Page 1

AUT OMATION

Operator’s Manual

PRODUCTS

GROUP, INC.

MND

Modbus Network Display

DOC. 9003708

Rev. A1, 5/14

Automation Products Group, Inc.

APG...Providing tailored solutions for measurement applications

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • E-mail: sales@apgsensors.com

Page 2

MND Rev . A1, 5/14

Table of Contents

Warranty...............................................................................................................3

Display Wiring ...................................................................................................4-5

Using the MND .....................................................................................................6

Access Modes ....................................................................................................... 7

Menu Flow Chart ..................................................................................................8

Units of Measure ..................................................................................................9

Enter Bu on Func on ..........................................................................................9

Advanced Se ngs .........................................................................................10-11

Auto-Off ..........................................................................................................11

Decimal Place ..................................................................................................11

Digit Mask .......................................................................................................11

Digit Shi ........................................................................................................11

Mul plier ........................................................................................................11

Bar Graph ........................................................................................................11

Overload .........................................................................................................11

Ba ery Indicator ............................................................................................. 11

Outputs .........................................................................................................12-15

Analog Se ngs ............................................................................................... 12

Solid State Relay Se ngs ...........................................................................12-15

Switched Source Power ..................................................................................16

Communica ons Se ngs ..............................................................................17-19

Sensor Labels ......................................................................................................20

Percent Full Mode ..............................................................................................20

Back Light ...........................................................................................................20

Analog Input Setup .............................................................................................21

Using the APG Modbus So ware ..................................................................22-25

Communica ons Setup Examples ......................................................................26

Rese ng to Factory Defaults .............................................................................27

Specifi ca ons ......................................................................................................28

Sensor Register Lists ......................................................................................29-30

Automation Products Group, Inc.

APG...Providing tailored solutions for measurement applications

2

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

Page 3

Rev . A1, 5/14 MND

• Warranty and Warranty Restric ons

APG warrants its products to be free from defects of material and workmanship

and will, without charge, replace or repair any equipment found defec ve

upon inspec on at its factory, provided the equipment has been returned,

transporta on prepaid, within 24 months from date of shipment from factory.

THE FOREGOING WARRANTY IS IN LIEU OF AND EXCLUDES ALL OTHER

WARRANTIES NOT EXPRESSLY SET FORTH HEREIN, WHETHER EXPRESSED OR

IMPLIED BY OPERATION OF LAW OR OTHERWISE INCLUDING BUT NOT LIMITED

TO ANY IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A

PARTICULAR PURPOSE.

No representa on or warranty, express or implied, made by any sales

representa ve, distributor, or other agent or representa ve of APG which is

not specifi cally set forth herein shall be binding upon APG. APG shall not be

liable for any incidental or consequen al damages, losses or expenses directly

or indirectly arising from the sale, handling, improper applica on or use of the

goods or from any other cause rela ng thereto and APG’s liability hereunder, in

any case, is expressly limited to the repair or replacement (at APG’s op on) of

goods.

Warranty is specifi cally at the factory. Any on site service will be provided at

the sole expense of the Purchaser at standard fi eld service rates.

All associated equipment must be protected by properly rated electronic/

electrical protec on devices. APG shall not be liable for any damage due

to improper engineering or installa on by the purchaser or third par es.

Proper installa on, opera on and maintenance of the product becomes the

responsibility of the user upon receipt of the product.

Returns and allowances must be authorized by APG in advance. APG will

assign a Return Material Authoriza on (RMA) number which must appear

on all related papers and the outside of the shipping carton. All returns are

subject to the fi nal review by APG. Returns are subject to restocking charges as

determined by APG’s “Credit Return Policy”.

Automation Products Group, Inc.

APG...Providing tailored solutions for measurement applications

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

3

Page 4

MND Rev . A1, 5/14

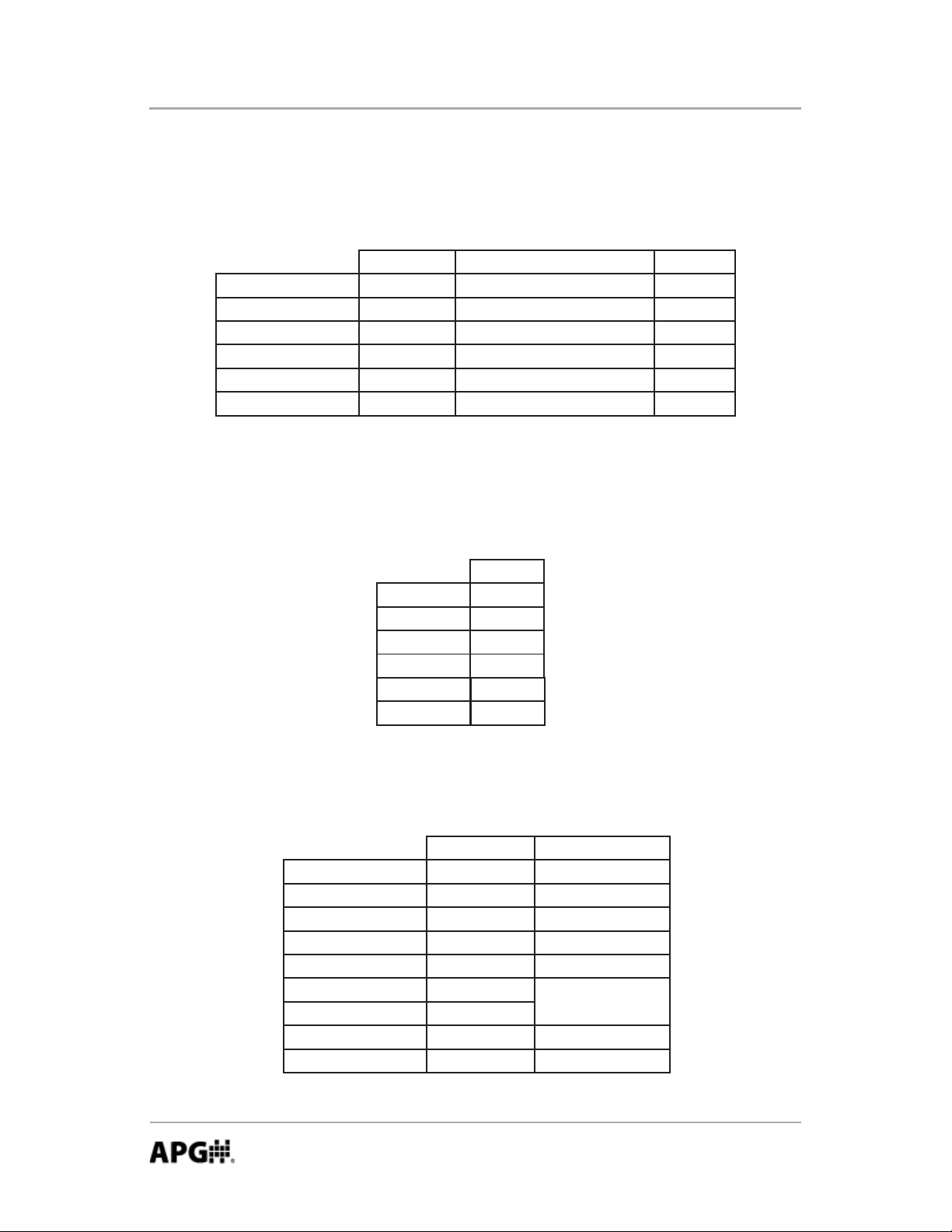

Display Wiring

4 Conductor Cable

V+

V- (com)

RS-485 A

RS-485 B

‡

Switched Source

No Outputs

*Red

*Black

White

Green

Switched Voltage Source

Black

White

Green

Red

4-20 mA

*no connection on internal battery powered option

‡

refer to Switched Power Source description on page 16 for more information

5 Conductor Cable

0-5 Vdc

V+

V- (com)

RS-485 A

RS-485 B

0-5 Vdc

4-20 mA

Red

Black

White

Green

Orange

4-20 mA

Red

White

Green

Black

8 Conductor Cable

(2) SS Relays

V+

V- (com)

RS-485 A

RS-485 B

SS Relay 1

SS Relay 1

SS Relay 2

SS Relay 2

Red

Black

White

Green

Yellow

Orange

Blue

Brown

0-5 Vdc

Automation Products Group, Inc.

APG...Providing tailored solutions for measurement applications

4

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

0-5 Vdc + (2) SS

Red

Black

White

Green

Yellow

Blue

(shared common)

Brown

Orange

Page 5

Rev . A1, 5/14 MND

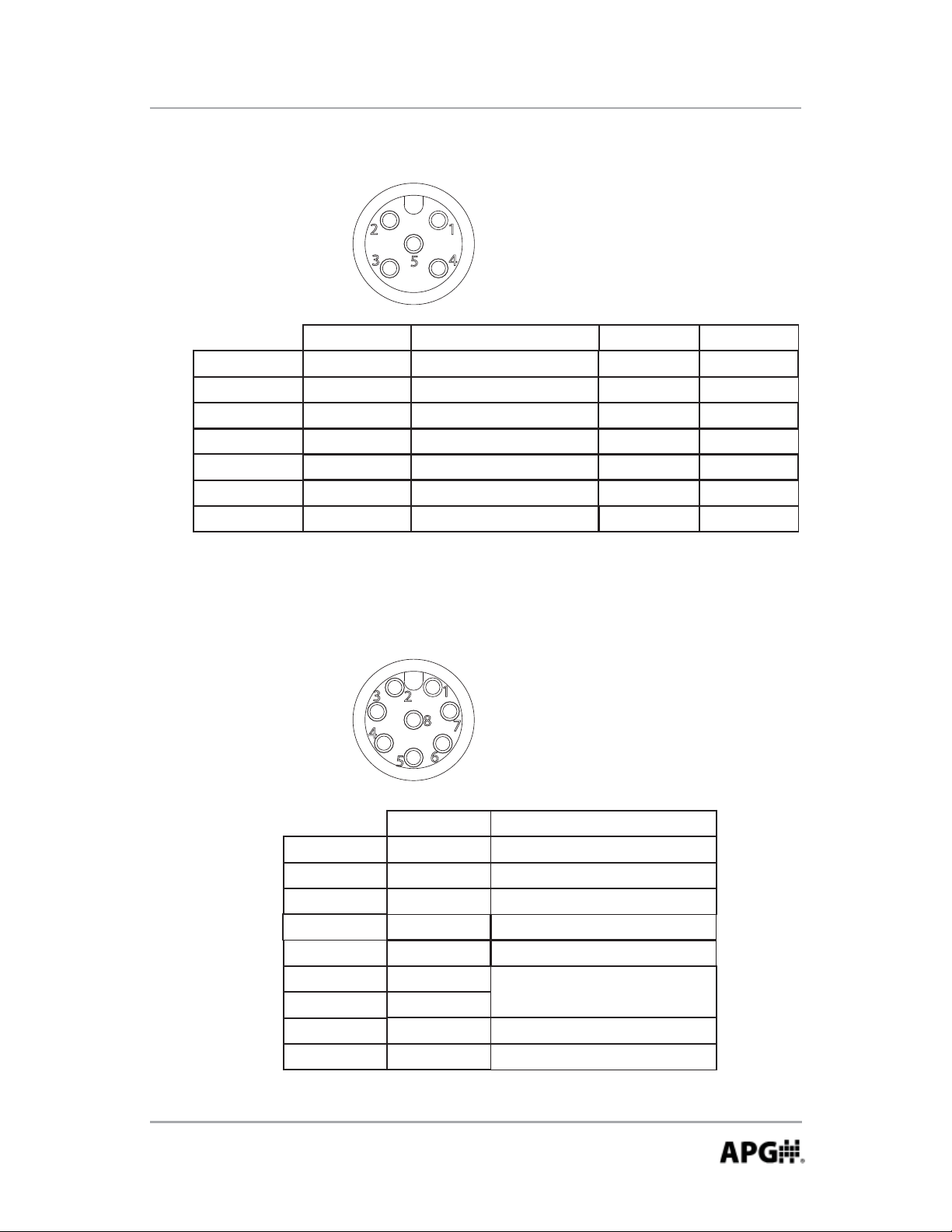

5 Pin Micro-Connector

1 = Brown

12

2 = White

3 = Blue

4

4 = Black

5 = Grey

Pin 1 (brown)

Pin 1 (brown)

Pin 3 (blue)

Pin 1 (brown)

Pin 3 (blue)Pin 3 (blue)

Pin 5 (grey)

V+

V- (com)

RS-845 A

RS-485 B

Switch Source

0-5 Vdc

4-20 mA

3

5

‡

No Outputs

Switched Power Source 4-20 mA 0-5 Vdc

*Pin 1 (brown)

*Pin 3 (blue)

Pin 2 (white) Pin 2 (white) Pin 2 (white)Pin 2 (white)

Pin 4 (black) Pin 4 (black) Pin 4 (black)Pin 4 (black)

*

no connection for internal battery powered option

‡

refer to page X for more information

8 Pin Micro-Connector

1

2

8

6

5

Pin 7 (blue)

Pin 5 (grey)

Pin 6 (pink)

Pin 8 (red)

V+

V- (com)

RS-485 A

RS-485 B

SS Relay 1

SS Relay 1

SS Relay 2

SS Relay 2

0-5 V

3

4

(2) SS Relays

Pin 2 (brown)

Pin 1 (white)

Pin 3 (green)

Pin 4 (yellow)

Pin 1 = White

Pin 2 = Brown

Pin 3 = Green

Pin 4 = Yellow

7

Pin 5 = Grey

Pin 6 = Pink

Pin 7 = Blue

Pin 8 = Red

0-5 Vdc + 2 Solid State Relays

Pin 2 (brown)

Pin 7 (blue)

Pin 1 (white)

Pin 3 (green)

Pin 4 (yellow)

Pin 5 (grey)

shared common

Pin 6 (pink)

Pin 8 (red)

Automation Products Group, Inc.

APG...Providing tailored solutions for measurement applications

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

5

Page 6

MND Rev . A1, 5/14

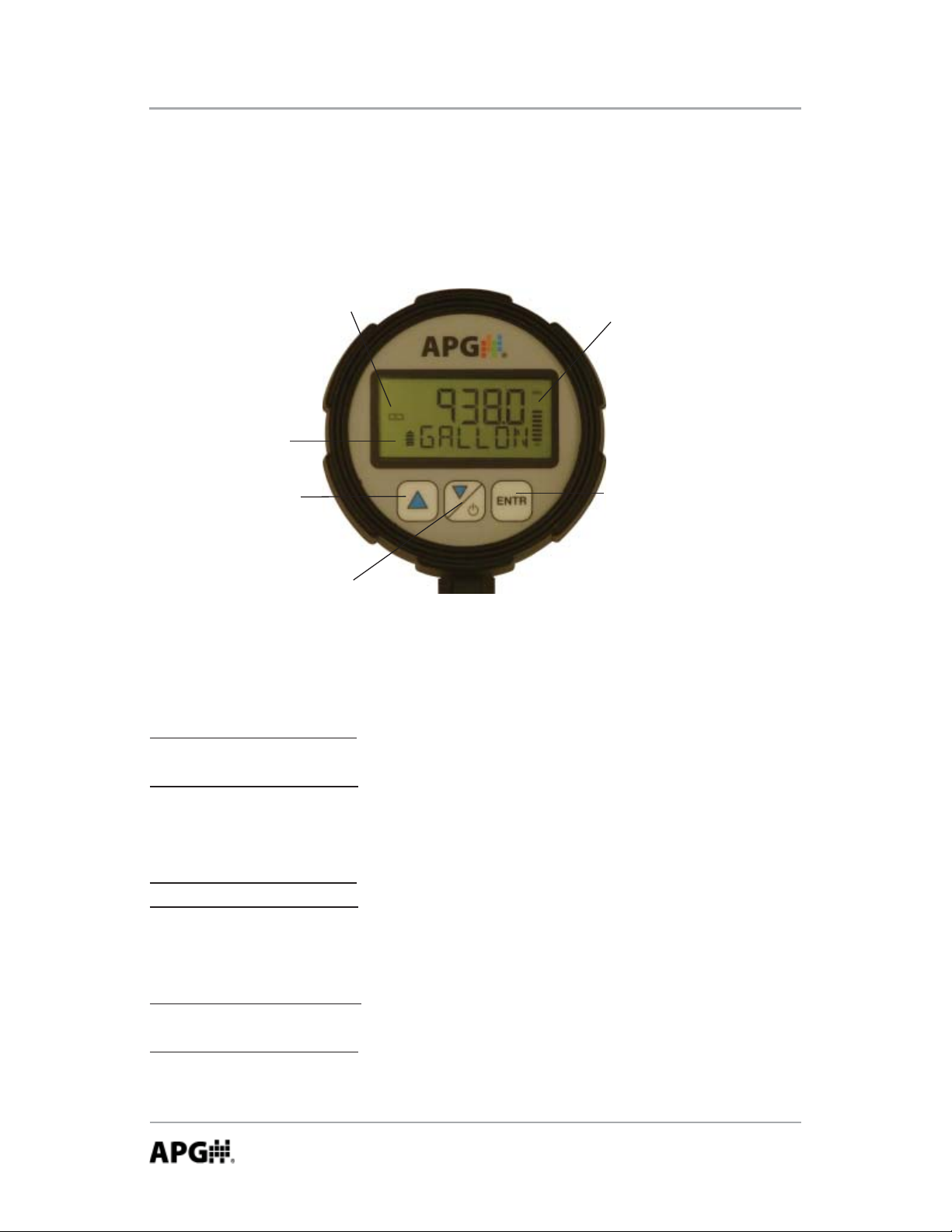

Using the MND

Output Status Indicator

Scalable Bar Graph

Ba ery Meter

Increase Bu on

Enter Bu on

Decrease/Power Bu on

Increase Bu on

Func on in Opera ng Mode: cycles through sensor readings when setup to display

mul ple sensors readings.

Func on within Setup Menu: press to cycle upward through menu op ons or to increase

mode se ng values.

Decrease/Power Bu on

Func on in Opera ng Mode: press and hold for 1 second to power on or off the MND.

Func on within Setup Menu: press to cycle downward through menu op ons or

decrease mode se ng values.

Enter Bu on

Func on in Opera ng Mode: cycles between the current, maximum, and minimum

readings.

Func on within Setup Menu: press to enter into the selected menu or to accept a se ng

op on within a menu.

Automation Products Group, Inc.

APG...Providing tailored solutions for measurement applications

6

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

Page 7

Rev . A1, 5/14 MND

*Access Modes

The MND has several opera ng modes which will limit or lock access to the setup

menus. Refer to the mode descrip ons at the bo om of the page for more informa on.

To access the opera ng mode se ng, follow the steps below.

Step 1: Simultaneously press and hold the Decrease bu on and the Enter bu on for

approximately 5 seconds to bring up the *3 digit mode access number.

Step 2: Use the Increase/Decrease bu ons to change the value of he fl ashing digit,

and Enter bu on to accept the value and advance to the next digit. The mode

op ons are as follows:

Mode Descrip on

000 Full Access. All menu op ons are accessible, including those that

may not be applicable to all MND confi gura ons.

001 Locks access to all setup menus. The Increase Bu on will scroll

through sensor readings when the MND is confi gured for mul ple

sensors. The Decrease/Power Bu on will turn on/off the display.

The Enter bu on will scroll between the maximum, minimum and

the current reading.

002 Hides the Output menu. All other setup menus are accessible.

003 Hides the analog op ons in the Output menu--only the relay op ons

are accessible.

004 Hides the relay op ons in the Output menu--only the analog op ons

are accessible.

005 All menus are hidden and all bu ons are lock, except the Decrease/

Power bu on, which will power on/off the MND.

*Also see “

Se ng Mode Access Password” under Sensor Label sec on of page 20.

Automation Products Group, Inc.

APG...Providing tailored solutions for measurement applications

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

7

Page 8

MND Rev . A1, 5/14

Menu Flow Chart

Main Menu

AL SET

AH SET

AL CAL

AH CAL

T1TYPE

T1REAd

T1 WIN

T2TYPE

T2REAd

T2 WIN

EXIT

COMM

OUTPUT

bAUd R

PARITY

STOPbT

C TYPE

SENAdR

NUMSEN

REGNUM

FUNCTN

REGTYP

SCANRT

WRITE

AdRCHG

EXIT

dEC PL

MASK

SHIFT

MLTPLR

bAR 0

bAR100

OVR-Ld

bAT EN

bATFUL

bATLOW

EXIT

MAXMIN

TEMP C

TEMP F

2 REAd

2Rd 1C

2Rd 1F

CU FT

MCU FT

GALLON

CU M

LITERS

CU IN

bARREL

PCTFUL

CUSTOM

AdVSETAUTO

Main Menu

ENTR

UNITS

DISPLAYED VALUE

54321

GALLON

SENLAb

Main Menu

PCTFUL

bLIGHT

SEN 1

SEN 2

SEN 3

SEN 4

SEN 5

SEN 6

SEN 7

SEN 8

SEN 9

SEN 10

LOERST

EXIT

SEN 1

SEN 2

SEN 3

SEN 4

SEN 5

SEN 6

SEN 7

SEN 8

SEN 9

SEN 10

LOERST

EXIT

MOdE

bRTNES

EXIT

EXIT

INPUT

Main Menu

SAM RT

AVERGE

EXIT

Automation Products Group, Inc.

APG...Providing tailored solutions for measurement applications

8

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

Page 9

Rev . A1, 5/14 MND

• UNITS (Units of Measure Label)

Allows the user to select the unit of measure label that will appear on the lower display

line.

Op ons:

CU FT (Cubic Feet) LITERS (Liters)

MCU FT (Million Cubic Feet) CU IN (Cubic Inches)

GALLON (Gallons) bARREL (Barrels)

CU M (Cubic Meters) PCTFUL (Percent Full)

CUSTOM (Custom Units)

NOTE: the units of measure selected will be applied to all sensor readings and cannot

be set individually for each sensors.

NOTE: the units label will automa cally display PCTFUL (percent full) for any reading

being displayed in Percent Full mode (see page 21 for more informa on).

• ENTR (Enter Bu on Func on)

Selects the func on of the ENTER bu on when in standard opera ng mode.

Enter Bu on Func on:

0

*2RD1F cycles between 2 readings & temperature in

*2RD 1C cycles between 2 readings & temperature in

*2 REAd cycles between 2 readings.

TEMP F cycles between the reading and the temperature in

TEMP C cycles between the reading and the temperature in

MAXMIN cycles between the present reading and the highest and

lowest readings.

F.

0

C.

0

F.

0

C.

*2nd reading is applicable to MP dual-fl oat sensors only.

Automation Products Group, Inc.

APG...Providing tailored solutions for measurement applications

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

9

Page 10

MND Rev . A1, 5/14

• AdVSET (Advanced Se ngs)

AUTO (Auto Off ): The Auto-Off feature will automa cally power off the MND whenever

no bu ons are pressed within the specifi ed me frame. The minimum Auto-Off me is

15 seconds. To disable the Auto-Off feature, set the value to 65535 (default).

NOTE: the Auto-Off cannot be set to less than the relay “On Time” se ng when using

the Timed Relay op on (see Outputs).

dEC PL (Decimal Place): defi nes where the decimal point will be displayed within the

reading.

NOTE: most APG sensors have the ability to set the number of decimal places of the

readings being sent to the MND. Refer to the sensor manual for more informa on.

MASK (Digit Mask): allows the user to mask the value of the least signifi cant digit(s), up

to 3 places, so that masked digit(s) will always display 0 and will not increment.

SHIFT (Digit Shi ): allows the user to shi the reading to the right by dividing the

reading by 10, 100, or 1000.

MLTPLR (Mul plier): allows the user to apply a conversion mul plier to the sensor

readings. For example, a mul plier se ng of 2.0 will double the reading received from

the sensor.

NOTE: most APG sensors have the capability to apply a conversion mul plier to the

reading before the value it is sent to the MND.

bAR 0 (Bar Graph 0%) & bAR100 (Bar Graph 100%): defi ne the readings associated

with 0% and 100% on the display bar graph. Bars will appear/disappear in 10%

increments of the total span.

NOTE: the bar graph limits will be applied to all sensor readings when mul ple sensor

are being displayed, and cannot be set individually for each sensor.

(Advance Se ngs con nued on next page)

10

Automation Products Group, Inc.

APG...Providing tailored solutions for measurement applications

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

Page 11

Rev . A1, 5/14 MND

OVR-Ld (Overload): allows the user to set an overload warning if the reading increases

beyond the specifi ed value.

NOTE: when displaying the readings from mul ple sensors, the Overload se ng

will be applied to the readings of all the sensors and cannot be set for each sensor

individually. By default the Overload is set to 99999 so that the overload warning will

only be displayed when a sensor reading is greater than 5-digit limit of the display.

bAT EN (Ba ery Enabled): allows the user to select either No Ba ery, Internal Ba ery

or RST Ba ery op ons. The Internal Ba ery op on is used to monitor the voltage of a

ba ery powered MND. The RST Ba ery op on is used to monitor the supply voltage of

an RST-5000 module ac ng as the master device.

NOTE: the Internal ba ery indicator is limited to ba ery voltages less than 15 Vdc.

bATFUL (Ba ery Full Voltage): sets the voltage associated with a full ba ery indica on.

bATLOW (Ba ery Low Voltage): sets the voltage associated with a low ba ery

indica on.

Automation Products Group, Inc.

APG...Providing tailored solutions for measurement applications

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

11

Page 12

MND Rev . A1, 5/14

• OUTPUT (Outputs)

The MND is off ered with op onal outputs, such as solid-state relays, or 4-20 mA

or 0-5 Vdc analog signals. Not all output menu op ons are applicable to all MND

confi gura ons.

NOTE: when displaying the readings from mul ple sensors, the Sensor Address se ng

determines which sensor is controlling the output(s) of the MND.

AL SET (Analog Low Set-point): sets the reading associated with the low analog value

(either 4mA or 0V). Used for analog output or analog input.

AH SET (Analog High Set-point): sets the reading associated with the high analog value

(either 20mA or 5V). Used for analog output or analog input.

AL CAL (Analog Low Calibra on): adjusts the low end of the analog output (either 4mA

or 0V). Increasing/decreasing the value will cause an increase/decrease at the low end

of the analog output.

AH CAL (Analog High Calibra on): adjusts the high end of the analog output (i.e. either

20mA or 5V). Increasing/decreasing the value will cause an increase/decrease at the

high end of the analog output.

T1TYPE & T2TYPE (Trip 1&2 Type): determines the basic func onal logic of the solid-

state relay outputs as described in the Trip Type descrip ons on pages 14-16.

NOTE: the MND’s solid-state relays are rated for a maximum switched load of 120 mA.

T1REAd & T2REAd (Trip 1&2 Reading): defi nes the display reading that corresponds

to a change in the state of the associated relay output, as determined by the Trip Type

selected.

T1 WIN & T2 WIN (Trip 1&2 Window): defi nes the secondary value (beginning from

the Trip Reading) for Exclusive, Inclusive, and Hysteresis Near & Far Trip Types (refer to

descrip ons below). For example: if the Trip Reading is set to 250, and the secondary

trip value is desired at a reading of 350, then the Trip Window should be set to 100.

(250 + 100 = 350)

12

Automation Products Group, Inc.

APG...Providing tailored solutions for measurement applications

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

Page 13

Rev . A1, 5/14 MND

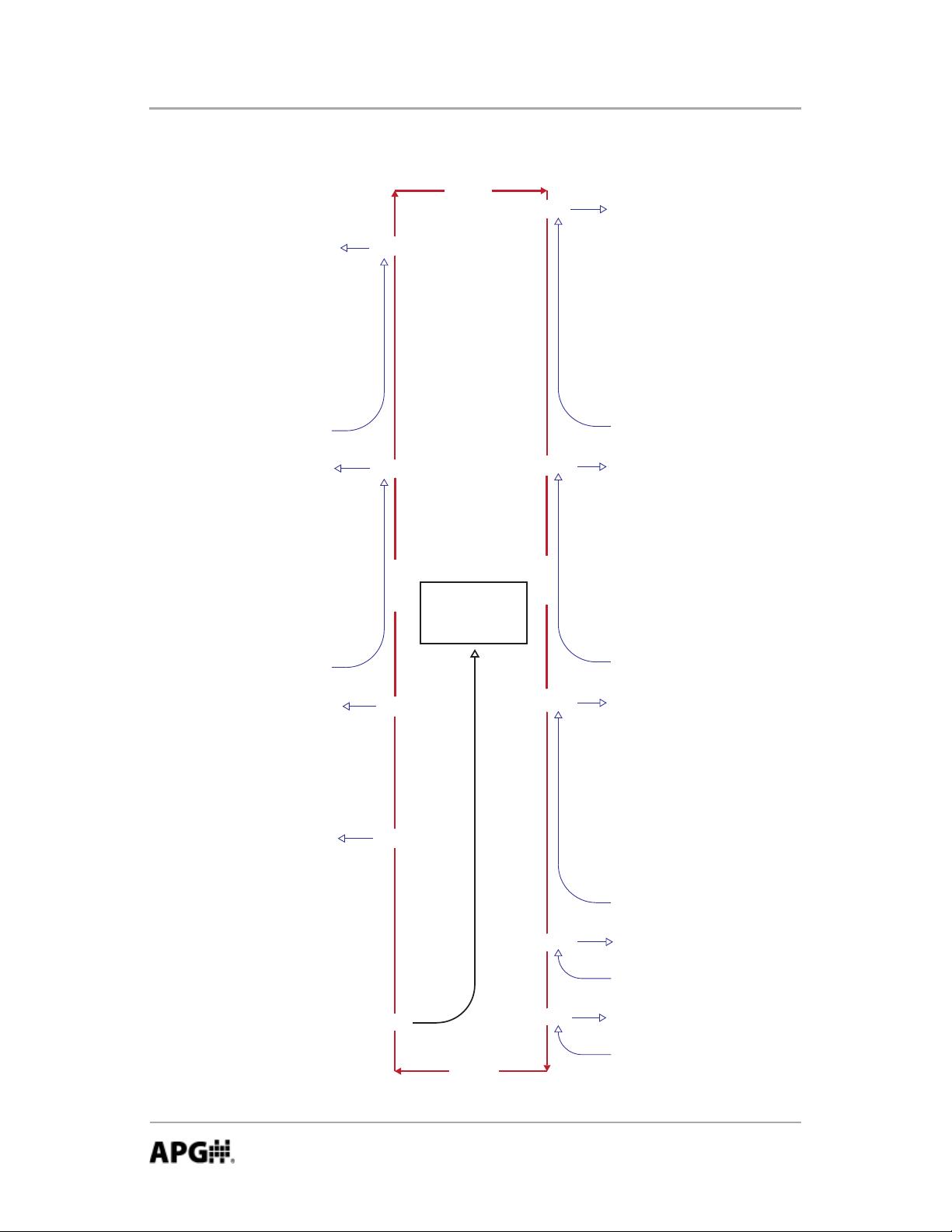

Trip Type Descrip ons

Refer to the chart on the next page for an illustra on of Near, Far, Exclusive, Inclusive

and Hysteresis Near & Far trip types.

NEAR:

The output will ac vate whenever the reading is less than the Trip Reading se ng (refer

to chart on next page).

EXCLSV (Exclusive):

The output will ac vate whenever the reading is less than the Trip Reading OR greater

than the Trip Reading + Trip Window (refer to chart on next page).

H NEAR (Hysteresis Near):

The output will ac vate un l the reading is greater than the Trip Reading + Trip Window,

at which point the output will deac vate and remain in that state un l the reading is less

than the Trip Reading (refer to chart on next page).

FAR :

The output will ac vate whenever the reading is greater than the Trip Reading (refer to

chart on next page).

INCLSV (Inclusive):

The output will ac vate whenever the reading is greater than the Trip Reading and less

than the Trip Reading + Trip Window (refer to chart on next page).

H FAR (Hysteresis Far):

The output will ac vate when the reading increases beyond the Trip Reading + Trip

Window, and will remain ac ve un l the reading falls below the Trip Reading. The

output will remain deac vated un l the reading is once again greater than the Trip

Reading + Trip Window (refer to chart on next page).

ON:

Holds the output closed whenever the display is powered.

OFF:

Disables the output.

(con nued on pages 15-16)

Automation Products Group, Inc.

APG...Providing tailored solutions for measurement applications

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

13

Page 14

MND Rev . A1, 5/14

Trip Type Descrip ons (con nued)

ZERO READING

TRIP READING

TRIP WINDOW

NEAR

EXCLUSIVE

HYSTERESIS NEAR

FAR

ON

(closed)

ON

(closed)

ON

(closed)

OFF

(open)

OFF

(open)

OFF

(open)

ON

(closed)

OFF

(open)

ON

(closed)

ON

(closed)

OFF

(open)

14

INCLUSIVE

HYSTERESIS FAR

APG...Providing tailored solutions for measurement applications

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

OFF

(open)

OFF

(open)

Automation Products Group, Inc.

ON

(closed)

OFF

(open)

ON

(closed)

OFF

(open)

ON

(closed)

Page 15

Rev . A1, 5/14 MND

Trip Type Descrip ons (con nued)

LOERST

(LOE/RST):

forces the output to follow the state of the corresponding output of an LOE or RST

sensor ac ng as the master device. For example, whenever output T1 of the LOE/RST

ac vates/deac vates, then output T1 of the MND will ac vate/deac vate as well.

TIME R (Timed Interval):

sets the output to ac vate on a med interval. The Interval-Time (

me between ac va ons (in minutes), and the On-Time (

ON SEC) determines how

long the output remains ac ve at each interval (in seconds).

NOTE: when using the Timed Interval in conjunc on with the Auto-Off feature, the

MND will wake (power on) at each Interval and will remain powered on for the

dura on of the relay On-Time regardless of the Auto-Off se ng.

INTERVAL TIME

(in minutes)

“ON” TIME

(in seconds)

Relay “OFF”(open)

INTMIN) sets the

Relay “ON” (closed)

*H TEMP (Heater Temperature):

The LCD heater is controlled using Trip Relay 1. Set the heater “on” temperature

using the Trip 1 Reading (

T1READ) parameter (in

0

C). The Trip 1 Window (T1 WIN)

parameter is used to set the “off ” temperature, defi ned by the number of degrees above

the on temperature.

For Example: to ac vate the heater at -30

0

C and deac vate the heater above -10 0C

T1TYPE set to H TEMP

T1READ set to -0030

T1 WIN set to 00020

*Op onal Feature

Automation Products Group, Inc.

APG...Providing tailored solutions for measurement applications

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

15

Page 16

MND Rev . A1, 5/14

Switched Power Source

This op on is designed to allow an internal ba ery powered MND to share the ba ery

power with one of APG’s Modbus sensors (MNU, MP, or MPT series) to create a simple

yet complete monitoring system. Whenever relay 1 (T1) is ac ve, the ba ery voltage

will be applied to the switched power source output (which should be connected to the

voltage input of the sensor). By se ng relay 1 to “On” and then se ng up a short Auto-

Off mer (refer to Advanced se ngs), the user can simply push the power bu on on

the MND to wake the system and poll the sensor to get the reading. The Auto-Off will

automa cally power down the system to save ba ery life. APG recommends an Auto-

Off se ng of 15-20 second in order to maximize ba ery life.

WARNING! the switched power output sources voltage directly from the ba ery, and

cau on must be taken not to let the output come in contact with any of the other

output lines (DC common or the communica on lines).

16

Automation Products Group, Inc.

APG...Providing tailored solutions for measurement applications

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

Page 17

Rev . A1, 5/14 MND

• COMM (Communica ons)

bAUd R (Baud Rate): 2400, 9600, 19200, 38400

PARITY: even, odd, none

STOPbT (Stop Bit): 1, 2

NOTE: all APG Modbus based sensors communicate using 9600 baud, no parity and 1

stop bit.

C TYPE (Communica ons Type):

MASTER: sets the MND to operate as the master device.

SNIFER (Sniff er): sets the MND to passively monitor communica ons between a

master device and one or more sensors. The master device must be ac vely polling

the sensor(s) in order for the MND to update the reading(s).

LRSNIF (LOE/RST Sniff er): func ons the same as Sniff er mode with addi on of

monitoring the readings from an LOE series or RST-5000 series Ethernet based sensor

(ac ng as the master device).

SETUP: sets the MND to act operate as a “slave” device in order to be programmed

using the APG Modbus so ware.

NOTE: the Sensor Address parameter (see below) is used to set the MND’s own

sensor address when in opera ng in Setup mode.

*AINPUT: displayed reading is based on the analog input signal and related se ngs

(*Op onal feature. Refer to INPUT menu sec on for more informa on).

SENAdR (Sensor Address): sets the address number of the sensor to be displayed when

only one sensor is being monitored. The Sensor Address is also used to set the MND’s

own address when opera ng in Setup mode.

NOTE: in order to monitor readings from mul ple sensors, the assigned sensor

address numbers must begin at 1 and increment sequen ally. For example, if 5

sensors are to be monitored, the sensor addresses must be set to 1 thru 5.

NOTE: when displaying the readings from mul ple sensors, the Sensor Address se ng

determines which sensor is controlling the output(s) of the MND.

Automation Products Group, Inc.

APG...Providing tailored solutions for measurement applications

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

17

Page 18

MND Rev . A1, 5/14

NUMSEN (Number of Sensors): sets the number of sensors to be monitored. When

using the MND to display readings from mul ple sensors, the sensor addresses must

begin at 1 and increment sequen ally (see note above).

REGNUM (Register Number): sets the register number to be displayed. The readings of

APG sensors are stored in register 30303.

NOTE: the register number is entered using only the last 3 digits of the full register

number. For example, register 30303 would be entered as 303, or register 40401

would be entered as 401.

FUNCTN (Func on): sets the func on code for the register to be displayed; 3 = holding

resister, 4 = input register. Sensor readings are stored in input registers, while sensor

parameter values are stored in holding registers.

REGTYP (Register Type): sets the bit type of the register to be displayed. Op ons are:

signed, 8 bit, low byte (S8L) signed, 16 bit (S16)

signed, 8 bit, high byte (S8H) unsigned, 16 bit (U16)

unsigned, 8 bit, low byte (U8L) signed, 32 bit (S32)

unsigned, 8 bit, high byte (U8H) unsigned, 32 bit (U32)

NOTE: the readings of APG’s sensors are stored as an unsigned 32-bit value. Refer

to the sensor’s user manual for a list of register numbers and their corresponding

register types.

SCANRT (Scan Rate): determines how o en the MND polls the sensor(s) (in seconds)

when opera ng in Master mode.

18

Automation Products Group, Inc.

APG...Providing tailored solutions for measurement applications

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

Page 19

Rev . A1, 5/14 MND

WRITE: allows the MND, opera ng in Master mode, to write a value to a specifi c

holding register of a specifi c sensor. When Write is selected, the MND will guide you

through the following steps:

Sensor Address: set the address number of the target sensor.

Register Number: set the register number you wish to change.

Register Type: set the type of register being wri en (16-bit or 32-bit).

Register Value: set the value you want to write to the selected register.

Write Yes/No: select Yes to write the new register value and complete the

procedure, or No to cancel the write, and return to the Communica ons menu.

Write func on example: changing the Empty Distance value (register 40407) to 2150

in sensor address number 5.

Sensor Address: 05

Register Number: 407

Register Type: U16 (unsigned 16-bit).

Register Value: 02150

Write Yes/No: select Yes by pressing Enter.

AdRCHG (Address Change): allows the user to quickly change a sensor’s address when

the MND is opera ng as the Master device. Simply enter the current address of sensor

you wish to change (NOW), then enter the new address you wish to write to the sensor

(NEW).

Automation Products Group, Inc.

APG...Providing tailored solutions for measurement applications

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

19

Page 20

MND Rev . A1, 5/14

• SENLAb (Sensor Labels)

Allows the user to assign a custom label for each sensor being displayed (up to 10

sensors + an LOE/RST master). The sensor label will appear on the lower display line,

which will alternate between the Sensor Label and the selected Unit of measure.

NOTE: Se ng a Mode Access Password (refer to Access Modes on page 7).

If a label is assigned for Sensor 10, the label becomes the password to access the

Mode se ng. If the label for sensor 10 is set to the default of

password will be required to access the Mode se ng.

10AAAA, then no

• PCTFUL (Percent Full)

Allows sensor readings to be displayed as a percentage of full based on a user defi ned

100% value.

To enable the Percent Full feature, select

number you want to display as a percentage of full, and enter the value associated with

100%. 0% (empty) is assumed to be 0. Se ng the value to 00000 (default) will disable

the Percent Full feature.

NOTE: the label

for all sensors running in Percent Full mode.

NOTE: when controlling one of the MND’s outputs with a sensor setup to display in

Percent Full mode, the se ngs controlling the output need to be entered based on

the underlying readings and not the displayed percentage value.

PCTFUL will be automa cally be displayed as the units of measure

PCTFUL in the main menu. Select the sensor

• *bLIGHT (Back Light) *Op onal Feature

The Mode op ons include: On, Off , 30 Sec, 1 min, 2 min, 4 min, 8min and 16 min. To

adjust the backlight intensity, select brightness (

down arrow bu ons to increase/decrease the brightness.

bRTNES) in the menu and use the up/

20

Automation Products Group, Inc.

APG...Providing tailored solutions for measurement applications

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

Page 21

Rev . A1, 5/14 MND

• *INPUT (Analog Input) *Op onal Feature

Used to adjust how the MND reads the analog input signal.

SAM RT: determines how o en the MND reads the analog input signal.

AVERGE: determines how many readings of the analog signal will be averaged together

to become the displayed reading. A higher average se ng will result in smoother

readings but will also cause slower response to rapid changes.

The following is a list of parameters required to read an analog input:

COMM menu:

Set C-TYPE to AINPUT.

OUTPUT menu:

Set AL SET to the value associated with a 4mA input signal.

Set AH SET to the value associated with a 20mA input signal.

*Adjust AL CAL and AH CAL as necessary.

INPUT menu:

*Adjust SAM RT as necessary.

*Adjust AVERAGE as necessary.

*parameters normally do not require adjustment.

Automation Products Group, Inc.

APG...Providing tailored solutions for measurement applications

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

21

Page 22

MND Rev . A1, 5/14

Programming the MND using APG Modbus So ware

The MND’s “Setup” communica ons type (see C-TYPE on page 17) allows the MND to be

programmed using so ware instead of the bu ons on the display. The so ware used

to program the MND is the same so ware used to program any of APG’s line of Modbus

sensors (MNU, MP, PT series). Interfacing with the so ware also allows the user to save

MND confi gura ons to a PC, or to write a previously saved confi gura on back to the

MND (see page 24).

Use the following steps to establish communica ons and program the MND via the APG

Modbus so ware:

Step 1: Use the bu ons on the MND to enter the Communica ons menu and change the

Communica ons Type (C-TYPE) to “SETUP”.

Step 2: While s ll in the MND Communica ons menu, take note of the Sensor Address

(SENAdR) se ng. This se ng will become the MND’s address when communica ng to

the so ware.

Step 3: Install and run the APG Modbus so ware.

Step 4: Click on “Confi gure” in the top menu,

then select “Communica on” to bring up the

Communica on Confi gura on window.

(con nued on next page)

22

Automation Products Group, Inc.

APG...Providing tailored solutions for measurement applications

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

Page 23

Rev . A1, 5/14 MND

Step 5: Check the USB Communica on

box when using an RST-6001 RS-485 to

USB converter.

or

Select the Com Port assigned to the

RS-485 to RS-232 converter being used.

Step 6: Ensure Sensor #

matches the Sensor Address

se ng in the MND.

Step 7: Select MND

Step 8: Once all the changes have been

made, click “Save Confi g” then click “Close”

Step 9: Click on “Sensor 1 “ to enter the

programming window for the MND.

Automation Products Group, Inc.

APG...Providing tailored solutions for measurement applications

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

(con nued on next page)

23

Page 24

MND Rev . A1, 5/14

Step 10: When the programming window opens, the register values should automa -

cally populate (if not, click the “Receive All” bu on at the bo om of the window). To

change a single parameter, simply click on the value you wish to change, enter the

desired value, then click the adjacent “Send” bu on to write the new value to the MND.

Step 11: To change mul ple parameters, individually click on the values

you wish to change, enter the desired values, then click the “Send All”

bu on at the bo om of the window to write all the values to the MND.

A er clicking “Send” or “Send All”,

a green window indicates good

communica on and the value was

successfully wri en to the MND.

APG...Providing tailored solutions for measurement applications

24

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

A yellow window indicates the value was

not wri en due to either a communica on

failure or the value exceeds the allowable

limits for that parameter.

Automation Products Group, Inc.

Page 25

Rev . A1, 5/14 MND

Saving a Se ngs Confi gura on

To save the current se ngs confi gura on, click on “File”, then select “Save Mode

Values”. Choose the fi le name and loca on where you wish to save the fi le, then click

“Save”

Recalling a Saved Se ngs Confi gura on

To upload a previously saved se ngs confi gura on to the MND, click on “File”, then se-

lect “Load Mode Values”. Choose a fi le you wish to upload, then click “Open”. This will

load the parameter values into the so ware. Click the “Send All” bu on at the bo om

of the window to write the parameters to the MND.

Automation Products Group, Inc.

APG...Providing tailored solutions for measurement applications

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

25

Page 26

MND Rev . A1, 5/14

Communica ons Setup Examples

For APG sensors, the sensor readings are stored in register 303, which is an unsigned

32-bit register.

MND master displaying readings from a single sensor (address 1):

C-Type = Master

Number of Sensors = 1

Sensor Address = 1

Register Number = 303

Func on = 4

Register Type = U32 (unsigned 32-bit)

MND master displaying mul ple sensor readings (addresses 1-6):

C-Type = Master

Number of Sensors = 6

Sensor Address = n/a (sensors addresses must begin at 1)

Register Number = 303

Func on = 4

Register Type = U32 (unsigned 32-bit)

MND in Sniff er mode displaying readings from a single sensor (address 3):

C-Type = Sniff er

Number of Sensors = 1

Sensor Address = 3

Register Number = 303

Func on = 4

Register Type = U32 (unsigned 32-bit)

MND displaying the readings from 2 sensors + an LOE ultrasonic:

C-Type = LOE/RST Sniff er (LRSNIF)

Number of Sensors = 2 (the LOE sensor is assumed and not included in the count)

Sensor Address = n/a (sensors addresses are assumed to begin at 1)

Register Number = 303

Func on = 4

Register Type = U32 (unsigned 32-bit)

26

Automation Products Group, Inc.

APG...Providing tailored solutions for measurement applications

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

Page 27

Rev . A1, 5/14 MND

Rese ng the MND to factory defaults

Simultaneously press and hold the Decrease/Power bu on and Enter bu on for

approximately 5 seconds. This will bring up the 3 digit opera ng mode number. Change

the mode number to 125 and press the enter bu on. This will reset all parameter values

to the following factory defaults:

Parameter Value

Units Gallons

Auto-Off 65535 (disabled)

Decimal Place 0

Digit Mask Off

Digit Shi 0

Mul plier 1.000

Bar Graph 0 0

Bar Graph 100 10000

Over Load 99999 (max display value)

Ba ery Gauge Enable No Ba ery

Ba ery Full 13.5 V

Ba ery Low 11.0 V

Analog Low Reading 0

Analog High Reading 99999

Analog Low Calibra on 0

Analog High Calibra on 16383

T1 Type Off

T1 Reading 1000

T1 Window 500

T2 Type Off

T2 Reading 1000

T2 Window 500

Baud Rate 9600

Parity None

Stop Bits 1

C-Type Master

Sensor Address 1

Number of Sensors 1

Register Number 303

Func on 4

Register Type U32 (unsigned 32-bit)

Scan Rate 000.5 seconds

Sensor Labels Sen 1 - Sen 11

Percent Full 00000 (disabled)

Automation Products Group, Inc.

APG...Providing tailored solutions for measurement applications

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

27

Page 28

MND Rev . A1, 5/14

Specifi cations

Environmental:

Housing: IP67

Storage Temp: -40 to 160

Operating Temp: 0 to 160

Electrical:

Batteries: 9 V Lithium or 3.6 V Lithium (no outputs)

External Power: 9-28 Vdc

Physical:

Case Material: injection molded material EMI-X PDX-W-88341

4-20 mA Output:

Input Voltage Requirements: 9 Vdc min (no load) to 28 Vdc max

Signal Variance: +/-0.16 mA at set points

Output/Input: 2-wire loop-powered

Resolution: 14 bit

Protection: reversed polarity

0

F (-40 to 710C)

0

F (-18 to 710C)

0-5 VDC Output:

Input Voltage Requirements: 9 to 28 VDC

Signal Variance: +/-0.05 VDC at set points

Type: non-isolated 3-wire

Resolution: 1 4 bit

Protection: reversed polarity

Trip Point Solid State Relay Outputs:

Maximum Switched Voltage: 120 V AC/DC

Maximum Switched Current: 120 mA

Automation Products Group, Inc.

APG...Providing tailored solutions for measurement applications

28

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

Page 29

Rev . A1, 5/14 MND

MNU Series Ultrasonic

Input Registers (0x04):

Register Type Returned Data

30300 U16 Raw Distance/Level Reading (in mm)

30302 S16 Temperature Reading (in

30303-30304 U32 Calculated Reading (in selected units, no decimal)

Holding Registers (0x03):

Register Type Descrip on Value Range

40400 U16 Device Address 1 to 255

40401 U16 Units 1 to 3

40402 U16 Applica on Type 0-10

40403 U16 Volume Units 0 to 6

40404 U16 Decimal Place 0 to 3

40405 U16 Max Distance 0 to 10364 mm

40406 U16 Full Distance 0 to 10364 mm

40407 U16 Empty Distance 0 to 10364 mm

40408 U16 Sensi vity 0 to 100

40409 U16 Pulses 0 to 20

40410 U16 Blanking 0 to 10364 mm

40411 U16 Gain Control 0 to 4

40412 U16 Averaging 0 to 100

40413 U16 Filter Window 0 to 10364 mm

40414 U16 Out of Range Samples 0 to 255

40415 U16 Sample Rate 50 to 1000 msec.

40416 U16 Mul plier 1 to 1999

40417 S16 Off set +/- 10364 mm

40418-40419 reserved

40420 U16 Temperature Compensa on 0 = off , 1 = on

40421-40435 reserved

40436-40437 U32 Parameter 1 Data 0 to 100000 mm

40438-40439 U32 Parameter 2 Data 0 to 100000 mm

40440-40441 U32 Parameter 3 Data 0 to 100000 mm

40442-40443 U32 Parameter 4 Data 0 to 100000 mm

40444-40445 U32 Parameter 5 Data 0 to 100000 mm

0

C, signed)

Automation Products Group, Inc.

APG...Providing tailored solutions for measurement applications

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

29

Page 30

MND Rev . A1, 5/14

MP Series Magnetostric ve

Input Registers (0x04):

Register Type Returned Data

30300 U16 Raw Top Float Reading (in mm, unsigned)

30301 U16 Raw Bo om Float Reading (in mm, unsigned)

30302 S16 Temperature Reading (in

30303-30304 U32 Calculated Top Float Reading (in selected Units)

30305-30306 U32 Calculated Bo om Float Reading (in selected Units)

Holding Registers (0x03):

Register Type Descrip on Value Range

40400 U16 Device Address 1 to 255

40401 U16 Units 1 to 3

40402 U16 Applica on Type 0-10

40403 U16 Volume Units 0 to 6

40404 U16 Decimal Place 0 to 3

40405 U16 Max Distance 0 to 10364 mm

40406 U16 Full Distance 0 to 10364 mm

40407 U16 Empty Distance 0 to 10364 mm

40408 U16 Sensi vity 0 to 100

40409 U16 Pulses 0 to 20

40410 U16 Blanking 0 to 10364 mm

40411 reserved

40412 U16 Averaging 0 to 100

40413 U16 Filter Window 0 to 10364 mm

40414 U16 Out of Range Samples 0 to 255

40415 U16 Sample Rate 50 to 1000 msec.

40416 U16 Mul plier 1 to 1999

40417 S16 Off set +/- 10364 mm

40418-40420 reserved

40421 S16 RTD Off set (0C) -100 to 100

40422 U16 Float Window 0 to 1000 mm

40423 U32 Top Float Off set +/- 10364 mm

40424 U32 Bo om Float Off set +/- 10364 mm

40425 U32 Gain Off set 0 to 255

40426-40435 reserved

40436-40437 U32 Parameter 1 Data 0 to 100000 mm

40438-40439 U32 Parameter 2 Data 0 to 100000 mm

40440-40441 U32 Parameter 3 Data 0 to 100000 mm

40442-40443 U32 Parameter 4 Data 0 to 100000 mm

40444-40445 U32 Parameter 5 Data 0 to 100000 mm

0

C, signed)

30

Automation Products Group, Inc.

APG...Providing tailored solutions for measurement applications

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

Page 31

Rev . A1, 5/14 MND

Notes

Automation Products Group, Inc.

APG...Providing tailored solutions for measurement applications

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

31

Page 32

AUT OMATION

PRODUCTS

GROUP, INC.

APG...Providing tailored solutions

for measurement applications

Automation Products Group, Inc.

Tel: 1/888/525-7300

1/435/753-7300

Fax: 1/435/753-7490

e-mail: sales@apgsensors.com

www.apgsensors.com

Automation Products Group, Inc.

1025 W. 1700 N.

Logan, UT 84321

To order additional copies of this manual, ask for APG part number PN9000000 Rev. A, 6/09

Loading...

Loading...