Page 1

PRODUCTS

AUTOMATION

Operator’s Manual

GROUP, INC.

LPU-2127

Rev. A5, 1/14

APG...Providing tailored solutions for measurement applications

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • E-mail: sales@apgsensors.com

Automation Products Group, Inc.

Page 2

LPU-2127 Rev. A5, 1/14

Table of Contents

Warranty ......................................................................................... 3

Introducing...................................................................................... 4

Understanding Ultrasonics ............................................................. 5

Installation ...................................................................................... 7

Hazardous Mounting.................................................................... 8

Wiring.............................................................................................. 9

Programming ................................................................................ 10

Operation ................................................................................... 11

Calibration ................................................................................. 13

Utilities ...................................................................................... 14

Mode Sheet ................................................................................... 16

Specifications ................................................................................ 19

Certificate of Compliance ............................................................ 20

Automation Products Group, Inc.

2

APG...Providing tailored solutions for measurement applications

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

Page 3

Rev. A5, 1/14 LPU-2127

• Warranty and Warranty Restrictions

APG warrants its products to be free from defects of material and workmanship

and will, without charge, replace or repair any equipment found defective upon

inspection at its factory, provided the equipment has been returned,

transportation prepaid, within 24 months from date of shipment from factory.

THE FOREGOING WARRANTY IS IN LIEU OF AND EXCLUDES ALL OTHER

WARRANTIES NOT EXPRESSLY SET FORTH HEREIN, WHETHER

EXPRESSED OR IMPLIED BY OPERATION OF LAW OR OTHERWISE

INCLUDING BUT NOT LIMITED TO ANY IMPLIED WARRANTIES OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE.

No representation or warranty, express or implied, made by any sales

representative, distributor, or other agent or representative of APG which is not

specifically set forth herein shall be binding upon APG. APG shall not be liable

for any incidental or consequential damages, losses or expenses directly or

indirectly arising from the sale, handling, improper application or use of the

goods or from any other cause relating thereto and APG’s liability hereunder, in

any case, is expressly limited to the repair or replacement (at APG’s option) of

goods.

Warranty is specifically at the factory. Any on site service will be provided at

the sole expense of the Purchaser at standard field service rates.

All associated equipment must be protected by properly rated electronic/

electrical protection devices. APG shall not be liable for any damage due to

improper engineering or installation by the purchaser or third parties. Proper

installation, operation and maintenance of the product becomes the

responsibility of the user upon receipt of the product.

Returns and allowances must be authorized by APG in advance. APG will

assign a Return Material Authorization (RMA) number which must appear on

all related papers and the outside of the shipping carton. All returns are subject

to the final review by APG. Returns are subject to restocking charges as

determined by APG’s “Credit Return Policy”.

Automation Products Group, Inc.

APG...Providing tailored solutions for measurement applications

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

3

Page 4

LPU-2127 Rev. A5, 1/14

Introducing

The LPU series are loop-powered ultrasonic sensors. The LPU provides a

low-power non-contact level measurement solution. These units are provided

with 4-tactile switches and a 4-digit LCD display to provide the user feedback

in programming and sensor performance data.

Sensor features include:

• Loop powered for low power consumption.

• Built-in keypad and display for easy setup and distance readings.

• Rugged Kynar transducer housing for harsh environments and high degree

of chemical compatibility.

• Microprocessor-controlled.

• Listed by CSA for operation in Class 1 Division 2 Groups C & D and Class

1 Zone 2 A Ex nA IIB hazardous areas.

• NEMA 4X rating for outdoor applications.

Automation Products Group, Inc.

4

APG...Providing tailored solutions for measurement applications

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

Page 5

Rev. A5, 1/14 LPU-2127

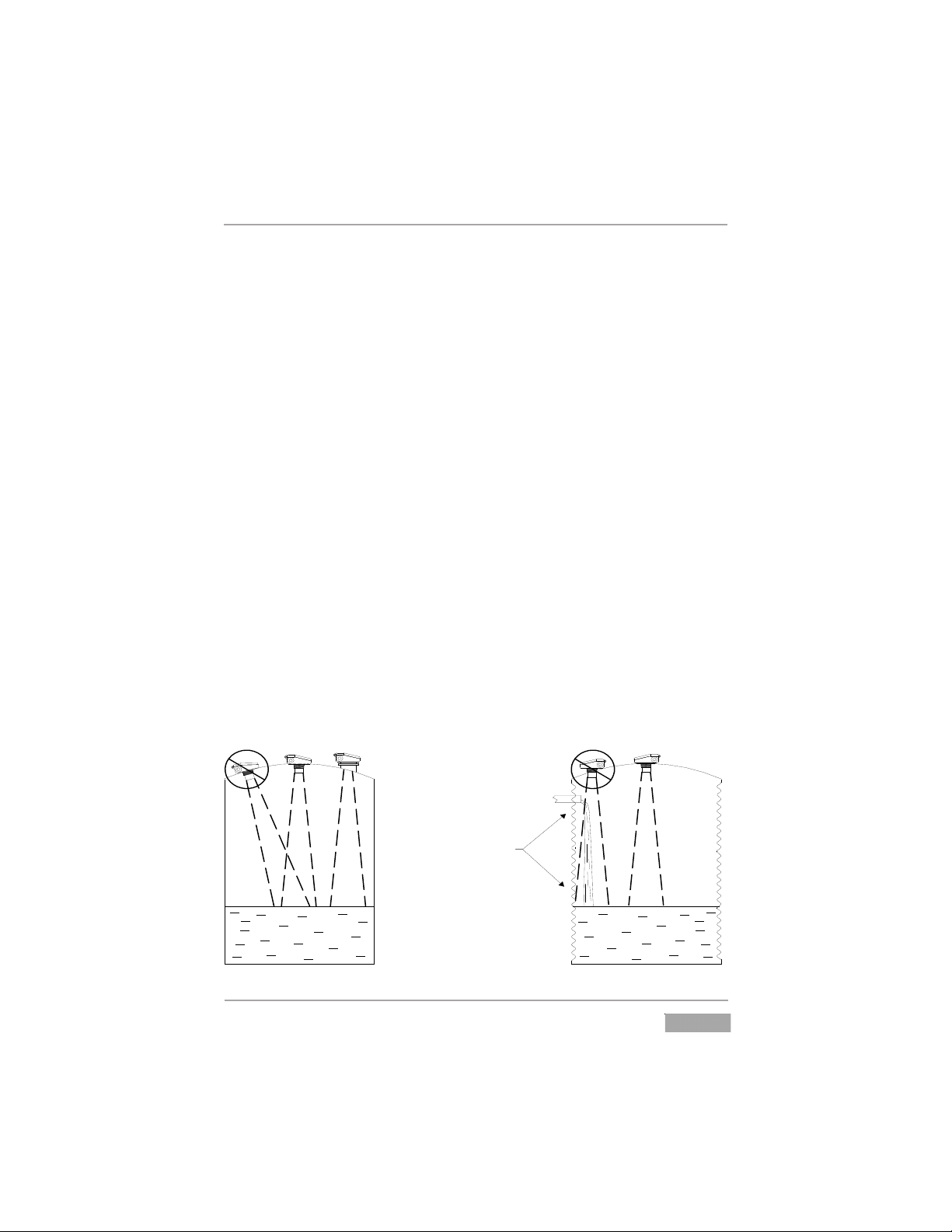

detection

area

beam spread

low sensitivity

and

pulses

high sensitivity

and

pulses

Understanding Ultrasonics

Ultrasonic sensors measure distance

using a transducer to send out

ultrasonic bursts. Each burst contains a

series of 1-20 pulsed sound waves that

emit in the shape of a cone, reflect off

the target, and are received by the

sensor. The time required for the sound

burst to travel to and from the target is

converted into a distance measurement

by the sensor.

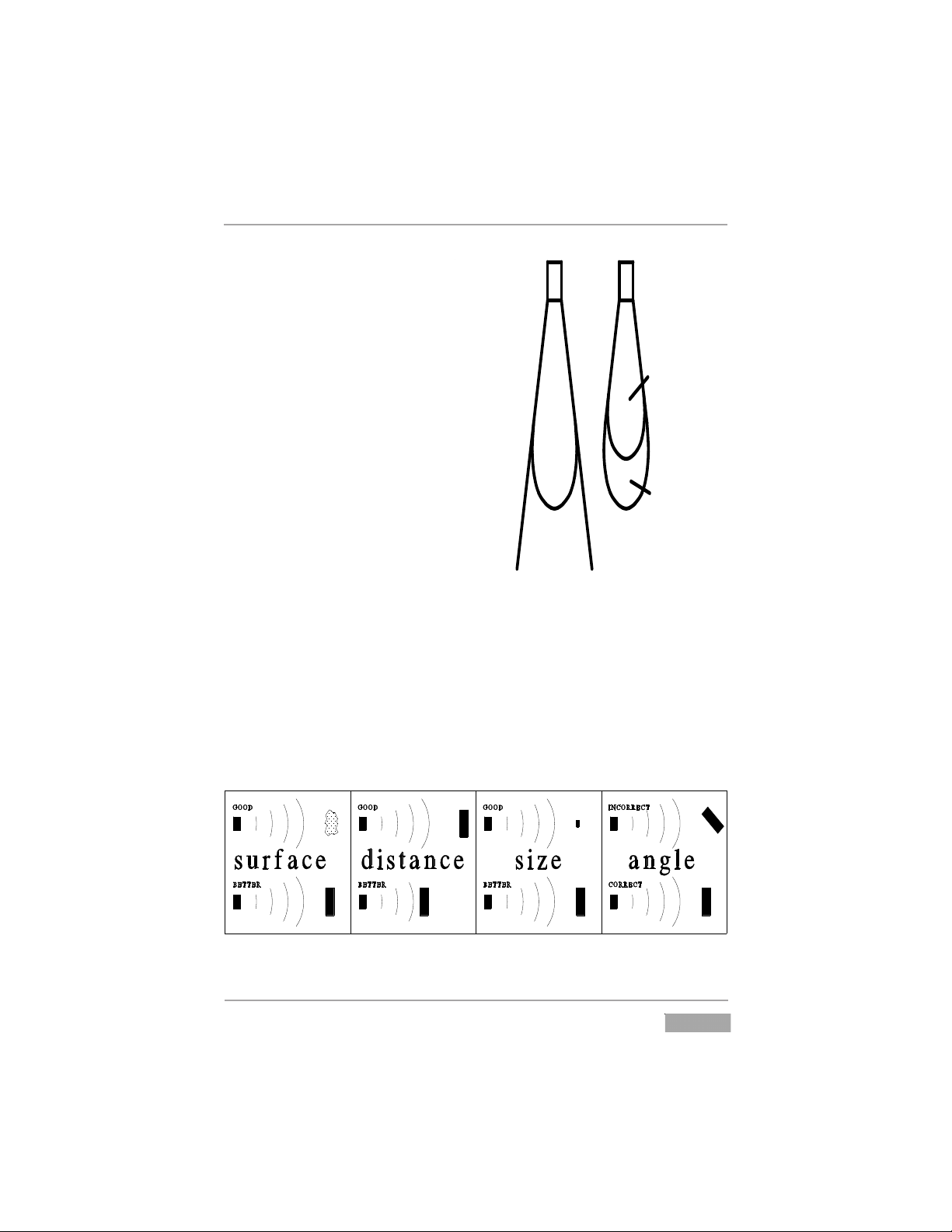

Ultrasonic sensing is affected by

several factors including the target

surface, distance, size, and angle. The

following considerations will help

ensure the best possible target

conditions.

Surface

The ideal target surface is hard and smooth and perpendicular to the sensor.

This surface will reflect a greater amount of signal than a soft, sound wave

absorbent surface. A target with poor sound wave reflection characteristics will

reduce the operating distance of the sensor and decrease its accuracy.

APG...Providing tailored solutions for measurement applications

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

Automation Products Group, Inc.

5

Page 6

LPU-2127 Rev. A5, 1/14

Distance

The shorter the distance from the sensor to an object, the stronger the

returning echo will be. Therefore, as the distance increases, the object requires

better reflective characteristics to return a sufficient echo.

Size

A large object will have a greater surface area to reflect the signal than a

small one, therefore, a large target will be detected at a greater distance than a

small target. The surface area recognized as the target is generally the portion

closest to the sensor.

Angle

The inclination of the object's surface facing the ultrasonic sensor affects the

reflectivity of the object. The portion perpendicular to the sensor returns the

echo. If the entire surface is at a great enough angle, the signal will be reflected

away from the sensor and no echo will be detected. Generally a target at an

angle greater than 5 degrees off perpendicular will not be detected.

Automation Products Group, Inc.

6

APG...Providing tailored solutions for measurement applications

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

Page 7

Rev. A5, 1/14 LPU-2127

DO NOT mount the sensor

where the beam will intersect

objects such as fill streams,

pipes, ladder rungs, wall seams,

or corrugated tank walls.

Installation

The LPU sensor should be mounted so that it has a clear sound path to the

level monitored. Mount the sensor away from tank walls and inlets. The path

should be free from obstructions and as open as possible for the 9° off axis

beam pattern. Follow the guidelines mentioned in "Understanding

Ultrasonics", earlier in this manual. When using a stand pipe to mount the

sensor above the tank, the stand pipe should be seamless and no longer than 4

inches to provide a smooth path for the sound waves to propagate into the

tank. Seams from couplers, nipples or gaskets can cause erroneous echoes and

degrade the sensors performance. The LPU can be mounted in a coupler, or

flange using the 2” NPT threaded case.

Caution: Do not over tighten! The sensor should be threaded in only hand

tight.

The minimum detection range of the LPU is approximately 1 ft. The sensor

should be mounted to ensure the target does not come closer than the

minimum range or erroneous readings may result.

See the Hazardous Mounting section of this manual before mounting the

LPU sensor in a hazardous area.

APG...Providing tailored solutions for measurement applications

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

Automation Products Group, Inc.

7

Page 8

LPU-2127 Rev. A5, 1/14

Automation Products Group, Inc.

APG...Providing tailored solutions for measurement applications

8

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

Page 9

Rev. A5, 1/14 LPU-2127

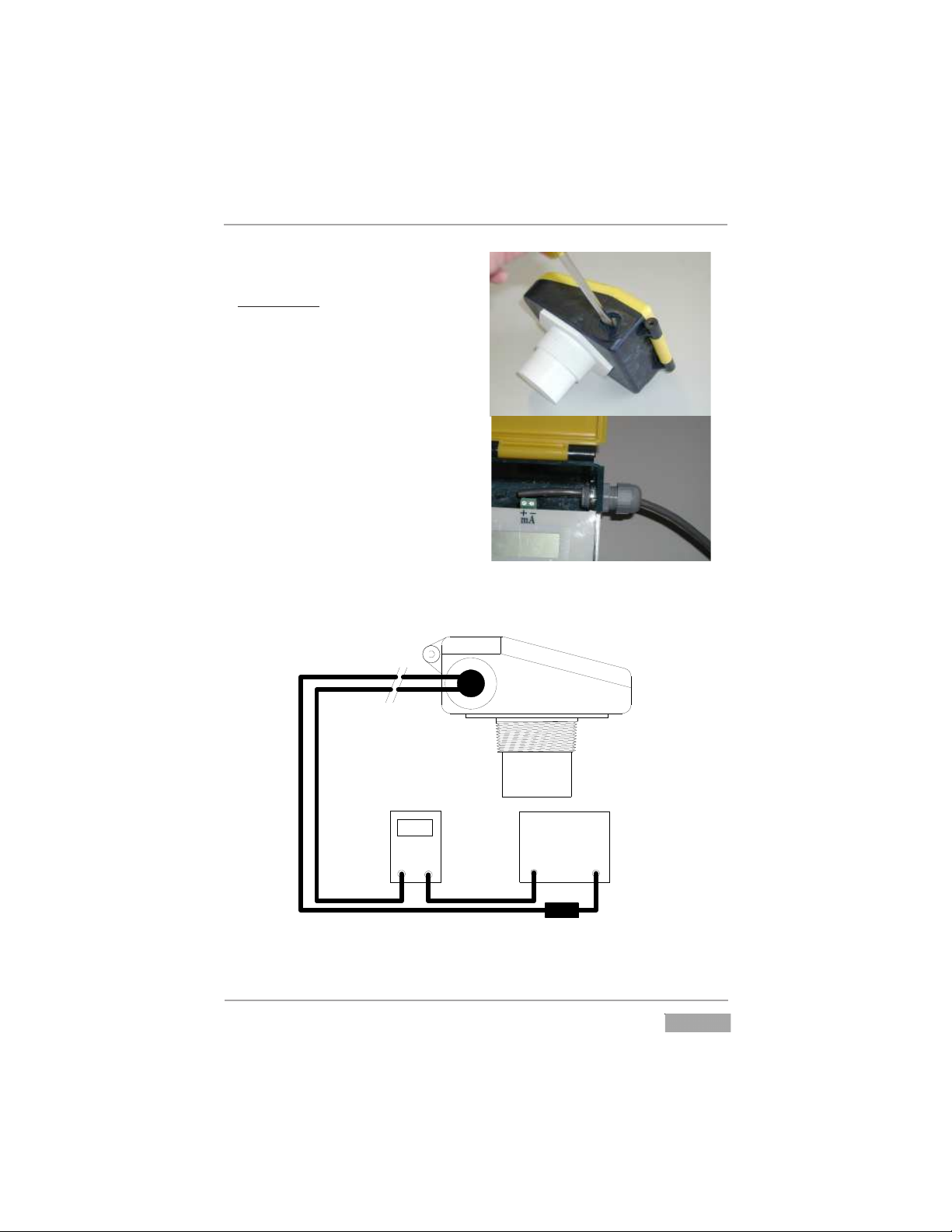

4.25

Ammeter

COM

mA

Power Supply

(24Vdc)

+

-

4 to 20ma Out

+24vdc

Load Resistance

or Input Card

Wiring

Cable Entry

1. Remove the cable knock out with

lid closed.

2. Clear flashing.

3. Open lid.

4. Install cable gland or conduit

connection.

5. Connect cable as shown:

12 to 28 VDC to (+) Terminal

4 to 20 ma output to (-) Terminal

APG...Providing tailored solutions for measurement applications

Automation Products Group, Inc.

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

9

Page 10

LPU-2127 Rev. A5, 1/14

Programming

The LPU is programmed using modes, similar to a digital wrist watch. The

LPU display and programming buttons can be accessed by loosening the screw

that secures and seals the sensor’s lid. The LCD display shows the distance

measurement. The display is also used to view the individual modes and their

values when programming.

The LPU has four programming buttons, MODE UP, MODE DOWN, VALUE

UP, and VALUE DOWN. The MODE UP/DN buttons allow the user to select

the desired mode while VALUE UP/DN buttons allow the user to view and alter

the settings.

To select a mode, press the MODE UP or MODE DOWN button until the

desired mode is displayed. Press the VALUE UP or VALUE DOWN button once

to view the current setting of that mode.

To change the selected mode setting, press the VALUE UP or VALUE DOWN

button until the desired value is displayed.

To STORE or SAVE the changed mode value, press the MODE UP or MODE

DOWN button once. At this point, the display will show the distance

measurement. The values are stored in a nonvolatile memory, and will not be

lost when power is turned off.

A list of the 17 modes is located on the LPU MODE SHEET near the end of

this manual.

10

Automation Products Group, Inc.

APG...Providing tailored solutions for measurement applications

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

Page 11

Rev. A5, 1/14 LPU-2127

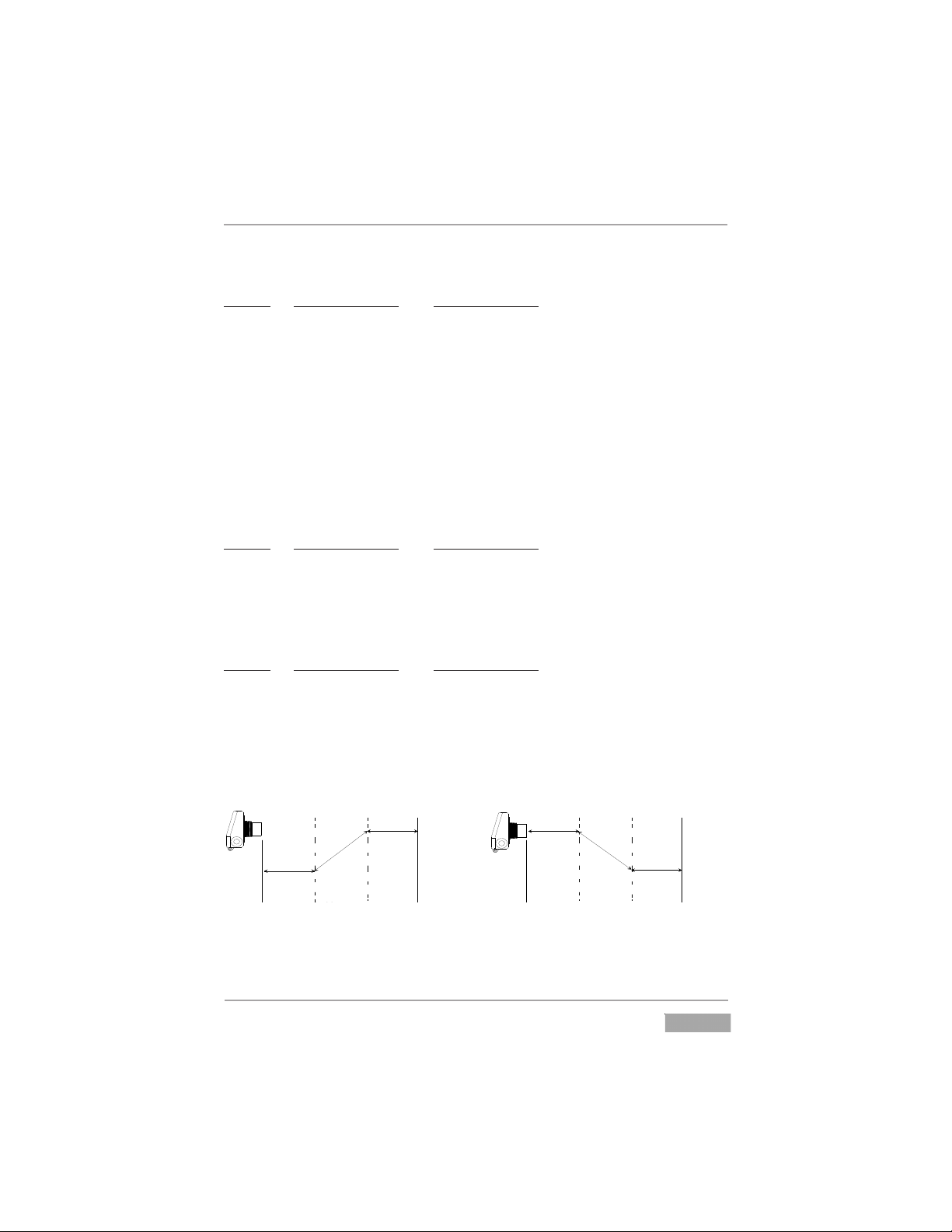

Zero Point Max. Distance Zero Point Max. Distancemode 11 mode 12 mode 11 mode 12

20 ma

4 ma

4 ma

20 ma

Operation

MODE DESCRIPTION PARAMETERS

1 Units Range = 0-2

Default = 0

0 = feet

1 = inches

2 = mm

Mode 1 is used to select the units of measurement that will be used

throughout the setup process and also for display. The units will also

determine the resolution of the display and the outputs. The resolution is: feet

0.01, inches 0.1 and millimeters 1.

NOTE: All modes must be set using the units selected in Mode 1.

MODE DESCRIPTION PARAMETERS

2 4 mA distance Units = Mode 1

Range = 0-9999

Default = 1.00 ft.

Mode 2 sets the 4 mA distance.

MODE DESCRIPTION PARAMETERS

3 20 mA distance Units = Mode 1

Range = 0-9999

Default = 25.00 ft.

Mode 3 sets the 20 mA distance.

APG...Providing tailored solutions for measurement applications

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

Automation Products Group, Inc.

11

Page 12

LPU-2127 Rev. A5, 1/14

Operation (continued)

MODE DESCRIPTION PARAMETERS

4 Response Time Range = 1-3

Default = 1

1 = 3.3 ft/min (1m/min)

2 = 15ft/min (4.5m/min)

3 = >15 ft/min (4.5/min)

Mode 4 is used to select the desired response time. The response time

adjustment is the limit to which the LPU-2127 can keep up with different rates

of change. The response time parameter automatically sets internal filter

parameters for the programmed rate of change. More filter equates to a steadier

output. The most filter is used in setting 1, the least in setting 3.

MODE DESCRIPTION PARAMETERS

5 Fail-safe Range = 0 - 2

Default = 1

0 = hold last

1 = 22 mA

2 = 3.75 mA

Mode 5 sets the output condition that the sensor will revert to in the event of

a loss of echo condition. If this mode is set to 0, the sensor will hold the last

reading until the signal is regained. If set to 1, the output of the sensor will go

to 22 mA If set to 2, the output will go to 3.75 mA.

MODE DESCRIPTION PARAMETERS

6 Fail-safe Units = Seconds

Delay Range = 5-9999

Default = 15

Mode 6 sets the delay, in seconds, before the output will show a loss of echo

condition. When the LPU does not receive an echo, it will hold the last valid

condition for the number of seconds entered in Mode 5. When this time has

expired, the display and output will change to their fail-safe settings.

Most applications do not require the user to manipulate modes beyond 6.

Automation Products Group, Inc.

12

APG...Providing tailored solutions for measurement applications

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

Page 13

Rev. A5, 1/14 LPU-2127

Calibration

MODE DESCRIPTION PARAMETERS

7 4 mA Trim Range = 0-9999

Default = 5000

Mode 7 fine tunes the minimum current sourced on the analog output.

MODE DESCRIPTION PARAMETERS

8 20 mA Trim Range = 0-9999

Default = 5000

Mode 8 fine tunes the maximum current sourced on the analog output.

MODE DESCRIPTION PARAMETERS

9 Calibration Range = 0-1999

Default = 1000

Mode 9 is used to calibrate the sensor for variations in the speed of sound

due to variations in atmospheres. The default of 1000 is used for most

applications. Assume a decimal after the first digit.

MODE DESCRIPTION PARAMETERS

10 Distance Offset Units = Mode 1

Range = -3.00 to 3.00

Default = 0

Mode 10 is used to change the zero point of the sensor.

APG...Providing tailored solutions for measurement applications

Automation Products Group, Inc.

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

13

Page 14

LPU-2127 Rev. A5, 1/14

Step 1: Point the sensor at a target that is approximately at the

maximum measurement range. Adjust the Mul plier value so

that the sensor distance reading matches the actual measured

distance to the target.

Distance Calibra on

Use a wall or other large ß at target for calibra on at longer ranges.

Step 3: Repeat steps 1 and 2 un l the reading at each endpoint

matches the actual measured distance. The accuracy at both endpoint should improve with each repe on of steps 1 and 2.

measure

measure

Step 2: Point the sensor at a target that is approximately at the

minimum measurement range. Adjust the O! set value so that the

sensor distance reading matches the actual measured distance to

the target.

Automation Products Group, Inc.

14

APG...Providing tailored solutions for measurement applications

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

Page 15

Rev. A5, 1/14 LPU-2127

Utilities

MODE DESCRIPTION PARAMETERS

11 Temperature Range = 0 - 2

Compensation Default = 1

0 = OFF

1 = ON

2 = View Temperature (degrees C)/ON

Mode 11 activates or deactivates the internal temperature compensation

circuit. The speed of sound changes with changes in temperature, therefore

changes in temperature can affect distance measurements. These affects can be

minimized by activating temperature compensation. If the mode is exited

while viewing temperature, temperature compensation is turned ON.

MODE DESCRIPTION PARAMETERS

12 AutoSense Range = 0 - 1

Default = 1

0 = Manual (user controls Sensitivity and Pulses)

1 = AutoSense (sensor controls Sensitivity and

Pulses)

Mode 12 activates or deactivates AutoSense. When operating with this

mode active, the LPU-2127 will automatically change the sensitivity and

pulses to match the application. Modes 13 and 15 limit the maximum level

that sensitivity and pulses can be manipulated when operating in AutoSense.

Modes 13 and 15 set the sensitivity and pulses when operating in manual

mode.

MODE DESCRIPTION PARAMETERS

13 Sensitivity Range = 0 - 100%

Default = 100%

Mode 13 sets the level of gain that is applied to the echo. When operating in

AutoSense, this parameter limits the gain that can be applied to the echo. If

operating in manual, this parameter sets the receive gain. When in manual

mode, set the sensitivity to the minimum value that will allow the target to be

reliably tracked through the full range of environmental conditions.

Automation Products Group, Inc.

APG...Providing tailored solutions for measurement applications

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

15

Page 16

LPU-2127 Rev. A5, 1/14

Utilities (Continued)

MODE DESCRIPTION PARAMETERS

14 Blanking Units = Determined by Mode 1

Range = 0.5 -16 ft.

Default = 1.00 ft.

Mode 14 sets the blanking distance. The blanking distance is the zone from

the sensor to a point where the first echo will be accepted. Because of the

physical properties of an ultrasonic sensor, objects cannot be detected closer

than approximately 1 foot from the face of the transducer. This distance varies

according to how much energy is being transmitted (Mode 5) and the

installation. Low pulses and soft mounting may allow target detection as close

as 6 inches. The blanking distance can also be used to ignore unwanted targets

close to the sensor such as welds, seams, pipe fittings, or gaskets.

MODE DESCRIPTION PARAMETERS

15 Pulses Range = 1-20

Default = 16

Mode 15 sets the maximum number of pulses the sensor can transmit when

operating in AutoSense or simply the number of pulses when operating in

manual (Mode 12). The LPU emits a burst of pulses and measures the time it

takes for the burst to travel to and from the target. The more pulses that are

sent in a burst, the stronger the returning echo. When operating in manual

mode, increase the strength of the transmission by increasing the number of

pulses for detecting soft targets in damping environments. In acoustically

active environments or small enclosed areas, decrease the number of pulses to

decrease the energy transmitted and reduce multiple echoes.

MODE DESCRIPTION

16 Software Version

Mode 16 displays the software version of the LPU.

MODE DESCRIPTION

17 Reset

Mode 17 resets the LPU to factory default settings

Automation Products Group, Inc.

16

APG...Providing tailored solutions for measurement applications

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

Page 17

Rev. A5, 1/14 LPU-2127

Mode Sheet

MODE DESCRIPTION PARAMETERS EXPLANATION

1 Units Range = 0 - 2

0 - feet

1- inches

2 - mm

Default = 0

2 4mASet Point Units = Mode 1

Range = 0 - 9999

Default = 1.00

3 20mA Set Point Units = Mode 1

Range = 0 - 9999

Default = 25.00

4 Response Time Range = 1-3

Default = 1

1 = 3.3 ft/min (1m/min)

2 = 15ft/min (4.5m/min)

3 = >15 ft/min (4.5/min)

5 Fail-Safe Range = 0 - 2

Default = 0

0 = Hold last reading

1 = 22ma

2 = 3.75ma

6 Fail-Safe Units = seconds

Delay Range=5-9999

Default = 15

Sets the units to be displayed and

used in setup. NOTE: Set Mode 1

before any other modes.

Sets the end point for the 4 mA

analog limit.

Sets the end point for the 20 mA

analog limit.

Sets the reaction rate of the sensor.

Sets the output status in the event

of a loss of echo condition.

Sets the delay in seconds before

the output will show a loss of echo

condition.

7 4mA Trim Range = 0 - 9999

Default = 5000

8 20mA Trim Range = 0 - 9999

Default = 5000

9 Calibration Range = 0000 - 1999

Default = 1000

Automation Products Group, Inc.

APG...Providing tailored solutions for measurement applications

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

Fine tunes the 4 mA analog

output.

Fine tunes the 20 mA analog

output.

Sets the calibration factor.

Assume a decimal after first digit.

17

Page 18

LPU-2127 Rev. A5, 1/14

Mode Sheet (continued)

MODE DESCRIPTION PARAMETERS EXPLANATION

10 Offset Distance Range =-999 - +999

Default = 0

11 Temperature Range = 0 - 2

Compensation Default = 1

0 = OFF

1 = ON

2 = View/ON

12 Autosense Range = 0 - 1

Default = 1

0 = OFF

1 = ON

13 Sensitivity Range = 0 - 100%

Default = 100

14 Blanking Units = Mode 1

Range = 0.5 to 16 ft.

Default = 1.00

15 Pulses Units = Pulses

Range = 1 - 20

Default = 16

16 Software

Version

Sets an offset for the display.

Activates or deactivates internal

Temperature Compensation.

Activates or deactivates AutoSense.

Sets to top sensitivity level. Zero is

the lowest sensitivity settomg and

100 is the highest.

Sets a dead zone in front of the

transducer where echoes are

ignored.

Sets the number of ultrasonic

pulses transmitted in each burst. 20

being the strongest transmit setting.

Displays the Software Version

17 Reset Range = 0 - 1

Default = 0

Automation Products Group, Inc.

18

APG...Providing tailored solutions for measurement applications

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

Resets the mode parameters to their

default values. Entering a 1 will

reset the parameters.

Page 19

Rev. A5, 1/14 LPU-2127

Signal Strenth Indicator

Bars located on the left side of the LCD display indicate the strength of the return signal

from the sensor.

Excellent

Good

Fair

Loss of Echo

Automation Products Group, Inc.

APG...Providing tailored solutions for measurement applications

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

19

Page 20

LPU-2127 Rev. A5, 1/14

5.500"

6.050"

2.000"

4.000"

2.400"

2.300"

2" NPT

Specifications — LPU-2127

Operating Range ............................ 1 ft. to 25 ft. (0.3 m - 7.62 m)

Supply Voltage ............................... 12 to 28 VDC

Output ............................................. 4-20 mA (Max 600 ohms @ 24 VDC)

4-20 mA (Max 150 ohms @ 12 VDC)

(Includes barrier resistance)

Resolution ...................................... 0.1 in. (2.54 mm)

Accuracy .........................................+/- 0.25% of range with no temp gradient

Sensor Adjustments ........................Programmable modes

Maximum Current Draw ................ 22 mA max

Transducer Type .............................Flat ceramic sealed PVDF face

Operating Temperature................... -40 to 60°C

Internal Temp. Compensation ....... Yes

Sample Rate ................................... 3 seconds at 4ma - 0.6seconds at 20 ma

Beam Pattern .................................. 9° off axis

Enclosure........................................ NEMA 4X , IP65

Cable Connection .......................... 2 terminals

Dimensions

20

Automation Products Group, Inc.

APG...Providing tailored solutions for measurement applications

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

Page 21

Rev. A5, 1/14 LPU-2127

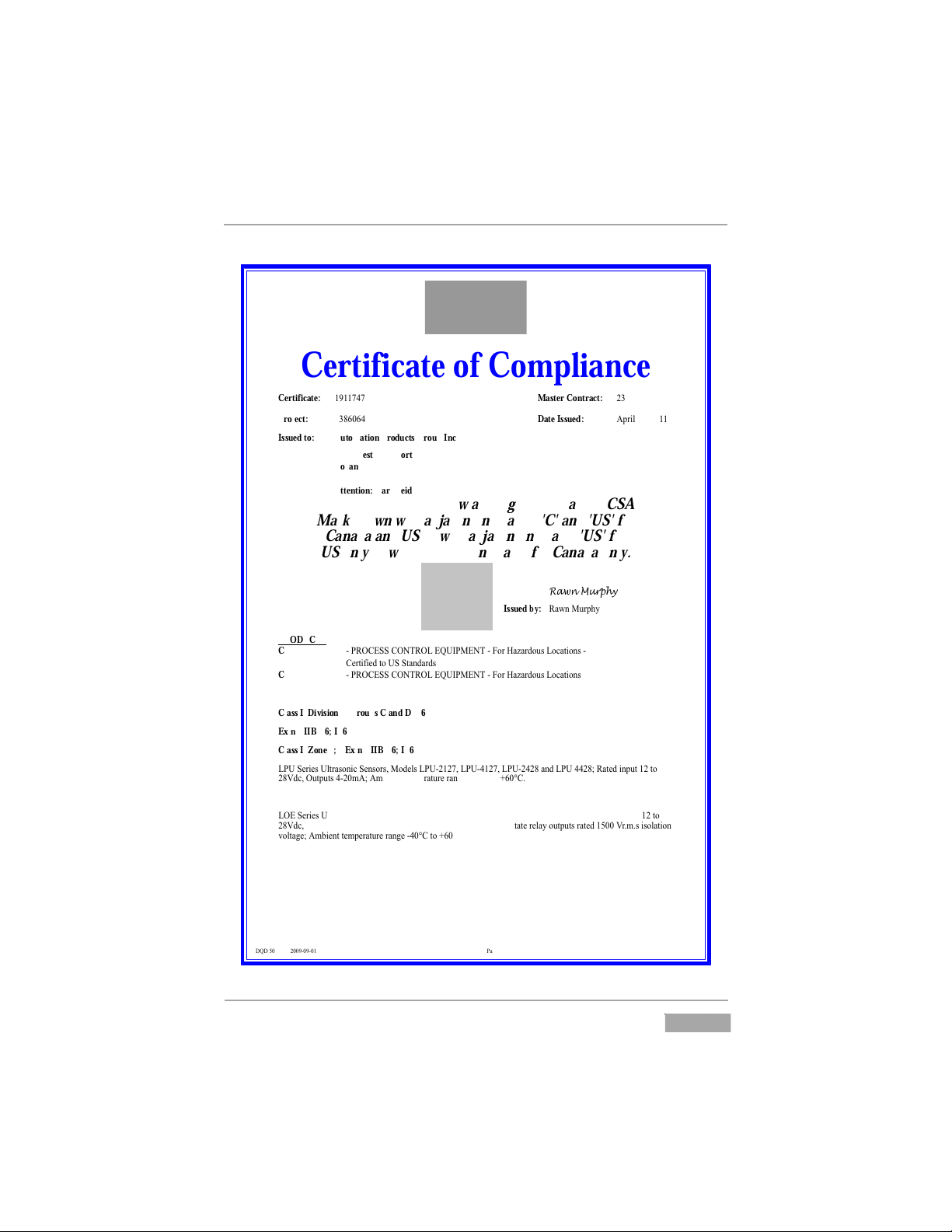

Certificate of Compliance

Certificate:

! "#"

Master Contract:

$%"#&#

Project:

$%&'('#

Date Issued:

)*+,-.$!/.$(

010.2(".3456.$((!7(!7( 89:4;.

Issued to: Automation Products Group Inc

1025 West 1700 North

Logan, UT 84321

USA

Attention: Karl Reid

The products listed below are eligible to bear the CSA

Mark shown with adjacent indicators 'C' and 'US' for

Canada and US or with adjacent indicator 'US' for

US only or without either indicator for Canada only.

!"#$%&'()*

Issued by:

39<=.>?+*@A

PRODUCTS

CLASS 2258 82

7.83BCDEE.CBFG3BH.D1IJ8>DFG.7.KL+.M9N9+OL?P.HLQ9R,L=P.7

C4+R,S,4O.RL.IE.ER9=O9+OP

CLASS 2258 02

7.83BCDEE.CBFG3BH.D1IJ8>DFG.7.KL+.M9N9+OL?P.HLQ9R,L=P

.

Class I, Division 2, Groups C and D, T6

Ex nA IIB T6; IP65

Class I, Zone 2; AEx nA IIB T6; IP65

H8I.E4+,4P.I-R+9PL=,Q.E4=PL+P/.>LO4-P.H8I7$ $"/.H8I7# $"/.H8I7$#$&.9=O.H8I.##$&T.39R4O.,=*?R. $.RL

$&UOQ/.B?R*?RP.#7$(V)T.)VW,4=R.R4V*4+9R?+4.+9=:4.7#(XC.RL.Y'(XC6.

.

HBD.E4+,4P.I-R+9PL=,Q.E4=PL+P/.>LO4-P.HBD7$ $'/.HBD7' $'/.9=O.HBD7% %'T.39R4O.,=*?R.#&U0C.L+. $.RL

$&UOQ/.$((.V).QL=R9,=,=:.R<L.L*R,Q9--A7QL?*-4O.>BEKDG.PL-,O7PR9R4.+4-9A.L?R*?RP.+9R4O. 2((.U+6V6P.,PL-9R,L=

5L-R9:4T.)VW,4=R.R4V*4+9R?+4.+9=:4.7#(XC.RL.Y'(XC6

FLR4;

Z.G@4.HBD.E4+,4P.P@9--.W4.*L<4+4O.WA.9.P?,R9W-4.Q4+R,S,4O.C-9PP.$.*L<4+.P?**-A6

Automation Products Group, Inc.

APG...Providing tailored solutions for measurement applications

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

21

Page 22

LPU-2127 Rev. A5, 1/14

Certificate:

! "#"

Master Contract:

$%"#&#

Project:

$%&'('#

Date Issued:

)*+,-.$!/.$(

010.2(".3456.$((!7(!7( 89:4;.$

.

CLASS 2258 04 - PROCESS CONTROL EQUIPMENT - Intrinsically Safe, Entity - For Hazardous

Locations

CLASS 2258 84 - PROCESS CONTROL EQUIPMENT - Intrinsically Safe, Entity - For Hazardous

Locations - Certified to US Standards

Class I, Division 1, Groups C and D, T3

Ex ia IIB, T3 (Canada); IP65

Class I, Zone 0; AEx ia IIB, T3 (USA); IP65

<8=7$#$&.9>?.<8=7##$&.@-A+9BC>,D.B4>BC+BE.39A4?.,>*@A. $.AC.$&F0G/.H@A*@AB.#7$(I)/.)IJ,4>A.A4I*4+9A@+4

+9>:4.7#(KG.AC.L'(KG6..M>A,AN.89+9I4A4+B.FI9O.P.$&F0G/.QI9O.P. %(I)/.8,6.(6! R/.G,.P.(>S/.<,.P. (TU/

,>A+,>B,D9--N.B9V4.WX4>.DC>>4DA4?.,>.9DDC+?9>D4.W,AX.Q>BA9--9A,C>.?+9W,>:.!(($"#"6

.

.

.

APPLICABLE REQUIREMENTS

.

.

.G)YZG[).[A9>?9+?.G$$6$.YC6.(7\! ]4>4+9-.34^@,+4I4>AB.7.G9>9?,9>.M-4DA+,D9-.GC?4/.89+A

QQ

.G[).[A9>?9+?.G$$6$.YC6 #$7\ !&" 8+CD4BB.GC>A+C-.M^@,*I4>A.Q>?@BA+,9-.8+C?@DAB

.G)YZG[).[A9>?9+?.G$$6$.YC6 2"7!$ Q>A+,>B,D9--N.[9V4.9>?.YC>7Q>D4>?,54.M^@,*I4>A.VC+

=B4.,>.U9_9+?C@B.<CD9A,C>B

.G)YZG[).[A9>?9+?.G$$6$.YC6$ %7\ !&" YC>7,>D4>?,54.M-4DA+,D9-.M^@,*I4>A.VC+.=B4.,>.G-9BB.Q/

0,5,B,C>.$.U9_9+?C@B.<CD9A,C>B.Q>?@BA+,9-.8+C?@DAB

.G)YZG[).[A9>?9+?.M'(("!7(7($ M-4DA+,D9-.)**9+9A@B.VC+.MO*-CB,54.]9B.)AICB*X4+4B.`

89+A.(;.]4>4+9-.34^@,+4I4>AB

.G)YZG[).[A9>?9+?.M'(("!7 7($ M-4DA+,D9-.)**9+9A@B.VC+.MO*-CB,54.]9B.)AICB*X4+4B.`

89+A. ;.Q>A+,>B,D.[9V4AN.a,a

.G)YZG[).[A9>?9+?.M'(("!7 27($ M-4DA+,D9-.)**9+9A@B.VC+.MO*-CB,54.]9B.)AICB*X4+4B.7

89+A. 2;.bN*4.CV.8+CA4DA,C>.a>a

.G)YZG[).[A9>?9+?.G$$6$.YC6.'(2$!7(2 04:+44B.CV.8+CA4DA,C>.8+C5,?4?.JN.M>D-CB@+4B.cQ8

GC?4d

.=<.[A9>?9+?.2(& Q>?@BA+,9-.GC>A+C-.M^@,*I4>A

.=<.[A9>?9+?.! % Q>A+,>B,D9--N.[9V4.)**9+9A@B.9>?.)BBCD,9A4?.)**9+9A@B

VC+.=B4.,>.G-9BB.Q/.QQ/.9>?.QQQ/.0,5,B,C>. /.U9_9+?C@B

cG-9BB,V,4?d.<CD9A,C>B

22

Automation Products Group, Inc.

APG...Providing tailored solutions for measurement applications

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

Page 23

Rev. A5, 1/14 LPU-2127

Certificate:

! "#"

Master Contract:

$%"#&#

Project:

$%&'('#

Date Issued:

)*+,-.$!/.$(

010.2(".3456.$((!7(!7( 89:4;.%

.)<=>?>=).=@9AB9+B. $6 $6( 7$((" <CA,AD4AB,54.E-4D@+,D9-.EFG,*H4A@.IC+.JK4.,A.L-9KK

>.9AB.>>/.0,5,K,CA.$/.9AB.L-9KK.>>>.0,5,K,CAK. .9AB.$

M9N9+BCGK.OL-9KK,I,4BP.QCD9@,CAK

.JQ.=@9AB9+B.'(("!7( E-4D@+,D9-.)**9+9@GK.IC+.ER*-CK,54.S9K.)@HCK*T4+4K.U

89+@.(;.S4A4+9-.34FG,+4H4A@K

JQ.=@9AB9+B.'(("!7 E-4D@+,D9-.)**9+9@GK.IC+.ER*-CK,54.S9K.)@HCK*T4+4K

89+@. ;.>A@+,AK,D.=9I4@V.W,W

JQ.=@9AB9+B.'(("!7 2 E-4D@+,D9-.)**9+9@GK.IC+.ER*-CK,54.S9K.)@HCK*T4+4K

89+@. 2;.E-4D@+,D9-.)**9+9@GK.X,@T.YV*4.CI.8+C@4D@,CA

WAW

>EL.'(2$! 04:+44K.CI.8+C@4D@,CA.8+C5,B4B.ZV.EAD-CKG+4K.O>8

LCB4P

..

MARKINGS

YT4.IC--CX,A:.H9+[,A:K.9+4.*+C5,B4B.CA.L=)7)DD4*@4B.OL-9KK."!$$7( /.\,-4.AGHZ4+.!!% 'P.9BT4K,54.-9Z4K@CD[.8+CBGD@.<GHZ4+."&" .H9AGI9D@G+4B.ZV.%].LCH*9AV/.XT,DT.,K.KG,@9Z-4.IC+.,ABCC+.C+.CG@BCC+.GK4.CA

8-9K@,D.S+CG*.^>>/.9@.9.H9R,HGH.K4+5,D4.@4H*4+9@G+4.CI.&(_L.C+.T,:T4+6..YT4.-9Z4-.K@CD[.KT9--.Z4.*+,A@4B.X,@T

CA4.CI.@T4.9**+C54B.*+,A@4+.9AB.,A[.DCHZ,A9@,CAK.9K.K*4D,I,4B.,A.@T4.H9AGI9D@G+4+K.-,K@,A:.9AB.@T4.I,A,KT4B.-9Z4,K.9II,R4B.@C.@T4.TCGK,A:6

` ]9AGI9D@G+4+aK.A9H4/.b)G@CH9@,CA.8+CBGD@K.S+CG*c/.C+.L=).]9K@4+.LCA@+9D@.<GHZ4+.b$%"#&#c/.9Bd9D4A@

@C.@T4.L=).]9+[.,A.-,4G.CI.]9AGI9D@G+4+aK.A9H46

` ]CB4-.AGHZ4+;.9K.K*4D,I,4B.,A.@T4.83e0JLY=.K4D@,CA/.9ZC546

` E-4D@+,D9-.+9@,A:K;.9K.K*4D,I,4B.,A.@T4.83e0JLY=.K4D@,CA/.9ZC546

` )HZ,4A@.@4H*4+9@G+4.+9@,A:;.9K.K*4D,I,4B.,A.@T4.83e0JLY=.K4D@,CA/.9ZC54.OH9V.Z4.9ZZ+45,9@4BP6

` ]9AGI9D@G+,A:.B9@4.,A.]]ff.IC+H9@/.C+.K4+,9-.AGHZ4+/.@+9D49Z-4.@C.HCA@T.CI.H9AGI9D@G+46

` YT4.L=).]9+[.X,@T.bLc.9AB.bJ=c.,AB,D9@C+K/.9K.KTCXA.CA.@T4.L4+@,I,D9@4.CI.LCAIC+H,@V6

` M9N9+BCGK.QCD9@,CA.B4K,:A9@,CA;.9K.K*4D,I,4B.,A.@T4.83e0JLY=.K4D@,CA/.9ZC546

` Y4H*4+9@G+4.LCB4;.9K.K*4D,I,4B.,A.@T4.83e0JLY=.K4D@,CA/.9ZC54.O]9V.9**49+.CA.DCA@+C-.B+9X,A:P6

` L-9KK.>.0,5,K,CA. .9BB,@,CA9-.]9+[,A:K.7

` bER,9c.IC--CX4B.ZV.b>>gc

` b><Y3><=>L)QQf.=)\Ec

` bh)3<><SU.Ei8Qe=>e<.M)j)30.U.=Jg=Y>YJY>e<.e\.Le]8e<E<Y=.])f.>]8)>3

><Y3><=>L.=)\EYfc.OEFG,59-4A@.XC+B,A:.,K.9DD4*@9Z-4P6

` bh)3<><SU.Ye.83E^E<Y.>S<>Y>e<.e\.\Q)]])gQE.e3.Le]gJ=Y>gQE.)Y]e=8ME3E=/

0>=Le<<EY.8ehE3.gE\e3E.=E3^>L><Sc6

` b>AK@9--.*4+.0+9X,A:.!(($"#&c.OC+.4FG,59-4A@P;.9K.K*4D,I,4B.,A.@T4.83e0JLY=.K4D@,CA/.9ZC54

` L-9KK.>.0,5,K,CA.$.9BB,@,CA9-.]9+[,A:K.U

` bER.A)c.IC--CX4B.ZV.b>>gc

` bh)3<><SU.0e.<eY.0>=Le<<ELY.E1J>8]E<Y.J<QE==.)3E).>=.k<eh.Ye.gE.<e<7

M)j)30eJ=c6

` bh)3<><S.U.8eYE<Y>)Q.EQELY3e=Y)Y>L.LM)3S><S.M)j)30.U.=EE.><=Y3JLY>e<=c.OC+

4FG,59-4A@P6

APG...Providing tailored solutions for measurement applications

Automation Products Group, Inc.

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

23

Page 24

LPU-2127 Rev. A5, 1/14

Certificate:

! "#"

Master Contract:

$%"#&#

Project:

$%&'('#

Date Issued:

)*+,-.$!/.$(

010.2(".3456.$((!7(!7( 89:4;.#

< =>+.?@4.A8B.C4+,4D.B-?+9D>E,F.C4ED>+D/.?@4.G>+HD.I34J4+4EF4.,ED?9--9?,>E.H+9G,E:.EKLM4+.!(($"#2N.O>+

4PK,59-4E?Q;.9D.D*4F,J,4H.,E.?@4.83R0BSTC.D4F?,>E/.9M>54

< =>+.?@4.ARU.C4+,4D.B-?+9D>E,F.C4ED>+D/.?@4.G>+HD.I34J4+4EF4.,ED?9--9?,>E.H+9G,E:.EKLM4+.!((%#'!N.O>+

4PK,59-4E?Q;.9D.D*4F,J,4H.,E.?@4.83R0BSTC.D4F?,>E/.9M>54

< =>+.?@4.ARU.C4+,4D.B-?+9D>E,F.C4ED>+D/.?@4.L9EK9-.D@9--.F>E?9,E.?@4.J>-->G,E:.G>+HD;..IV)3WXWY.Z

WRWSRW0BSTX[U.CB3=)SU.R=.T\U.\RBCXWY.])^._U.S\)3YU0._^.WRWSRW0BSTX[U

]U0X)/.SAU)W.VXT\.).0)]8.SART\N

Note - Jurisdictions in Canada may require these markings to also be provided in French language. It is the

responsibility of the manufacturer to provide bilingual marking, where applicable, in accordance with the

requirements of the Provincial Regulatory Authorities. It is the responsibility of the manufacturer to determine

this requirement and have bilingual wording added to the "Markings".

Automation Products Group, Inc.

APG...Providing tailored solutions for measurement applications

24

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

Page 25

Rev. A5, 1/14 LPU-2127

APG...Providing tailored solutions for measurement applications

Automation Products Group, Inc.

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

25

Page 26

LPU-2127 Rev. A5, 1/14

26

Automation Products Group, Inc.

APG...Providing tailored solutions for measurement applications

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

Page 27

PRODUCTS

AUTOMATION

Operator’s Manual

GROUP, INC.

APG...Providing tailored solutions for measurement applications

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • E-mail: sales@apgsensors.com

Automation Products Group, Inc.

Loading...

Loading...