Page 1

AUT OMATION

Operator’s Manual

PRODUCTS

GROUP, INC.

LOE-2126

LOE-3136

LOE-6126

Internet Enabled Ultrasonic Sensor

Rev. B, 1/12

Automation Products Group, Inc.

APG...Providing tailored solutions for measurement applications

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • E-mail: sales@apgsensors.com

Page 2

LOE Series Rev. B, 1/12

Table of Contents

Warranty......................................................................................... 3

Understanding Ultrasonics .......................................................... 4-5

Installa on ...................................................................................... 6

Powering the LOE ........................................................................... 7

Extended Network .......................................................................... 8

Sensor Setup (DHCP) ...................................................................... 9

Accessing the Internal Web Pages .................................................. 9

Network Se ngs .......................................................................... 10

Basic Parameters ..................................................................... 11-14

Trip Point Control .................................................................... 15-18

Confi guring Website Alarms ...................................................... 18

Applica on Parameters ........................................................... 19-24

Modbus Se ngs ...................................................................... 25-26

Using Level and Flow Website ................................................. 27-33

Se ng Website Alarms ........................................................ 28-31

Sensor Rest .............................................................................. 32-33

Specifi ca ons ................................................................................ 34

Dimensions ................................................................................... 35

Automation Products Group, Inc.

APG...Providing tailored solutions for measurement applications

2

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

Page 3

Rev. B, 1/12 LOE Series

Warranty and Warranty Restric ons

APG warrants its products to be free from defects of material and workmanship

and will, without charge, replace or repair any equipment found defec ve

upon inspec on at its factory, provided the equipment has been returned,

transporta on prepaid, within 24 months from date of shipment from factory.

THE FOREGOING WARRANTY IS IN LIEU OF AND EXCLUDES ALL OTHER

WARRANTIES NOT EXPRESSLY SET FORTH HEREIN, WHETHER EXPRESSED OR

IMPLIED BY OPERATION OF LAW OR OTHERWISE INCLUDING BUT NOT LIMITED

TO ANY IMPLIED WARRANTIES OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE.

No representa on or warranty, express or implied, made by any sales

representa ve, distributor, or other agent or representa ve of APG which is

not specifi cally set forth herein shall be binding upon APG. APG shall not be

liable for any incidental or consequen al damages, losses or expenses directly

or indirectly arising from the sale, handling, improper applica on or use of the

goods or from any other cause rela ng thereto and APG’s liability hereunder, in

any case, is expressly limited to the repair or replacement (at APG’s op on) of

goods.

Warranty is specifi cally at the factory. Any on site service will be provided at

the sole expense of the Purchaser at standard fi eld service rates.

All associated equipment must be protected by properly rated electronic/

electrical protec on devices. APG shall not be liable for any damage due

to improper engineering or installa on by the purchaser or third par es.

Proper installa on, opera on and maintenance of the product becomes the

responsibility of the user upon receipt of the product.

Returns and allowances must be authorized by APG in advance. APG will

assign a Return Material Authoriza on (RMA) number which must appear

on all related papers and the outside of the shipping carton. All returns are

subject to the fi nal review by APG. Returns are subject to restocking charges as

determined by APG’s “Credit Return Policy”.

Automation Products Group, Inc.

APG...Providing tailored solutions for measurement applications

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

3

Page 4

LOE Series Rev. B, 1/12

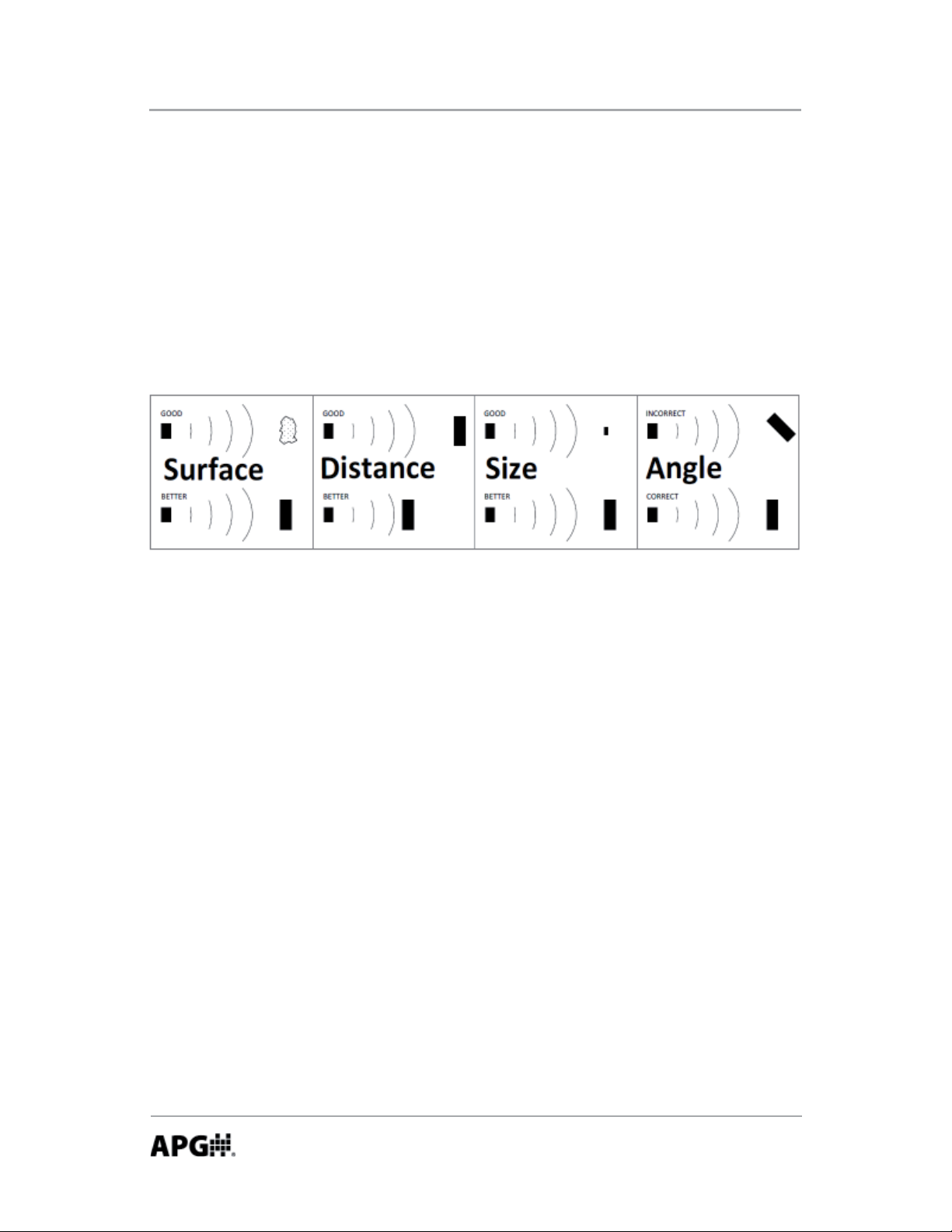

• Understanding Ultrasonics

Ultrasonic sensors use a transducer to transmit bursts of ultrasonic sound

waves. Each burst contains a series of pulsed sound waves that emit in the

shape of a cone, refl ect off the target, and are detected by the sensor. The me

required for the sound waves to travel to and from the target is converted into

a distance measurement by the sensor. Ultrasonic sensing is aff ected by several

factors including the target surface, distance, size, and angle. The following

considera ons will help ensure the best possible target condi ons.

Surface

The ideal target surface is hard and smooth. This type of surface will refl ect a

greater amount of signal than a so or uneven surface. Sound wave absorbent

materials, such as granules and powders, will reduce the opera ng range of the

sensor and decrease measurement accuracy.

Distance

Sound wave a enua on increases as the distance traveled increases.

Therefore, targets at longer ranges require be er refl ec ve characteris cs than

targets that are closer to the sensor.

Size

A large object will have a greater surface area to refl ect the signal than a

smaller one. Therefore, a large target will be detected at a greater distance

than a small target. The surface area recognized as the target will generally be

the por on closest to the sensor.

Automation Products Group, Inc.

APG...Providing tailored solutions for measurement applications

4

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

Page 5

Rev. B, 1/12 LOE Series

Angle

The inclina on of the object’s surface in rela on to the sensor face will aff ect

the strength of the refl ected sound waves. Surfaces perpendicular to the

sensor will refl ect more signal directly back to the sensor. If a surface is more

than a few degrees off perpendicular, enough of the signal will be refl ected

away from the sensor that the target will not be detected. Generally speaking,

a target angle greater than 5 degrees off perpendicular will not be detected.

The target angle becomes increasingly cri cal as the distance to the target

increases.

Environmental Condi ons

Temperature, humidity, vapors, dust, and pressure can aff ect the sensor’s

performance. APG ultrasonic sensors are designed to compensate for many of

these condi ons. However, if the condi ons are extreme, sensor performance

can be degraded enough to require the use of a longer-range sensor than

normal condi ons would require. Ultrasonic sensors may not be suitable for

applica ons with heavy chemical vapors (such as solvents or gasoline), heavy

dust or when signifi cant surface foam is present.

>Žǁ^ĞŶƐŝƟǀŝƚLJΘWƵůƐĞƐĞƚĞĐƟŽŶƌĞĂ ,ŝŐŚ^ĞŶƐŝƟǀŝƚLJΘWƵůƐĞƐĞƚĞĐƟŽŶƌĞĂ

.

8

f

f

7

t

f

t

.

6

f

t

.

5

.

4

f

t

.

f

3

2

f

f

t.

1

3

.

8

in

e

a

m

a

l

b

c

y

p

i

T

t.

in

7

.

6

.

e

a

d

s

p

r

t

.

in

1

1

.4

.

n

o

f

a

.

2

.

in

1

5

a

tr

u

l

1

9

s

e

n

ic

s

o

.

.

in

8

in

2

2

p

e

s

o

o

r

n

.

in

.6

.

2

6

g

a

a

t

in

r

t

.

3

m

t

3

4

n

.

i

0

.

4

m

u

im

a

x

Automation Products Group, Inc.

APG...Providing tailored solutions for measurement applications

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

t

.

1

0

f

t

.

9

.

2

in

s

e

f

9

°

.

.

3

8

in

t

g

.

in

s

e

t

it

iv

y

n

s

it

5

Page 6

LOE Series Rev. B, 1/12

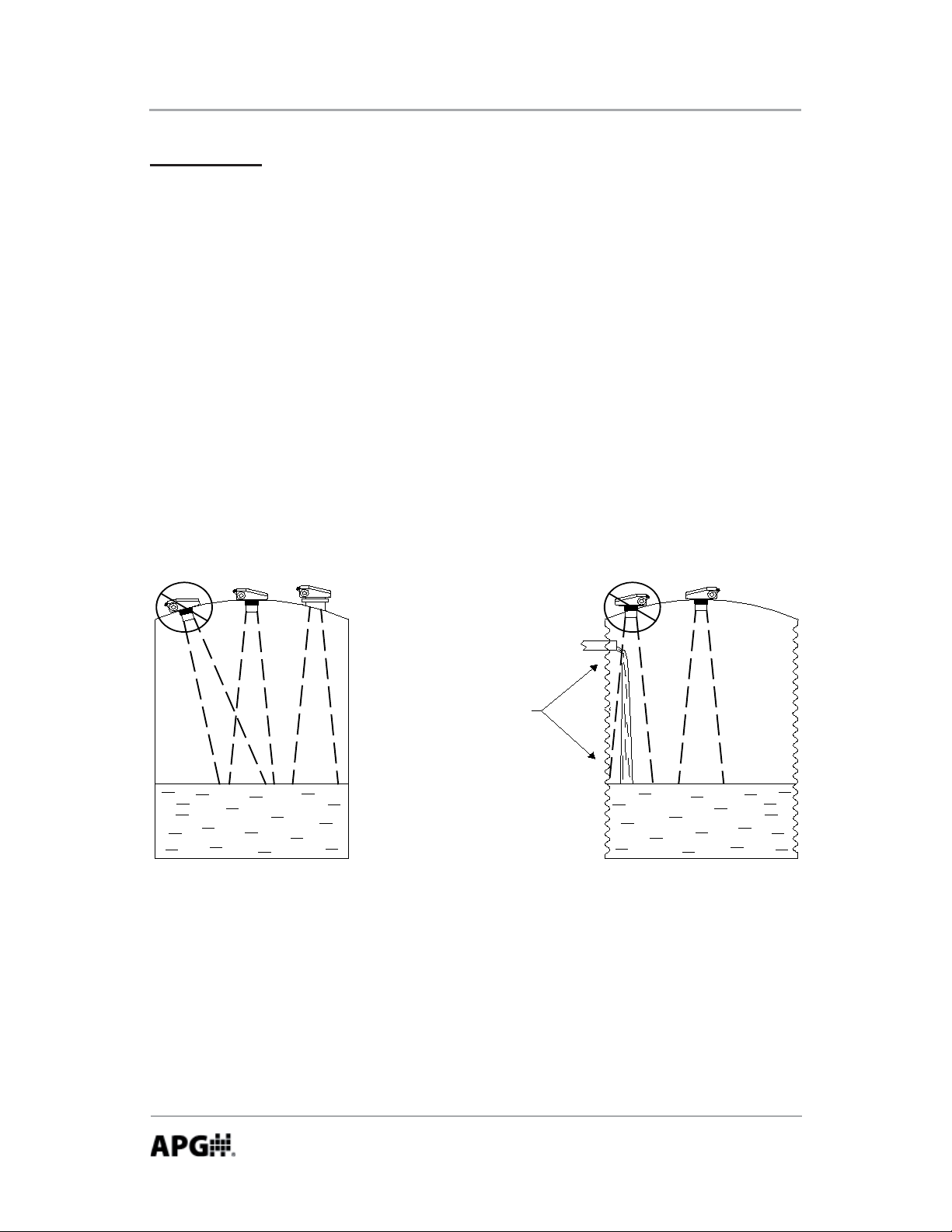

DO NOT mount the sensor

where the beam will intersect

objects such as fill streams,

pipes, ladder rungs, wall seams,

or corrugated tank walls.

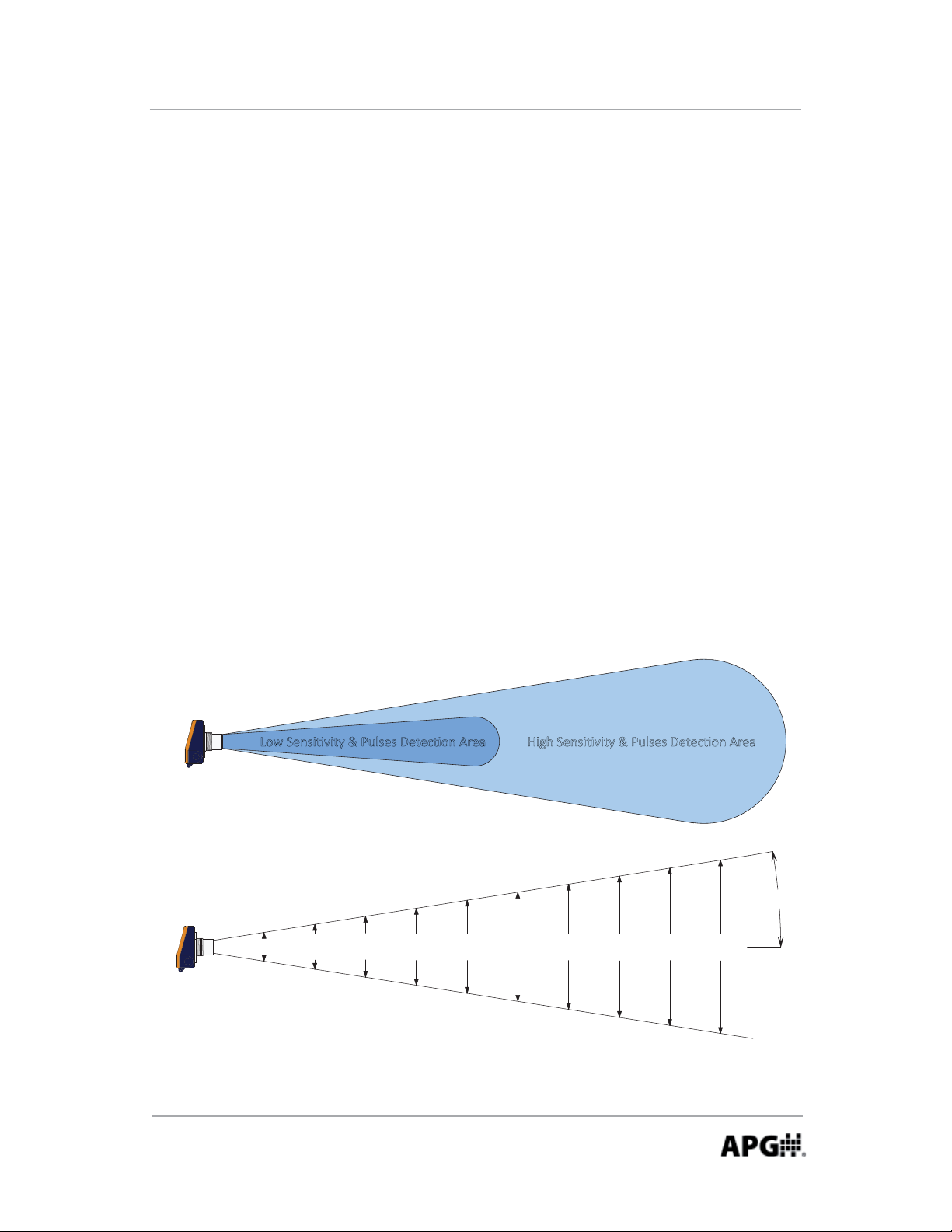

Installa on

The LOE must be mounted in a loca on with an unobstructed column of air to

the target. The beam-spread chart on the previous page can be used as a rough

guide to determine the required diameter of the air column for ranges of 10

feet or less. A 3 to 4 foot diameter air column is typically suffi cient even at the

maximum range of the sensor.

The sensor should be mounted to ensure the target does not come closer than

the minimum sensing range (blanking distance).

The sensor should be mounted so that the sensor face is perpendicular to the

target surface. Even just a few degrees off -perpendicular can cause a loss of

echo condi on. Proper alignment becomes increasingly important as the range

to the target increases.

Stand Pipe Moun ng

When using a stand pipe to raise the sensor above a tank, use a single seamless

piece of pipe to provide the sound waves a smooth path to propagate into the

tank. Because the sound waves becomes concentrated along the pipe walls,

even small sharp edges, such as seams or burs, can cause errant readings.

6

Automation Products Group, Inc.

APG...Providing tailored solutions for measurement applications

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

Page 7

Rev. B, 1/12 LOE Series

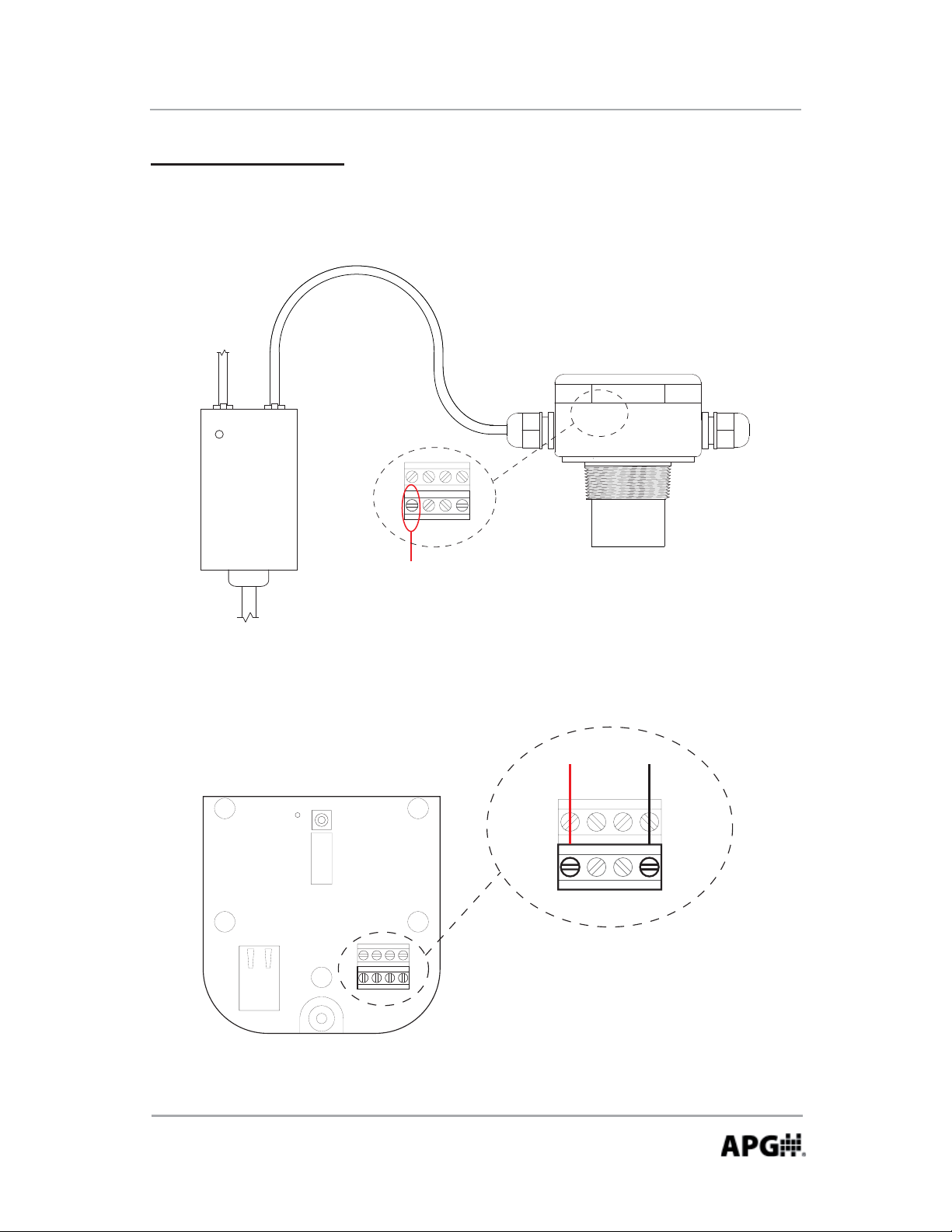

Powering the LOE

The LOE can be powered using a 48 V POE connec on or a standard 12-28 Vdc

power supply.

POE Wiring

To

Network

Connection

LAN + DCLAN

POWER

POE

Power

Injector

24V BAGND

RS-485

To A C

power

12-28 Vdc Power Supply Wiring

COM

OK

SEND/

RESET

24V B A GND

RS-485

Terminal inside housing

supplies 24 Vdc to power

attached Modbus devices

when powering the LOE

from a POE source.

To 12-28 Vdc Power Supply

+

24V BAGND

RS-485

-

Automation Products Group, Inc.

APG...Providing tailored solutions for measurement applications

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

7

Page 8

LOE Series Rev. B, 1/12

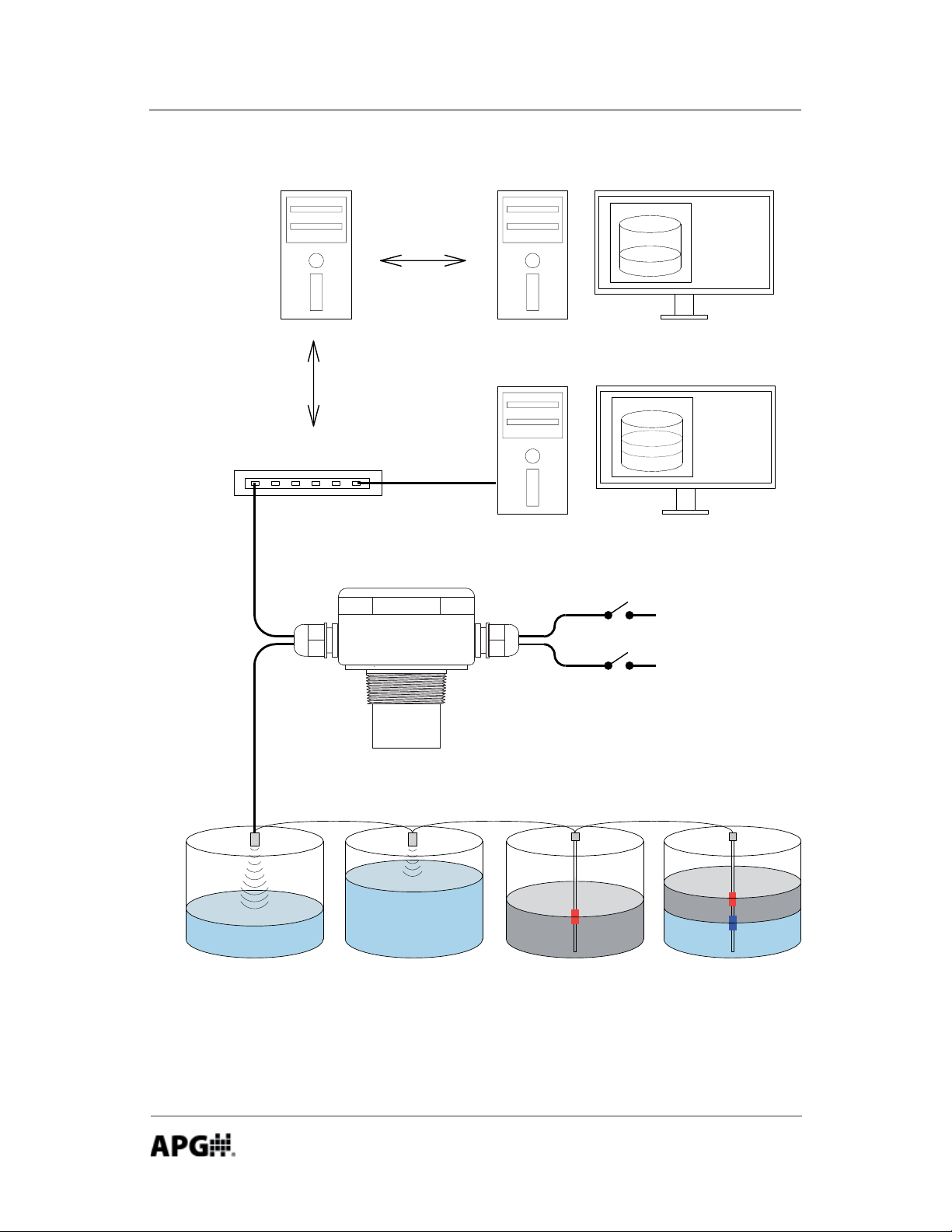

Extended Network

Server Hosting

Website and

Logged Data

Connection

to

Internet

Network / Internet Connection

Computer

on

Internet

Computer

on

Local

Network

Solid State Relays

Modbus Input

8

MNU Ultrasonic Sensors MP Magnetostrictive Float Level Sensors

Automation Products Group, Inc.

APG...Providing tailored solutions for measurement applications

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

Page 9

Rev. B, 1/12 LOE Series

Sensor Setup via DHCP (automa c IP confi gura on)

Connect the LOE to a network that provides access to the internet, and apply

power to the sensor. The COM LED should begin to fl ash once every 30

seconds, indica ng the DHCP is a emp ng to establish communica on with the

web site. Once communica on is established, the COM LED will illuminated.

NOTE: see Troubleshoo ng DHCP if COM LED con nues to fl ash from more than

2-3 minutes.

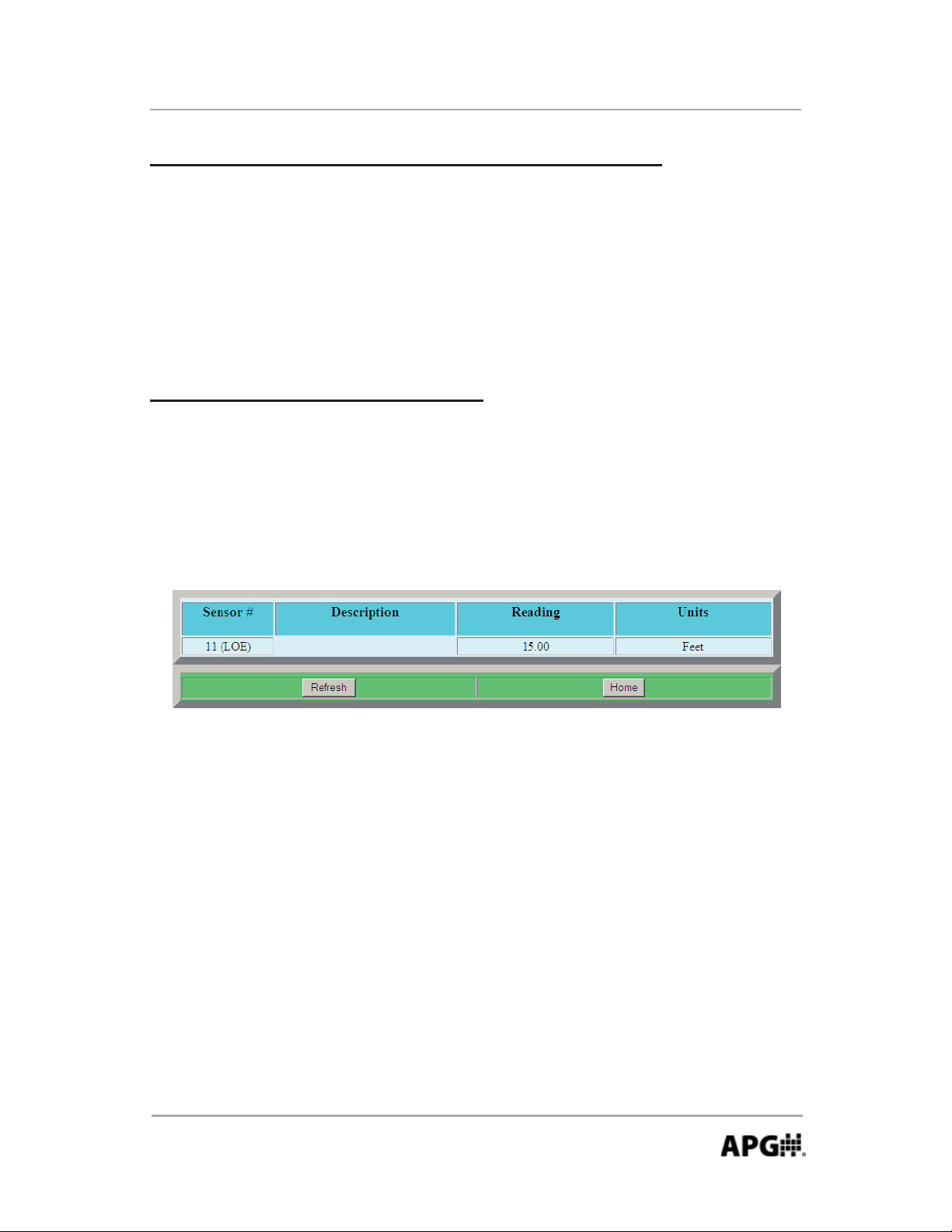

Accessing the Internal Web Pages

To access the sensor’s se ngs, open an Internet browser, and in the address

bar enter: loe_# where # is the sensor’s serial number beginning at the

fi rst whole number. For example if the serial number is L000001275, then

you would enter loe_1275 into the browser address bar. The following screen

should appear:

NOTE: if typing the loe_# does not work, it may indicate the DHCP has saved

a previous name for the IP assigned. Power down the sensor and have the

System Administrator delete this name from the DHCP server.

Next, click the “Home” bu on and use the following default login when

prompted:

Username: admin Password: password

NOTE: use the Security link on the main page to set the desired Username

and Password.

Automation Products Group, Inc.

APG...Providing tailored solutions for measurement applications

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

9

Page 10

LOE Series Rev. B, 1/12

Chick the “Home” bu on again to enter the main page. The sensor parameters

are described in the ensuing pages.

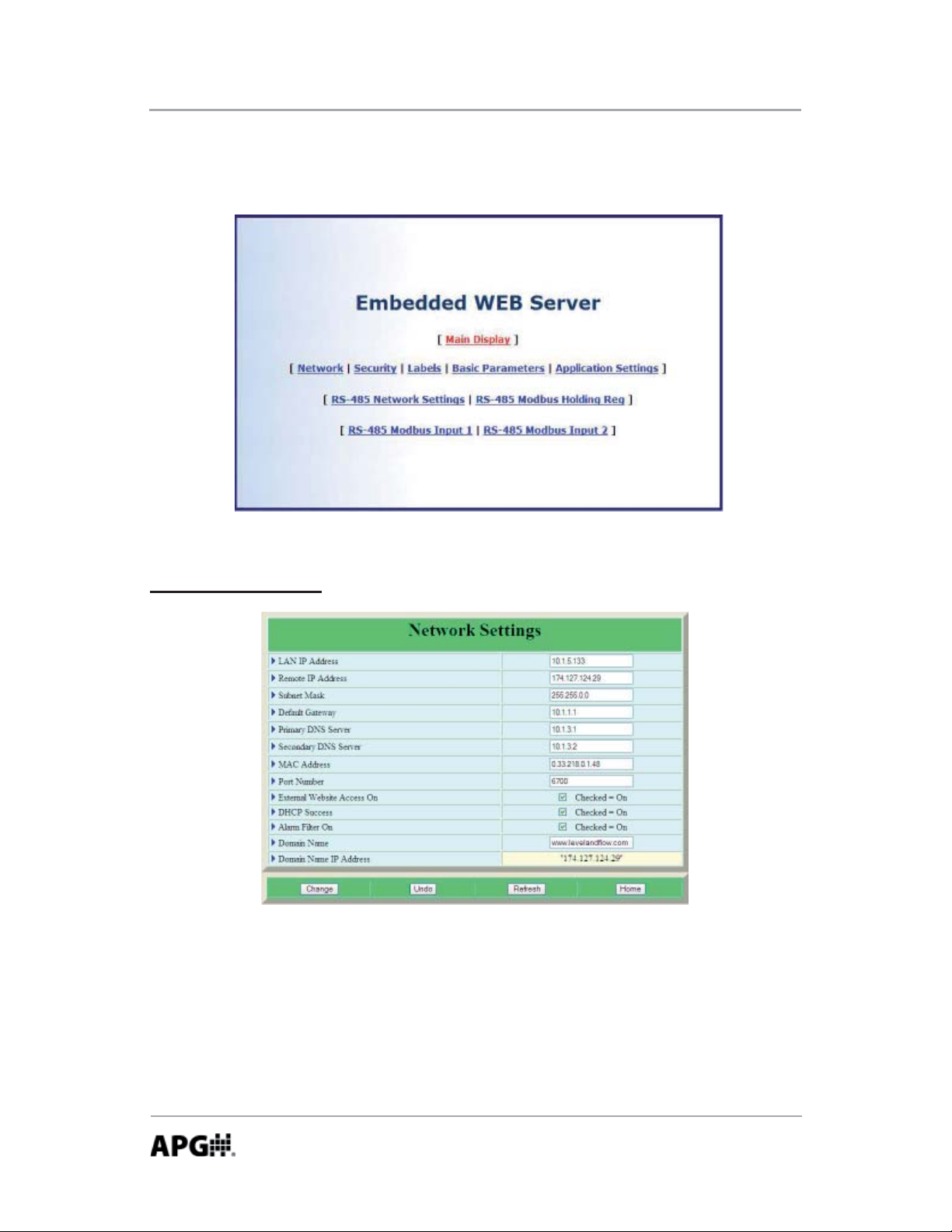

Network Se ngs

The Network Se ngs are provided for advanced users only and shouldn’t nor-

mally require changes. The LOE comes defaulted with DHCP enabled, meaning

the sensor only requires access to internet and it will automa cally connect to

the www.levelandfl ow.com website and confi gure its own Network Se ngs.

NOTE: refer to page

APG...Providing tailored solutions for measurement applications

10

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

18 for a descrip on of the Alarm Filter func on.

Automation Products Group, Inc.

Page 11

Rev. B, 1/12 LOE Series

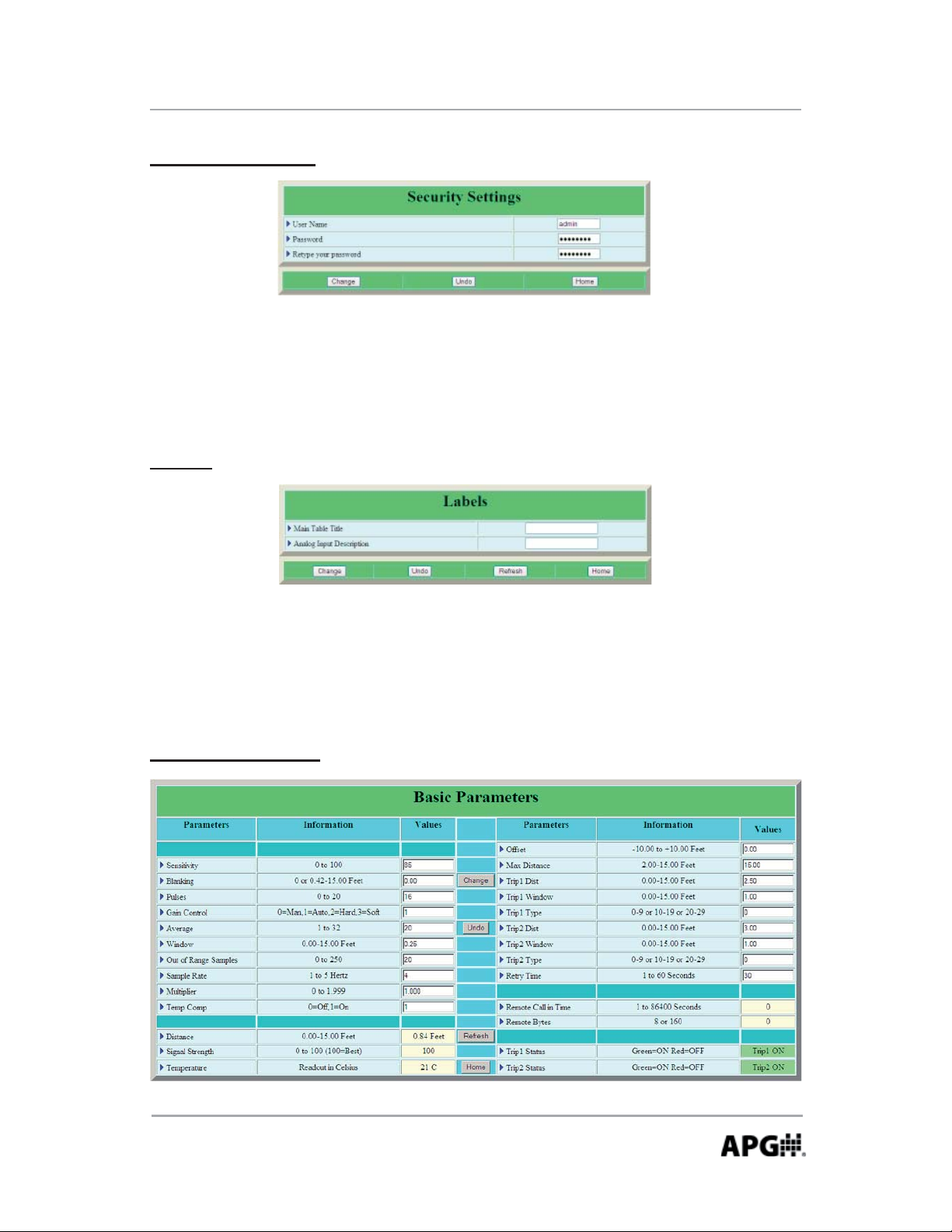

Security Se ngs

The Security Se ngs allow the user to set the username and password required

to access the sensor se ngs. The default Username is admin and the Password

is password.

Labels

Allows the user to assign custom labels to the Main Display. Labels apply only

to the internal webpage--labels on the www.levelandfl ow.com website must be

set through the website.

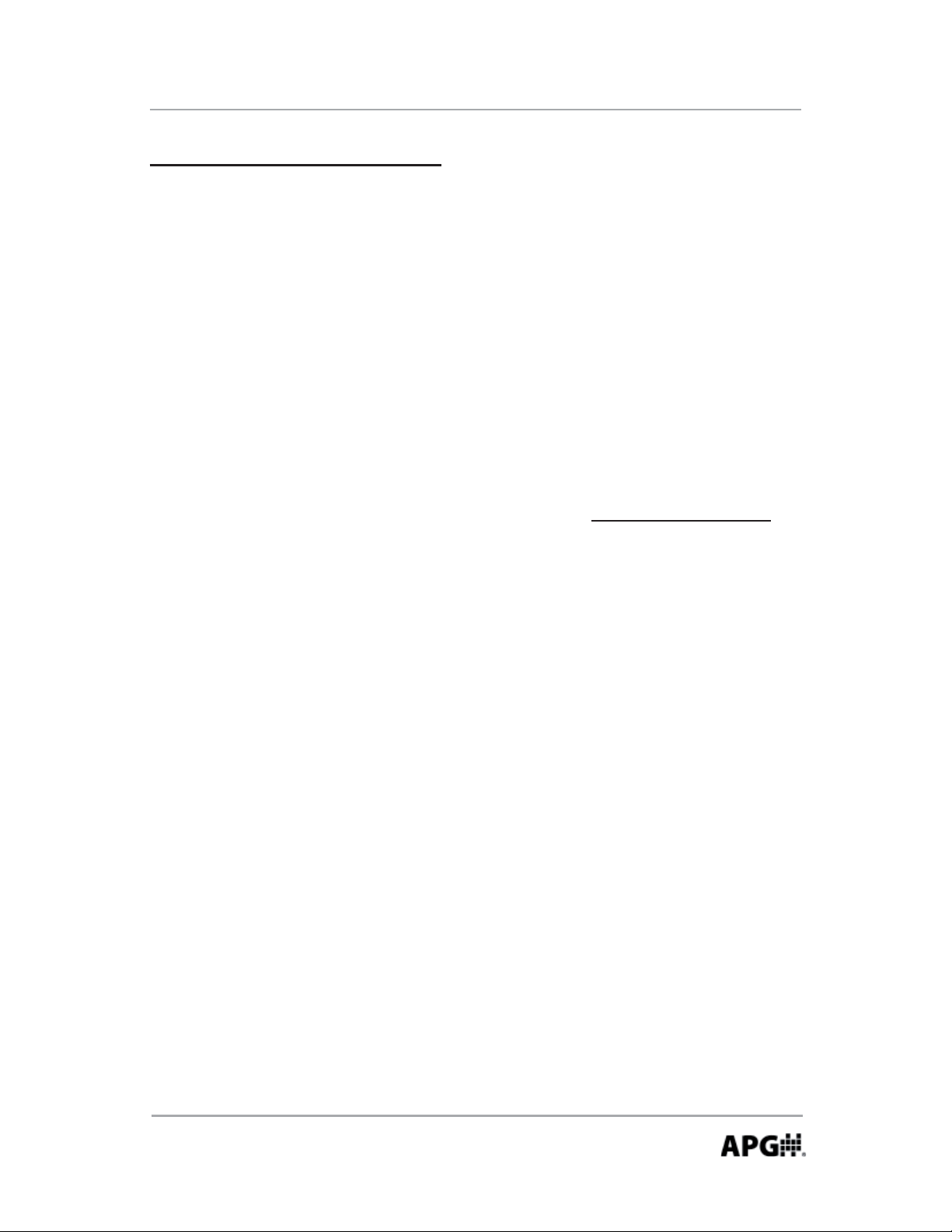

Basic Parameters

Automation Products Group, Inc.

APG...Providing tailored solutions for measurement applications

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

11

Page 12

LOE Series Rev. B, 1/12

Basic Parameters (con nued)

Sensi vity

Controls the level of amplifi ca on applied to the target signal. The sensi vity

se ng is expressed as a percentage; 0 to 100%. When opera ng in Autosense

mode, the Sensi vity se ng acts as an upper limit constraint (see Gain Control

for details).

Blanking

Sets the distance, beginning at the sensor face, to the point where the sensor

will begin looking for target signals. All targets closer than the blanking distance

will be ignored. The blanking should never be set to less than the minimum

range specifi ca on of the sensor. If the target enters the blanking area, errant

readings will occur.

NOTE: the LOE-6126 has the ability to track a target to as close as 1” from

the sensor face. This feature is limited to targets that will remain perfectly

perpendicular to the sensor face.

Control to 1 (Autosense) and then se ng the Blanking to 0.

This feature is enabled by se ng the Gain

Pulses

Controls the number of sound wave pulses being sent in each ultrasonic

burst. The greater the number of pulses, the stronger the transmi ed signal.

When opera ng in Autosense mode, the Pulses se ng acts as an upper limit

constraint (see Gain Control for details).

Gain Control (0, 1, 2, 3)

Determines the method in which gain is applied to returning target signals. In

Manual mode, the Sensi vity and Pules se ngs are applied as a sta c values.

In Autosense Mode, the sensor self-adjusts the Pulses and Sensi vity levels

(within the bounds of their respec ve se ngs) in order to op mize the signal

strength.

0 = Manual Mode (sta c Sensi vity & Pulses values)

1 = Autosense (auto-adjus ng Sensi vity & Pulses values)

2 = Hard-Target (increases gain slowly as distance increases)

3 = So -Target (increases gain quickly as distance increase)

12

Automation Products Group, Inc.

APG...Providing tailored solutions for measurement applications

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

Page 13

Rev. B, 1/12 LOE Series

Basic Parameters (con nued)

Averaging

Defi nes the number of target readings that will be averaged together. Each

qualifi ed sample (see Filter Window and Out of Range Samples below) is placed

into a fi rst-in, fi rst-out (FIFO) buff er and averaged with previous samples to gen-

erate a steady output. A higher Averaging se ng will result in smoother read-

ings, but will also result in slower the response me to rapid target changes.

Window

Sets the width of the target acceptance window. The target acceptance

window is a zone, centered around the current target reading, within which

any target detected will be considered legi mate and fi gured into the averaging

buff er. Any target detected outside of the Window will be considered “out of

range” and will be ignored based on the se ng in the Out of Range Samples

parameter (see below). The Filter Window extends both direc ons, both closer

than and further away from, the current target reading. For example, if the

sensor is detec ng a target at 5 . and the Filter Window is set at 1 ., then any

target detected between 4 . and 6 . will be accepted.

Out of Range Samples

Determines the number of consecu ve target readings that must fall outside

of the acceptance window before the “out of range” target is recognized and

included in the averaging buff er. For example, suppose the Out Of Range

Samples is set to 10. If a target is suddenly detected outside of the acceptance

window, it will be ignored un l it has been detected for 10 consecu ve samples,

at which point it will be qualifi ed as a legi mate target. If the “out of range”

target was detected for only 9 consecu ve samples before moving out of the

sensing area, it would never be acknowledged as a target and the reading

would stay with the last qualifi ed target sample.

Sample Rate

Sets the interval between target readings. Op ons allow rates from once per

second (1 Hz) to 5 mes per second (5 Hz). It is highly recommended that the

Sample Rate be set only as fast as is necessary for the applica on.

Automation Products Group, Inc.

APG...Providing tailored solutions for measurement applications

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

13

Page 14

LOE Series Rev. B, 1/12

Basic Parameters (con nued)

Mul plier

Sets the conversion Mul plier that will be applied to the sensor readings. The

default is 1.000 (see note below) and typically does not need to be adjusted.

However, since the speed of sound is not constant through all environments,

the mul plier parameter allows the user to adjust for varia ons in atmosphere

when maximum accuracy is required.

Temperature Compensa on (0 = Off , 1 = On)

Used to enable or disable the internal temperature compensa on of the sen-

sor. Enabling the internal temperature compensa on can reduce the eff ects of

temperature changes by 50% or more, depending on the temperature gradient

through the sensing range.

Off set

Used to adjust the zero reference point of the sensor. When the Off set is set to

0, the zero reference of the sensor is at the face of the transducer. Se ng the

Off set to a nega ve number will move the zero reference backward (behind the

sensor face), while a posi ve se ng will move the reference forward (in front

of the sensor face).

Maximum Distance

Sets the distance (beginning from the sensor face) to the point where the sensor will stop looking for target signals. Targets detected beyond the Maximum

Distance value will be ignored by the sensor.

Automation Products Group, Inc.

APG...Providing tailored solutions for measurement applications

14

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

Page 15

Rev. B, 1/12 LOE Series

Trip Point Relay Control

The standard version of the LOE comes equipped with two solid-state relay

outputs (trip points), which can be programmed to perform one of several

logic func ons. In addi on, the LOE can be confi gured to ini ate immediate

email and/or text message alerts whenever either of the trip relays ac vates or

deac vates (see Immediate Website Alarms for more informa on).

NOTE: all Trip Point distance values are referenced from the face of the

sensor, regardless of the type of calculated reading being performed by the

sensor (level, volume, etc.). Refer to Trip Type chart for more informa on.

Trip Distance: sets the distance from the sensor face to the closest ac on point

(refer to Trip Type chart).

Trip Window: sets the distance, beginning from the Trip Distance loca on, to

the farthest ac on point (refer to Trip Type chart).

Trip Type: determines the type of opera onal logic performed by the trip point

relay (see descrip ons below and refer to the Trip Type chart).

Type 0 (Near): ac vates the relay when a target is closer than the Trip

Distance. The Trip Window is not used with Trip Type 0.

Type 1 (Exclusive): ac vates the relay when a target is closer than the Trip

Distance or farther than the Trip Distance + the Trip Window.

Type 2 (Hysteresis Near): When the target comes closer than the Trip

Distance, the relay will ac vate and remain on un l the target moves

beyond the Trip Distance + Trip Window. The relay will then deac vate and

remain off un l the target once again comes closer than the Trip Distance.

Used for emptying control or high alarm with hysteresis to prevent cha er.

Type 3 (Far): ac vates the relay when the target is beyond the Trip Distance.

The Trip Window is not used with Trip Type 3.

Automation Products Group, Inc.

APG...Providing tailored solutions for measurement applications

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

15

Page 16

LOE Series Rev. B, 1/12

Trip Point Relay Control (con nued)

Type 4 (Inclusive): ac vates when the target is within the trip window. This

can be used for various presence detec on applica on.

Type 5 (Hysteresis Far): When the target moves beyond the Trip Distance

+ Trip Window, the relay will ac vate and remain on un l the target moves

closer than the Trip Distance. The relay will then deac vate and remain off

un l the target once again moves beyond the Trip Distance + Trip Window.

Used for fi lling control or low alarm with hysteresis to prevent cha er.

Type 6: Disables the trip point relay.

Type 7 (Loss of Echo): the relay will ac vate if the sensor enters a loss of

echo condi on (no targets detected).

Type 8 (Timed Relay): sets the relay to ac vate at a specifi ed interval. The

Trip Distance parameter sets the me interval between relay ac va ons (in

minutes), and the Trip Window determine how long the relay remains ac ve

at each interval (in seconds).

Type 9 (Rate of Change): allows the user to defi ne a maximum rate of

change (distance over me), which if exceeded will ac vate the relay. The

Trip Distance parameter is used to defi ne the me value, and the Trip

Window parameter is used to defi ne the distance value.

Retry Time

Sets the delay between a empts to connect to the Website a er a failed

connec on. The Retry Time is also used to set the delay before repor ng trip

alarms to the website. Refer to Alarm Filter .

16

Automation Products Group, Inc.

APG...Providing tailored solutions for measurement applications

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

Page 17

Rev. B, 1/12 LOE Series

Trip Type Chart

Trip Typ e 0

(near)

Trip Typ e 1

(exclusive)

Trip Type 2

(hysteresis near)

Trip

Distance

ON

(closed)

ON

(closed)

ON

(closed)

Trip

Window

OFF

(open)

OFF

(open)

ON

(closed)

OFF

(open)

ON

(closed)

OFF

(open)

OFF

(open)

ON

(closed)

Trip Typ e 3

(far)

OFF

(open)

ON

(closed)

OFF

(open)

Trip Typ e 4

(inclusive)

ON

OFF

(open)

Trip Type 5

(hysteresis far)

(closed)

OFF

(open)

ON

(closed)

Automation Products Group, Inc.

APG...Providing tailored solutions for measurement applications

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

17

Page 18

LOE Series Rev. B, 1/12

Website Alarms: the LOE’s trip relay outputs can be confi gured to report to the

levelandfl ow.com website whenever an alarm condi on is detected, regardless

of the sensors fi xed call-in interval. An Immediate alarm can then be setup on

the website to ini ate email and/or text message alerts whenever an alarm is

reported (see using the levelandfl ow website for more informa on).

NOTE: Immediate website alarms are subject to the Retry Time delay (30 to

180 second) as set in the LOE’s Basic Parameters page. Addi onal delays may

occur in establishing a connec on to the website, depending on the speed

and quality of the local internet connec on.

Confi guring the LOE for Website Alarms:

Placing a “1” in front of any of the Trip Types designates a closed or ac ve

output as an alarm condi on. For example; Trip Type 3 would be designated

as 13, and would send out an immediate alarm whenever the trip relay is

ac ve (closed).

Placing a “2” in front of any of the Trip Types designates an open or inac ve

output as an alarm condi on. For Example; Trip Type 3 would be designated

as 23, and would immediately report an alarm whenever the trip relay is

inac ve (open).

Alarm Filter: (located in the LOE’s Network Se ngs page) enabling the Alarm

Filtering op on can help prevent nuisance email and/or text message alerts

from being sent. If Alarm Filtering is enabled, all alarms condi ons that clear

before the Retry Time delay expires will not be reported to the website, and no

alert messages will be sent. If Alarm Filtering is disabled, all trip alarms will be

reported to the website (and alert messages sent), even if the alarm condi on

has cleared when the Retry Time expires.

18

Automation Products Group, Inc.

APG...Providing tailored solutions for measurement applications

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

Page 19

Rev. B, 1/12 LOE Series

Applica on Parameters

Full Distance

Sets the distance (beginning from the sensor face) to the point where the tank

is considered full. Typically set to the Blanking Distance (see Basic Parameters).

Empty Distance

Sets the distance (beginning from the sensor face) to the point where tank is

considered empty. This will typically be the same as the tank depth unless the

sensor is mounted on a stand pipe.

Applica on Type

Determines the type of calculated measurement the sensor will perform. The

LOE can measure the distance to the target, the depth of a level, or one of several volumetric calcula ons (refer to pages 13-21).

Automation Products Group, Inc.

APG...Providing tailored solutions for measurement applications

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

19

Page 20

LOE Series Rev. B, 1/12

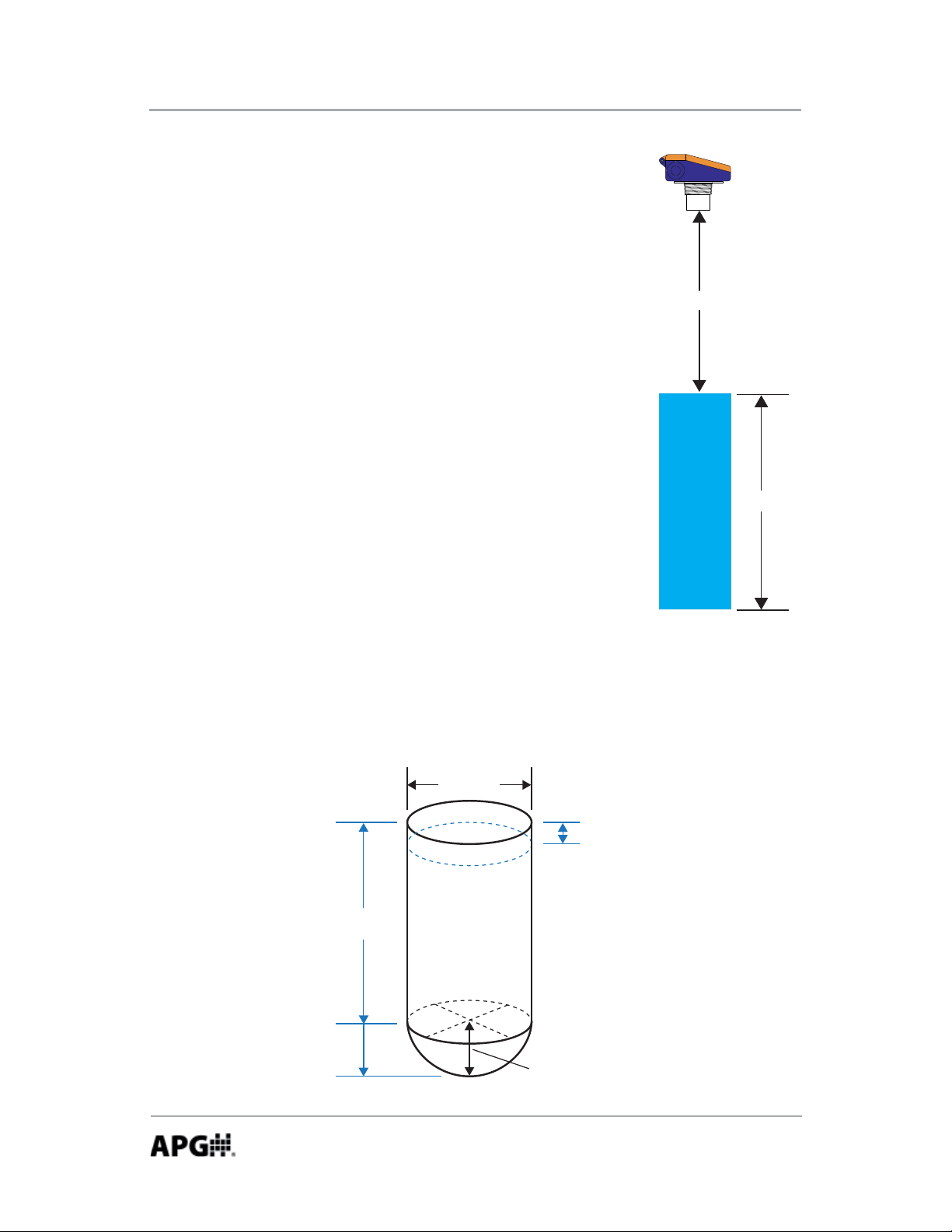

0 = Distance (factory default): measures the distance from

the face of the sensor to the target surface. Required

parameter se ngs: Units

Distance

1 = Level: subtracts the measured target distance from

the user defi ned Empty Distance to provide a depth of

level measurement. Required parameter se ngs: Units,

Full Distance, Empty Distance.

Level

2 = Standing Cylindrical Tank with Hemispherical Bo om

Enter all dimensions shown below into the Tank Parameter fi elds and select the

desired Volume Units.

Diameter

Full

Distance

Empty

Distance

or

ŽƩŽŵ

Radius

20

Automation Products Group, Inc.

APG...Providing tailored solutions for measurement applications

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

Page 21

Rev. B, 1/12 LOE Series

3 = Standing Cylindrical Tank with Conical Bo om

Enter all dimensions shown below into the Tank Parameter fi elds and select the

desired Volume Units.

Diameter

Full

Distance

Empty

Distance

Cone

Length

Cone

Diameter

4 = Standing Rectangular Tank with Chute

Enter all dimensions shown below into the Tank Parameter fi elds and select the

desired Volume Units.

Full

Distance

Empty

Distance

or

Tank X

Tank Y

Chute

Length

Chute Y

Chute X

Automation Products Group, Inc.

APG...Providing tailored solutions for measurement applications

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

21

Page 22

LOE Series Rev. B, 1/12

5 = Horizontal Cylindrical Tank with Spherical Ends

Enter all dimensions shown below into the Tank Parameter fi elds and select the

desired Volume Units.

Full

Distance

Diameter

End

Radius

Length

Empty

Distance

6 = Spherical Tank

Enter all dimensions shown below into the Tank Parameter fi elds and select the

desired Volume Units.

Full

Distance

Empty

Distance

Diameter

7 = Pounds: allows the user to apply a conversion mul plier to the calculated

level reading. The conversion Mul plier is entered in Tank Parameter 1.

Example: suppose the level depth is calculated to be 5.45 feet (based on

the Empty Distance se ng). If the conversion Mul plier is set to 7.150, the

calculated result would be (7.15 x 5.45) 38.968.

Automation Products Group, Inc.

APG...Providing tailored solutions for measurement applications

22

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

Page 23

Rev. B, 1/12 LOE Series

9 = Ver cal Oval Tank

Enter all dimensions shown below into the Tank Parameter fi elds and select the

desired Volume Units.

Full

Distance

Empty

Distance

Width

Depth

Length

10 = Horizontal Oval Tank

Enter all dimensions shown below into the Tank Parameter fi elds and select the

desired Volume Units.

Full

Distance

Empty

Distance

Depth

Length

Width

Automation Products Group, Inc.

APG...Providing tailored solutions for measurement applications

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

23

Page 24

LOE Series Rev. B, 1/12

Volume Units: selects the unit of measure for the volumetric Applica on

Types (types 2-6, 9, 10).

1 = Feet^3

2 = Million feet^3

3 = Gallons

4 = Meters^3

5 = Liters

Tank Parameters: used to enter tank dimensions or the conversion mul plier,

depending on the Applica on Type selected (see Applica on Types for more

informa on).

NOTE: the Tank Parameter labels will automa cally change to refl ect the

parameters required for the Applica on Type selected.

Units: selects the Units of measurement for the distance or level Applica on

Type (types 0 or 1), and sets the Units of measure to be used for all parameters

requiring dimensional value.

1 = Feet

2 = Inches

3 = Meters

24

Automation Products Group, Inc.

APG...Providing tailored solutions for measurement applications

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

Page 25

Rev. B, 1/12 LOE Series

Modbus

The LOE has the capability to interface with up to 10 of APG’s Modbus based

sensors. The LOE acts as the Master device, querying the Modbus sensors and

repor ng their readings to the website along with the LOE’s own readings.

NOTE: each Modbus sensor will show up on the website as a sub-sensor to

it’s LOE master. For example, if the LOE’s serial number is L00001219, then

Modbus sensor 1 would be displayed as L00001219_1 and so forth.

RS-485 Modbus Input 1 & 2

These pages are used to confi gure the parameters of Modbus sensor currently

selected (see “Sensor Number to View” under “RS_485 Network Se ngs”

page). Not all parameters are applicable to every Modbus sensor. Refer to the

Modbus sensor’s user manual for parameter descrip ons.

RS-485 Modbus Holding Registers

This page is available to view the readings of the Modbus sensor that is currently selected.

Modbus TCP/IP

Using the LOE’s IP address and port number 502, the LOE’s readings can be

polled at address number 11 on registers 30303-30304.

Example:

0001: Transac on Iden fi er

0000: Protocol Iden fi er

0006: Message Length (6 bytes to follow)

0B: The Unit Iden fi er (0B hex = 11)

04: The Func on Code (read Holding Registers)

012E: The Data Address of the fi rst register requested. (12E hex = 303)

0002: The total number of registers requested. (read 2 registers; 303 to 304)

Byte order (hex values)

00 01 00 00 00 06 0B 04 01 2E 00 02

Automation Products Group, Inc.

APG...Providing tailored solutions for measurement applications

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

25

Page 26

LOE Series Rev. B, 1/12

RS-485 Se ngs

Baud Se ngs: selects the communica on baud rate between the LOE and the

a ached Modbus sensors. Refer to the Modbus sensor’s documenta on for

the appropriate se ng (typically 9600 Baud).

Number of Sensors On Line: sets the number of Modbus sensors that are connected to the LOE.

Sensor Number to View: used to select the sensor number to be viewed or

programmed (also see “New Sensor Number” below). The parameters of the

selected sensor will populate the RS-485 Modbus Input pages, and the sensor’s

readings can be viewed in the RS-485 Holding Register page.

New Sensor Number: used to change the sensor number of the sensor currently being viewed (see “Sensor Number to View” above). Each Modbus sensor connected to the LOE must be assigned a unique sensor number (0 to 10).

Duplicate sensor numbers will cause errors in communica on.

Delay Between Call-in Times: sets the delay between cycles of querying all attached Modbus sensors.

26

Automation Products Group, Inc.

APG...Providing tailored solutions for measurement applications

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

Page 27

Rev. B, 1/12 LOE Series

Using the levelandfl ow.com website

APG’s www.levelandfl ow.com website provides access to sensor readings, as

well as the capability to setup email/text-message alerts and remotely adjust

sensor parameters (dependent on assigned user access rights).

General Naviga on

Sites Tab: Displays the list of sites assigned to the user.

Click on a site box to view the list of the sensors that are assigned to that site.

Click on an individual sensor to access the readings data as well as to adjust

sensor parameters (for those with access rights).

Profi le Tab: allows the user to manage their profi le.

NOTE: the La tude, Longitude and Zoom se ng are for se ng your default

view when entering the Google Maps feature. Simply click the Set bu on,

fi nd your loca on on the map and click on the loca on to set a marker.

Ensure the zoom at the desired level and click the “Set User’s Google map

start loca on” bu on to save the loca on.

Data Logging and Retrieval

Begin Date and End Date: Used to set the me period for the data to be

retrieved.

Chart: Retrieves the data in the form of a line chart.

Excel: Retrieves the data as an Microso Excel fi le.

View Data: Retrieves a list of sensor readings along with the associated me

stamp.

Alarm History: displays a list of alarms that have previously occured.

View Parameters: displays a list of all sensor parameters as of the last me the

sensor logged into the website.

Automation Products Group, Inc.

APG...Providing tailored solutions for measurement applications

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

27

Page 28

LOE Series Rev. B, 1/12

Sensor Se ngs

Edit Info: allows the user to assign descrip on tags, set me zone informa on,

and set a sensor loca on on the Google Maps feature.

Se ng the Sensor Google Maps Loca ons: click on the “Edit Info” bu on and

then click the “Set” bu on, fi nd the sensor’s loca on on the map and click on

it’s loca on to set a marker. Ensure the zoom at the desired level and click

the “Set sensors Google map loca on” bu on to save the loca on.

Edit Parameters: allows users (with access rights) to adjustment sensor

parameters.

NOTE: parameter changes made from the website will only take eff ect a er

the LOE reports to the website at the next scheduled call-in interval.

Edit Alarms: allows users (with access rights) to add alarms to send email or

text message alerts whenever an alarm condi on occurs and when the alarm

condi on clears (see website “Se ng Website Alarms” sec on below).

Website Alarms

There are three diff erent types of website alarms: Immediate, Interval, and

Heartbeat. Refer to descrip ons below.

Immediate Alarms: results from an alarm condi on on one of the LOE’s solid

state relays (Trip 1 & Trip 2). If one of the trip relays enters an alarm condi on,

the LOE will report the alarm to the website without wai ng for the next

scheduled call-in interval.

NOTE: in addi on to se ng an alarm on the website, the LOE’s trip relays

must also be confi gured for website alarming. See “Confi guring the LOE for

Website Alarms” on page X for details.

28

Automation Products Group, Inc.

APG...Providing tailored solutions for measurement applications

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

Page 29

Rev. B, 1/12 LOE Series

Interval Alarms: alarm condi on is based solely on the sensor readings as

reported at the scheduled call-in interval. i.e. the alarm is a func on of the

website and is not generated by the sensor itself.

Heartbeat Alarm: once every 4 hours the website checks the call-in status of all

sensors that have been assigned a heartbeat alarm. If the LOE missed the last

scheduled login, an alert message would then be sent to no fy the user(s) that

the sensor is not reported to the website.

Immediate Alarm Se ngs

NOTE: the trip relay(s) must be confi gured for website alarming. See

“Confi guring the LOE for website alarms” on page

Label: sets the alarm label that will be included in the alert message tle.

X for details.

Message: allows the user to enter a brief message that will be included in the

body of the email or text alert message.

Call Type: selects the type of alert message to be sent. If “None” is selected,

the alarm condi on will show on the website but no message will be sent.

Sent: (view only) shows the status of the Delay count (see Delay below).

Delay: sets the number of mes the alarm must ac vate before an alarm

message will be sent. Se ng the Delay to 0 will disable the alarm.

Auto Clear: when checked, the Delay count will reset to 0 and begin again at

the end of each cycle, resul ng in a new alert message each me the Delay

count is reached. If Auto Clear is unchecked, the alert message will be sent

when the Delay count is reached, but no further messages will be sent unless

the alarm condi on clears and then reac vates and is processed though the

Delay count fi lter. If the alarm condi on clears and Auto Clear is unchecked, an

“Alarm Clear” message will be sent to the contact.

Contact: selects the user to receive the alert message (based the email address

and/or cell phone number in their user profi le).

Automation Products Group, Inc.

APG...Providing tailored solutions for measurement applications

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

29

Page 30

LOE Series Rev. B, 1/12

Interval Alarm Se ngs

Label: sets the alarm label that will be included in the alert message tle.

Message: allows the user to enter a brief message that will be included in the

body of the email or text alert message.

Call Type: selects the type of alert message to be sent. If “None” is selected,

the alarm condi on will show on the website but no message will be sent.

Alarm Point: defi nes the value (in the unit of measure of the sensor reading)

for the alarm condi on. If the box below is checked, the alarm condi on will

occur whenever the sensor reading is greater than the Alarm Point value. If

le unchecked, the alarm condi on will be whenever the sensor reading is less

than the Alarm Point value.

Off set Clear: sets an off set, star ng from the Alarm Point and extending away

from the alarm zone, that must be reached before the alarm condi on will

clear. This is to prevent repeated alarm cha er if the target is fl uctua ng back

and forth across the Alarm Point.

Sent: (view only) shows the status of the Delay count (see Delay below).

Delay: sets the number of mes the alarm must ac vate before an alarm

message will be sent. Se ng the Delay to 0 will disable the alarm.

Auto Clear: when checked, the Delay count will reset to 0 and begin again at

the end of each cycle, resul ng in a new alert message each me the Delay

count is reached. If Auto Clear is unchecked, the alert message will be sent

when the Delay count is reached, but no further messages will be sent unless

the alarm condi on clears and then reac vates and is processed though the

Delay count fi lter. If the alarm condi on clears and Auto Clear is unchecked, an

“Alarm Clear” message will be sent to the contact.

Contact: selects the user to receive the alert message (based the email address

and/or cell phone number in their user profi le).

Automation Products Group, Inc.

APG...Providing tailored solutions for measurement applications

30

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

Page 31

Rev. B, 1/12 LOE Series

Heartbeat Alarm Se ngs

Label: sets the alarm label that will be included in the alert message tle.

Message: allows the user to enter a brief message that will be included in the

body of the email or text alert message.

Call Type: selects the type of alert message to be sent. If “None” is selected,

the alarm condi on will show on the website but no message will be sent.

Sent: (view only) shows the status of the Delay count (see Delay below).

Delay: sets the number of mes the alarm must ac vate before an alarm

message will be sent. Se ng the Delay to 0 will disable the alarm.

Auto Clear: when checked, the Delay count will reset to 0 and begin again at

the end of each cycle, resul ng in a new alert message each me the Delay

count is reached. If Auto Clear is unchecked, the alert message will be sent

when the Delay count is reached, but no further messages will be sent unless

the alarm condi on clears and then reac vates and is processed though the

Delay count fi lter. If the alarm condi on clears and Auto Clear is unchecked, an

“Alarm Clear” message will be sent to the contact.

Contact: selects the user to receive the alert message (based the email address

and/or cell phone number in their user profi le).

Adding a new contact to an exis ng alarm

If more than one contact needs to receive an email and/or text message alert, a

duplicate alarm must be added and assigned to the new contact. Simply select

the alarm you wish to duplicate, click on the “Copy” bu on, select the new

“Contact”, and click the “Add” bu on.

Automation Products Group, Inc.

APG...Providing tailored solutions for measurement applications

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

31

Page 32

LOE Series Rev. B, 1/12

Sensor Reset

Cau on! Performing the following procedure will reset all Network se ngs,

including disabling the DHCP. A crossover Ethernet cable will be required to

access the LOE’s internal webpage and re-enable the DHCP.

Disconnected the sensor from power. Press and hold down the reset bu on

while reapplying power. Con nue to hold the bu on for another 10 seconds

a er applying power. The LOE is now reset to default parameter values. In

order to access the internal webpage, follow the instruc ons below:

Computer Setup:

1. Click Start, Control Panel, and then open the Network Connec ons.

2. Right click on the Local Area Connec on and click Prope es.

3. In the center box scroll down and select Internet Protocol (TCP/IP) and then

click the Proper es bu on.

4. Select Use the following IP address and enter in the following:

IP Address: 169.254.0.201

Subnet Mask: 255.255.255.0

NOTE: if “Use the following IP address” is already checked and network

parameters have been assigned, contact your network administrator for

assistance.

LOE Setup:

5. Connect the sensor to a computer’s Ethernet port using a crossover Ethernet

cable.

NOTE: if a POE-injector is being used, the crossover cable will be between

the computer and the injector’s LAN port. Use a standard Ethernet cable

between the injector’s LAN+DC port and the LOE.

6. Apply power to the LOE. The sensor should start cking and the COM LED

should fl ash approximately every 30 seconds.

32

Automation Products Group, Inc.

APG...Providing tailored solutions for measurement applications

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

Page 33

Rev. B, 1/12 LOE Series

7. Open the computer’s Internet browser and enter the LOE’s default IP address

192.254.0.200 into the browser address bar (i.e., h p://169.254.0.200). This

should bring up the LOE’s Internal webpage.

8. Enter the Network Se ngs page and check the boxes to enable the External

webpage Access and the DHCP, then click “Change”. The sensor will no longer

respond.

9. Disconnect the LOE from the computer and use a standard Ethernet cable

to connect the LOE to a connec on that provides access to the Internet. A er

a few seconds, the Com LED should illuminate and remain solid, indica ng the

LOE has established communica on with the website.

10. Go back to step 1-3 and change the computer Ethernet port’s Internet

Protocal proper es back to “Obtain an IP address automa cally”.

Automation Products Group, Inc.

APG...Providing tailored solutions for measurement applications

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

33

Page 34

LOE Series Rev. B, 1/12

Specifi ca ons

Opera ng Range

LOE-2126 .....................................1 to 25 feet (305 to 7620 mm)

LOE-3136 .....................................1.5 to 40 feet (457 to 12192 mm)

LOE-6126 .....................................6 to 180 inches (152 to 4572 mm)

Opera ng Voltage ............................48 VDC Power over Ethernet (POE); requires

POE injector or switch

Total Current Draw ..........................40mA @ 48 VDC

Maximum Power Ra ng ..................2.0 W

Ra ngs .............................................IP65

Available Outputs ............................Ethernet TCP/IP to internal web page or

APG website

Ethernet TCP/IP Modbus

2 - Isolated solid state relays (400 V, 130 mA

max.)

Resolu on .......................................0.1 in. (2.54 mm)

Accuracy ..........................................+/- 0.25% of range with no temp gradient

Sensor Adjustments ........................Programmable modes via website

Transducer Type ..............................Flat ceramic sealed PVDF face

Opera ng Temperature ...................-40 to 140°F (-40 to 60°C)

Sample Rate.....................................1 to 12 Hz

Beam Pa ern ...................................9° off axis

Cable Connec on ............................RJ-45 + terminal strip for relaysf

34

Automation Products Group, Inc.

APG...Providing tailored solutions for measurement applications

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

Page 35

Rev. B, 1/12 LOE Series

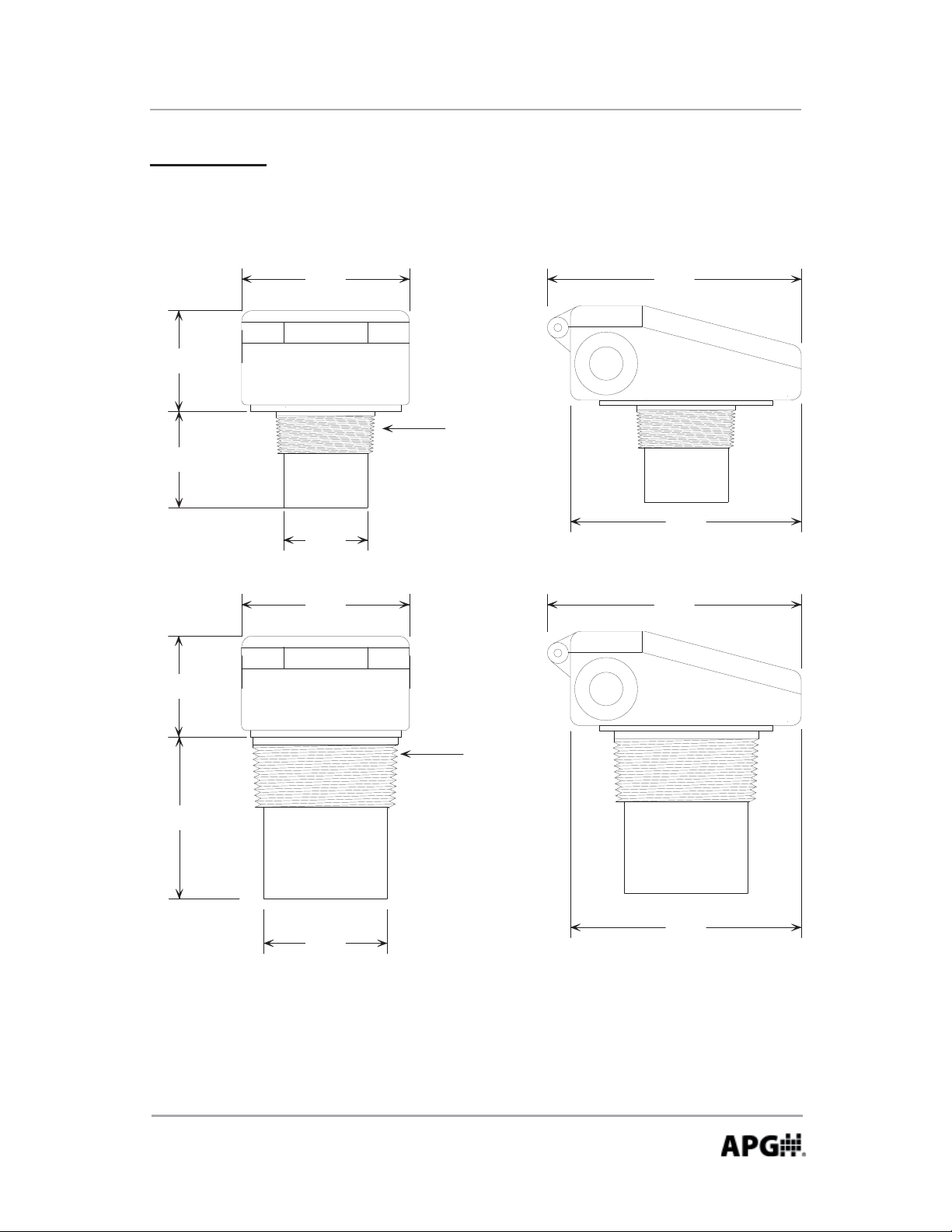

Dimensions

LOE-2126 & 6126

4

.

0

0

"

2

.

4

0

"

T

P

N

"

2

2

.

3

0

"

2

.

"

0

0

LOE-3136

6

.

0

5

"

"

5

.

5

0

0

"

4

.0

0

"

.4

2

T

P

N

3

"

6

"

3

.

8

"

3

.

0

0

"

5

6

.0

0

"

5

.

5

Automation Products Group, Inc.

APG...Providing tailored solutions for measurement applications

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

35

Page 36

AUT OMATION

PRODUCTS

GROUP, INC.

APG...Providing tailored solutions

for measurement applications

Automation Products Group, Inc.

Tel: 1/888/525-7300

1/435/753-7300

Fax: 1/435/753-7490

e-mail: sales@apgsensors.com

www.apgsensors.com

Automation Products Group, Inc.

1025 W. 1700 N.

Logan, UT 84321

Loading...

Loading...