated as 23, and

would ini# ate a website alarm whenever the trip is inac# ve (off ).

Page 34

MNU Series Ultrasonic Sensors Rev. B1, 5/13

34

Automa! on Products Group, Inc.

APG...Providing tailored solu• ons for measurement applica• ons

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

Type 6: n/a

Type 7 (Loss of Echo): the relay will ac! vate if the sensor enters a loss of echo condi! on (no targets detected).

Type 8 n/a

Type 9 (Rate of Change): allows the user to defi ne a maximum rate of change (distance over ! me), which if

exceeded will ac! vate an alarm. The Trip Distance parameter is used to defi ne the ! me value, and the Trip

Window parameter is used to defi ne the distance value.

Trip

Distance

Trip

Window

Empty

Distance

Zero Reference

Point

ON

ON

Trip Type 1

;ĞdžĐůƵƐŝǀĞͿ

OFF

(Increasing)

ON

Trip Type 2

(hysteresis near)

OFF

OFF

(Decreasing)

ON

OFF

ON

Trip Type 4

;ŝŶĐůƵƐŝǀĞͿ

OFF

OFF

(Decreasing)

ON

OFF

(Increasing)

Trip Type 5

(hysteresis far)

ON

ONOFF

Trip Type 3

(far)

ON OFF

Trip Type 0

(near)

Page 35

Rev. B1, 5/13 MNU Series Ultrasonic Sensors

35

Automa! on Products Group, Inc.

APG...Providing tailored solu• ons for measurement applica• ons

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

• Inspec! on and Maintenance

The MNU series sensor requires li! le maintenance, but should be inspec" on

periodically to ensure the sensor remains in good working order. Keep the

sensor clean from heavy buildup on the sensing face. On models equipped

with a micro-connector cable connec" on, ensure that the connec" on is

securely " ghtened and sealed against the elements.

Page 36

MNU Series Ultrasonic Sensors Rev. B1, 5/13

36

Automa! on Products Group, Inc.

APG...Providing tailored solu• ons for measurement applica• ons

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

• Specifi ca! ons

Opera! ng Range

MNU-5400: 4 to 72 in. (101 to 1829 mm)

MNU-7400: 6 to 144 in. (150 to 3658 mm)

MNU-6400: 10 to 180 in. (178 to 4572 mm)

MNU-2400: 1 to 25 ! . (305 to 7620 mm)

MNU-3400: 1.5 to 40 ! . (458 to 12192 mm)

Opera! ng Voltage: 12-24 Vdc

Opera! onal Current Draw: 35 mA @ 12 Vdc; 20 mA @ 24 Vdc

Housing: PBT/Polycarbonate blend

Moun! ng

MNU-2424, 5424, 6424, 7424: 2 in. NPT

MNU-3434: 3 in. NPT

Transducer Type

MNU-2424, 5424, 6424, 7424: PVDF faced ceramic

MNU-3434: PBT/Polycarbonate faced ceramic

Environmental Ra! ng: NEMA 6P

Sample Rate: 1 to 50 Hz (programmable)

Response Time: Programmable (50 ms minimum)

Resolu! on: 0.1 in. (2.5 mm)

Accuracy: +/- 0.25% of detected range (with no temperature gradient)

Sensor Adjustments: Modbus RTU (RS-485).

Opera! ng Temperature: -30 to 140

0

F (-34 to 60 0C)

Beam Pa# ern: 90 off -axis (maximum)

Electrical Connec! on: 4-conductor twisted-pair cable or 4-pin micro-connector

Frequency

MNU-5424: 170 kHz

MNU-7424: 90 kHz

MNU-6424 & 2424: 69 kHz

MNU-3434: 43 kHz

Page 37

Rev. B1, 5/13 MNU Series Ultrasonic Sensors

37

Automa! on Products Group, Inc.

APG...Providing tailored solu• ons for measurement applica• ons

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

3.06”

4.5”

3/4” NPT

1” NPT

3.06”

2.0”

4.0”

3/4” NPT

1” NPT

MNU-5414

MNU-5414-M

Page 38

MNU Series Ultrasonic Sensors Rev. B1, 5/13

38

Automa! on Products Group, Inc.

APG...Providing tailored solu• ons for measurement applica• ons

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

• Dimensions

MNU-2424, 5424, 6424, 7424

3.06”

4.15”

3/4” NPT

2” NPT

3.06”

2.0”

3.6”

3/4” NPT

2” NPT

MNU-2424-M, 5424-M,

6424-M, 7424-M

Page 39

Rev. B1, 5/13 MNU Series Ultrasonic Sensors

39

Automa! on Products Group, Inc.

APG...Providing tailored solu• ons for measurement applica• ons

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

MNU-3434

3/4” NPT

3” NPT

6”

4.17”

2.0”

3/4” NPT

5.52”

4.17”

3” NPT

MNU-3434-M

Page 40

AUTOMATION

APG...Providing tailored solu• ons

for measurement applica• ons

P R O D U C T S

GROUP, INC.

Automa• on Products Group, Inc.

Tel: 1/888/525-7300

1/435/753-7300

Fax: 1/435/753-7490

e-mail: sales@apgsensors.com

www.apgsensors.com

Automa• on Products Group, Inc.

1025 W. 1700 N.

Logan, UT 84321

Loading...

Loading...